Waste salt recycling system and method based on thermal power plant energy saving and environment protection integration

An energy-saving and environmental protection technology for thermal power plants, applied in the field of waste salt recycling system, can solve the problems of high disposal costs, lack of technical means, high operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

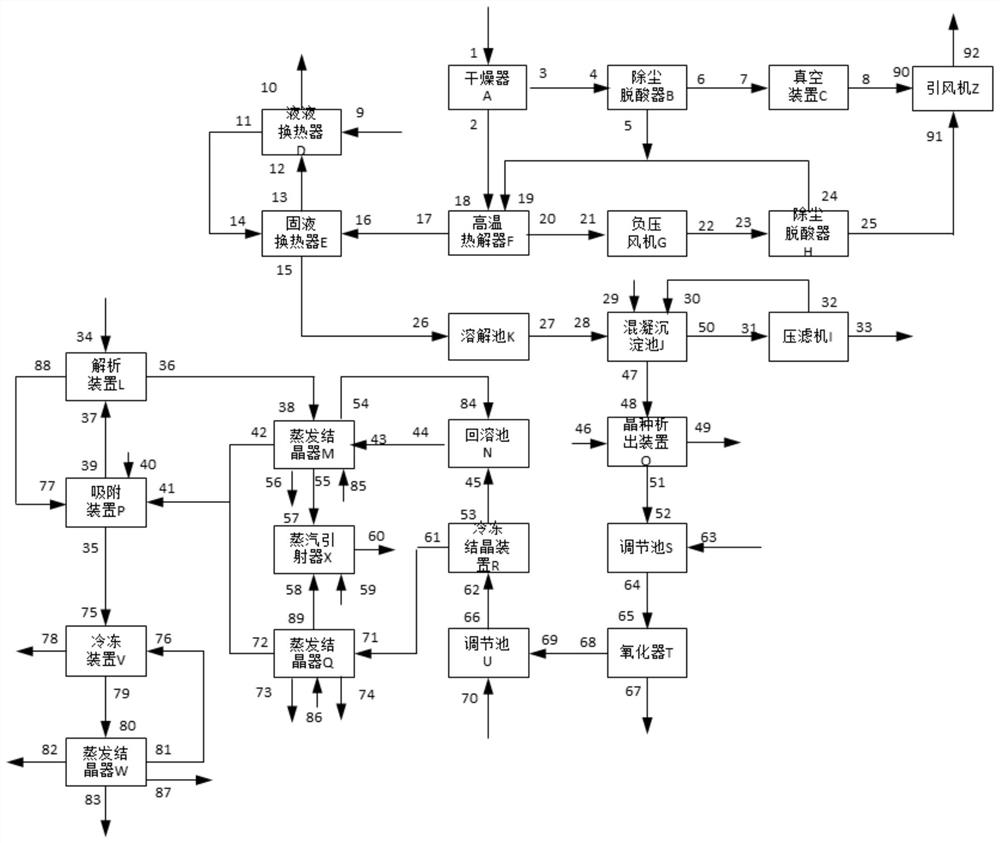

[0050] figure 1 A structural block diagram of a waste salt recycling system based on the integration of energy saving and environmental protection in thermal power plants provided for the embodiment of the present invention, the system includes: dryer A, dedusting and deacidifying device B, vacuum device C, and liquid-liquid heat exchanger D , solid-liquid heat exchanger E, high-temperature pyrolyzer F, negative pressure fan G, dust removal and deacidification device H, dissolution tank K, coagulation sedimentation tank J, filter press I, seed crystal precipitation device O, regulating tank S, Oxidizer T, adjustment tank U, freezing crystallization device R, remelting tank N, evaporation crystallizer M, steam ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com