Patents

Literature

45results about How to "Easy to mix and process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

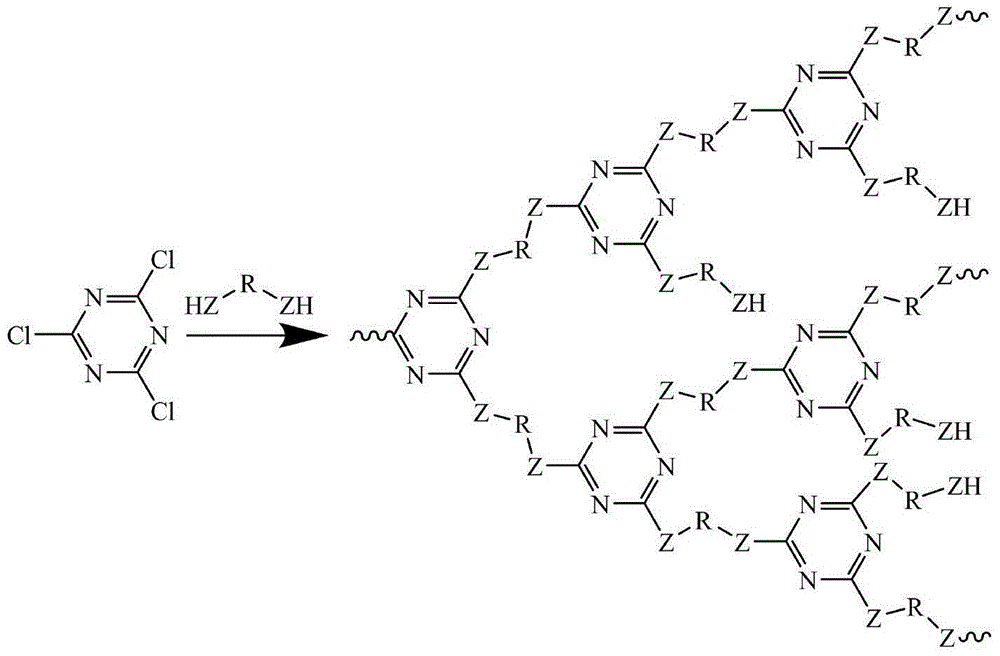

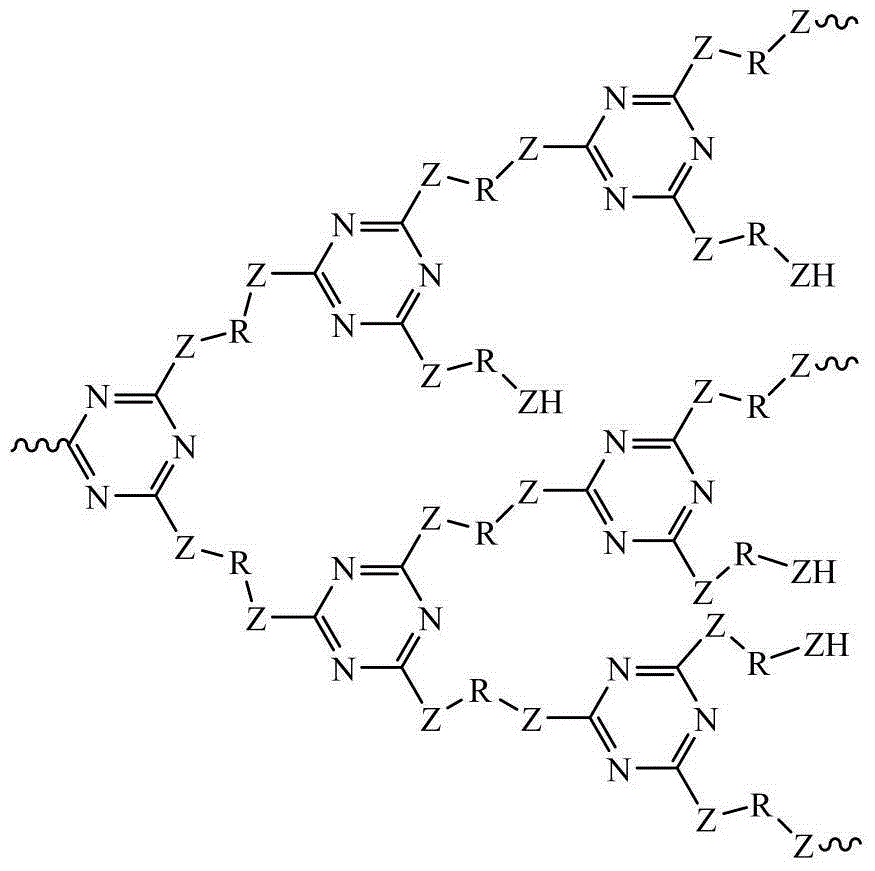

Hyperbranched polyphosphazene flame retardant charring agent and preparing method thereof

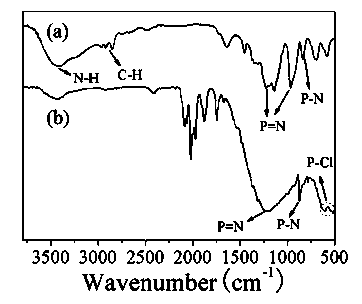

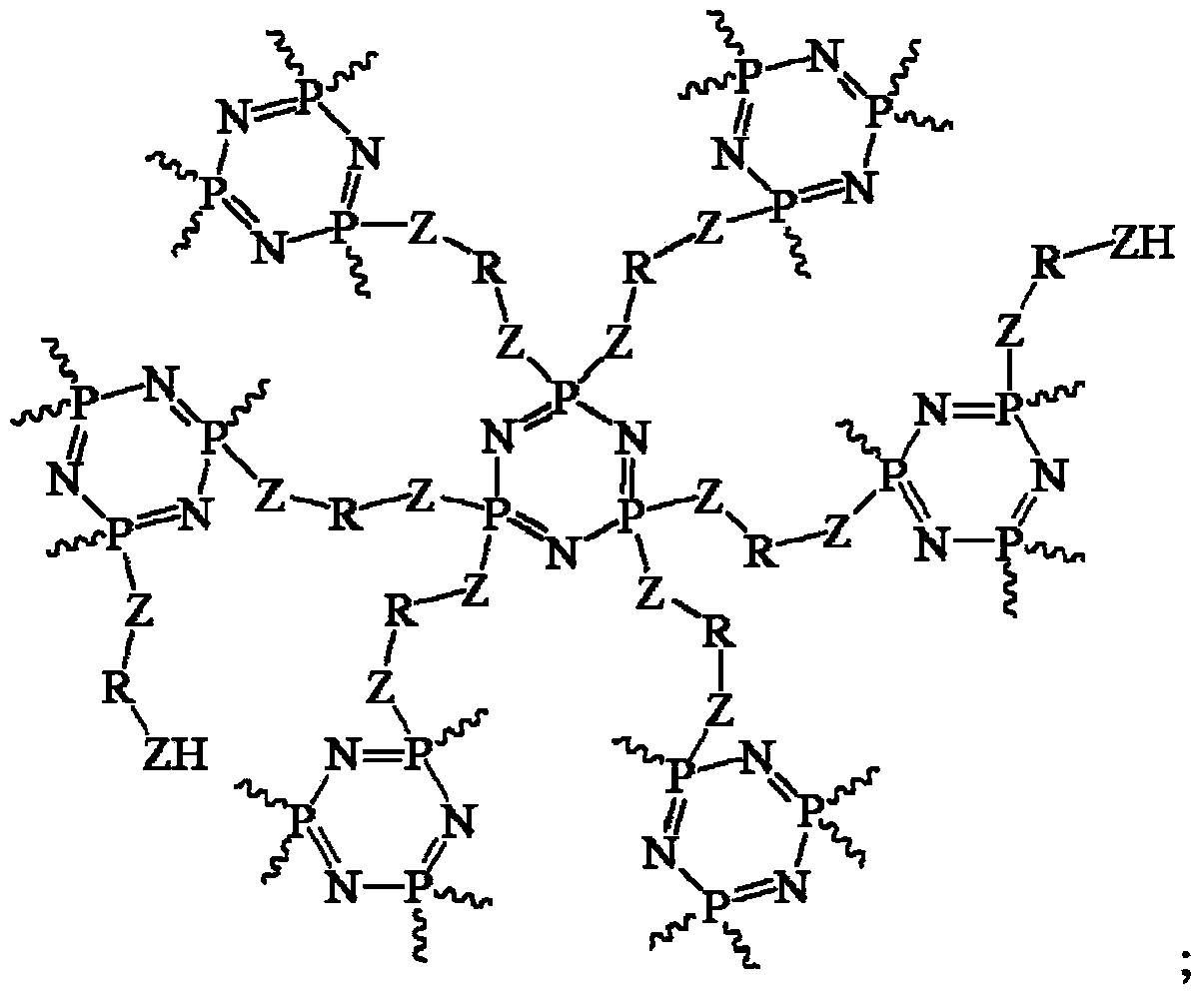

An efficient hyperbranched polyphosphazene flame retardant charring agent is prepared by reacting hexachlorocyclotriphosphazene with a binary compound containing two active groups. The charring agent has characteristics of good foaming charring performance, excellent flame retardant effects and good processing performance, and can be widely used in plastics, rubber, coating, adhesives, and other polymer materials. A preparing method adopts a one-pot method, and has characteristics of continuous reaction process, short reaction time and high production efficiency. By controlling the mole ratio of the hexachlorocyclotriphosphazene to the binary compound, no end-capping agent is added in the reaction process. When compared with the addition of end-capping agents in synthesis processes in triazine type charring agent patents, the synthetic process of the charring agent is simplified.

