a kind of na 3 fso 4 Method for preparing flaky single crystal α-alumina for seeding

A kind of flaky single crystal, alumina technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The above-mentioned one is Na 3 FSO 4 A method for preparing flaky single crystal α-alumina as a seed crystal, wherein in step a, Na 3 FSO 4 Seed crystals can be prepared by the following method: Take NaF and Na 2 SO 4 , add water to dissolve, stir and mix, then evaporate, so that Na 3 FSO 4 Crystals are precipitated and separated to obtain Na 3 FSO 4 Crystal; where, according to the molar ratio, NaF:Na 2 SO 4 =1:0.5~2. Wherein the Na mentioned in step a 2 SO 4 for Na 2 SO 4 ·nH 2 O, where n is an integer between 0 and 10, namely Na 2 SO 4 including anhydrous (Na 2 SO 4 ) and other different hydrous compounds (Na 2 SO 4 ·nH 2 O).

[0042] The above-mentioned one is Na 3 FSO 4 The method for preparing flake single crystal α-alumina as a seed crystal, wherein the aluminum-containing raw material in step a is at least one of aluminum hydrate or transition phase alumina.

[0043] Further, the above-mentioned one is Na 3 FSO 4 A method for preparin...

Embodiment 1

[0050] Weigh 4.2g NaF and 7.1g NaF at a molar ratio of 1:0.5 2 SO 4 , add 50g of water, heat and stir to dissolve to obtain a clear solution, then evaporate the excess water to promote Na 3 FSO 4 Crystal precipitation, solid-liquid separation, Na 3 FSO 4 Crystal 9g. Weigh anhydrous sodium sulfate (Na 2 SO 4 ) 10g to form a solution, then add monohydrate boehmite (Boehmite, AlOOH) 10g, stir evenly and dry in an oven, then weigh 1.75g seed crystal Na 3 FSO 4 (to generate 20% of the mass of α-alumina), grind and mix evenly, then transfer to a corundum crucible for calcination. After heating up to 900°C at a rate of 3°C / min, keep it warm for 2 hours, cool down to room temperature with the furnace, dissolve the material in the crucible with hot water, wash it several times to remove residual molten salt, and dry to obtain flaky α-alumina.

