Patents

Literature

1158 results about "Zirconium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

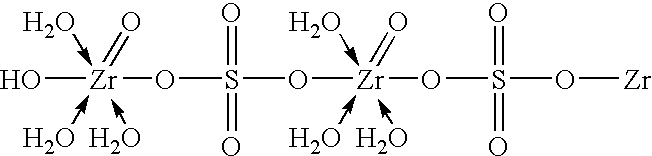

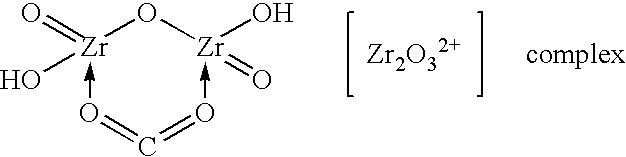

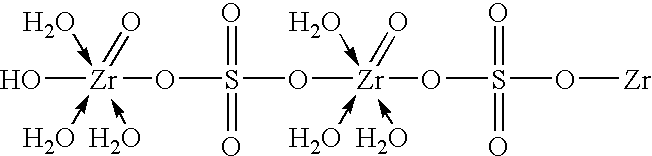

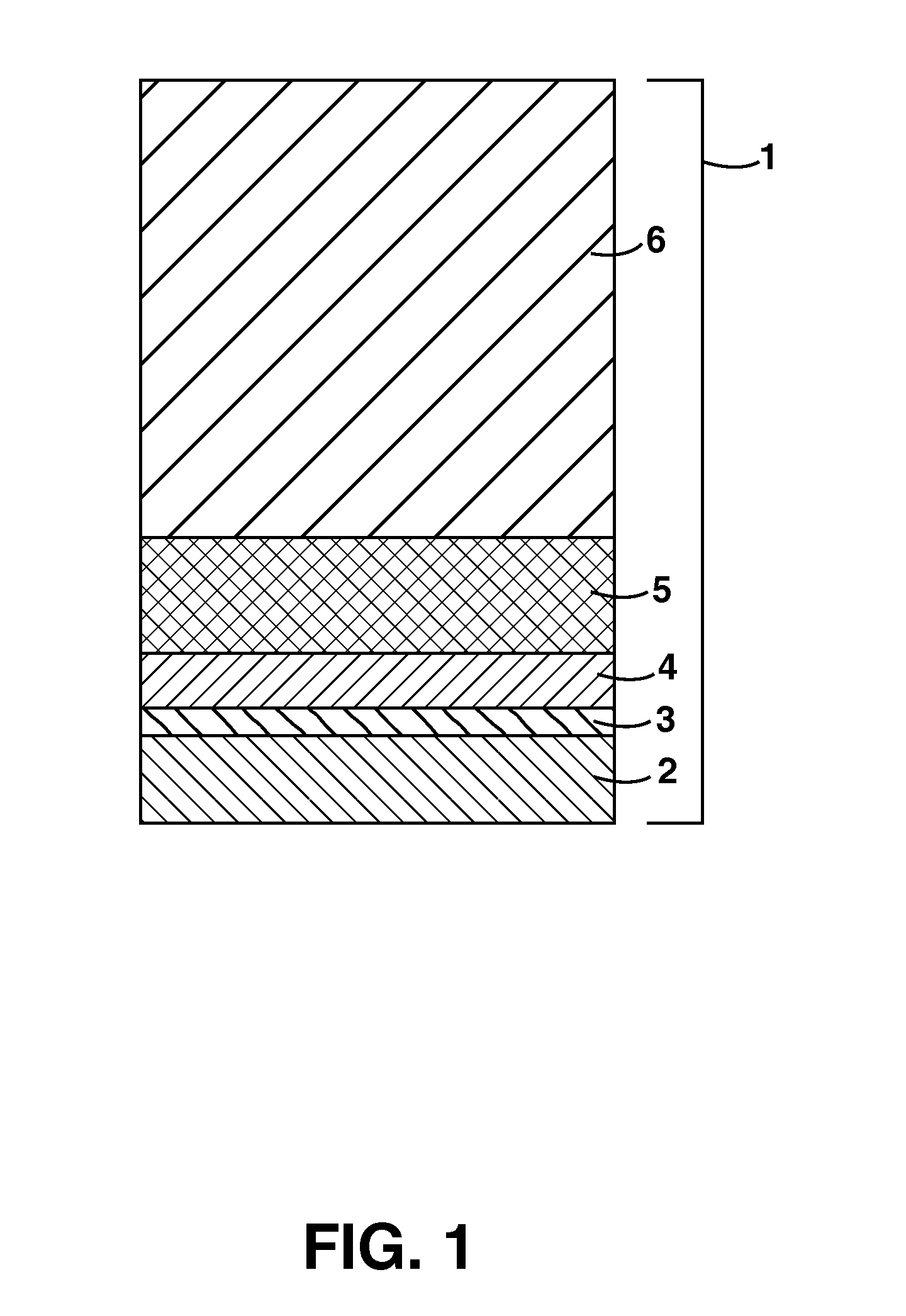

Zirconium phosphates (zirconium hydrogen phosphate) are acidic, inorganic cation exchange materials that have a layered structure with formula Zr(HPO₄)₂∙nH₂O. Zirconium phosphates have high thermal and chemical stability, solid state ion conductivity, resistance to ionizing radiation, and the capacity to incorporate different types of molecules with different sizes between their layers. There are various phases of zirconium phosphate which vary in their interlaminar spaces and their crystalline structure. Among all the Zirconium phosphate phases the most widely used are the alpha (Zr(HPO₄)₂∙H₂O) and the gamma (Zr(PO₄)(H₂PO₄)∙2H₂O) phase. Zirconium phosphate have been widely used in several applications such as: drug delivery, catalysis, nanocomposite, nuclear waste management, clinical dialyzer, among others.