Owner:苏州安鸿泰新材料有限公司

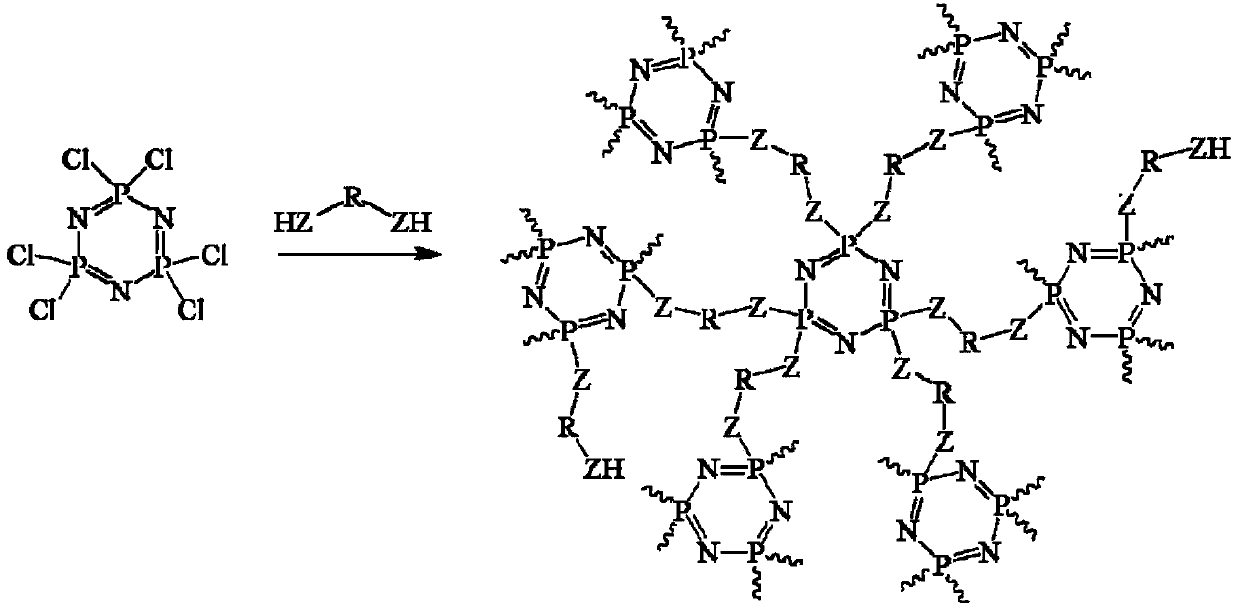

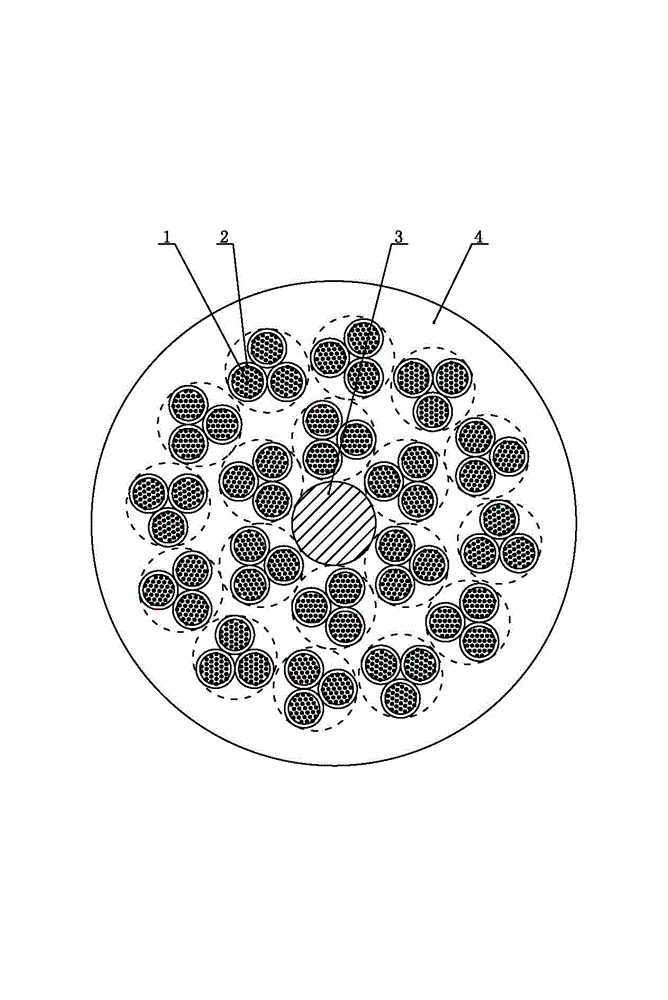

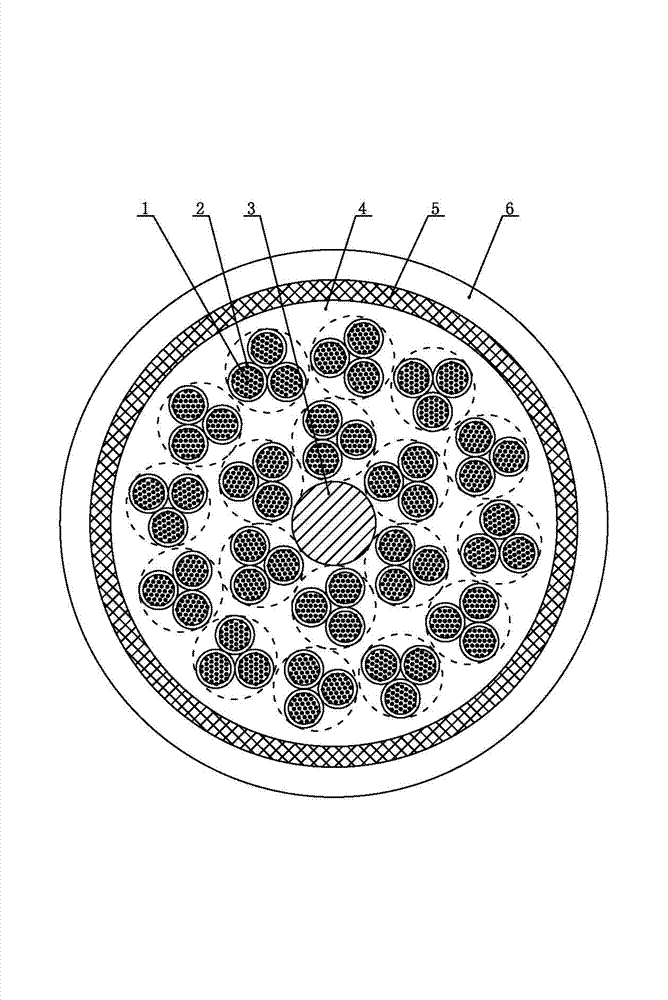

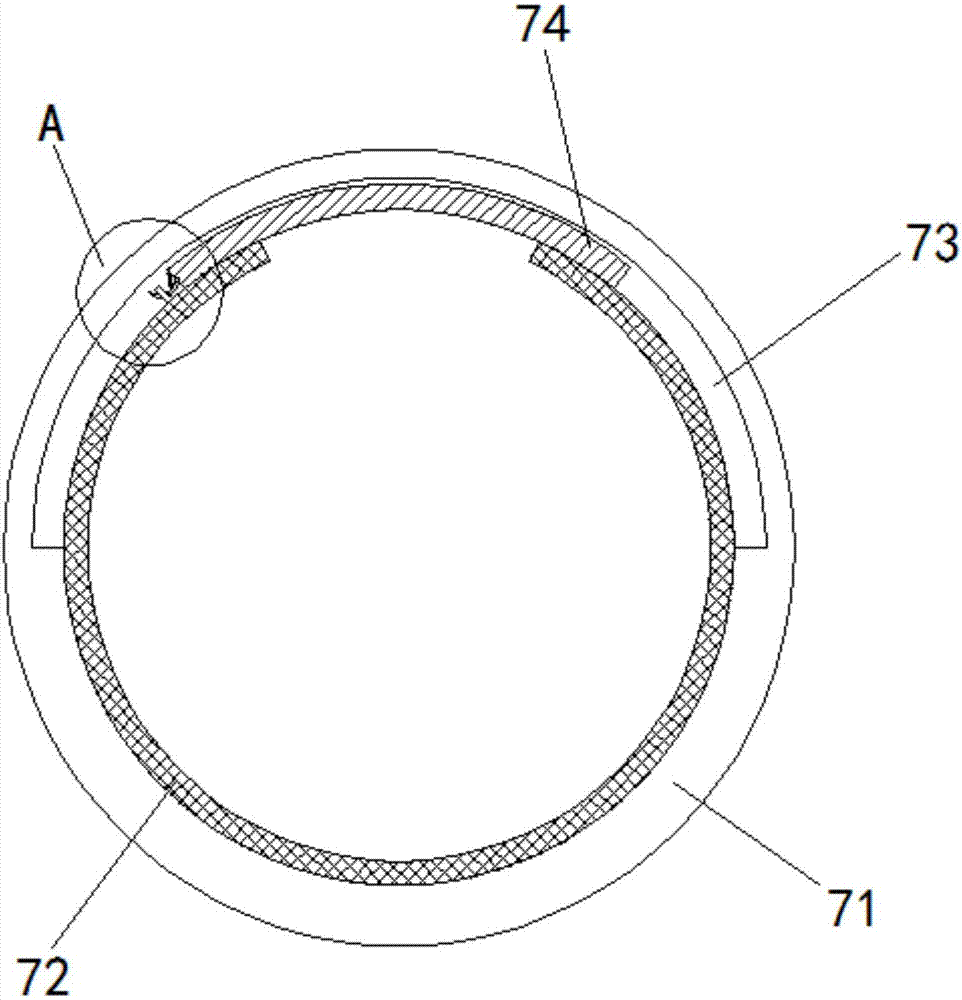

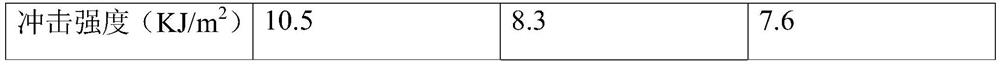

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

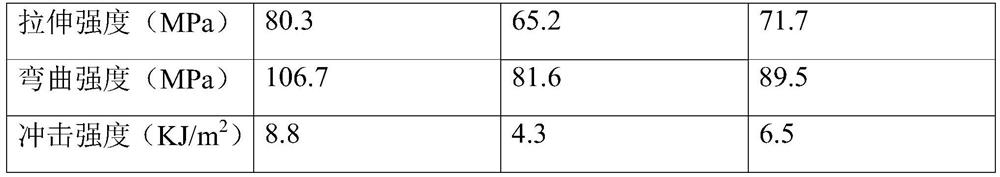

Ecological environment-friendly wood-plastic composite panel for advertisement board and preparation method of panel

InactiveCN104191772AImprove thermal stabilityFluffy structureSynthetic resin layered productsChemical recyclingEnvironmental resistanceEcological environment

The invention discloses an ecological environment-friendly wood-plastic composite panel for an advertisement board and a preparation method of the panel, belonging to the technical filed of manufacture of wood-plastic composite materials. The panel is of a three-layer composite structure and is composed of outer surface soft layers and a middle hard layer, wherein the hard layer is clamped between the two soft layers which are completely the same; the thickness of the hard layer is 0.5-5mm, and the thickness of each soft layer is 0.25-2.5mm. By taking recycled wastes such as sunflower straws and wood-plastic waste and PVC as basic materials, the ecological environment-friendly wood-plastic composite panel comprising a soft-surface thermoplastic elastomer as the outer surface layer and a hard support as the middle layer is produced, and is a good substitute for an existing advertisement board. The ecological environment-friendly wood-plastic composite panel is environmentally friendly and low-carbon, harmless to environment and a human body, good in water-resisting property, easy in demolding, long in service life, unlikely to deform, smooth in surface, and good in fire resistance and photostability, and also has antibacterial insect-prevention effect, and the dimension of the composite panel can be specified by customers.

Owner:民勤县华安再生资源开发有限公司

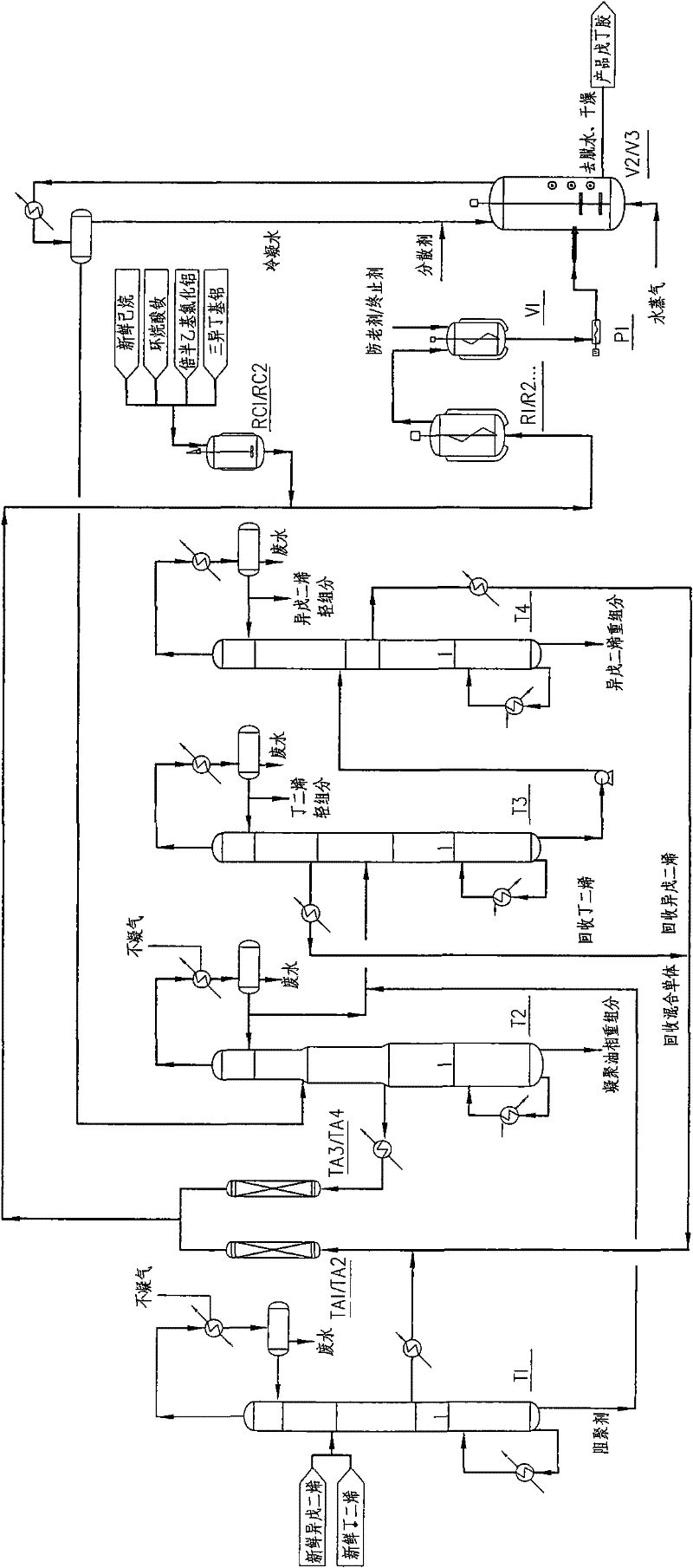

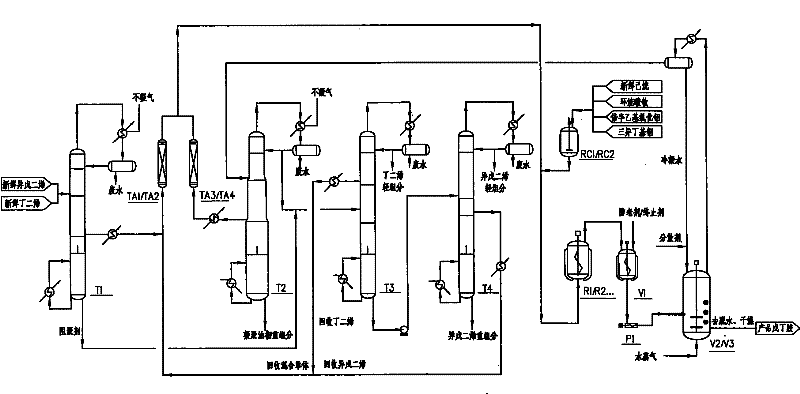

Method for producing rare-earth isoprene butadiene rubber

ActiveCN102234356AIncrease production energy consumptionReduce production energy consumptionSpecial tyresPolymer scienceRare earth

The invention discloses a method for producing rare-earth isoprene butadiene rubber. Two refined monomers, namely isoprene and 1, 3-butadiene are proportioned and mixed, and subjected to polymerization reaction in the presence of a rare earth catalyst to form random copolymer rubber. A multi-tower circular preparation process flow is adopted, and the problem of low purity of recovered monomers and solvents caused by crossed boiling points of various monomers and impurities thereof is solved, so that the production efficiency and molecular weight of the rare-earth isoprene butadiene rubber areimproved and the whole production cost is reduced. In the rare-earth isoprene butadiene rubber, the molar content of polyisoprene units is 40 to 90 percent, the cis-content in the polyisoprene units is more than 95 percent, the cis-content in polybutadiene units is more than 99 percent, the weight-average molecular weight is 2,000,000 to 3,000,000, the molecular weight distribution is 3 to 7, andthe anti-ageing agent content is 1 to 2 percent. The rare-earth isoprene butadiene rubber copolymer can replace a binary blend of natural rubber (or high cis-isoprene rubber) and butadiene rubber, and has the characteristics of capacity of being easily mixed, low themogenesis, wear resistance, crack growth resistance and the like.

Owner:FUSHUN YIKESI NEW MATERIAL

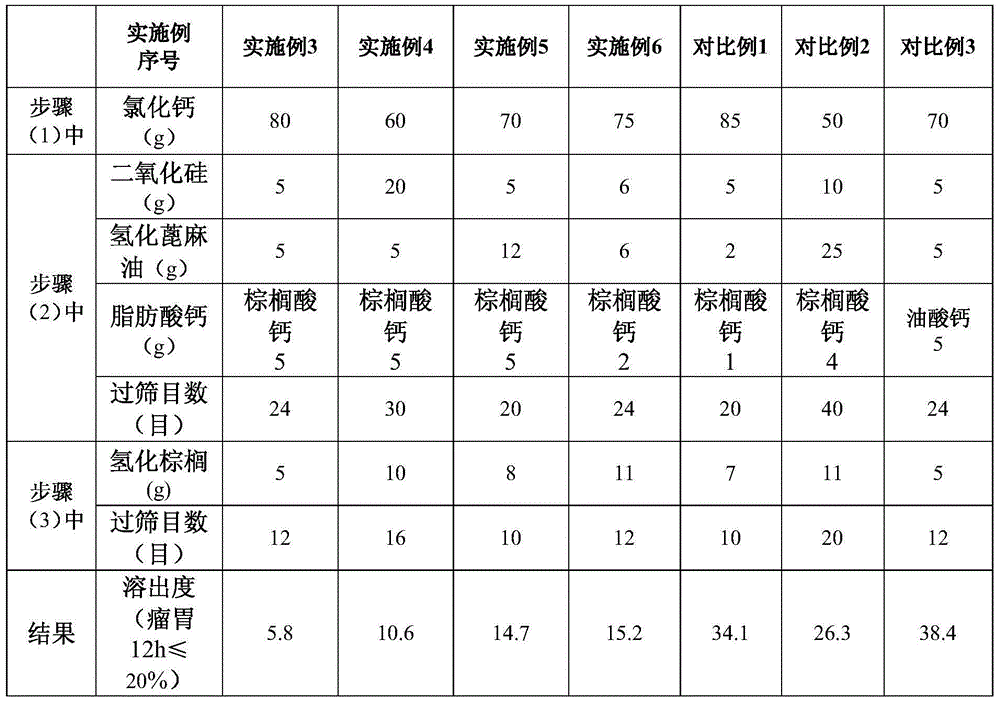

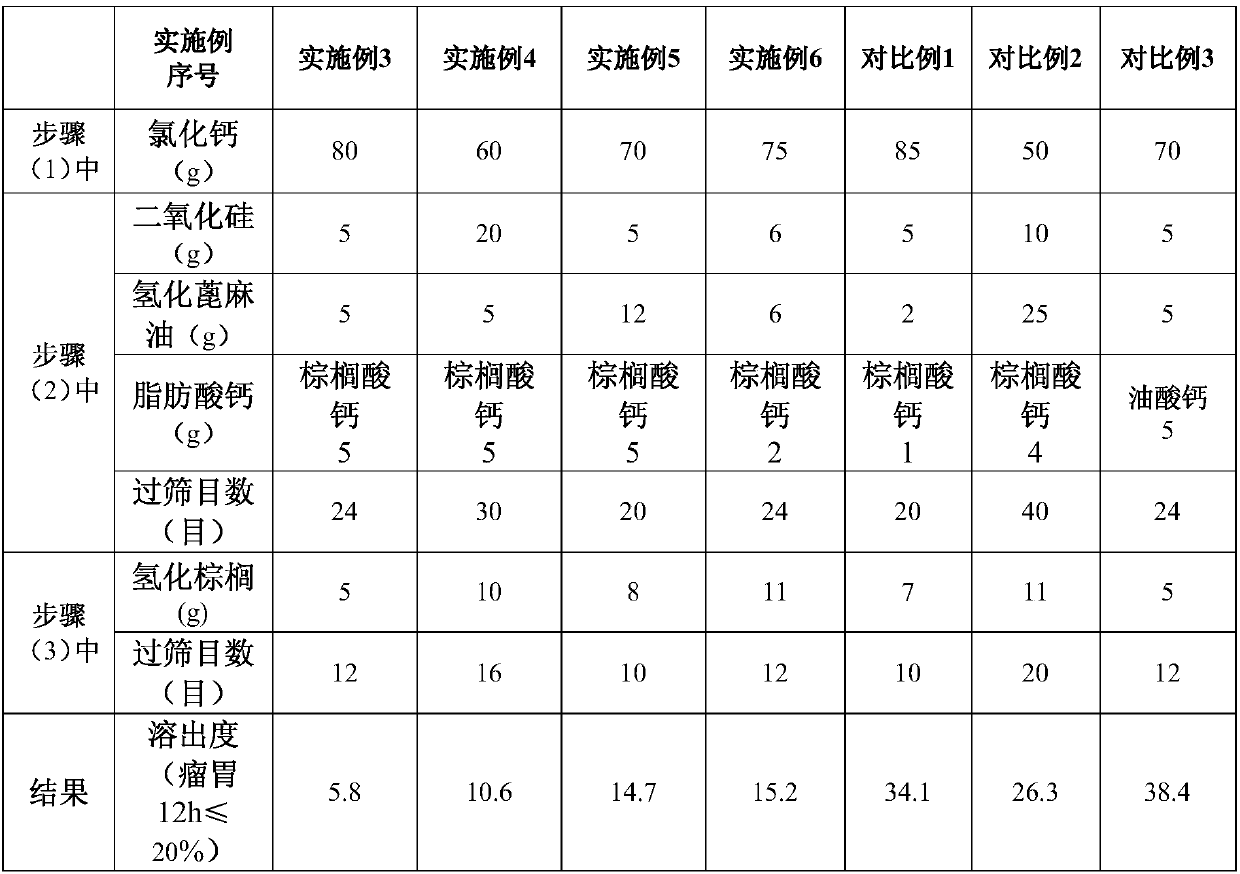

Envelope calcium chloride and preparation method thereof

ActiveCN104585480AEnsure safe passageImprove bioavailabilityAnimal feeding stuffHydrogenated Palm OilChloride

The invention discloses envelope calcium chloride and a preparation method thereof. The envelope calcium chloride is prepared from the following raw materials in parts by weight: 5-20 parts of hydrogenated palm oil, 5-20 parts of hydrogenated castor oil, 4-30 parts of silicon dioxide, 1-20 parts of fatty acid calcium and 60-85 parts of calcium chloride. The preparation method is characterized in that the envelope calcium chloride which can be taken as a feed additive is obtained by taking the hydrogenated palm oil, the hydrogenated castor oil, silicon dioxide and fatty acid calcium as envelope materials and taking the calcium chloride as a core material through a multiple-time pelletizing and enveloping technology. The envelope calcium chloride can make up the defects that the calcium chloride raw material easily absorbs water, and also can guarantee that calcium chloride safely passes through a rumen to smoothly reach the intestinal tract, so that the biological utilization rate of calcium chloride is greatly increased.

