Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Alkali metal sulfites/sulfates preparation form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

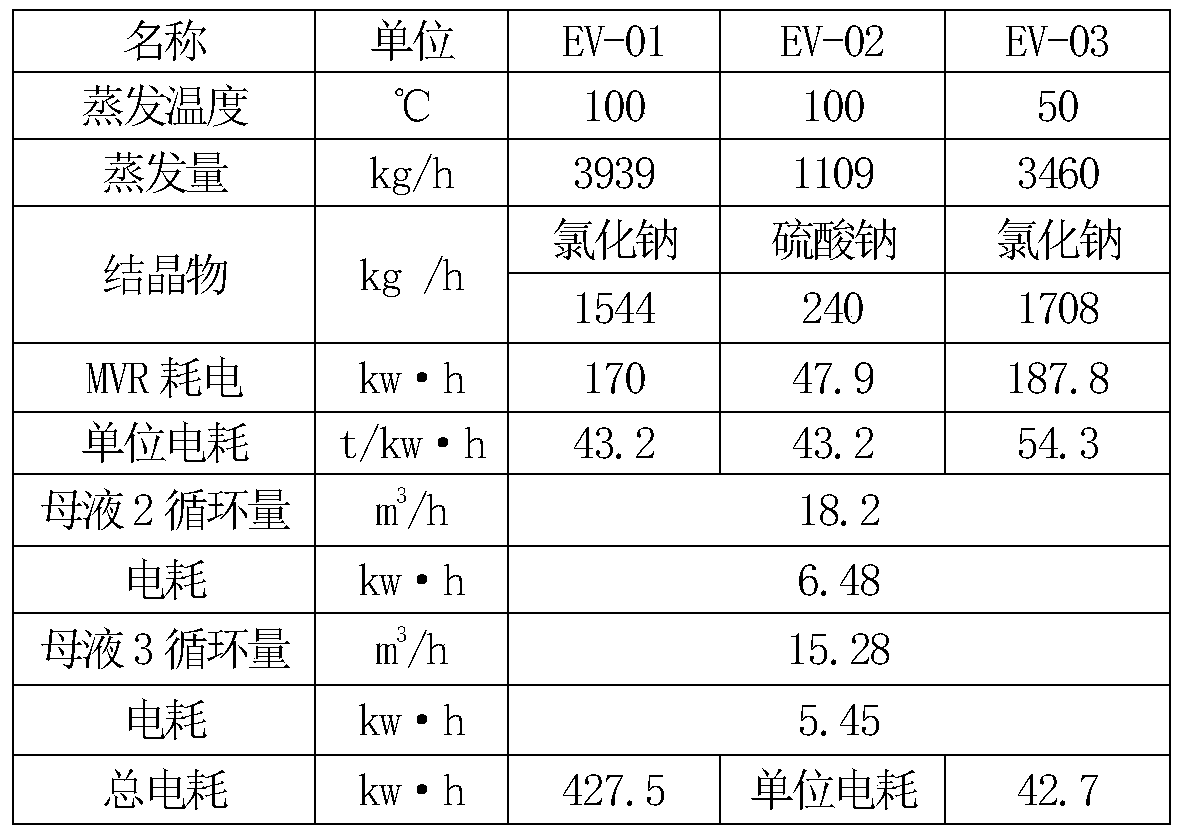

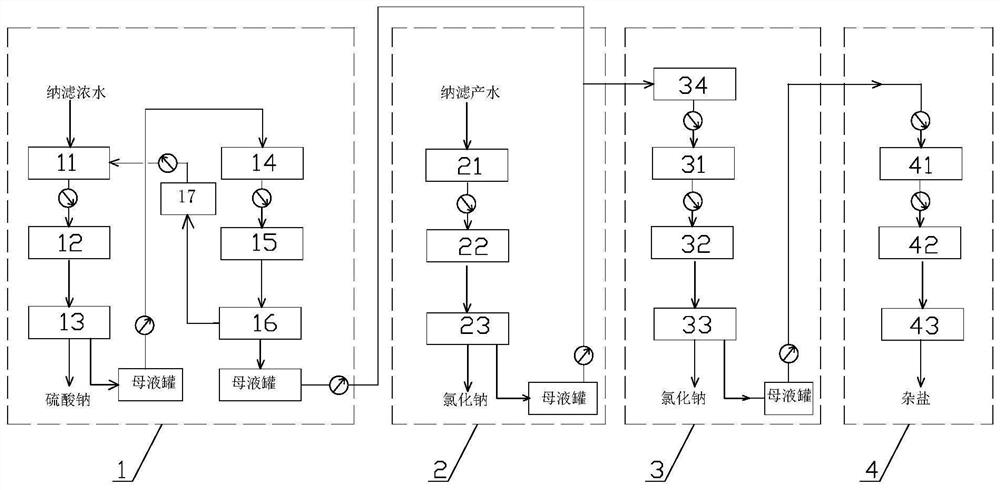

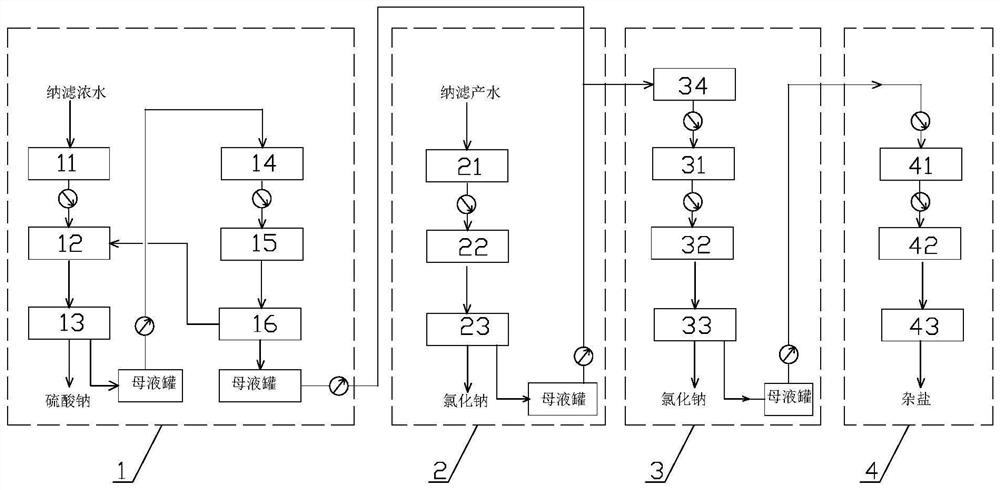

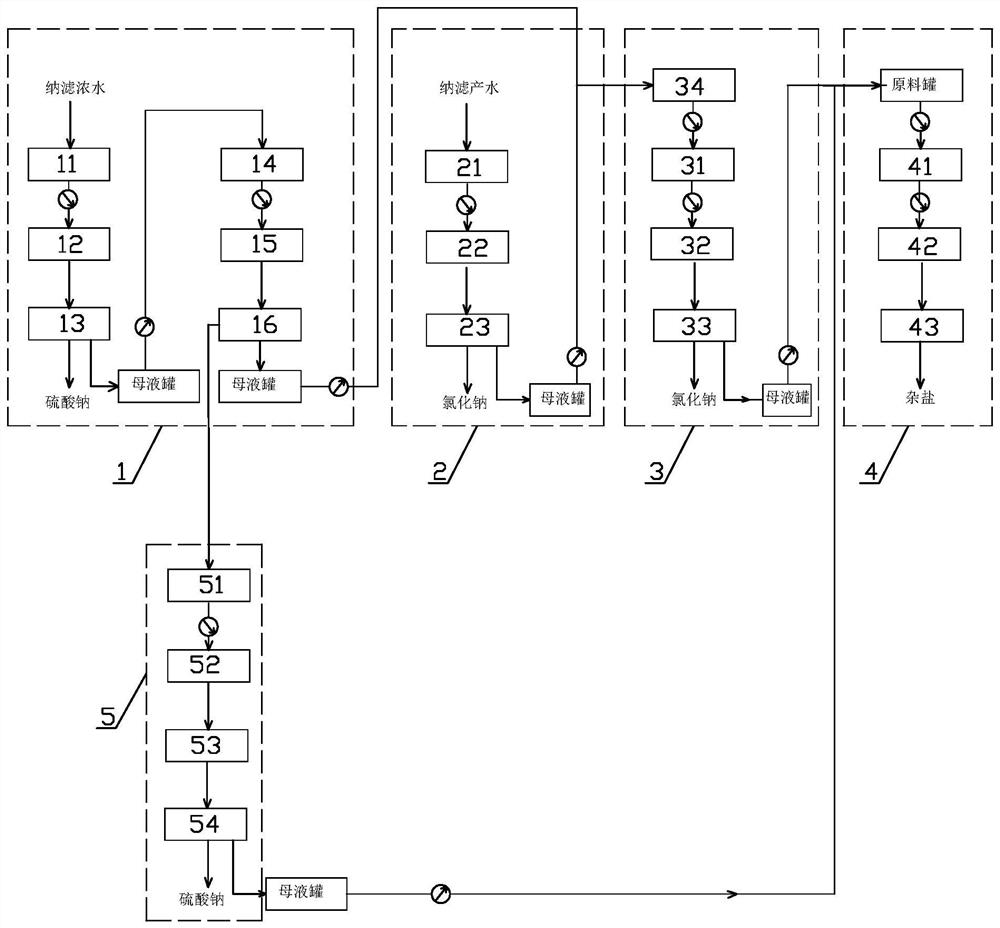

Desulfurization wastewater quality-divided crystallization processing method and processing device

PendingCN109970267ARealize fractional crystallizationReduce usageAlkali metal sulfites/sulfates preparation formWater contaminantsUltrafiltrationFiltration

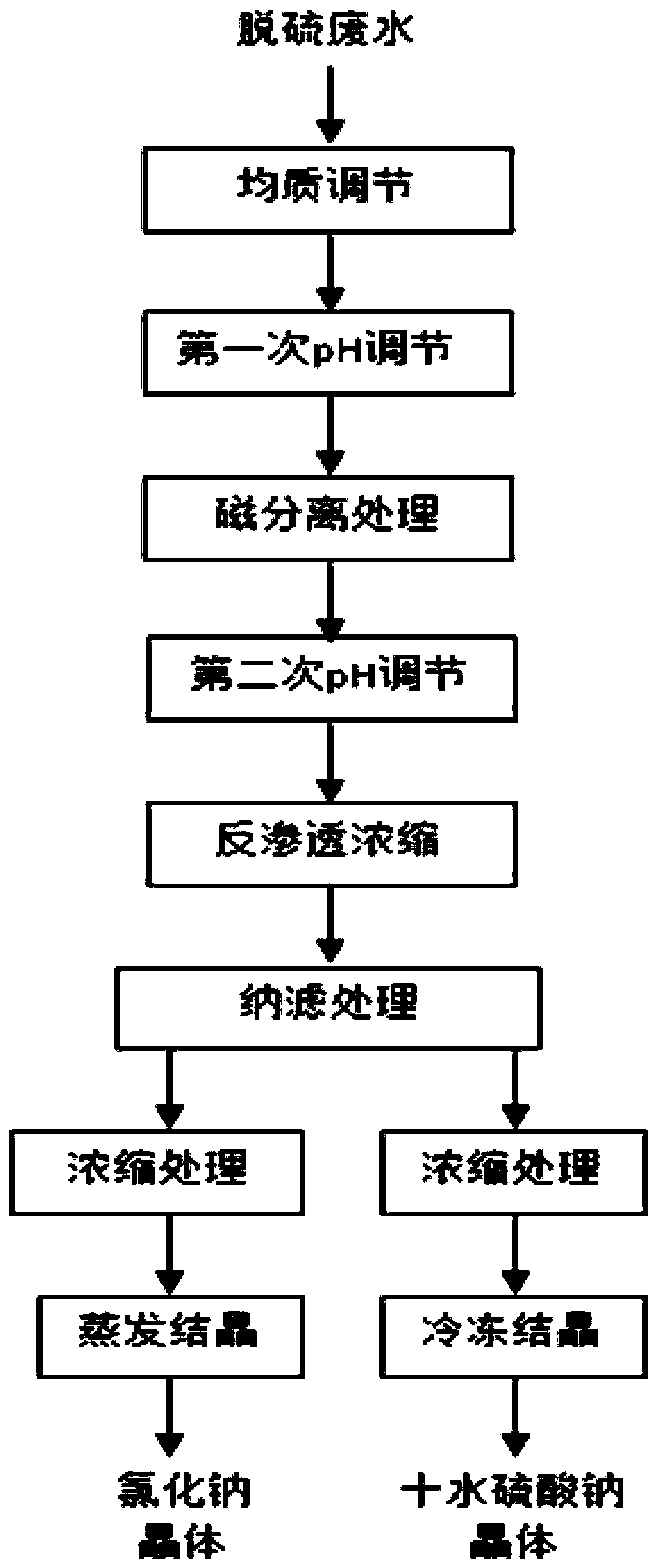

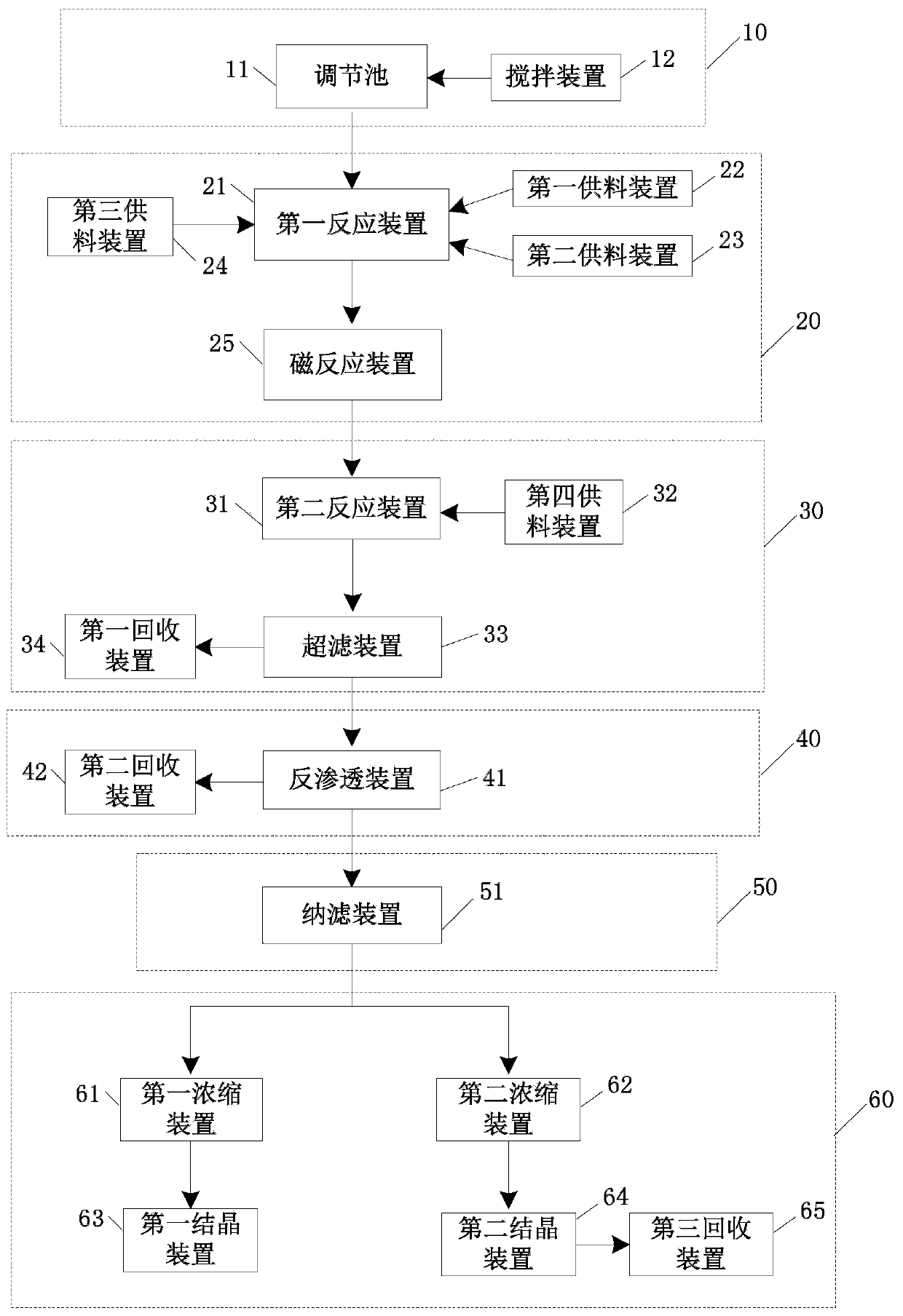

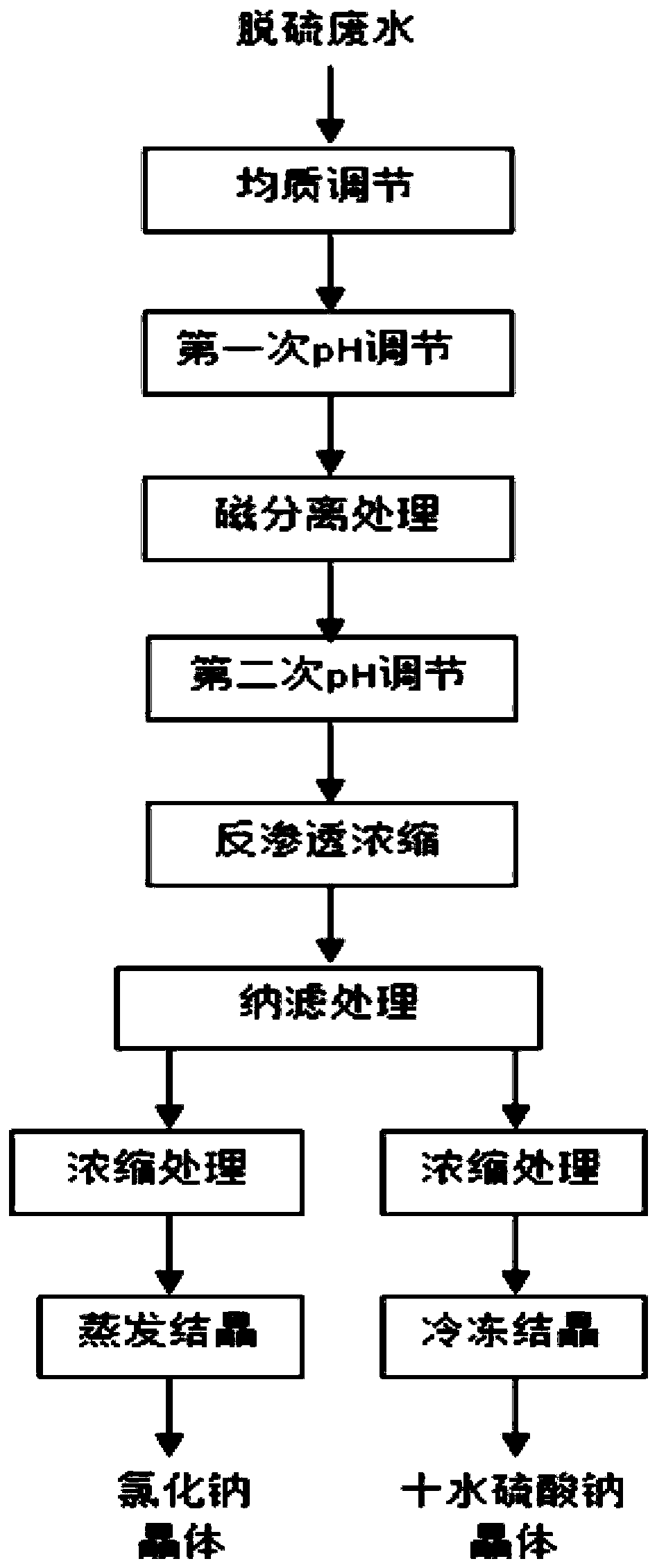

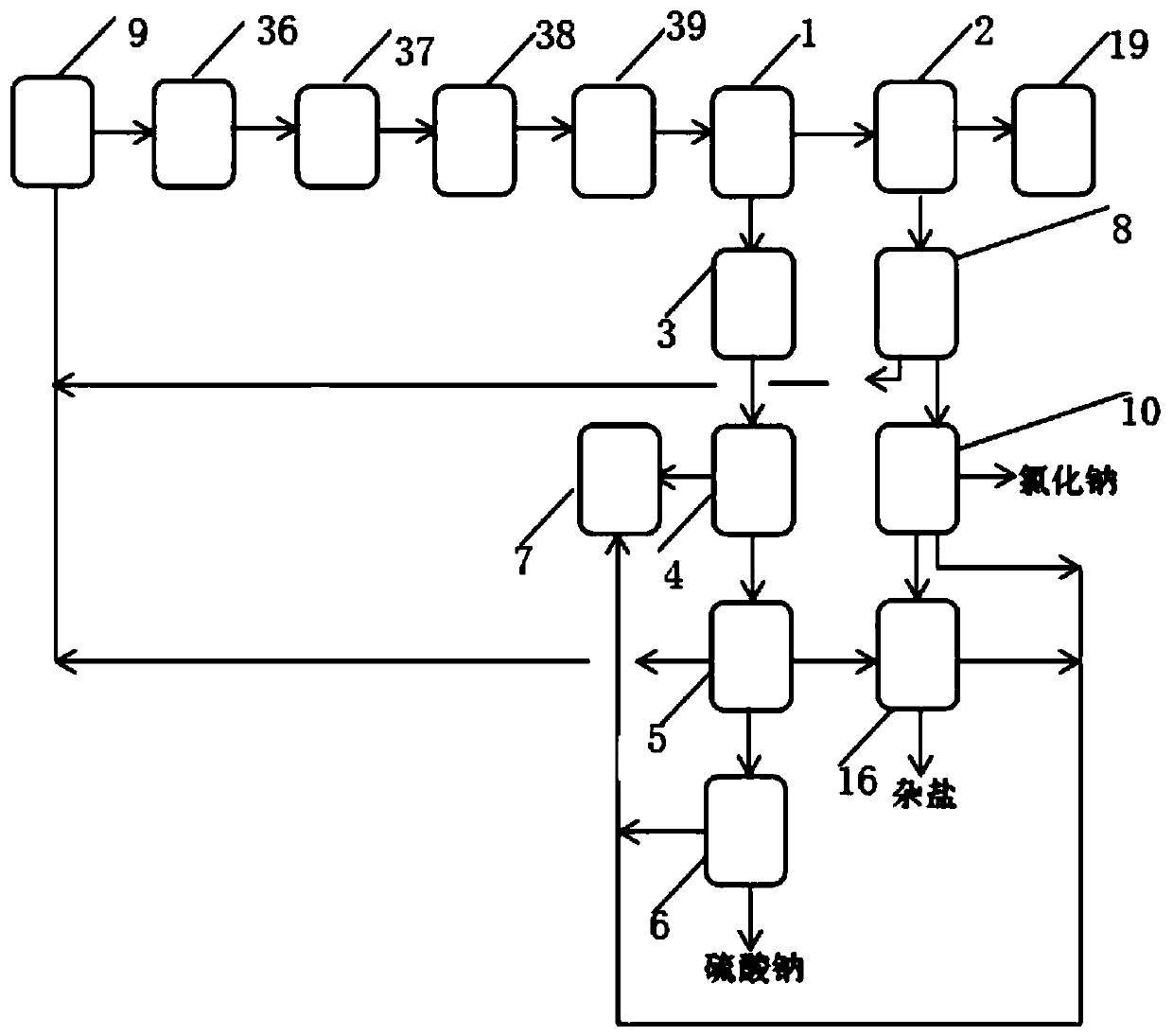

The invention provides a desulfurization wastewater quality-divided crystallization processing method and a processing device. Desulfurization wastewater contains sodium chloride and sodium sulfate. The method comprises following steps: adjusting the pH of desulfurization wastewater to 9-12 for the first time, adding an organic sulfur agent and iron ore particles into adjusted desulfurization wastewater, carrying out magnetic separation to obtain precipitates and supernate; adjusting the pH of the supernate to 6.5-7.5 for a second time, carrying out ultrafiltration to obtain concentrated water; subjecting the concentrated water to a reverse osmosis treatment to obtain a reverse osmosis concentrated solution; subjecting the reverse osmosis concentrated solution to a nano filtration treatment to obtain nano filtration producing water and nano filtration concentrated water; subjecting the nano filtration producing water to a concentration treatment and a crystallization treatment in sequence to obtain sodium chloride crystals; and subjecting the nano filtration concentrated water to a concentration treatment and a crystallization treatment in sequence to obtain sodium sulfate decahydrate crystals. Solved are the problems that in conventional desulfurization wastewater quality-divided crystallization processing, the effect is influenced by heavy metal ions, and the salt crystallization amount is large.

