Patents

Literature

234results about How to "With mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

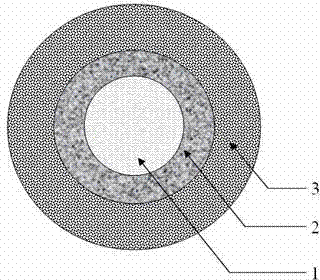

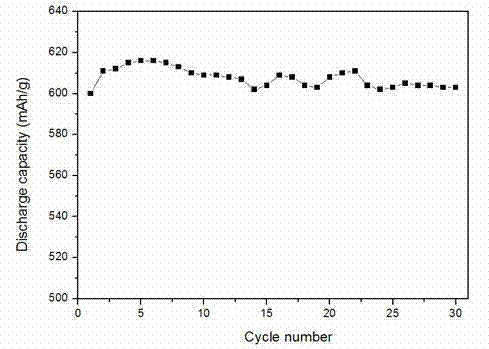

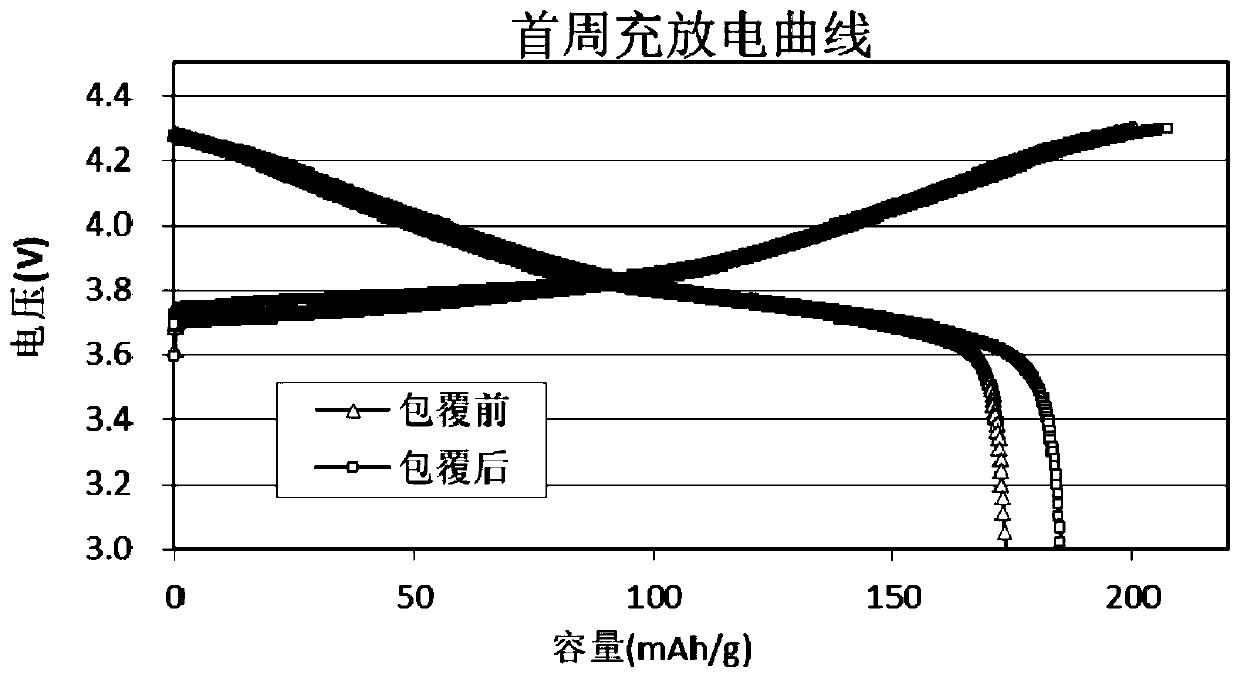

Lithium ion battery cathode material with two-shell layer structure and preparation method thereof

InactiveCN103545497ASimple preparation processWith mass productionCell electrodesElectrical batteryAlumina zirconia

The invention relates to a lithium ion battery cathode material with a two-shell layer structure, which is characterized by consisting of two shell layers, wherein the first shell layer is a metal oxide shell layer, and the second shell layer is made of an intangible carbon shell layer material; the first shell layer wraps the surface of silicon particles, and the second shell layer wraps the surface of the first shell layer; the metal oxide shell layer is one of aluminum oxide, zirconium oxide and zinc oxide; and the intangible carbon shell layer is prepared by carbonizing sucrose, glucose and polyethylene. The reaction interface of the electrolyte and silicon powder is lowered and the side reaction is reduced by use of oxide; and with the flexibility and scalability of the carbon material, the problem of chalking caused by the silicon volume expansion is reduced. Moreover, the invention also provides a preparation method of the cathode material, wherein the method realizes simple preparation and has the possibility of batch production.

Owner:CHINA FIRST AUTOMOBILE

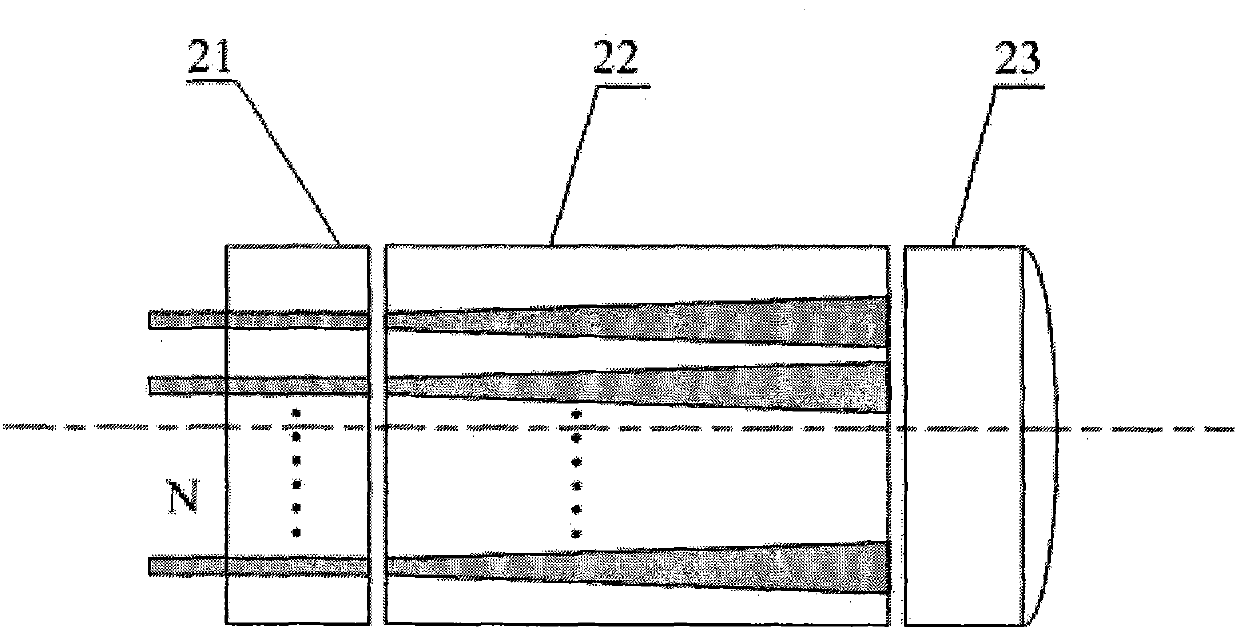

Filter based on axial direction apodized grating

ActiveCN106896446ARealize downloadLarge toleranceOptical waveguide light guideSingle mode waveguidesSideband

The present invention discloses a filter based on axial direction apodized grating. Input single mode waveguide is connected with the upper end port of the left end of an asymmetrical gradual changing directional coupler through input gradual changing waveguide, and the lower end port of the left end of the asymmetrical gradual changing directional coupler is connected with bending waveguide to realize reflection signal download; and the upper end port of the right end of the asymmetrical gradual changing directional coupler is connected with the left end of an antisymmetrical multimode waveguide grating, and the right end of the antisymmetrical multimode waveguide grating is connected with the output single mode waveguide through output gradual changing waveguide. The separation of grating reflection signals employs the asymmetrical gradual changing directional coupler with large tolerance and small insertion loss to realize download of the grating signals; based on a grating filter, the filter based on axial direction apodized grating is large in tolerance and wide in bandwidth regulation range and cannot be limited by the FSR so as to realize filters with various different bandwidth demands; and moreover, the axial direction position regulation of grating teeth realizes apodization so as to realize a grating filter with large sideband suppression ratio and greatly improve the performance of the grating filter.

Owner:ZHEJIANG UNIV

Preparation method of aminated sponge/graphene three-dimensional composite structural material

InactiveCN103525113AEvenly dispersedGood water solubilityPigment treatment with non-polymer organic compoundsEthylene diamineThermal treatment

The invention relates to the field of synthesis of a novel macro nanomaterial, and in particular relates to a preparation method of an aminated sponge / graphene three-dimensional composite structural material. The preparation method specifically comprises the following steps: adding ethylene diamine and ammonia water into aqueous solution of oxidized graphene; immersing a piece of sponge with a certain size in the solution obtained in the previous step; placing the mixed solution at a certain temperature to perform heating treatment; forming the aminated three-dimensional sponge / graphene three-dimensional composite structural material in a self-assembly mode. The material has better mechanical performance and can be machined into various shapes according to the requirements of different types. The method has the advantages of simplicity, low equipment requirement, low raw material price, high product quality and capability of realizing large-scale industrial production.

Owner:TONGJI UNIV

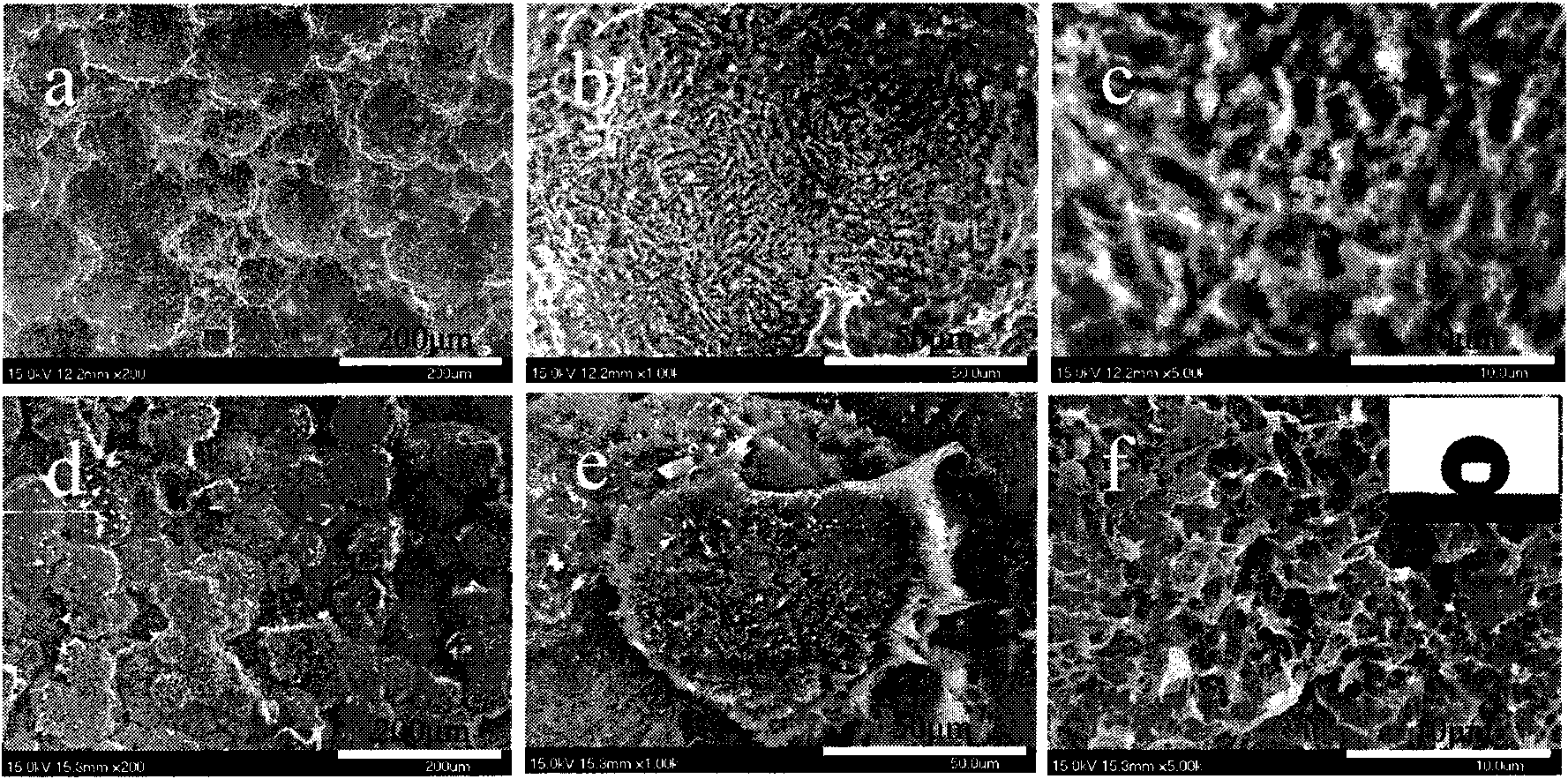

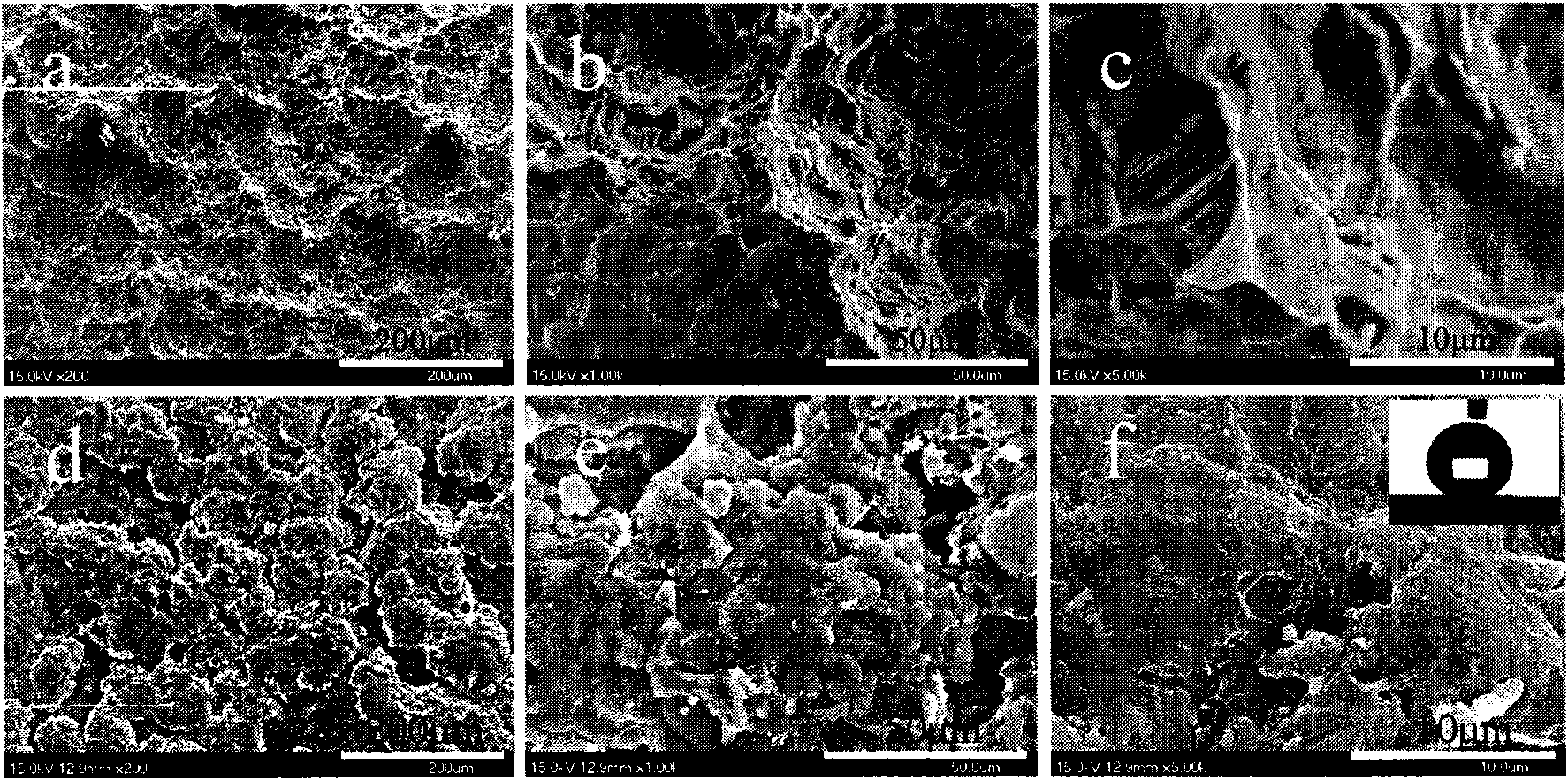

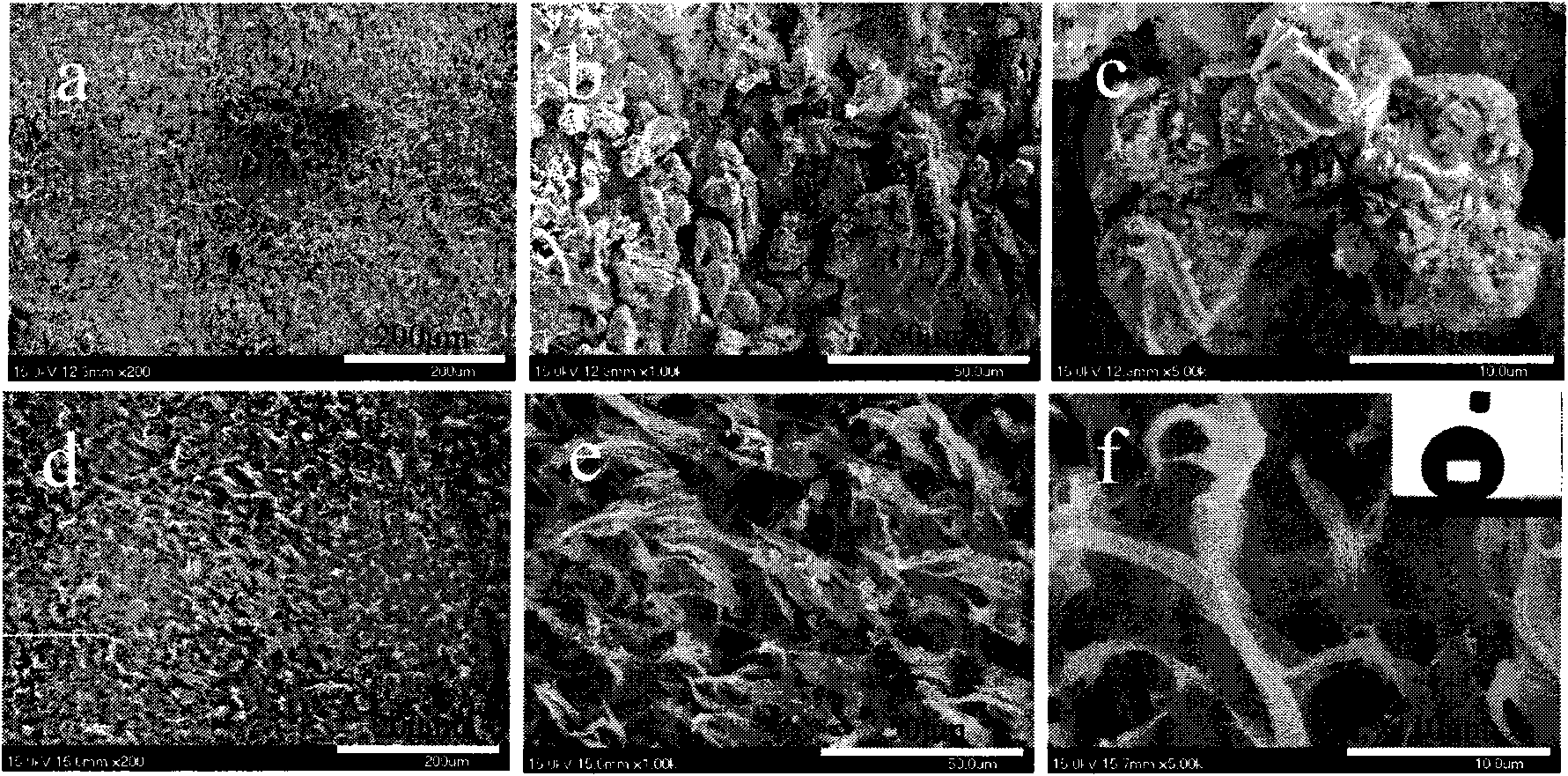

Method for preparing polymer superhydrophobic surface using controlled etched metal surface as template

The invention provides a method for preparing polymer superhydrophobic surface using controlled etched metal surface as template. The method comprises: (1) cleaning metal surface and drying; (2) immersing the cleaned metal into chemical etching liquid at 1-90 degrees centigrade, standing or stirring in speed of 60-120r / min to react for 1min-2h, taking out, washing by deionized water and drying; (3) using the metal surface etched in the step (2) as template, hot pressing the thermoplastic polymer on the template surface, cooling, and peeling the shaped polymer to obtain the material with superhydrophobic surface. Compared with the present methods for preparing polymer superhydrophobic surface, the invention achieves the advantages of simple process, repeatedly-usable template, low cost and no harmful organic solvent used in preparation process; can be combined with flow casting method film production technology in industrial; and have excellent prospect of large-scale production.

