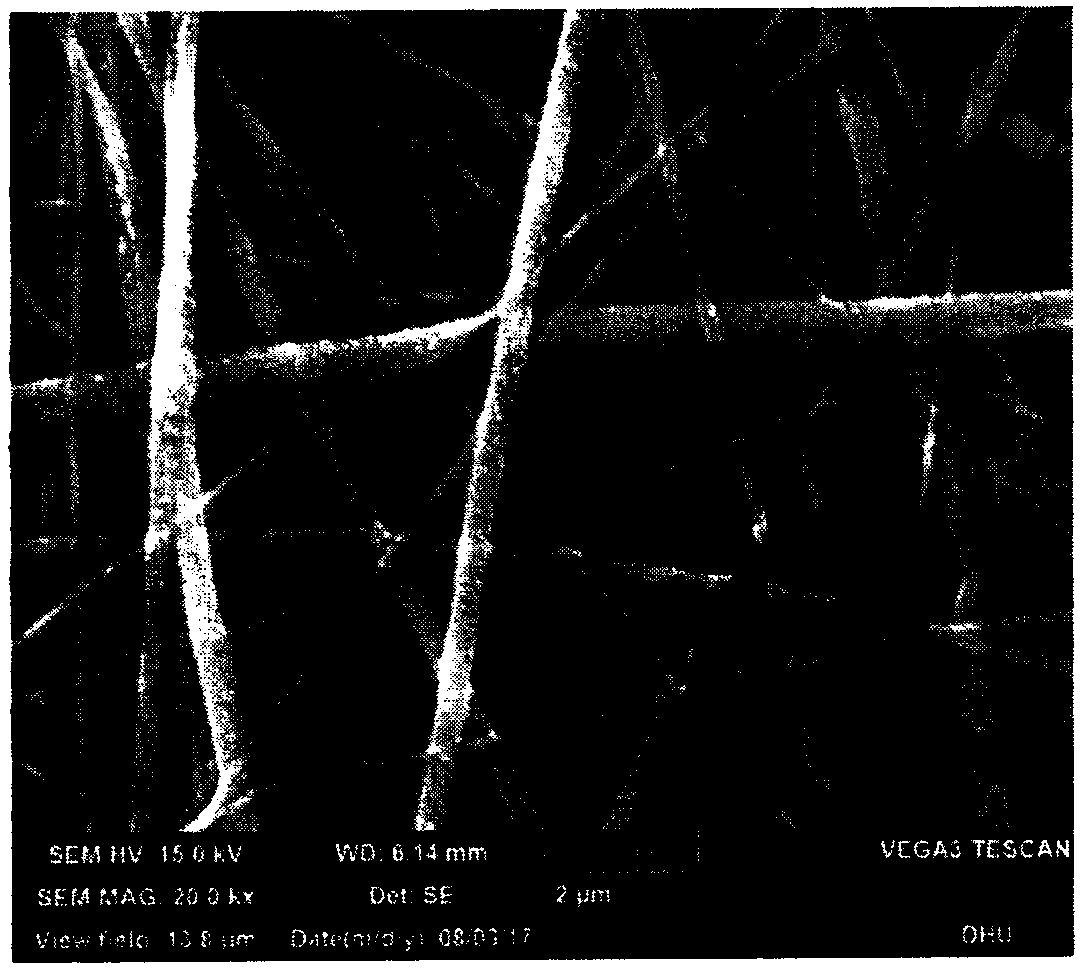

Manufacturing method of flexible titanium dioxide/carbon composite porous nanofiber membrane material

A technology of nanofiber membrane and titanium dioxide, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc. It can solve the problems of low TiO2 content, easy brittleness of composite fiber materials, and reduced long-term service performance, so as to achieve good flexibility , short calcination time, and the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A controllable preparation method of a flexible titanium dioxide / carbon composite porous nanofiber membrane material, the specific steps are:

[0042] (1) Configure a precursor solution consisting of a titanium source, a high molecular polymer and a solvent: at 25 ° C, the high molecular polymer 3 × 10 -7 mol polyvinylpyrrolidone (Aladdin, molecular weight 1,300,000) and 4×10 -6 mol polyoxyethylene polyoxypropylene ether block copolymer (BASF, molecular weight 10,000) dissolved in solvent 7×10 -3 L was stirred in ethanol / acetic acid with a volume ratio of 4.2:2.6 for 240min, then added 0.06mol isopropyl titanate and stirred for 60min and mixed evenly to obtain a precursor solution;

[0043] (2) Electrospinning the above precursor solution under electrostatic high voltage to obtain the precursor nanofiber film on the receiving device. Control the temperature of the receiving device on the metal drum to 25°C; the parameters of the electrospinning are set as follows: rel...

Embodiment 2

[0046] A controllable preparation method of a flexible titanium dioxide / carbon composite porous nanofiber membrane material, the specific steps are:

[0047] (1) Configure a precursor solution consisting of titanium source, high molecular polymer and solvent: mix high molecular polymer 7×10 at 25°C -7 mol polyvinyl butyral (Aladdin, 170,000~250,000) and 4×10 -6 mol polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (Aladdin, molecular weight 5,500) is dissolved in solvent 7.5×10 -3 L volume ratio is 4.5: 2.4 ethanol / acetic acid and stirs 240min, then adds titanium source 5 * 10 successively -3 mol n-butyl titanate was stirred for 120 minutes and mixed evenly to obtain a precursor solution;

[0048] (2) Electrospinning the above precursor solution under electrostatic high voltage to obtain the precursor nanofiber film on the receiving device. Control the temperature of the receiving device on the metal drum to 25°C; the parameters of the electrospin...

Embodiment 3

[0051] A controllable preparation method of a flexible titanium dioxide / carbon composite porous nanofiber membrane material, the specific steps are:

[0052] (1) Configure a precursor solution consisting of titanium source, high molecular polymer and solvent: mix high molecular polymer 5×10 at 25°C -7 mol polyvinylidene fluoride (Alfa Aisha, molecular weight 570,000) and 2×10 -6 mol polyoxyethylene polyoxypropylene ether block copolymer (BASF, molecular weight 10,000) was dissolved in solvent 3×10 -4 Stir in L of N,N-dimethylformamide for 240min, then add titanium source 4.5×10 -3 mol isopropyl titanate was stirred for 60 minutes and mixed evenly to obtain a precursor solution;

[0053] (2) Electrospinning the above precursor solution under electrostatic high voltage to obtain the precursor nanofiber film on the receiving device. Control the temperature of the receiving device on the metal drum to 25°C; the parameters of the electrospinning are: relative humidity 45%, perfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com