Elliptical light spot optical fiber collimator

An optical fiber collimator and elliptical light spot technology, which is applied in the field of optical communication devices and optical fiber sensing, can solve problems such as the difficulty of microlens processing technology, and achieve the effects of easy expansion of the number of optical fibers, simple structure, and mature manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

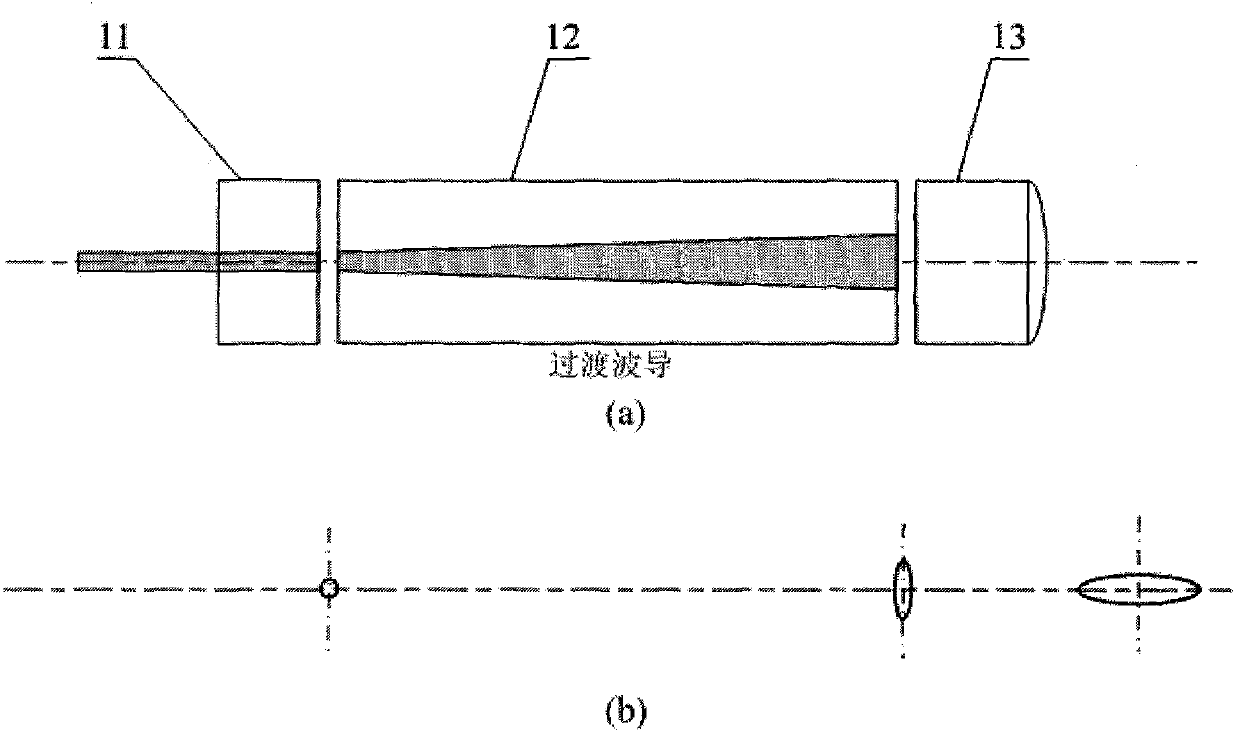

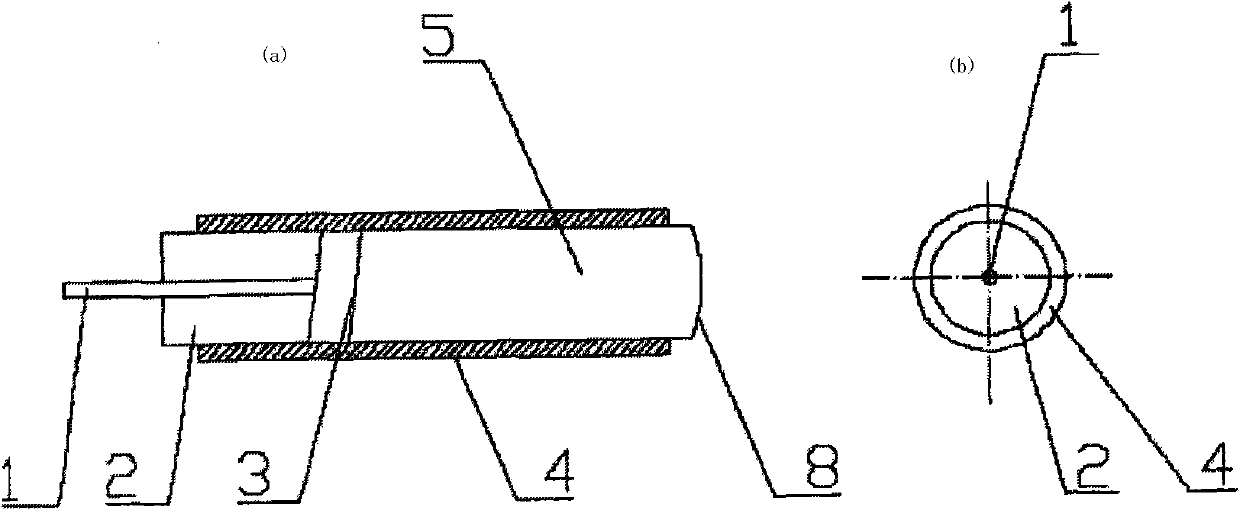

[0014] Single Fiber Elliptical Spot Fiber Collimator: Refer to image 3 (a), use the planar optical waveguide technology to manufacture, scribe, and polish the end face to obtain the planar optical waveguide converter, in which there is at least one transitional waveguide, select the single-core optical fiber and the transitional waveguide of the planar optical waveguide converter for optical coupling, adjust the two The relative distance and angle of the end faces until the transmission light loss from the optical fiber to the waveguide is the lowest, and the two are fixed with glue as an integral end, and then the optical path between the end and the collimating microlens is adjusted and fixed. Methods According to the conventional circular spot single-fiber collimator