System and method for producing ecological cement through garbage fly ash and sludge cooperative mixed combustion in cement kiln

A technology of garbage fly ash and ecological cement, which is applied in the direction of combustion method, cement production, combustion type, etc., can solve the unsolved problems of heavy metal ion garbage fly ash treatment, and achieve the elimination of heavy metal leaching hazards, saving treatment agent costs, and acid resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

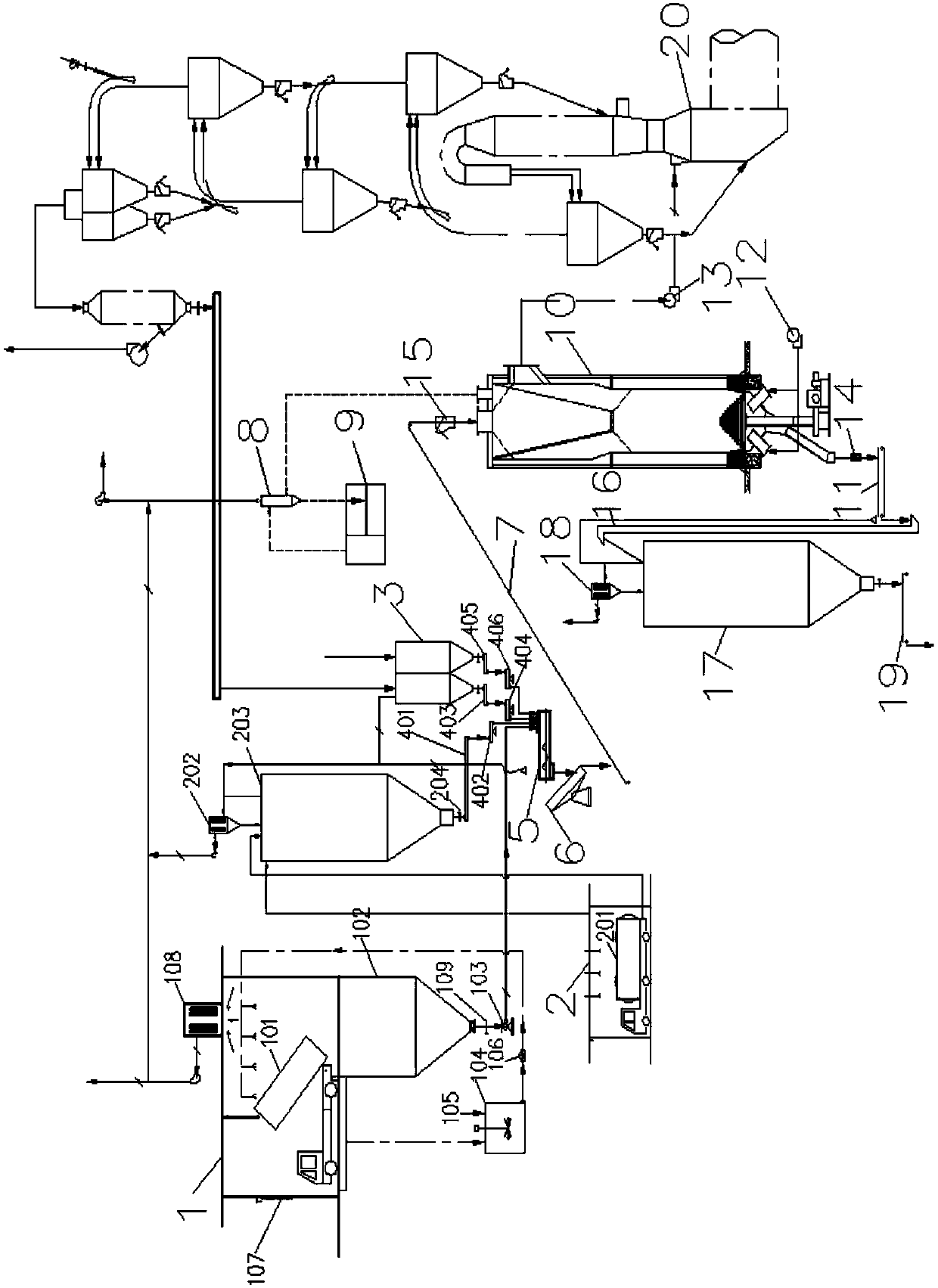

[0063] Such as figure 1 As shown, the present invention provides a system for co-combusting garbage fly ash and sludge to make ecological cement in a cement kiln, including: sludge pretreatment unit, garbage fly ash storage unit, batching storage unit, material mixing system, incineration device , clinker storage device, cement kiln system, the sludge pretreatment unit, garbage fly ash storage unit and ingredient storage unit are respectively connected to the material mixing system through pipelines, and the material mixing system is connected to the incineration device. The incineration device is connected with the clinker storage device, and the incineration device is also provided with a pipeline to connect with the cement kiln system;

