Nano-silver antibacterial agent and preparation method and application thereof

An antibacterial agent and nano-silver technology, applied in the field of antibacterial agents, can solve the problems of complex production of nano-silver antibacterial agents, unfavorable industrial production, and restrictions on the development of nano-silver antibacterial agents, and achieve excellent dyeing resistance and anti-discoloration performance, which is conducive to industrialization Production, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of nano-silver antibacterial agent, comprising the steps of:

[0030] Add 25 parts by weight of zirconium phosphate and 5 parts by weight of citric acid to 100 parts by weight of deionized water to form a suspension, then add 0.8 parts by weight of silver nitrate, stir for 12 hours, then add 2 parts by weight of titanate, After continuing to stir for 12 hours, filter, dry, calcinate and pulverize to obtain the nano-silver antibacterial agent.

[0031] Preferably, the titanate is butyl titanate.

[0032] Preferably, the particle size of the zirconium phosphate is 6 μm.

[0033] Preferably, the temperature of the calcination is 800°C, and the time is 2.5h

[0034] As mentioned above, a nano-silver antibacterial agent can be applied to the preparation of anti-mildew degradable resin.

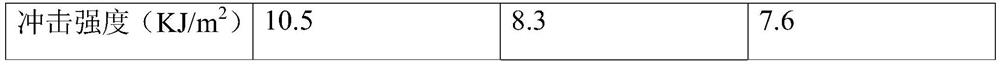

[0035] The mildew-proof degradable resin is composed of 65 parts by weight of polylactic acid, 35 parts by weight of acrylate grafted modified starch, 15 parts by wei...

Embodiment 2

[0041] A preparation method of nano-silver antibacterial agent, comprising the steps of:

[0042] Add 20 parts by weight of zirconium phosphate and 1 part by weight of citric acid to 100 parts by weight of deionized water to form a suspension, then add 0.3 parts by weight of silver nitrate, stir for 2 hours, and then add 1 part by weight of titanate After continuing to stir for 2 hours, filter, dry, calcinate and pulverize to obtain the nano-silver antibacterial agent.

[0043] Preferably, the titanate is butyl titanate.

[0044] Preferably, the particle size of the zirconium phosphate is 5 μm.

[0045] Preferably, the temperature of the calcination is 700°C, and the time is 2h

[0046] As mentioned above, a nano-silver antibacterial agent can be applied to the preparation of anti-mildew degradable resin.

[0047] The mildew-proof degradable resin is composed of 70 parts by weight of polylactic acid, 30 parts by weight of acrylate grafted modified starch, 10 parts by weight o...

Embodiment 3

[0053] A preparation method of nano-silver antibacterial agent, comprising the steps of:

[0054] Add 30 parts by weight of zirconium phosphate and 10 parts by weight of citric acid to 100 parts by weight of deionized water to form a suspension, then add 1.3 parts by weight of silver nitrate, stir for 24 hours, then add 3 parts by weight of titanate, After continuing to stir for 24 hours, filter, dry, calcinate and pulverize to obtain the nano-silver antibacterial agent.

[0055] Preferably, the titanate is butyl titanate.

[0056] Preferably, the particle size of the zirconium phosphate is 7 μm.

[0057] Preferably, the temperature of the calcination is 900°C, and the time is 3h

[0058] As mentioned above, a nano-silver antibacterial agent can be applied to the preparation of anti-mildew degradable resin.

[0059] The mildew-proof degradable resin is composed of 60 parts by weight of polylactic acid, 40 parts by weight of acrylate grafted modified starch, 20 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com