System and treatment process for purification and salt separation of electroplating high-salt wastewater

A high-salt wastewater treatment technology, applied in water/sewage treatment, biological water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of high-salt wastewater treatment, complex components, etc., and achieve continuous production , Improve the separation effect, the effect of smooth and simple system flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

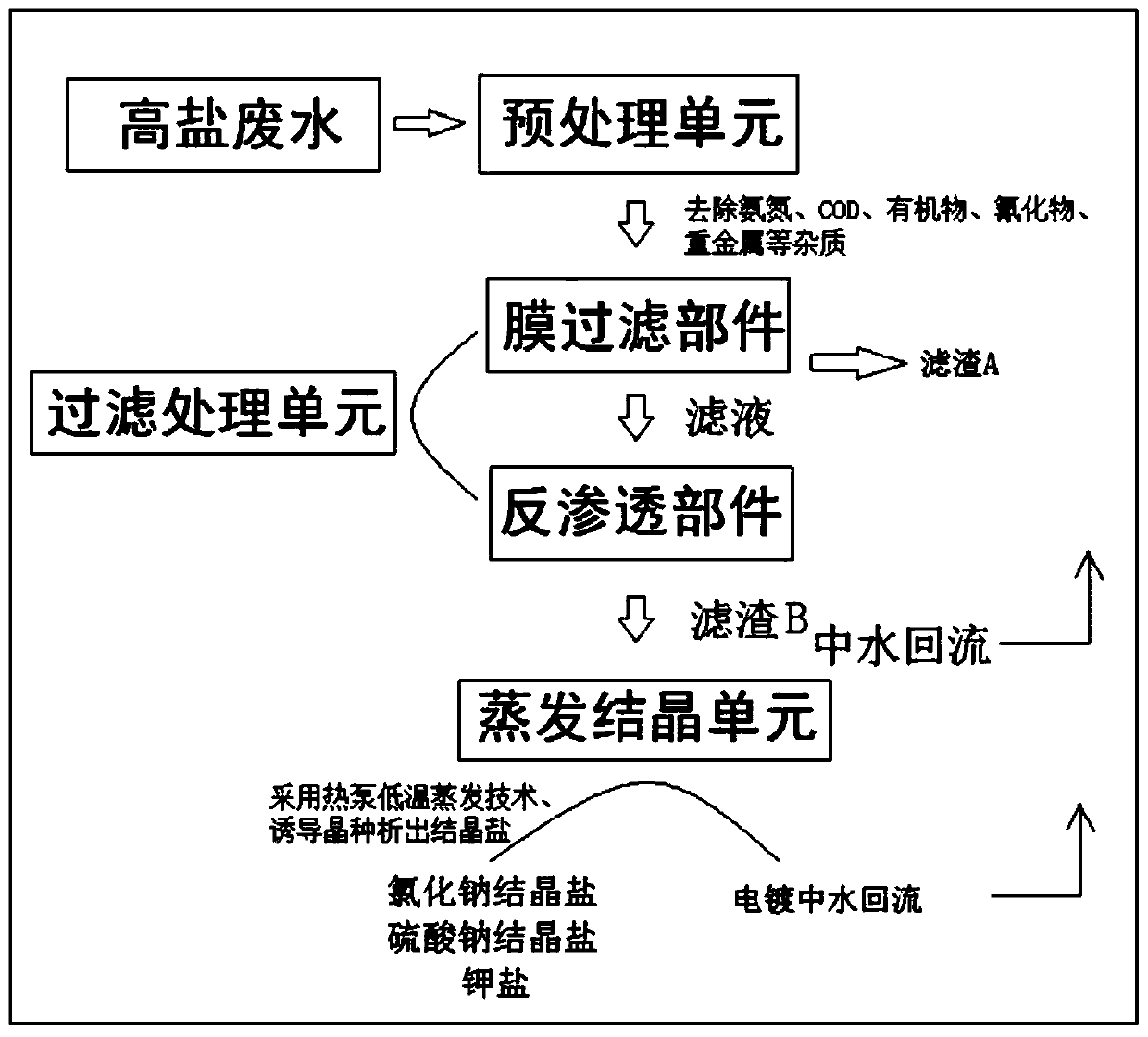

[0031] An electroplating high-salt wastewater purification and salt separation system, which includes:

[0032] Pretreatment unit: used to treat ammonia nitrogen, COD, cyanide and metal substances in wastewater;

[0033] Filtration treatment unit: used to filter the pretreated wastewater to obtain super-concentrated waste liquid and return water;

[0034] Evaporation and crystallization unit: using heat pump low-temperature evaporation components and induced seeds to treat super-concentrated waste liquid to recover crystallized salt;

[0035] The pretreatment unit, filtration treatment unit and evaporation crystallization unit are connected in sequence.

[0036] The filtration treatment unit includes a membrane filter unit and a reverse osmosis unit, and the high-salt wastewater first enters the membrane filter unit to filter impurities after passing through the pretreatment unit;

[0037] The membrane filter part and the reverse osmosis part are connected in sequence, the f...

Embodiment 2

[0043] An electroplating high-salt wastewater purification and salt separation process:

[0044] The high-salt wastewater from an electroplating factory was purified and salt-separated. After multiple tests, the salt content of the high-salt wastewater was 21-30wt%, Cl - The concentration is 1500~2000 mg / L, SO 4 2- The concentration is 2000~2500 mg / L, K + The concentration is 600~850 mg / L, COD 130~160 mg / L, Ni 2+ The concentration is 200~350 mg / L, Zn 2+ The concentration is 200~350 mg / L, Cr 2+ The concentration is 200~350 mg / L, Cu 2+ The concentration is 200~350 mg / L;

[0045] 1) Pretreatment of high-salt wastewater: add microbial strains to high-salt wastewater to remove ammonia nitrogen, COD, organic matter and cyanide in the wastewater, and after standing still, add hydroxide ions and carbonate ions to generate hydroxide in the wastewater Chromium precipitation, nickel hydroxide precipitation, copper hydroxide precipitation, zinc carbonate and other precipitates are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com