Compressive handling equipment and process for organic solid waste

A comprehensive treatment and organic solid waste technology, applied in the direction of solid waste removal, etc., can solve the problems of difficult control of solid waste comprehensive treatment process, inability to effectively monitor and control the fermentation environment, integration and poor intelligence, etc., to achieve Reduced management and personnel burden, small footprint, and strong deodorizing and sterilizing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

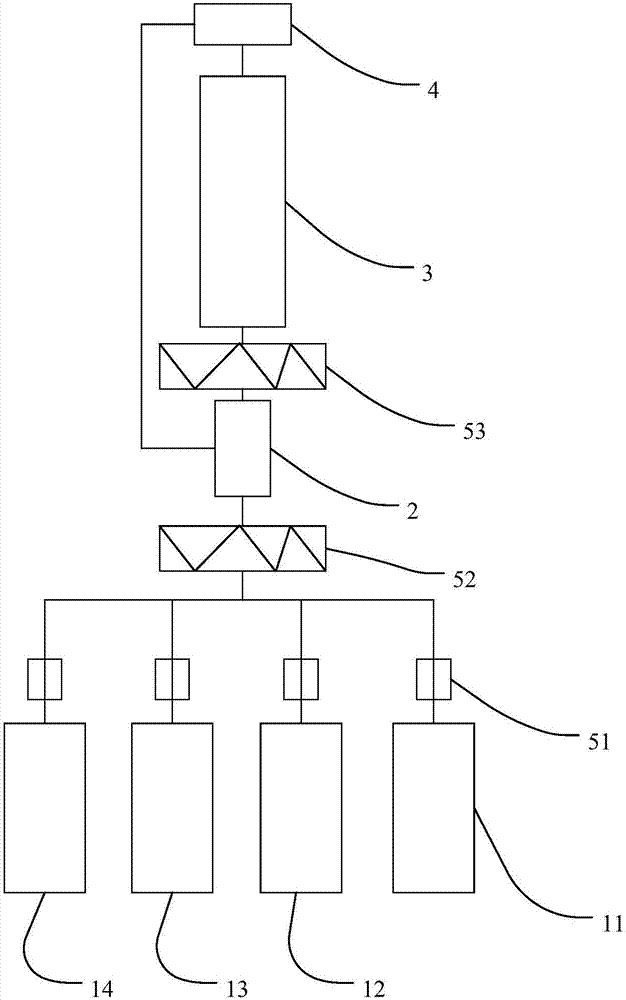

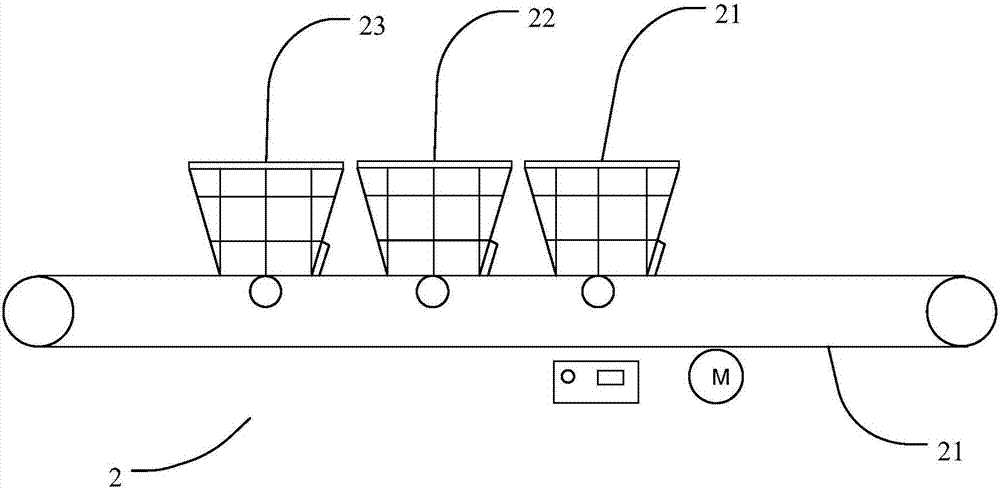

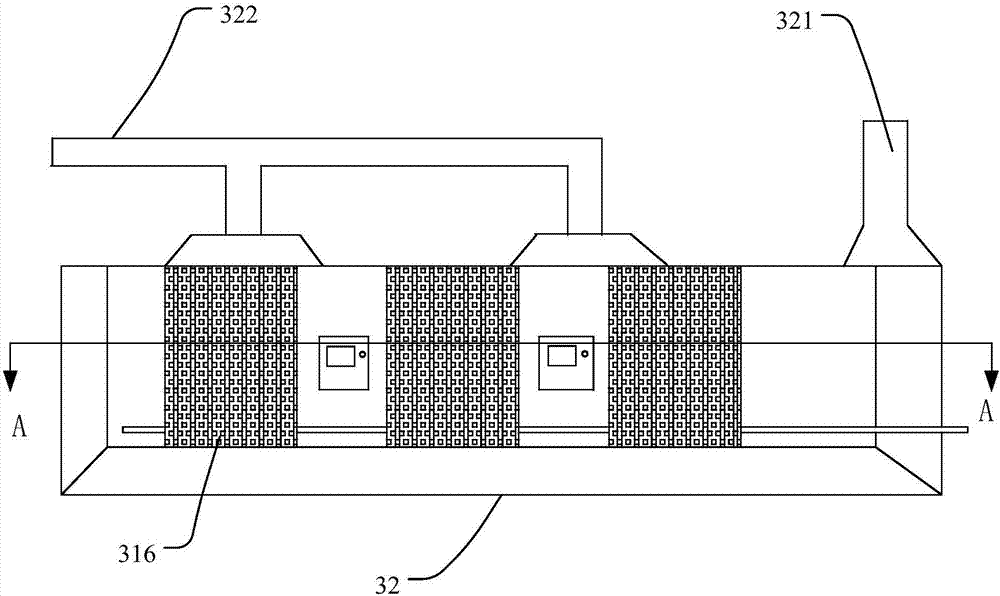

[0056] Such as figure 1 As shown, the organic solid waste comprehensive treatment equipment provided by the present invention can process a variety of organic waste materials, make organic carbon soil and put it into the natural environment again for recycling and reuse. The organic solid waste comprehensive treatment equipment includes a plurality of storage bins, a first mixer 52 , a batching device 2 , a fermentation tank 3 and a screening device 4 . A plurality of the storage bins are respectively connected to the feed inlet 321 of the first mixer 52 for sorting and storing waste materials to be processed, and the outlet of the first mixer 52 is connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com