Owner:CHINA ENFI ENGINEERING CORPORATION

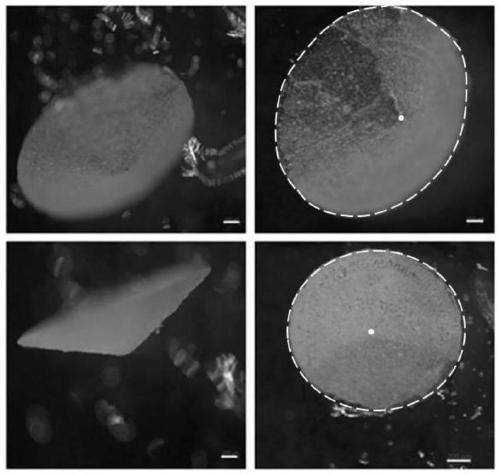

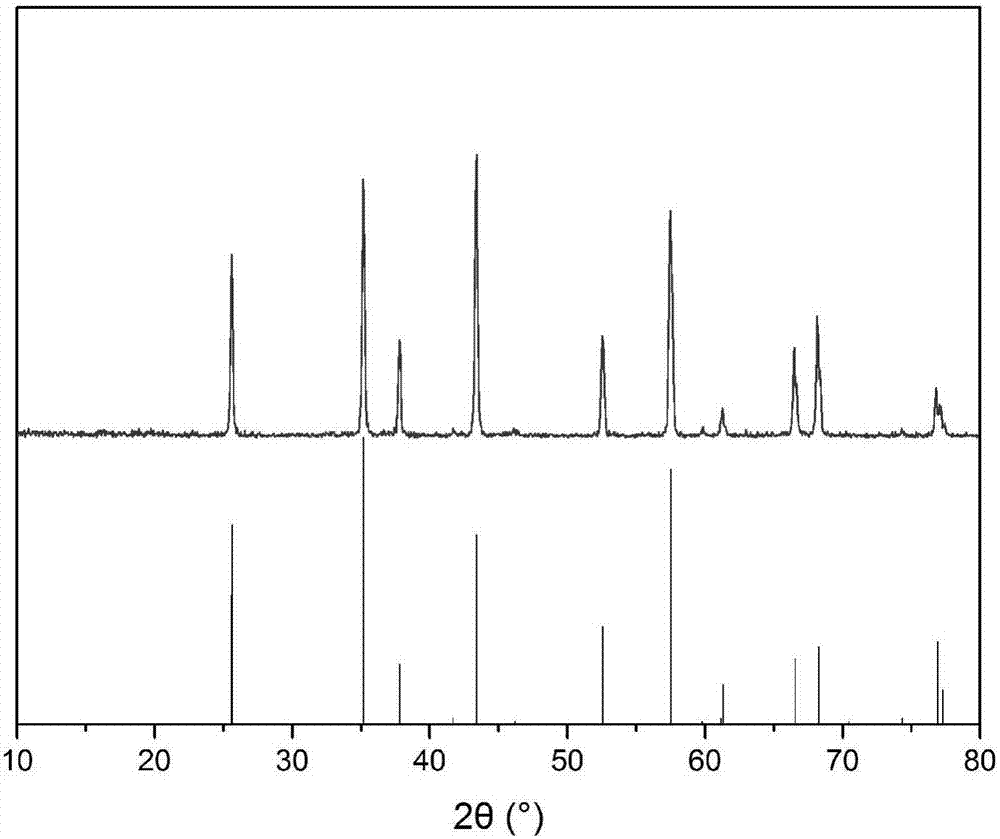

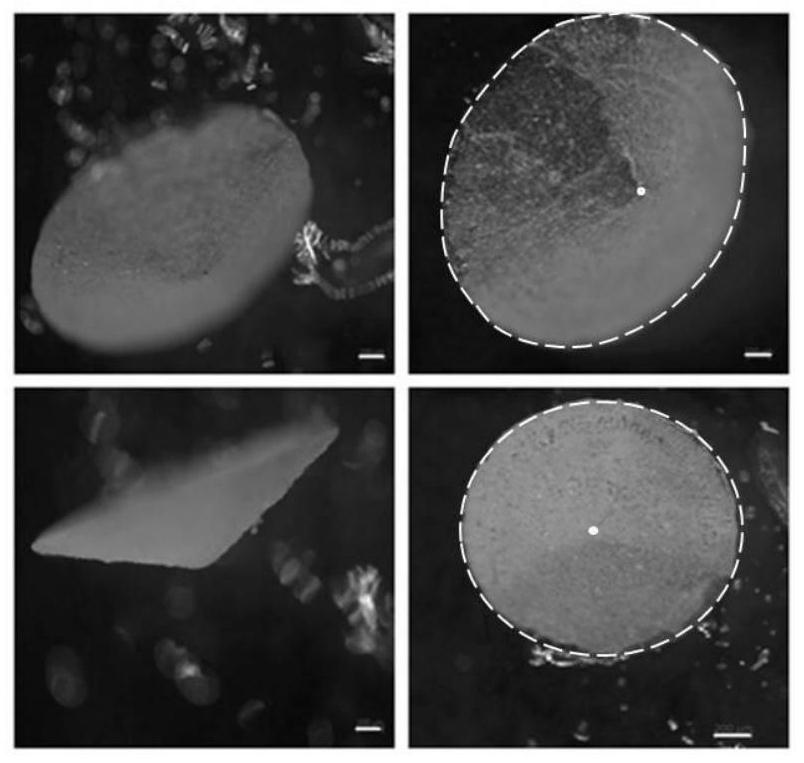

Method for preparing platy-monocrystal alpha-aluminum oxide with Na3FSO4 as seed crystals

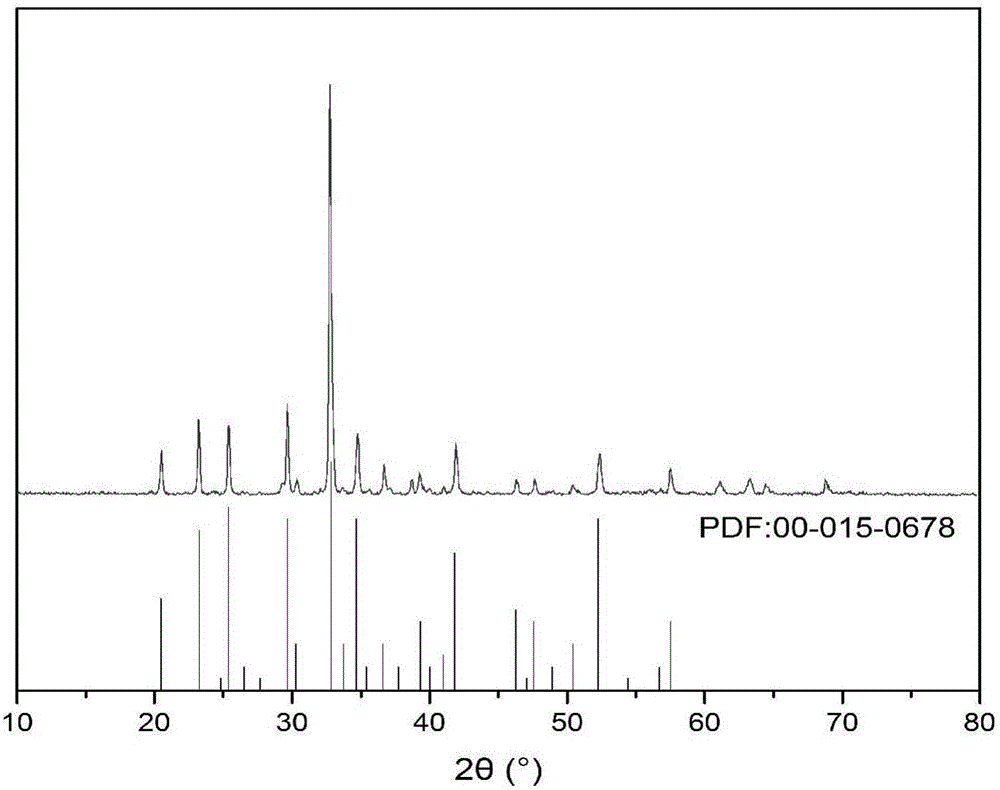

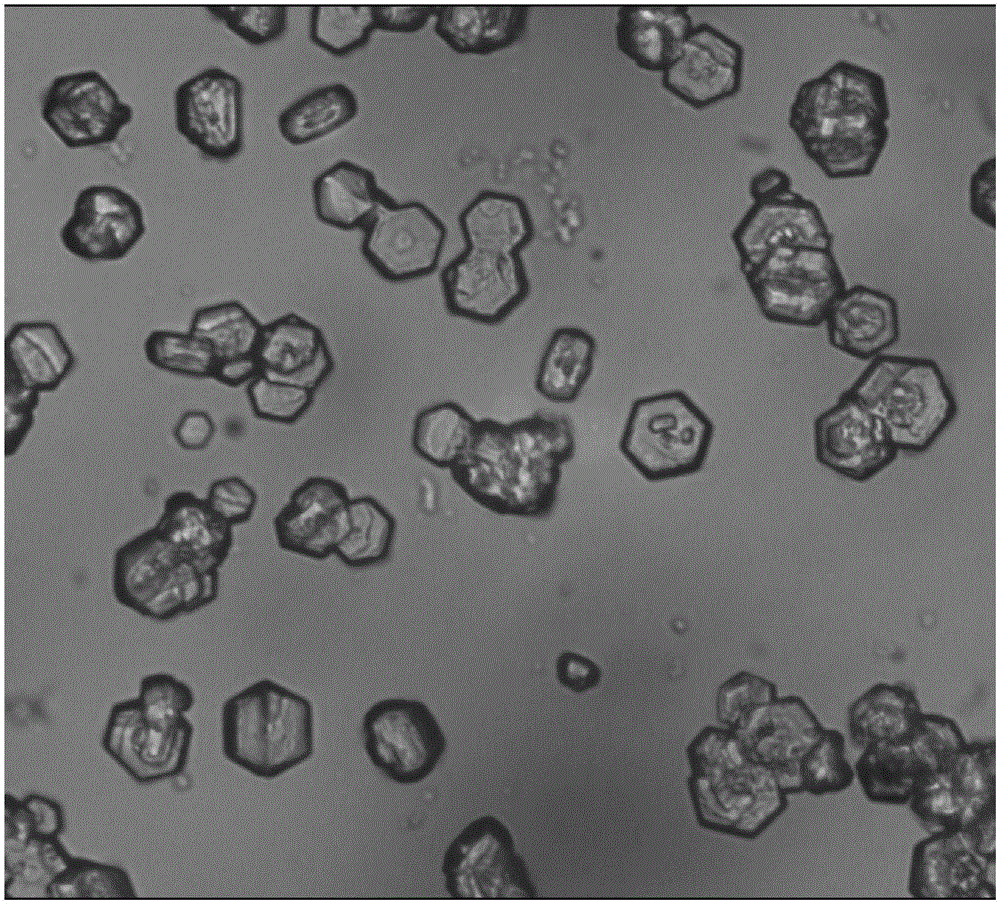

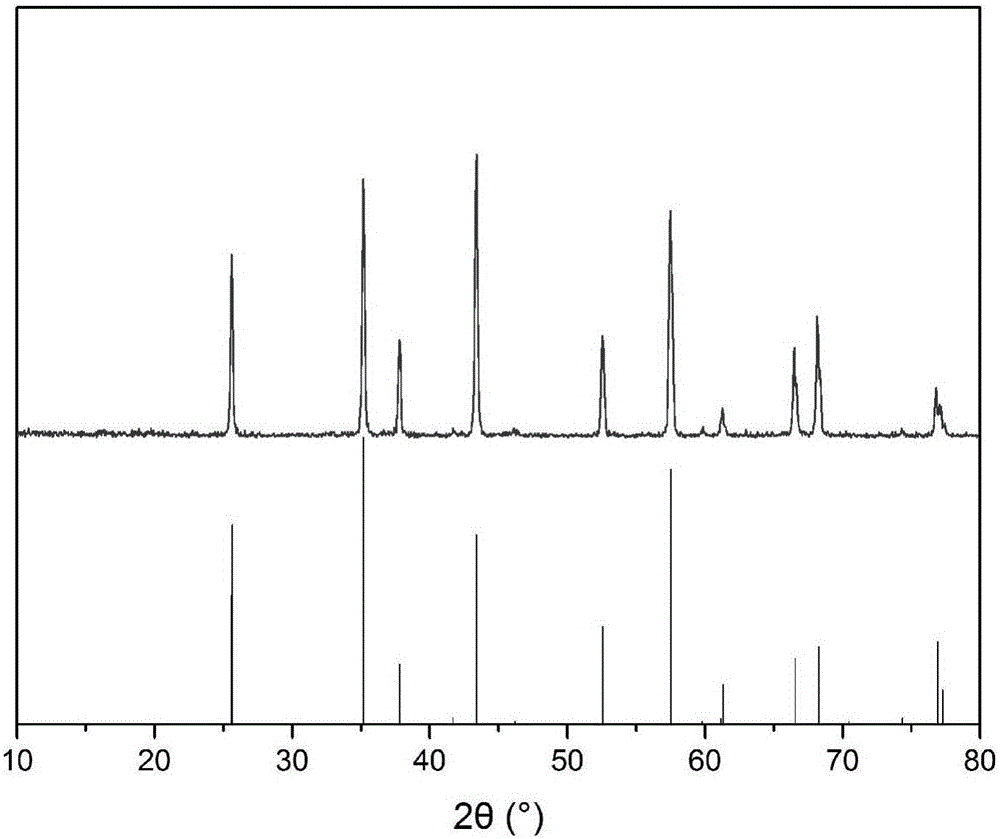

InactiveCN105858694AObvious hexagonal sheet structureCalcination temperature is lowAlkali metal sulfites/sulfates preparation formAluminium compoundsRoom temperatureMolten salt

The invention relates to a method for preparing platy-monocrystal alpha-aluminum oxide with Na3FSO4 as seed crystals and belongs to the field of preparation of inorganic nonmetal power materials. The method comprises the following steps that firstly, fused salt and Na3FSO4 crystals are added into raw materials containing aluminum and mixed evenly, and a mixed material is obtained; secondly, the mixed material is roasted at 650-1000 DEG C, the roasted mixed material is cooled to the room temperature and then dissolved with hot water at 50-100 DEG C, washing, filtering and drying are carried out, and platy-monocrystal alpha-aluminum oxide is obtained. According to the method, Na3FSO4 seed crystals for preparation are of an obvious hexagonal platy structure, and greatly assist in forming platy aluminum oxide; the roasting temperature is low, and reduction of energy consumption is promoted.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

