Method for preparing magnesium potassium titanate by directly utilizing magnesium oxide

A technology of potassium magnesium titanate and magnesium oxide, which is applied in the fields of chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of restricting the large-scale popularization and application of potassium magnesium titanate, increasing the production cost of potassium magnesium titanate, and unfavorable scale Production and other problems, to achieve the effect of reducing equipment corrosion loss, reducing calcination time, and strong activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

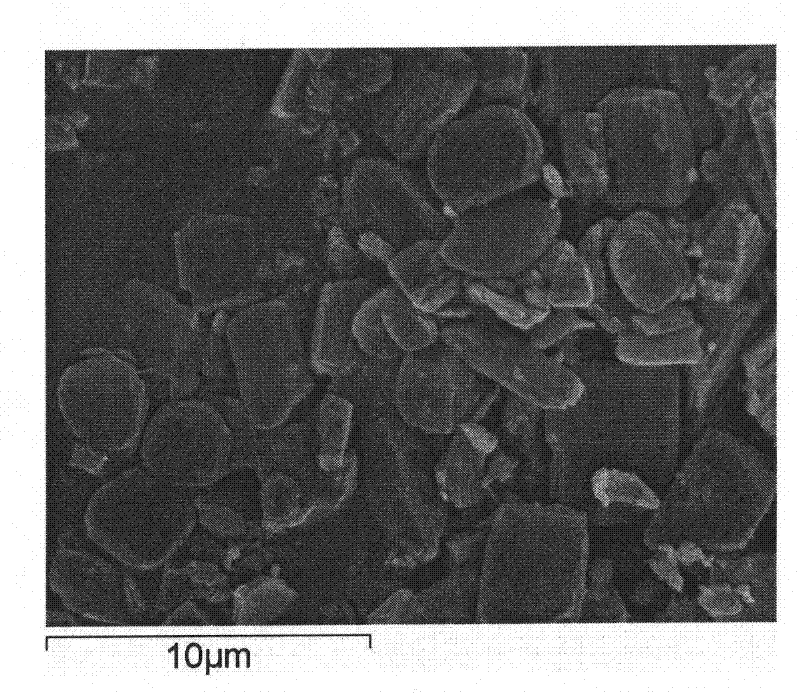

Embodiment 1

[0058] Potassium carbonate, light-burned magnesia and titanium dioxide are respectively expressed in K 2 O, MgO, TiO 2 In terms of molar ratio K 2 O:MgO:TiO 2 =1.3:1:4, fully mix the above three raw materials, add an appropriate amount of water during the mixing process, and the amount of water added is based on the convenience of subsequent molding; then use the mold to pressurize the above mixture into a 5cm high , Cylindrical shape with a diameter of 6cm, the diameter of the channel is 6mm, and the distance between the holes is 1cm; the above-mentioned cylindrical blank is heated to 1100°C in a microwave shuttle kiln, kept for 2 hours, then cooled to 800°C with the furnace, and then air-cooled to room temperature ; Grind the calcined product to 150 mesh with a Raymond mill, and the product obtained is potassium magnesium titanate in the form of white powder. The X-ray diffraction analysis shows that the chemical formula of the product obtained is K 2 MgTi 4 o 10 , nam...