Owner:ZHEJIANG UNIV OF TECH

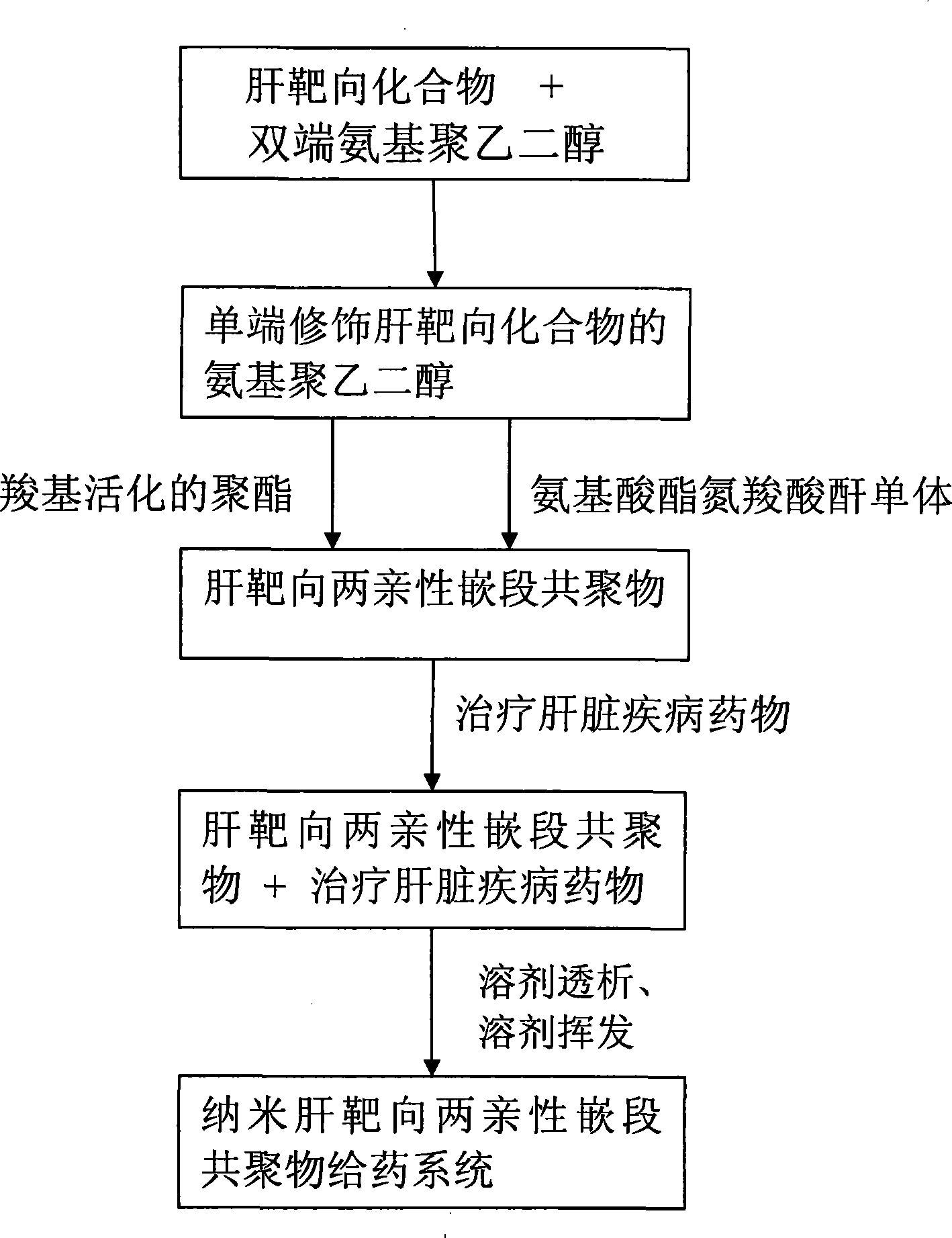

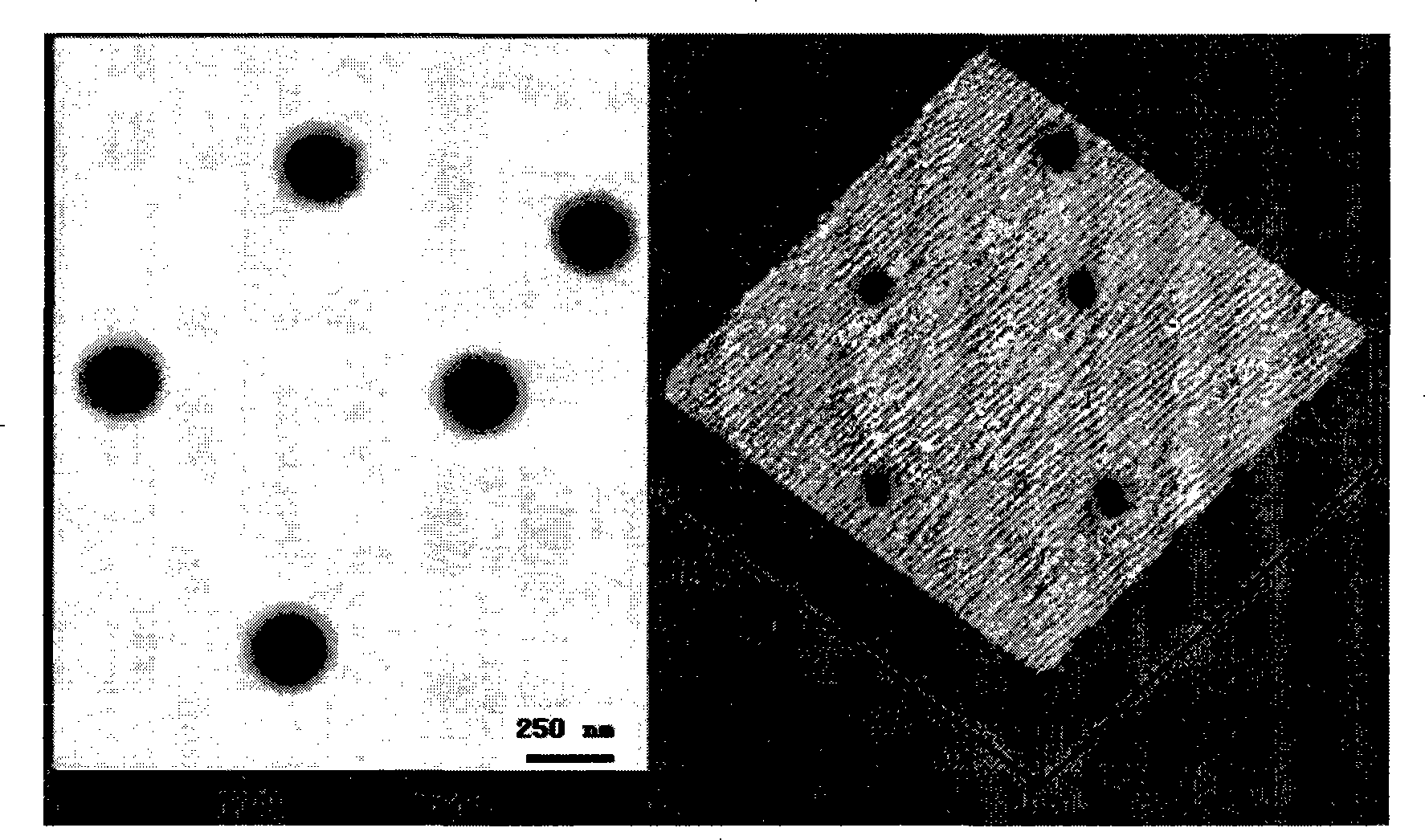

Nano liver target direction amphipathic nature block copolymers drug administration system and preparation

InactiveCN101249266AGood biocompatibilityImprove solubilityOrganic active ingredientsDigestive systemDiseaseLife quality

The invention relates to a drug delivery system of nanometer liver targeting amphiphilic block copolymer and a preparation method thereof. The nanometer liver targeting drug delivery system is obtained by adopting liver targeting amphiphilic block copolymer which can be biologically degraded and which has good biocompatibility as the carrier material and embedding drugs for treating liver diseases by a solvent dialysis method or a solvent evaporation method; the weight ratio of the carrier material to the drug is 1:0.1 to 1.2. The drug delivery system has the advantages of simple operation, mild condition and cheap raw material; the prepared drug delivery system has good biocompatibility and both effects of active targeting and passive targeting, and can realize high targeting and sustained release drug delivery to the liver by means of injection, thus solving the defects of bad targeting and low bioavailability of present anticancer drugs and improving the life quality of patients, with broad application prospects.

Owner:NANKAI UNIV

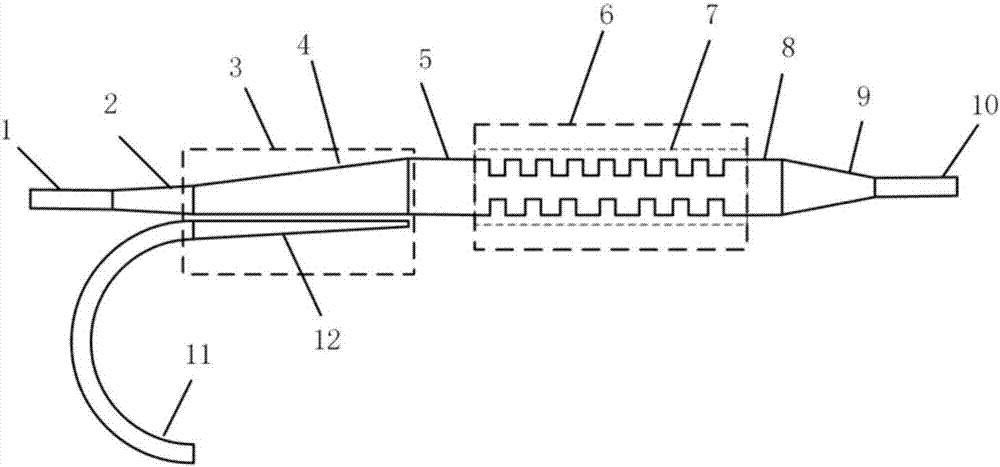

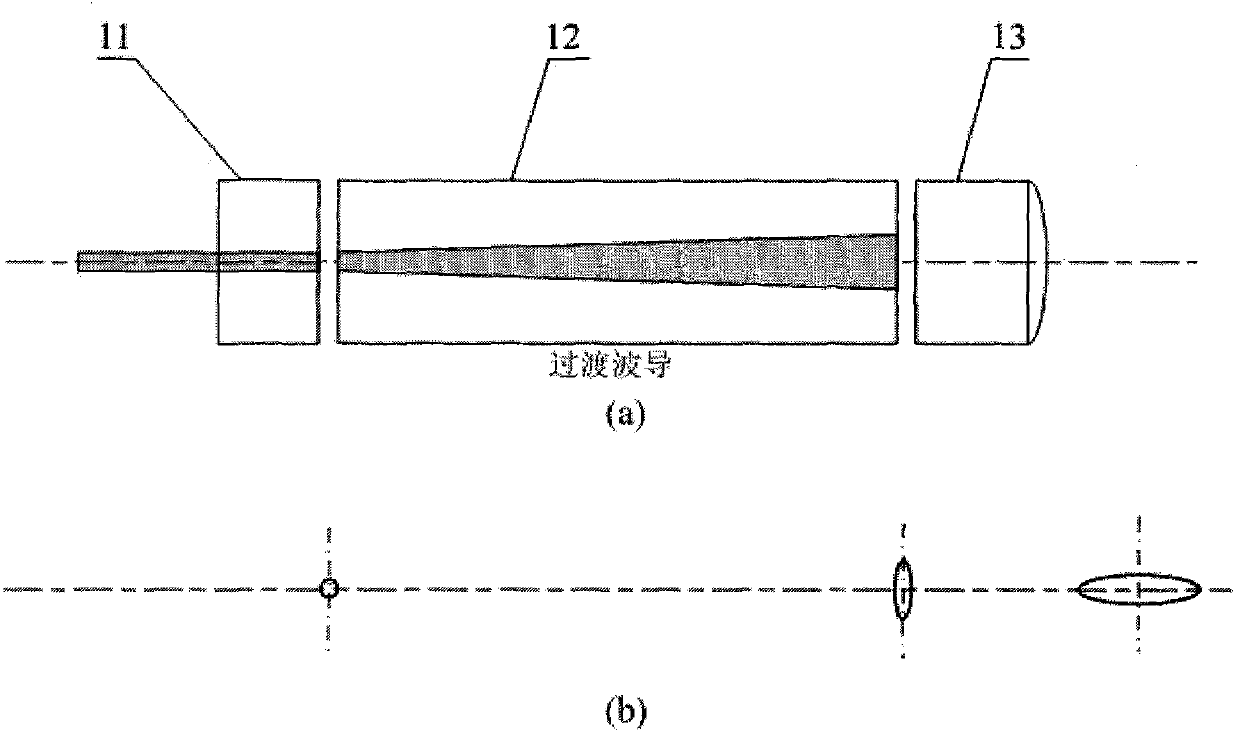

Elliptical light spot optical fiber collimator

InactiveCN102183822ASimple structureThe preparation process is matureCoupling light guidesOptical waveguide light guideLight spotTransducer

The invention relates to an elliptical light spot optical fiber collimator, which is characterized by consisting of three parts through coupling in turn, namely an optical fiber head 11, a planar optical waveguide transducer 12 and a collimating micro-lens 13, wherein the planar optical waveguide transducer 12 widens or compresses a waveguide in a width or thickness direction through a transitional waveguide, and circular mode field light spots output through a single mode fiber are coupled to enter the planar optical waveguide transducer, are transmitted through the transitional waveguide and converted into elliptical mode field light spots, and pass through the collimating micro-lens to form elliptical light spot collimating beams. The elliptical light spot optical fiber collimator has a key component of the planar optical waveguide transducer, can be manufactured in batch by a mature planar waveguide process, and is low in cost and easy to implement. An optical switch or an attenuator is manufactured from the elliptical light spot optical fiber collimator and the micro-lens, so that the moving direction of the translational micro-lens is consistent with the short axis direction of the elliptical light spots, and the requirement on the travel of the micro-lens can be greatly reduced.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

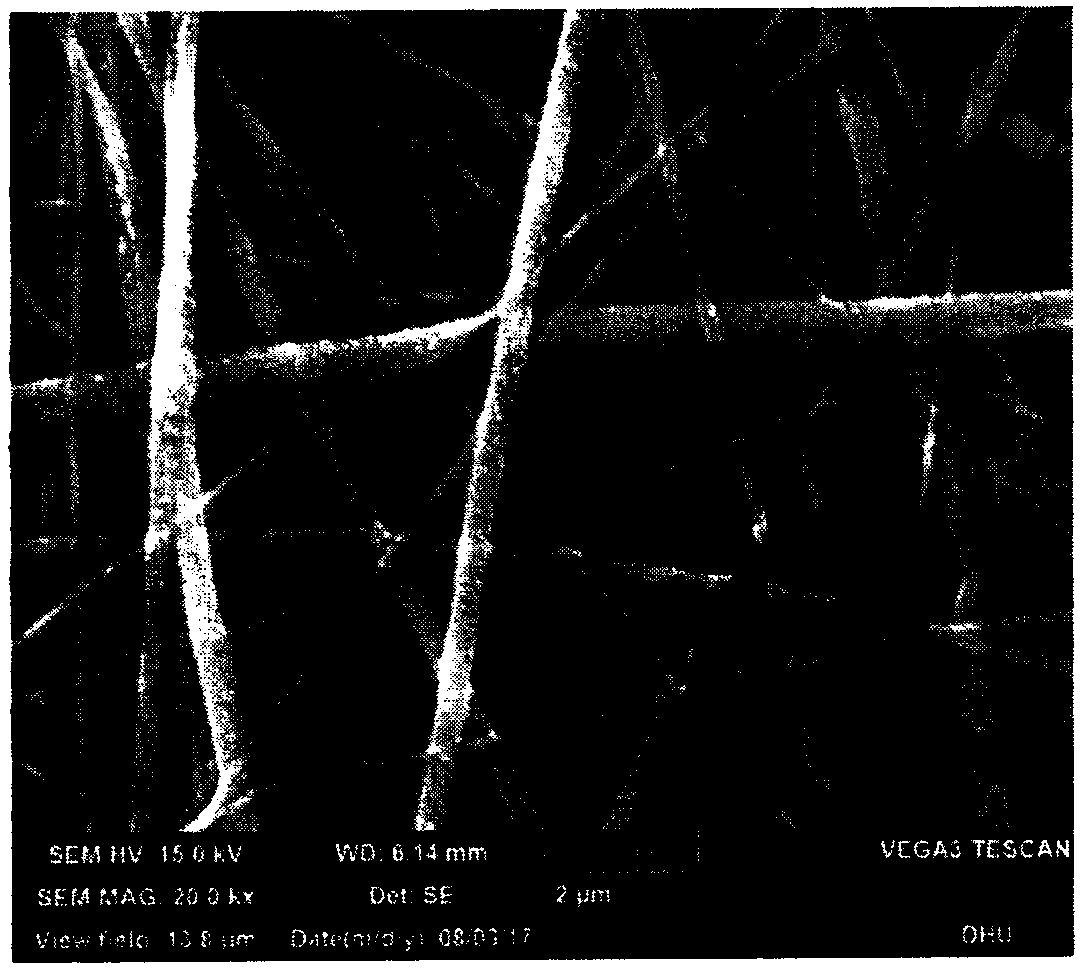

Manufacturing method of flexible titanium dioxide/carbon composite porous nanofiber membrane material

PendingCN109112728ACalcination temperature is lowShort calcination timeElectro-spinningNon-woven fabricsCarbon compositesFiber

The invention provides the manufacturing method of a flexible titanium dioxide / carbon composite porous nanofiber membrane material. The method comprises the following steps of step1, dissolving a titanium source and a high molecular polymer in an organic solvent to obtain a precursor solution; step2, carrying out electrostatic spinning on the obtained precursor solution under electrostatic high pressure to obtain a precursor nanofiber membrane on a receiving device; and step3, calcining The precursor nanofiber membrane under the protection of an inert gas atmosphere to obtain the flexible titanium dioxide / carbon composite porous nanofiber membrane material. In the invention, an electrostatic spinning technology is simple, there are many spinning raw materials, a calcining temperature for manufacturing the flexible composite porous nanofiber is low, calcining time is short, manufacturing cost is greatly reduced and production efficiency is increased, and a large scale production potential is possessed.

Owner:DONGHUA UNIV

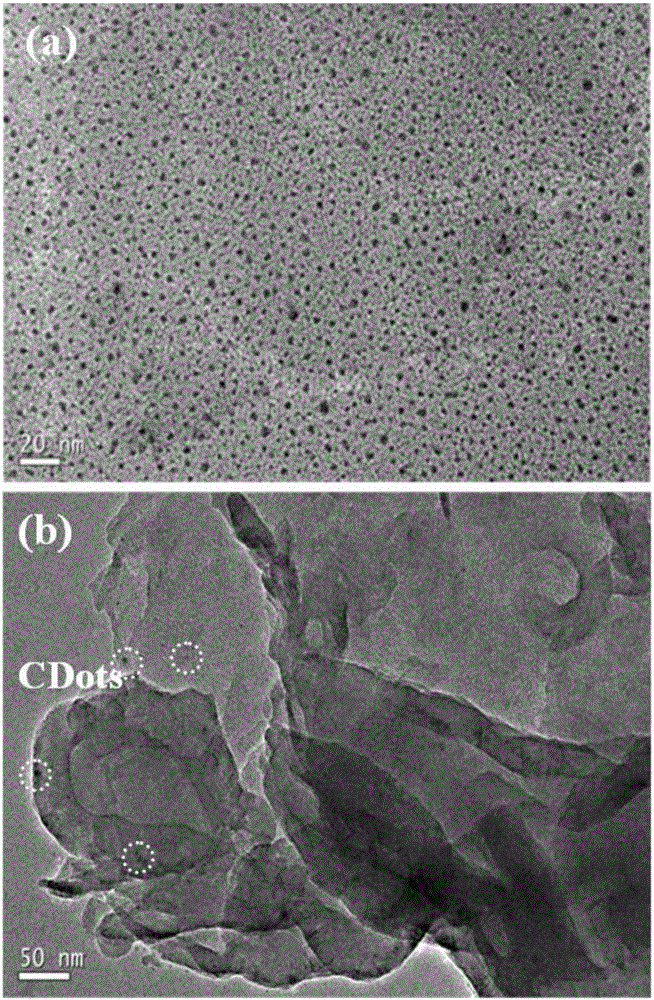

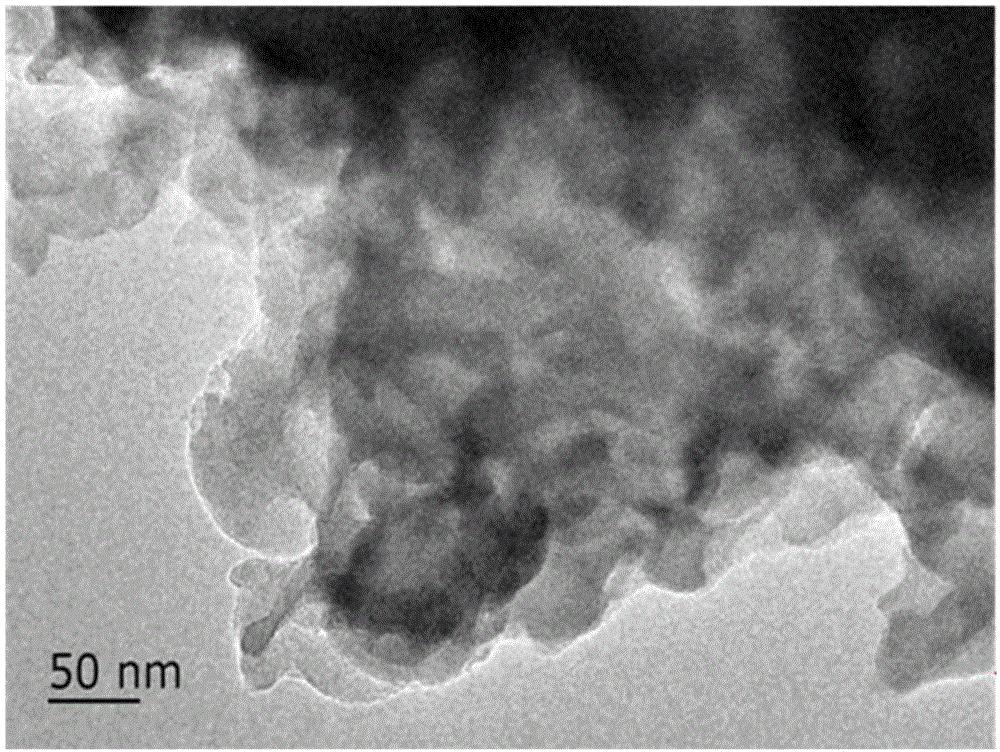

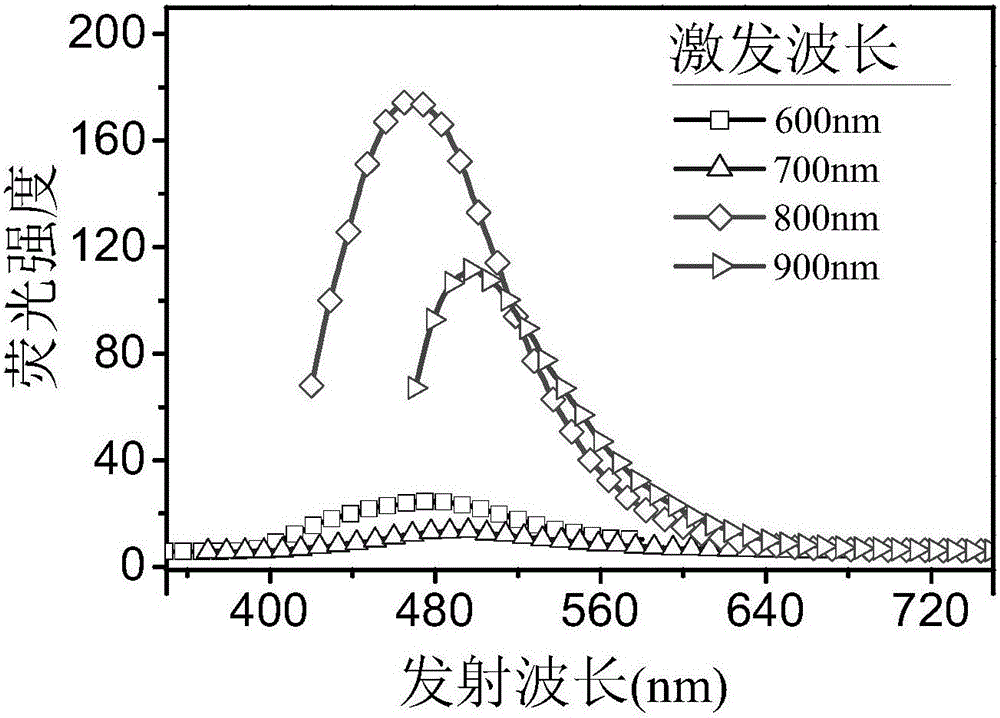

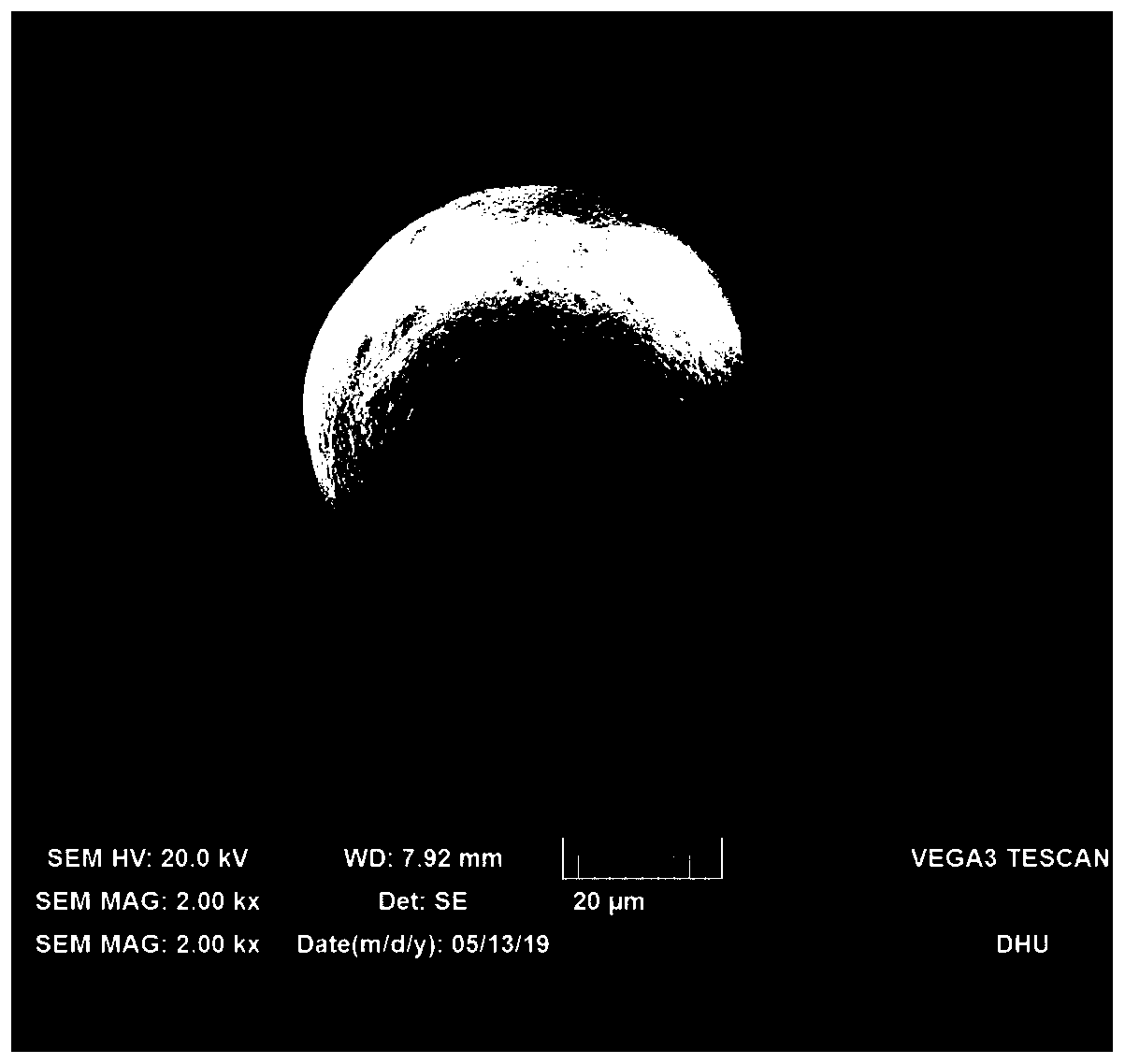

Carbon dot and graphite phase carbon nitride compound photocatalyst as well as preparation method and application thereof

InactiveCN107519907AThe synthesis process is simpleGood repeatabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationDiamineGraphite

The invention discloses a carbon dot and graphite phase carbon nitride compound photocatalyst as well as a preparation method and application thereof. The method comprises the following steps: adding glucose into ethidene diamine and superpure water, performing a reaction at 150-160 DEG C after ultrasonic dissolution, centrifugalizing the obtained solution which is cooled to room temperature to remove large particles, and drying and grinding to obtain carbon dot powder; and then adding dicyandiamide into the carbon dot powder and the superpure water, drying the mixture to calcine at 450-550 DEG G after ultrasonic dissolution, and grinding and sieving the mixture to obtain the carbon dot and graphite phase carbon nitride compound photocatalyst after being cooled to room temperature. By adopting a thermal aggregation method, the photocatalyst is simple in synthetic process and good in repeatability and has basic conditions of large-scaled production. The carbon dot and graphite phase carbon nitride compound photocatalyst can convert long wave light into short wave light which can be used by graphite phase carbon nitride, so that the catalytic ability of the graphite phase carbon nitride is improved. The compound photocatalyst can degrade antibiotics under sunlight.