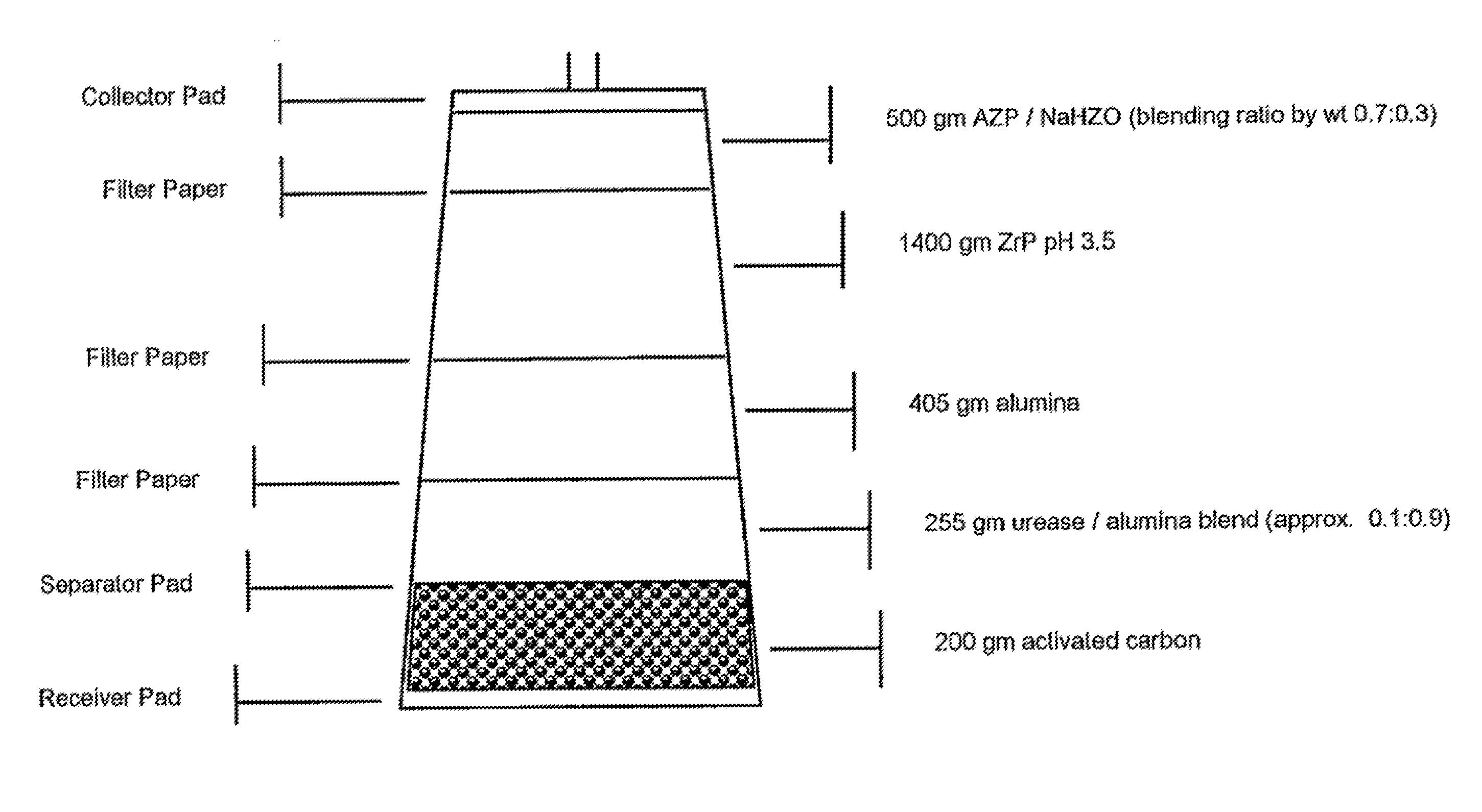

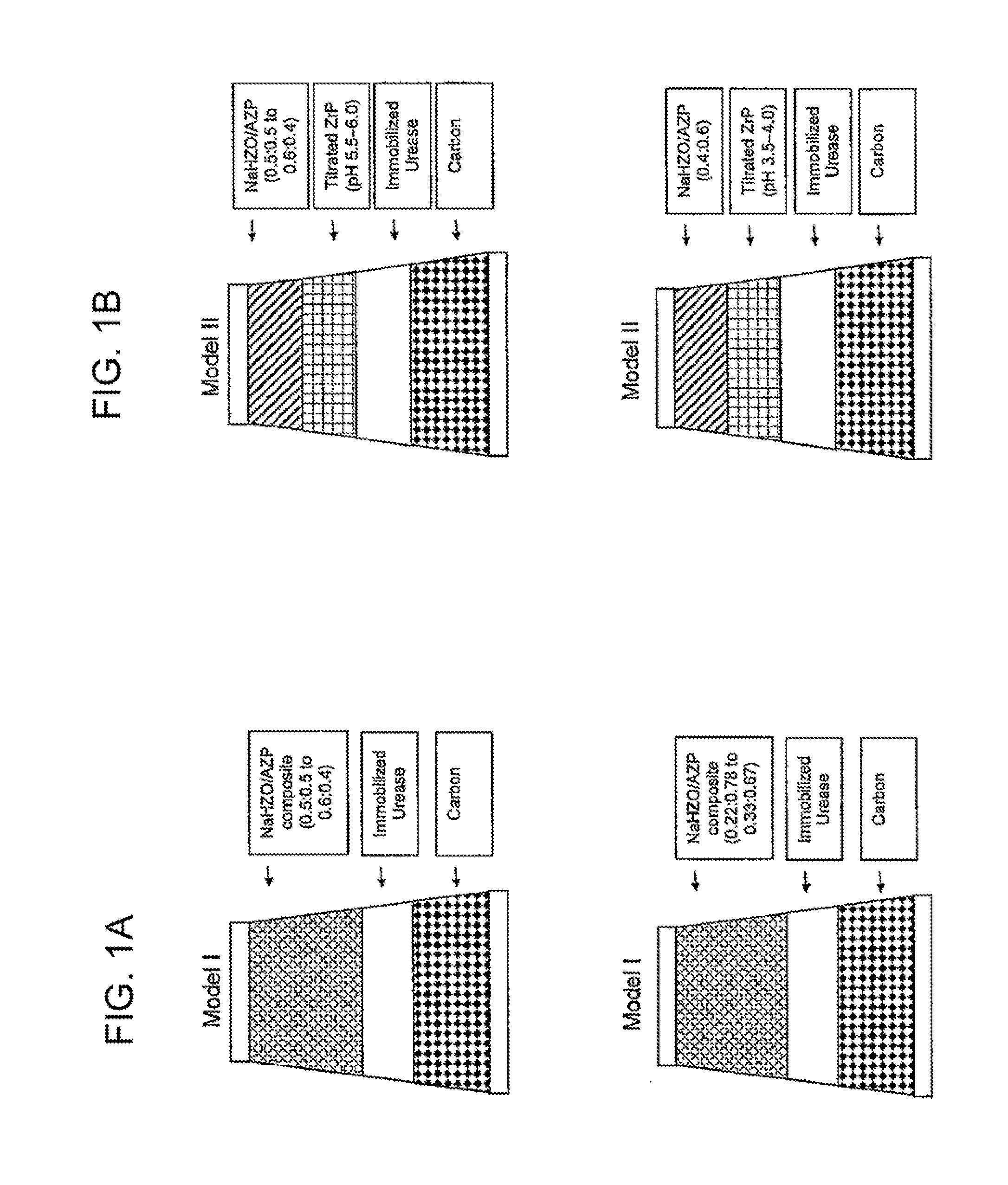