Owner:HANGZHOU KINGTECHINA FEED CO LTD

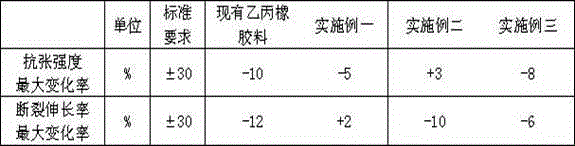

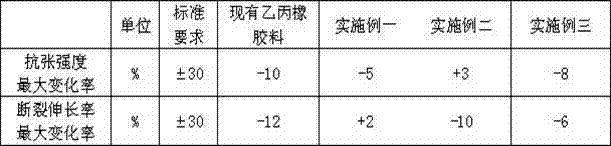

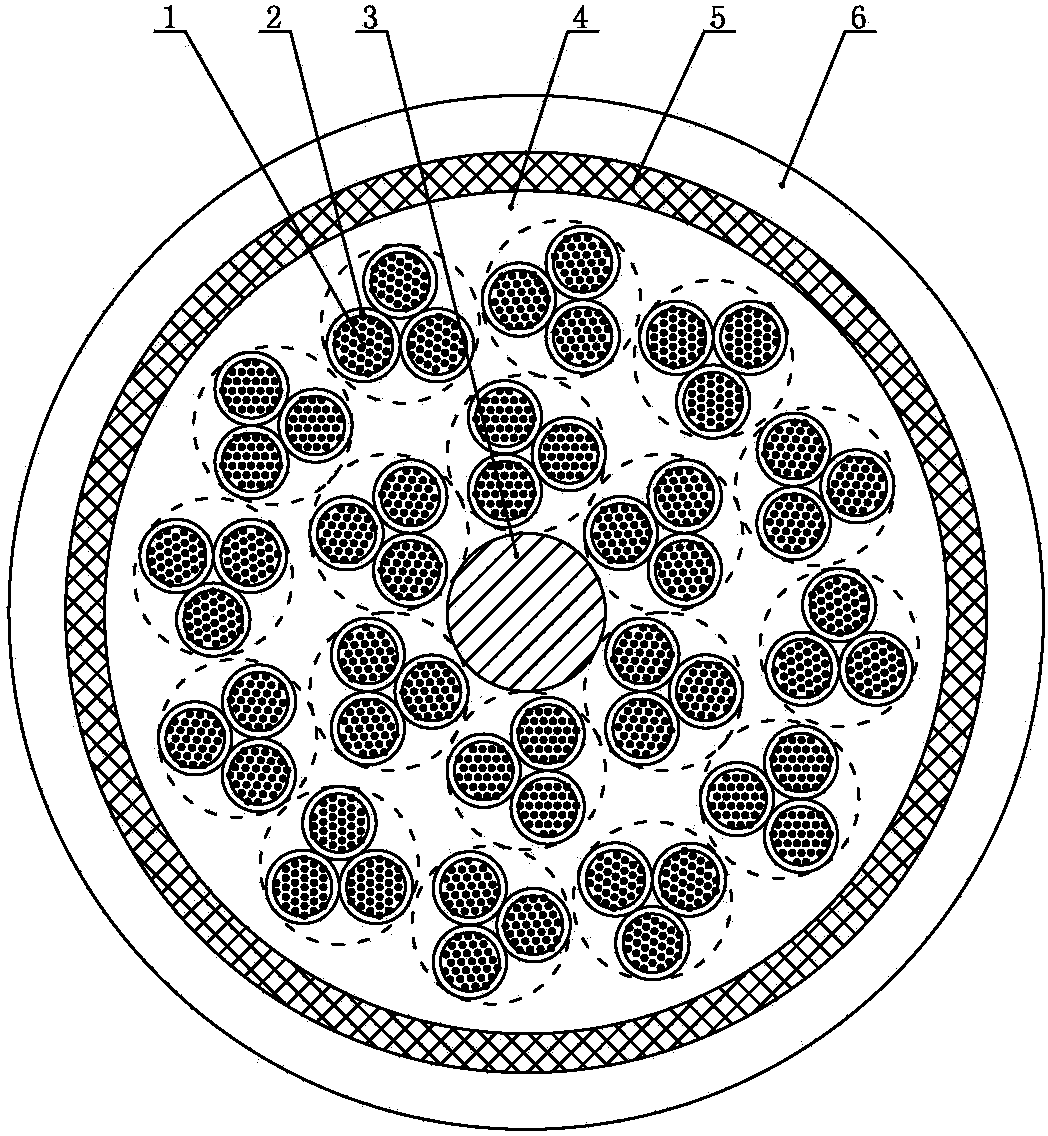

Highly flexible cable for drag chain and manufacturing method thereof

InactiveCN102751014AGood oil resistanceGood physical and mechanical propertiesNon-insulated conductorsClimate change adaptationCopper conductorMicrocrystalline wax

The invention discloses a highly flexible cable for a drag chain and a manufacturing method thereof. An oil-resistant rubber insulating layer is wrapped on the periphery of a stranded copper conductor in an extruding way to form an insulating core wire; a plurality of insulating core wires are re-stranded into an insulating core wire bundle; a plurality of insulating core wire bundles are arranged around a highly elastic torsion-resistant reinforcing core in a way of a concentric circle and are stranded into a cable core; and an oil-resistant sheath is wrapped on the periphery of the cable core in the extruding way. The insulating layer comprises the following raw materials in parts by weight: 15 parts of ethylene propylene rubber K21, 15 parts of chlorinated polyethylene rubber CM352, 0.5 to 0.6 parts of vulcanizing agent DCP, 0.2 to 0.3 parts of vulcanizing agent TAIC, 0.3 to 0.5 parts of anti-aging agent MB, 0.1 to 0.3 parts of anti-aging agent RD, 1.0 to 2.0 parts of paraffin oil, 1 to 2 parts of chlorinated paraffin-52, 0.5 to 1.0 part of microcrystalline wax, 1.5 to 2.5 parts of active magnesium oxide, 0.4 to 0.7 parts of calcium stearate, 10 to 15 parts of ultrafine talcum powder, 1 to 2 parts of gas phase method white carbon black, 6 to 8 parts of calcined clay and 0.2 to 0.4 parts of coloring agent. The cable is good in insulating and mechanical performances and is oil-resistant.

Owner:JIANGSU YUANYANG DONGZE CABLE

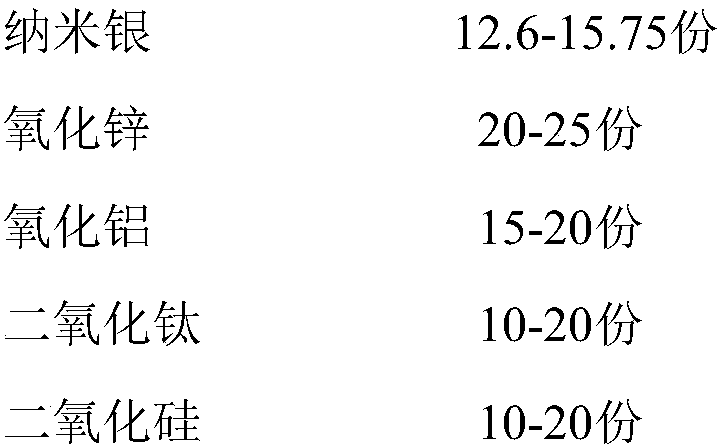

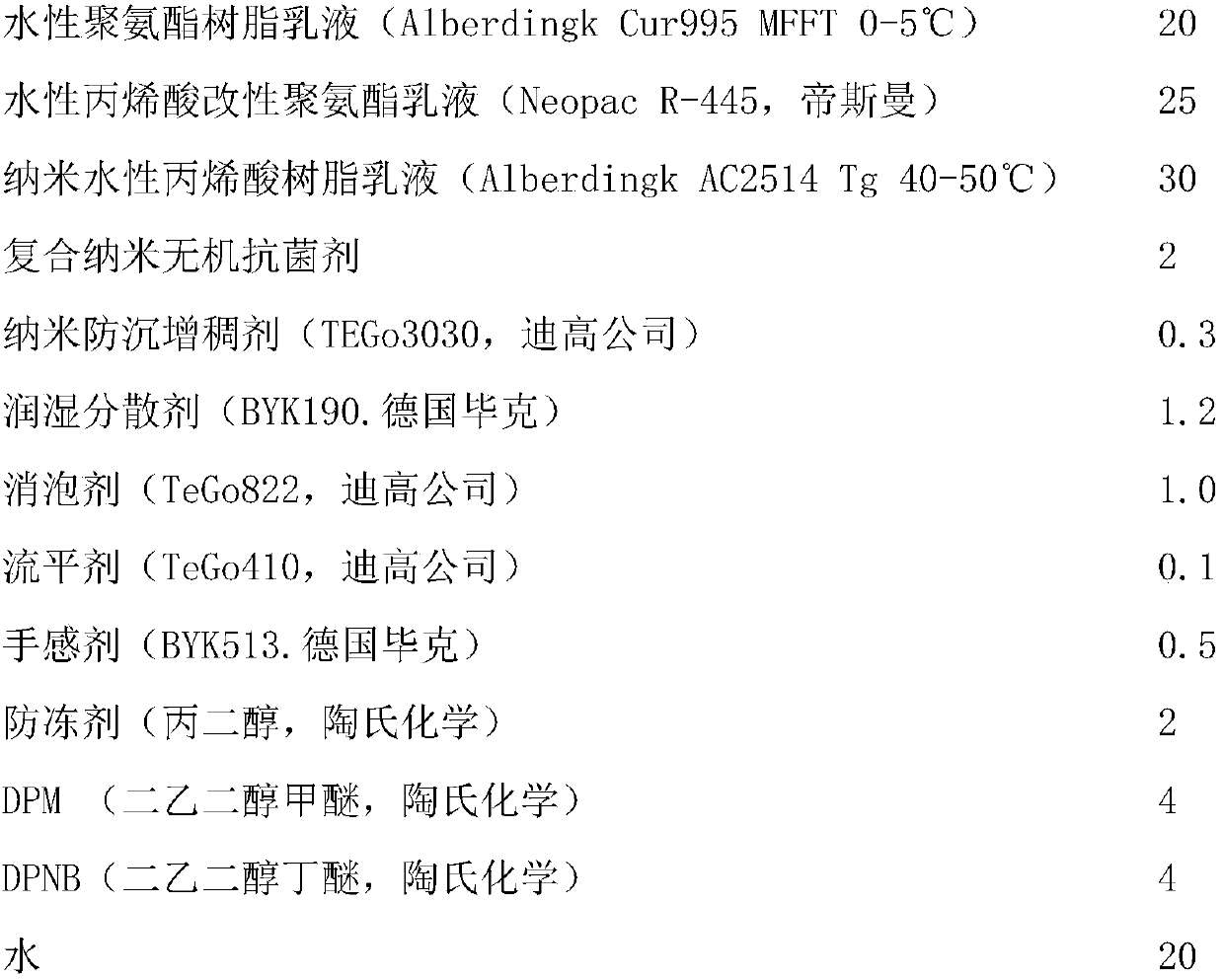

Composite nanometer inorganic antibacterial agent, and nanometer antibacterial waterborne wood lacquer antifreezing topcoat and preparation method thereof

InactiveCN109535807ALow costImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesSodium BentoniteLacquer

The invention belongs to the field of special coatings, and discloses a composite nanometer inorganic antibacterial agent. The composite nanometer inorganic antibacterial agent comprises the followingcomponents by weight: 12.6 to 15.75 parts of nanometer silver, 20 to 25 parts of zinc oxide, 15 to 20 parts of aluminium oxide, 10 to 20 parts of titanium dioxide, 10 to 20 parts of silicon dioxide,5 to 7 parts of organic bentonite and 15 to 20 parts of water. The composite nanometer inorganic antibacterial agent provided by the invention has the advantages of greenness, environmental protection, long-lasting antibacterial function, etc., is easy for mixing and processing, and solves the process problems of easy sedimentation, easy discoloration and easy agglomeration in the production and processing processes of ordinary inorganic antibacterial agents at the same time. Meanwhile, the invention also discloses a nanometer antibacterial waterborne wood lacquer antifreeze topcoat. The nanometer antibacterial waterborne wood lacquer antifreeze topcoat provided by the invention has the above-mentioned advantages, and also has the advantages of good fullness, good paint film hardness, goodyellowing resistance and thermal stability and excellent wear resistance.

Owner:YINGDE YAJIA PAINT

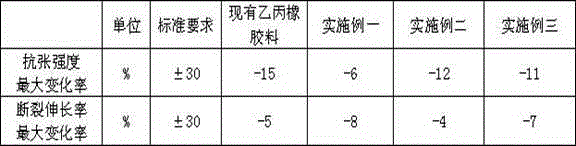

High-flexibility shielding cable for drag chain and manufacturing method thereof

ActiveCN102820083AGood oil resistanceGood physical and mechanical propertiesClimate change adaptationFlexible cablesCarbon blackParaffin oils

The invention discloses a high-flexibility shielding cable for a drag chain and a manufacturing method thereof and belongs to the field of cables. An oil-resisting rubber insulating layer is extruded on the periphery of a stranded copper conductor, so as to form an insulating core wire; a plurality of insulating core wires are stranded into an insulting core wire beam; multiple strands of insulting core wire beams are arrayed around a high-elasticity anti-torque reinforcing core and are stranded into a cable core; an oil-resisting inner jacket, a mixed knitted shielding layer and an oil-resisting outer jacket are arranged on the periphery of the cable core; and the insulating layer comprises the following raw materials by weight part: 15 parts of ethylene propylene rubber K21, 15 parts of chlorinated polyethylene rubber CM3 52, 0.5-0.6 parts of DCP (Dibasic Calcium Phosphate), 0.2-0.3 parts of TAIC (Tri-Allyl Iso-cyanurate), 0.3-0.5 parts of anti-aging agents MB, 0.1-0.3 parts of anti-aging agents RD, 1.0-2.0 parts of paraffin oil, 1-2 parts of chlorinated paraffin-52, 0.5-1.0 part of microcrystalline wax, 1.5-2.5 parts of active magnesium oxide, 0.4-0.7 parts of calcium stearate, 10-15 parts of superfine talcum powder, 1-2 parts of gaseous phase white carbon black, 6-8 parts of roasted argil and 0.2-0.4 parts of coloring agent. The high-flexibility shielding cable is excellent in insulating and mechanical properties and is oil-resisting.

Owner:嘉兴顾翔制冷设备有限公司

Production method of zinc sulfate monohydrate

InactiveCN102351240AAvoid damageStable physical and chemical propertiesZinc sulatesInorganic ChemicalSlag

A production method of zinc sulfate monohydrate belongs to the technical field of inorganic chemical industry and comprises the following steps of: 1) dissolving waste zinc to obtain a zinc sulfate solution and solid impurities; 2) carrying out air oxidation on the zinc sulfate solution to obtain a first purified zinc sulfate solution; 3) adding a zinc powder and active carbon into the first purified zinc sulfate solution to obtain a second purified zinc sulfate solution and second purified slag; 4) adding the zinc powder into the second purified zinc sulfate solution to obtain a third purified zinc sulfate solution and third purified slag; 5) carrying out evaporation concentration and centrifugal separation on the third purified zinc sulfate solution to obtain hydrous zinc sulfate and a mother liquor; 6) drying the hydrous zinc sulfate to obtain the product zinc sulfate monohydrate. The technologies of two extraction and three purification, mother liquor circulation and diversion as well as two-iron activation are adopted to prepare high-efficient reductive feed grade zinc sulfate product.