transmission application coupling method. The two opposite end faces of the optical fiber head and the planar optical waveguide converter, as well as the two opposite end faces of the planar optical waveguide ...

Embodiment 2

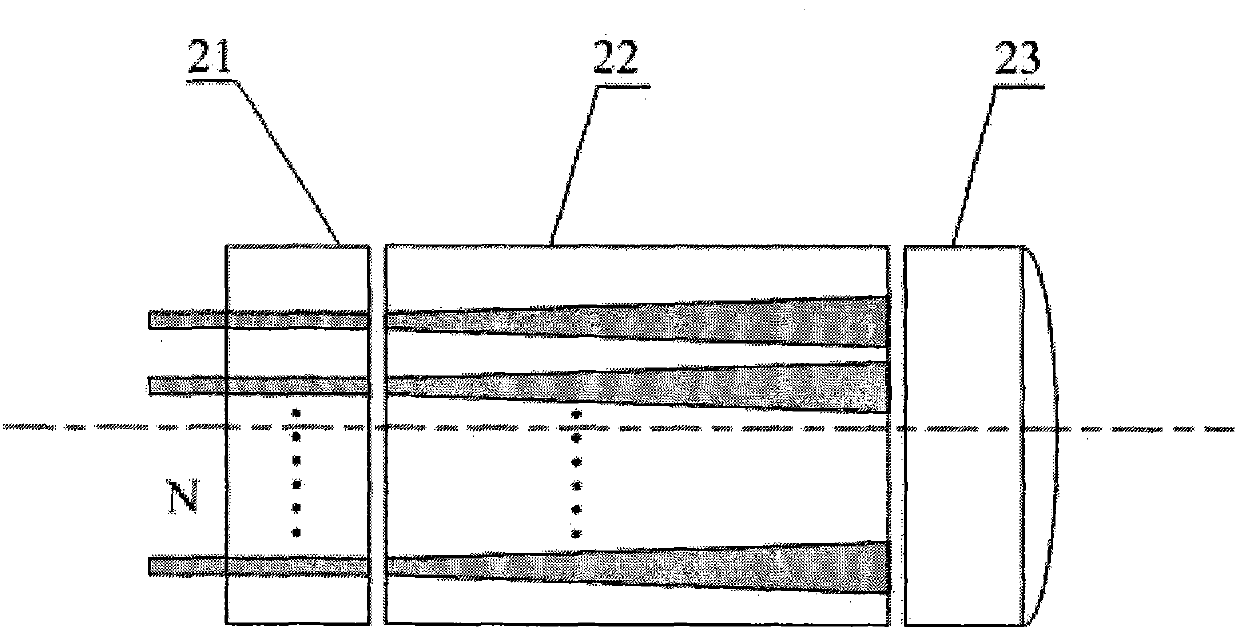

[0016] According to the single-fiber elliptical-spot fiber collimator structure of the present invention, it is easy to think of adopting a double-core or linearly arranged multi-core fiber head or a one-dimensional fiber array to realize a dual-fiber elliptical-spot collimator and a multi-fiber elliptical-spot collimator. refer to Figure 4 , the optical fiber head adopts a double-core or linearly arranged multi-core optical fiber head or a one-dimensional optical fiber array, the number of optical fibers is N≥2, the planar optical waveguide converter is made by planar optical waveguide technology, obtained by scribing and end-face polishing, and the number of transitional waveguides≥ N, the minimum distance between the transitional waveguides meets the requirements of the on-chip crosstalk index, and the geometric aperture of the collimating microlens meets the aberration requirements of N parallel optical paths. The packaging process is as follows: first complete the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com