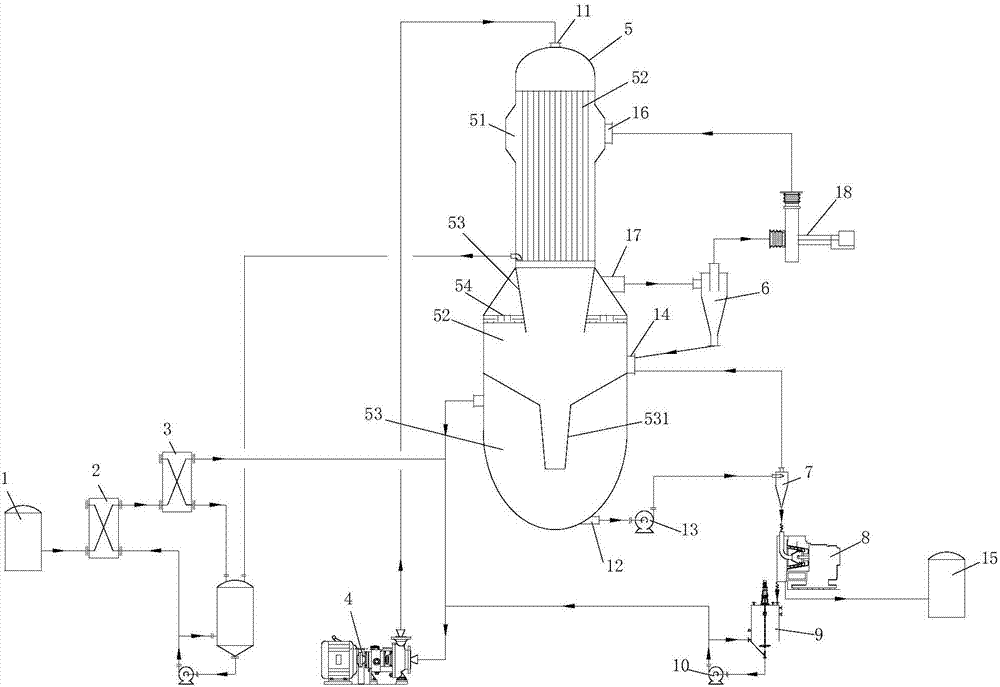

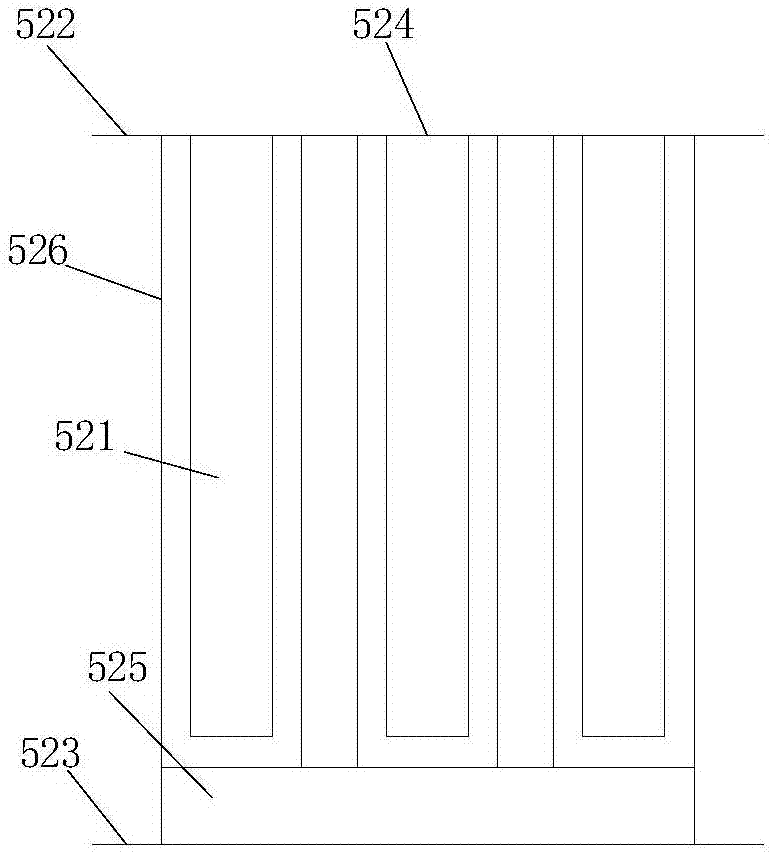

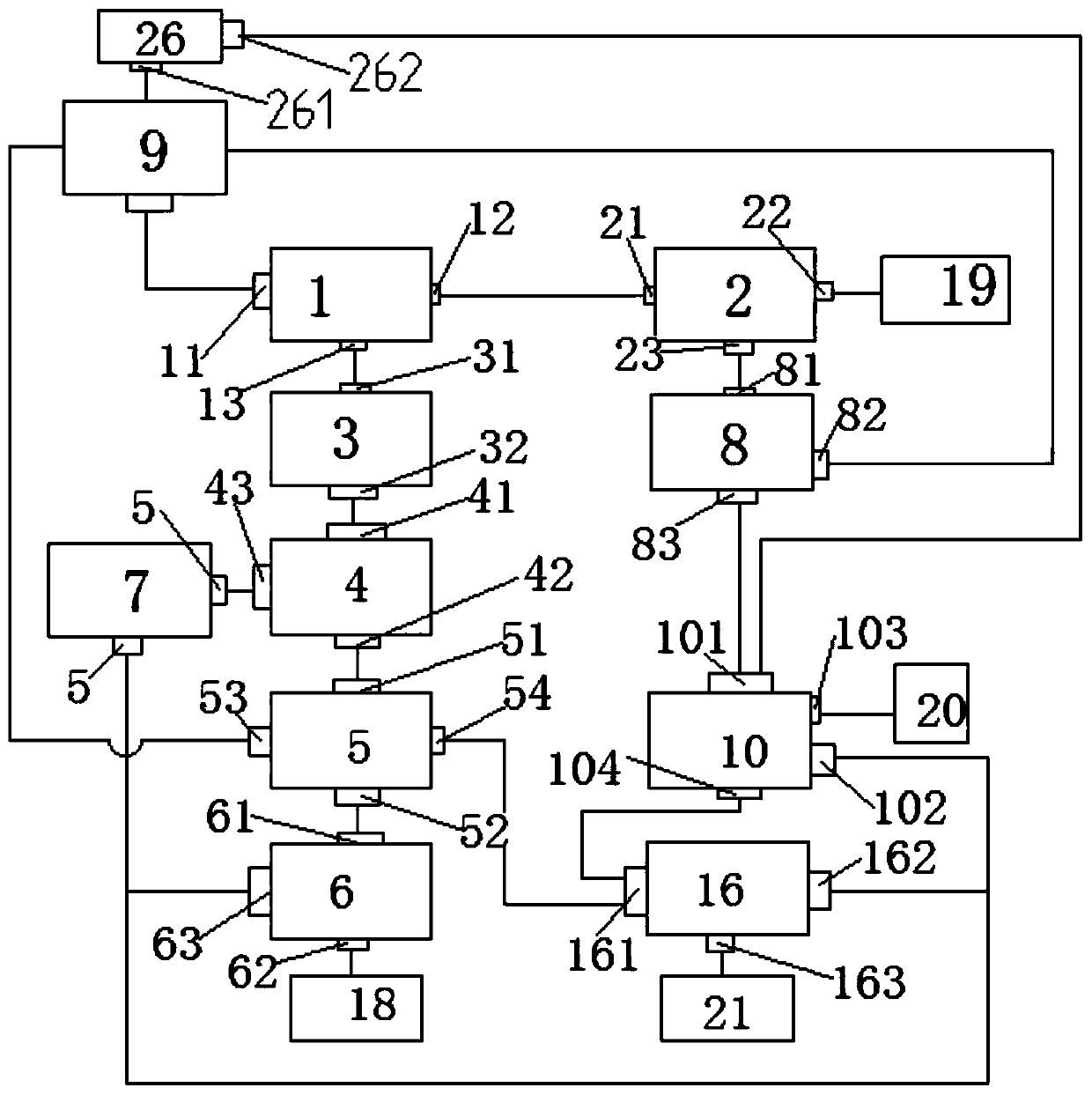

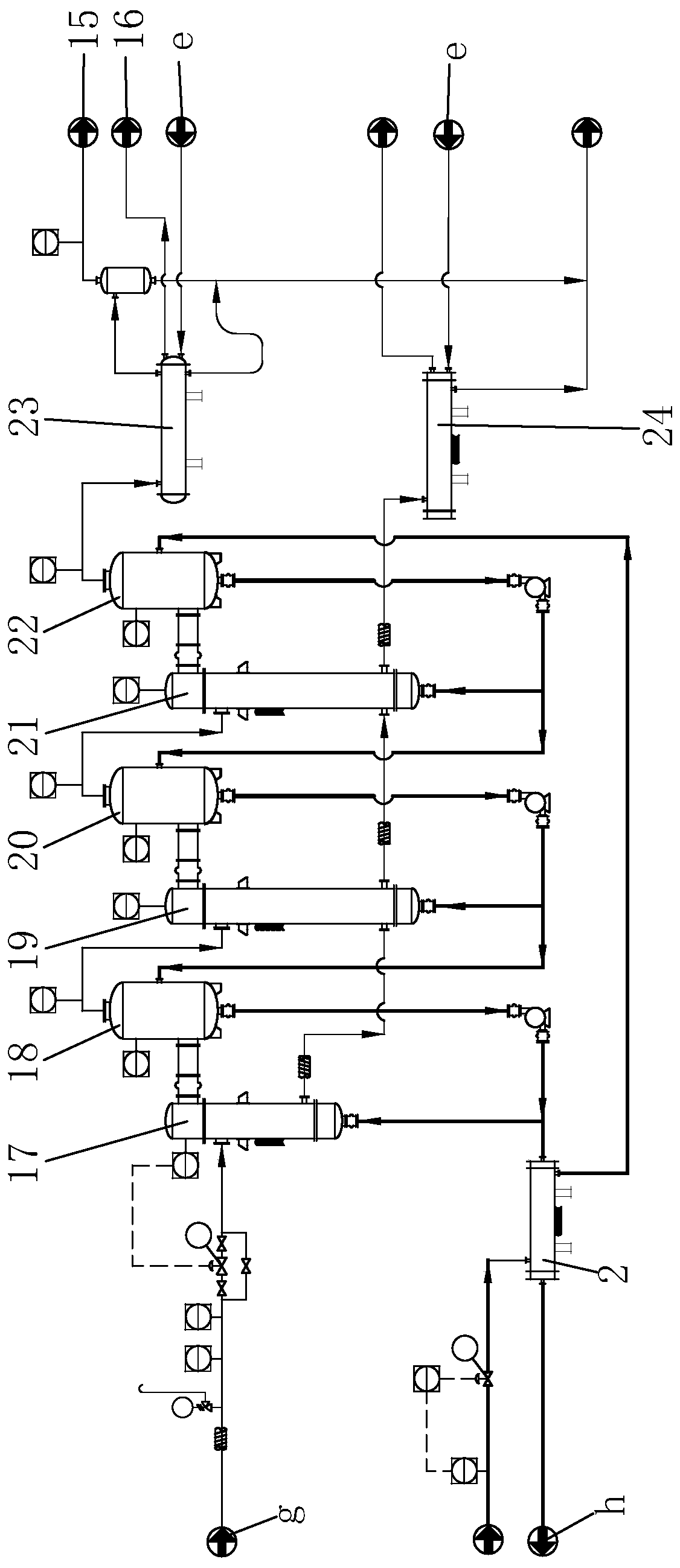

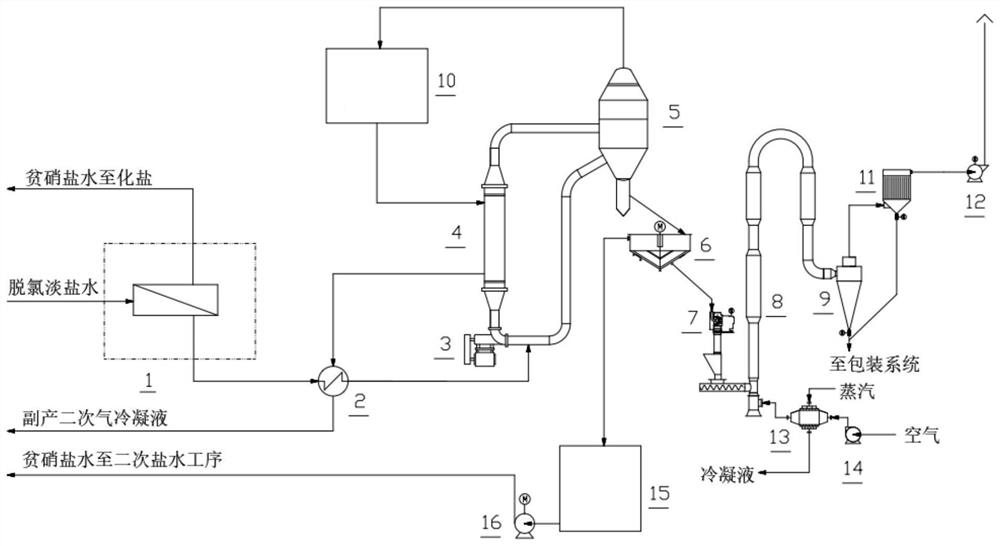

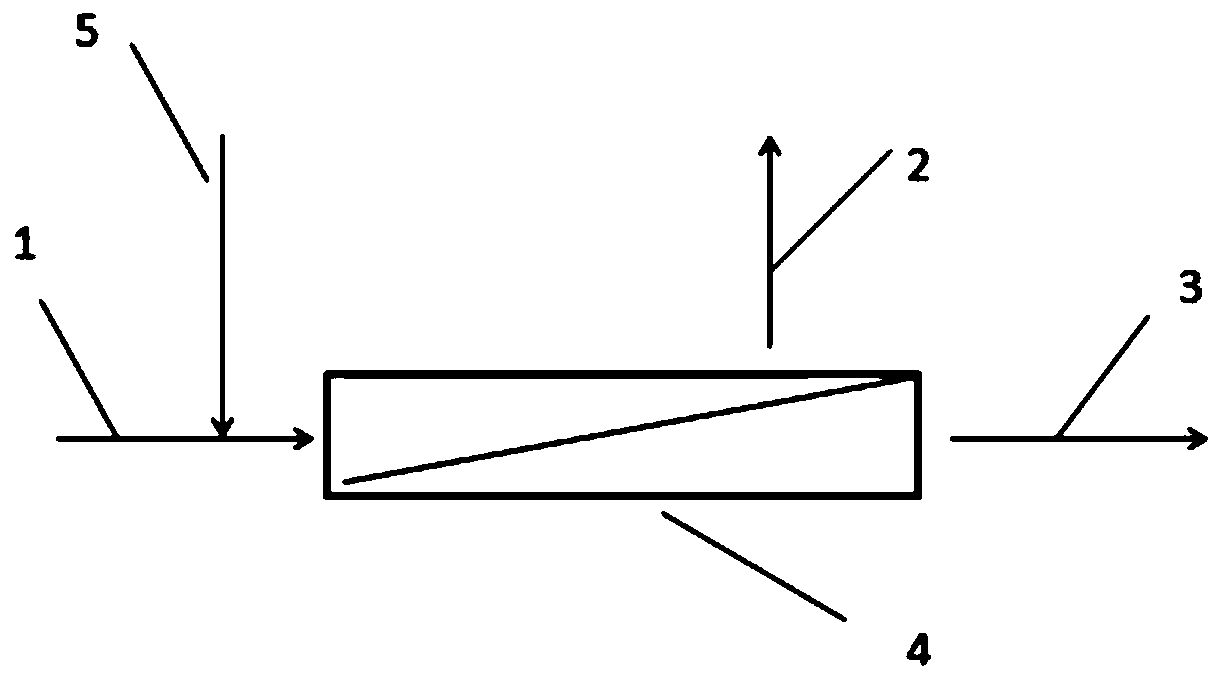

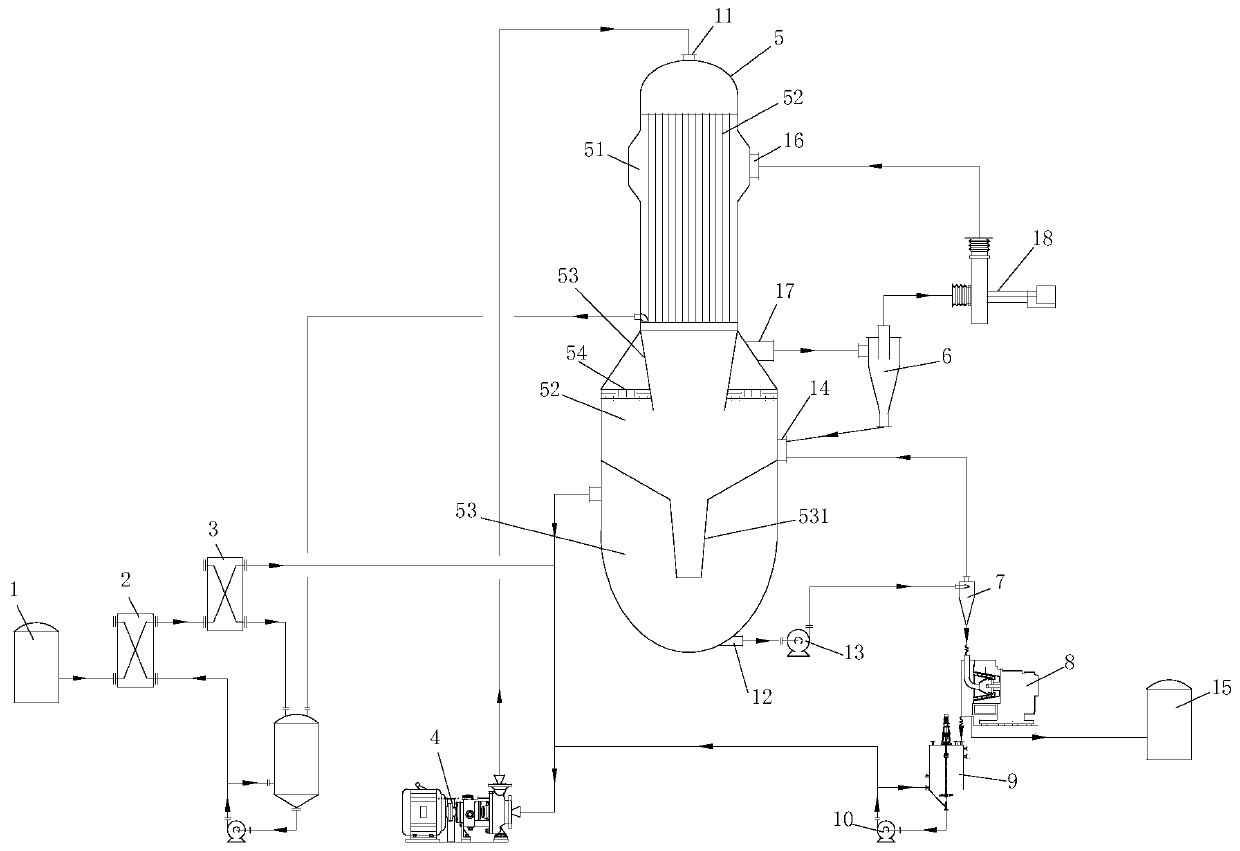

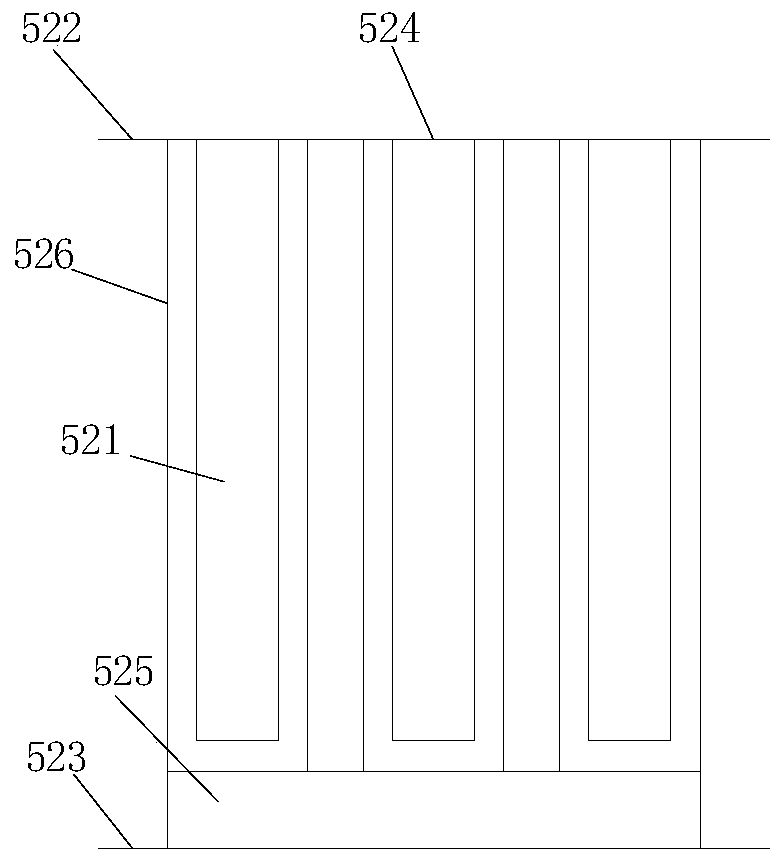

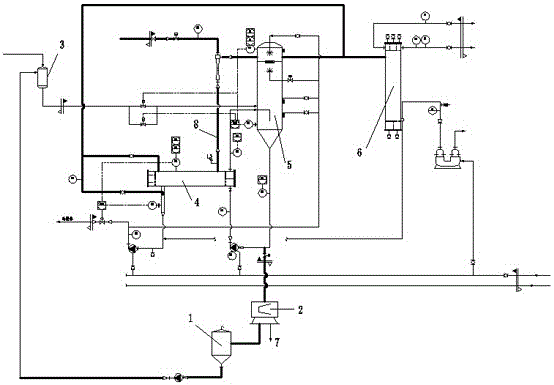

Sodium-sulfate-containing wastewater crystallizing system

ActiveCN107128988AImprove evaporation effectExtended service lifeAlkali metal sulfites/sulfates preparation formWater contaminantsEvaporationSmall footprint

The invention relates to a sodium-sulfate-containing wastewater crystallizing system. A wastewater heater is communicated with an inlet of a circulating pump, an outlet of the circulating pump is communicated with a feeding port of an evaporation crystallizing tank, a discharging port of the evaporation crystallizing tank is communicated with a solid-liquid separator, a discharging pump is arranged between the solid-liquid separator and the evaporation crystallizing tank, and the solid-liquid separator is further communicated with a liquid inlet of the evaporation crystallizing tank; a centrifugal separator is connected with the solid-liquid separator, a mother liquid tank and a finished product collection tank, the mother liquid tank is connected with the inlet of the circulating pump through a backflow pump, a steam inlet and a steam outlet are arranged on the evaporation crystallizing tank, an inlet of a steam-liquid separator is communicated with the steam outlet while an outlet of the same is communicated with the steam inlet through a centrifugal compressor, and an outlet of the steam-liquid separator is further communicated with a liquid inlet of the evaporation crystallizing tank. The sodium-sulfate-containing wastewater crystallizing system is compact in structure, small in occupied area, low energy consumption, long service life and good evaporation crystallizing effect.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

Brine wastewater advanced treatment and efficient recovery utilization technology

InactiveCN110436689AEfficient recyclingLess investmentAlkali metal sulfites/sulfates preparation formTreatment involving filtrationHigh concentrationReverse osmosis

The invention belongs to technical field of chemical brine wastewater treatment, and particularly relates to a brine wastewater advanced treatment and efficient recovery utilization technology. Brinewastewater from a brine wastewater recycling unit flows through a nanofiltration unit, and is further subjected to treatment of an oxidized unit, an evaporation concentration unit, a sodium sulfate freezing crystallization unit, a mirabilite melt crystallization unit, a reverse osmosis unit, a high concentration EDM device I, a sodium chloride evaporative crystallization unit, a carnallite dryingunit, the treatment cost of the brine wastewater is significantly lowered, recycled water can serve as circulating water, a sodium sulfate sodium chloride industrial salt and carnallite are obtained,zero discharge of the brine wastewater is achieved, and environmental pollution is reduced.

Owner:JIUTAI ENERGY INNER MONGOLIA +2

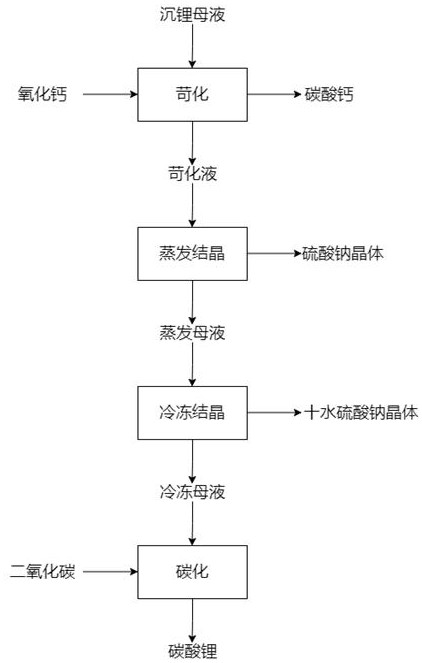

Method for recovering high-purity lithium carbonate by causticizing and freezing lithium precipitation mother liquor to remove mirabilite

PendingCN113912090AHigh priceGood application effectAlkali metal sulfites/sulfates preparation formAlkali metal sulfite/sulfate purificationSulfate radicalsLithium carbonate

The invention discloses a method for causticizing and freezing lithium precipitation mother liquor to remove mirabilite and recycle high-purity lithium carbonate. The method comprises the following steps of 1, lime causticizing, 2, evaporation concentration, 3, freezing crystallization and 4, carbonization lithium precipitation. The method has the beneficial effects that calcium oxide is added to remove the influence of carbonate ions in the lithium precipitation mother liquor, sodium sulfate decahydrate formed by sodium sulfate under a low-temperature condition is utilized to remove sulfate ions and sodium ions after concentration, and then carbon dioxide is absorbed and carbonized to obtain high-purity lithium carbonate. Therefore, the carbonate ions are removed through causticization of cheap quick lime, so that the complex route that in a traditional route, sulfuric acid is added for acidification to remove the carbonate ions, and sodium carbonate needs to be continuously supplemented for lithium precipitation after follow-up concentration is avoided. Besides, the added raw materials are few and cheap, and the cost is low. The high-purity lithium carbonate is finally recycled and prepared, and compared with industrial-grade and battery-grade lithium carbonate, the high-purity lithium carbonate is better in application effect and higher in value.