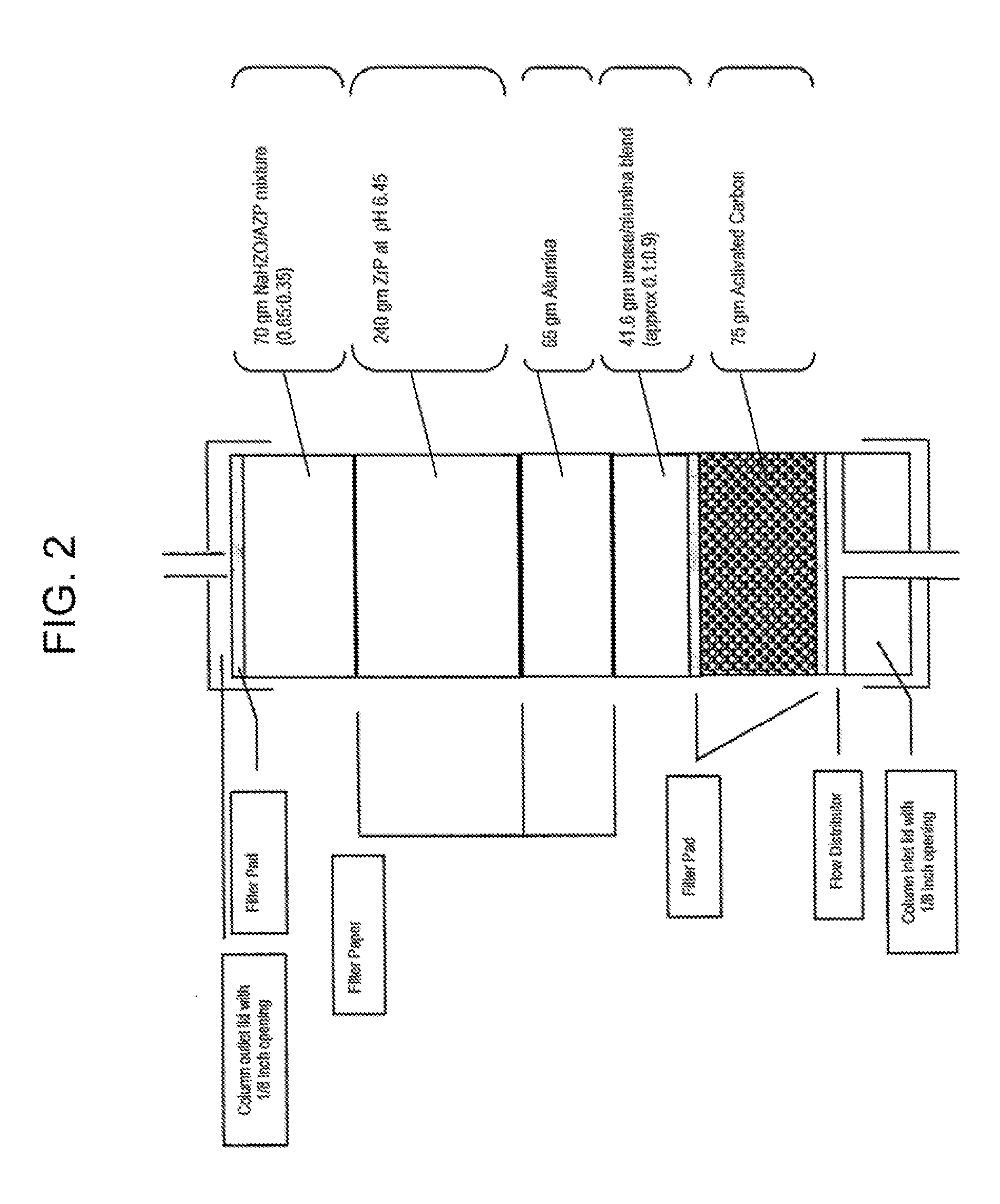

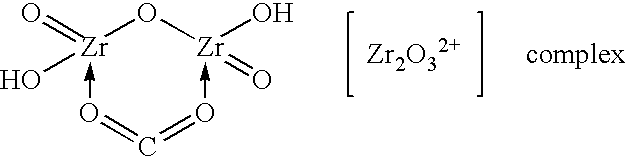

Acid Zirconium Phosphate and Alkaline Hydrous Zirconium Oxide Materials For Sorbent Dialysis