Owner:HANGZHOU FUYANG XINXING INDAL

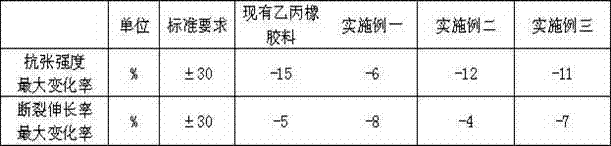

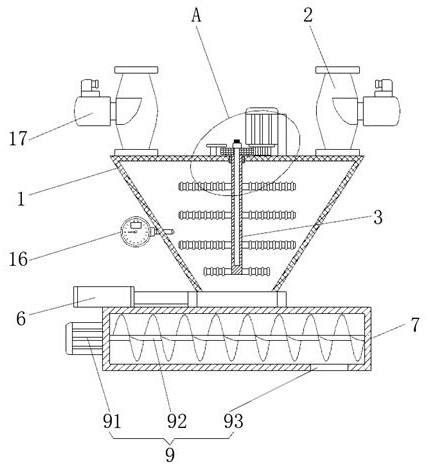

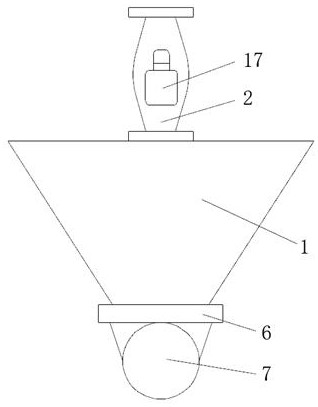

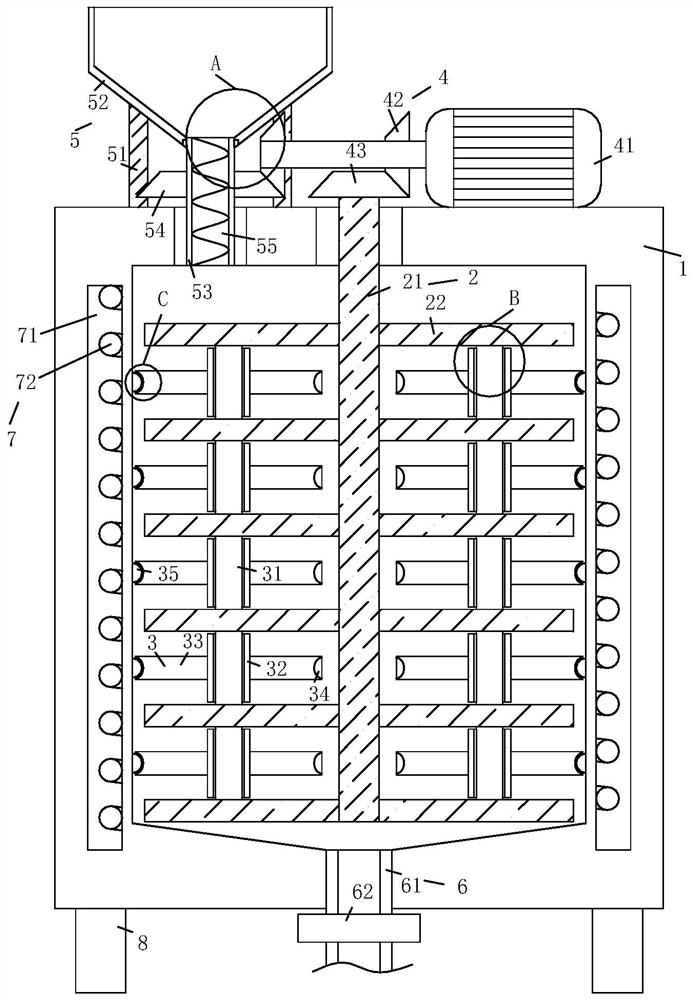

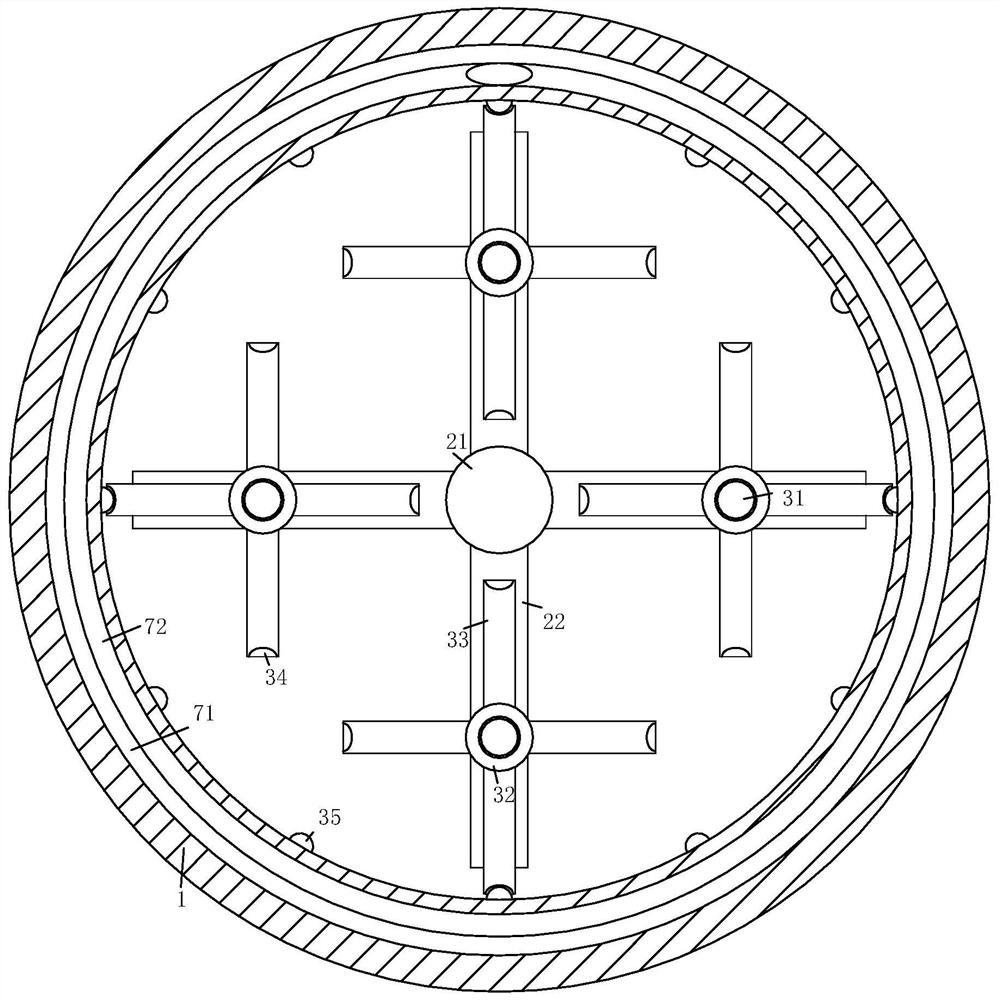

Stirring machine for sweet potato powder processing

InactiveCN107970801AStir wellImprove stirring efficiencyRotary stirring mixersMixing methodsWater pipeEngineering

The invention relates to a stirring machine for sweet potato powder processing which comprises a support, a water pump, a water conveying pipe, stirring blades, a stirring box, a rotating shaft and amotor, wherein a fixing hoop is arranged at the upper end of the support, supporting short tubes are connected with the interior of the fixing hoop, and the stirring box is connected with the supporting short tubes. According to the stirring machine for sweet potato powder processing, a plurality of the framework-shaped stirring blades are arranged on the rotating shaft, the framework-shaped stirring blades are composed of bottom rods and semi-arc rods, and inner straight rods are arranged in the framework-shaped stirring blades; in a process that the stirring blades rotate along the rotatingshaft, sweet potato powder or solution in the stirring box can flow through gaps among the inner straight rods on the stirring blades; thus, stirring can be evener; furthermore, a stirring efficiencyis greatly improved; meanwhile, branch straight rods can smash powder balls which are formed by the sweet powder wrapped by the solution in the stirring box in a rotating process along with the stirring blades, and the powder in the stirring box can be timely and effectively combined with a water solute; a stirring speed is further improved, and quality of the sweet potato powder solution is ensured.

Owner:赵孝利

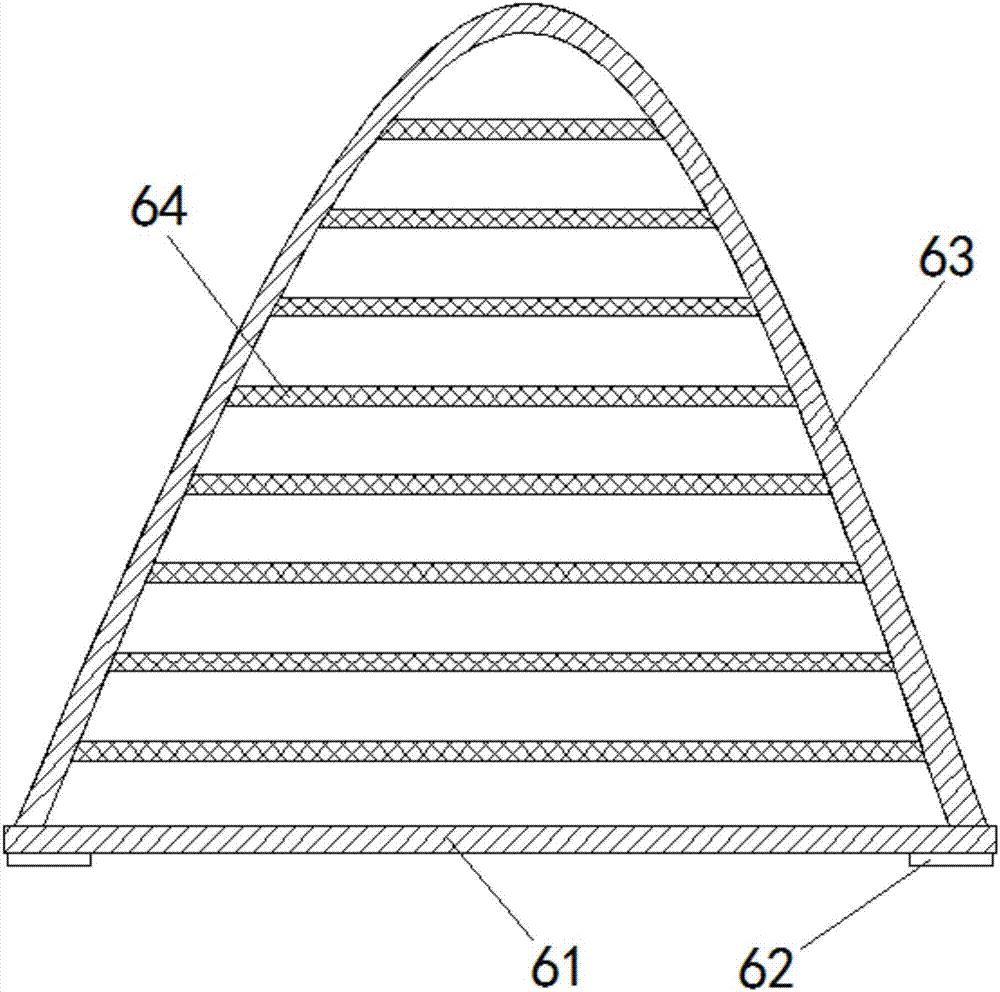

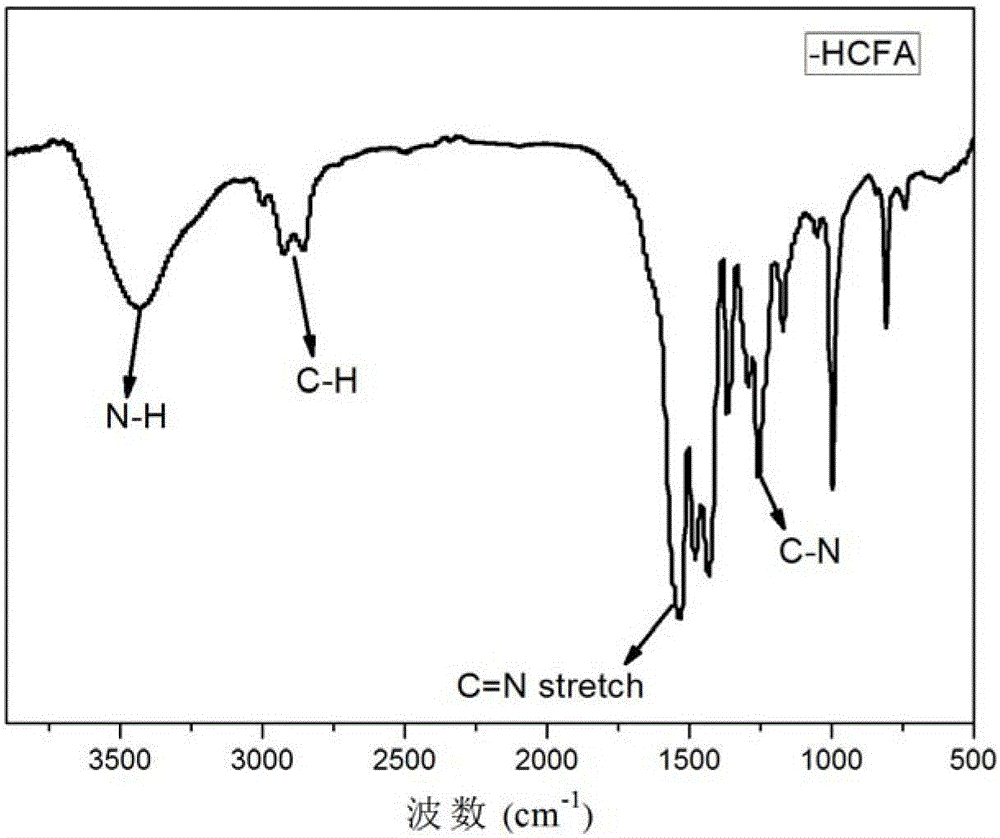

A kind of preparation method of hyperbranched triazine char-forming agent

The invention discloses a preparation method of a novel hyperbranched triazine char forming agent, which comprises the following steps: adding a dissolved diamine solution at 0-10 DEG C, gradually and dropwisely adding a dispersed cyanuric chloride solution, and reacting for 1-4 hours; heating to 30-70 DEG C, adding an acid-binding agent, and reacting for 3-8 hours; heating to 90-150 DEG C, and reacting for 6-10 hours; and stopping stirring, carrying out vacuum filtration, washing with water, and drying to obtain the triazine hyperbranched char forming agent. Compared with the prior art, the invention has the advantages of continuous reaction process, short reaction time, cheap raw materials, low solvent consumption, no addition of any blocking agent in the reaction process, simplified synthesis technique, high heat stability and high char forming ratio.

Owner:合肥安聚达新材料科技有限公司

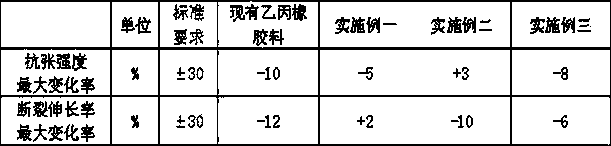

Flame-proof armored rope core conveyer belt

ActiveCN100457580CImprove tensile propertiesImprove flame retardant performanceConveyorsPhosphateNeoprene

The invention relates to a flame-proof steel belt conveyor, which is based on the adhesive property between the flame-proof layer and the steel wire to improve the flame-proof, anti-abrasion, and conducting static electricity property of glue material by adjusting the proportion of raw material, adding flame-proof lubricant and using new conducting carbon black, to improve the whole property of invention and meet the standard of MT668-1997. Said invention mainly comprises steel wires and flame-proof covering glue layer. Wherein, the formulation of flame-proof covering glue layer comprises: neoprene in 80-100 deals; zinc oxide in 4-20 deals; accelerant (as melaniline) in 2-8 deals; conducting carbon black in 4-15 deals; solid flame-proof agent (as antimony oxide) in 20-59 deals; liquid flame-proof agent (as triaryl phosphate) in 5-20 deals; white carbon black in 5-20 deals; and solid frame-proof lubricant MB-202 in 3-8 deals.

Owner:QINGDAO RUBBER SIX CONVEYER BELT

Epoxy asphalt concrete for roads and bridges and preparation method thereof

The invention discloses epoxy asphalt concrete for roads and bridges and a preparation method thereof. The epoxy asphalt concrete for roads and bridges is prepared from the following raw materials byweight: 10%-20% of epoxy resin, 3%-6% of a curing agent, 20%-35% of aggregate, 25%-35% of a filler, 1%-5% of a coupling agent, 10%-20% of modified asphalt, 5%-10% of glass fibers and 5%-8% of water. According to the epoxy asphalt concrete for roads and bridges and the preparation method, through adding the epoxy resin and utilizing modified filtration, and by combining the filler components with different ratios and using the batch mixing process, the control is easily achieved, the mixing processing is conveniently performed, the texture uniformity is easily improved, the structural performance of the asphalt concrete can be effectively improved, aging deformation resistance is improved, the pavement laying effect is easily improved, and stability is easily improved, facilitating promotion and the use.