Embodiment 2

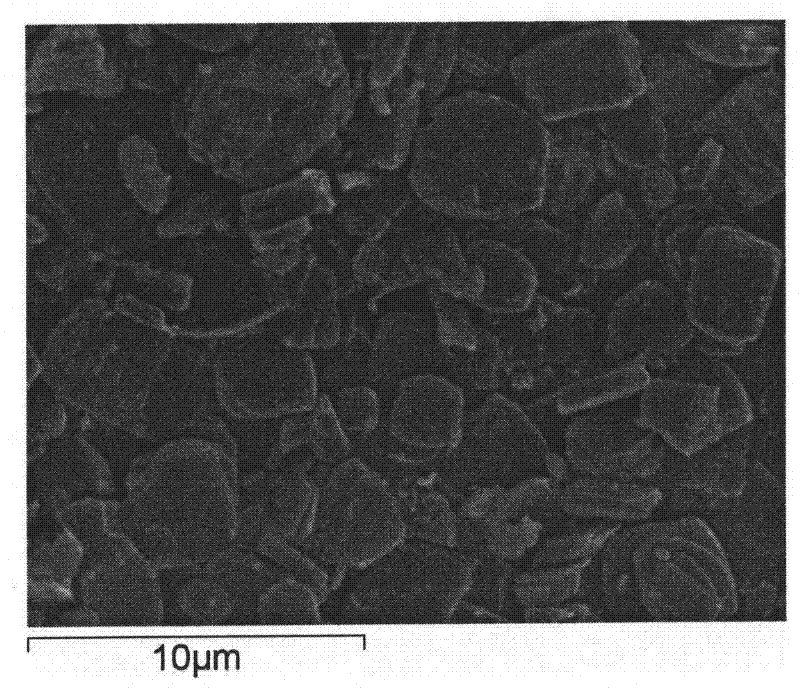

[0060] Potassium carbonate, modified activated magnesia and titanium dioxide were denoted by K 2 O, MgO, TiO 2 In terms of molar ratio K 2 O:MgO:TiO 2 =1.9:1:4, fully mix the above three raw materials, add an appropriate amount of water during the mixing process, the amount of water added is based on the convenience of subsequent molding; then use the mold to press the above mixture into a 6cm× 5cm×5cm cuboid, the diameter of the channel is 6mm, and the hole-to-hole spacing is 1cm; the above-mentioned cuboid blank is heated to 1150°C in a gas-fired shuttle kiln assisted by microwave heating, kept for 2 hours, and then cooled to 800°C with the furnace, Cool in air to room temperature; grind the calcined product to 100 mesh with a Raymond mill, then wash with water, stir, filter, and finally heat-treat at 600°C for 5 hours, and the product obtained is potassium magnesium titanate in the form of white powder. The X-ray diffraction analysis shows that the chemical formula of th...

Embodiment 3

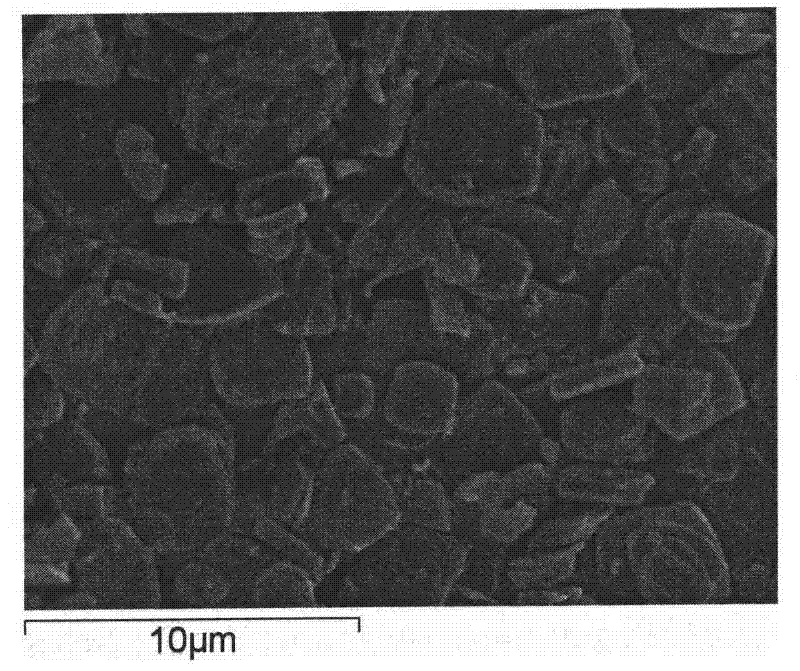

[0062] Potassium carbonate, underburned magnesia and titanium dioxide are respectively expressed in K 2 O, MgO, TiO 2 In terms of molar ratio K 2 O:MgO:TiO 2 = 1.6:1:4, fully mix the above three raw materials, add an appropriate amount of water during the mixing process, the amount of water added is based on the convenience of subsequent molding; then use the mold to pressurize the above mixture into a 6cm× 5cm×5cm cuboid, the diameter of the channel is 6mm, and the hole-to-hole spacing is 1cm; the above-mentioned cuboid blank is heated to 1150°C in an electric heating shuttle kiln, kept for 2 hours, then cooled to 800°C with the furnace, and then air-cooled to room temperature; The calcined product was pulverized to 100 mesh with a Raymond mill, then washed with water, stirred, filtered, and finally heat-treated at 600°C for 5 hours, and the obtained product was potassium magnesium titanate in the form of white powder. The X-ray diffraction analysis shows that the chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com