Owner:GUANGDONG UNIV OF TECH

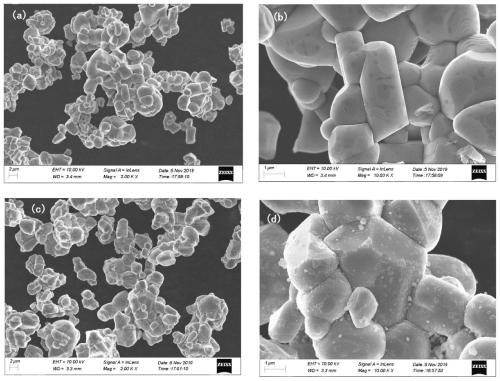

Composite binder, silicon-based negative electrode plate and preparation method thereof

ActiveCN110350196AFix stability issuesImproved magnification performanceNegative electrodesSecondary cellsCarbon compositesOrganic solvent

The invention provides a composite binder, a silicon-based negative electrode plate and a preparation method thereof. The preparation method of the silicon-based negative electrode plate comprises thefollowing steps of carrying out mixing on polyvinylidene fluoride of different molecular weights through a ball mill, so as to obtain a composite binder; dissolving the composite binder in an organicsolvent to obtain a binder glue solution; dispersing a conductive agent in the binder glue solution to obtain a conductive glue solution; adding silicon-carbon composite material powder and the organic solvent into the conductive glue solution to prepare electrode slurry; coating the electrode slurry on a negative current collector, and carrying out vacuum high-temperature desolventizing treatment on the current collector coated with the electrode slurry; and carrying out roll pressing on the obtained negative electrode plate to obtain the silicon-based negative electrode plate. According tothe prepared silicon-based negative electrode plate, the performance of a lithium battery electrode material can be effectively improved, the rate performance of the battery is improved, and the cyclelife of the battery is prolonged.

Owner:DONGHUA UNIV

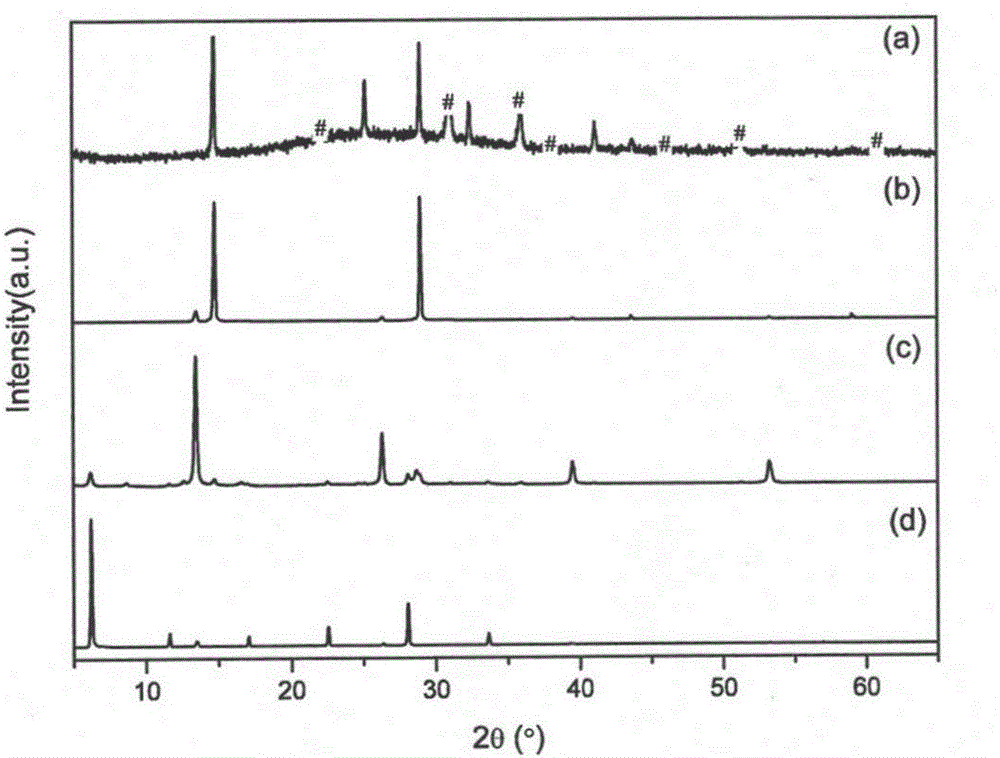

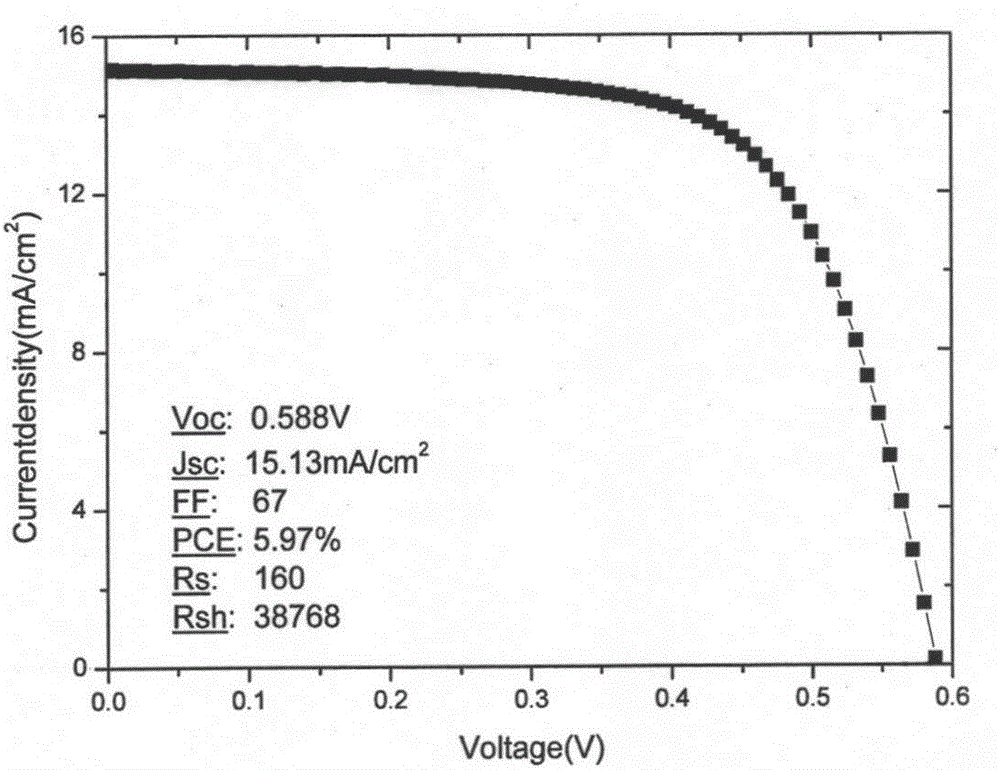

Low-dimensional tin halide perovskite, preparation method thereof and application of perovskite

InactiveCN106784324AHigh air stabilityGood visible light absorption propertiesSolid-state devicesSemiconductor/solid-state device manufacturingSolventOrganic inorganic

The invention provides low-dimensional tin halide perovskite, a preparation method thereof and an application of the perovskite. The low-dimensional tin halide perovskite is characterized in that a phenethylamine compound is doped. The preparation method of the low-dimensional tin halide perovskite is characterized by including the steps: 1 dissolving a tin source compound, an organic-inorganic source compound and the phenethylamine compound in a polar solvent, adding fluoride serving as a reducing agent and stirring the compounds for 1-2 hours at the temperature of 70 DEG C to obtain precursor solution; 2 cooling and filtering the precursor solution, dripping the precursor solution onto a substrate, performing spin-coating and then performing annealing for 20-30 minutes at the temperature of 100 DEG C to obtain a low-dimensional tin halide perovskite film. The perovskite film is low in toxicity, has a low-dimensional structure, high stability, good visible light absorption property and capability of realizing high photoelectric conversion efficiency in a thin-film solar cell, and the photoelectric conversion efficiency can reach about 6%.

Owner:SHANGHAI TECH UNIV

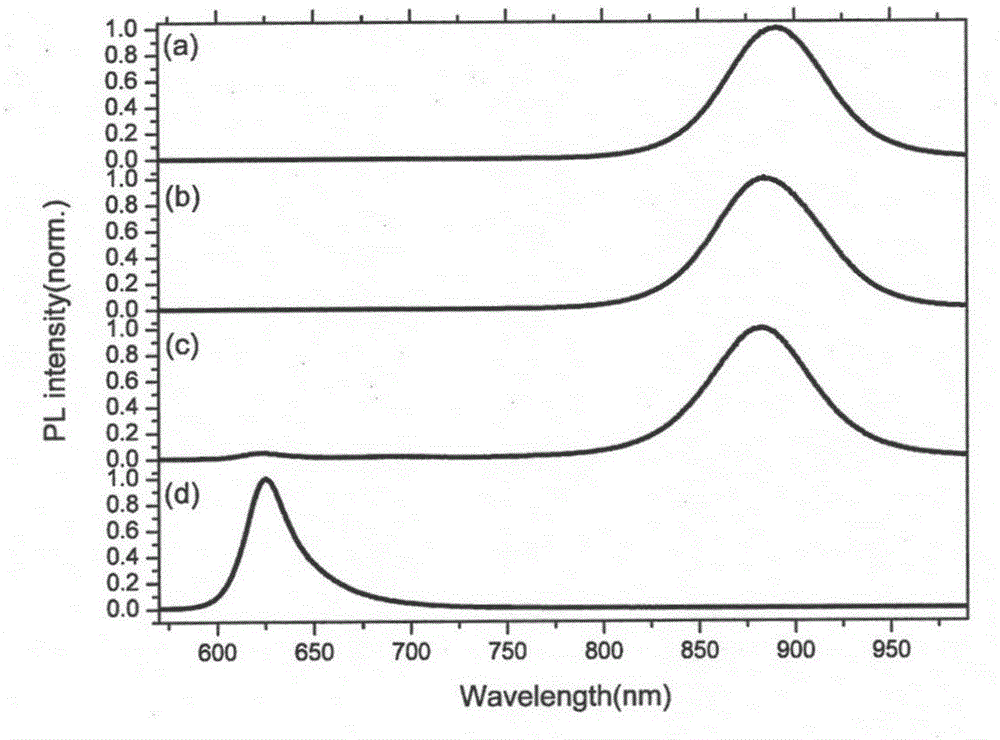

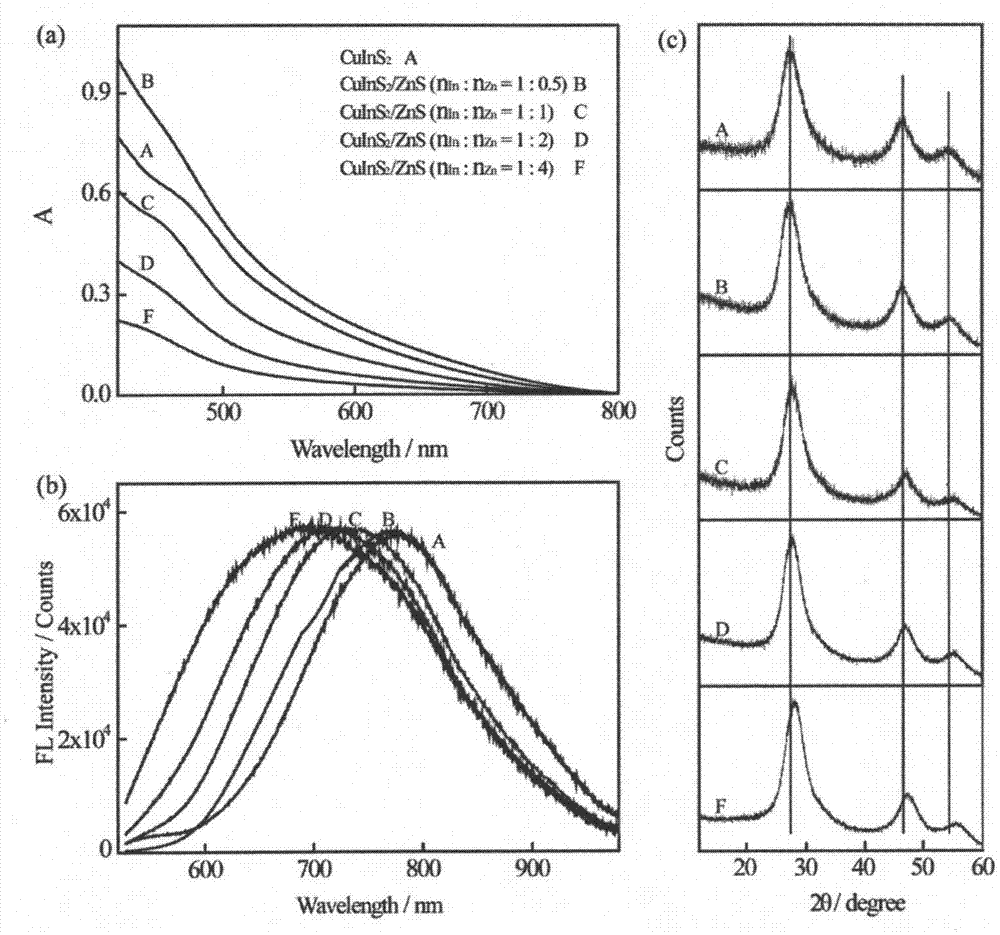

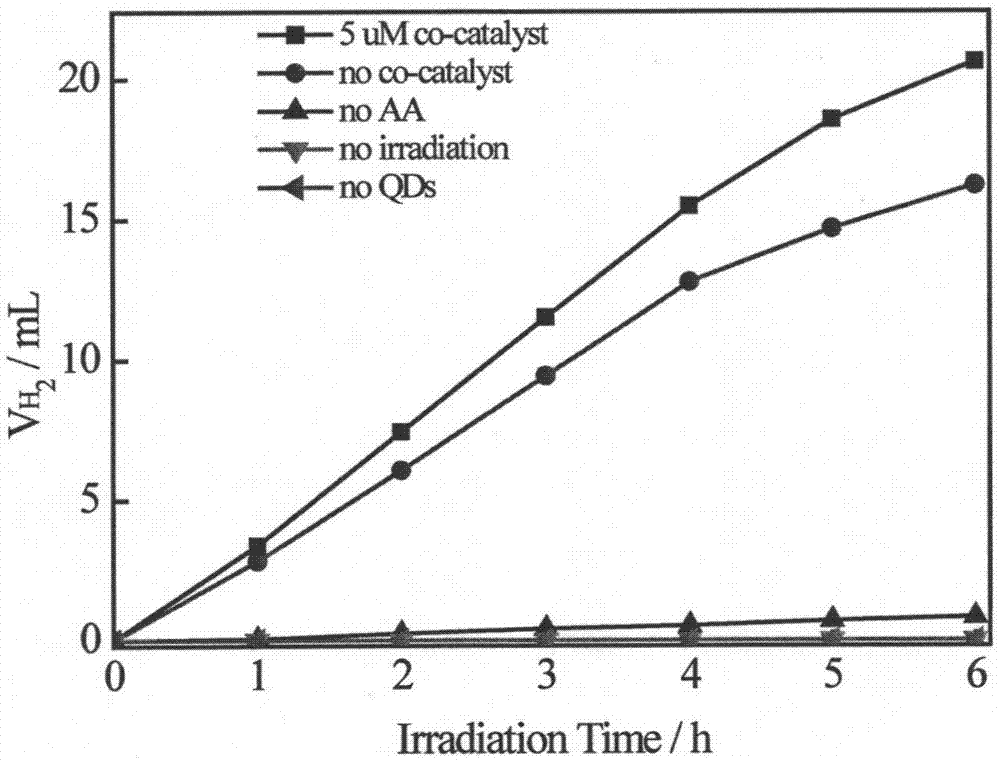

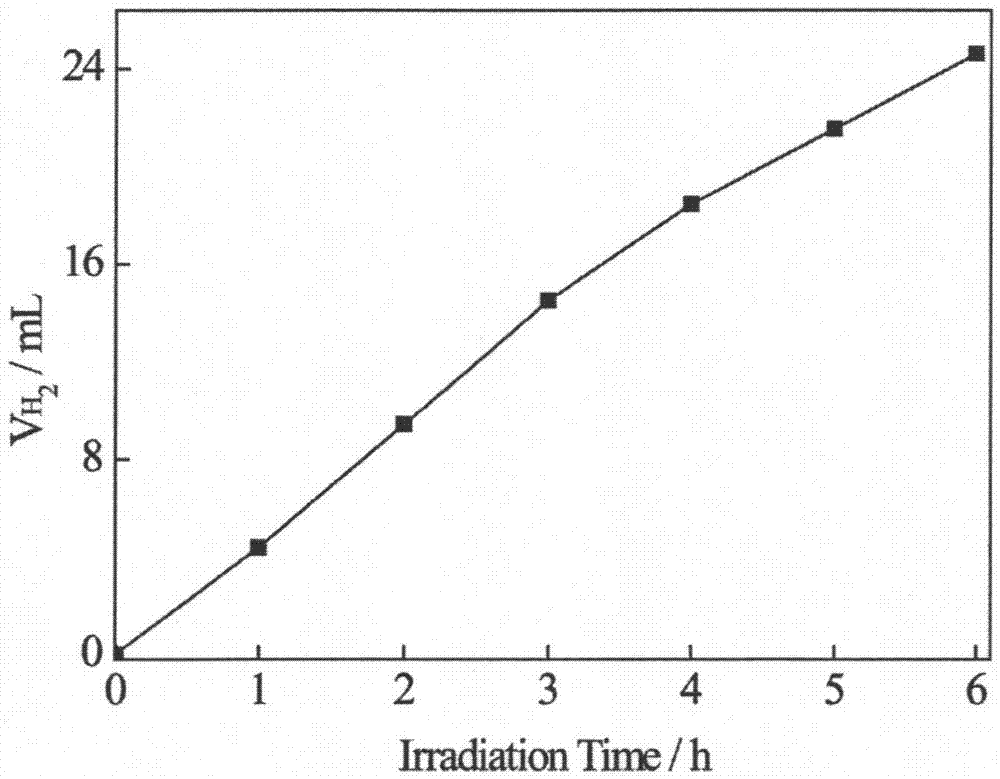

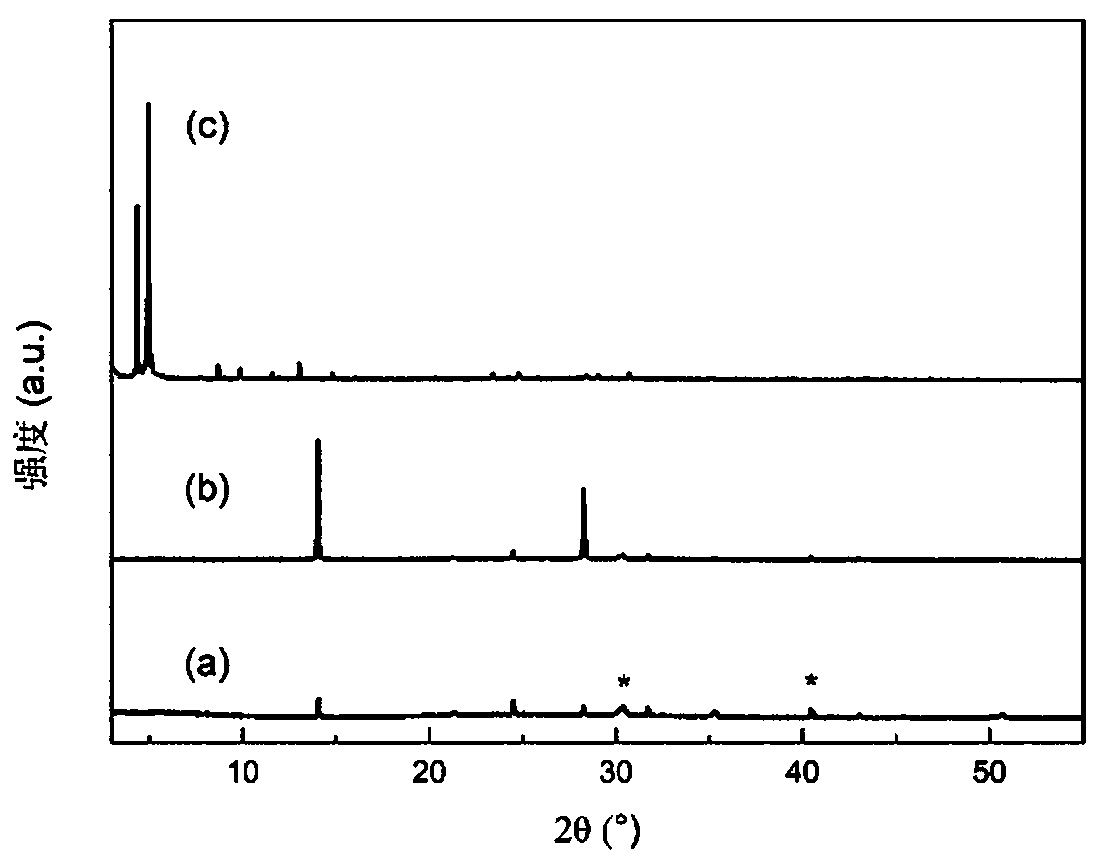

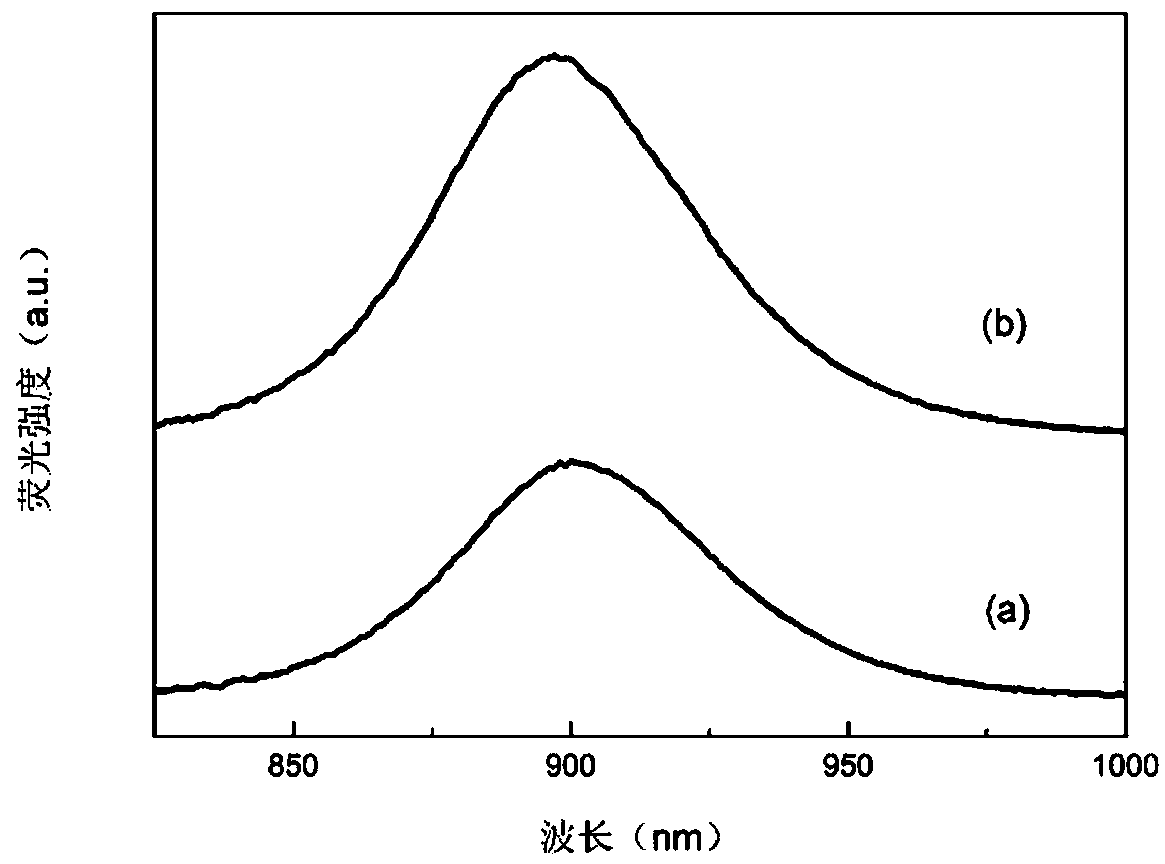

CuInS2 quantum dots, CuInS2/ZnS quantum dots and their preparation and application