Owner:张海龙

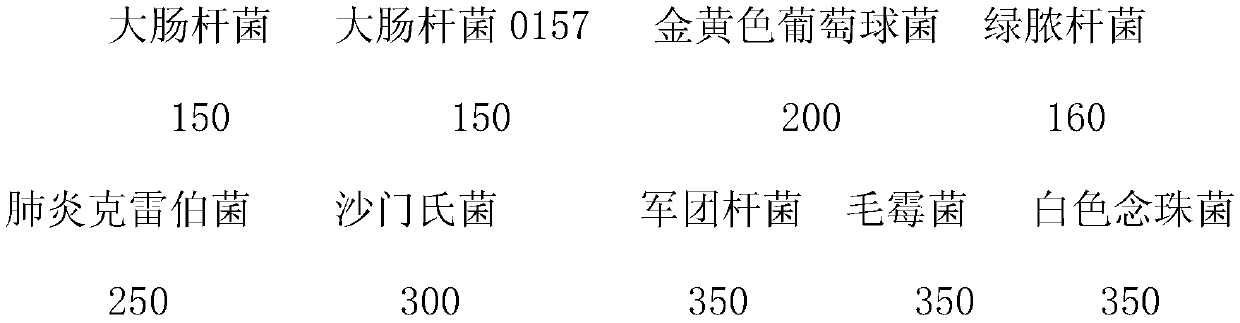

Nano-silver antibacterial agent and preparation method and application thereof

The invention relates to the technical field of antibacterial agents, in particular to a nano-silver antibacterial agent and a preparation method and application thereof. The preparation method comprises the steps of: adding 20-30 parts by weight of zirconium phosphate and 1-10 parts by weight of citric acid into 100 parts by weight of deionized water to obtain suspension liquid, then adding 0.3-1.3 parts by weight of silver nitrate and stirring for 2-24 h, then adding 1-3 parts by weight of titanate and continuing to stir for 2-24 hours, and carrying out filtering, drying, calcining and crushing to obtain the nano-silver antibacterial agent. The nano-silver antibacterial agent disclosed by the invention is a broad-spectrum antibacterial agent in which silver ions and titanium dioxide are exchanged and loaded on zirconium phosphate. The antibacterial agent is superfine powder with uniform granularity, has extremely low hygroscopicity and high heat resistance and can be easily mixed and processed in fibers, films and plastic resin molded products. The physical and chemical properties are very stable, and the dyeing resistance and the discoloration resistance are excellent in the processing process and the using process.

Owner:广东赞誉防霉科技有限公司

High-flexibility shielding cable for drag chain and manufacturing method thereof

ActiveCN102820083BGood oil resistanceGood physical and mechanical propertiesClimate change adaptationFlexible cablesCopper conductorShielded cable

