Carbon dot and graphite phase carbon nitride compound photocatalyst as well as preparation method and application thereof

A technology of graphitic carbon nitride and composite light, which is applied in the field of photocatalysis, can solve the problems of ineffective use of solar energy, high recombination rate of photogenerated carriers, and low utilization rate of visible light, achieving high application prospects and use value, Improve the catalytic ability and inhibit the effect of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

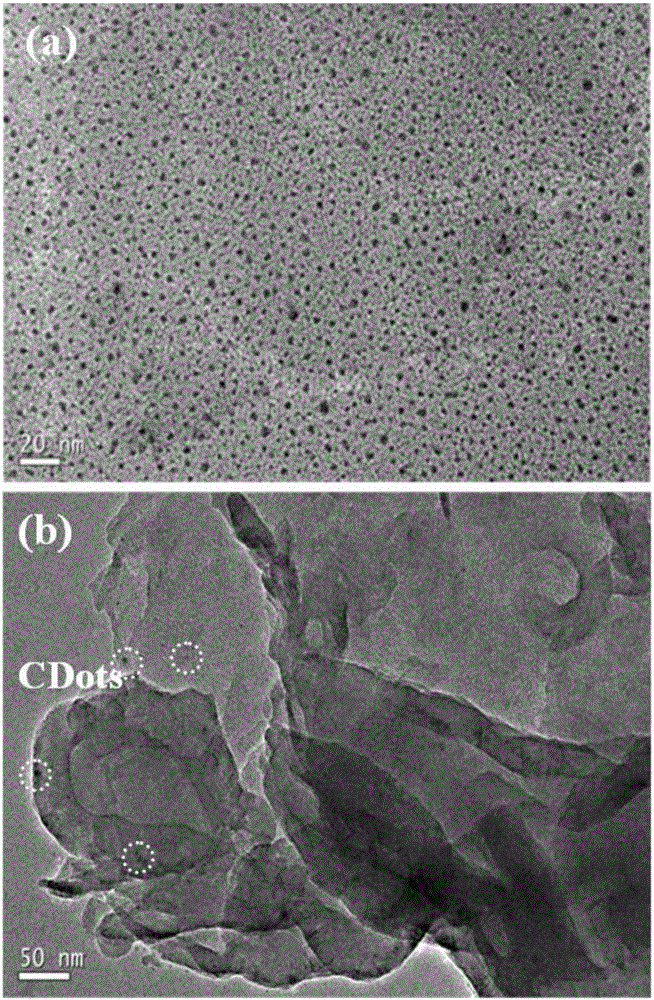

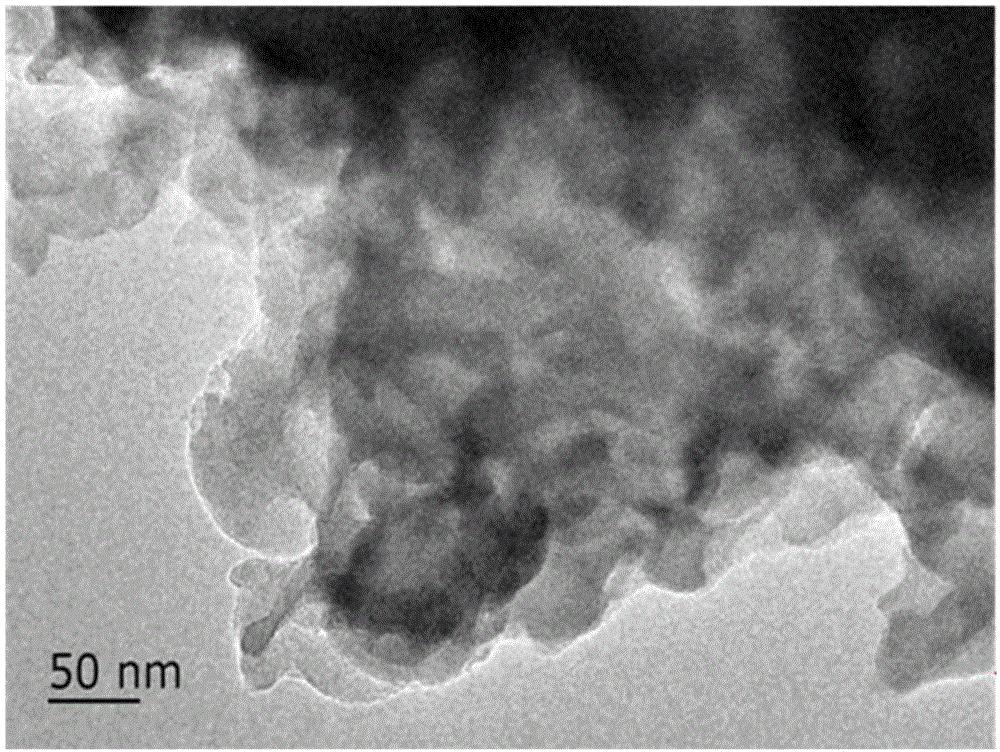

[0032] A CDots / g-C 3 N 4 The preparation of composite photocatalyst comprises the following specific steps:

[0033] 1. Weigh 1g of glucose, add 0.2ml of ethylenediamine and 15ml of ultrapure water to it, dissolve it by ultrasonic, transfer it to a polytetrafluoroethylene high-temperature hydrothermal reactor and react at 160°C for 3h. After it was cooled to room temperature, a brown aqueous solution was obtained. The solution was centrifuged to remove large particles, dried and ground to obtain a brown-black CDots powder.