InactiveCN107201226ALow toxicityEfficient Photolysis of Water for Hydrogen ProductionPhysical/chemical process catalystsNanoopticsQuantum efficiencyPtru catalyst

The invention provides CuInS2 quantum dots, CuInS2 / ZnS quantum dots and their preparation and application. A preparation method of the CuInS2 quantum dots is characterized by comprising the steps of 1, adding a copper-source compound, an indium-source compound and glutathione into water, adjusting pH to 7-10 to obtain mixed liquid A, and adding an aqueous solution containing a sulfur-source compound to obtain mixture B; 2, heating the mixture B to 70-100 DEG C, stirring at this temperature for 2-4 h, cooling, adding ethanol, centrifugally separating, and purifying to obtain the CuInS2 quantum dots. A quantum dot photocatalyst obtained herein has low toxicity, is able to produce hydrogen by water photocatalysis under zero co-catalysts, has good visible light absorption, and reaches about 10% of quantum efficiency in hydrogen production by photocatalysis at visible light band.

Owner:SHANGHAI TECH UNIV

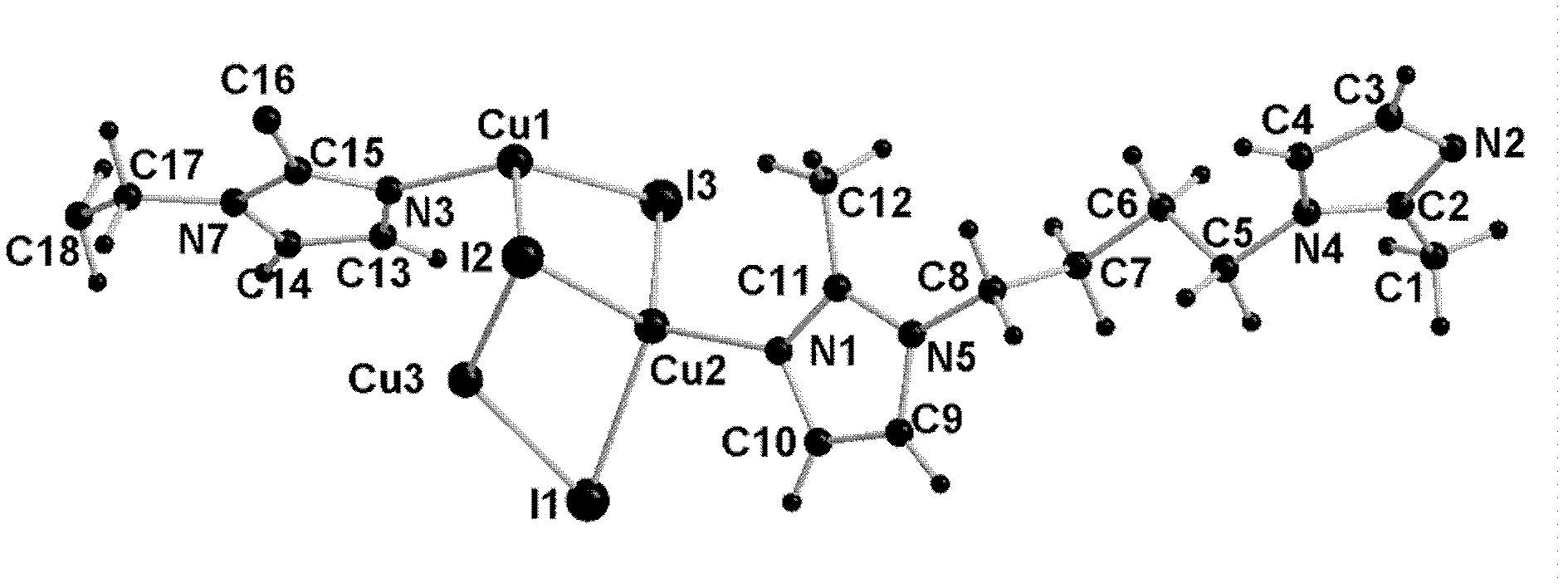

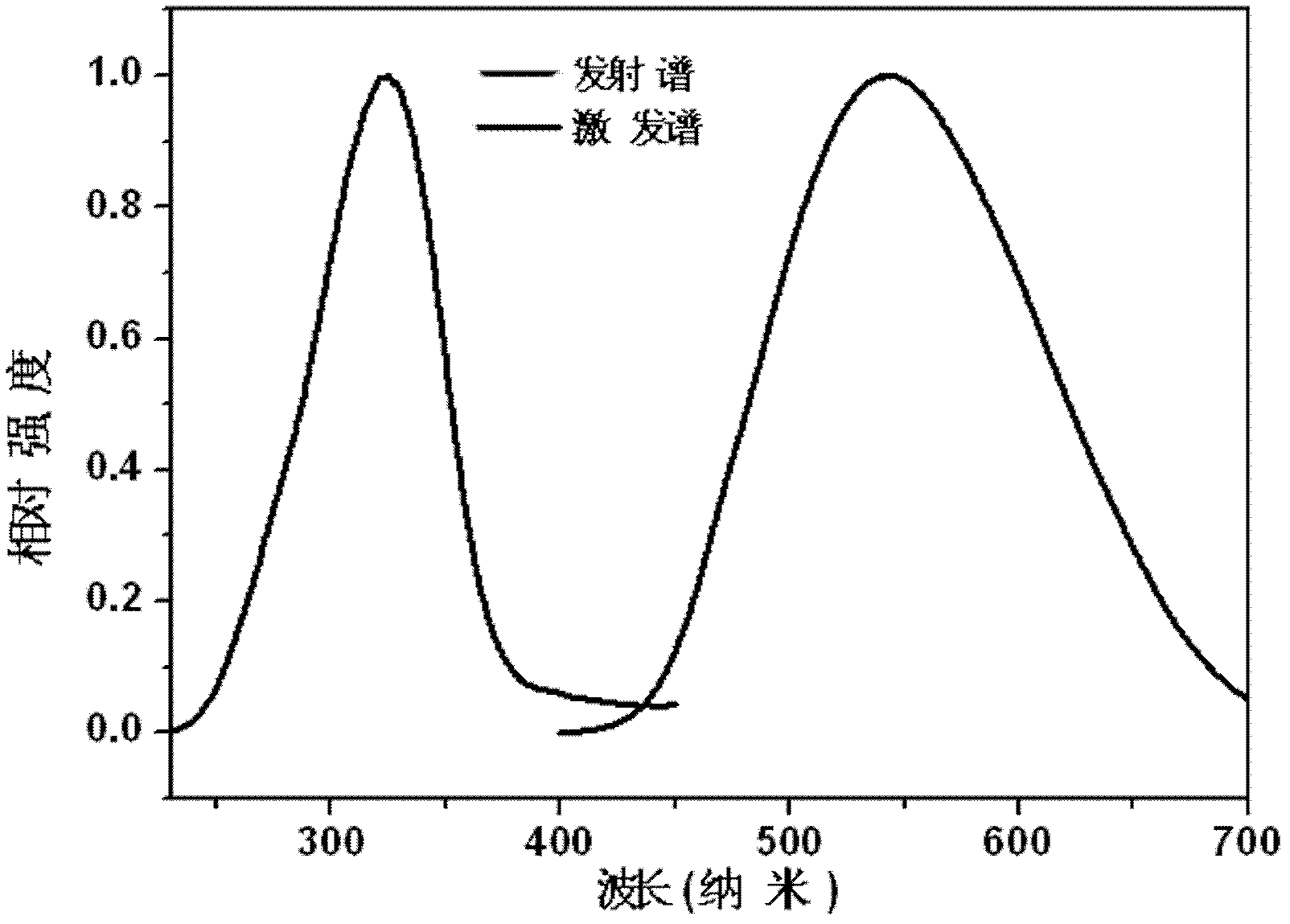

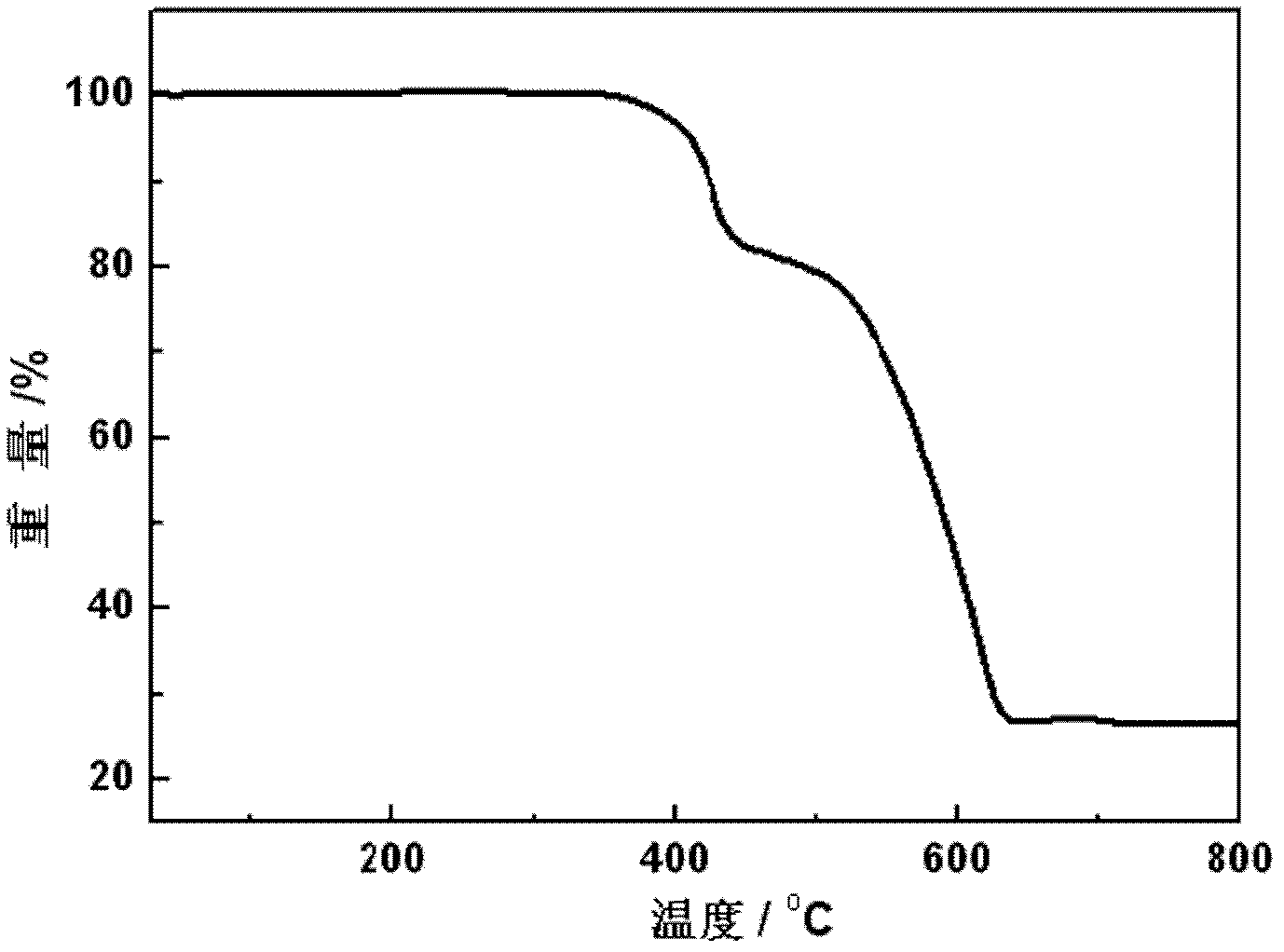

Yellow phosphor crystal material as well as preparation method and usage thereof

The invention provides a yellow phosphor crystal material as well as the preparation method and the usage thereof. The chemical formula of the material is [Cu6 (1, 4-two (2- methylimidazole 1-group) butane) 3 I 6] n. 1, 4- two (2-methylimidazole 1-group) butane is taken as a bridging ligand, and stable and higher luminous efficiency yellow phosphor 1, 4-two (2-methylimidazole 1-group) butane crystal material is prepared through temperate solvothermal or hydro-thermal method. The obtained crystal material can emit bright and yellow phosphorescence under the illumination of an ultraviolet lamp, the thermal stability is good, and the luminous efficiency is high.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

High-fluidity flame retardant master batch and preparation method thereof

The invention relates to the field of flame retardant master batches, in particular to a high-fluidity flame retardant master batch and a preparation method thereof. Fire retardant intercalated materials are packaged into an inorganic substance of the two-dimension sheet structure, and then are prepared into the high-fluidity flame retardant master batch by the aid of spherical inorganic particles. Fire retardant is protected through the two-dimension sheet structure so that good stability can be achieved, and the mobility is excellent under the assisting action of the two-dimension sheet structure and the spherical particles. The obtained flame retardant master batch has high fluidity, and the defect that an existing flame retardant master batch uses a lubricating agent like paraffin and thus the flame retardant property is lowered is overcome. When the high-fluidity flame retardant master batch is used for plastic products, good dispersity can be achieved, precipitation of the fire retardant is effectively prevented, and thus the fire resistance, processability and appearance performance of the flame retardant plastic products can all be improved.

Owner:江苏万纳普新材料科技有限公司

Curcuma zedoary oil solid lipid nano-particle and its preparation method

A lipid nanoparticle of zedoary oil used for preparing solid, liquid, injection, ointment, suppository, film, aerosol, etc is prepared from zedoary oil, medicinal phosphatide, emulsifier, solid lipid, liquid lipid and deoxidant through multiple methods.