Owner:嘉兴顾翔制冷设备有限公司

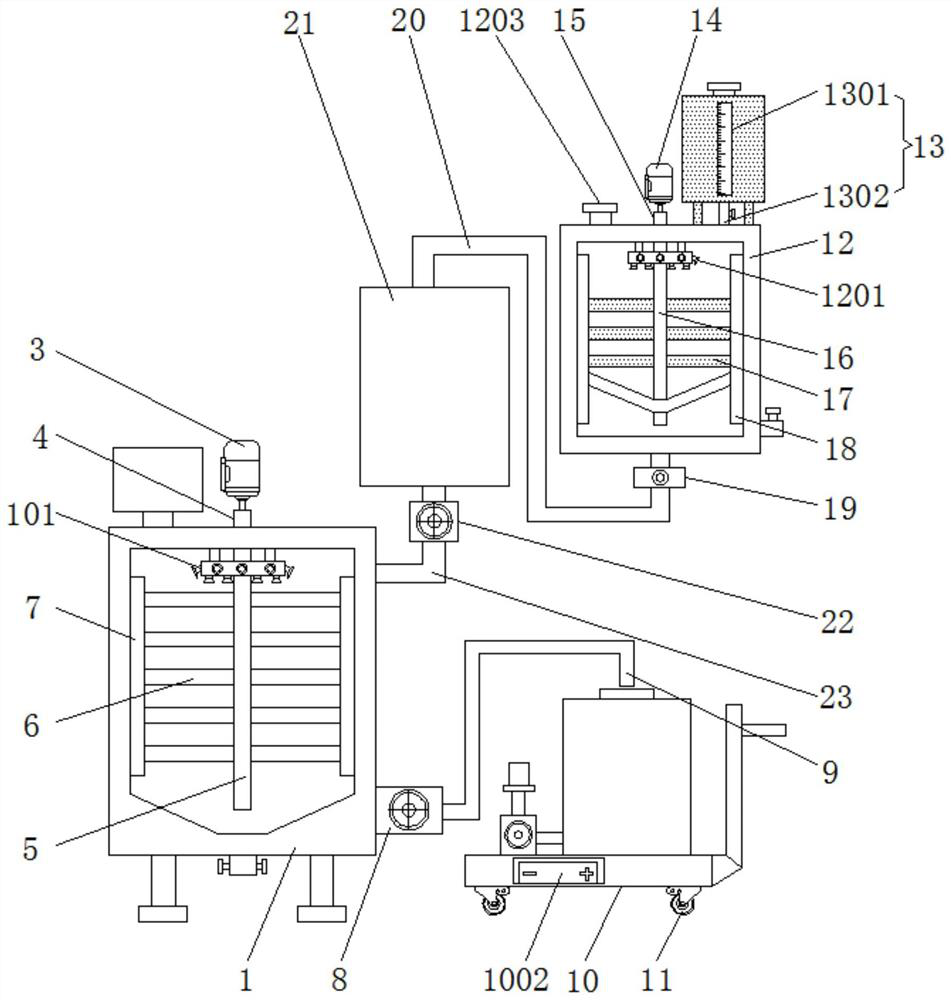

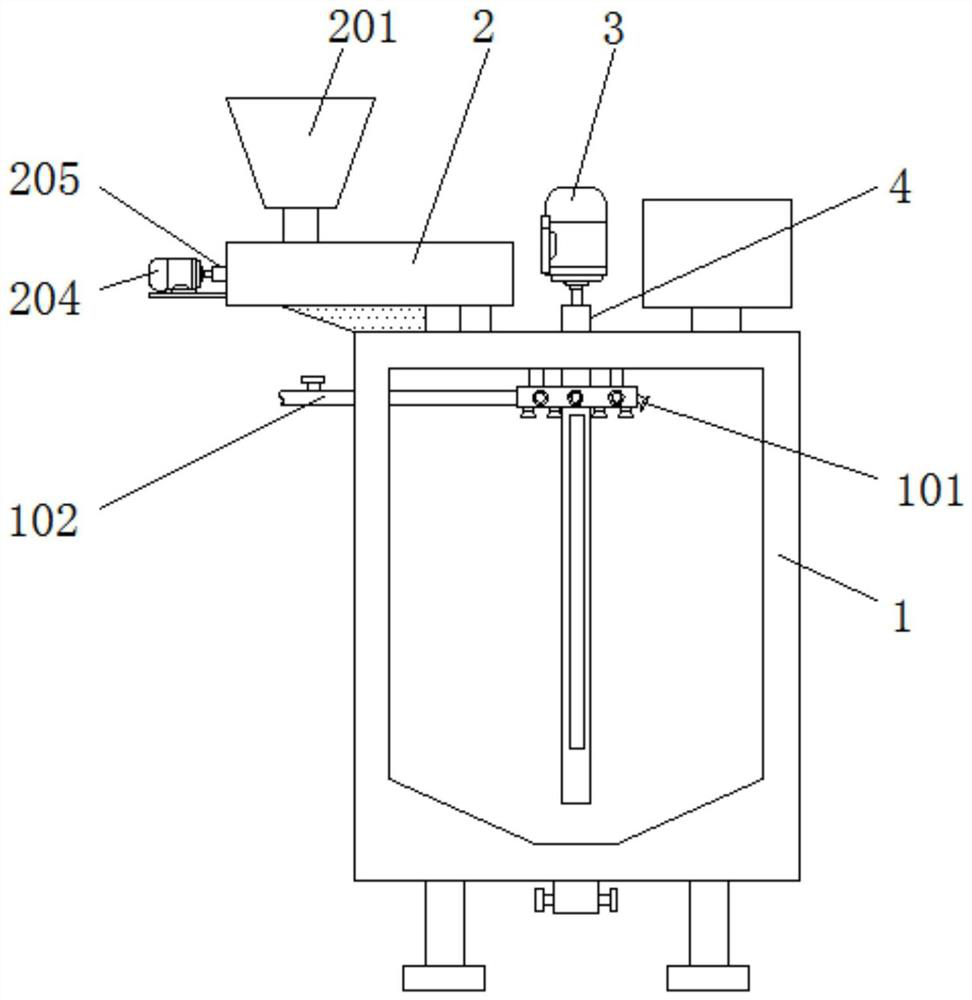

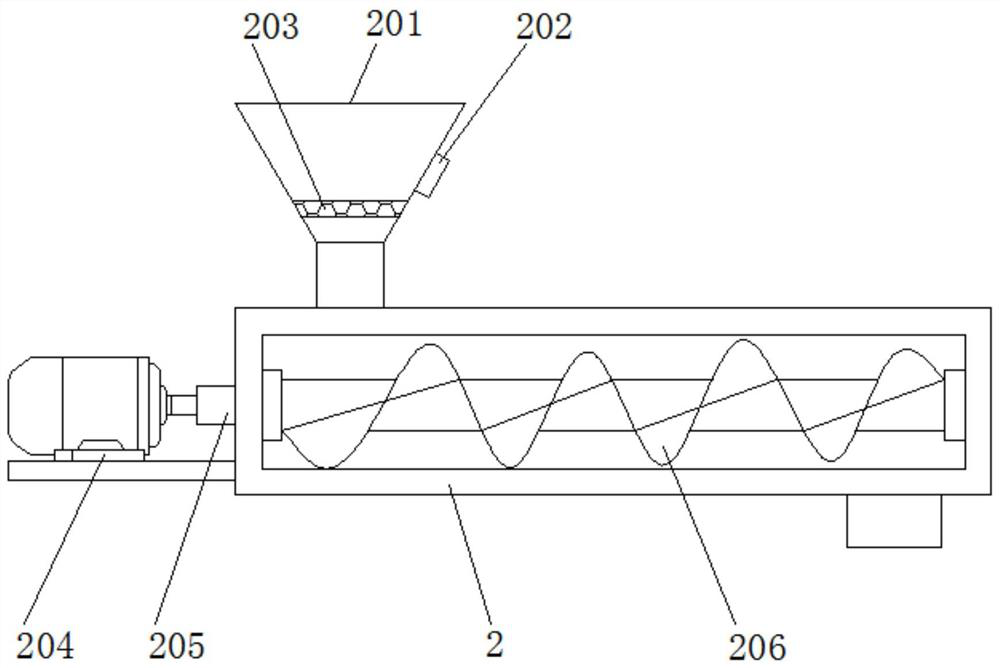

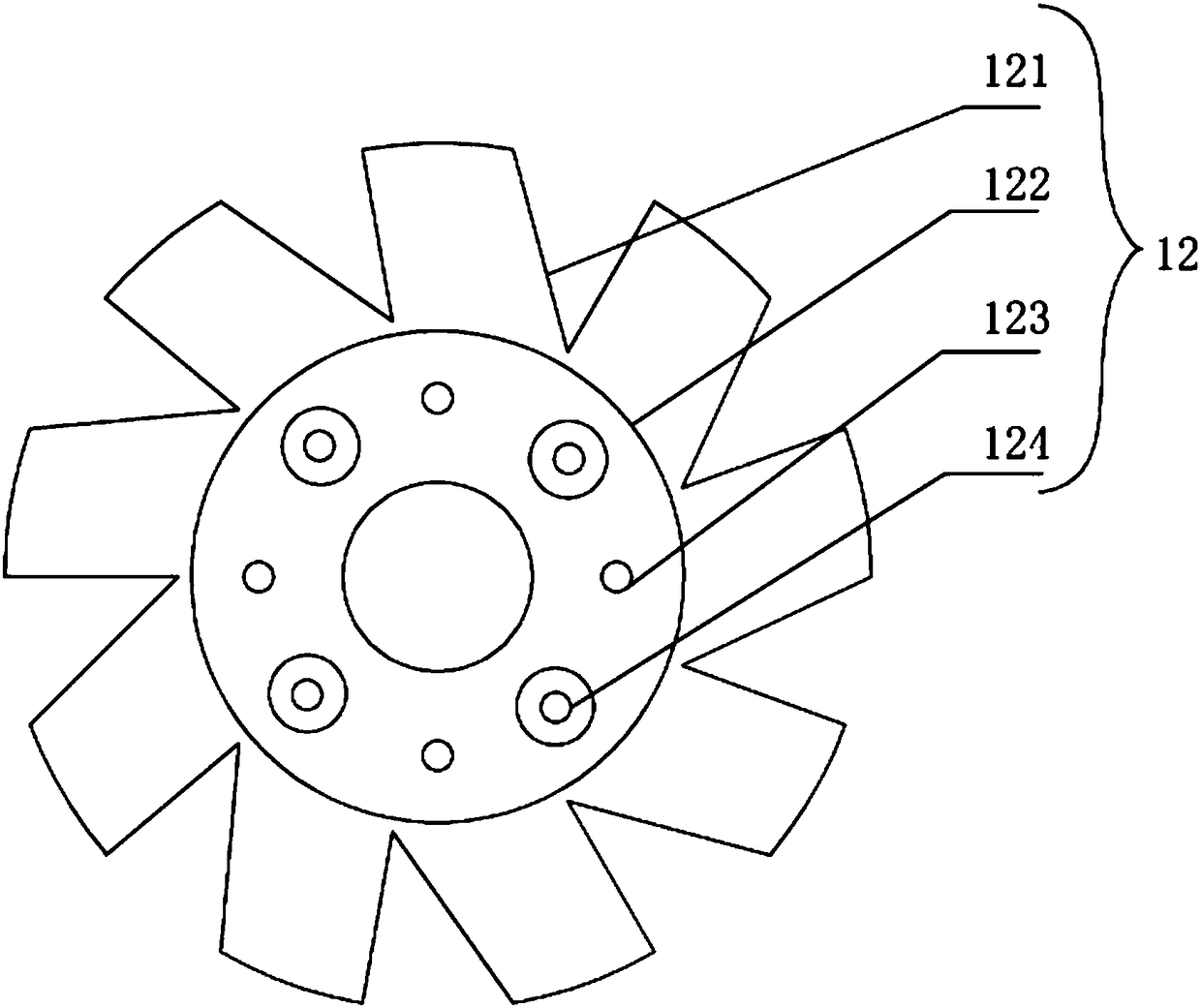

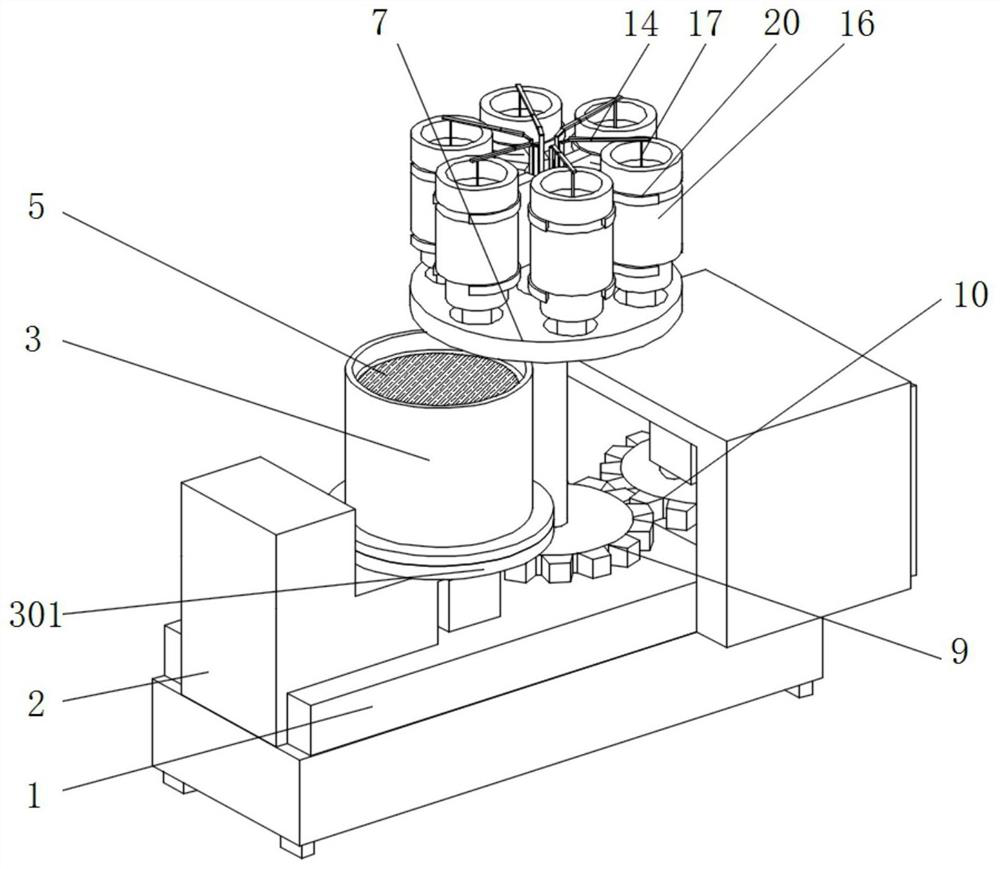

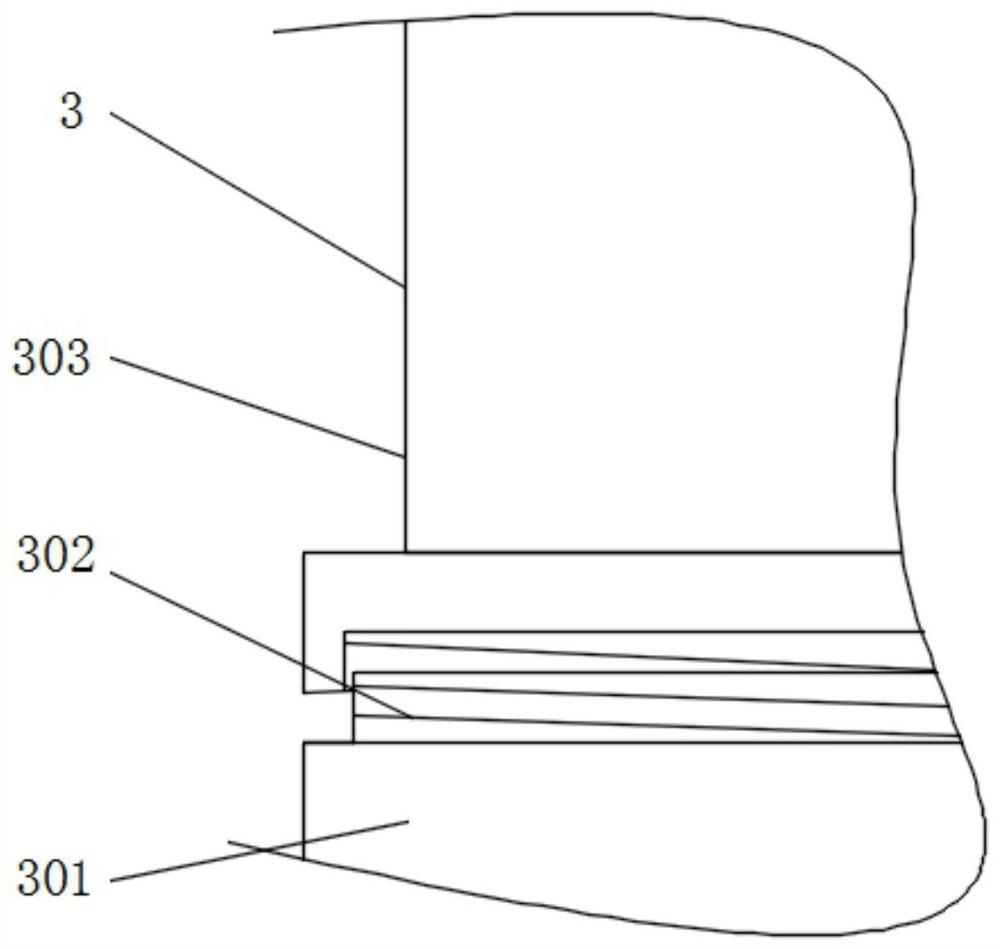

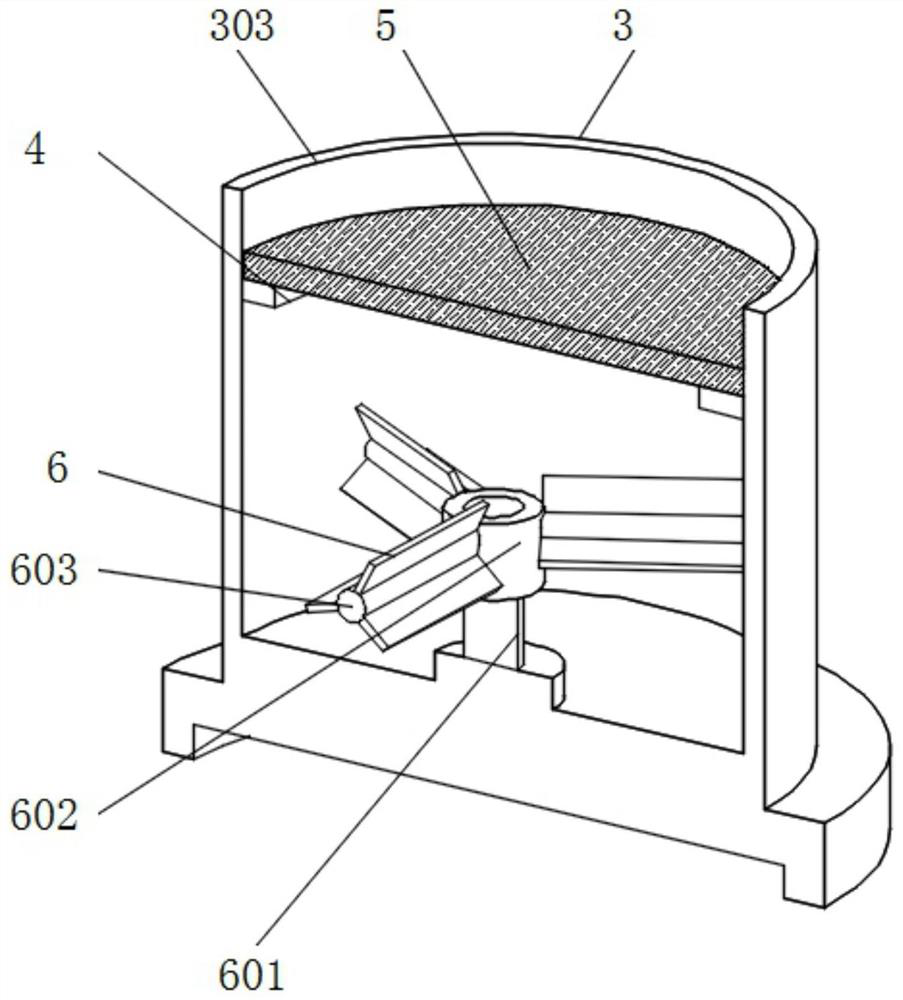

Positive electrode homogenizing device for lithium battery processing

InactiveCN112169640AQuality improvementImprove the mixing effectElectrode manufacturing processesRotary stirring mixersLiquid storage tankEngineering

The invention discloses a positive electrode homogenizing device for lithium battery processing. The device comprises a device body, a first liquid conveying pump, a glue making tank and a second liquid conveying pump, a material conveying pipe and a first motor are arranged at the upper end of the device body, the material conveying pipe is arranged on the left rear side of the first motor, and the second motor is connected with a second rotating shaft; the lower end of the second rotating shaft penetrates through the upper end of the glue making tank and is connected with a second transmission shaft, the second transmission shaft is rotatably connected to the inner top end of the glue making tank, the second liquid conveying pump is arranged at the lower end of the glue making tank, theend, away from the second liquid conveying pump, of a second connecting pipe is communicated with the upper end of a liquid storage tank, and a third liquid conveying pump is connected with a third connecting pipe. According to the positive electrode homogenizing device for lithium battery processing, a proper amount of a binder in a binder tank is added into the glue making tank, a proper amountof a solvent is added through a solvent feeding port, and the solvent and the binder are premixed and stirred through the second transmission shaft and a second stirring blade under the action of thesecond motor, so that subsequent mixing processing is facilitated.

Owner:江苏英能新能源科技有限公司

Material charging device for pet feed processing

PendingCN112493517AImprove mixing efficiencyEasy to cleanFeeding-stuffHollow article cleaningFeed processingProcess engineering

The invention discloses a material charging device for pet feed processing, and the material charging device for pet feed processing comprises a material charging box, the outer side of the top of thematerial charging box is connected with material charging pipes, a stirring pipe is mounted at the top of the material charging box in a moving mode, a first gear is fixedly connected to the top of the stirring pipe, a transmission assembly is fixedly connected to the right side of the top of the material charging box, the bottom of the material charging box is fixedly connected with a gate valve, and the bottom of the gate valve is connected with a conveying pipe. Through cooperative use of the material charging box, the material charging pipes, the stirring pipe, the first gear, the transmission assembly, the gate valve, the conveying pipe, a heating and mixing assembly and an anti-blocking conveying and material charging mechanism, the invention solves problems that the existing material charging device for feed processing can not mix and heat a variety of auxiliary materials in advance, resulting in poor reaction efficiency after material charging, and synchronous charging of a variety of auxiliary materials is prone to causing material blocking and falling in blocks, resulting in feed processing quality reduction. Therefore, the material charging device of the invention has advantages of heating-mixing and anti-blocking.

Owner:GUANGDE YOUWEIFANG PET FOOD

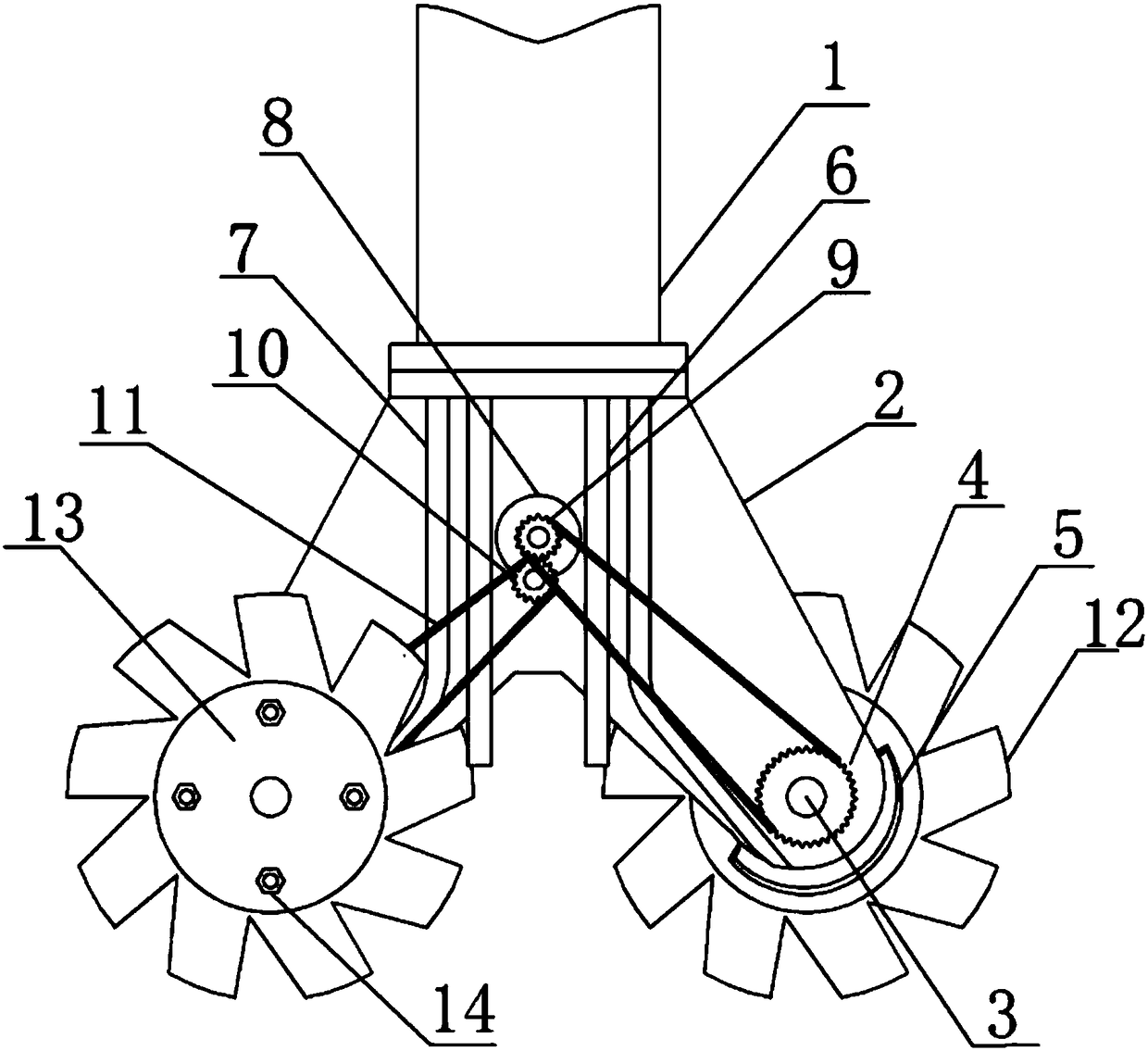

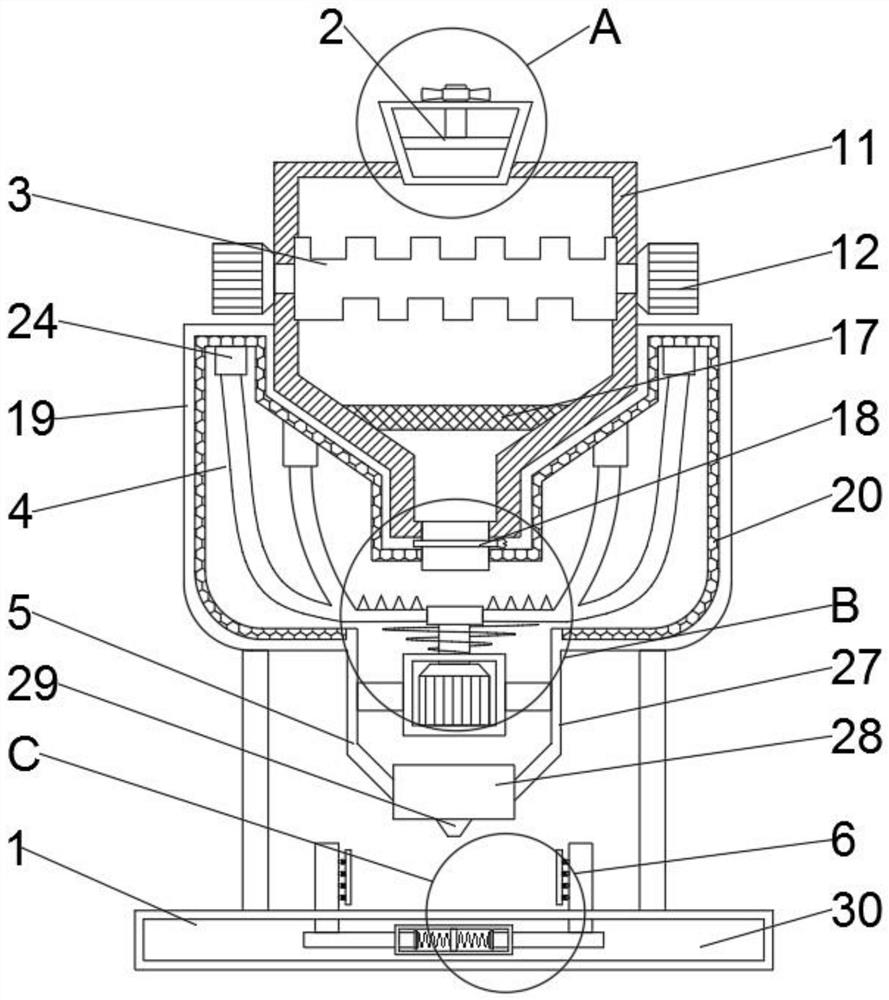

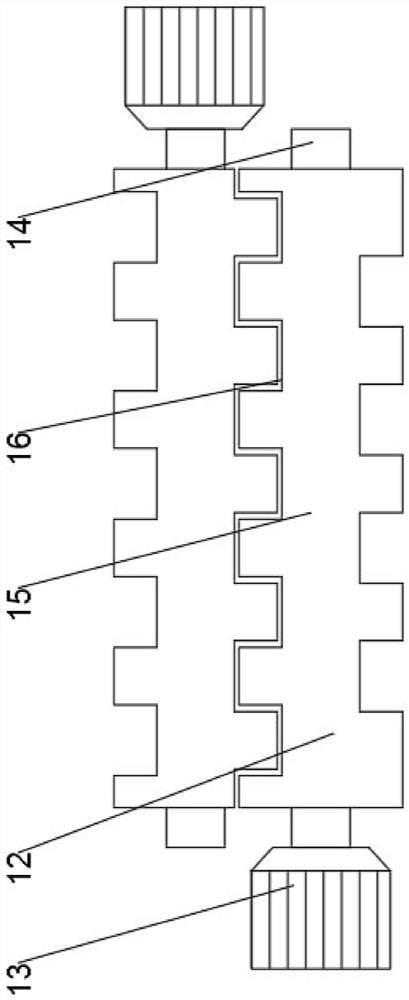

Hydraulic double-wheel milling deep mixer

PendingCN108487235ASo as not to damageEasy to mix and processBulkheads/pilesSlurry wallHydraulic motor

The invention discloses a hydraulic double-wheel milling deep mixer and belongs to the technical field of underground diaphragm wall construction. The hydraulic double-wheel milling deep mixer comprises a mounting rod, mud feeding pipelines and air supply pipelines. A mounting mechanism is mounted at the bottom of the mounting rod, rotating shafts are arranged in the inner cavities of the left andright ends of the bottom of the mounting mechanism. A motor rack is mounted on the surface of a rotating shaft of a hydraulic motor, a transmission gear is mounted in the inner cavity of the mountingmechanism through a mounting shaft, the surface of the transmission gear and the surface of the motor gear are buckled, and chains are mounted on the surface of the motor gear and the surface of thetransmission gear. The mud feeding pipelines and the air supply pipelines on the surface of the motor gear are all arranged in the inner cavity of the mounting rod, and the two mud feeding pipelines of the same structure penetrate through the inner cavity of the mounting mechanism. According to the hydraulic double-wheel milling deep mixer, walls of different widths are mixed and machined conveniently, and at the same time, the quality of machining is ensured.

