Device for space-modulating atomic layer chemical vapour deposition epitaxial growth and method thereof

A chemical vapor deposition and epitaxial growth technology is applied to the device and field of spatial modulation atomic layer chemical vapor deposition epitaxial growth, and can solve the problems of reducing film deposition rate, reducing equipment utilization rate, occurrence of parasitic reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

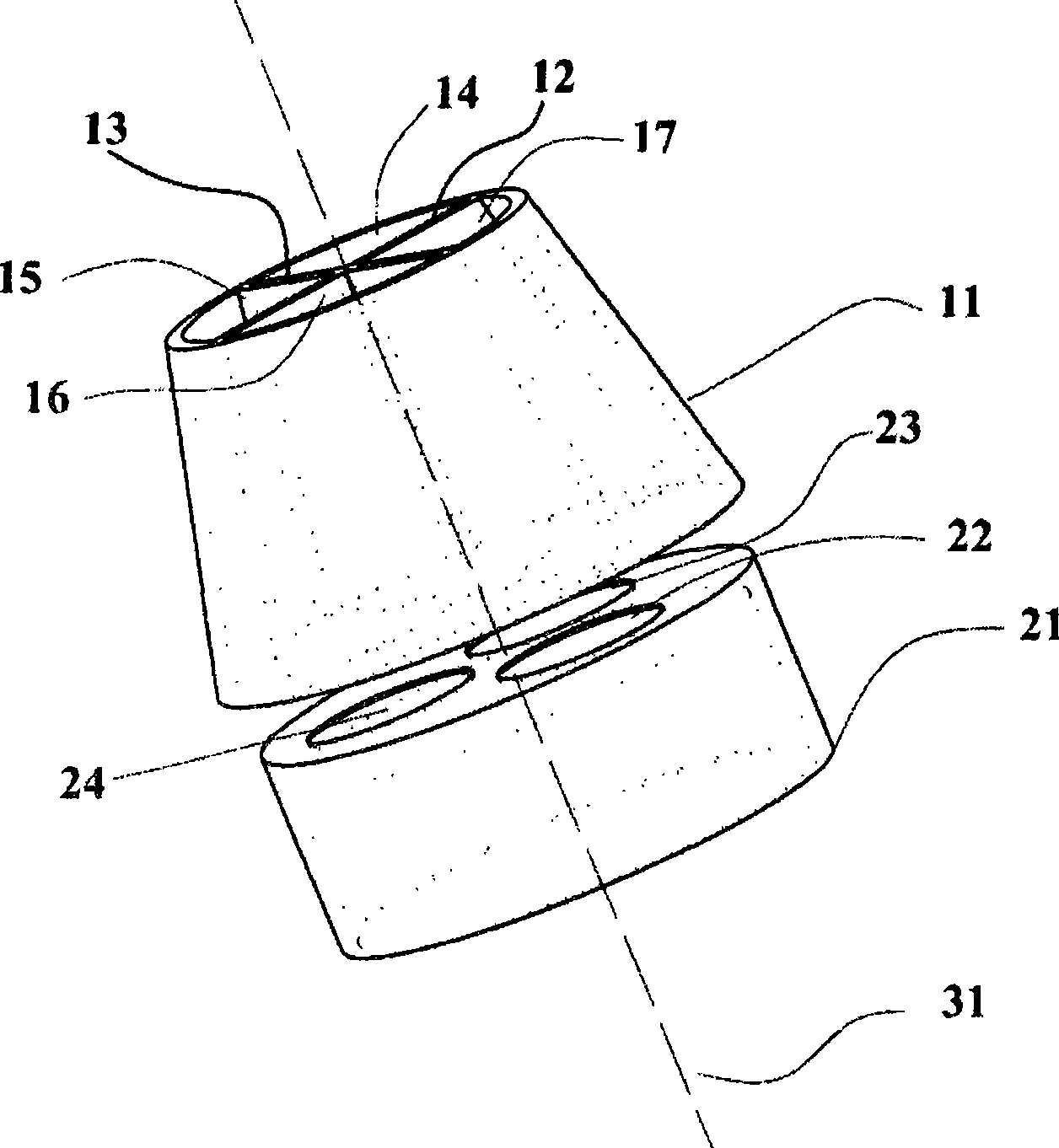

[0048] Different from traditional air intake awnings, partitioned air intake awnings are mainly composed of a hollow barrel-shaped part 11 . The barrel-shaped one is divided into four mutually independent and mutually equivalent regions 14, 15, 16 and 17 by two partitions 12 and 13. Each of these four zones functions the same as a traditional air intake hood. That is to say, various raw material gases required for material growth can be introduced from each zone. Moreover, the same raw material gas or different raw material gases are simultaneously fed into the four subregions.

[0049] Take aluminum nitride (AlN) as an example where the growth parasitic reaction is very serious. In the process of growing, figure 1 The air inlet hood 11 shown can be assigned as follows. Partition 14 passes trimethylaluminum (TMAl), partition 16 passes ammonia (NH 3 ), both partition 15 and partition 17 pass carrier gas (hydrogen H 2 or nitrogen N 2 ). Among them, TMAl and NH imported f...

Embodiment 1

[0066] Embodiment one: see attached figure 1 Shown is a schematic diagram of the reaction chamber structure of a spatially modulated atomic layer chemical vapor deposition system. Comprising a multi-partition 14, 15, 16 and 17 intake tent head 11 and a rotatable base 21 that is dug with grooves 22-24 for placing substrates, and an accommodating rotating base and intake tent Head, the cavity that isolates the reaction gas from the air.

[0067] Use example one: adopt the reaction chamber structure of embodiment one, when preparing high crystal quality zinc oxide (ZnO) film deposition, a kind of raw material gas diethylzinc enters from inlet pipe through partition 14, and another kind of raw material gas oxygen enters from The inlet pipe enters through partition 16, and the carrier gas argon enters from the inlet pipe through partitions 15 and 17. In this way, the raw material gas diethylzinc and oxygen are independently transported in the process of approaching the substrate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com