Owner:SHENYANG PHARMA UNIVERSITY

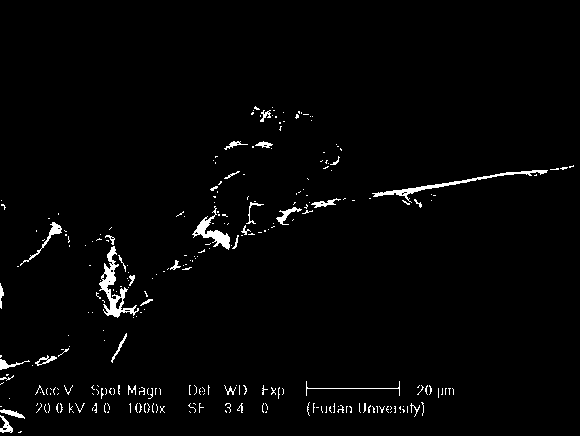

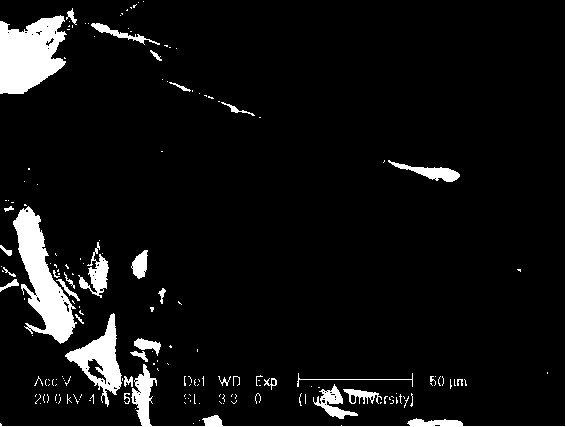

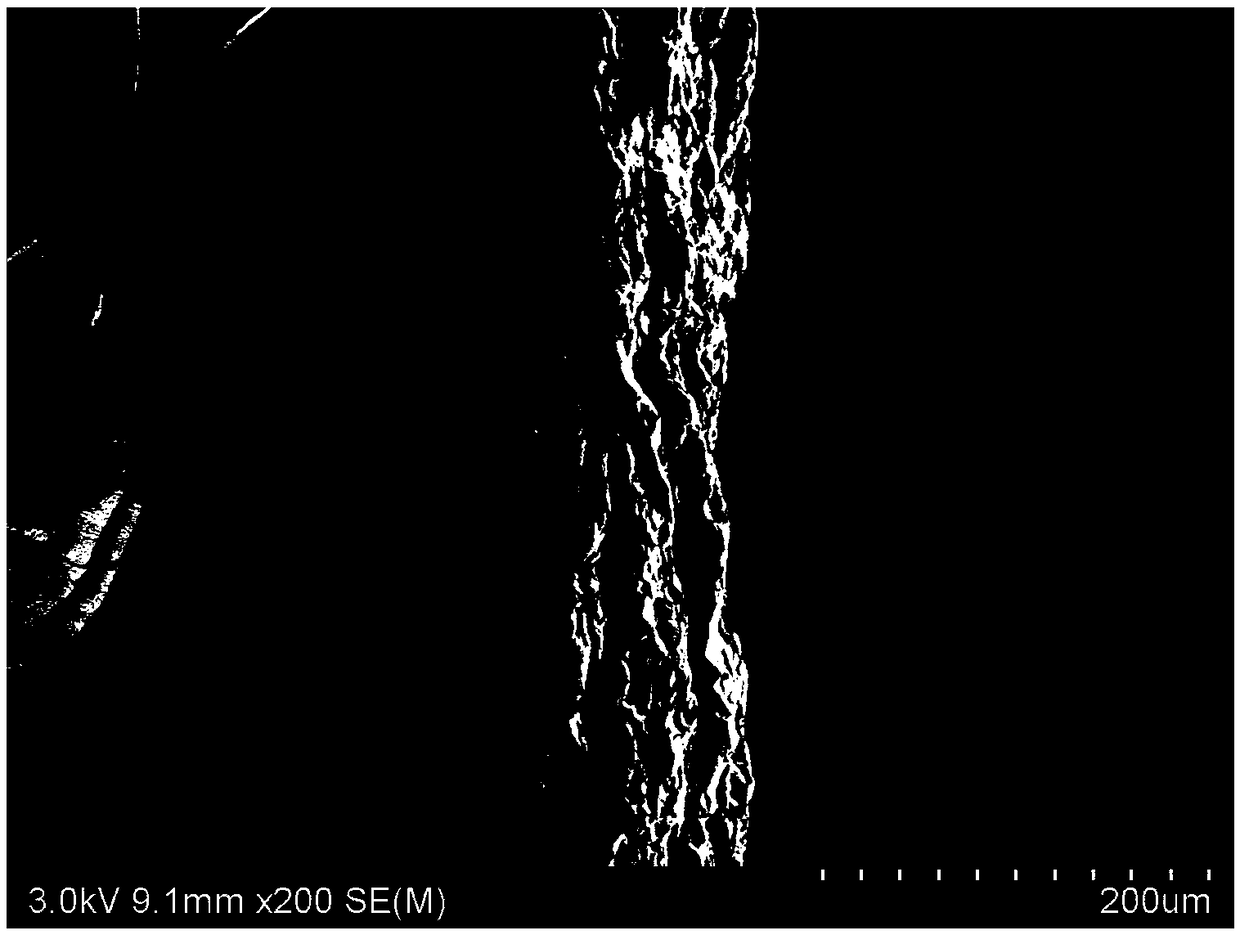

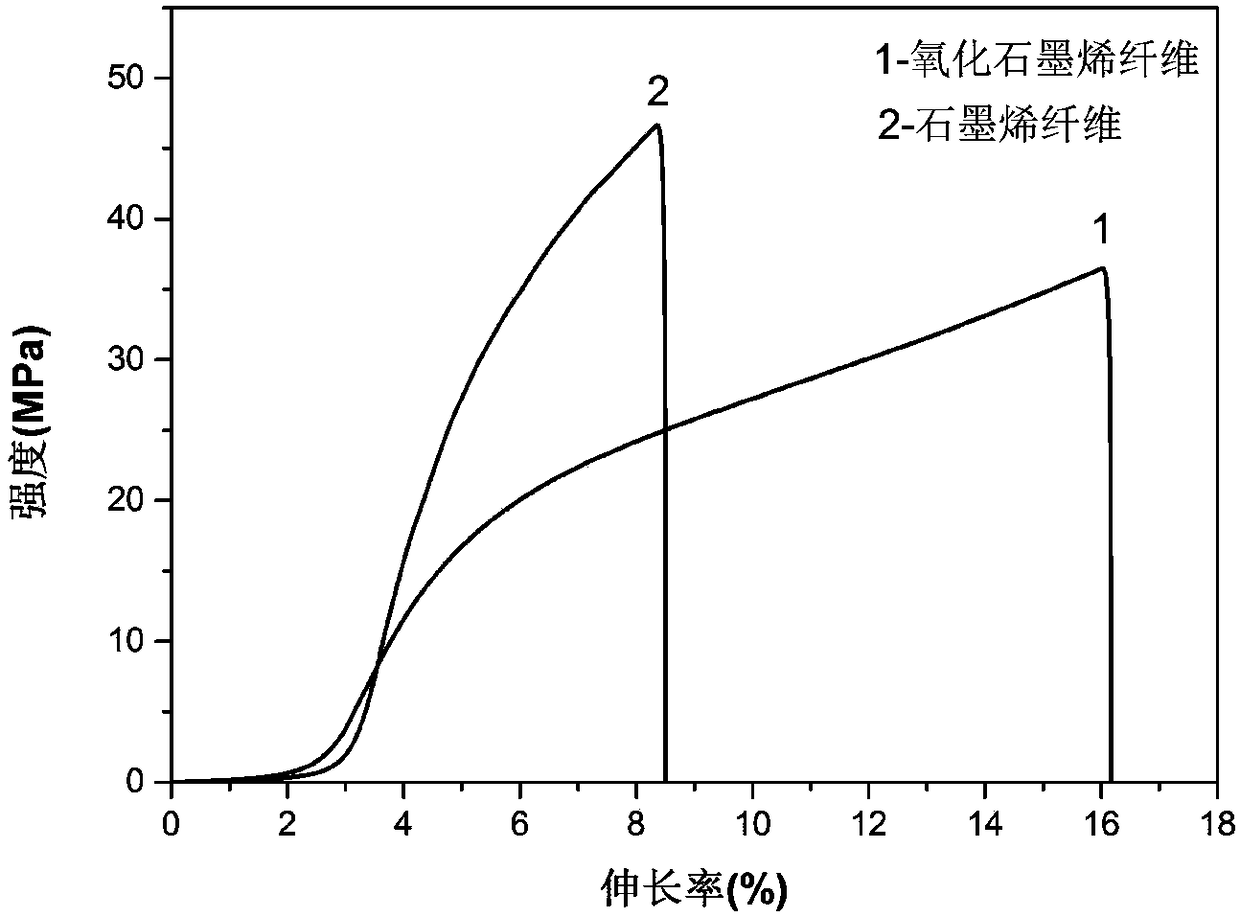

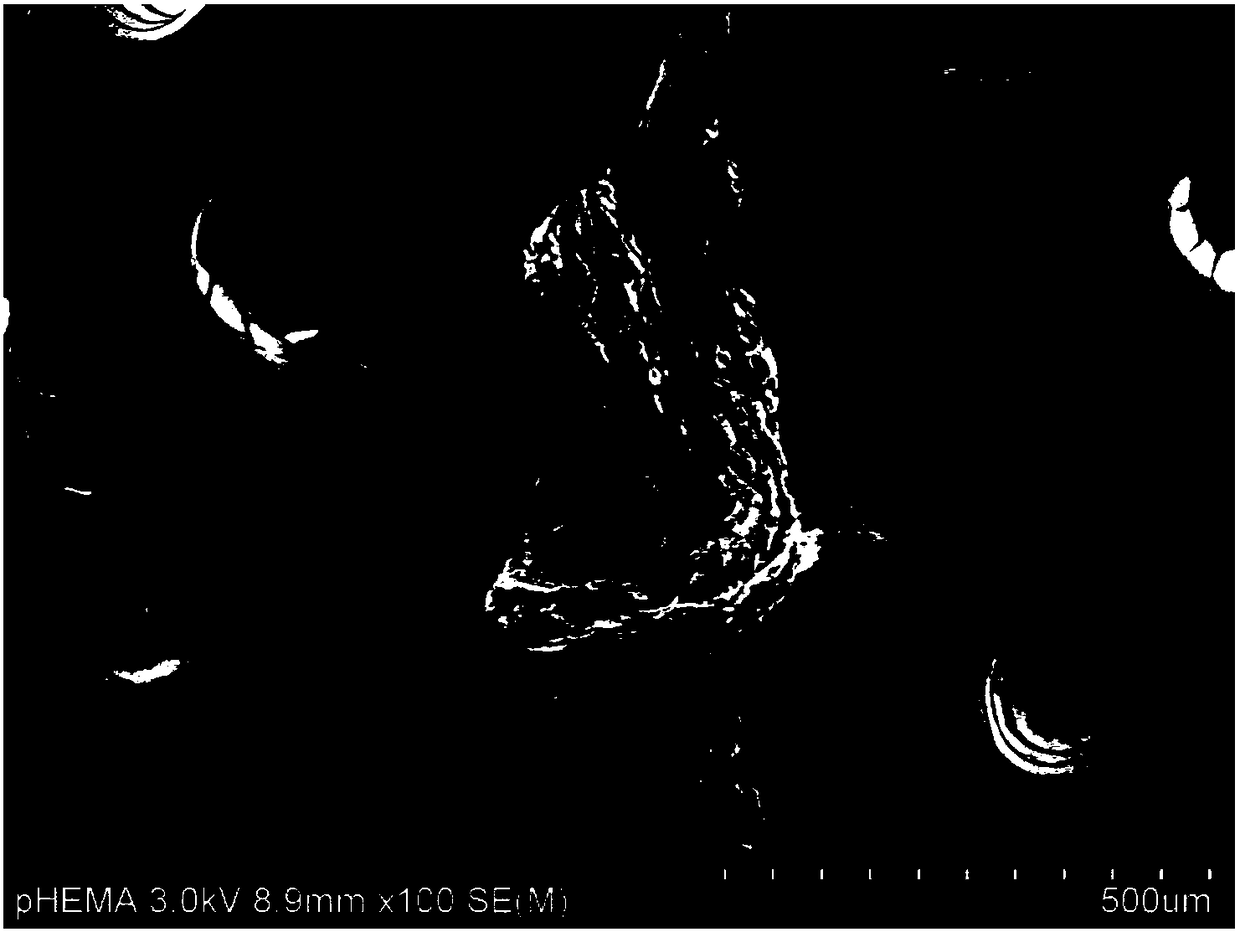

Dry spinning prepared ultrahigh-flexibility graphene fibers and preparation method thereof

InactiveCN108277556AWith liquid crystal propertiesGood fibrillationFibre chemical featuresDry spinning methodsFiberSupercapacitor

The invention discloses dry spinning prepared ultrahigh-flexibility graphene fibers and a preparation method thereof. The graphene fibers are prepared by preparing oxidized graphene fibers through anoxide graphene solution according to a dry spinning method, and then reducing the oxidized graphene fibers to obtain the graphene fibers. According to the method, the limitation on the idea that a long-chain type high polymer is the only material for preparing fibers is broken; the nano two-dimensional slice layer type oxizied graphene is utilized for the first time to continuously prepare the oxidized graphene fibers with outstanding flexibility according to the dry spinning method, and moreover, the graphene fibers with outstanding flexibility can also be successfully prepared according to areduction method. Compared with a wet spinning method, the method has the advantages that the preparation processes are simple and convenient, and the flexibility of the fibers is outstanding; large-scale production and application can be easily carried out; the graphene fibers are mainly applicable to flexible electrodes, supercapacitors and intelligent wearable equipment.

Owner:苏州圣菲尔新材料科技有限公司 +1

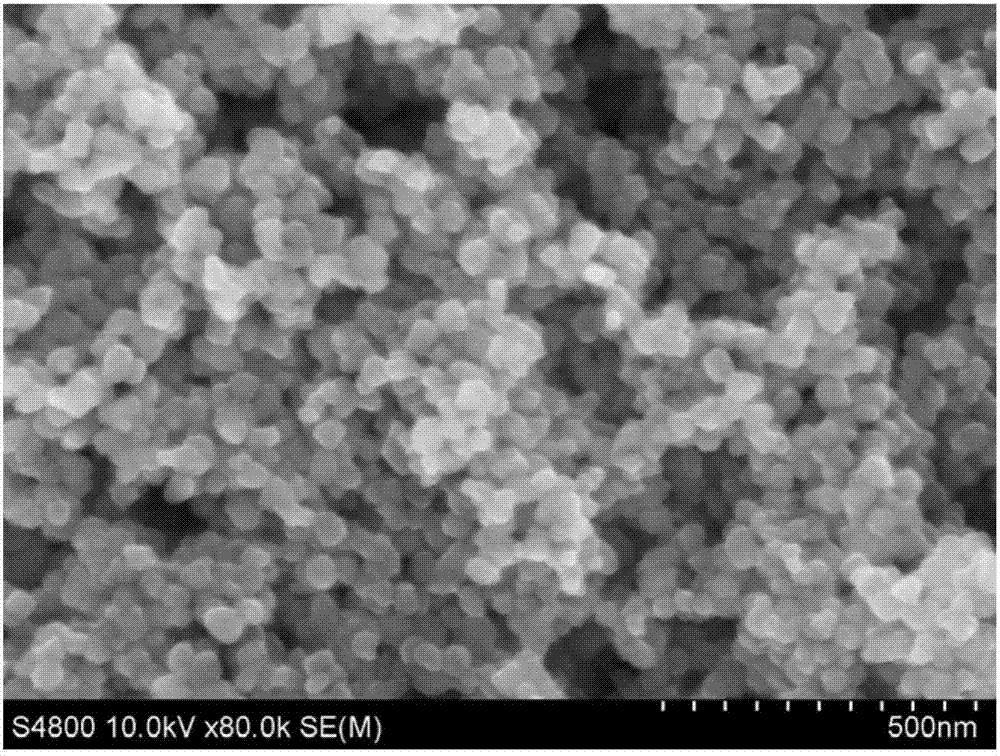

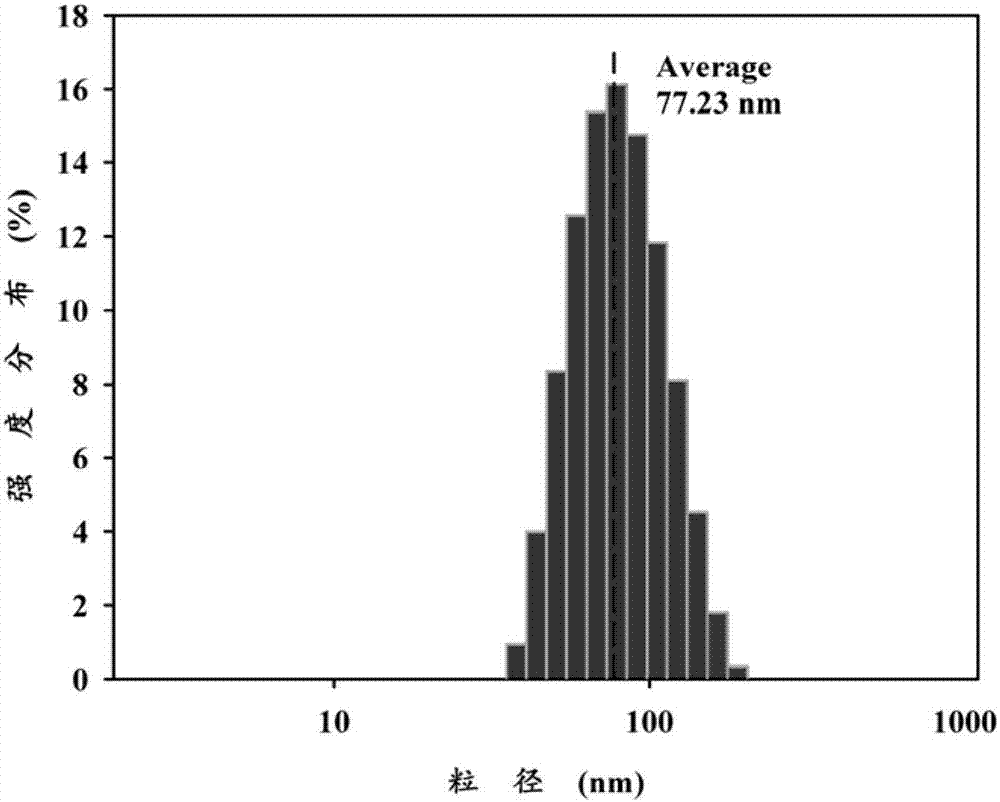

Vanadium dioxide ink for inkjet printing as well as preparation method and application of vanadium dioxide ink

The invention discloses vanadium dioxide ink for inkjet printing. The vanadium dioxide ink is prepared from the following components: nano vanadium dioxide powder, a dispersing agent, a bonding agent and a diluent, wherein the diluent is a mixed solution of dimethylbenzene and ethyl acetate or a mixed solution of the dimethylbenzene and butyl acetate. A preparation method of the vanadium dioxide ink disclosed by the invention comprises the following steps: carrying out mixed ultrasonic dispersion on the nano vanadium dioxide powder and the diluent to obtain vanadium dioxide dispersing liquid; carrying out mixed dispersion and grinding on the vanadium dioxide dispersing liquid and the dispersing agent in a sand mill; then adding the bonding agent, and continuously grinding in the sand mill until the materials are uniformly mixed, thus obtaining the vanadium dioxide ink for the inkjet printing. According to the vanadium dioxide ink disclosed by the invention, by regulating and controlling the particle size, stable dispersion, viscosity and surface tension of the nano vanadium dioxide ink, the vanadium dioxide ink suitable for the inkjet printing is successfully prepared; according to the nano vanadium dioxide ink disclosed by the invention, the smoothness of an inkjet printing process is ensured, a liquid drop shape can be formed during printing, a good printing effect is realized, and the requirement on film forming property of a printer is met.

Owner:NAT UNIV OF DEFENSE TECH

Multi-area continuous forming additive manufacturing laser forming equipment

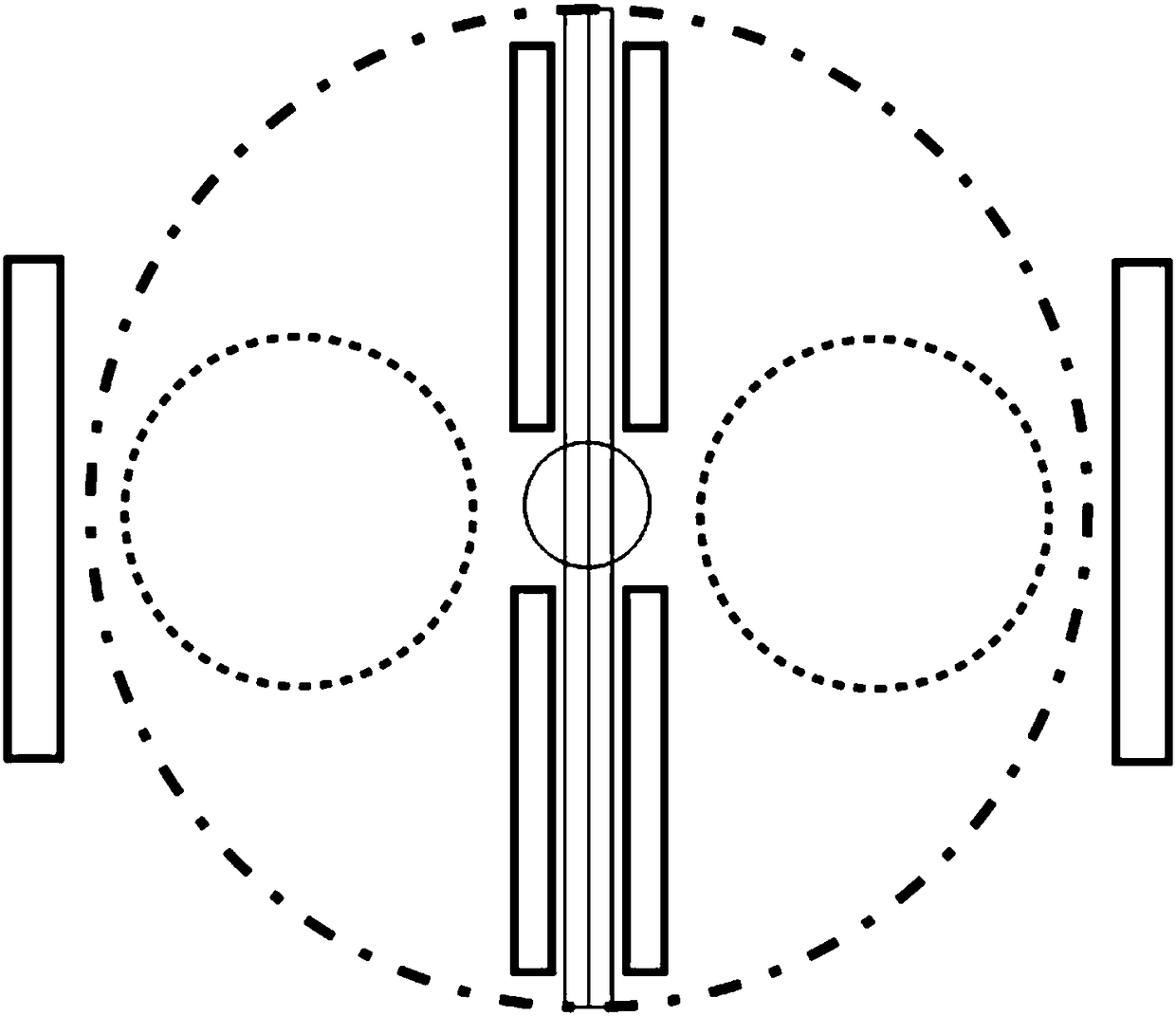

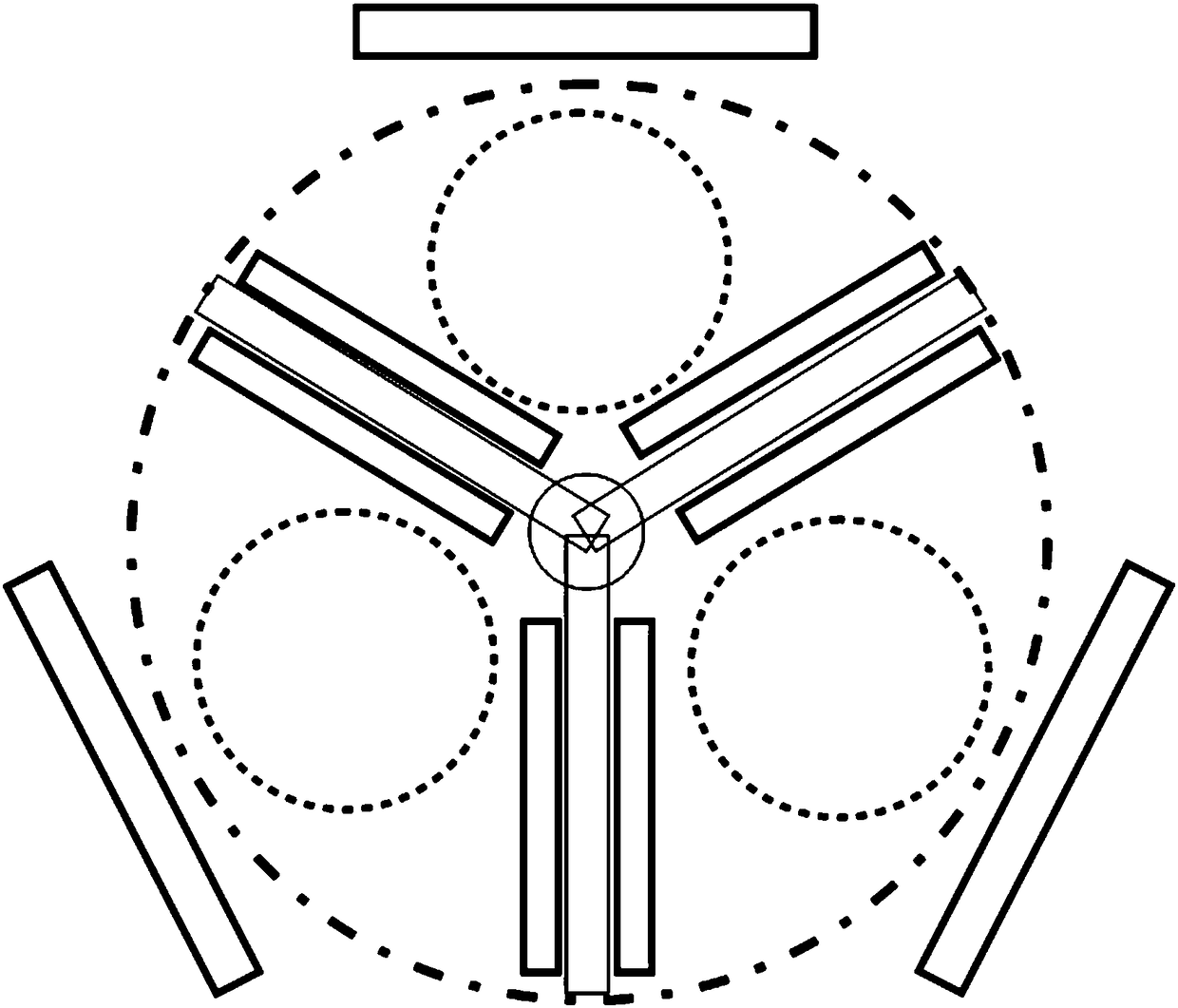

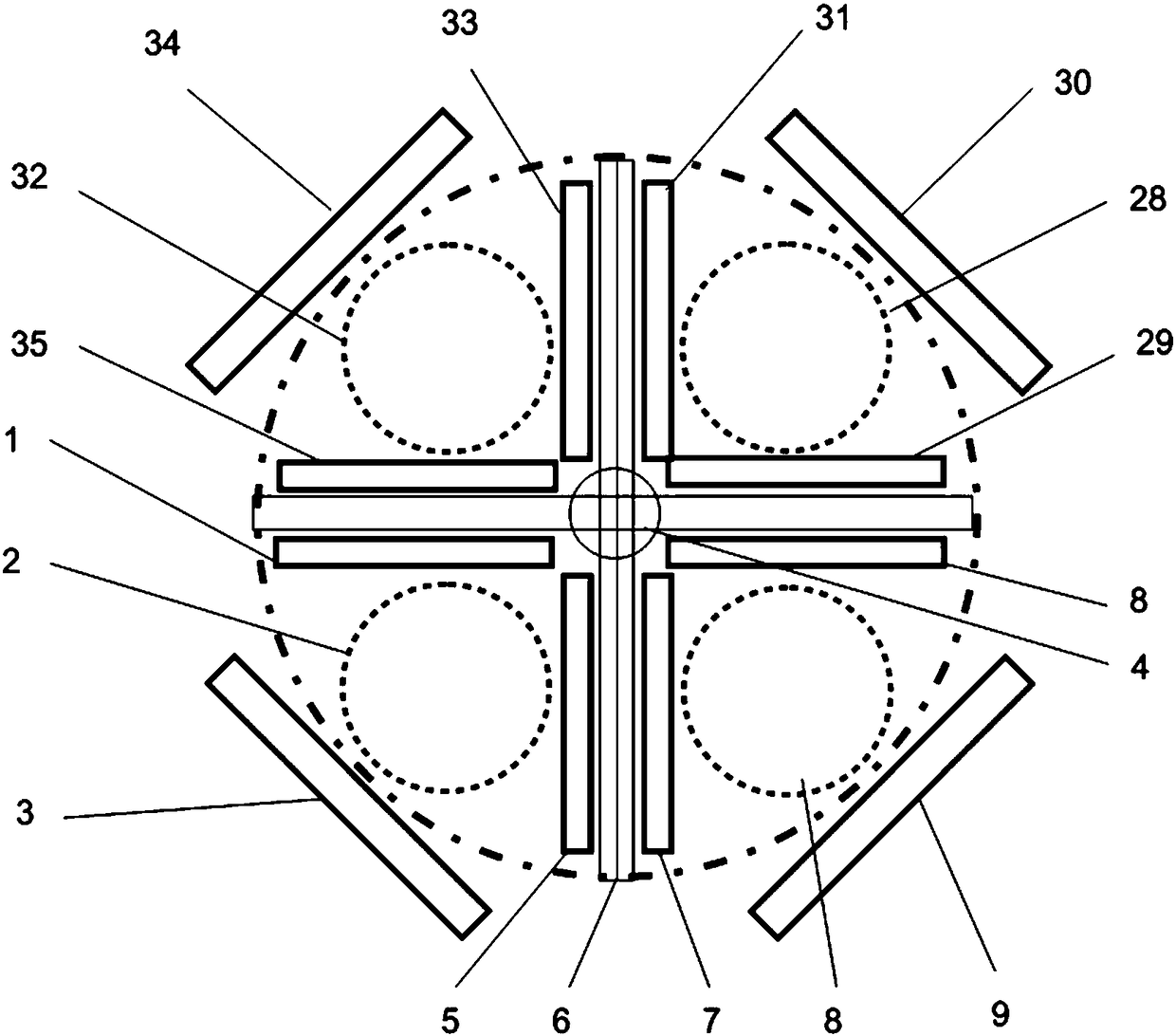

PendingCN108177339AWith mass productionCapable of mass productionAdditive manufacturing apparatus3D object support structuresMultiple formsComputer module

The invention discloses multi-area continuous forming additive manufacturing laser forming equipment. The multi-area continuous forming additive manufacturing laser forming equipment comprises a forming chamber and a plurality of forming shafts corresponding to the forming chamber. Each forming shaft corresponds to one circular forming area in the forming chamber. Each forming area is provided with a respectively-corresponding laser system. A rotation shaft is arranged among the multiple forming areas and provided with a powder paving mechanism provided with a plurality of scraper modules. Themulti-area continuous forming additive manufacturing laser forming equipment solves the technical problems that according to existing equipment, production of single forming areas can only be conducted, the equipment cannot continuously work, and accordingly the workpiece forming technology period is long, and a certain reference value is achieved for promoting development of 3D printing intelligent equipment with assembly line type technology production capability.