Owner:江苏科弘岩土工程有限公司

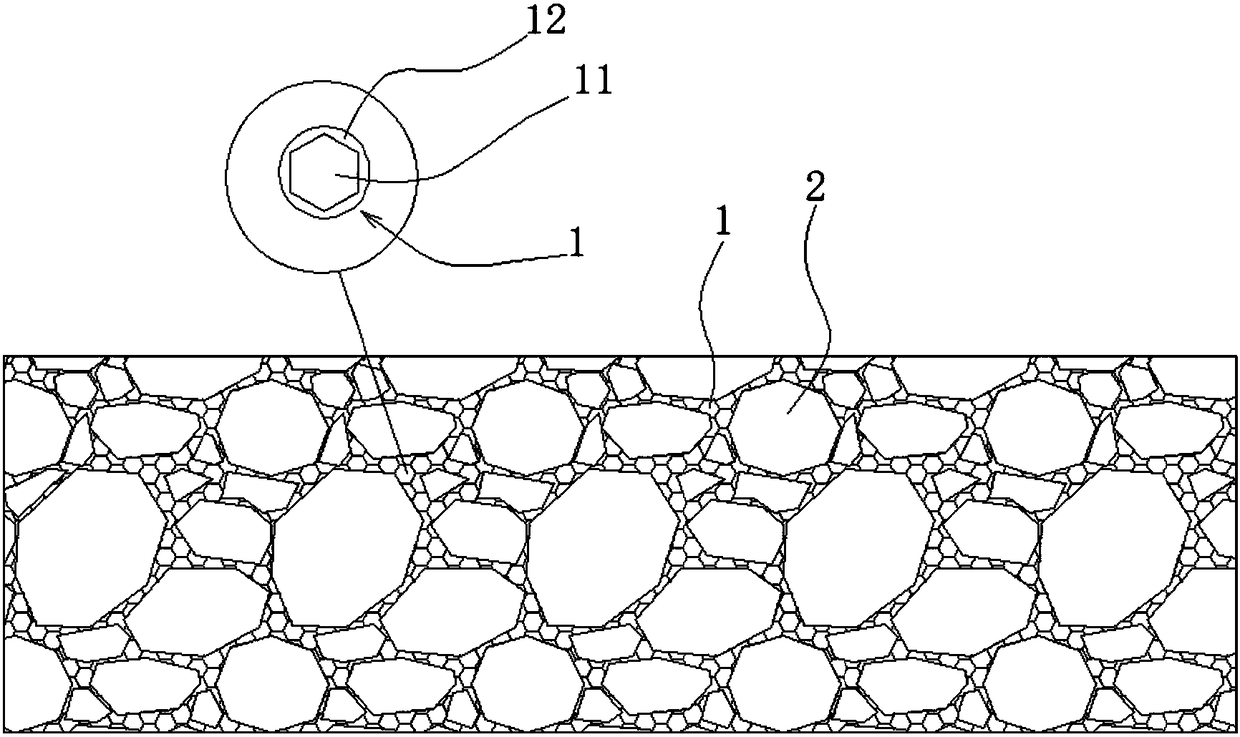

Mixing process and filling unit for vacuum stone

The invention discloses a mixing process and a filling unit for vacuum stone. The mixing process comprises the following steps: preparation of the filling unit: mixing a fine-particle-size solid granular filler with a liquid filler and allowing a soft liquid filling film to be formed on the surface of the solid granular filler; and mixing: mixing granular aggregates of different particle sizes with the filling unit to prepare a mixture. The invention provides the brand-new mixing process for the vacuum stone; according to the process, the fine-particle-size solid granular filler is mixed withthe liquid filler to prepare the filling unit, and the filling unit is then mixed granular aggregates of different particle sizes; and the process allows the liquid filler to be mixed with only fine-particle-size solid particles, so use amount is small, environment protection is realized, and stirring and processing are facilitated. During shaping of the vacuum stone in the mixing process, the filling unit is used for filling gaps among the filling granular aggregates, and the gaps among the granular aggregates are filled in and compacted, so air is discharged to form the vacuum stone.

Owner:ANHUI UISTONE GREEN MATERIAL HI TEC CO LTD

A kind of coated calcium chloride and preparation method thereof

ActiveCN104585480BEnsure safe passageImprove bioavailabilityAccessory food factorsWorking-up animal fodderHydrogenated Palm OilChloride

The invention discloses a coated calcium chloride and a preparation method thereof. The coated calcium chloride comprises the following raw materials in parts by weight: 5-20 parts of hydrogenated palm oil; 5-20 parts of hydrogenated castor oil; silicon dioxide 4 to 30 parts; 1 to 20 parts of fatty acid calcium; 60 to 85 parts of calcium chloride. In the present invention, hydrogenated palm oil, hydrogenated castor oil, silicon dioxide and fatty acid calcium are used as packaging materials, calcium chloride is used as a core material, and coated calcium chloride that can be used as a feed additive is obtained through multiple granulation and coating techniques. The coated calcium chloride not only makes up for the moisture-absorbing defect of the calcium chloride raw material, but also ensures that the calcium chloride passes through the rumen safely and reaches the intestinal tract smoothly, greatly improving the bioavailability of the calcium chloride.

Owner:HANGZHOU KINGTECHINA FEED CO LTD

Processing method of cyclocarya paliurus tea

The invention provides a processing method of cyclocarya paliurus tea, and relates to the field of tea drinks. The processing method of the cyclocarya paliurus tea comprises the following steps of: selecting materials, removing impurities, withering, de-enzyming, rolling and drying. By mixing and processing with mulberry leaf tea, cypress wood sieve is used for processing, and plant ash is used for alkalization, so that the processed mixed tea contains the advantages of traditional cyclocarya paliurus tea and mulberry tea and has the effects of easing pain, calming nerves and relaxing mind; the plant ash can reduce the influence of theanine, the weakly alkaline tea is more beneficial to human bodies, the dirt content of the obtained mixed tea is relatively low, and a drinker can drink themixed tea more securely.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE +1

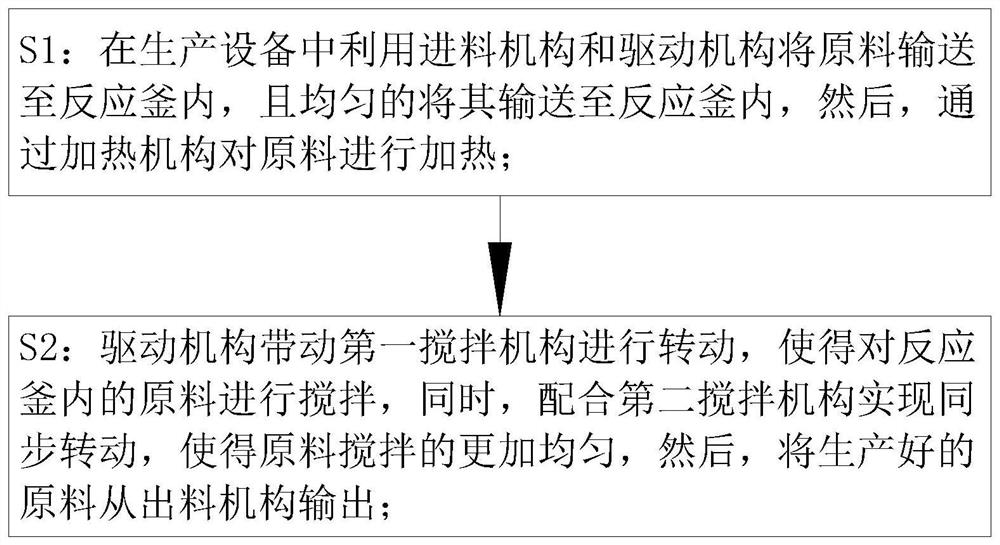

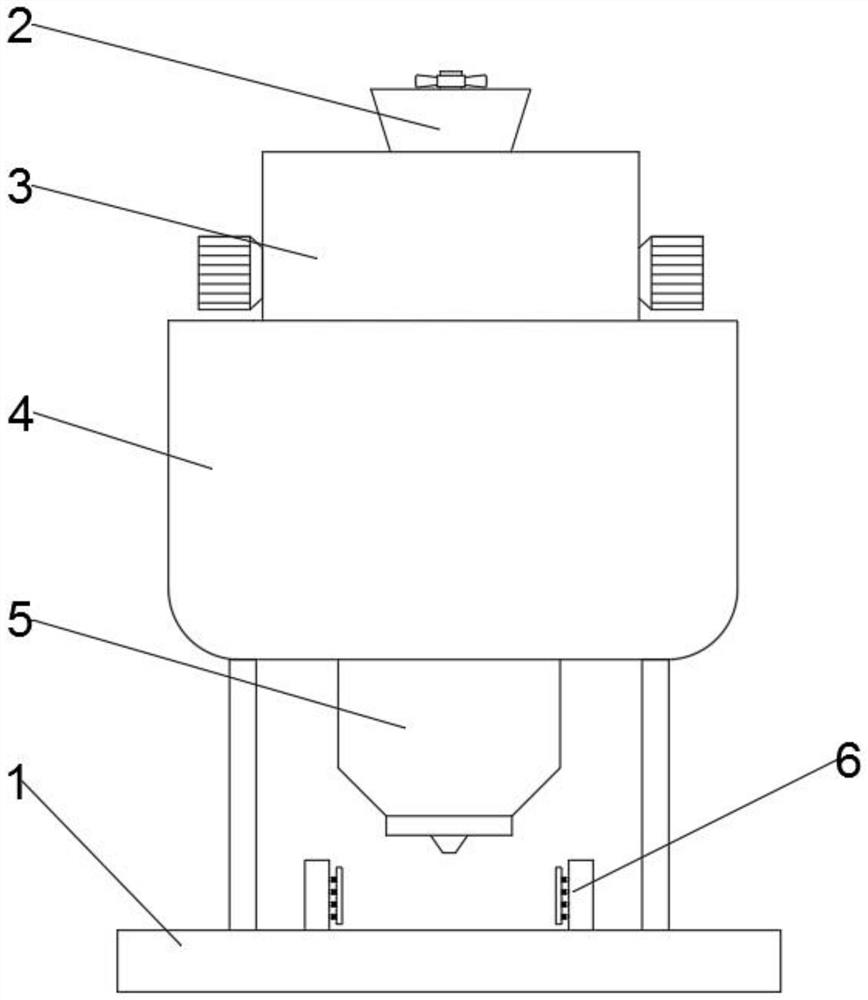

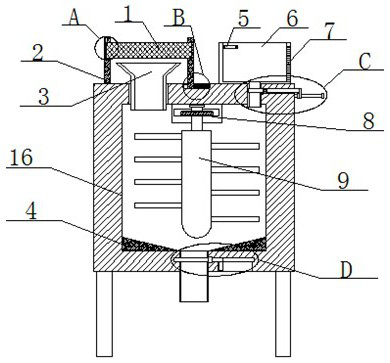

Production method of stone-like paint

InactiveCN111744446AImprove stirring efficiencyImprove the mixing effectChemical/physical/physico-chemical stationary reactorsFeed devicesElectric machineProcess engineering

The invention relates to the field of stone-like paint production and relates to a production method of stone-like paint. According to the method, production equipment comprises a hollow reaction kettle; a first stirring structure is arranged in the reaction kettle; a plurality of second stirring mechanisms are arranged in the first stirring mechanism; the upper surface of the reaction kettle is fixedly connected with a driving mechanism; when the production equipment is used, a driving motor is started; the driving motor drives first stirring rods to rotate through a rotating rod, so that rawmaterials in the reaction kettle are stirred through the first stirring rods, meanwhile, the first stirring rods drive fixed sleeves to rotate through fixed rods; second stirring rods are clamped with positioning blocks through positioning grooves, so that the fixed sleeves drive the second stirring rods to rotate while driving the second stirring rods to move, the raw materials in the reaction kettle are stirred again; and therefore, the stirring efficiency and stirring effect of the reaction kettle are improved, and the heating effect and the processing efficiency of the internal raw materials are further improved.

Owner:孔瑞扬

Antibacterial spectacle lens and manufacturing process thereof

The invention relates to the technical field of spectacle lenses, and in particular, relates to an antibacterial spectacle lens and a manufacturing process thereof. The antibacterial spectacle lens iscomposed of the following components in percentage by weight through extrusion and curing: 70 to 80 parts of allyl diglycol carbonate, 5 to 8 parts of polypropylene glycol, 2 to 3 parts of nano silicon dioxide, 0.5 to 1 part of silver ions, 0.5 to 1 part of zinc ions, 5 to 8 parts of an organic solvent and 2 to 4 parts of glass microparticles. The manufacturing process of the antibacterial spectacle lens comprises the following operation steps: step 1, weighing all the components of any one of the antibacterial spectacle lenses in claims 1-2 in percentage by weight, adding the weighed components into a grinding tank, and stirring and grinding; step 2, adding the components stirred and ground in the step 1 into a double-screw extruder, and carrying out melt extrusion; and step 3, carryingout injection molding through a mold. The spectacle lens provided by the invention has a lasting antibacterial function and strong light transmission.

Owner:江苏斯丹德检验认证有限公司

Plastic antibacterial agent as well as preparation method and application thereof

The invention relates to the technical field of antibiosis, in particular to a plastic antibacterial agent as well as a preparation method and application thereof. The nano-silver antibacterial agent disclosed by the invention is prepared by loading silver ions on zirconium phosphate exchange, and is compounded with nano-zinc oxide, so that the nano-silver antibacterial agent has broad-spectrum antibacterial property. The invention relates to a superfine powder with uniform granularity, which has extremely low hygroscopicity and high heat resistance and can be easily mixed and processed in fibers, films and plastic resin molded products. The physical and chemical properties are very stable, and the dyeing resistance and the discoloration resistance are excellent in the processing process and the using process. The product has very high safety and passes multiple environmental protection safety tests.