ActiveUS20100078387A1Avoid disadvantagesRestore balanceCation exchanger materialsOrganic anion exchangersIon exchangeDialysis fluid

Owner:FRESENIUS MEDICAL CARE HLDG INC

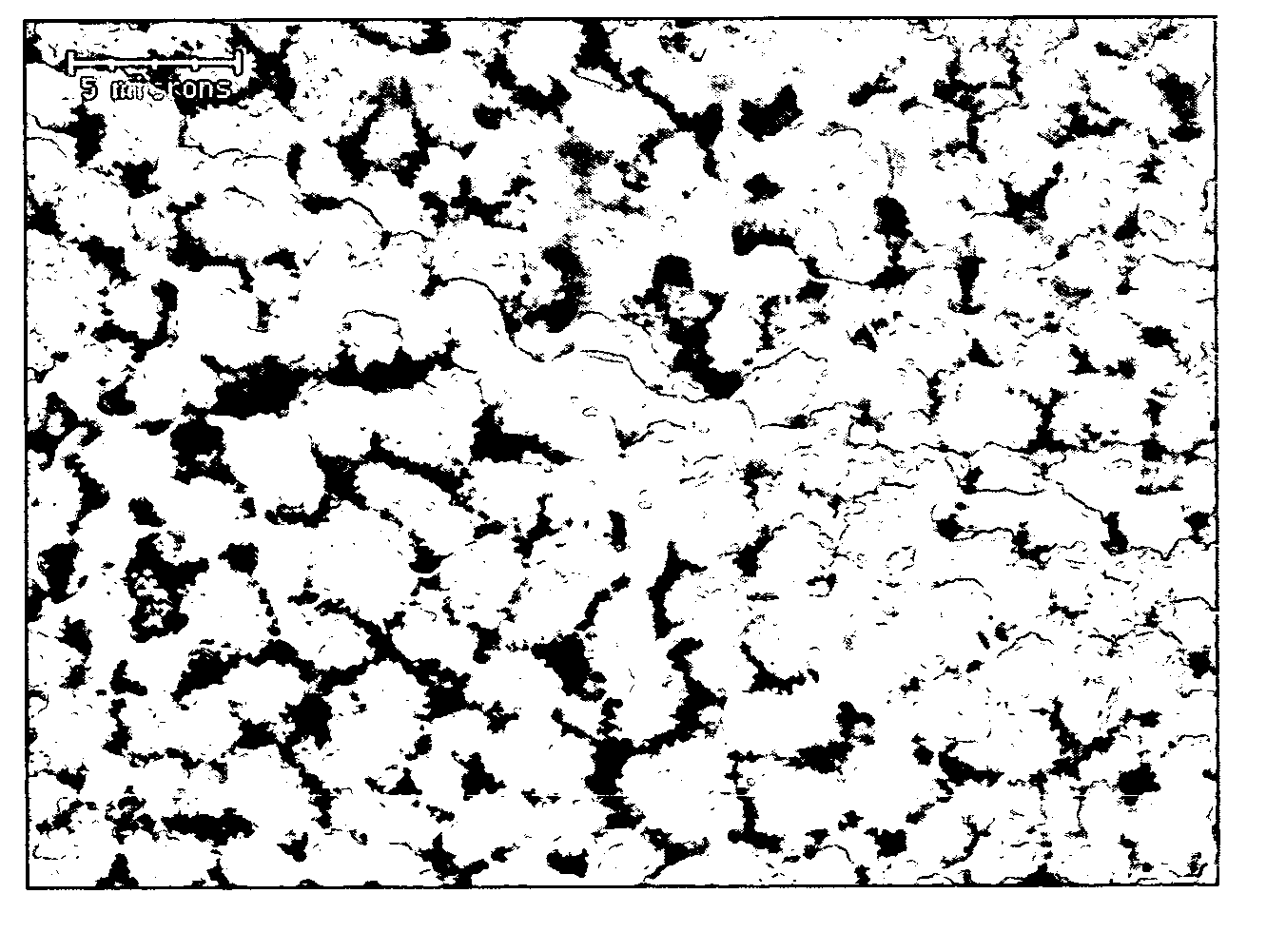

Method of synthesizing zirconium phosphate particles

InactiveUS7566432B2Inhibition of agglomerationReduce moistureSemi-permeable membranesPhosphatesO-Phosphoric AcidZirconium oxychloride

