Preparation method of magnetic nickel/carbon nanometer composite material and application thereof

A composite material, carbon nanotechnology, applied in chemical instruments and methods, alkali metal compounds, water/sewage treatment, etc., can solve the problems of difficult adjustment of metal nickel loading, unfavorable for large-scale industrial production, etc., and achieve high saturation magnetization. The effect of strength, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of magnetic nickel / carbon nanocomposite material, specifically comprising the following steps:

[0030] (1) Dissolve 0.414g 1,3,5-benzenetricarboxylic acid and 0.24g NaOH in 25mL water to make a solution, dissolve 0.071g nickel chloride hexahydrate and 0.495g zinc acetate in 25mL water and 50mL ethanol to make a solution solution, and then these two solutions were mixed and stirred at room temperature for 1 hour at a stirring speed of 500r / min, then centrifugally washed at a speed of 8000r / min, then put into an oven, and dried at 70°C for 5 hours to obtain nickel / zinc metal-organic framework precursors;

[0031] (2) Put the precursor obtained in step (1) into a quartz boat, use nitrogen as a protective gas in a tube furnace, heat up to 910°C at a heating rate of 5°C / min, keep it for 2 hours and start to cool down, After cooling to room temperature, the black magnetic nickel / carbon nanocomposite material was obtained.