Owner:广东赞誉防霉科技有限公司

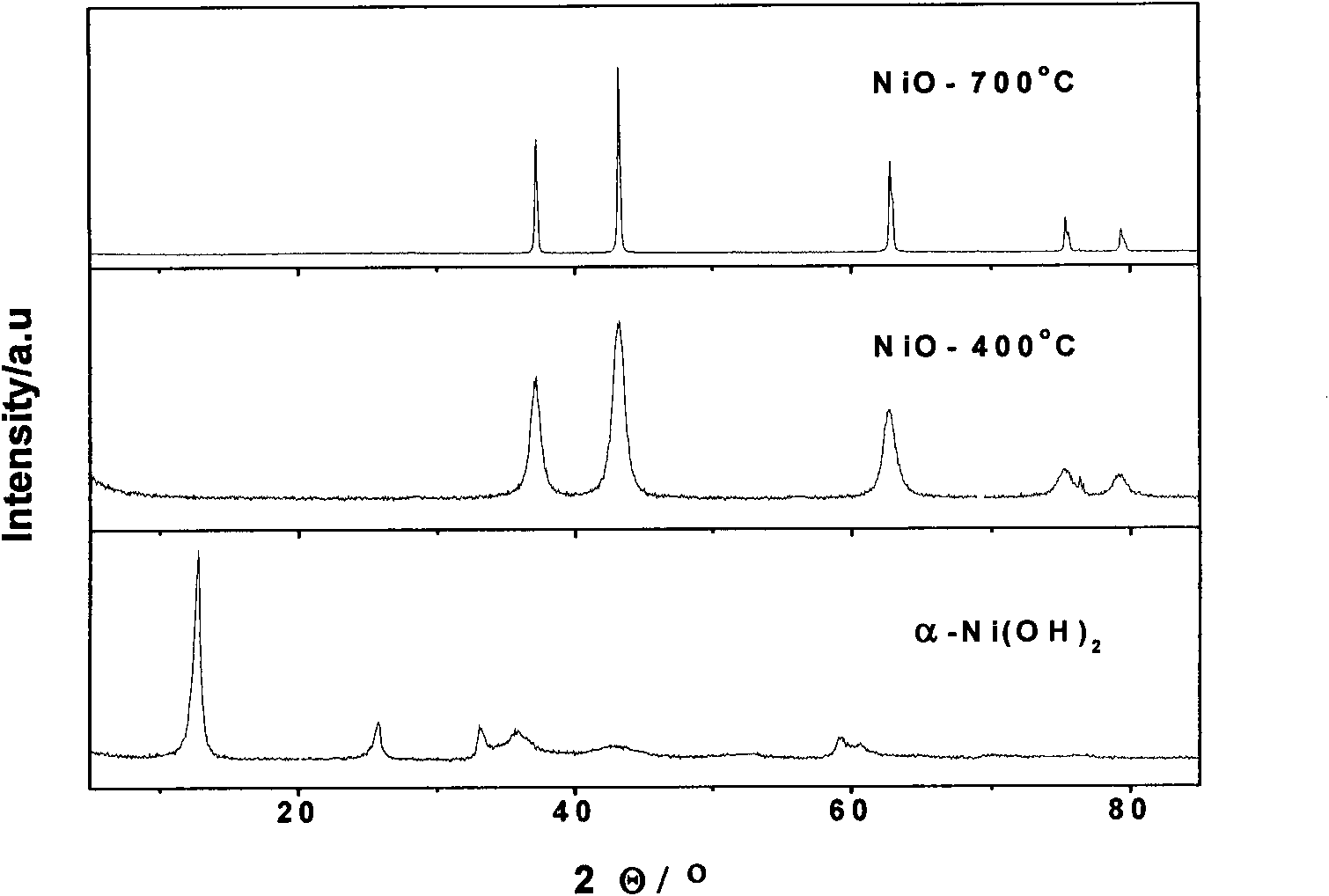

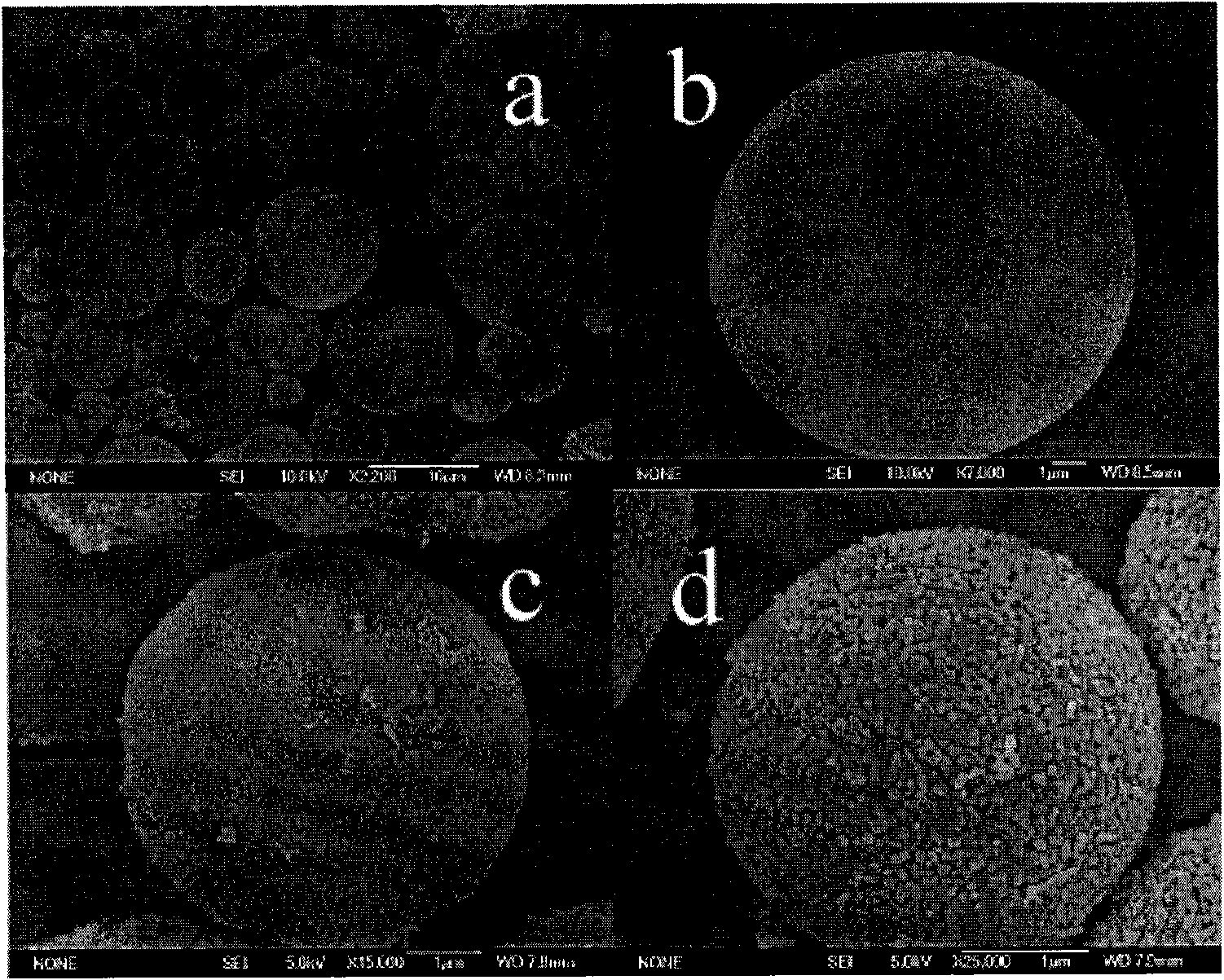

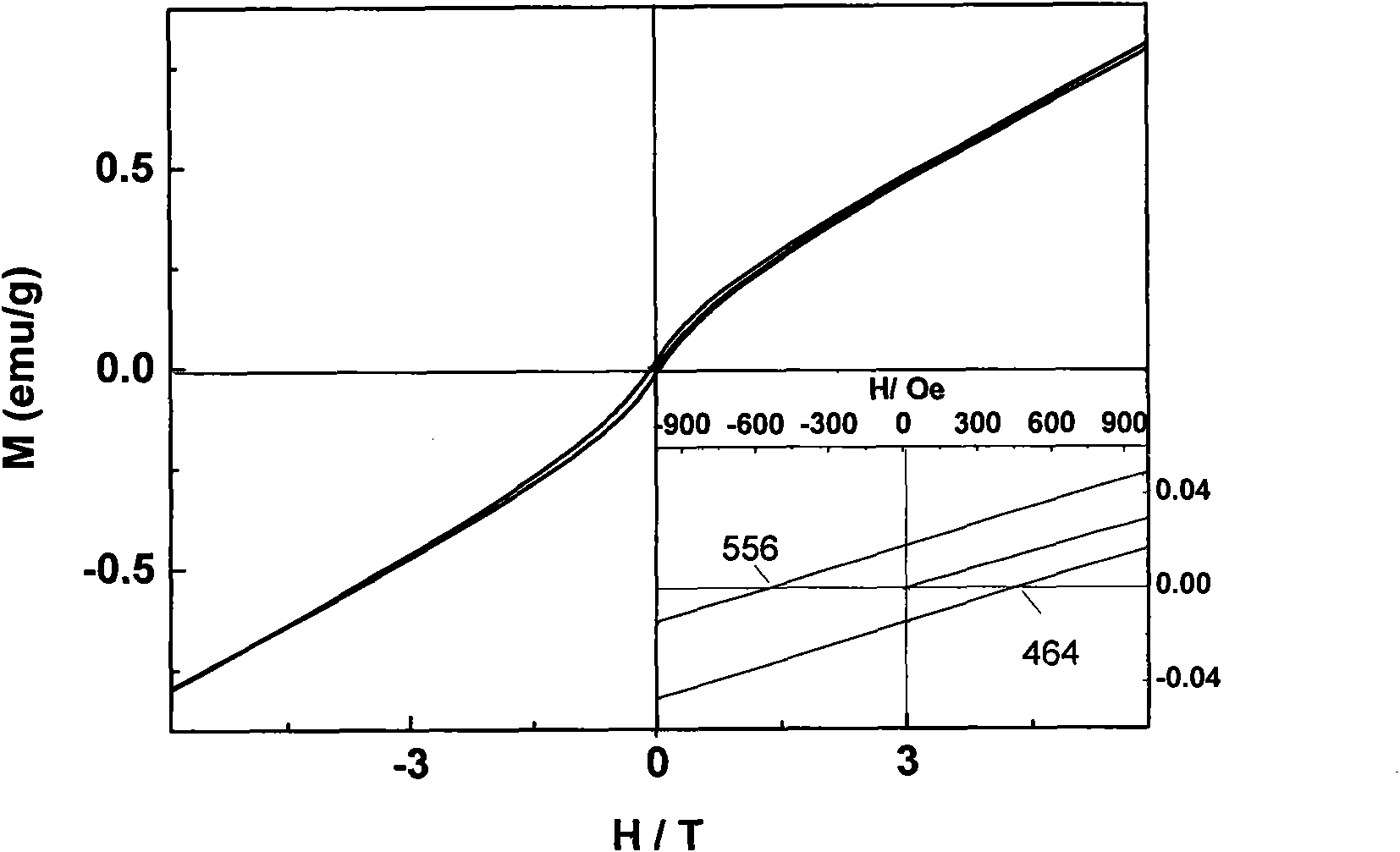

Nickel oxide microspheres with ferromagnetism and excellent electrochemical performance and synthetic method thereof

InactiveCN101830522ASimple preparation techniqueLow equipment requirementsElectrode manufacturing processesNickel oxides/hydroxidesMicrosphereRoom temperature

The invention relates to nickel oxide microspheres with ferromagnetism and excellent electrochemical performance and a synthetic method thereof. The preparation method comprises the following steps of: preparing alpha-Ni(OH)2 spherical precursors in a hydrothermal environment in the absence of template agent and alkali, and then sintering the precursors at the temperature of above 300 DEG C to form pure-phase nickel oxide microspheres. The size of the nickel oxide microspheres is 1 to 5 microns, each microsphere is assembled by 10 to 100 nanometers, the microspheres have obvious room temperature ferromagnetism, the coercive force of the microspheres can reach 500Oe, the obtained nickel oxide microspheres serve as an electrode material for a lithium ion battery, and the primary discharge capacity of the nickel oxide microspheres is 918mAh / g.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Rice growth balance regulating mixing device with automatic proportioning function

InactiveCN113069963AEasy to installProtect against splashingRotary stirring mixersTransportation and packagingBLENDER/MIXERAgricultural engineering

The invention discloses a rice growth balance regulating agent mixing device with an automatic proportioning function, and belongs to the field of rice growth balance regulating agent mixing devices. A rice growth balance regulating mixing device with an automatic proportioning function comprises a base and a stirring mechanism, a fixing frame is arranged at the top of the base, a mixing box is arranged at the top of the fixing frame, a fixing buckle is arranged on the inner wall of the mixing box, and a splash-proof net is arranged at the top of the fixing buckle. The stirring mechanism is arranged in the mixing box, a rotating frame is arranged on the side of the mixing box, a supporting rod is arranged at the bottom of the rotating frame, and a first gear is arranged on the outer side of the supporting rod; and the stirring mechanism is arranged, the rotating frame in the equipment can be directly controlled to rotate and adjust feeding according to needs, the corresponding batching barrels are controlled to open and close for discharging, stirring, mixing and processing below are facilitated, batching residues can be visually observed, automatic proportioning and mixing are facilitated, and meanwhile, material supplementing operation is facilitated.

Owner:HENAN ACAD OF AGRI SCI INST OF GRAIN CROPS

Stirring device for investment casting wax liquid

InactiveCN112569842AAvoid wastingReduce production efficiencyRotary stirring mixersTransportation and packagingInvestment castingProcess engineering

The invention discloses a stirring device for investment casting wax liquid. The stirring device comprises a rack, a feeding assembly, a grinding assembly, a stirring assembly, a discharging assemblyand a clamping assembly. The feeding assembly, the grinding assembly, the stirring assembly and the discharging assembly are sequentially connected in the working direction and arranged on the rack. The clamping assembly is arranged on the rack and located below the discharging assembly. The feeding assembly is arranged at the feeding end of the grinding assembly. By arranging the grinding assembly, wax block raw materials used for investment casting are smashed, the situation that due to the fact that the wax block raw materials are rough, the heating and stirring time is too long, energy waste is caused, and the production efficiency is reduced is avoided; the wax block is pretreated, so that the later stirring efficiency is improved; by arranging the stirring assembly and a stirring rodwith the stirring teeth, the stirring efficiency is improved, and the stirring process is accelerated; a guide piece is arranged, so that the stirring rod is prevented from being broken due to overlarge stress; by arranging a screw rod, guiding is conducted at the discharging end of a stirring hopper, and wax liquid is prevented from being blocked in the stirring hopper.

Owner:上海万泽精密铸造有限公司

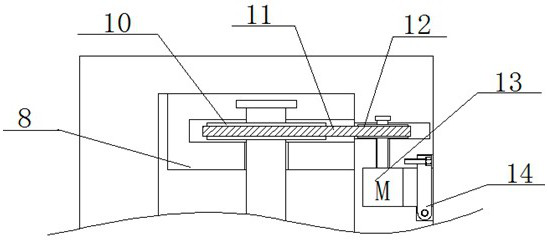

Rapid cement stirring equipment for constructional engineering

InactiveCN112847789AEasy to mix and processEasy to useDischarging apparatusCement mixing apparatusArchitectural engineeringMechanical engineering

The invention discloses rapid cement stirring equipment for constructional engineering. The equipment comprises a shell, wherein two supporting rods are fixedly installed at the bottom of the shell, a cavity is formed in the shell, a feeding port and a water inlet are formed in the top of the shell and communicate with the interior of the cavity, a funnel pipe is fixedly installed in the feeding port, an installation rod is fixedly installed at the top of the shell, a limiting net is fixedly installed on one side of the installation rod, a connecting spring groove is formed in the shell, a connecting spring is fixedly installed in the connecting spring groove, and a sliding rod is fixedly installed on one side of the connecting spring. According to the installation, cement and water can be conveniently stirred, mixed and processed, the time needed for mixing and stirring is shortened, adverse effects caused by too much or too little mixed water are avoided, the using effect of cement is improved, and construction of building engineering is facilitated.

Owner:徐广鑫

Preparation method of special color master batch for EVA shoe material

The invention belongs to the technical field of preparation of special color master batches, and particularly relates to a preparation method of a special color master batch for an EVA shoe material, which comprises the following steps: S1, mixing EVA carrier resin, pigment and filler, and adding into an internal mixer for internal mixing; s2, adding the internally mixed material blocks obtained in the step S1 into an open mill for thin-passing to obtain crushed material blocks; s3, mixing the crushed material blocks obtained in the step S2 with EVA wax, a coupling agent, a stabilizer, an antioxidant and a lubricant, and adding the mixture into an internal mixer for internal mixing; s4, adding the internally mixed material blocks obtained in the step S3 into a screw extruder for extrusion, granulating through a granulator, filtering the mixture through a screen to remove substandard products, and ventilating and cooling the mixture to obtain the special color master batch for the EVA shoe material. According to the special color master batch for the EVA shoe material, the EVA carrier resin is taken as a basic raw material, so that the colorability is good, and the special color master batch can be conveniently mixed with other raw materials for processing and forming.

Owner:淮安腾达色母有限公司

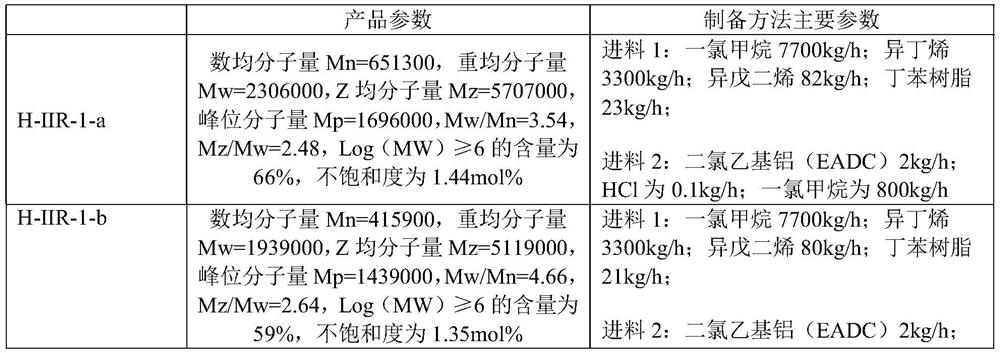

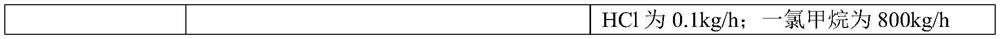

Rubber matrix for butyl rubber sealing plug, composition, vulcanized rubber and preparation method thereof

ActiveCN114106477AImprove mechanical propertiesGood physical and mechanical propertiesPolymer scienceVulcanization

The invention relates to the field of vulcanized rubber, and discloses a rubber matrix for a butyl rubber sealing plug, a composition, vulcanized rubber and a preparation method of the vulcanized rubber. The rubber matrix contains low-unsaturation high-molecular-weight butyl rubber and high-unsaturation middle-low-molecular-weight butyl rubber; the content weight ratio of the low-unsaturation high-molecular-weight butyl rubber to the high-unsaturation medium-low-molecular-weight butyl rubber is 100: (3-25); the butyl rubber with low unsaturation degree and high molecular weight has the characteristic of bimodal molecular weight distribution. According to the composition containing the rubber matrix for the butyl rubber sealing plug, provided by the invention, all the components are matched, so that the obtained vulcanized rubber has higher hardness and lower compression set, and also has more excellent sealing property, thermo-oxidative aging resistance and dimensional stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com