Owner:FUZHOU UNIV +1

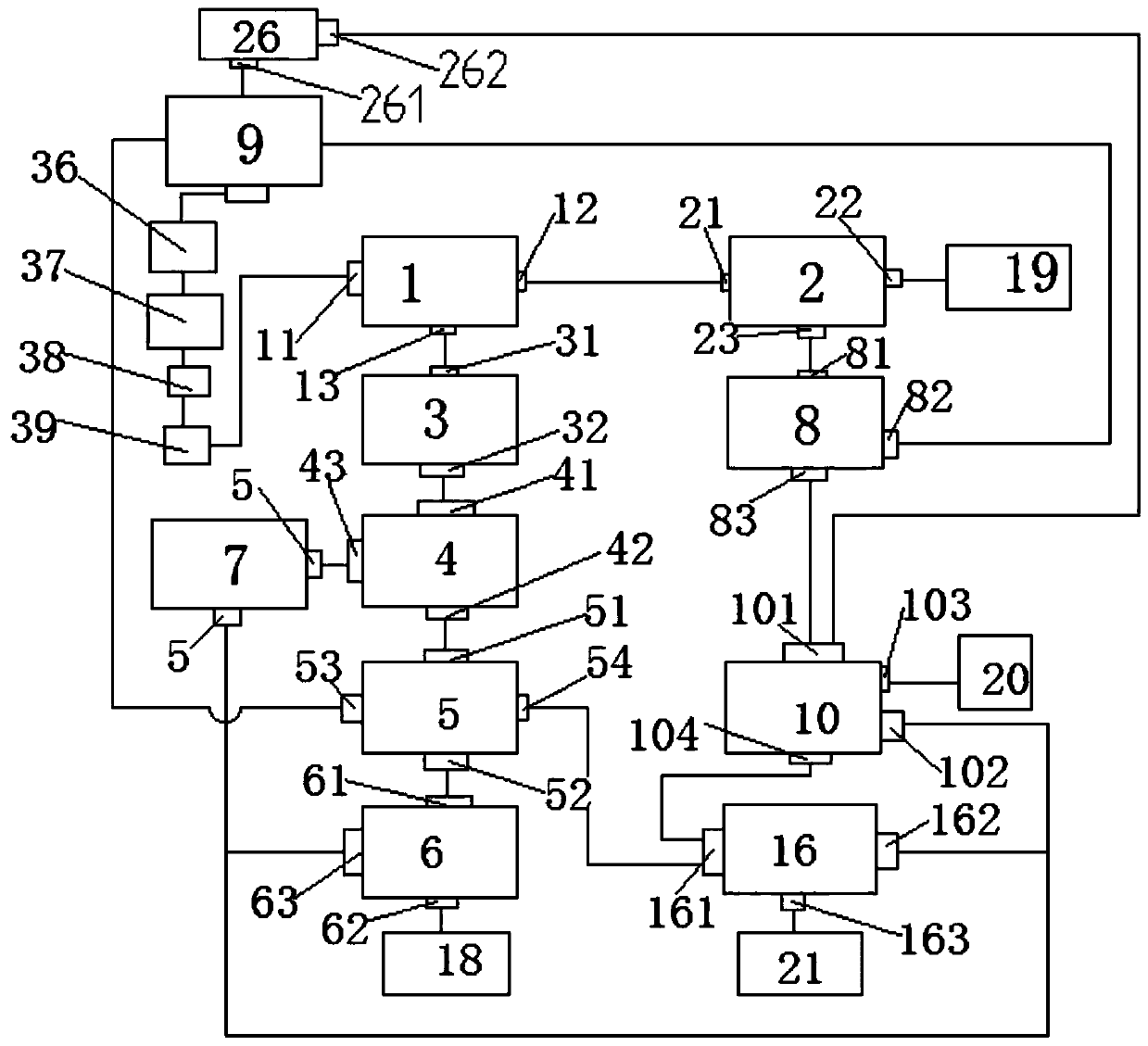

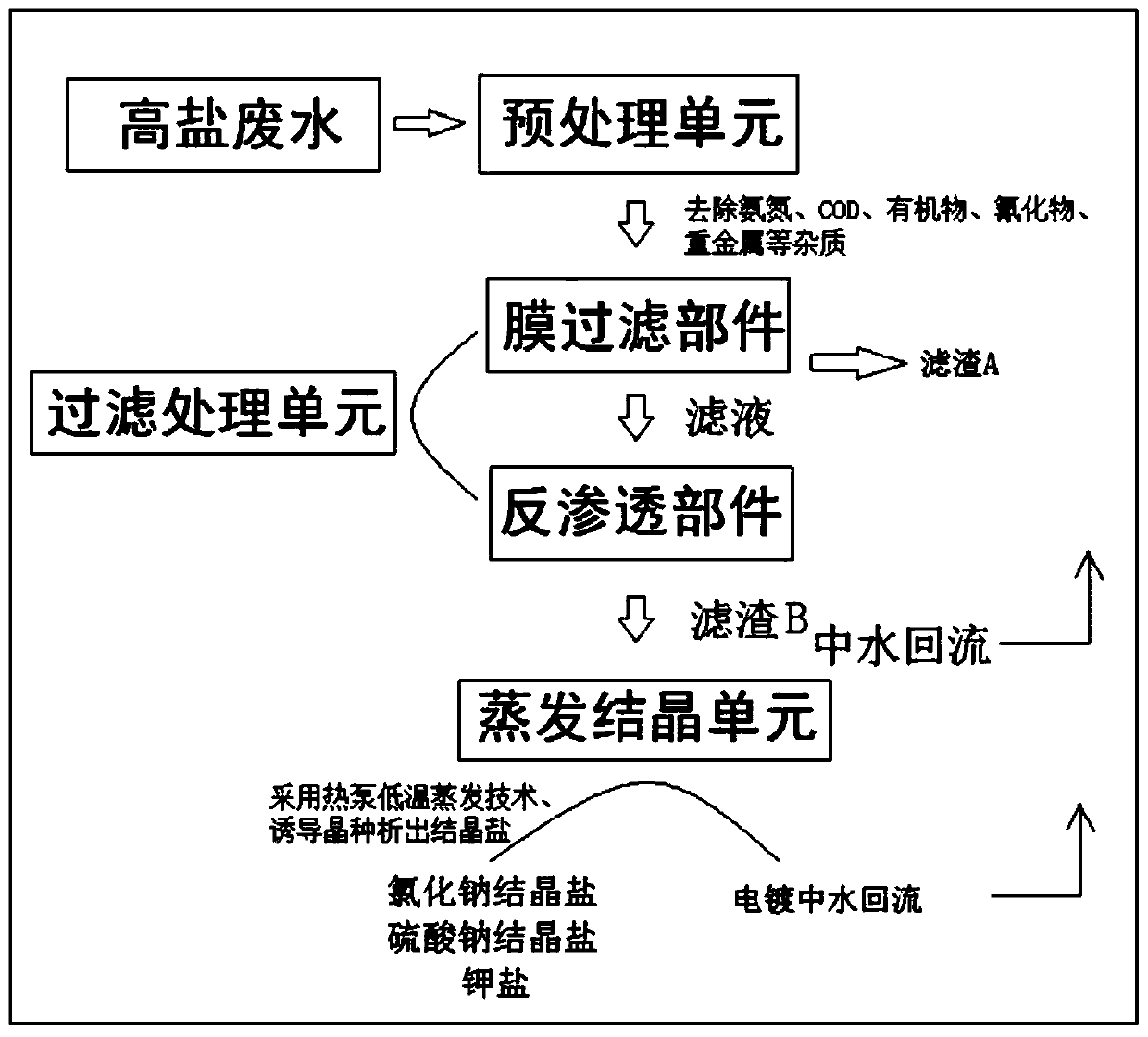

System and treatment process for purification and salt separation of electroplating high-salt wastewater

InactiveCN110386720AHigh purityImprove processing efficiencyAlkali metal sulfites/sulfates preparation formEnergy inputFiltrationReverse osmosis

The invention belongs to the technical field of polluted wastewater treatment, and specifically relates to a system and a treatment process for purification and salt separation of electroplating high-salt wastewater. The system comprises a high-salt wastewater pretreatment unit, a filtration treatment unit and an evaporation crystallization unit. The treatment process comprises the following steps: 1) high-salt wastewater pretreatment: a step of treating ammonia nitrogen, COD, organic matters and cyanide in wastewater, and allowing metal substances in the wastewater to be precipitated; 2) filtration treatment: a step of subjecting the wastewater to membrane filtration so as to obtain ultra-concentrated wastewater and a filtrate; 3) reverse osmosis treatment: a step of subjecting the filtrate to reverse osmosis filtration so as to obtain a filter residue and reflux reclaimed water; and 4) evaporation crystallization treatment: a step of allowing the filter residue to undergo pH value adjustment and crystallization treatment by using a heat-pump low-temperature evaporation technology and adding an inducing seed crystal so as to recover crystalline salt. According to the invention, byadoption of the heat-pump low-temperature evaporation technology, energy consumption is greatly saved; and a salt product and circulating reclaimed water are obtained, so zero discharge and resourceful utilization of the wastewater can be realized, and the purpose of circular economy is reached.

Owner:GUANGZHOU ANSAI CHEM IND

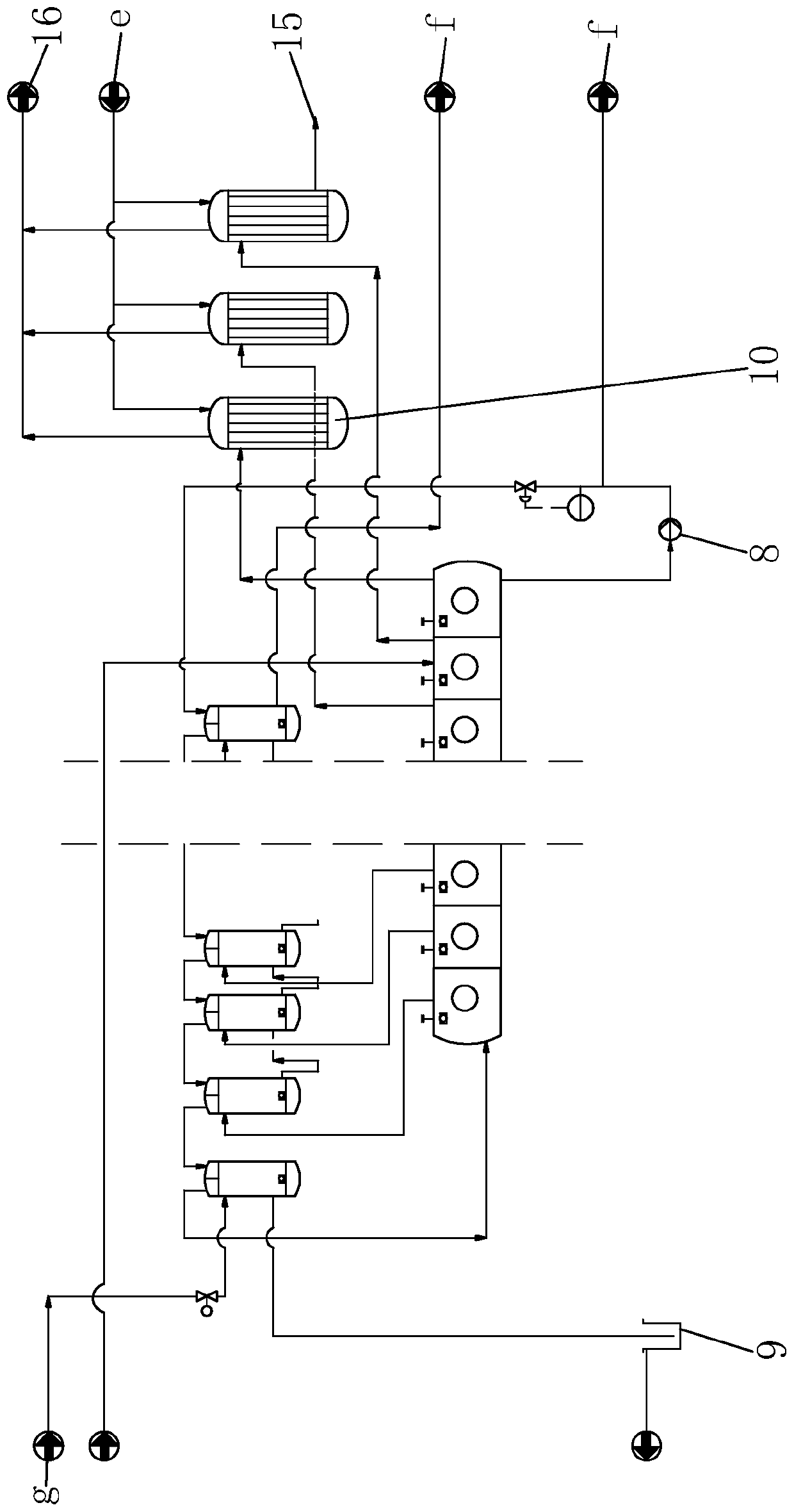

Production system and production process for continuously preparing anhydrous sodium sulfate in acid bath

ActiveCN110330039AImprove appearance qualityLarge particle sizeAlkali metal sulfites/sulfates preparation formAlkali metal sulfite/sulfate purificationLarge sizeSodium sulfate

The invention discloses a production system and a production process for continuously preparing anhydrous sodium sulfate in acid bath. The production system comprises a multistage flash evaporation device, an evaporator and a rotary airflow dryer; the multistage flash evaporation device is communicated with the evaporator through a preheater; the evaporator is communicated with a ripening tank; the ripening tank is communicated with a first-stage thickener; the first-stage thickener is communicated with a first-stage centrifugal machine; the first-stage centrifugal machine is communicated witha neutralizing tank; the neutralizing tank is communicated with a second-stage thickener; the second-stage thickener is communicated with the rotary airflow dryer; and by the production method of theproduction system, production of the anhydrous sodium sulfate is completed through multiple steps. The production system provided by the invention produces the anhydrous sodium sulfate by cooperatingthe multistage flash evaporation device and the evaporator with the rotary airflow dryer, so that the process flow route is shortened and the energy consumption is reduced; and meanwhile, sodium sulfate crystal particles obtained through production have large size, the crystal particles are uniform and full, and the apparent quality of the anhydrous sodium sulfate is high.

Owner:NANTONG SUNSHINE GRAPHITE EQUIP TECH

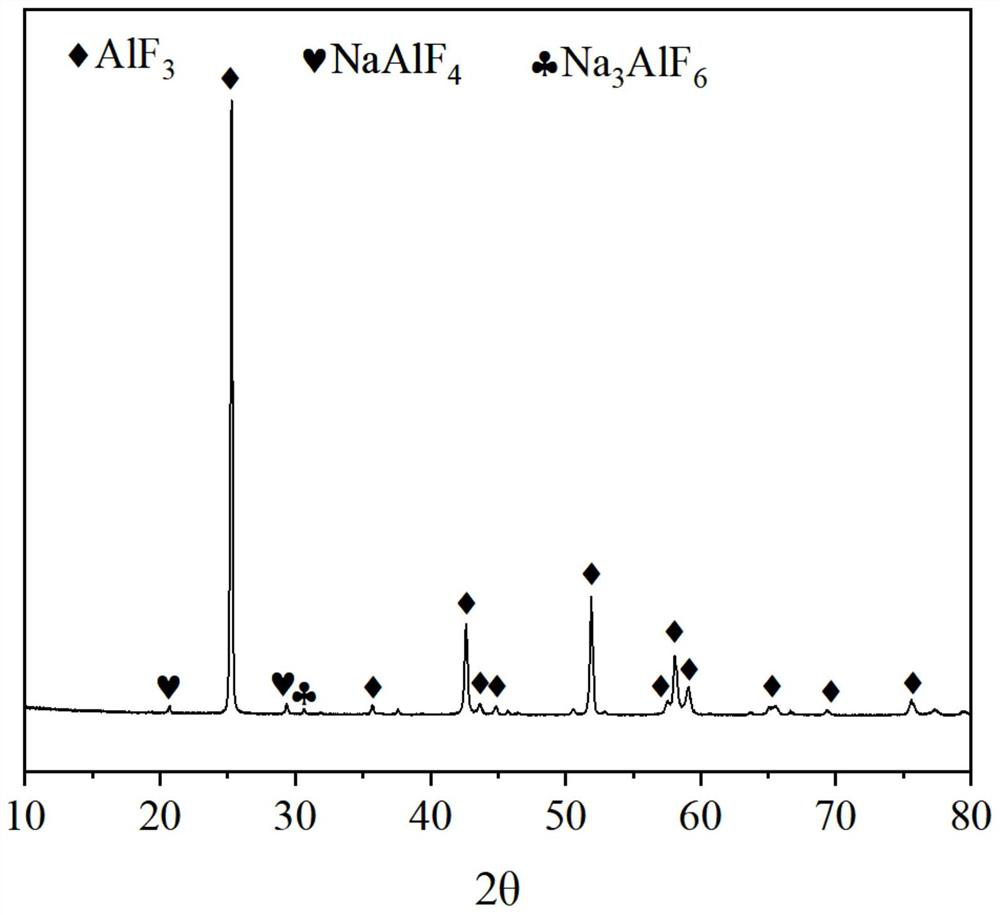

Method for treating fluorine-containing waste electrolyte

ActiveCN113149052AHigh purityHigh recovery rateAlkali metal sulfites/sulfates preparation formSulfate/bisulfate preparationAluminum fluorideAluminium electrolysis

The invention discloses a method for efficiently treating fluorine-containing waste electrolyte, which comprises the following steps: adding an additive and a reaction aid into the waste electrolyte, uniformly mixing, grinding to below 0.355 mm, roasting, cooling at a specific rate, crushing and washing to obtain an aluminum fluoride product, and concentrating filtrate to further extract other byproducts. According to the invention, the reaction aid is added to reduce the primary crystal temperature of the system, so that the reaction is carried out in a molten state, the mass transfer efficiency is high, the reaction conversion rate is high, and the content of effective aluminum fluoride in the product is high; meanwhile, the heat preservation time and the cooling rate are further controlled, so that aluminum fluoride grains generated by the reaction grow up, the obtained aluminum fluoride is good in flowability and can be well compatible with automatic discharging equipment of the current industrial aluminum electrolysis cell, and green and sustainable development of the electrolytic aluminum industry is achieved.

Owner:CENT SOUTH UNIV +1

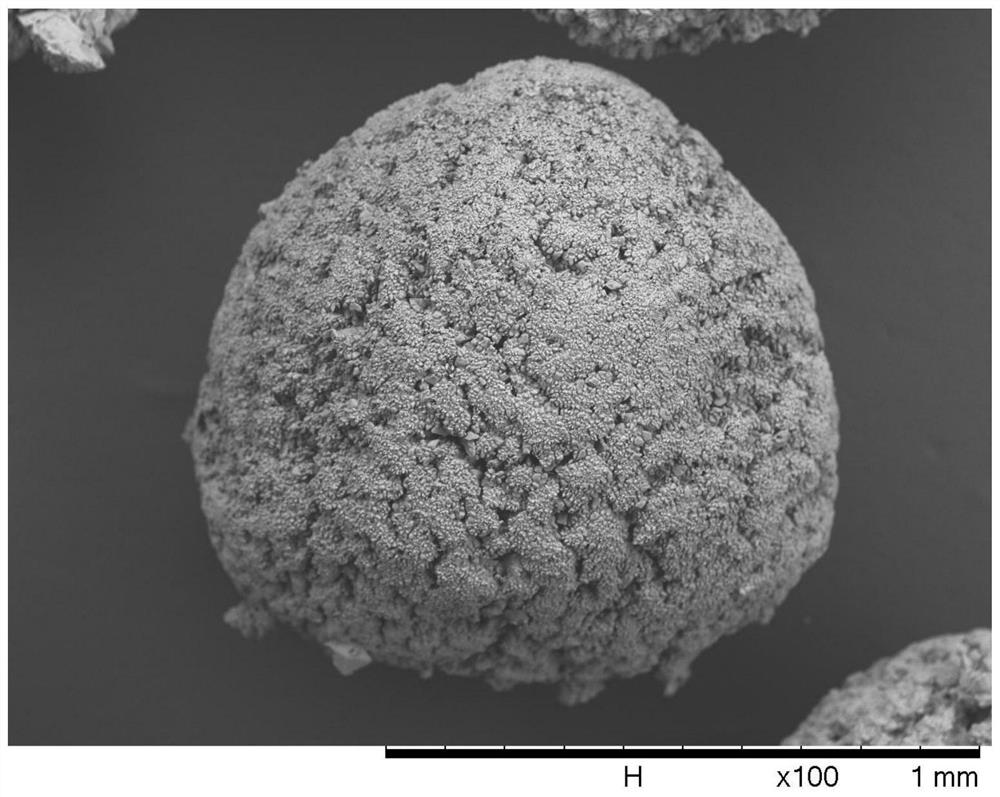

Method for the production of sulphate of potash granulates, sulphate of potash granulate obtained thereby, and use thereof

ActiveUS20170217849A1Improve mechanical stabilityImprove crack resistanceAlkali metal sulfites/sulfates preparation formAlkali metal sulfites/sulfates moisture absorption preventionBursting strengthSulfate

The invention relates to a method for producing sulphate of potash granulates, wherein 0.1 to 7.5 wt % of a sodium salt selected from among sodium chloride, sodium sulphate, sodium sulphate hydrates, sodium hydroxide and mixtures thereof are added to the sulphate of potash during the granulation process, the percentage by weight being in relation to the sulphate of potash used. In addition, 0.1 to 2.5 wt % of water are added prior to or during the granulation process. The invention also relates to the granulates obtained by said method as well as the use of sodium salts and glaserite and mixtures thereof for improving the mechanical properties of sulfate of potash granulates. The sulphate of potash granulates produced by the method of the invention have significantly greater bursting strength and significantly greater abrasion resistance than granulates known from the prior art.