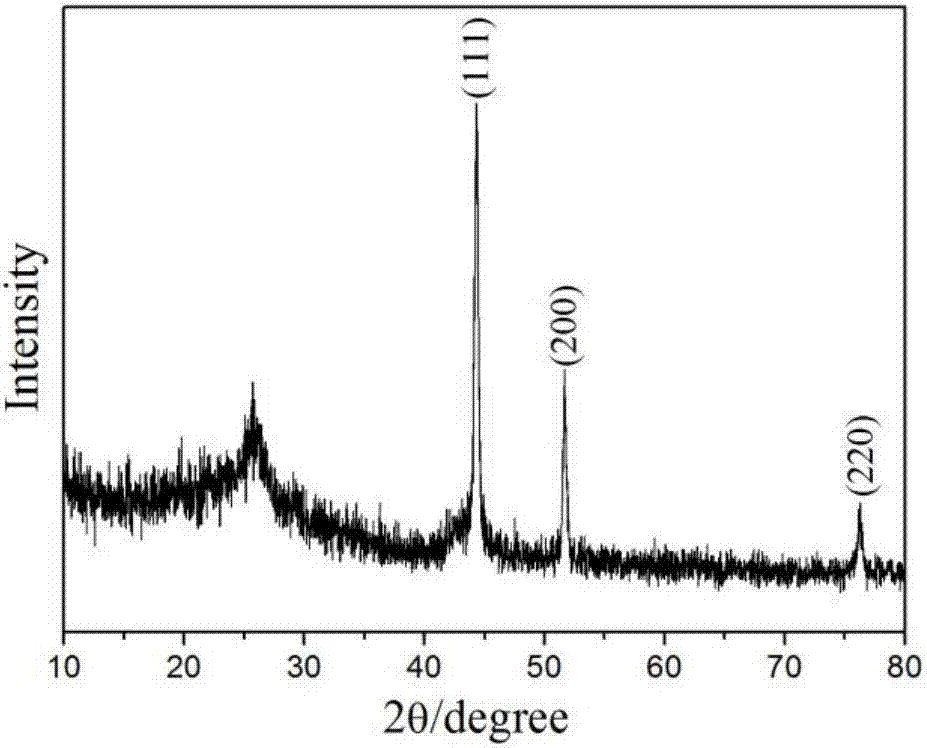

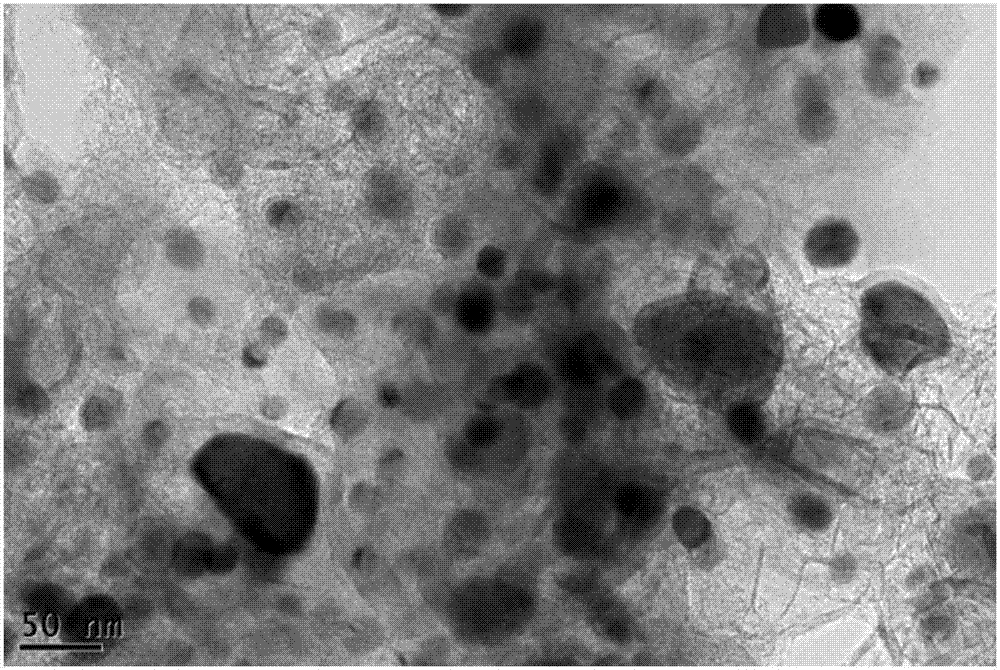

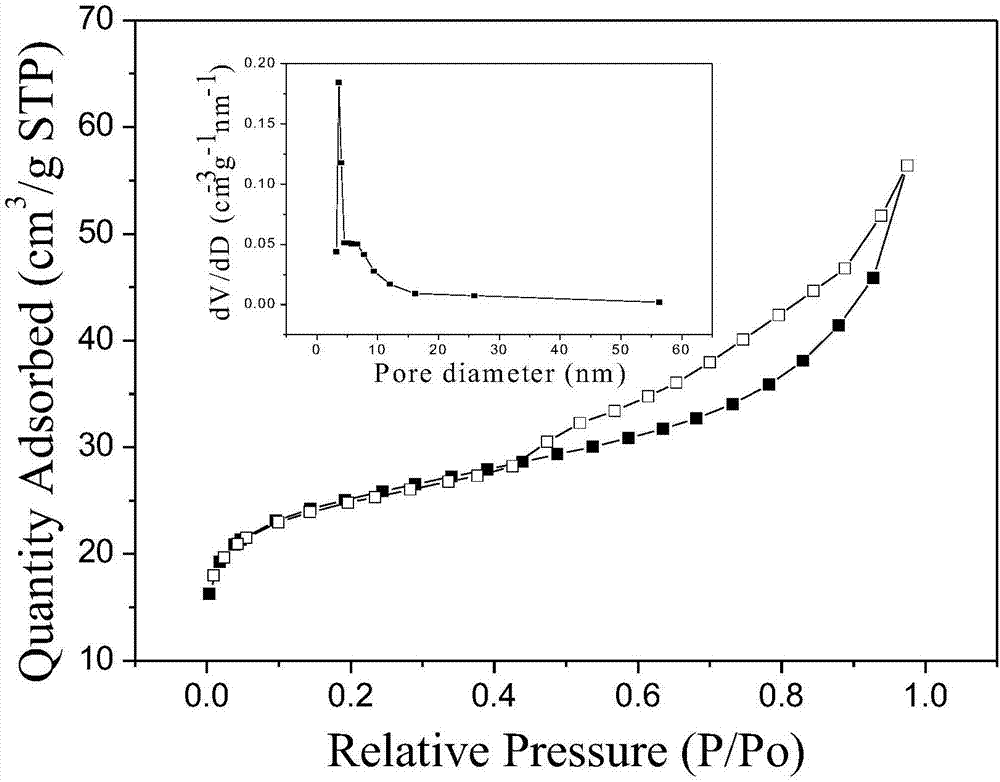

[0032] figure 1 The X-ray p...

Embodiment 2

[0036] The specific experimental procedure of the present embodiment is the same as that of Example 1, changing 0.071g of nickel chloride hexahydrate into 0.075g of nickel acetate tetrahydrate, and changing 0.495g of zinc acetate into 0.369g of zinc chloride.

Embodiment 3

[0038] The specific experimental procedure of the present embodiment is the same as in Example 1, changing 0.071g nickel chloride hexahydrate to 0.069g nickel nitrate hexahydrate, and changing 0.495g zinc acetate to 0.435g zinc sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com