Owner:HKUST TIANGONG INTELLIGENT EQUIP TECH (TIANJIN) CO LTD

Preparation method of trinickel disulfide-nickel electrode material for electrolytic water hydrogen production

The invention provides a preparation method of a trinickel disulfide-nickel electrode material for electrolytic water hydrogen production. Foamed nickel is used as a substrate; ethanol steam dissolvedwith thiourea is loaded through argon gas; meanwhile, ammonia gas is introduced for performing cold plasma etching on the nickel substrate; after cooling, a trinickel disulfide / nickel composite electrode material is obtained. The preparation method overcomes the defects that the working procedures of the compounding mode of the existing catalyst and electrode material are complicated; the combination performance is not excellent; the catalytic activity is poor. An oxidation layer at the plasma etching foam nickel surface is subjected to surface activation; the fast reaction of thiourea and nickel metal is promoted to form trinickel disulfide; the prepared catalyst and electrode material interface structure is stable. Further, alkaline gas is added, so that the surface appearance becomes coarse and porous; the specific surface area of the catalyst is increased; further, the catalytic activity of the composite electrode material is promoted. In addition, the preparation process is simple; large-scale production potential is realized.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

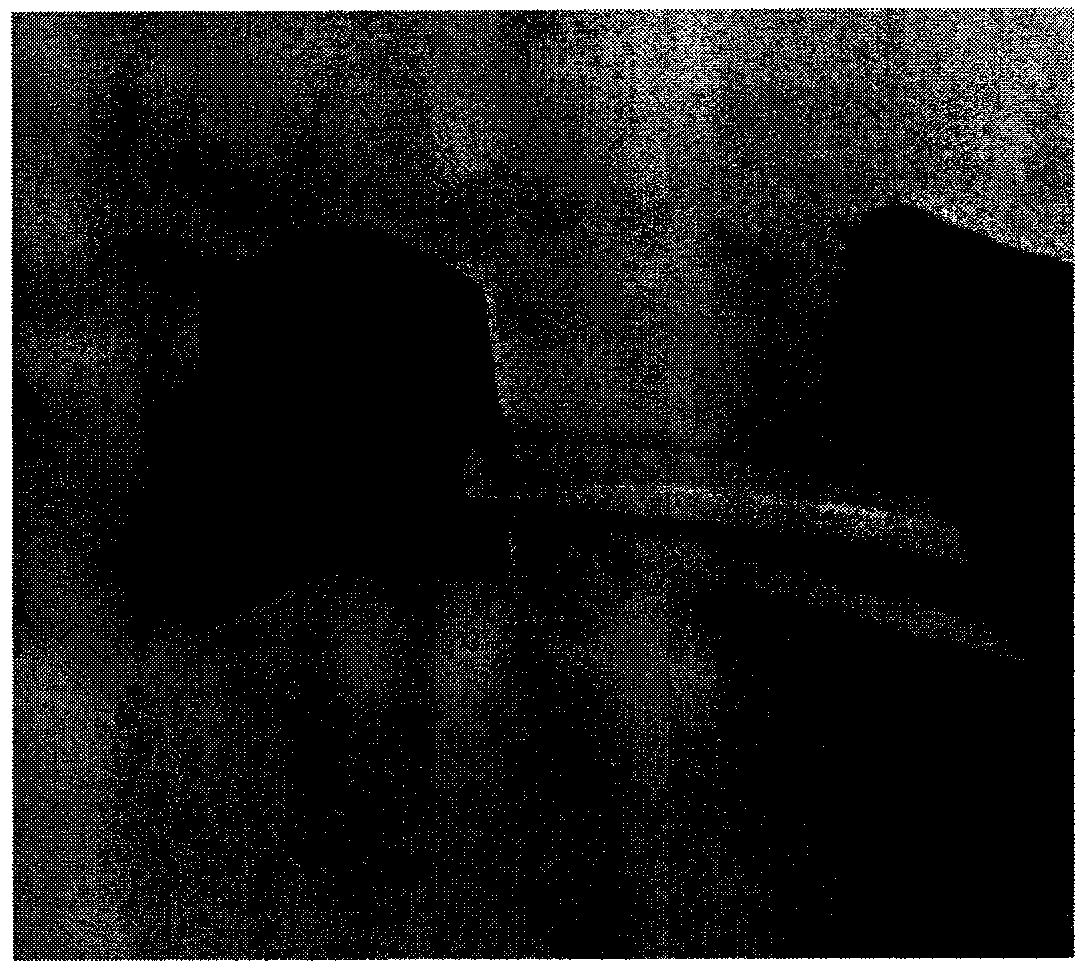

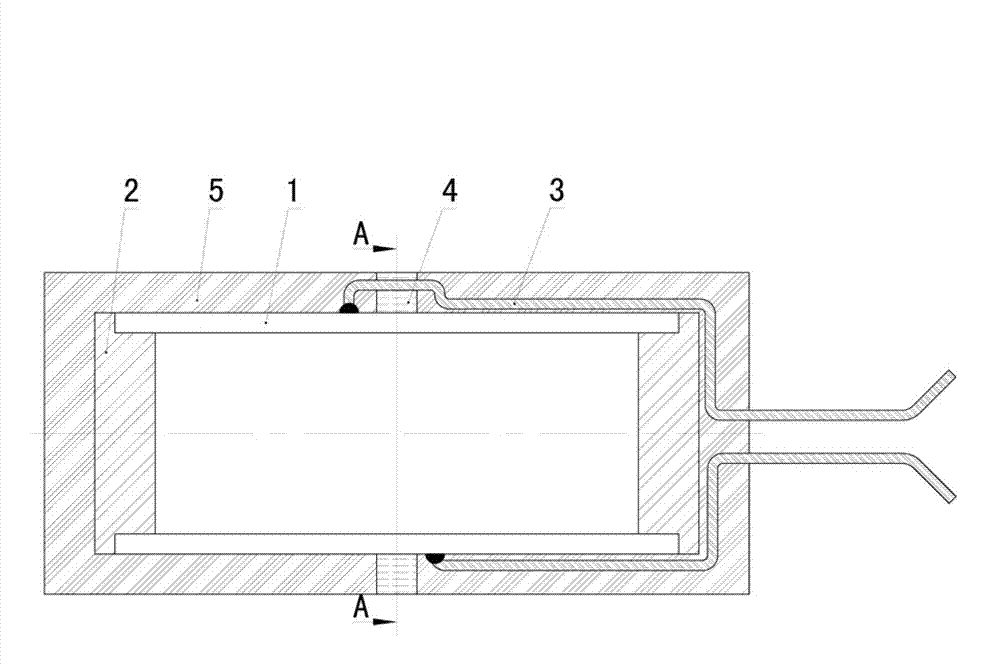

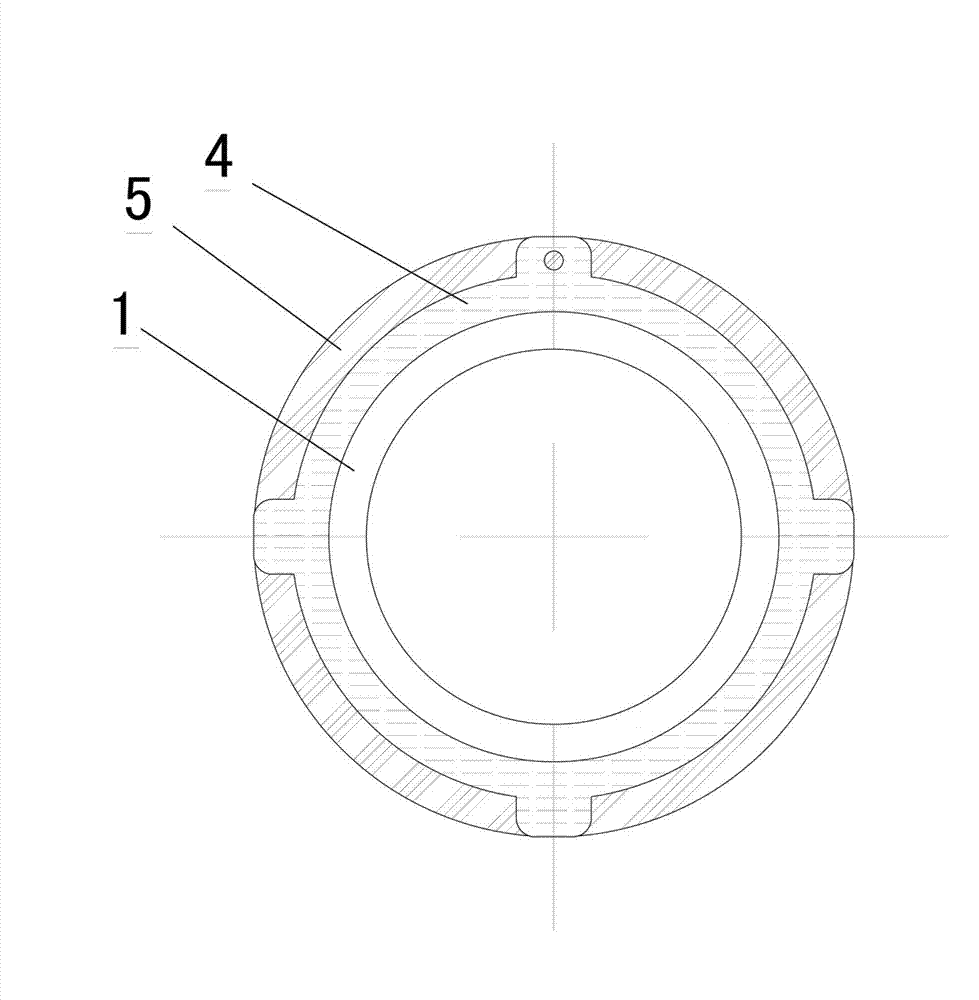

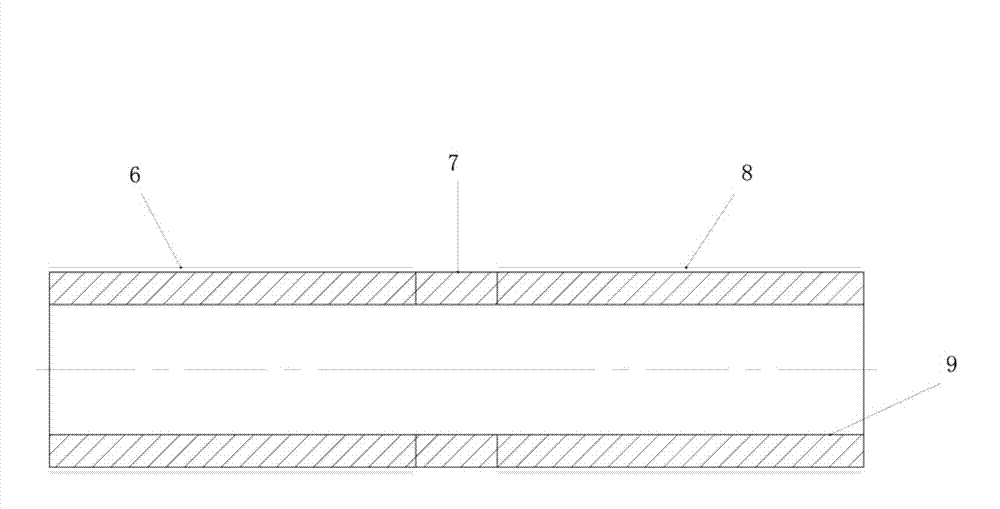

High hydrostatic pressure-resistant small piezoelectric hydrophone and manufacturing method thereof

ActiveCN102901981ACapable of withstanding high hydrostatic pressureWith mass productionSeismic signal receiversSeismology for water-covered areasHydrophoneElectricity

The invention discloses a high hydrostatic pressure-resistant small piezoelectric hydrophone and a manufacturing method thereof. The small piezoelectric hydrophone comprises a high-strength polyurethane coating layer, a piezoelectric ceramic round tube, a flexible rubber plug, a locating ring and two fine wires, wherein the appearance of the piezoelectric ceramic round tube is cylindrical; the polarization direction of the piezoelectric ceramic round tube is radially polarized; a gap with the width of 1-2mm is reserved on the excircle surface electrode of the piezoelectric ceramic round tube; the excircle surface electrode is divided into two sections; the polarization directions of the two sections of the round tube are opposite; the excircle electrode plus a direct current forward voltage is a positive electrode of the hydrophone; an excircle electrode plus a direct current negative voltage is a negative electrode of the hydrophone; the inner circle surface of the piezoelectric ceramic round tube is a common electrode; the appearance structure of the piezoelectric ceramic round tube is an integrated round tube; the circuit is formed by connecting two sections of round tubes with opposite polarities in series; and the locating ring is fixed at the gap. The high hydrostatic pressure-resistant small piezoelectric hydrophone has the beneficial effects of simple and reliable structure, small size, waterproofness, oil resistance and stable performance.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

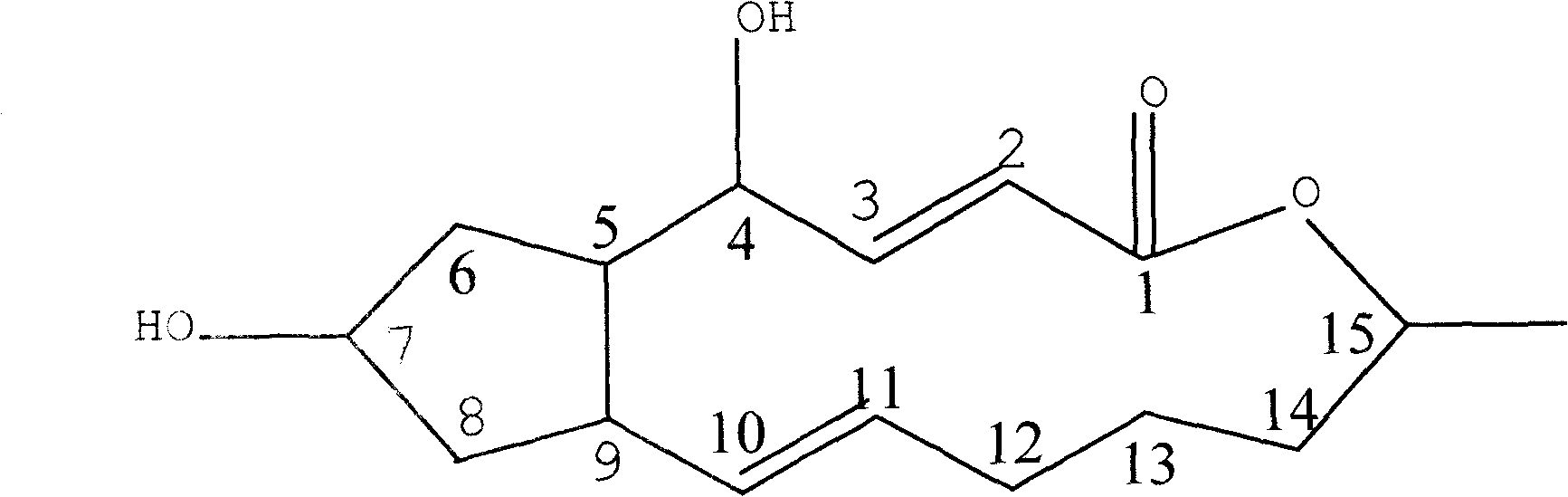

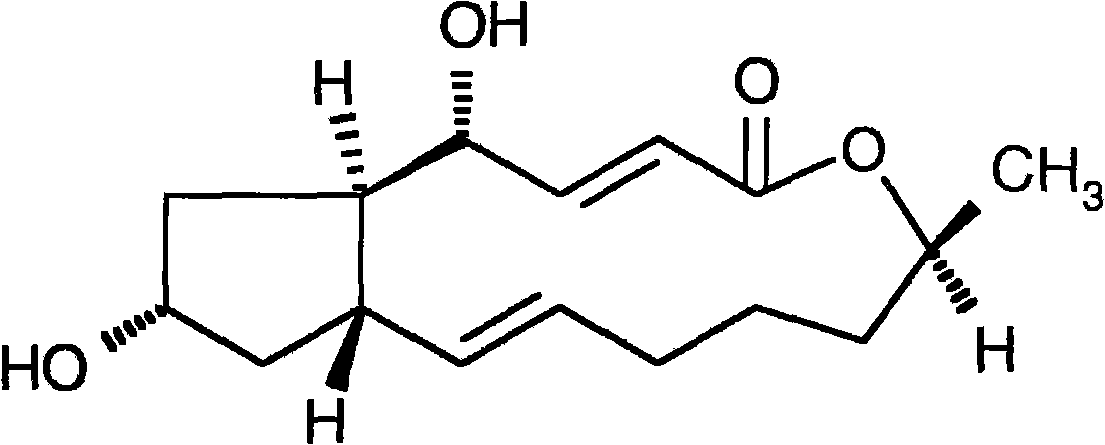

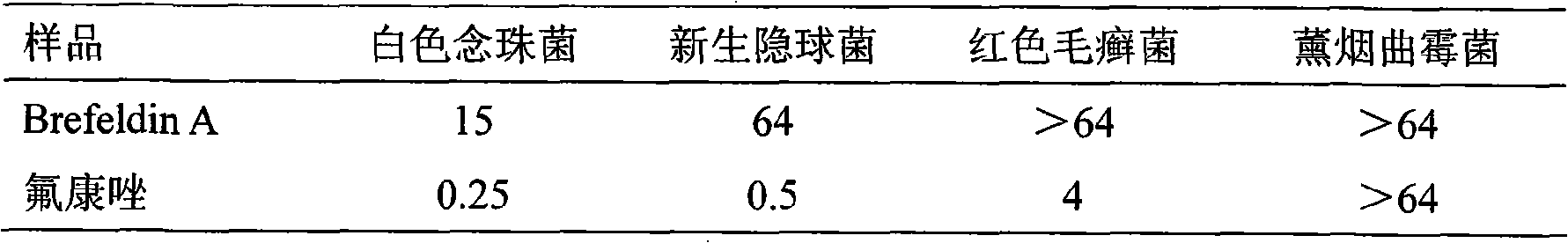

Brefeldin A-producing bacteria and method for preparing brefeldin A by fermentation

The invention relates to Brefeldin A-producing bacteria, a preparation method, a method for preparing the brefeldin A by fermentation and the application thereof. The Brefeldin A-producing bacteria has the advantages of easy selection, cultivation and storage, low cost, simple process, short preparation period, high yield, no usage of toxic raw material, less organic solvent, thorough guarantee of medicine resource, potential of mass production and favorable economic and social benefits, contributes to the maintenance of ecological balance and the protection of natural resources. The fermentation product of the invention, of which the main component is THSG, develops novel medical application, the Brefeldin A has high safety, low toxicity, stable property, stronger pharmacological action, simple preparation process, high yield and considerably wide range of application, is multipurpose, and can provide a novel source for medicines for preventing, diagnosing, detecting, protecting, curing and researching antimycotic, antiviral and antineoplastic diseases and the directly related diseases.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

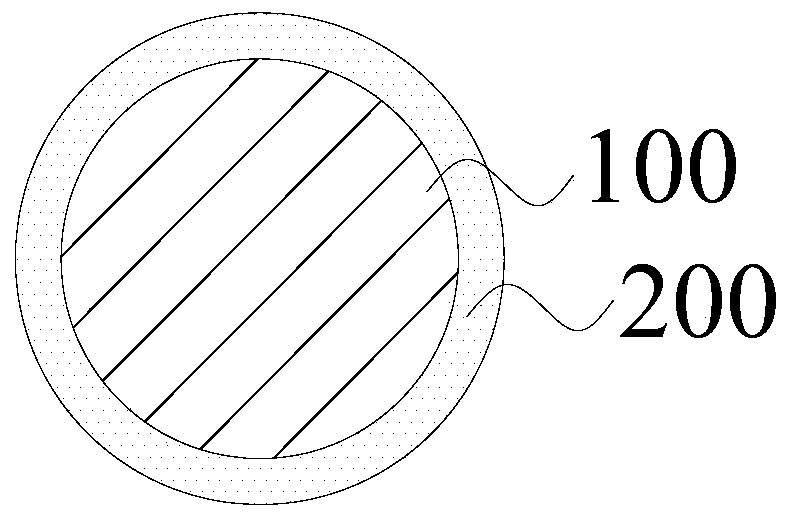

Cobalt-free layered cathode material and preparation method thereof and lithium ion battery

ActiveCN111435747ALow costImproved magnification performanceElectrode thermal treatmentSecondary cellsPhysical chemistryTitanium nitride

The invention provides a cobalt-free layered cathode material and a preparation method thereof and a lithium ion battery. The cobalt-free layered cathode material is of a core-shell structure, a material forming a shell of the core-shell structure comprises titanium nitride, and a material forming the inner core of the core-shell structure does not comprise cobalt and is of a single crystal structure. According to the cobalt-free layered cathode material provided by the invention, high-conductivity titanium nitride is coated on the surface of the cobalt-free inner core, so that the rate capability of the cathode material can be improved while the price cost of the cathode material is reduced, and the rate capability of the cobalt-free cathode material is better.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

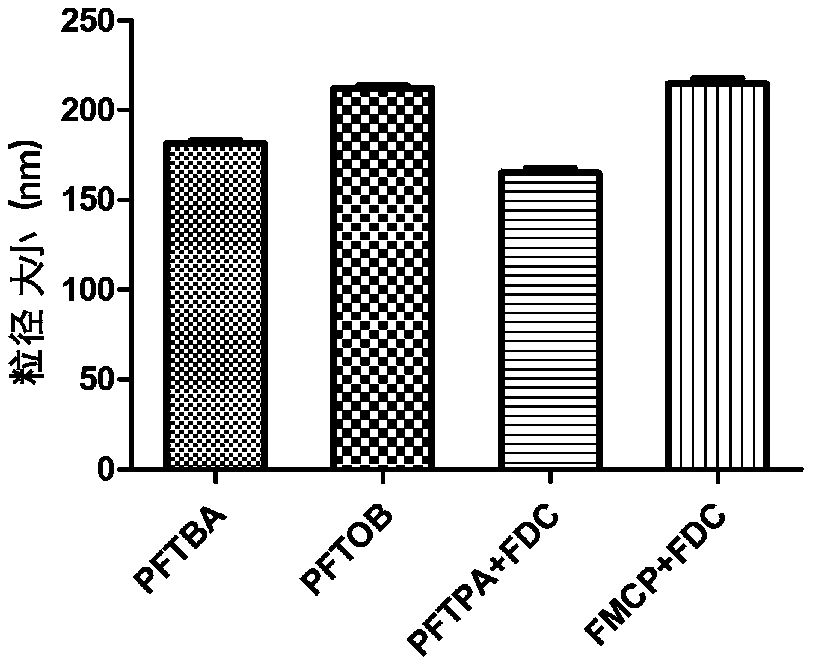

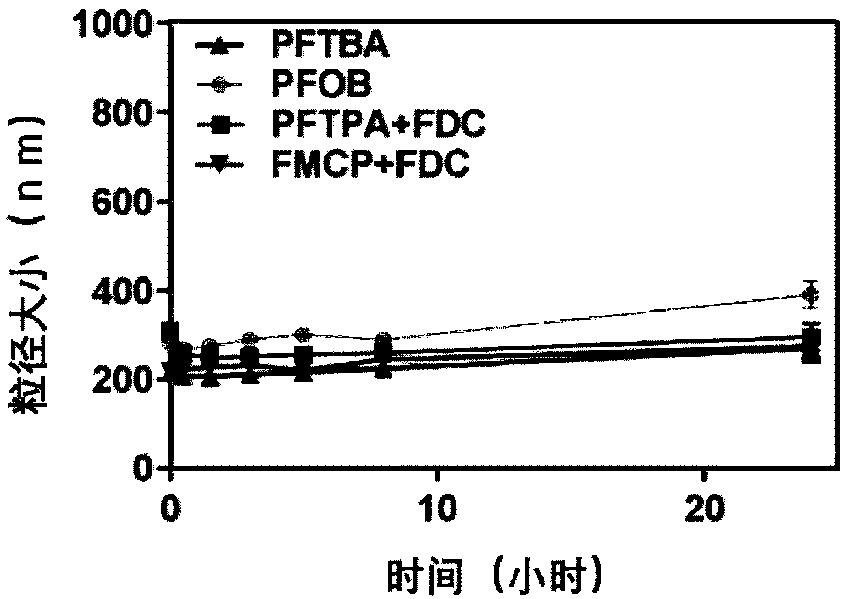

Perfluorocarbon albumin nanoparticles and preparation method and application thereof

ActiveCN108114273AReduce usageHigh biosecurityPeptide/protein ingredientsSkeletal disorderPlatelet inhibitorsMedicine

The invention discloses perfluorocarbon albumin nanoparticles which comprise albumins and perfluorocarbon compounds, wherein the albumins coat the perfluorocarbon compounds, and the mass ratio of theperfluorocarbon compounds to the albumins is (4-40): 1. The perfluorocarbon albumin nanoparticles have good biological safety as a novel blood platelet inhibitor. The perfluorocarbon albumin nanoparticles which are administrated will induce great reduction of quantity of blood platelets in a human body, various functions of the blood platelets can be also inhibited obviously, and the perfluorocarbon albumin nanoparticles have relatively good clinical applications and practical treatment meaning.