Owner:KALI & SALZ GMBH

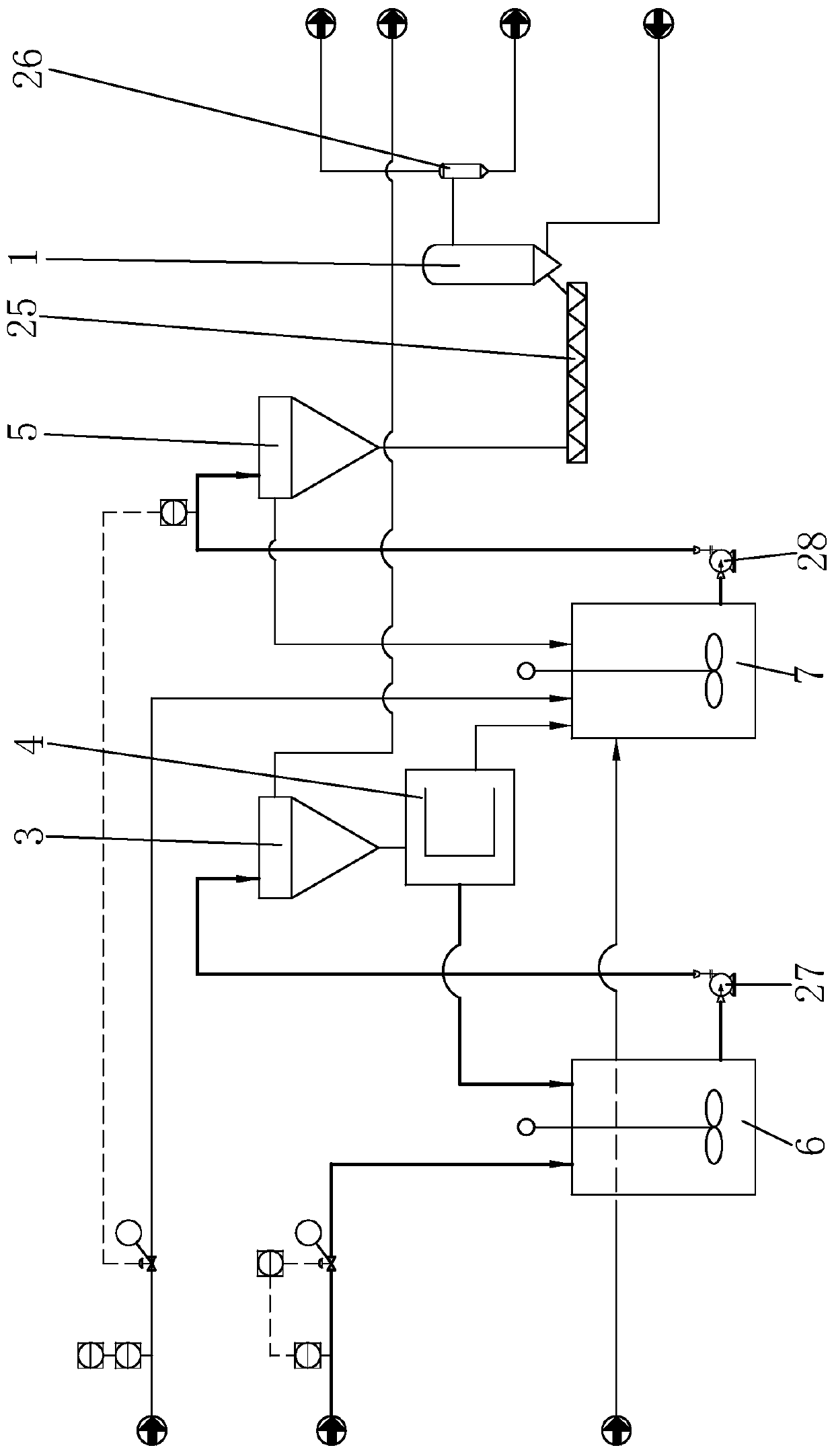

System and method for preparing byproduct potassium sulfate product through hydrothermal denitration of potassium chloride brine

PendingCN113184882ATo achieve the purpose of removing sulfateAvoid introducingAlkali metal sulfites/sulfates preparation formCalcium/strontium/barium chloridesPhysical chemistryPotassium sulfate

The invention relates to the technical field of chemical engineering, and discloses a system and method for preparing byproduct potassium sulfate product through hydrothermal denitration of potassium chloride brine, and the method comprises the following steps: a nanofiltration membrane unit receives dechlorinated light salt brine from an external potassium alkali device and conveys the dechlorinated light salt brine to a heat exchange unit for heat exchange; secondary gas condensate generated by an evaporative crystallization unit is conveyed to the heat exchange unit, in the heat exchange unit, the dechlorinated light salt brine exchanges heat with the secondary gas condensate, the dechlorinated light salt brine after heat exchange is conveyed to the evaporative crystallization unit to be evaporated and concentrated to obtain potassium sulfate crystals, and the secondary gas condensate after heat exchange is subjected to waste heat recovery treatment; and potassium sulfate crystals are treated by a centrifugal separating unit and then enter a drying unit to be dried, qualified potassium sulfate products are obtained, and centrifugal mother liquor obtained after centrifugal separating is output to a potassium alkali device to enter a secondary brine refining procedure. According to the method, the defects of a barium-method denitration process or a calcium-method denitration process used in current industrial production are effectively overcome, and the purposes of reducing cost and improving efficiency are achieved.

Owner:CHINA CHENGDA ENG

Industrial-grade anhydrous sodium sulfate preparation device and method

InactiveCN111533143AGuaranteed purityLess investmentAlkali metal sulfites/sulfates preparation formAlkali metal sulfite/sulfate purificationSulfatePhysical chemistry

The invention discloses an industrial-grade anhydrous sodium sulfate preparation device and method, and relates to the field of recycling sodium sulfate from light salt brine as industrial-grade anhydrous sodium sulfate. The device is characterized in that the device comprises a membrane concentration system, a continuous flow salting-out crystallization system, a centrifugal machine and a dryingmachine system which are connected in sequence. The membrane concentration system is used for concentrating the light salt brine containing sodium sulfate and discharging a concentrated solution containing supersaturated sodium sulfate. The continuous flow salting-out crystallization system is mainly used for crystallizing large-particle sodium sulfate crystals in a supersaturated sodium sulfate concentrated solution discharged by the membrane concentration system at normal temperature by a salting-out method and accurately controlling the supersaturation degree to separate out large-particlesodium sulfate crystals, and meanwhile, the purity of anhydrous sodium sulfate is ensured by utilizing a reflux design, and the centrifugal machine and drying machine system is used for drying. According to the invention, continuous preparation of large-particle high-purity anhydrous sodium sulfate is realized, and equipment investment and energy consumption are low when the anhydrous sodium sulfate is prepared at normal temperature.

Owner:SHANGHAI LYMAX ENVIRONMENTAL TECH CO LTD

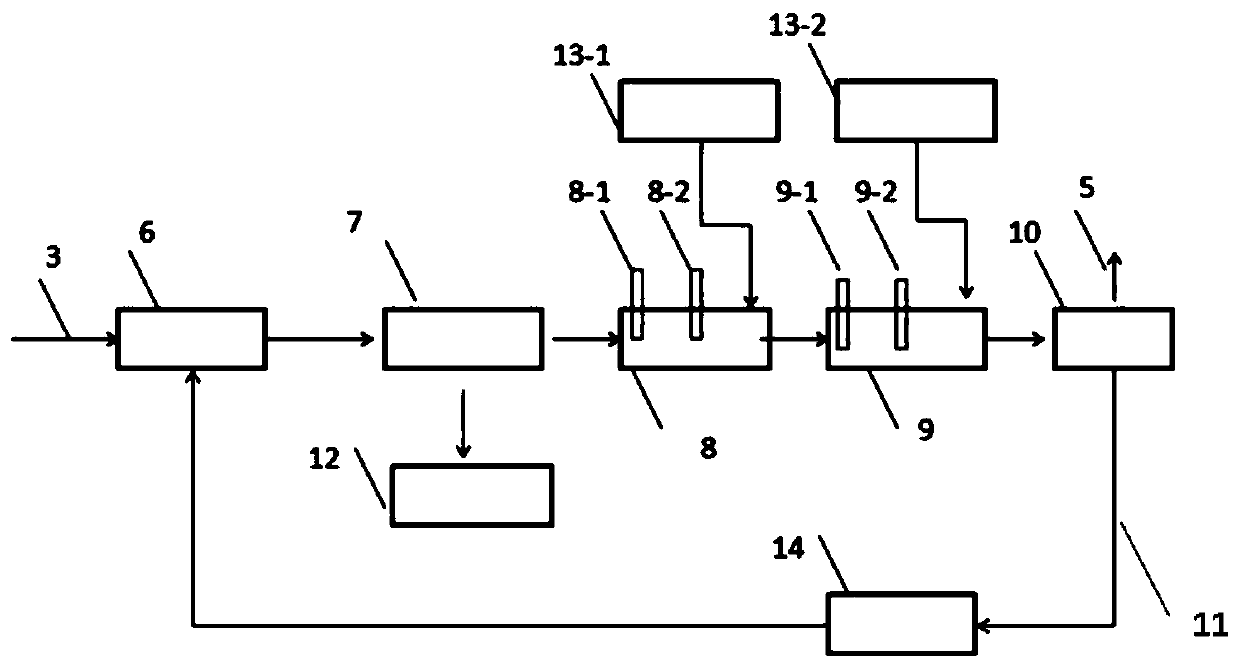

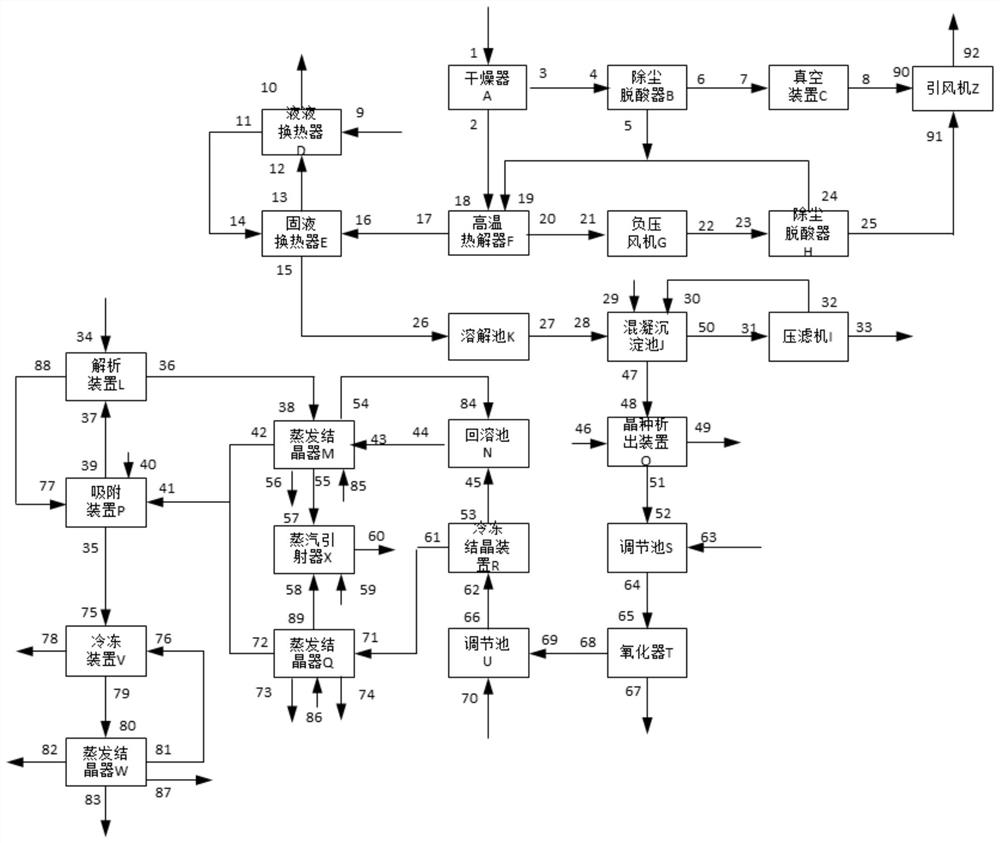

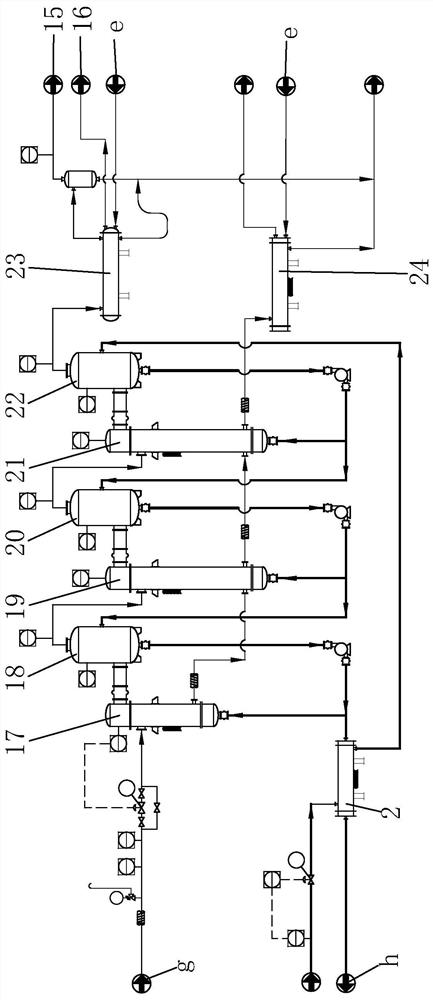

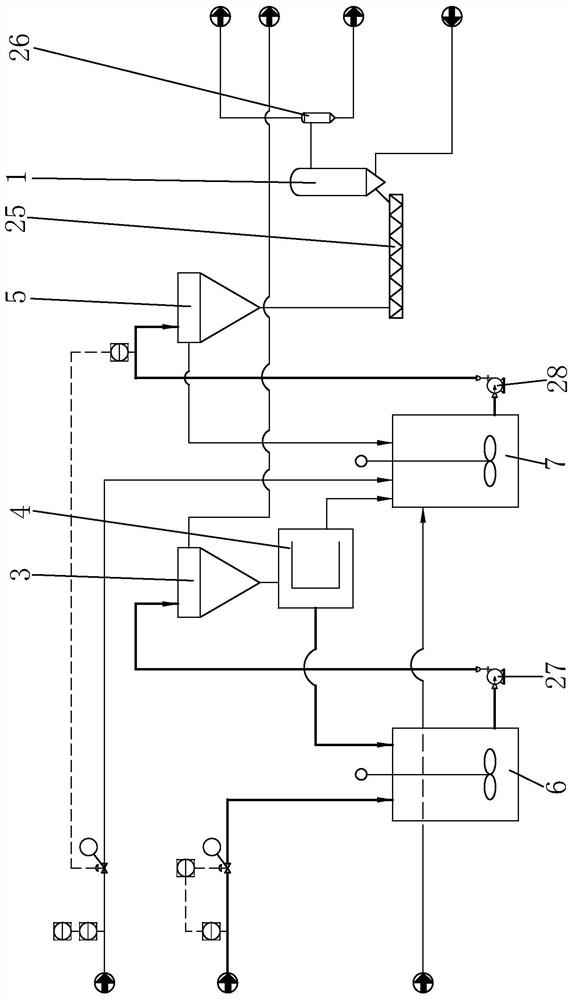

Waste salt recycling system and method based on thermal power plant energy saving and environment protection integration

PendingCN111672879AReduce disposal costsRealize secondary recyclingAlkali metal sulfites/sulfates preparation formDispersed particle filtrationDust controlFilter press

The invention relates to a waste salt recycling system and method based on thermal power plant energy saving and environment protection integration. The system comprises a dryer A, a dust removal deacidification device B, a vacuum device C, a liquid-liquid heat exchanger D, a solid-liquid heat exchanger E, a high-temperature pyrolyzer F, a negative-pressure draught fan G, a dust removal deacidification device H, a dissolving pond K, a coagulative precipitation tank J, a filter press I, a seed crystal precipitation device O, an adjusting pond S, an oxidizer T, an adjusting pond U, a freezing crystallization device R, a re-dissolution pond N, an evaporation crystallizer M, a steam ejector X, an evaporation crystallizer Q, a resolver L, an adsorption device P, a freezing device V, an evaporation crystallizer W and an induced draft fan Z. Harmful and recycling treatment of danger waste salt generated during industrial production can be achieved on the basis of energy gradient utilization and waste heat recycling thermotechnical processes, accompanying dioxin, danger waste smoke and other secondary pollution are eliminated, and the danger waste salt recycling treatment effective runningenergy consumption and danger waste salt treatment cost are obviously reduced.

Owner:北京赫宸智慧能源科技股份有限公司 +3

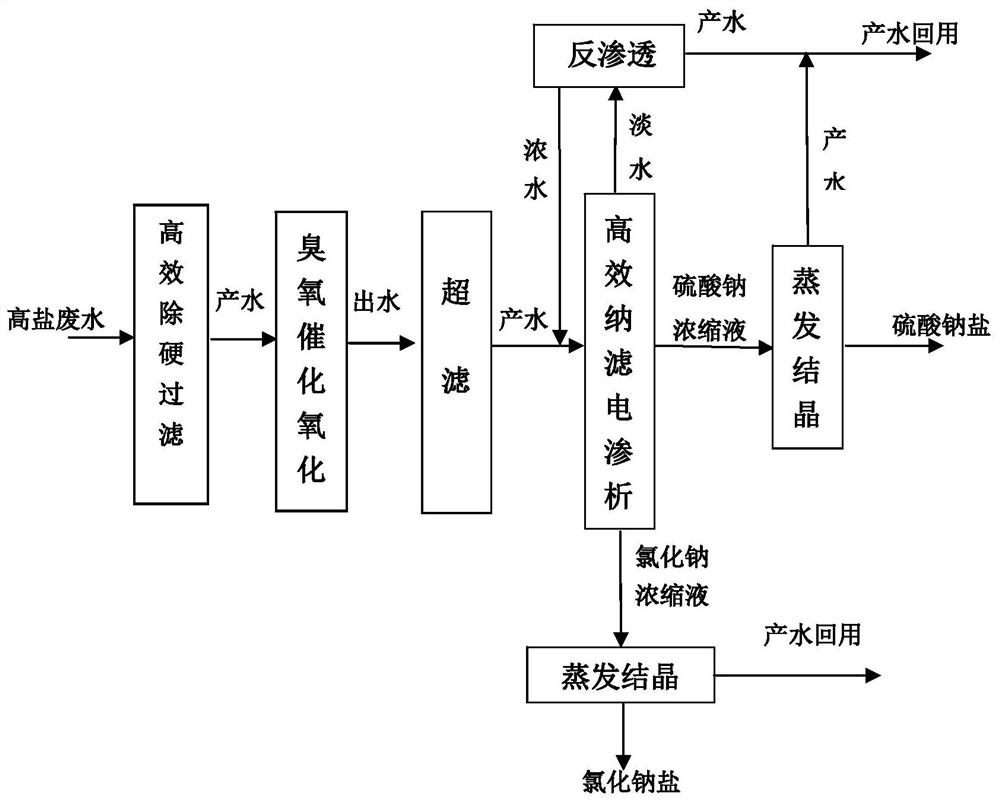

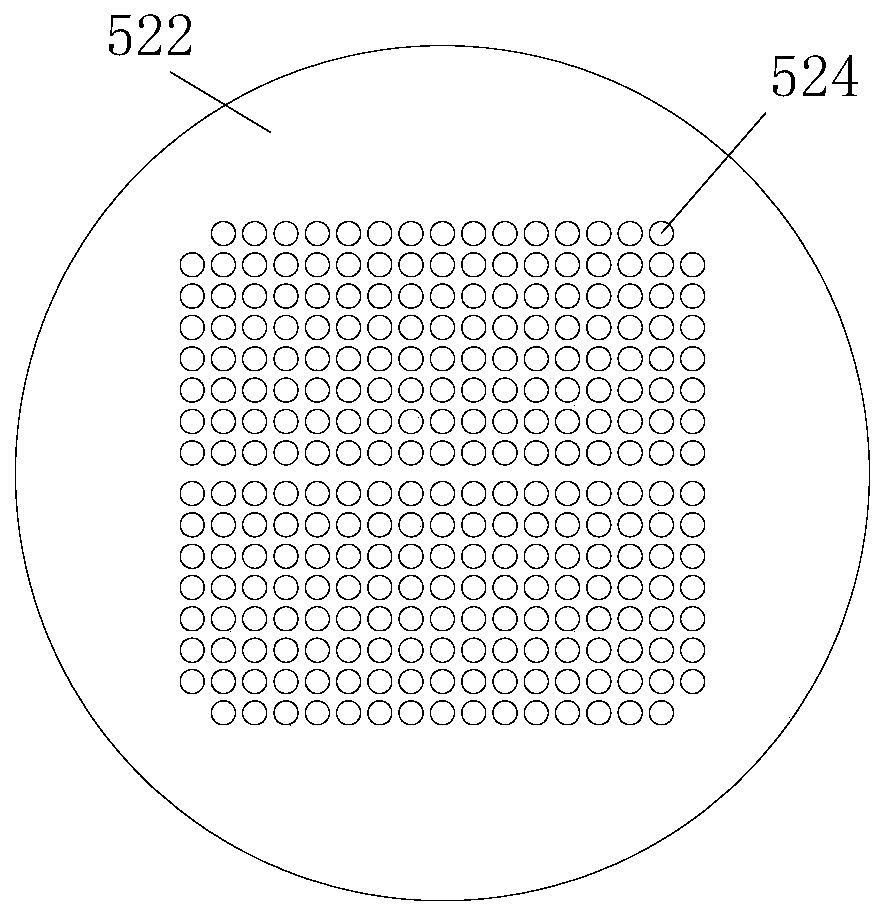

Quality-based and salt-based treatment device and method for high-salinity wastewater in coal chemical industry

PendingCN114195304AEfficient removalImprove effluent qualityAlkali metal sulfites/sulfates preparation formWater treatment parameter controlFiltrationReverse osmosis

The invention provides a quality-based and salt-based treatment device and method for coal chemical industry high-salinity wastewater. The coal chemical industry high-salinity wastewater is treated by adopting efficient hardness removal filtration, catalytic ozonation, ultrafiltration, efficient nanofiltration electrodialysis, reverse osmosis and evaporative crystallization, and by adopting the technology, a low-temperature heat source is effectively utilized, and near-zero emission and resource utilization of the coal chemical industry high-salinity wastewater are realized. Compared with the prior art, the process provided by the invention has the advantages of good effluent quality, high quality of recovered salts and good technical economy.

Owner:CHINA PETROLEUM & CHEM CORP +1

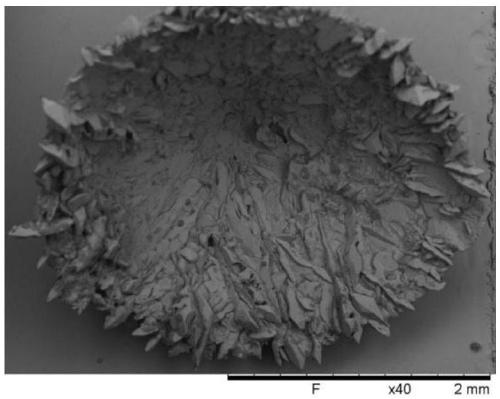

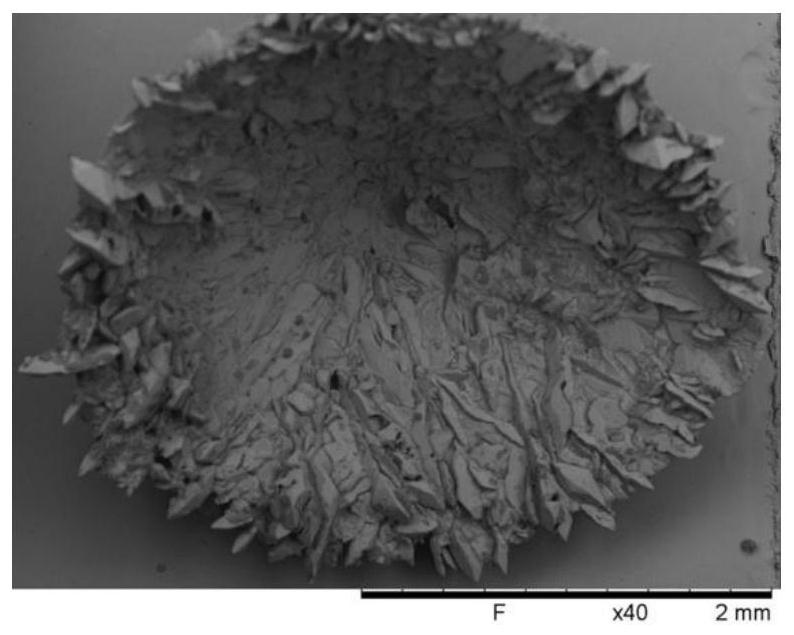

Method of preparing funnel-shaped sodium sulfate from high salt wastewater

ActiveCN109592698ALarge granularityEvenly distributedAlkali metal sulfites/sulfates preparation formGranularityWastewater

The invention relates to a method of preparing funnel-shaped sodium sulfate from high salt wastewater. The method comprises the following steps: heating the wastewater to 50-80 DEG C, adding sodium hydroxide to adjust the pH of the wastewater to 11-14, and controlling the stirring rate at 100-400 rpm; adopting a negative evaporative crystallizing mode till the volume of the evaporated water is 20-30% of original wastewater volume, wherein the vacuum degree is 0.04-0.07 MPa; and filtering and drying the obtained product to obtain the funnel-shaped sodium sulfate. The cone angle of the funnel ofthe sodium sulfate product with a special funnel-shaped crystal form is 120-150 degrees and the purity of sodium sulfate is greater than or equal to 95%. The granularity of particles is relatively great and the particles are distributed uniformly, and the grain size of the product is greater than or equal to 300 [mu]m.