Embodiment 2

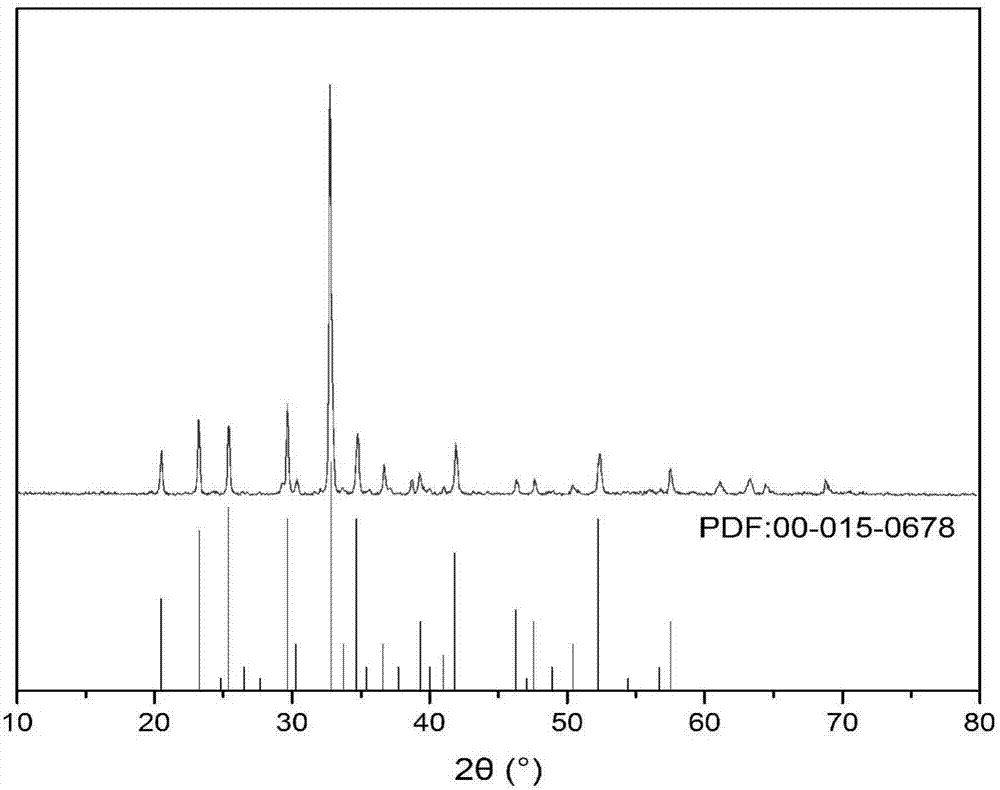

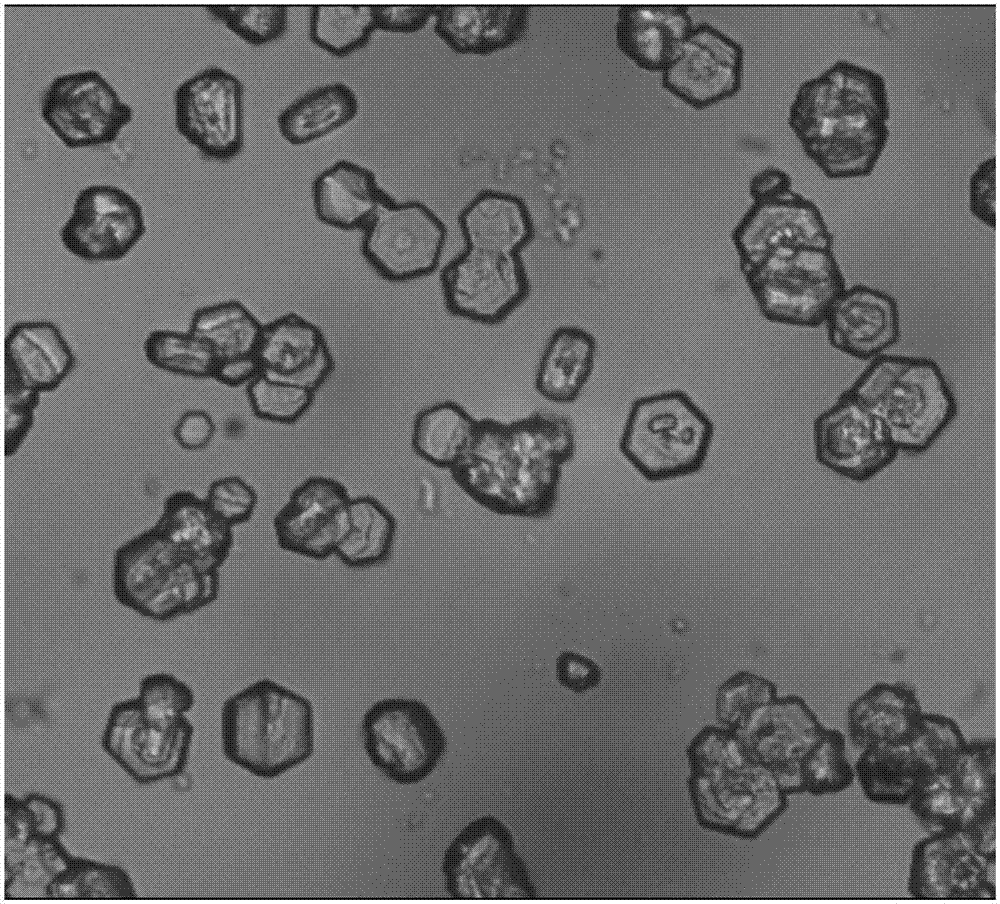

[0052] Weigh 4.2g NaF and 14.2g NaF at a molar ratio of 1:1 2 SO 4 , add 100g of water, heat and stir to dissolve to obtain a clear solution, and then evaporate the excess water to promote Na 3 FSO 4 Crystal precipitation, solid-liquid separation, Na 3 FSO 4 Crystals 18.2 g. X-ray diffraction pattern (see attached figure 1 ) confirmed that the prepared product was compatible with Na 3 FSO 4 The standard card (00-015-0678) matches well for Na 3 FSO 4 ; optical micrographs (see