Owner:NANJING UNIV

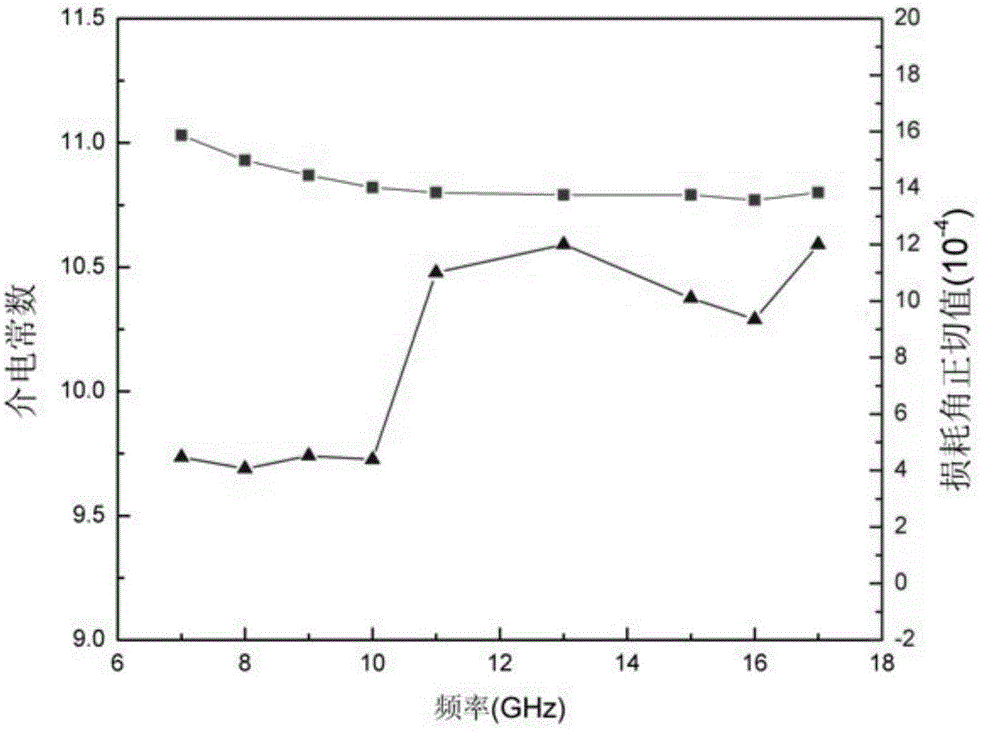

Preparation method for high-dielectric high temperature-resistant microwave dielectric composite material

InactiveCN104817290AAvoid the problem of too low viscosityAchieve preparationCompression moldingManufacturing technology

The invention relates to a microwave dielectric material and provides a preparation method for a high-dielectric high temperature-resistant microwave dielectric composite material, which belongs to the field of manufacturing technology for composite materials. The objective of the invention is to overcome the technical problem of low ceramic solid phase content in traditional preparation methods. The preparation method comprises the following steps: 1, surface modification of a ceramic filling material in virtue of a silane coupling agent; 2, mixing of ceramic powder with resin powder; and 3, compression molding. The composite material prepared in the invention has the characteristics of a high dielectric constant, low loss, high temperature resistance, high thermal conductivity, a small thermal expansion coefficient, simplicity and environmental protection. The preparation method provided by the invention is used for preparation of the high-dielectric high temperature-resistant microwave dielectric composite material.

Owner:HARBIN INST OF TECH

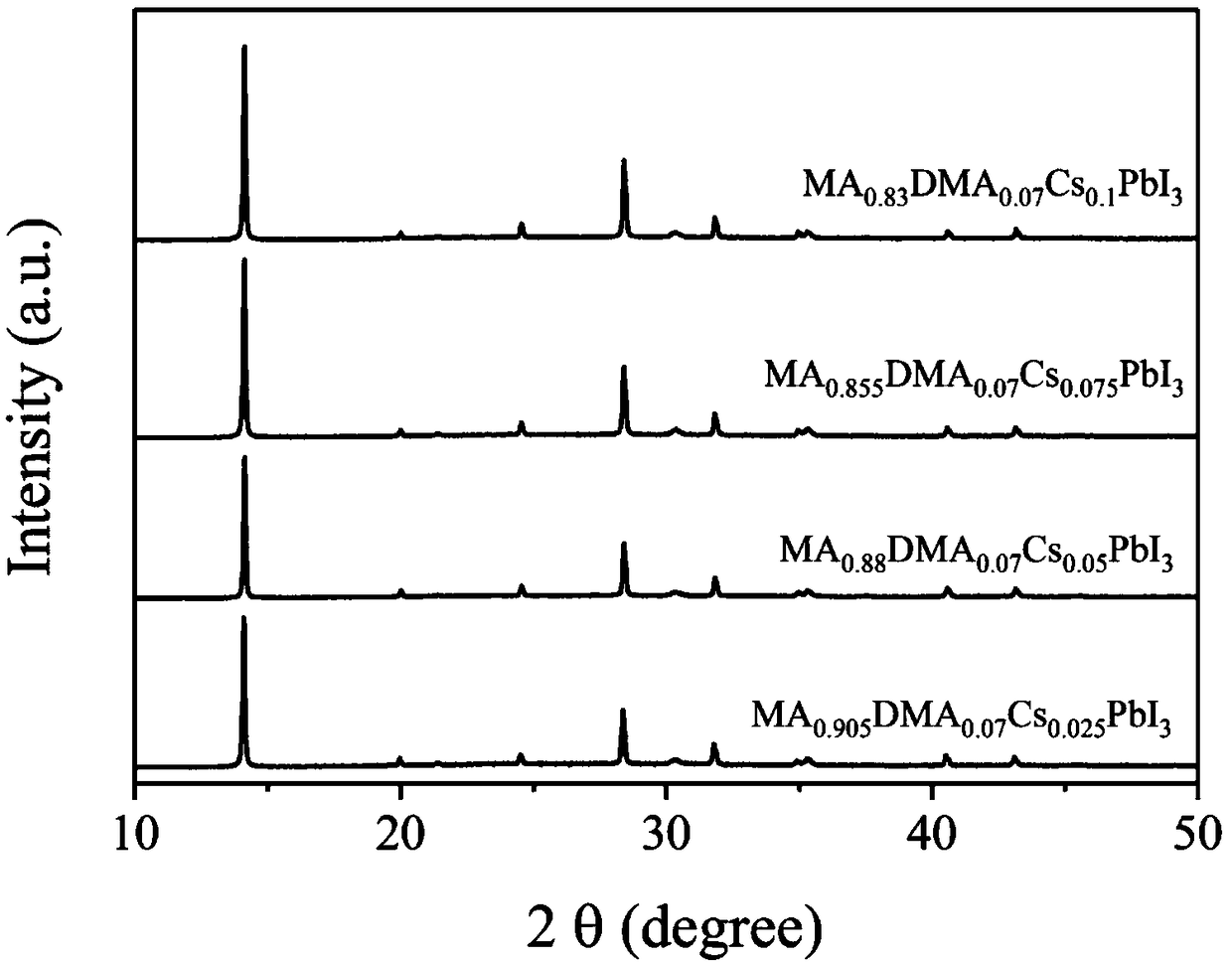

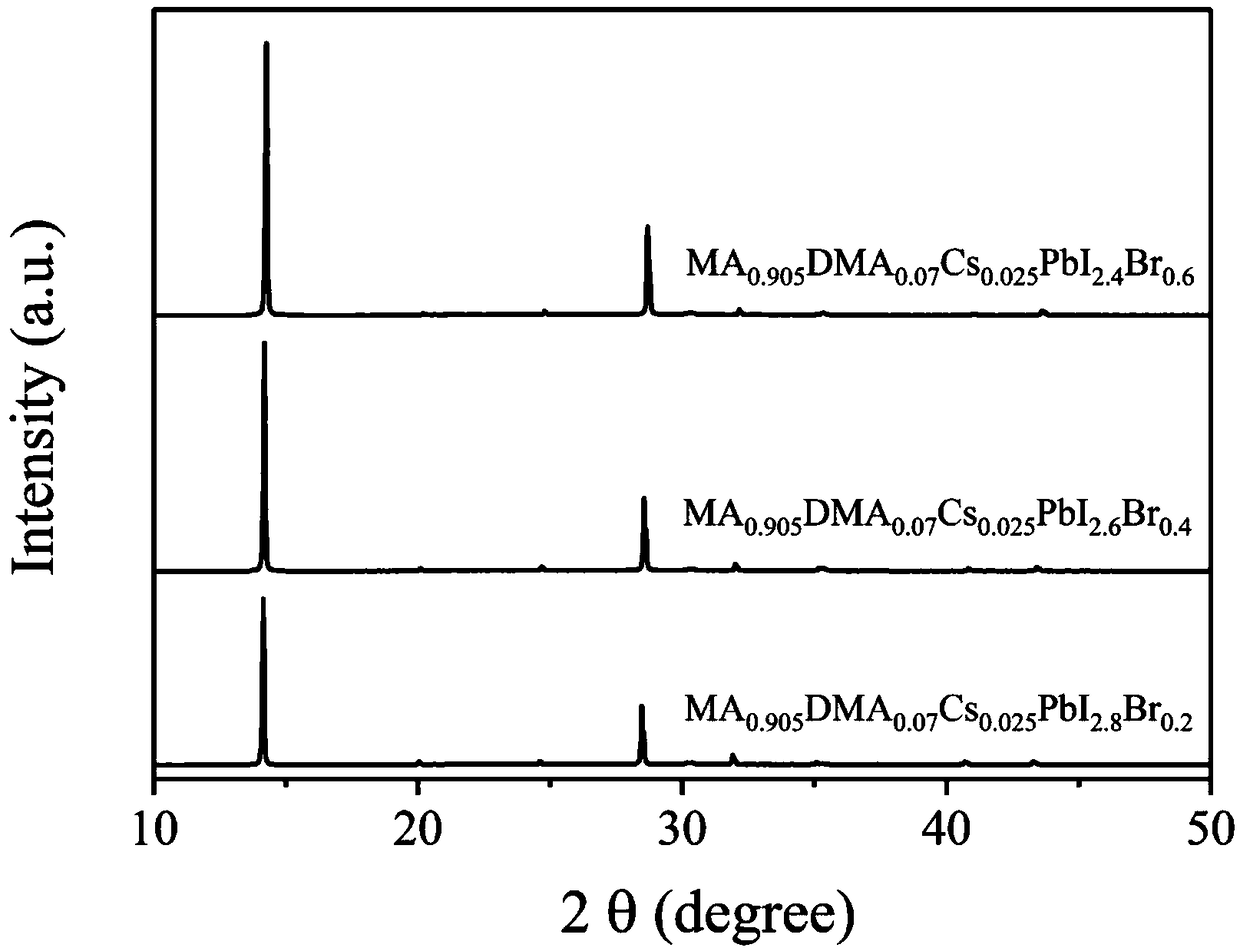

Perovskite material, method for preparing same and solar cell device with perovskite material

ActiveCN109360895AImprove stabilitySimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellNew energy

The invention relates to the field of new energy, in particular to a perovskite material, a method for preparing the same and a solar cell device with the perovskite material. A molecular formula of perovskite in the perovskite material is ABX<3>, wherein the A is selected from C<1-x-y>E<x>F<y>, the C is selected from MA and / or FA, the E is selected from DMA, the F is selected from one or a plurality of types of Cs, Rb and K, the B is selected from Pb and / or Sn, and the X is selected from one or a plurality of types of I, Br and Cl. The perovskite material, the method and the solar cell devicehave the advantages that the perovskite material is excellent in stability under atmospheric conditions, processes for preparing the perovskite material are simple and are convenient to implement, and the perovskite material and the solar cell device can be produced on a large scale; the prepared perovskite solar cell device is high in photoelectric conversion efficiency.

Owner:SHANGHAI TECH UNIV

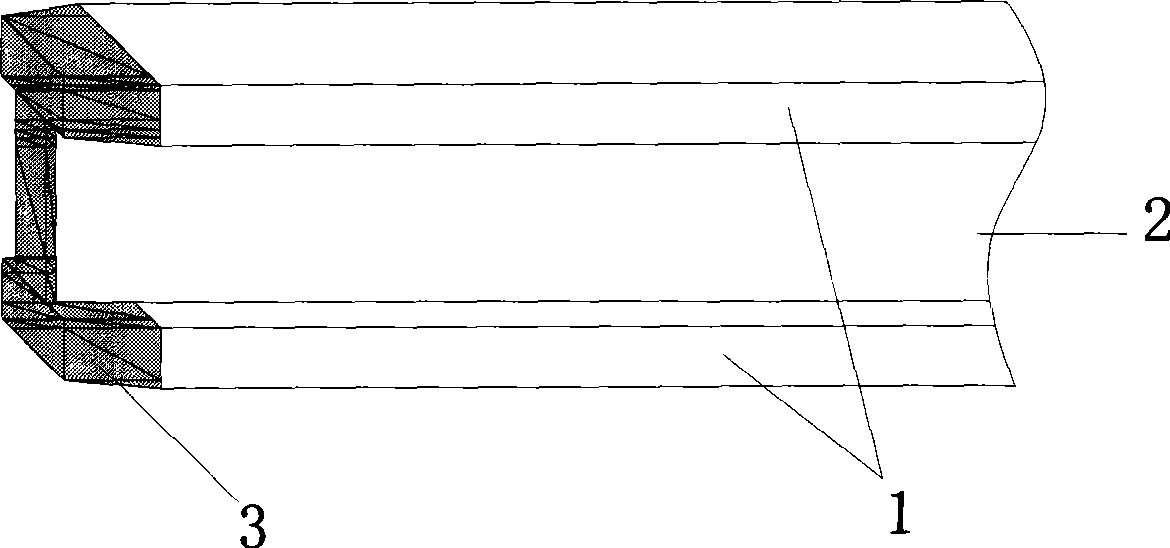

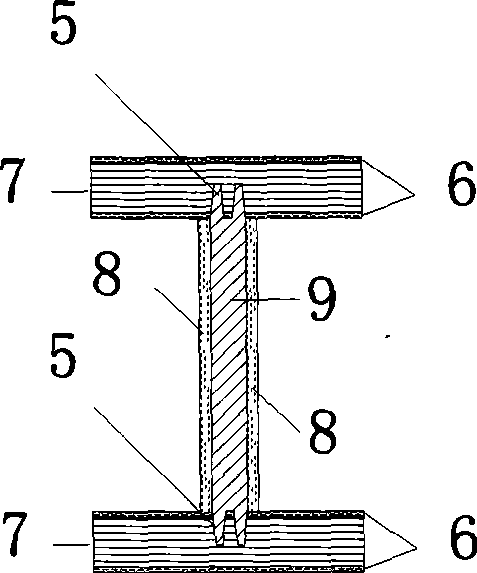

High-strength durable wooden I-shaped beam

InactiveCN101487331AIncrease stiffnessGood value for moneyForms/shuttering/falseworksGirdersShaped beamSingle plate

The invention provides a high-strength durable wood I-typed beam which has the advantages of high rigidity, lightweight, high-strength, convenient assembly and disassembly, easy cutting, high cost performance, high durability, turnover use for an average year, and industrialized production. The high-strength durable wood I-typed beam comprises a flange girth, a web plate and an end protective sleeve. The upper surface, lower surface and the interior of a flange girth substrate in the flange girth are provided with flange girth modified processing single plates. The surface and the interior of a web plate substrate in the web plate are provided with web plate modified processing single plates. The flange girth modified processing single plates and the web plate modified processing single plates are glue soaking processing single plates. The used adhesive selects water soluble phenol resin with low molecular weight or melamine-formaldehyde resin. The high-strength durable wood I-typed beam is mainly used as the supporter in a building moulding board system, and can also be used in the fields such as supporting members of building structure roofs, and the like.

Owner:NANJING UNIV OF TECH

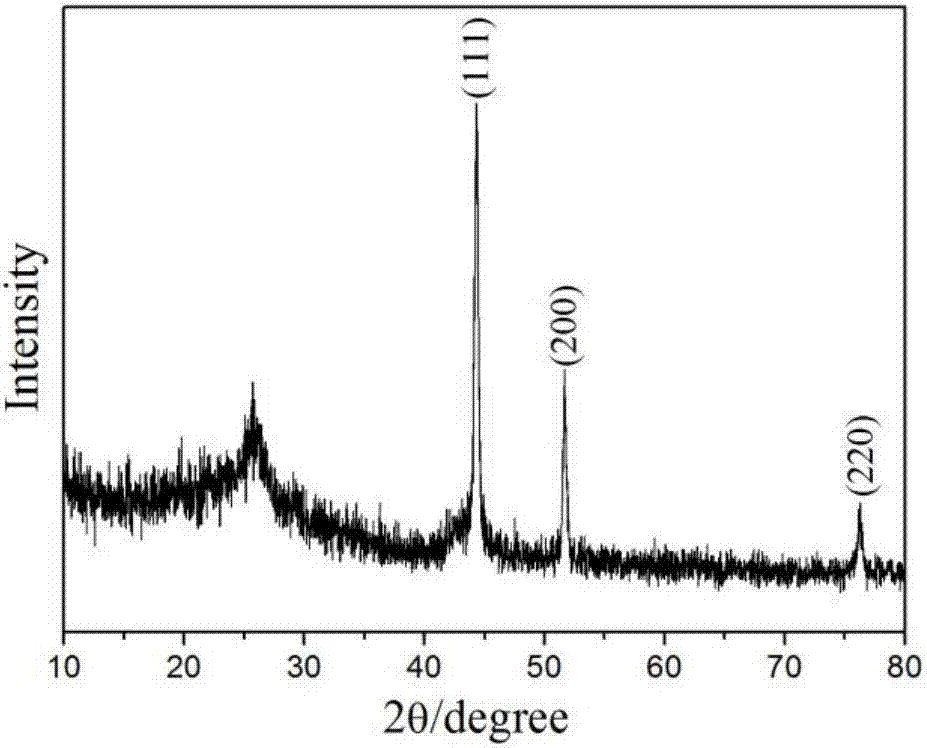

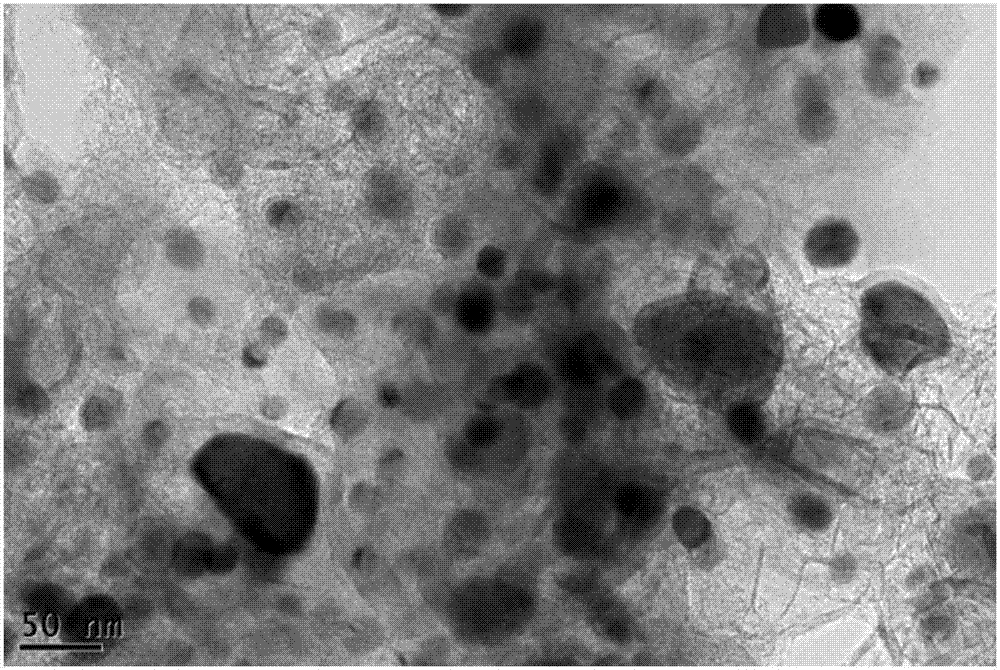

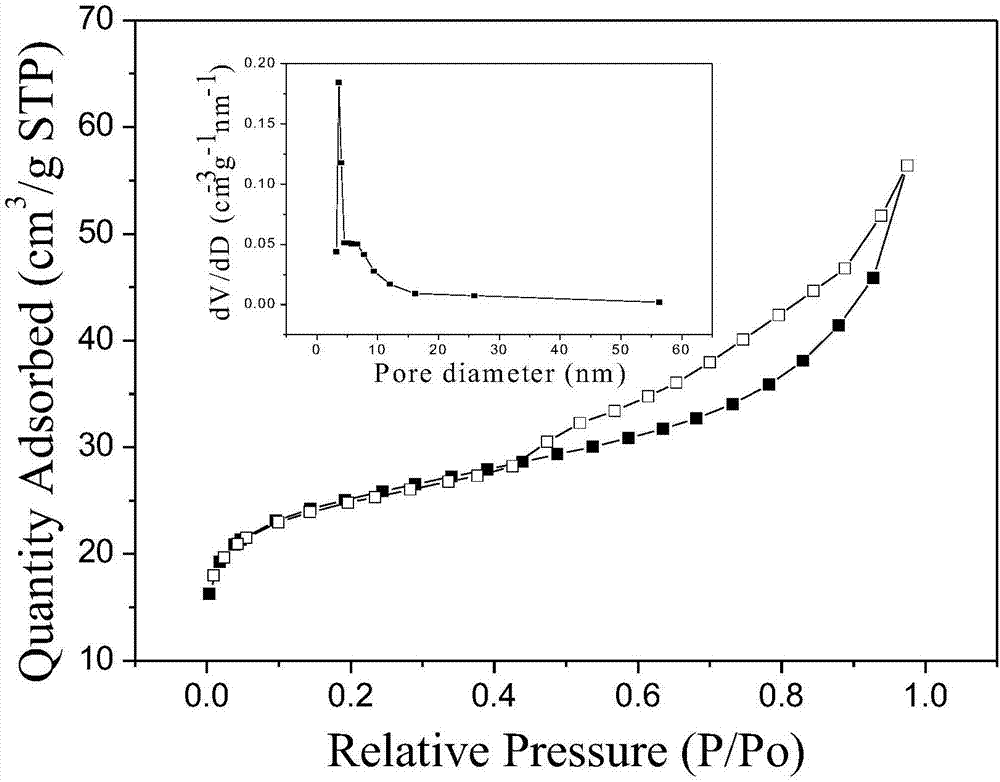

Preparation method of magnetic nickel/carbon nanometer composite material and application thereof

InactiveCN106975447AEasy to prepareLow costOther chemical processesWater contaminantsSolventChemistry

The invention provides a preparation method of a magnetic nickel / carbon nanometer composite material and application thereof. The preparation method comprises the following steps of (1) preparation of a metal organic framework precursor: dissolving 1,3,5-benzene tricarboxylic acid into an alkaline water solution, adding an alcohol and water mixed solution of soluble metal salt, mixing and stirring at normal temperature, centrifuging, washing and drying, so as to obtain the metal organic framework precursor; (2) preparation of a magnetic carbon composite material: calcining the precursor obtained in step (1) under the inertia gas atmosphere, and cooling, so as to obtain the magnetic carbon nanometer composite material. The preparation method of the magnetic nickel / carbon nanometer composite material has the advantages that the method is simple, and the cost is low; the solvent heat synthesizing in the reaction kettle in the preparation process of the precursor of the magnetic nickel / carbon nanometer composite material is not needed, and the potential of batch production is realized.