Owner:TIANJIN UNIV

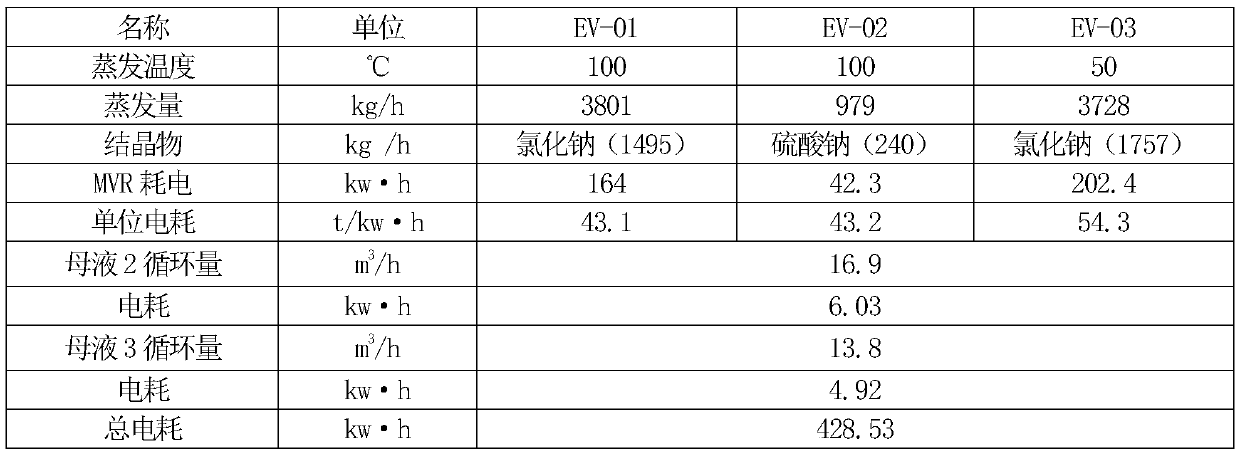

Salt-nitrate continuous separation method

InactiveCN110407234ATake advantage ofSimple processAlkali metal sulfites/sulfates preparation formAlkali metal sulfite/sulfate purificationNitrateConcentration ratio

A salt-nitrate separation method comprises the steps that the salt-nitrate concentration in a raw material is detected; if the salt-nitrate concentration ratio is larger than or equal to the co-saturation concentration ratio of salt and nitrate at a first temperature and the concentration of the salt is higher than the co-saturation concentration of the salt at the first temperature, A1, the raw material is introduced into a salt evaporation crystallizer to crystallize at the first temperature, and when the concentration of the nitrate is in the range from the co-saturation concentration of -0.5% of the nitrate at the first temperature to the co-saturation concentration of the nitrate at the temperature, a mother liquor 1 is formed; A2, the mother liquor 1 is transferred into a salt evaporation crystallization tank to crystallize at a second temperature, and when the concentration of the nitrate is in the range from the co-saturation concentration of -0.5% of the nitrate at the secondtemperature to the co-saturation concentration of the nitrate at the temperature, a mother liquor 2 is formed; A3, the mother liquor 2 is transferred into a nitrate evaporation crystallization tank tocrystallize at the first temperature, and when the concentration of the salt in a nitrate evaporation crystallizer is in the range from the co-saturation concentration of -0.5% of the salt at the first temperature to the co-saturation concentration of the salt at the temperature, a mother liquor 3 is formed; A4, the mother liquor 3 is transferred into the salt evaporation crystallization tank tocrystallize at the second temperature to form a mother liquor 2; step A3 and step A4 are repeated.

Owner:BEIJING HORIZON ENVIRONMENTAL TECH

Method for the production of sulphate of potash granulates, sulphate of potash granulate obtained thereby, and use thereof

ActiveUS10487018B2Easy to operateLess dustAlkali metal sulfites/sulfates preparation formAlkali metal sulfites/sulfates moisture absorption preventionBursting strengthSulfate

The invention relates to a method for producing sulphate of potash granulates, wherein 0.1 to 7.5 wt % of a sodium salt selected from among sodium chloride, sodium sulphate, sodium sulphate hydrates, sodium hydroxide and mixtures thereof are added to the sulphate of potash during the granulation process, the percentage by weight being in relation to the sulphate of potash used. In addition, 0.1 to 2.5 wt % of water are added prior to or during the granulation process. The invention also relates to the granulates obtained by said method as well as the use of sodium salts and glaserite and mixtures thereof for improving the mechanical properties of sulfate of potash granulates. The sulphate of potash granulates produced by the method of the invention have significantly greater bursting strength and significantly greater abrasion resistance than granulates known from the prior art.

Owner:KALI & SALZ GMBH

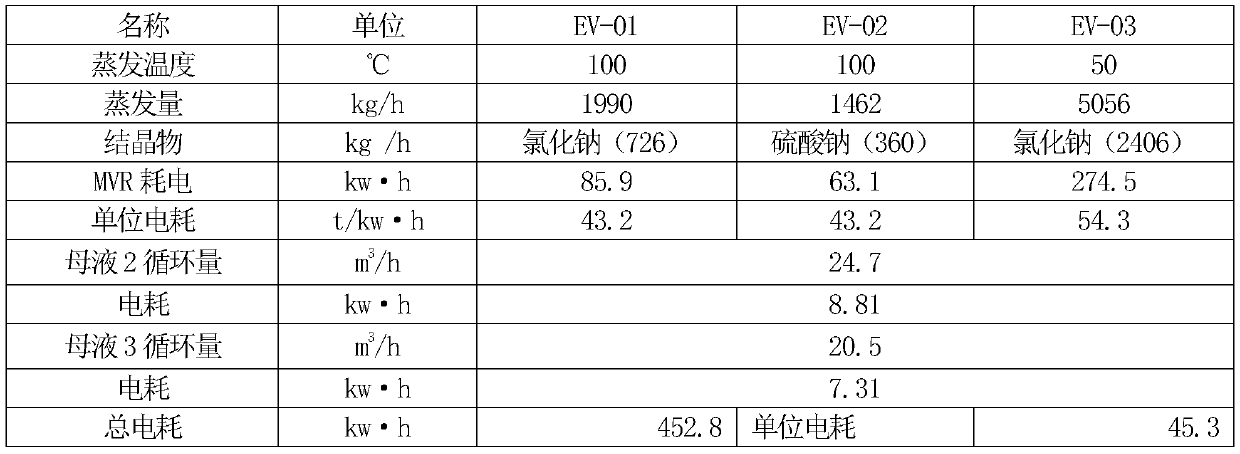

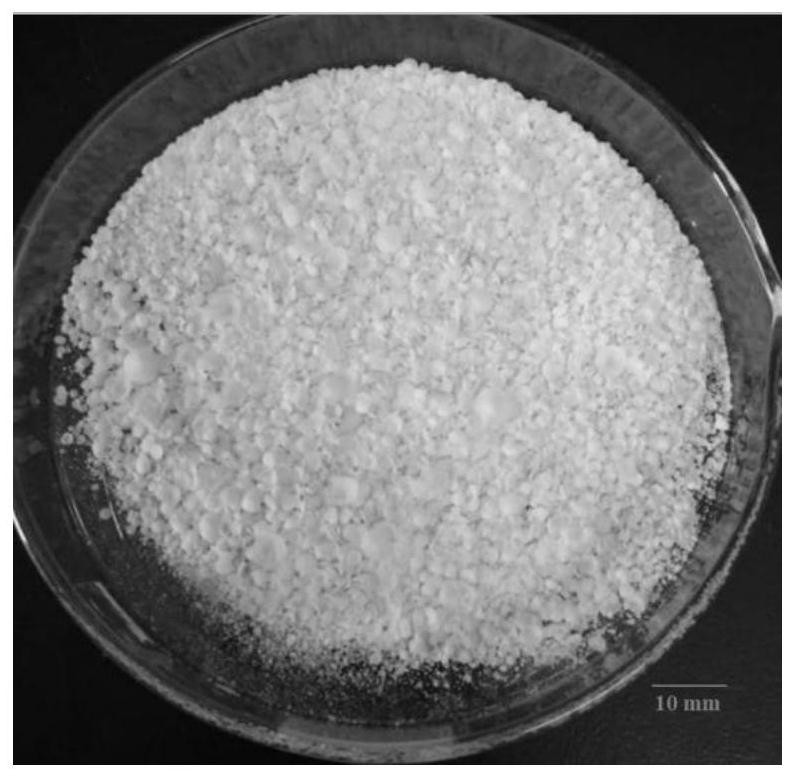

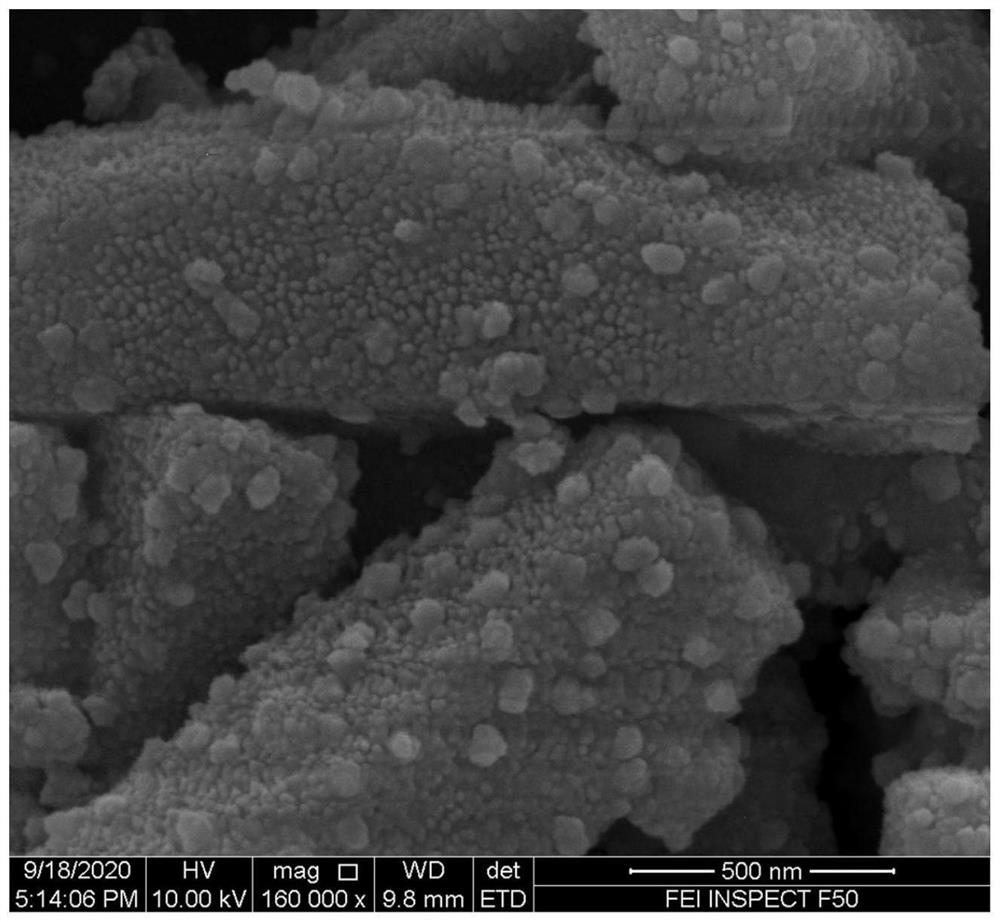

Surface roughening treatment method forpotassium sulfate particle

ActiveCN113387372AEasy to manufactureLow priceAlkali metal sulfites/sulfates preparation formNanotechnologyOrganic solventPolyvinyl alcohol

The invention discloses a surface roughening treatment method for potassium sulfate particles. The method comprises the following steps: dispersing potassium sulfate salt powder into an organic solvent at room temperature, stirring, adding a certain amount of a polyvinyl alcohol aqueous solution, heating to 80-100 DEG C, keeping the temperature for 0.5-2 hours, stopping stirring, drying a precipitate, and finally calcining at 500 DEG C or above to obtain the potassium sulfate salt powder with roughened particle surfaces.