[0034] 2. Weigh 3g of dicyandiamide and place it in an alumina crucible, add 0.01g of CDots powder and 15ml of ultrapure water into it, ultrasonically dissolve it and place it in an oven at 70°C, and transfer the crucible to a muffler after the water is completely evaporated In the furnace, the temperature was raised to 500°C at a rate of 3°C / min and kept at this temperature for 3 hours. After cooling to room temperature, grind and sieve to obtain CDots...

Embodiment 2

[0041] A CDots / g-C 3 N 4 The preparation of composite photocatalyst comprises the following specific steps:

[0042] 1. Weigh 3g of glucose, add 0.6ml of ethylenediamine and 10ml of ultrapure water to it, dissolve it by ultrasonic, transfer it to a polytetrafluoroethylene high-temperature hydrothermal reactor and react at 150°C for 5h. After it was cooled to room temperature, a brown aqueous solution was obtained. The solution was centrifuged to remove large particles, dried and ground to obtain a brown-black CDots powder.

[0043] 2. Weigh 1g of dicyandiamide and place it in an alumina crucible, add 0.1g of CDots powder and 10ml of ultrapure water into it, ultrasonically dissolve it and place it in an oven at 70°C, and transfer the crucible to a muffler after the water is completely evaporated In the furnace, the temperature was raised to 450°C at a rate of 2°C / min and kept at this temperature for 2 hours. After cooling to room temperature, grind and sieve to obtain CDots / ...

Embodiment 3

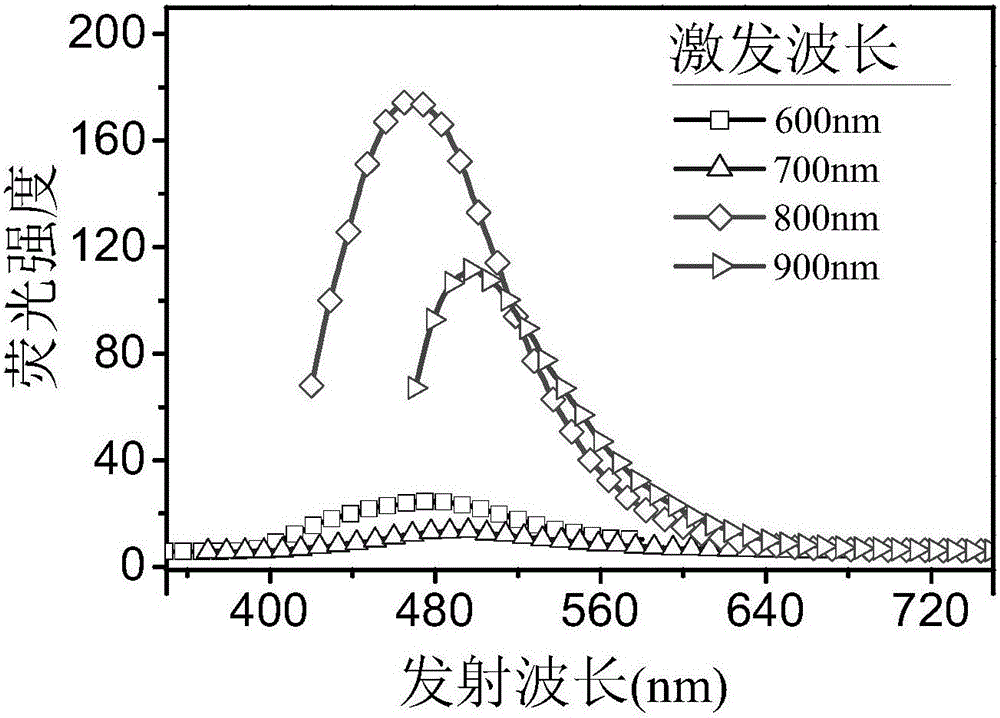

[0045] A CDots / g-C 3 N 4 The application of composite photocatalyst in antibiotic wastewater treatment comprises the following steps:

[0046] 1. Weigh 50 mg of CDots / g-C prepared in Implementation 1 3 N 4 The composite photocatalyst was placed in a photolysis tube, 50ml of ciprofloxacin solution with a concentration of 4mg / L was added, and placed in a photochemical reaction apparatus for 30 minutes to absorb in the dark.

[0047] 2. Use a 300w xenon lamp to configure a 290nm filter for photocatalytic reaction, and use liquid chromatography to measure the concentration C of the remaining ciprofloxacin in the solution after 40 minutes of reaction. According to the formula N=(C 0 -C)*100% calculates the removal rate N of ciprofloxacin, where C 0 is the initial concentration of ciprofloxacin.

[0048] 3. Weigh 50 mg of g-C prepared in Comparative Example 1 3 N 4 , repeat steps 1 and 2 to obtain the removal rate of catalyst to ciprofloxacin.

[0049] Table 1 is CDots / g-C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com