Owner:JIANGSU UNIV

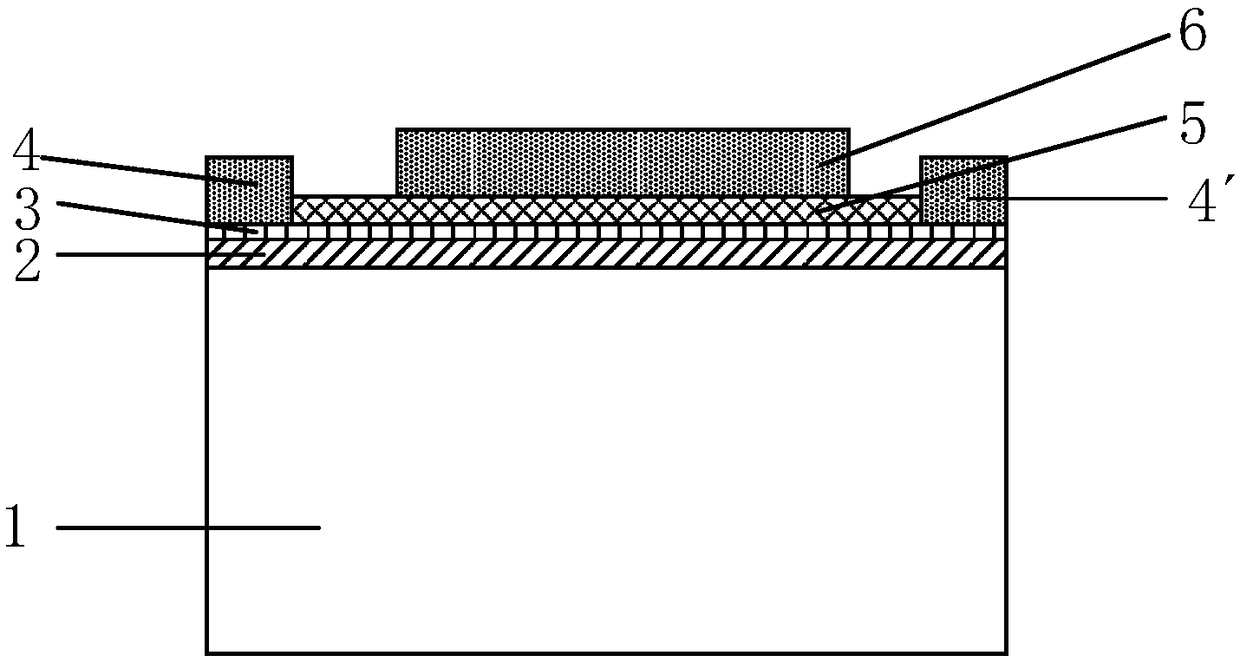

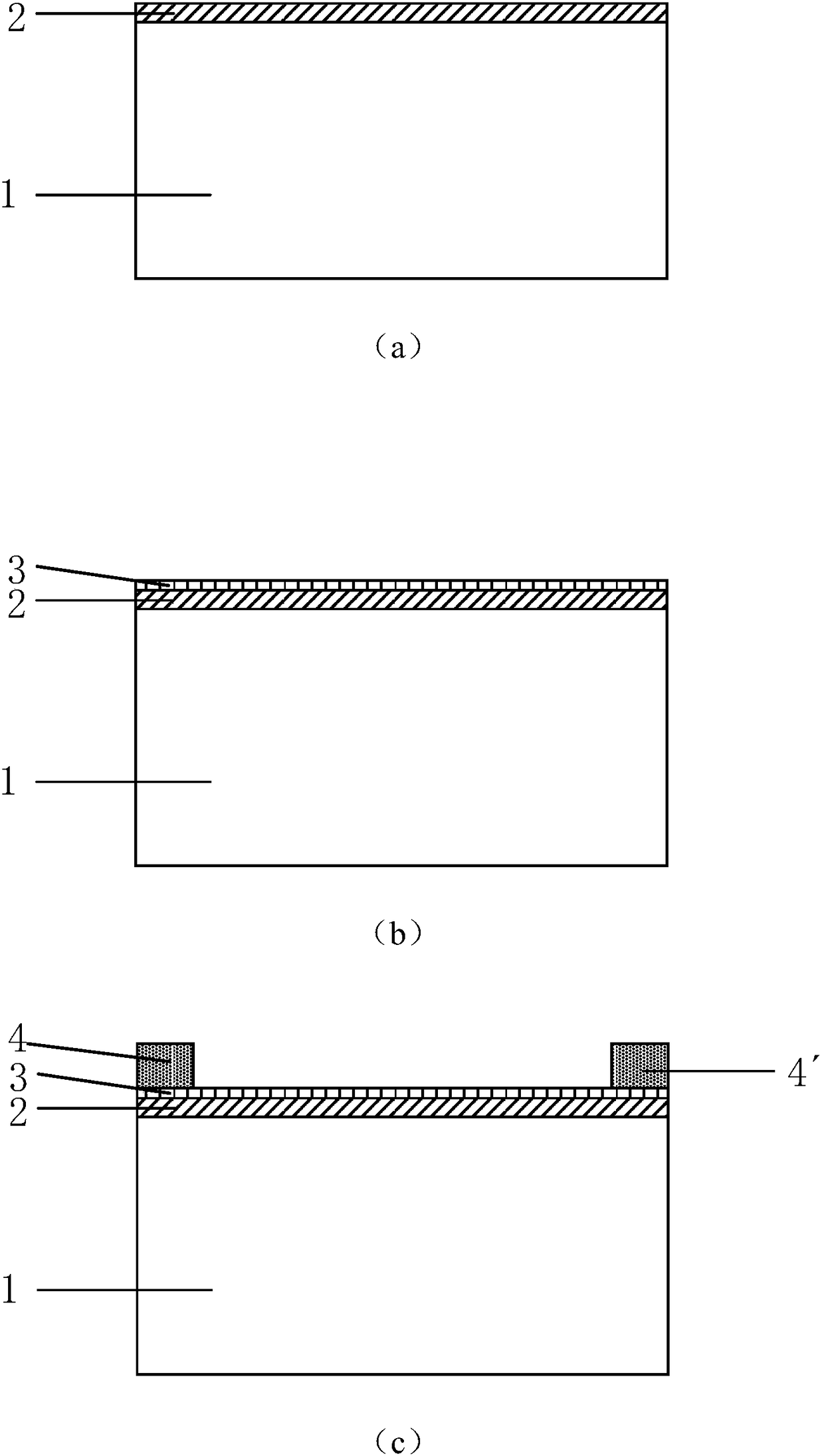

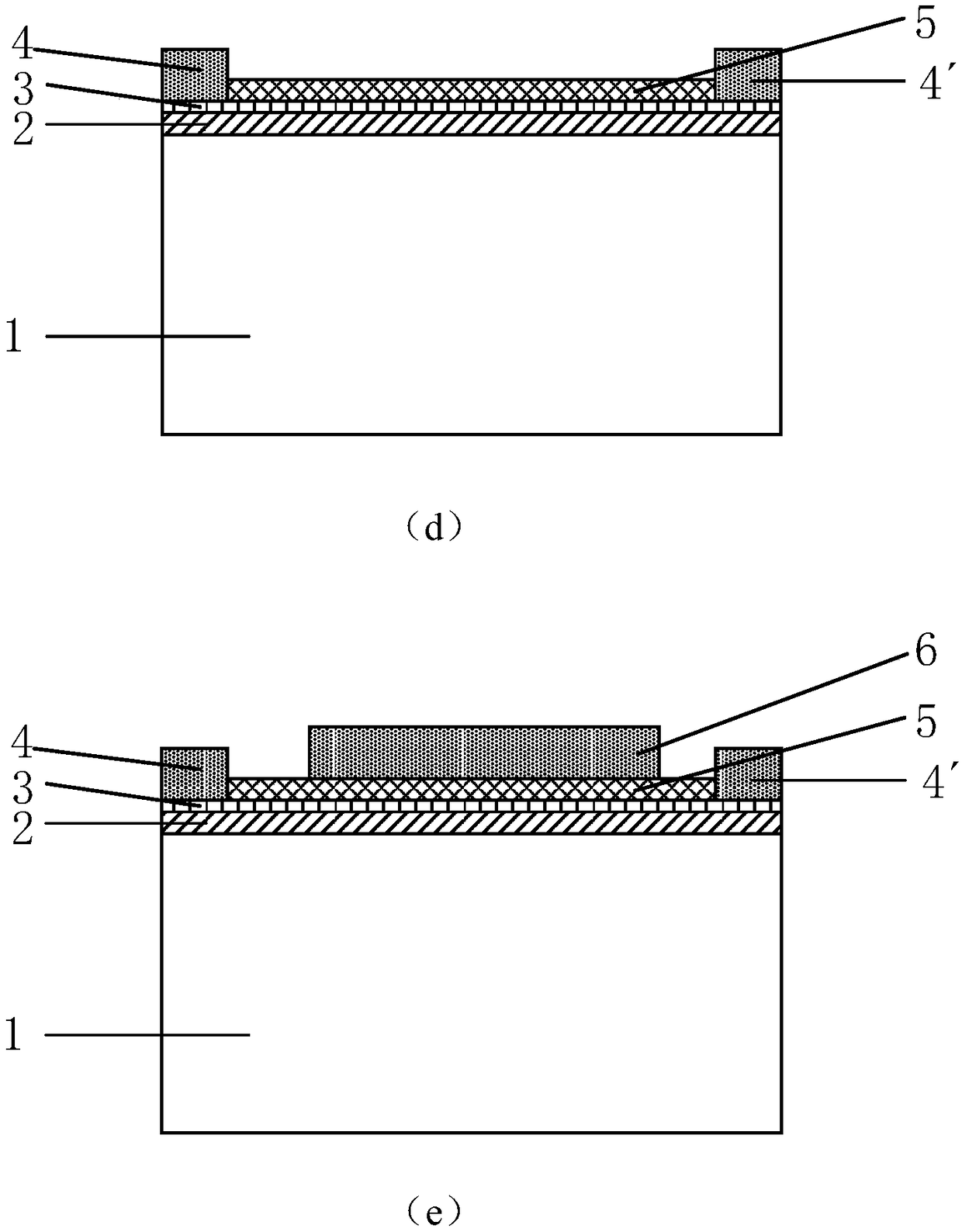

Two-dimensional semiconductor material negative capacitance field effect transistor and preparation method thereof

ActiveCN108831928AReduce deteriorationMetal Contact Fermi Pinning ImprovementSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceFerroelectricity

The invention discloses a two-dimensional semiconductor material negative capacitance field effect transistor and a preparation method thereof; a two-dimensional alloy semiconductor material HfZrSe2 is adopted as a channel material, and the surface of the channel material is oxidized in air to generate HfZrO2, and then annealing is carried out to obtain an HfZrO2 dielectric layer with a ferroelectric property; a high-k gate dielectric layer is deposited on the dielectric layer, and a gate dielectric with a mixed structure is formed. By means of the device structure, high gate dielectric and channel two-dimensional semiconductor material interfaces can be obtained, the deterioration of the interface state on the sub-threshold characteristic is reduced, and the super-steep sub-threshold slope is easily obtained; meanwhile, the high-k gate dielectric on the upper layer can protect the HfZrO2 dielectric of the ferroelectric characteristics below, so that the dielectric is isolated from theair, and the stability of the device is greatly improved. The device is simple in preparation process and large-scale production can be realized.

Owner:PEKING UNIV

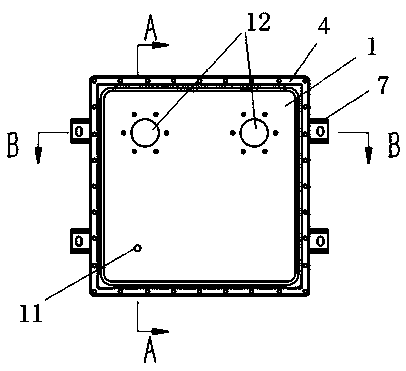

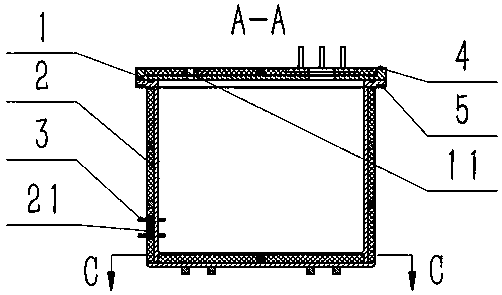

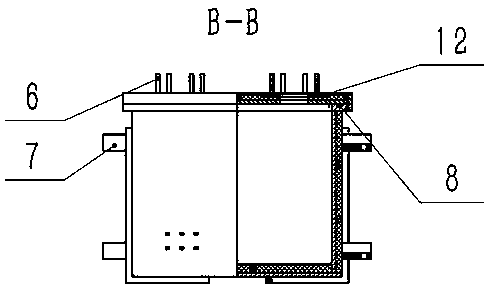

Compound material electrical insulating box and production method thereof

ActiveCN109501820AWeight increaseImprove insulation performanceCasings/cabinets/drawers detailsLocomotivesSurface layerEngineering

The invention discloses a compound material electrical insulating box and a production method thereof. The compound material electrical insulating box comprises a box body, a box cover connected withthe upper surface of the box body, and an input and output binding post installed on the lower portion of the front side surface of the box body, and further comprises box body external portion installation parts used for box body installation; the box body external portion installation parts are connected with both the left side surface and the right side surface of the box body; both the box body and the box cover are of sandwich structures, and the sandwich structures comprise surface layers made from a compound material, and sandwiches which are made from reinforcing ribs and foam. The boxbody is produced at first; then the box cover is produced, then a lower flange is bonded with the box body, and an upper flange is bonded with the box cover; finally, the box cover and the box body are connected fixedly in a sealed mode by bolts. The compound material electrical insulating box has the advantages of being high in strength, light in weight and good in insulating performance, and issuitable for being popularized and applied onto electrical equipment of railway vehicles. The electrical box produced by adopting the method has very good mechanical performance, corrosion resistanceperformance and insulating performance and a good lightweight effect.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

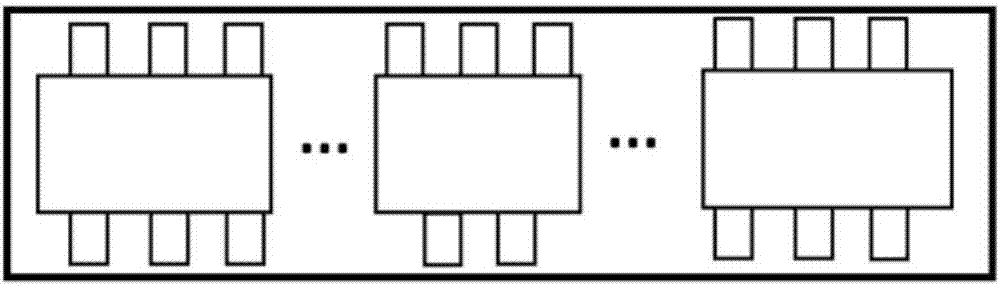

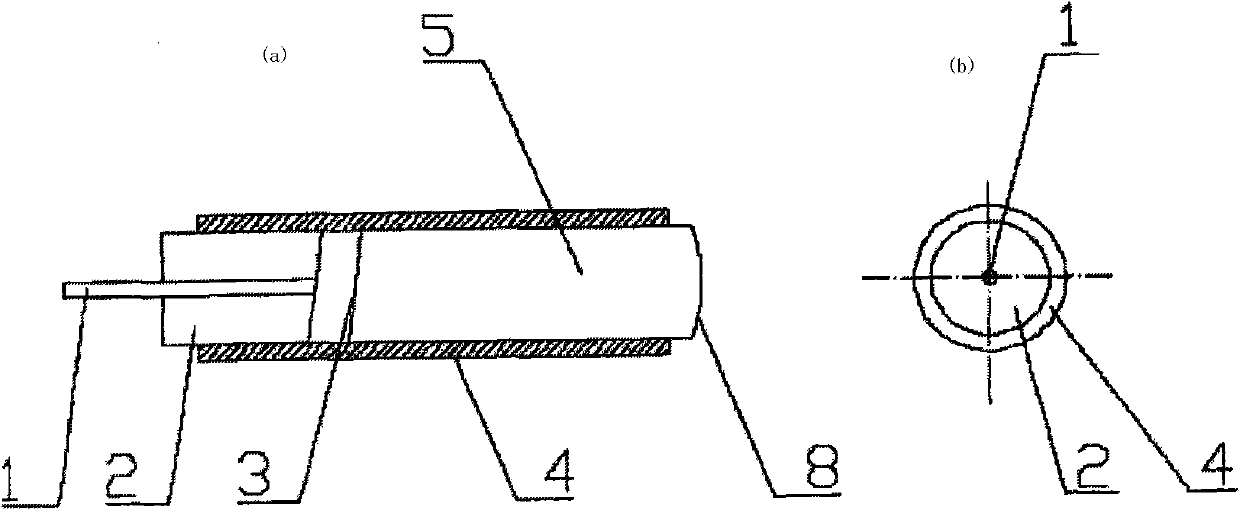

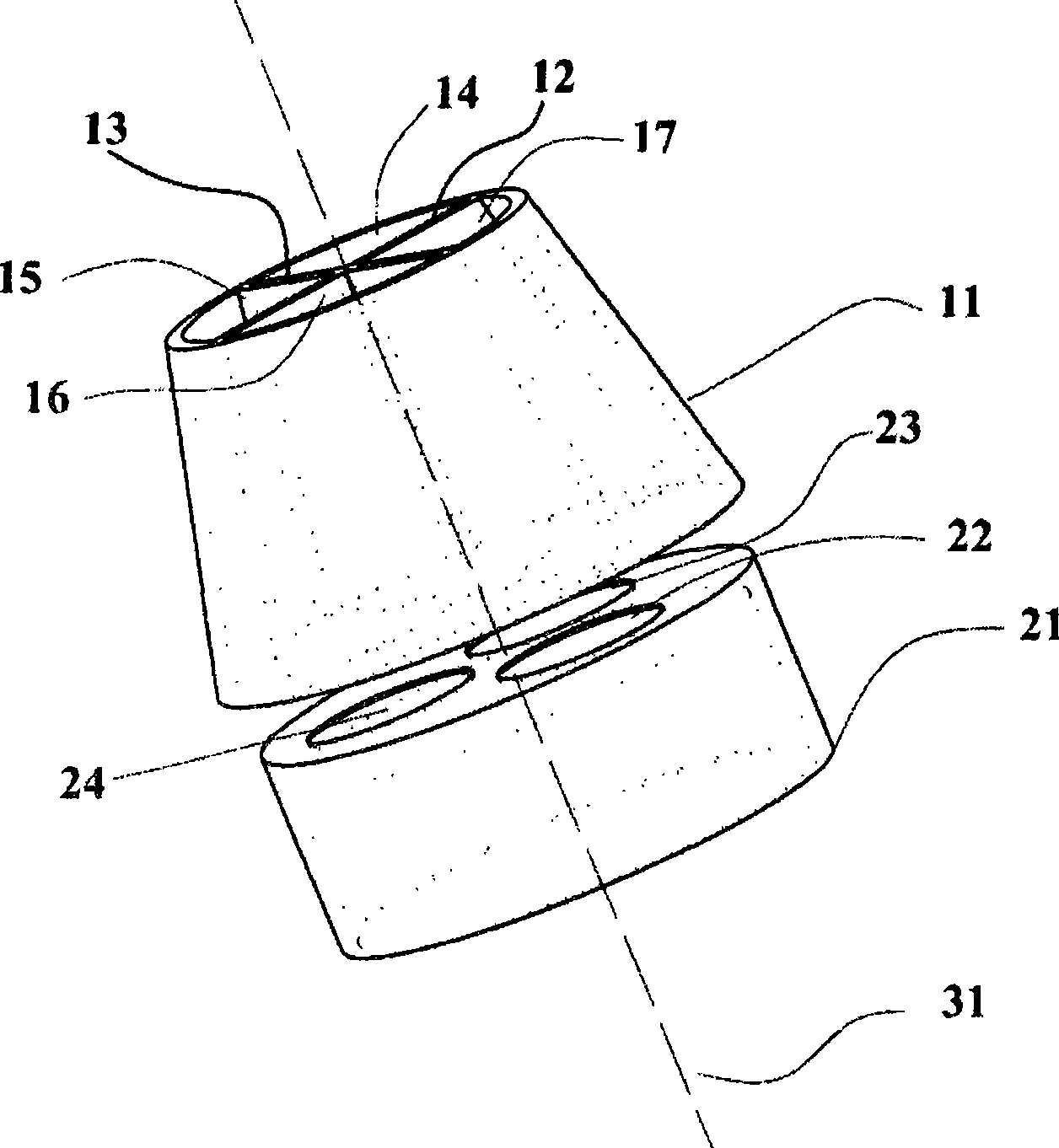

Device for space-modulating atomic layer chemical vapour deposition epitaxial growth and method thereof

InactiveCN101445955AAvoid parasitic reactionsImprove utilization efficiencyFrom chemically reactive gasesBasementGas phase

The invention relates to a device for space-modulating atomic layer chemical vapor deposition epitaxial growth. The device is characterized by comprising an air-intake shower and a base wherein, the air-intake shower is barrel-shaped and the interior of the air-intake shower is divided into a plurality of regions, and each region is an air-intake nozzle of feed gas; the base is a column and is provided with a plurality of circular grooves thereon, the circular grooves are used for placing a substrate; the diameter of the base is less than or equal to the diameter of the air-intake shower and the base can rotate; wherein, the air-intake shower is positioned at the side of base, the surface of which is provided with the circular groove; a certain distance exists between the air-intake shower and the base; one end of the air-intake shower, which is close to the base, is an air outlet; and the other end, which is far from the basement, is an air outlet.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Lead-free tin-based halide perovskite thin film, preparation method and application thereof

ActiveCN110862702AImprove stabilityGood light absorption propertiesSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneTin Fluorides

The present invention provides a preparation method of a lead-free tin-based halide perovskite thin-film solar cell. The preparation method is characterized by comprising the following steps: step one, dissolving a tin-based source compound, an organic and inorganic source halide and a polyphenyl aromatic amine compound in a mixed polar solvent in advance, at the same time adding tin fluoride as an antioxidant, and preparing a precursor solution; and step two, spin-coating the perovskite precursor solution on a prepared substrate plate, and then conducting an annealing treatment after the spin-coating is completed to obtain the tin-based halide perovskite thin film. The lead-free tin-based halide perovskite thin film has advantages of being good in film forming property, high in crystallinity and good in stability, and the lead-free perovskite solar cell which is friendly to environment and relatively high in stability and photoelectric conversion efficiency can be prepared based on the lead-free tin-based halide perovskite thin film.

Owner:NANJING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com