Owner:SOUTHEAST UNIV

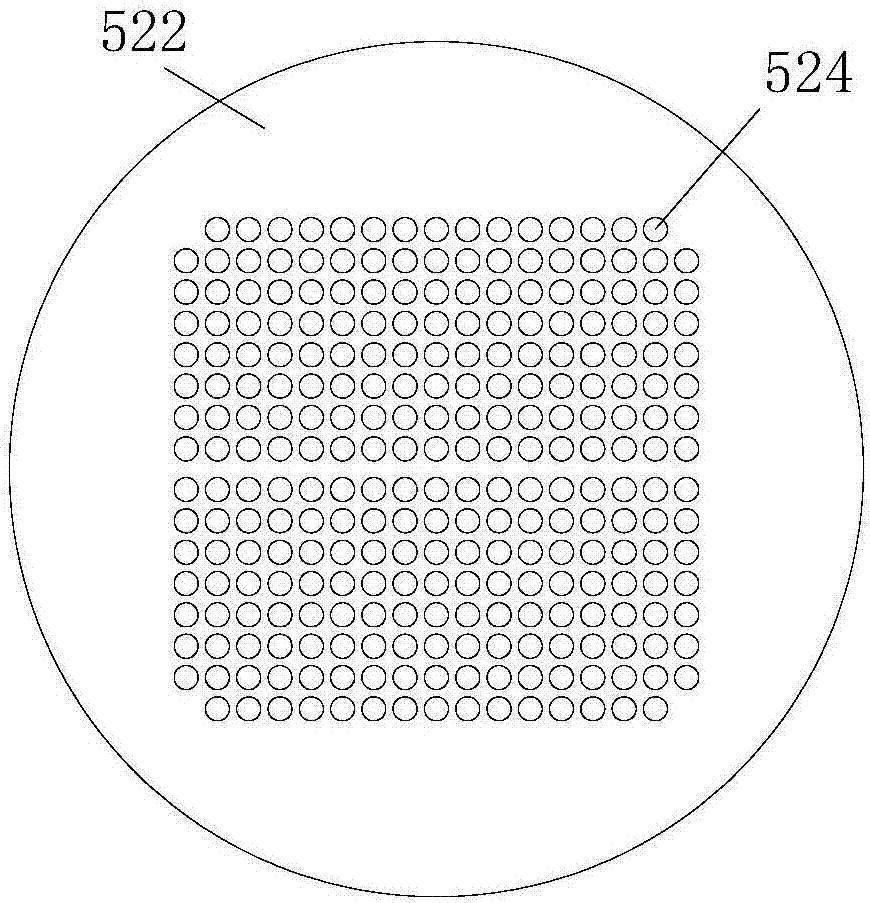

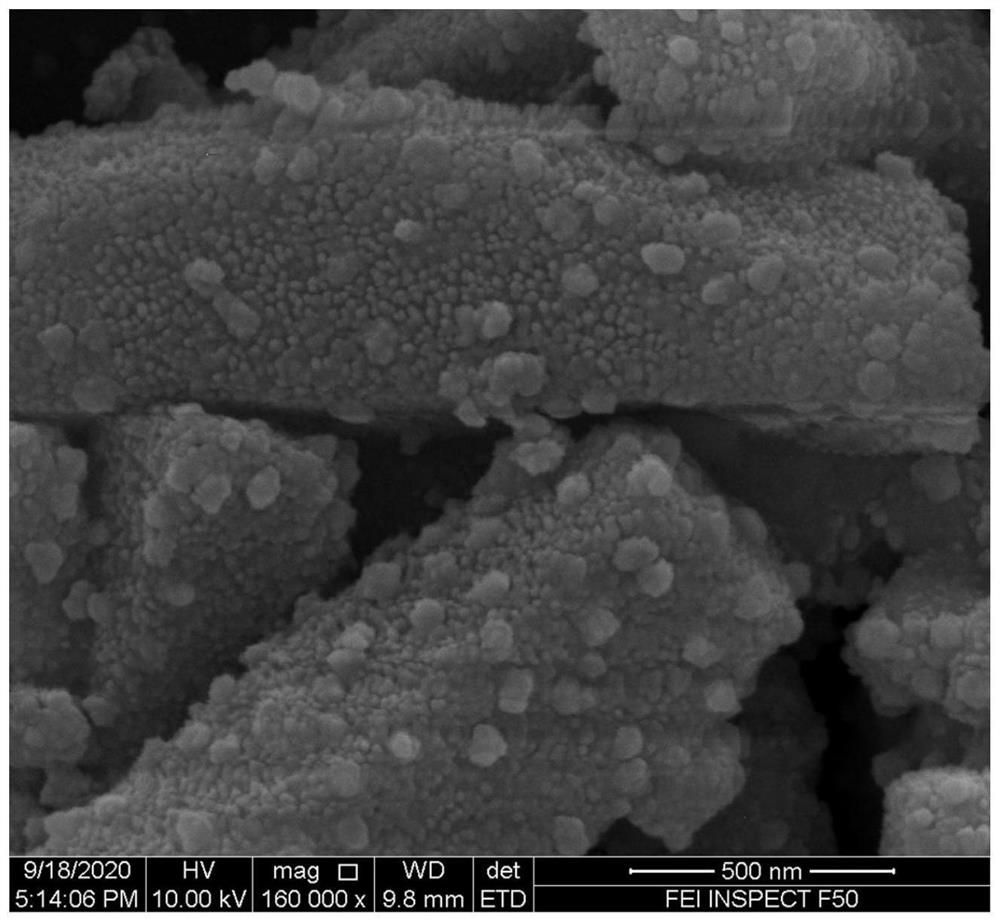

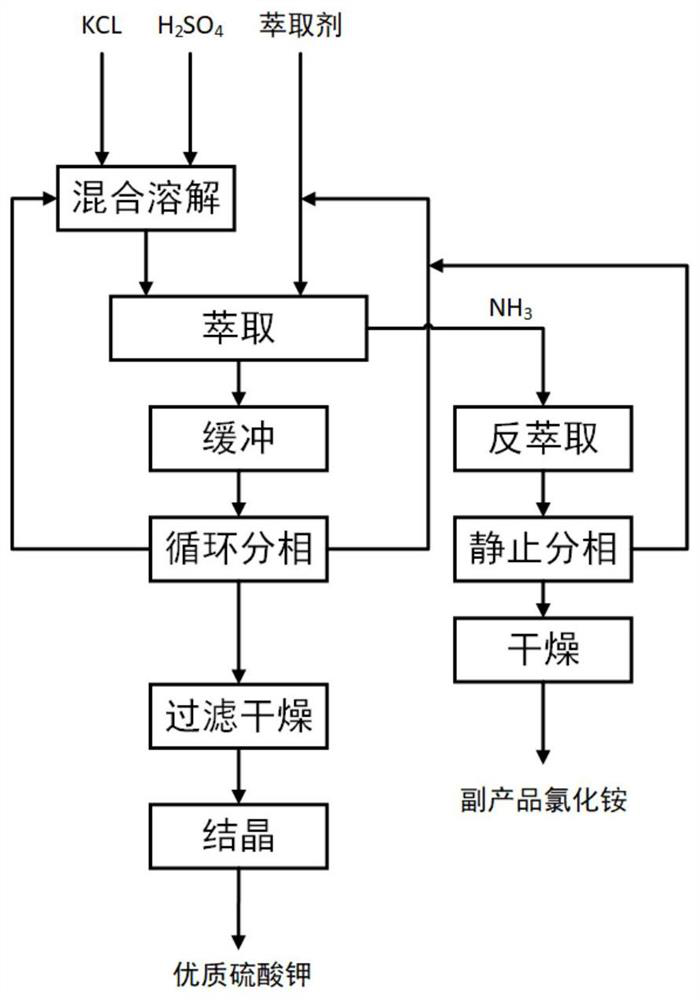

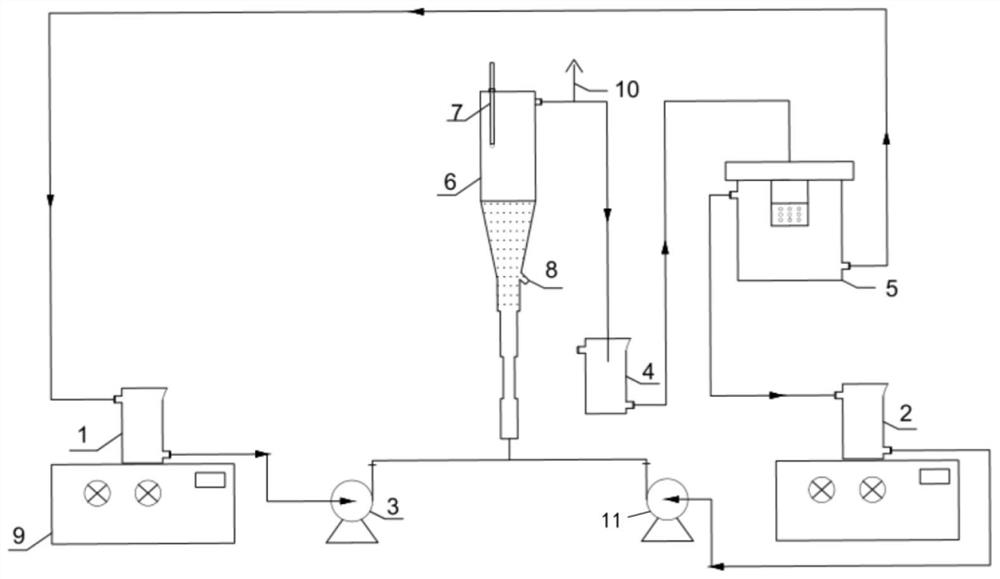

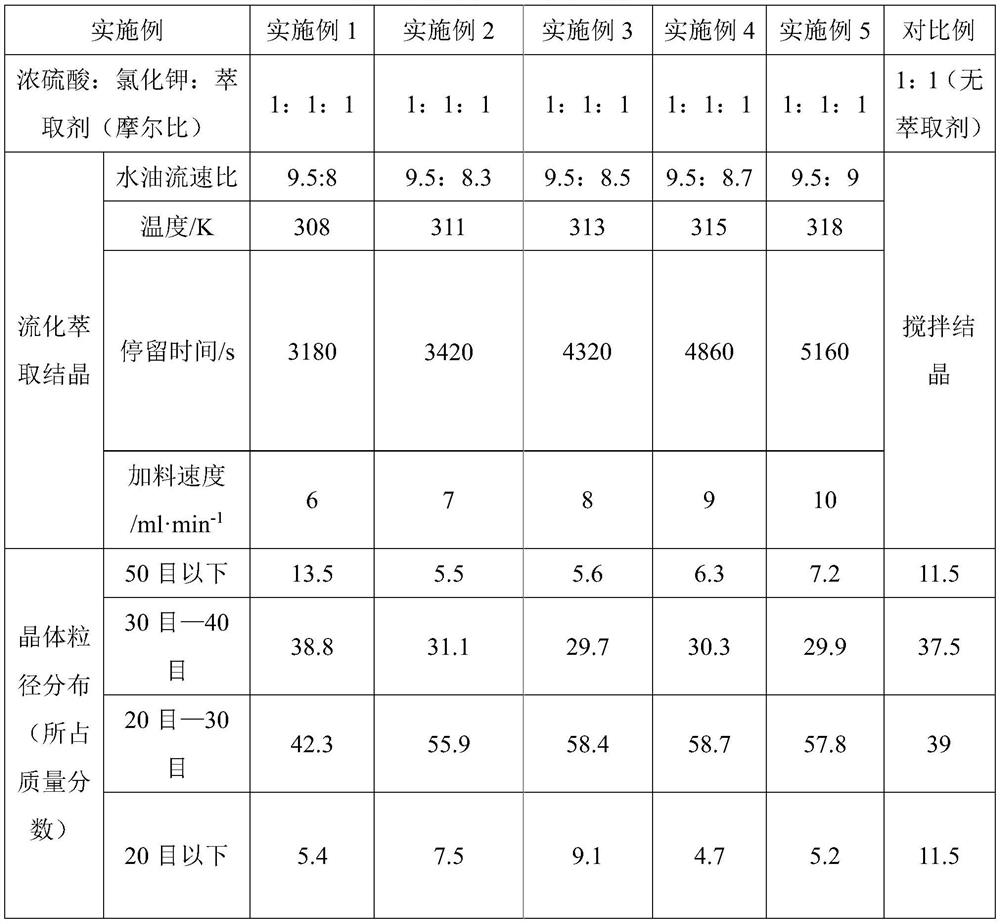

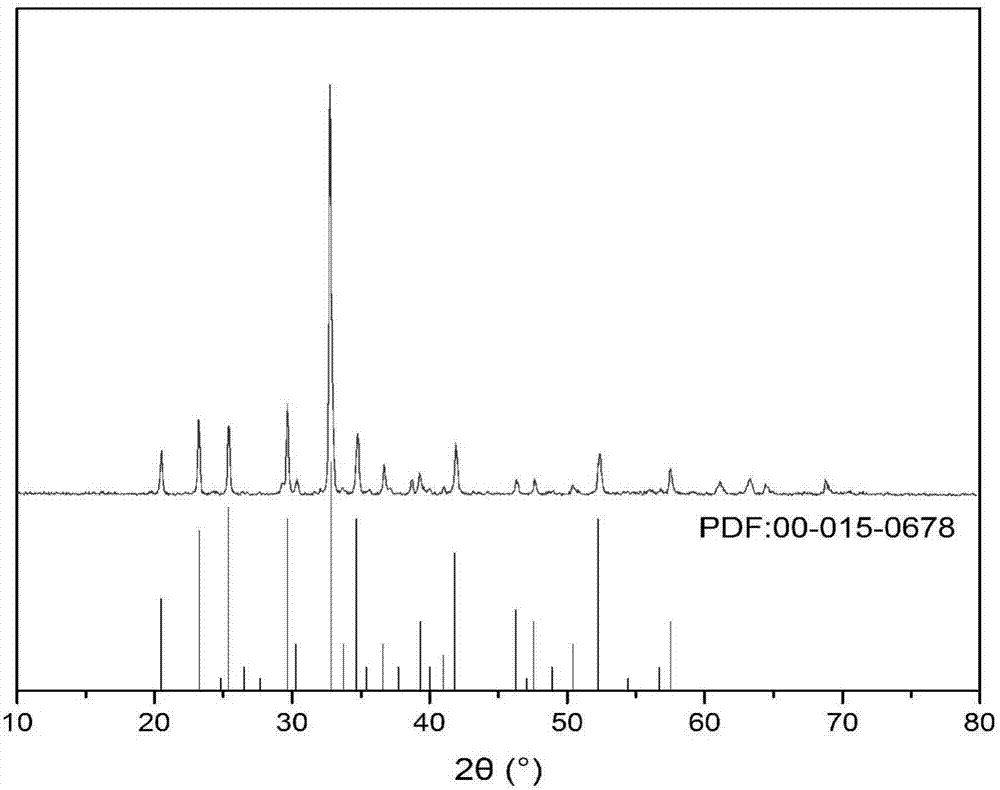

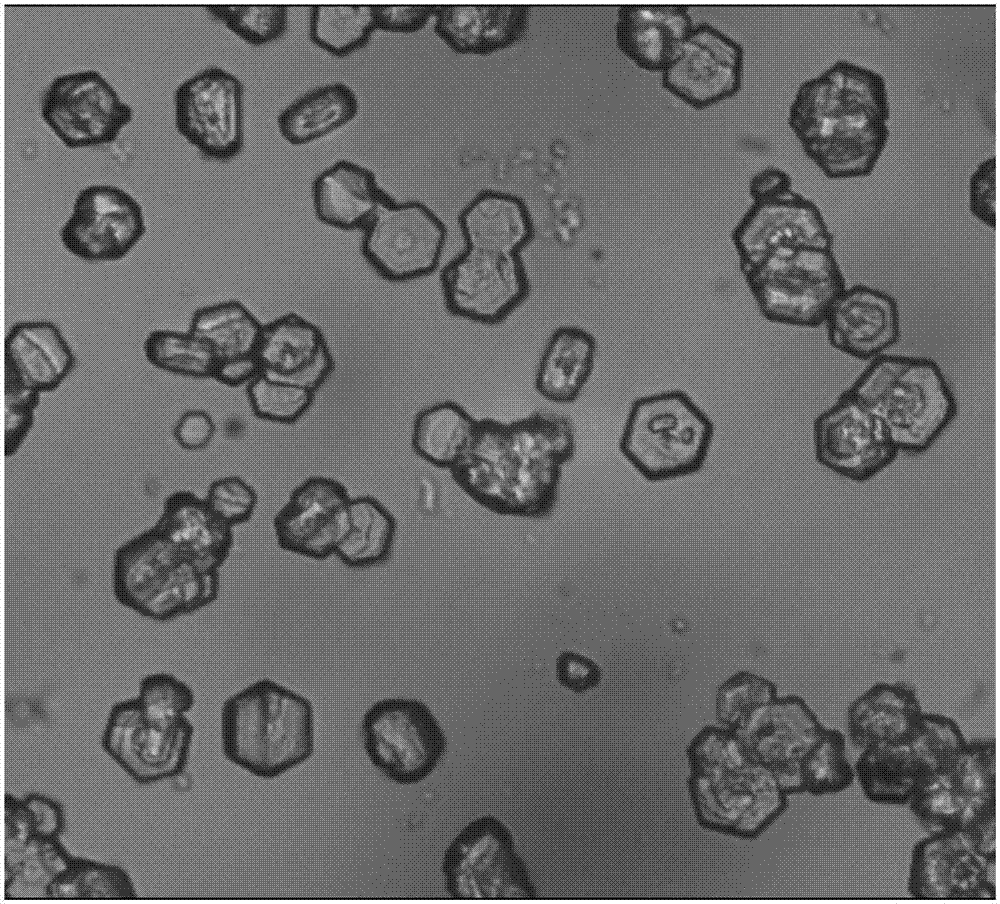

Novel extraction crystallization method for preparing potassium sulfate crystals, fluidization device and application of fluidization device

ActiveCN111960439AGood crystal shapeQuality improvementAlkali metal sulfites/sulfates preparation formAlkali metal sulfite/sulfate purificationPhysical chemistryPotassium sulfate

The invention discloses a novel extraction crystallization method for preparing potassium sulfate crystals, a fluidization device and application of the fluidization device. A fluidization method is adopted to replace stirring to generate driving force to enable crystals to grow on the surfaces of seed crystals, so that the environment is more uniform and stable, all crystal faces of the crystalsare uniformly supplied with solutes in a supersaturated solution, a solution continuously flows, the super-saturation degree of the solution in a bed is basically kept unchanged, and the obtained crystals are good in crystal form and high in quality. According to the fluidized bed fractional crystallization process production device for coupling extraction crystallization, the contact probabilityof crystals in the fluidization crystallizer and the contact probability of the crystals and the wall of the crystallizer are greatly reduced, and therefore secondary nucleation can be effectively reduced, and the crystals with a large size are obtained. Due to the application of the device, the production process is greatly simplified, the operation is coherent and convenient, a small amount of waste residues in the crystallizer are removed regularly, no three wastes are discharged, and the technological process is extremely environment-friendly.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

a kind of na 3 fso 4 Method for preparing flaky single crystal α-alumina for seeding

InactiveCN105858694BObvious hexagonal sheet structureCalcination temperature is lowAlkali metal sulfites/sulfates preparation formAluminium compoundsRoom temperatureMolten salt

The invention relates to a method for preparing platy-monocrystal alpha-aluminum oxide with Na3FSO4 as seed crystals and belongs to the field of preparation of inorganic nonmetal power materials. The method comprises the following steps that firstly, fused salt and Na3FSO4 crystals are added into raw materials containing aluminum and mixed evenly, and a mixed material is obtained; secondly, the mixed material is roasted at 650-1000 DEG C, the roasted mixed material is cooled to the room temperature and then dissolved with hot water at 50-100 DEG C, washing, filtering and drying are carried out, and platy-monocrystal alpha-aluminum oxide is obtained. According to the method, Na3FSO4 seed crystals for preparation are of an obvious hexagonal platy structure, and greatly assist in forming platy aluminum oxide; the roasting temperature is low, and reduction of energy consumption is promoted.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

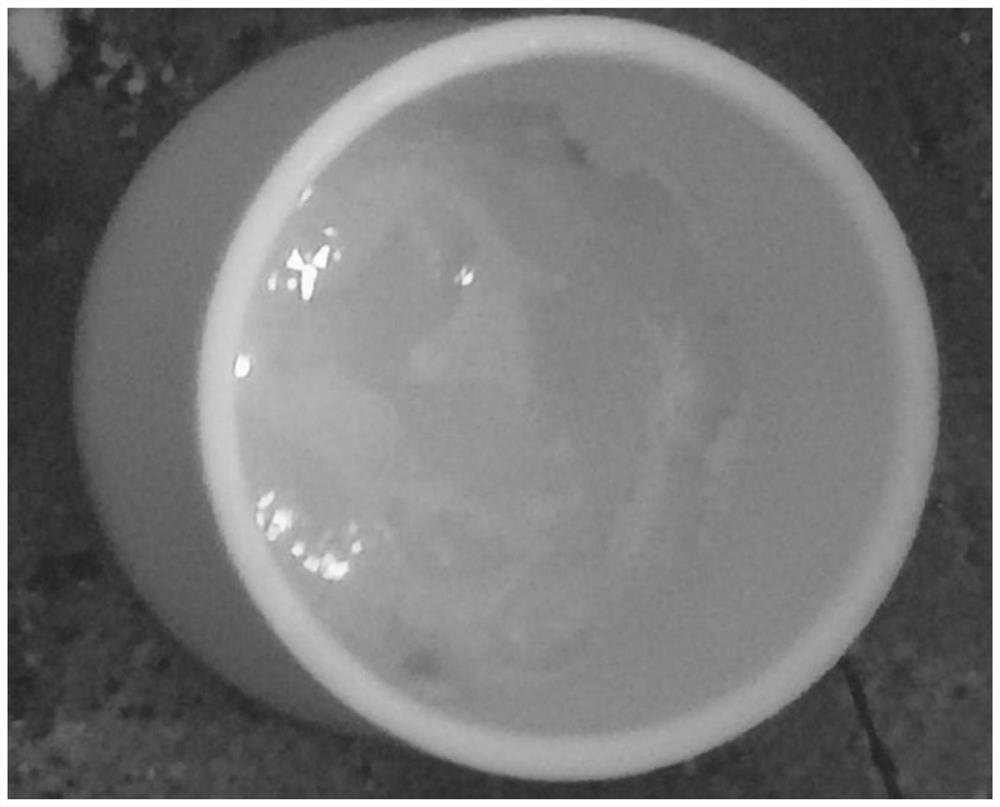

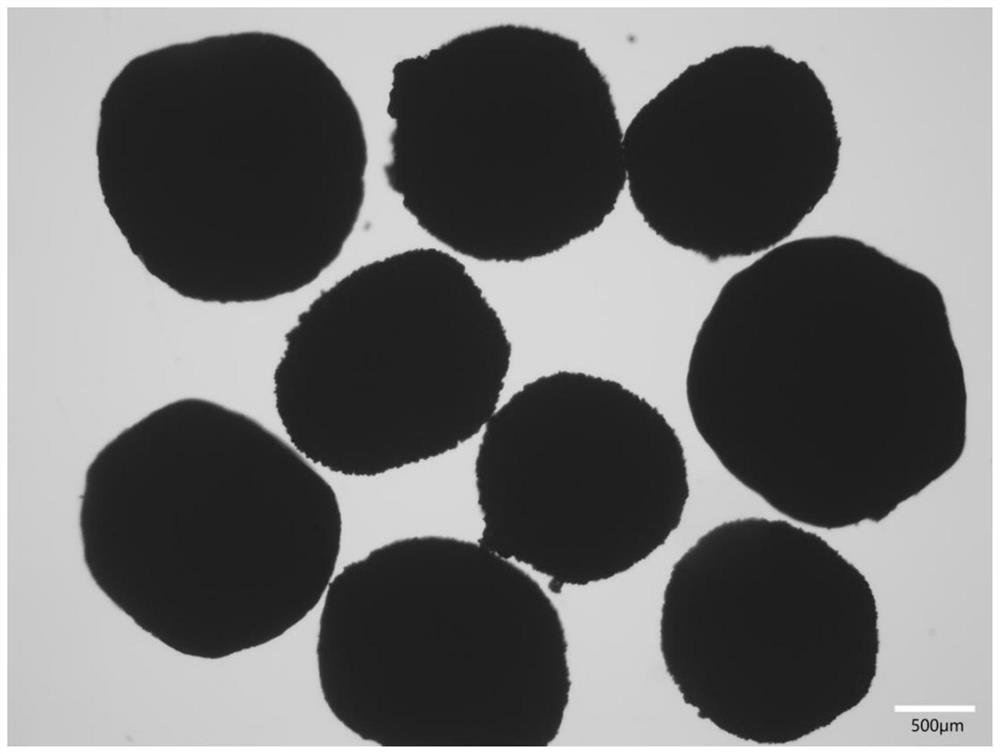

Preparation method of large-particle spherical sodium sulfate crystals

PendingCN111661856ALarge granularityImprove liquidityAlkali metal sulfites/sulfates preparation formAlkali metal sulfites/sulfates moisture absorption preventionOrganic solventSolvent

The invention discloses a preparation method of large-particle spherical sodium sulfate crystals. The preparation method comprises the following steps: at 35-50 DEG C, preparing a sodium sulfate aqueous solution with a certain concentration, wherein the mass ratio of solute sodium sulfate to water is 0.2: 1 to 0.45: 1; preparing a mixed solvent of an organic solvent and a bridging agent at the same temperature, wherein the mass ratio of the organic solvent to water is 1: 1 to 3: 1, and the volume ratio of the bridging agent to solute sodium sulfate is 0.5: 1 to 1: 1; then, dropwise adding a sodium sulfate aqueous solution into the organic solvent-bridging agent mixed solvent at a speed of 0.5-4% / min to separate out crystals, and continuously stirring; and after dropwise adding, keeping stirring for 0.5-5 hours; and filtering, washing and drying to obtain the spherical sodium sulfate crystals. The sodium sulfate crystals prepared by the method are good in sphericity degree and large inparticle size, and the average particle size is greater than 600 [mu]m; and the filtering performance is good, the flowability is high, caking is not likely to happen, the product production efficiency can be improved, and the caking phenomenon in transportation and storage is reduced.

Owner:云南省盐业有限公司 +2

A method for preparing funnel-shaped sodium sulfate from high-salt wastewater

ActiveCN109592698BLarge granularityEvenly distributedAlkali metal sulfites/sulfates preparation formDistilled waterWastewater

The invention relates to a method for preparing funnel-shaped sodium sulfate from high-salt wastewater; heating the wastewater to 50-80°C, adding sodium hydroxide to adjust the pH of the wastewater to 11-14, and controlling the stirring rate to 100-400rpm; using negative pressure Evaporation and crystallization, the vacuum degree is 0.04-0.07MPa, until the volume of evaporated water is 20%-30% of the volume of the original wastewater; the obtained product is filtered and dried to obtain funnel-shaped anhydrous sodium sulfate crystals. The sodium sulfate product with funnel-shaped special crystal form is prepared, the cone angle of the funnel is 120°-150°, the purity of sodium sulfate is ≥95%, the particle size is large and evenly distributed, and the product particle size is ≥300 μm.

Owner:TIANJIN UNIV

A waste water crystallization system containing sodium sulfate

ActiveCN107128988BGuaranteed not to scaleImprove evaporation effectAlkali metal sulfites/sulfates preparation formWater contaminantsEvaporationWastewater

The invention relates to a sodium-sulfate-containing wastewater crystallizing system. A wastewater heater is communicated with an inlet of a circulating pump, an outlet of the circulating pump is communicated with a feeding port of an evaporation crystallizing tank, a discharging port of the evaporation crystallizing tank is communicated with a solid-liquid separator, a discharging pump is arranged between the solid-liquid separator and the evaporation crystallizing tank, and the solid-liquid separator is further communicated with a liquid inlet of the evaporation crystallizing tank; a centrifugal separator is connected with the solid-liquid separator, a mother liquid tank and a finished product collection tank, the mother liquid tank is connected with the inlet of the circulating pump through a backflow pump, a steam inlet and a steam outlet are arranged on the evaporation crystallizing tank, an inlet of a steam-liquid separator is communicated with the steam outlet while an outlet of the same is communicated with the steam inlet through a centrifugal compressor, and an outlet of the steam-liquid separator is further communicated with a liquid inlet of the evaporation crystallizing tank. The sodium-sulfate-containing wastewater crystallizing system is compact in structure, small in occupied area, low energy consumption, long service life and good evaporation crystallizing effect.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

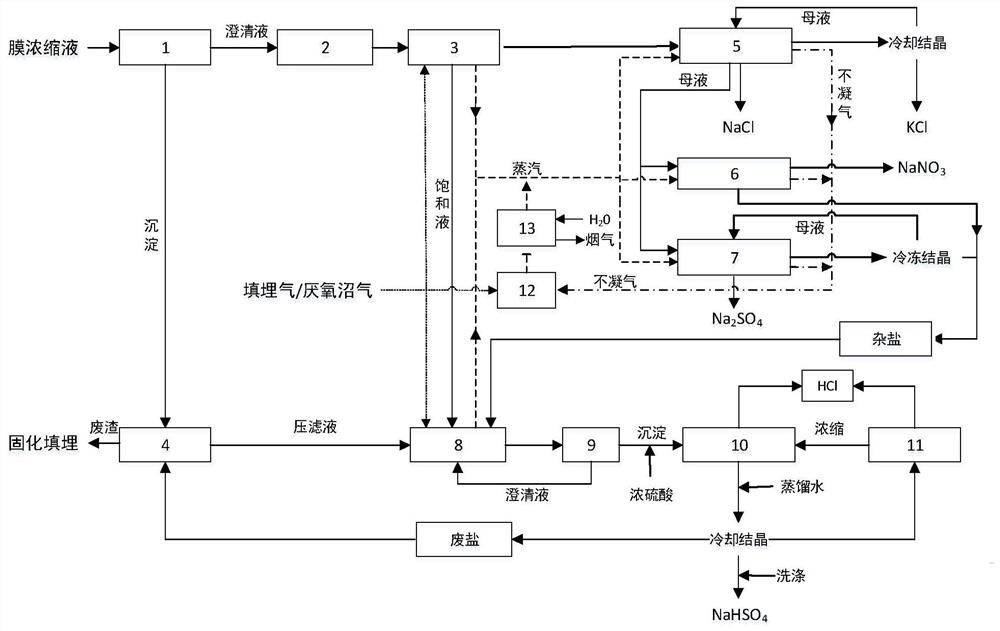

A system and method for the reduction and recycling of landfill leachate membrane concentrate

InactiveCN110818000BImprove economyPromote environmental protectionAlkali metal sulfites/sulfates preparation formChlorine/hydrogen-chlorideResource recoveryEnvironmental engineering

The invention discloses a landfill leachate film concentrate reduction and resource recovery treatment system and method. The treatment system includes a submerged combustion evaporation device, an industrial salt production device, a miscellaneous salt resource recovery device, and a waste residue processing device; The extraction device includes a forced circulation evaporation crystallizer for producing industrial salt KCl and NaCl with saturated membrane concentrate, and an industrial salt NaNO with the mother liquor from the forced circulation evaporation crystallizer. 3 、Na 2 SO 4 The flash cooling crystallizer and sodium sulfate evaporator, the miscellaneous salt resource recovery device includes a reaction kettle, and concentrated sulfuric acid is added to the reaction kettle, and the miscellaneous salt produced after the production of industrial salt enters the reaction kettle to react to produce NaHSO 4 , HCl, and the reacted waste salt enters the waste residue treatment device to be solidified and landfilled. The treatment system realizes the separation of industrial salt while immersing, burning, evaporating and reducing the membrane concentrate, reduces the circulation of salt in the environment and makes it a resource, and further improves the economy and environmental protection of landfill leachate membrane concentrate treatment. .

Owner:SOUTHEAST UNIV +1

A method for surface roughening treatment of potassium sulfate salt particles

ActiveCN113387372BEasy to manufactureLow priceAlkali metal sulfites/sulfates preparation formNanotechnologyOrganic solventPolyvinyl alcohol

The invention discloses a method for roughening the surface of potassium sulfate salt particles. First, disperse the potassium sulfate salt powder into an organic solvent at room temperature and stir, add a certain amount of polyvinyl alcohol aqueous solution, raise the temperature to 80-100°C and keep it for 0.5-2h, then stop stirring, dry the precipitate, and finally dry it at 500 Calcining above ℃, potassium sulfate salt powder with particle surface roughening can be obtained.

