Compound material electrical insulating box and production method thereof

A composite material and electrical insulation technology, which is applied in the direction of electrical components, electrical equipment casings/cabinets/drawers, casings/cabinets/drawer components, etc., can solve the difficulty of maintaining electrical equipment, cost and effort, and electrical systems Bulkiness and other problems, to achieve the effect of being suitable for mass production, good mechanical properties, and good insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

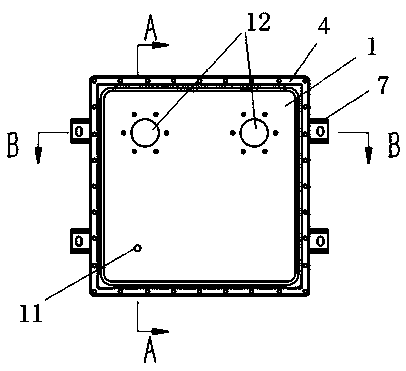

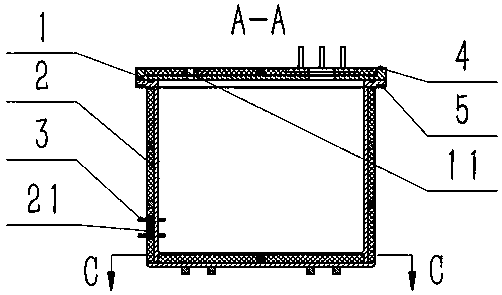

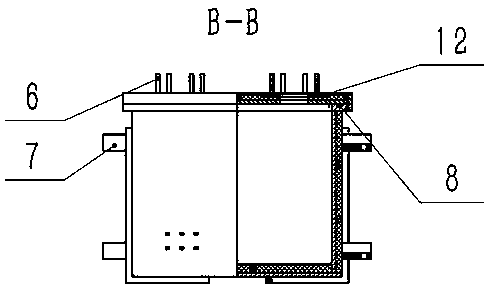

[0035] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , a composite material electrical insulation box, including box cover 1, box body 2, input and output terminals 3, upper flange 4, lower flange 5, guide post 6, box external mounting parts 7, sealing strip 8. The box body is a cuboid structure, the upper part of the box body has flange edges extending outward, and the inside of the box body is a cuboid cavity. Closed sealing grooves distributed around the opening of the upper end of the box body are provided on the edge of the flange near the inner wall, and the sealing strip 8 is located in the sealing grooves. A bolt hole 1 is provided on the periphery of the sealing groove on the casing, and the lower flange 5 is positioned at the bottom of the flange side of the casing 2, and the lower flange is provided with a bolt hole 2 that cooperates with the bolt hole 1 on the casing 2.

[0036] The front side wall (front side) of the box is provided with a cubo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com