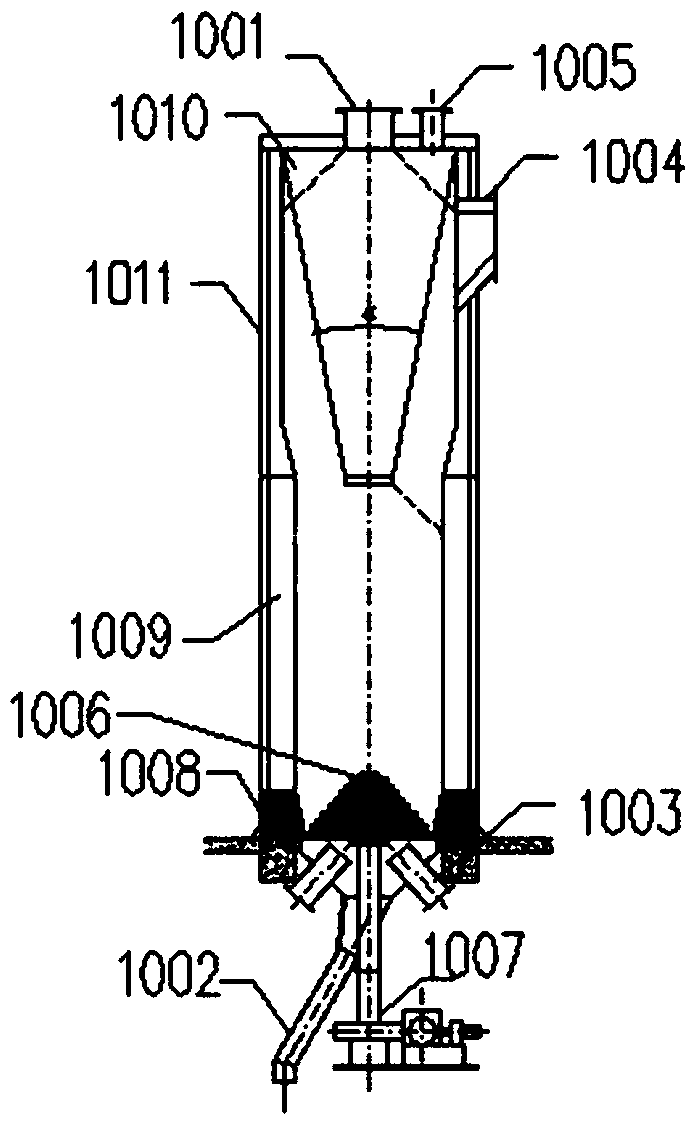

[0064] The incineration device comprises: an air-lock feeder 15, a vertical incinerator 10, a chain plate discharge machine 11, and a blower 12. The air-lock feeder 15 is connected to the vertical incinerator 10, and the vertical incinerato...

Embodiment 2

[0104] The difference between embodiment 2 and embodiment 1 is:

[0105] Present embodiment 2 provides a kind of method that cement kiln synergistically co-burns garbage fly ash and sludge to make ecological cement:

[0106] Preferably, the step (1) sludge pretreatment is carried out in a closed sludge pretreatment station, and the sludge pretreatment station is forced to exhaust air through a suction machine, and the air is sent to an incinerator for high-temperature oxidation and deodorization and then discharged In order to achieve the purpose of cost saving.

[0107] Preferably, the step (2) garbage fly ash is directly unloaded into the receiving pit by the automatic dump truck 201, and is lifted into the garbage fly ash storage by the hoist;

[0108] Preferably, the proportion of ecological cement raw materials in the step (4) is: 20% of sludge, 40% of garbage fly ash, 30% of cement kiln dust, and 10% of coal powder.

[0109] Preferably, step (5) granulation: the ecolog...

Embodiment 3

[0111] Preferably, the difference between embodiment 3 and embodiment 1 is that the proportion of ecological cement raw materials in the step (4) is: sludge 50%, garbage fly ash 32%, cement kiln dust 10%, coal powder 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com