Owner:SOUTHEAST UNIV

High-salinity wastewater evaporative crystallization system and method thereof

PendingCN113548706ALow purityIncrease productionAlkali metal sulfites/sulfates preparation formWater/sewage treatment by centrifugal separationSulfate radicalsPhysical chemistry

The invention discloses a high-salinity wastewater evaporative crystallization system which comprises a sodium sulfate crystallization unit, a first sodium chloride crystallization unit, a second sodium chloride crystallization unit and a carnallite crystallization unit. The high-salinity wastewater evaporative crystallization method comprises the following steps of (1) first sodium sulfate evaporative crystallization and freezing crystallization, (2) first sodium chloride evaporative crystallization, (3) second sodium chloride evaporative crystallization, and (4) carnallite evaporative crystallization. The method has the advantages that sodium chloride is subjected to two-stage salt production, and sodium chloride with different purities is produced; 2, sodium sulfate is subjected to evaporative crystallization and freezing crystallization in sequence, so that freezing crystallization blockage caused by direct freezing crystallization of a high sulfate radical solution can be avoided, most of sodium sulfate can be separated out, and the yield of sodium sulfate is increased; and 3, mirabilite produced by freezing crystallization can be conveyed to sodium sulfate evaporative crystallization and can also be directly conveyed to a sodium sulfate evaporative crystallization thickener, so that the investment and treatment cost are reduced.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Sodium sulfate TVR single-effect evaporation and crystallization system

InactiveCN105967210AEfficient separationAvoid erosionAlkali metal sulfites/sulfates preparation formEvaporationSmall footprint

The invention provides a sodium sulfate TVR single-effect evaporation and crystallization system which comprises a mother liquor tank, a centrifuge, a preheater, a TVR compressor, a cooling crystallizer and a condenser, wherein the mother liquor tank, the preheater, the cooling crystallizer and the centrifuge are sequentially connected. The system has a simple structure and a small floor area, and mother liquor can be cyclically evaporated and crystallized, so that the utilization ratio is high.

Owner:江苏格兰特干燥浓缩设备有限公司

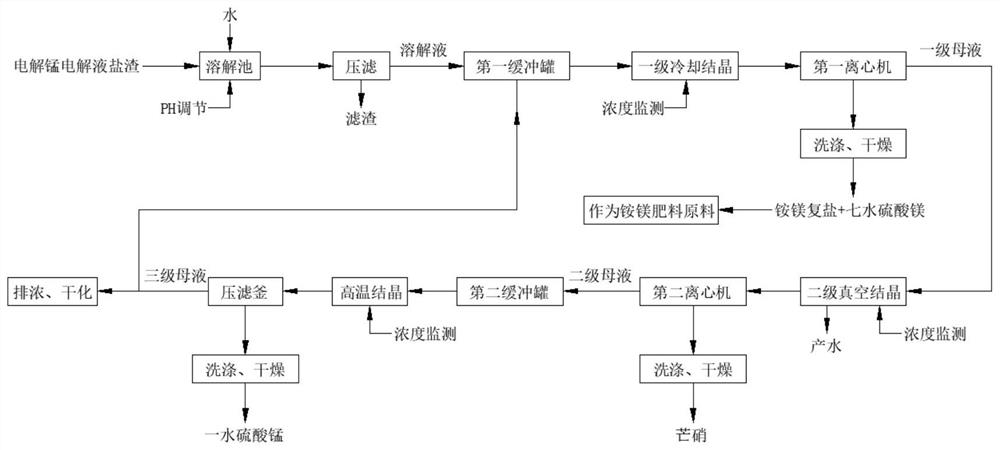

Method and system for separating salt from electrolytic manganese electrolyte salt slag

PendingCN114249339ALow running costEmission reductionAlkali metal sulfites/sulfates preparation formMagnesium fertilisersElectrolytic agentInorganic salts

The invention discloses an electrolytic manganese electrolyte salt residue salt separation method and system, and belongs to the field of wastewater treatment, and the system comprises a dissolving tank, a filter press, a primary buffer tank, a primary cooling crystallization system, a first centrifugal machine, a secondary vacuum crystallization system, a second centrifugal machine, a secondary buffer tank, a tertiary high temperature crystallization system, a filter press kettle and a concentrated discharge drying system. No agent is added, inorganic components of the electrolytic manganese residues are extracted according to basic physical properties of solid waste and physical separation, and the operation cost is low; inorganic salt is separated in a mother liquor circulation mode, the waste liquor discharge amount is small, and meanwhile a large amount of water resources are recycled. According to the method, the multi-component elemental salts (ammonium, magnesium and manganese) in the manganese slag are recovered in sequence instead of single-component salt recovery in the electrolytic manganese waste slag, the recovery rate is high, and the solid waste reduction treatment degree is high; the electrolytic manganese waste residue inorganic salt separation equipment mainly comprises a reactor and an evaporator, and is simple in system, low in equipment investment and easy to industrialize.

Owner:SHANGHAI LANBIN PETROCHEM EQUIP +1

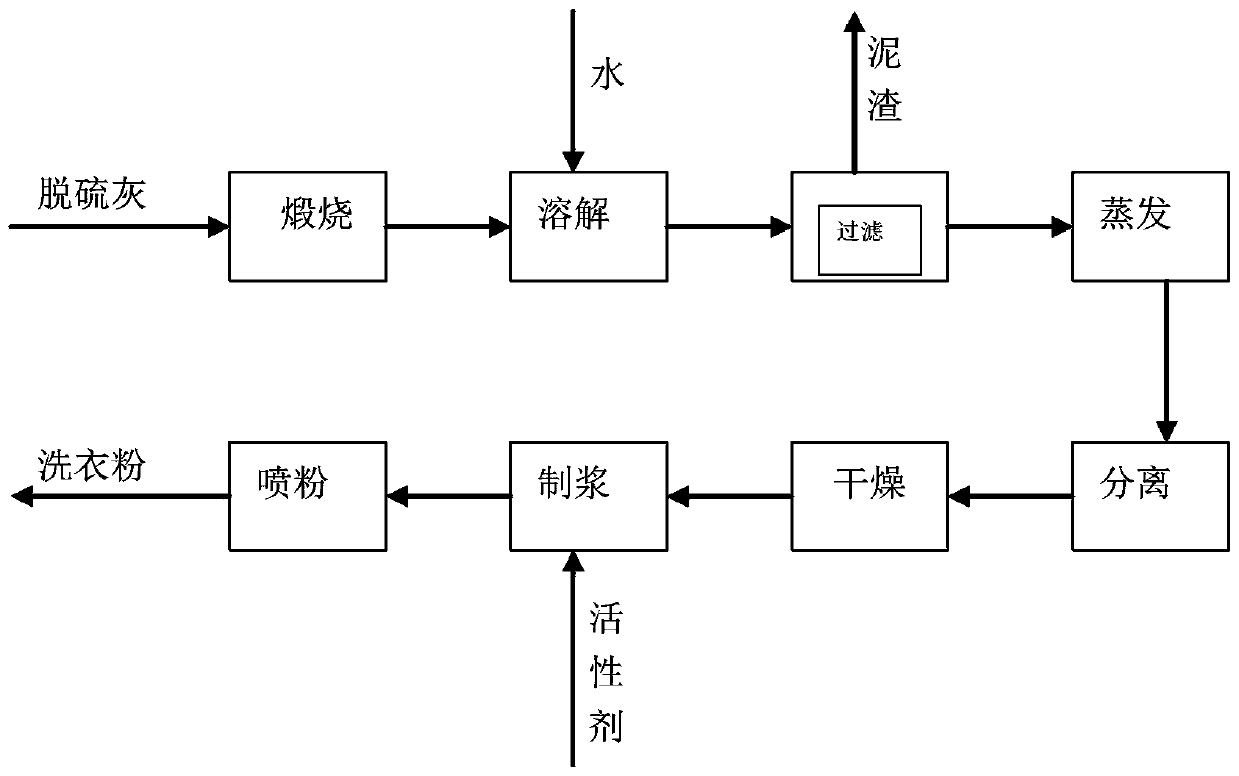

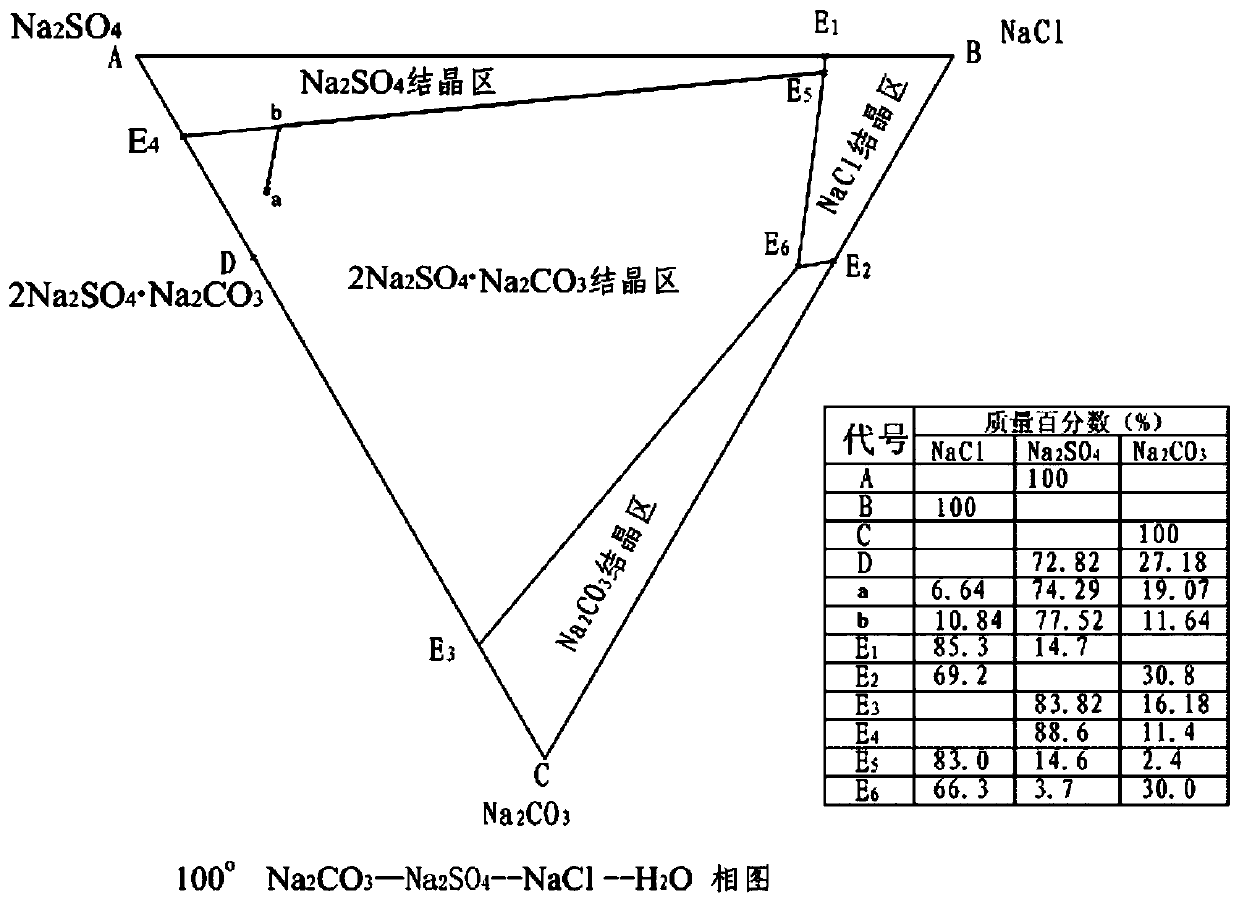

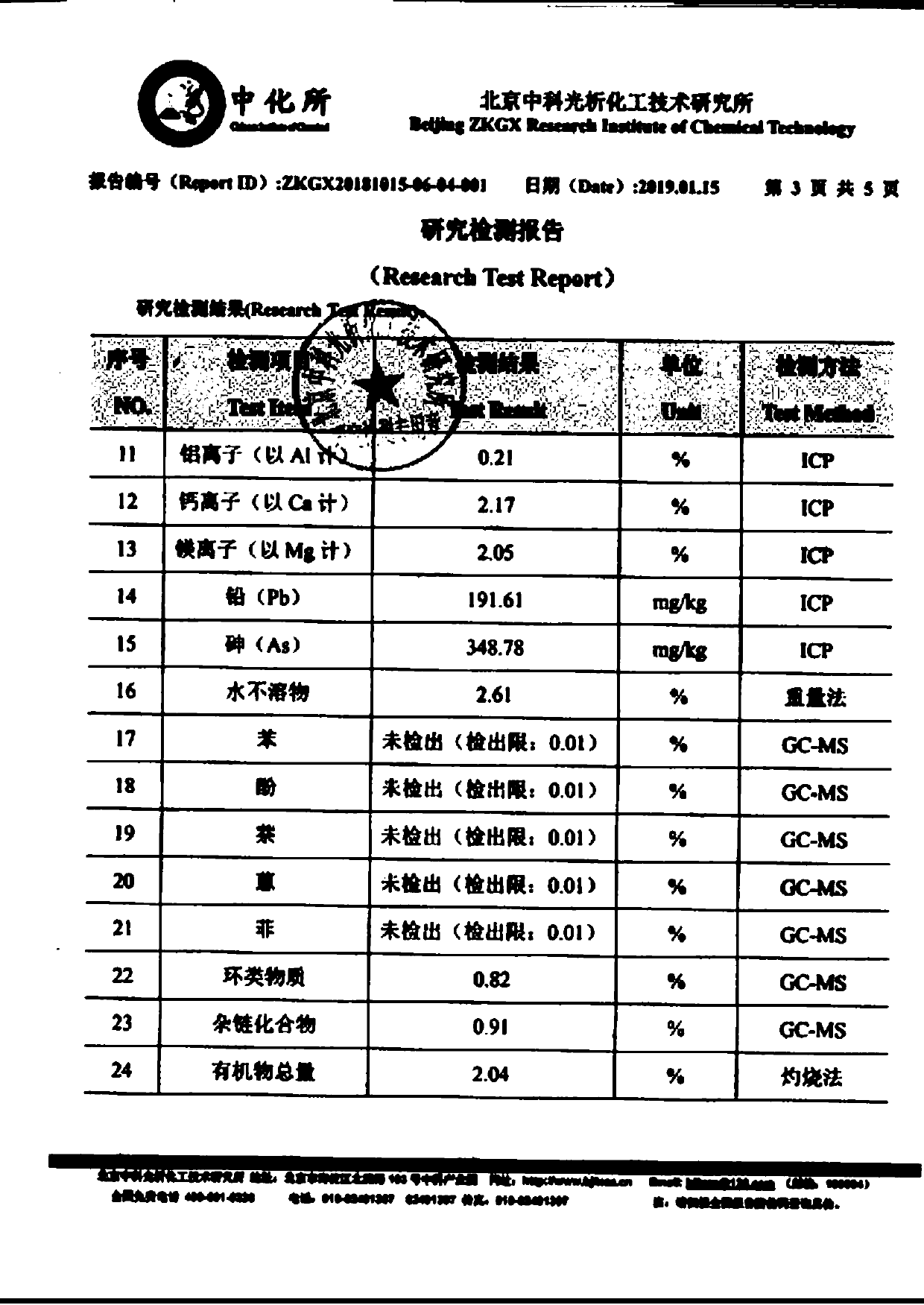

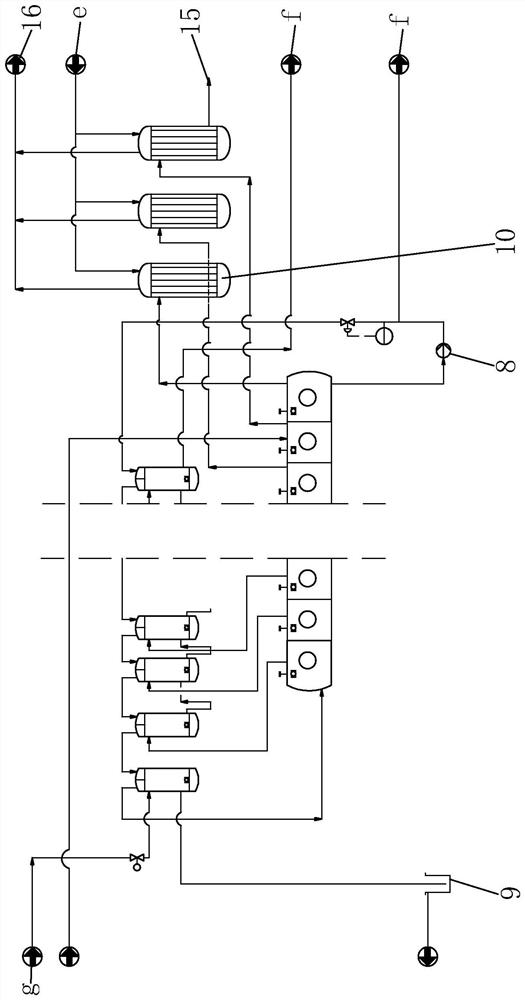

Mixed salt based on coke oven flue gas desulfurization ash, preparation method and application

ActiveCN111422885AHigh viscosityLow viscosityAlkali metal sulfites/sulfates preparation formInorganic/elemental detergent compounding agentsProcess engineeringEnvironmental engineering

The invention discloses mixed salt based on coke oven flue gas desulfurization ash, a preparation method and application, belongs to the technical field of environmental protection, and relates to thecoke oven flue gas desulfurization ash. The mixed salt based on the coke oven flue gas desulfurization ash is a mixed salt of sodium sulfate and alkali mirabilite, and is obtained by calcining the desulfurization ash at a high temperature, dissolving the calcined desulfurization ash in water, and carrying out evaporative crystallization at a temperature of less than 100 DEG C. The method solves aseries of environmental protection problems generated after coke oven flue gas desulfurization, turns waste into wealth, is suitable for large-scale popularization in the coking industry, and realizes environmental protection, resource reutilization and sustainable development.

Owner:山西焦化股份有限公司 +1

A kind of production system and production process for continuously producing sodium sulfate in acid bath

InactiveCN110330039BImprove appearance qualityLarge particle sizeAlkali metal sulfites/sulfates preparation formAlkali metal sulfite/sulfate purificationMulti-stage flash distillationProcess engineering

The invention discloses a production system and production process for continuously producing sodium sulfate in an acid bath. The production system includes a multi-stage flash device, an evaporator, and a rotary airflow dryer; the multi-stage flash device passes through a preheater A and an evaporation The evaporator is connected with the aging tank, the curing tank is connected with the primary thickener; the primary thickener is connected with the primary centrifuge, and the primary centrifuge is connected with the neutralization tank; the neutralization tank It is connected with the secondary thickener, and the secondary thickener is connected with the rotary airflow dryer; the production method of the production system completes the production of Yuanming powder through multiple steps. The production system of the present invention adopts multi-stage flash evaporation device, evaporator to cooperate rotary airflow drier to produce Yuanming powder, has shortened technological process route, and has reduced energy consumption, and the sodium sulfate crystal particle size that produces simultaneously is bigger, and crystal particle Uniform and plump, the apparent quality of Yuanmingfen is high.

Owner:NANTONG SUNSHINE GRAPHITE EQUIP TECH

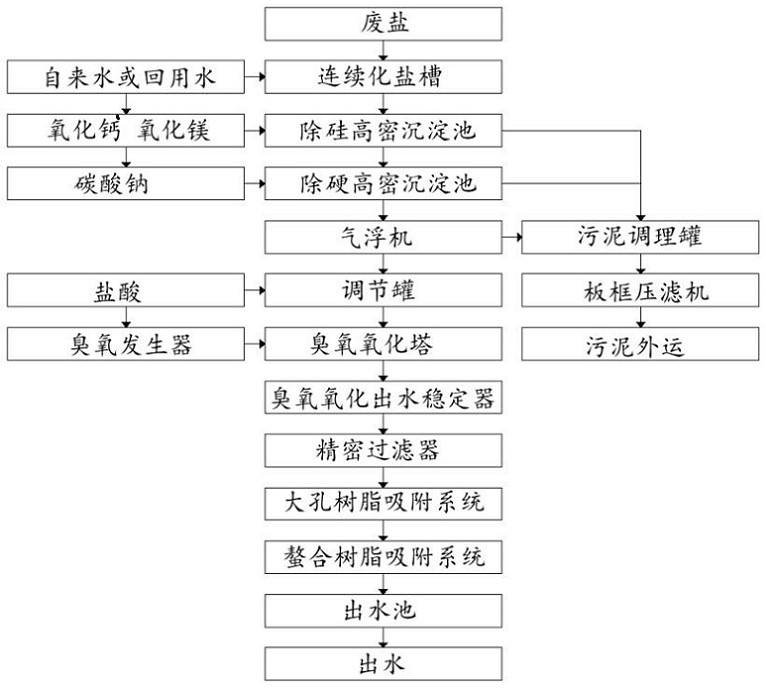

Method for deeply refining saline water by resource utilization of waste salt

InactiveCN112979034AReasonable recyclingGuarantee product qualityAlkali metal sulfites/sulfates preparation formSludge treatmentSaline waterMagnesium salt

The invention discloses a waste salt resource utilization brine deep refining method which comprises the following steps: 1, conveying waste salt into a salt dissolving barrel, adding water, stirring and dissolving to obtain crude brine; 2, the crude brine obtained in the step 1 is put into a silicon removal and hardness removal system, a chemical agent is added, and effluent of the silicon removal and hardness removal system contains part of ash and small particles of calcium salt and magnesium salt which are not completely settled. According to the method, the incinerated waste salt is subjected to silicon removal, hardness removal, advanced oxidation, resin adsorption and other treatments, the obtained brine effluent can be subjected to evaporation treatment, the condensate can be recycled to a crude salt dissolution section, the evaporated and crystallized salt is a product, the whole set of advanced treatment process ensures the product quality of the evaporated and crystallized salt, the reasonable recycling of the waste salt is realized, the environmental pressure is relieved, and the economic value is very good.

Owner:JIANGSU RUIDA TECH CO LTD

Popular searches

Waste water treatment from gaseous effluents Multistage water/sewage treatment Water/sewage treatment by neutralisation Alkali metal chlorides Alkali metal halide purification Water/sewage treatment by freezing Alkali metal halide formation shape Water/sewage treatment by heating Water/sewage treatment by oxidation Lithium carbonates/bicarbonates

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com