attached figure 2 ) can be seen that the prepared Na 3 FSO 4 The crystal morphology is a complete hexagonal plate with uniform size.

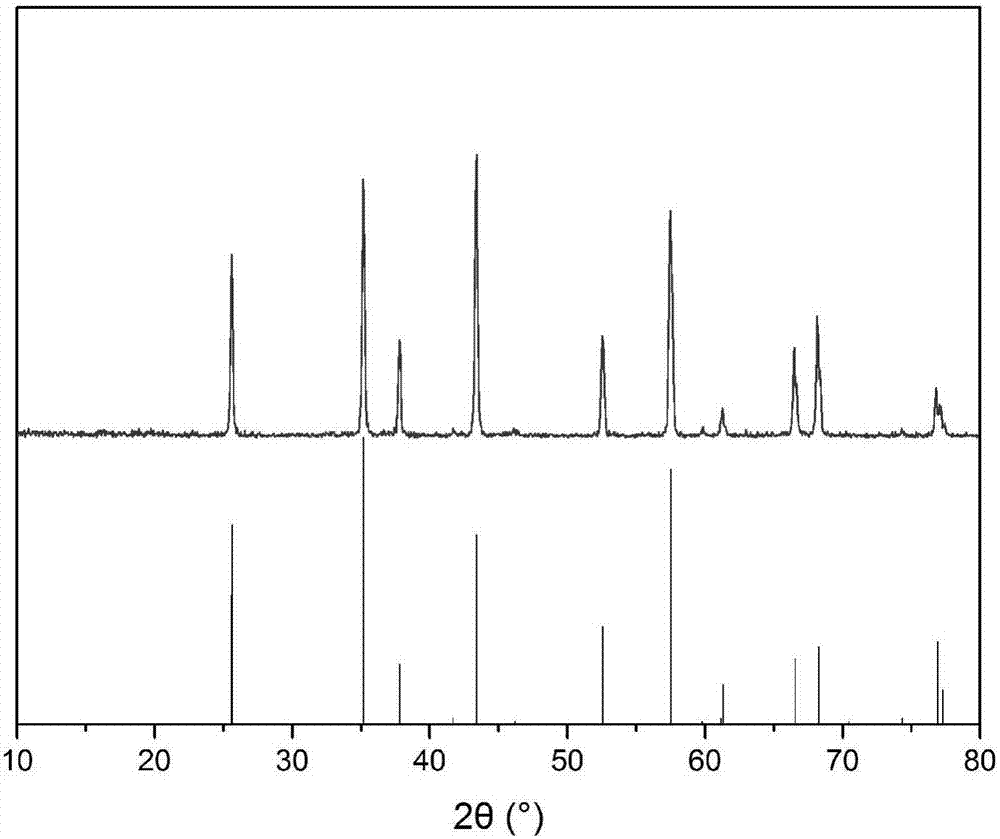

[0053] Weigh sodium chloride (NaCl) 12g, anhydrous sodium sulfate (NaCl) 2 SO 4 ) 42g, after mixing evenly, add 18g aluminum hydroxide (Al(OH) 3 ) Grinding and mixing, adding 2.19g seed crystal Na 3 FSO 4 (to generate 18% of the mass of α-alumina), after grinding and mixing evenly, put it into a corundum crucible for calcination. After heating up to 750°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com