Ultrathin high-purity ceramic wafer and preparation process thereof

A preparation process and technology of ceramic sheets, which are applied in the field of ultra-thin high-purity ceramic sheets and their preparation, can solve the problems of serious shrinkage of ultra-thin ceramic sheets, reduced thermal conductivity, and increased number of grain boundaries, and achieve excellent dielectric properties and thermal conductivity. The effect of smooth surface and lower calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

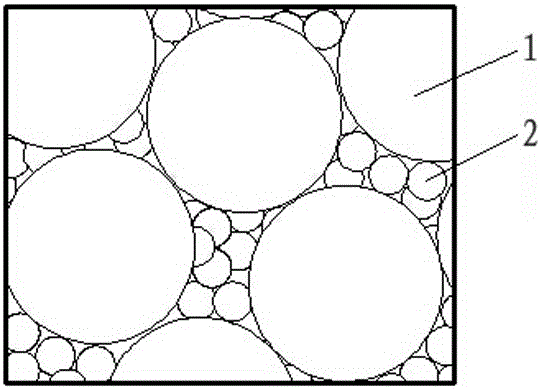

[0022] A preparation process of an ultra-thin high-purity ceramic sheet mainly includes the following steps: according to the total amount of 65g of ceramic materials, the pure alumina powder with a median diameter of 2 μm and the pure alumina powder with a median diameter of 120nm are calculated with a volume ratio of 90:10 2 g triolein, 27 g mixed solvent of butanone and absolute ethanol, wherein butanone / absolute ethanol=5 / 4, ball milled for 24 hours. After ball milling, add 3gPVB, a mixture of 2.95gDBP and polyethylene glycol, wherein DBP / polyethylene glycol=3 / 2, and ball mill for 12 hours. Then add 0.05g defoamer, and carry out vacuum defoaming in a vacuum tank for 20min. The resulting slurry had a solids content of 65%. Cast the slurry on a casting machine, accurately set the height of the cutting edge of the casting head, the speed of the steel belt and the temperature of each drying zone, and obtain a thickness of 0.2 mm for the cast ceramic green sheet after drying. ...

Embodiment 2

[0024] A preparation process of an ultra-thin high-purity ceramic sheet mainly includes the following steps: according to the total amount of ceramic material 74g, the pure alumina powder with a median diameter of 3 μm and the pure alumina powder with a median diameter of 200nm are calculated with a volume ratio of 70:30 Add 0.9g of ammonium polyacrylate to 11.6g of water, add 74g of ceramic powder after stirring, and finally add an appropriate amount of ammonia water until the pH value is 10, and ball mill for 24 hours to prepare a water-based ceramic slurry for later use. Stir and mix 8.5g of 48% styrene-acrylic emulsion and 1.5g of 20% polyvinyl alcohol aqueous solution for 2 hours to prepare a mixed binder. Add the above-mentioned mixed binder to the water-based ceramic slurry, add 2.5 g of glycerol, 0.05 g of defoamer and 0.95 g of film-forming aid, and continue ball milling for 10 hours to obtain ceramic slurry. The resulting slurry had a solids content of 70%. The resu...

Embodiment 3

[0026] A preparation process of an ultra-thin high-purity ceramic sheet mainly includes the following steps: according to a total amount of 70 g of ceramic materials, the pure aluminum nitride powder with a median diameter of 1 μm and the pure aluminum nitride powder with a median diameter of 150 nm are calculated with a volume ratio of 75:25. The amount of aluminum powder is weighed separately; add 1.6g triolein, 24g mixed solvent of butanone and absolute ethanol, wherein butanone / absolute ethanol=5 / 4, and ball mill for 24 hours. After ball milling, add 2gPVB, a mixture of 2.35gDBP and polyethylene glycol, wherein DBP / polyethylene glycol=3 / 2, and ball mill for 12 hours. Then add 0.05g defoamer, and carry out vacuum defoaming in a vacuum tank for 20min. The resulting slurry had a solids content of 75%. Cast the slurry on a casting machine, accurately set the height of the cutting edge of the casting head, the speed of the steel belt and the temperature of each drying zone, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com