Rubber matrix for butyl rubber sealing plug, composition, vulcanized rubber and preparation method thereof

A technology of butyl rubber and rubber matrix, which is applied in the field of vulcanized rubber, can solve problems such as dependence, and achieve the effects of avoiding migration, good physical and mechanical properties, and easy mixing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

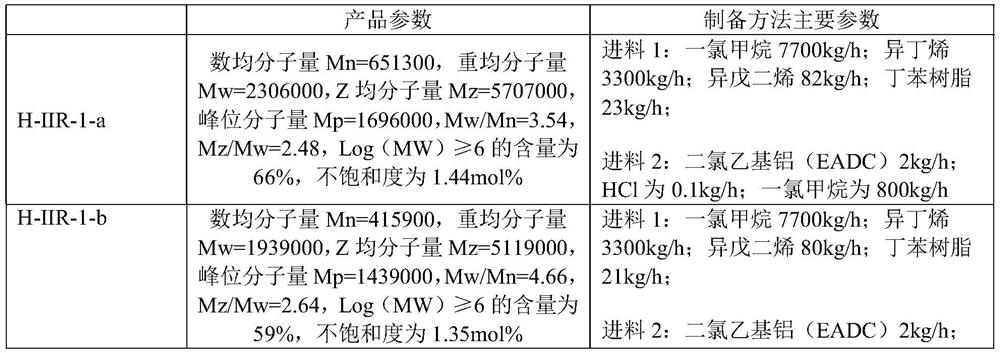

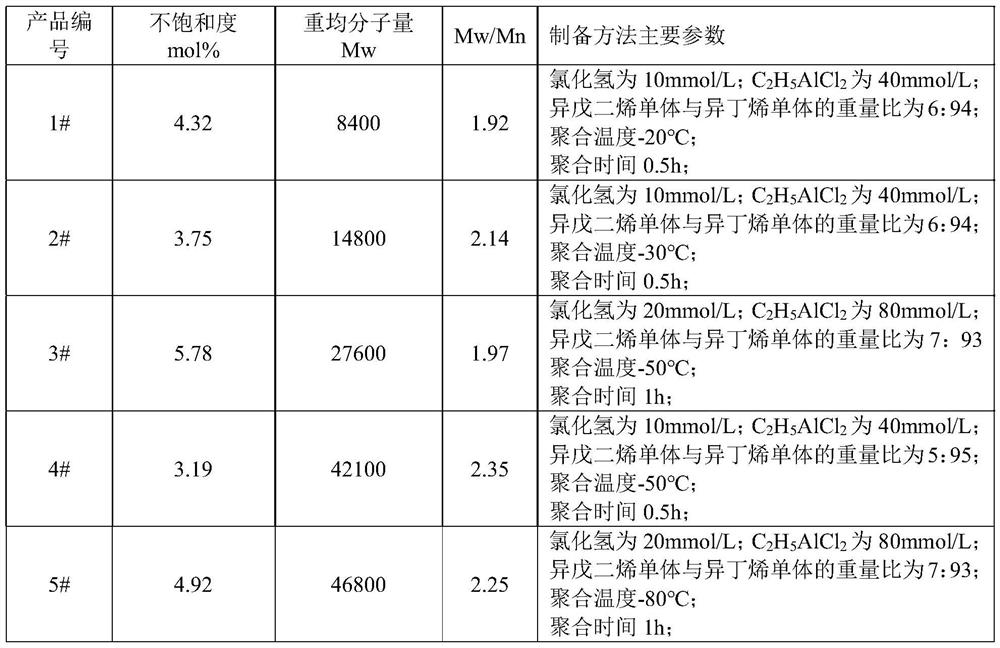

preparation example Construction

[0052] In the method for preparing vulcanized rubber of the present invention, it may also include discharging the mixed rubber for a period of time, for example, for 3-5 hours.

[0053] In the method for preparing vulcanized rubber of the present invention, it may also include that the second-stage mixed rubber is thinned longitudinally in an open mill, for example, for 6 times, and then sheeted.

[0054] Exemplarily, the injection molding process described in the present invention includes: weighing - kneading - preformed sheet - vacuum injection molding (primary vulcanization) - furnace setting (secondary vulcanization) - punching - —Cleaning—Packing and warehousing. Among them, the injection molding process, that is, the primary vulcanization process, the temperature is controlled at 200-220°C, the vacuum degree is ≥700mmHg, the pressure is 2-3MPa, and the vulcanization time is 120-300s; the furnace setting process, that is, the secondary vulcanization process, the tempera...

Embodiment 6

[0099] The present embodiment adopts the formula similar to embodiment 1 to carry out, and difference is, the butyl rubber (1#) of low molecular weight in the high degree of unsaturation used in the present embodiment is 3 parts by weight, and all the other are all the same as embodiment 1 The same, the specific formulations are listed in Table 3.

Embodiment 7

[0101] The present embodiment adopts the formula similar to embodiment 1 to carry out, and difference is, the butyl rubber (1#) of low molecular weight in the high degree of unsaturation used in the present embodiment is 25 parts by weight, all the other are all the same as embodiment 1 The same, the specific formulations are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com