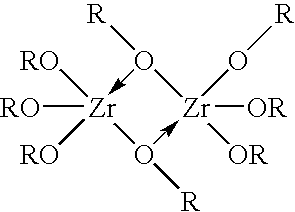

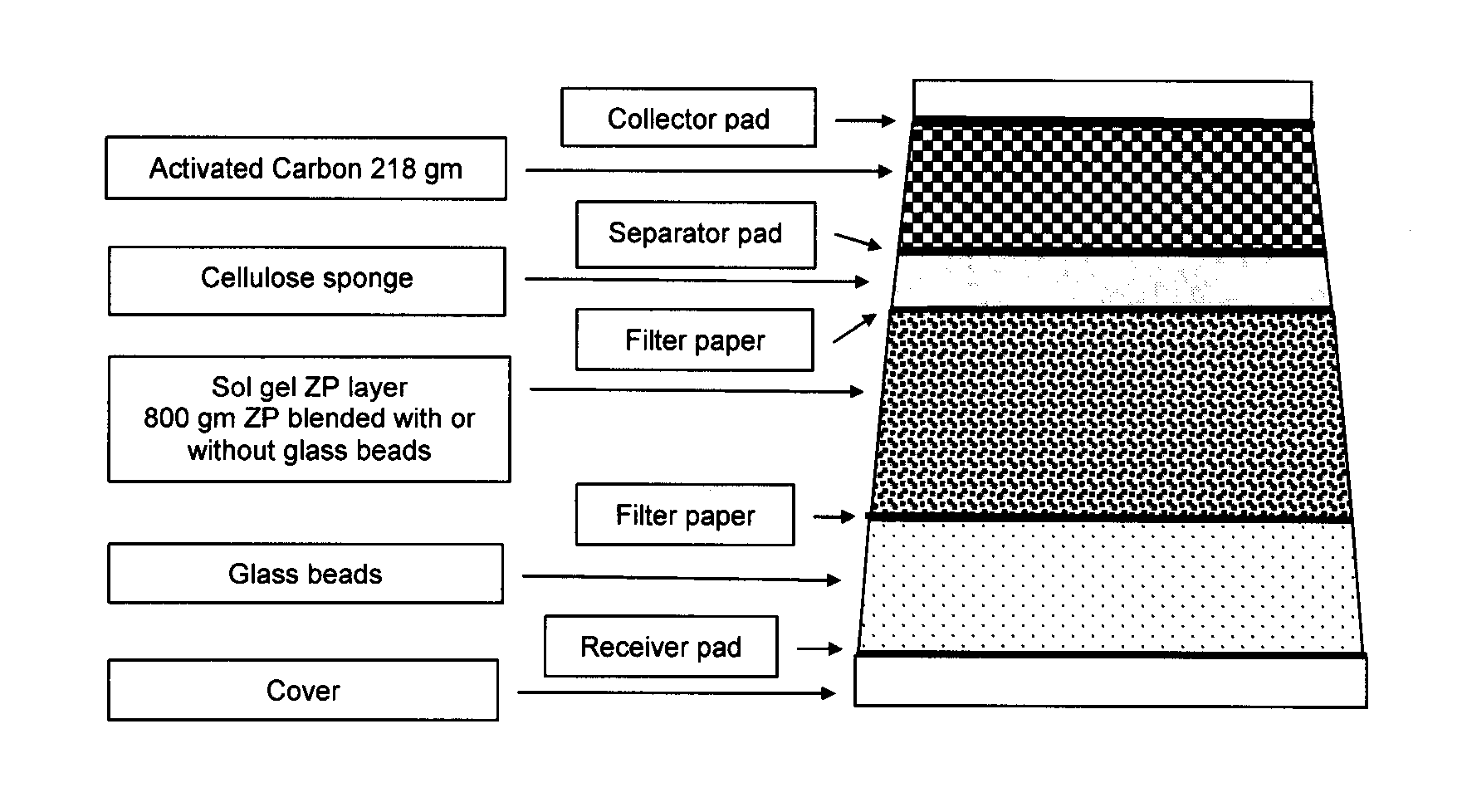

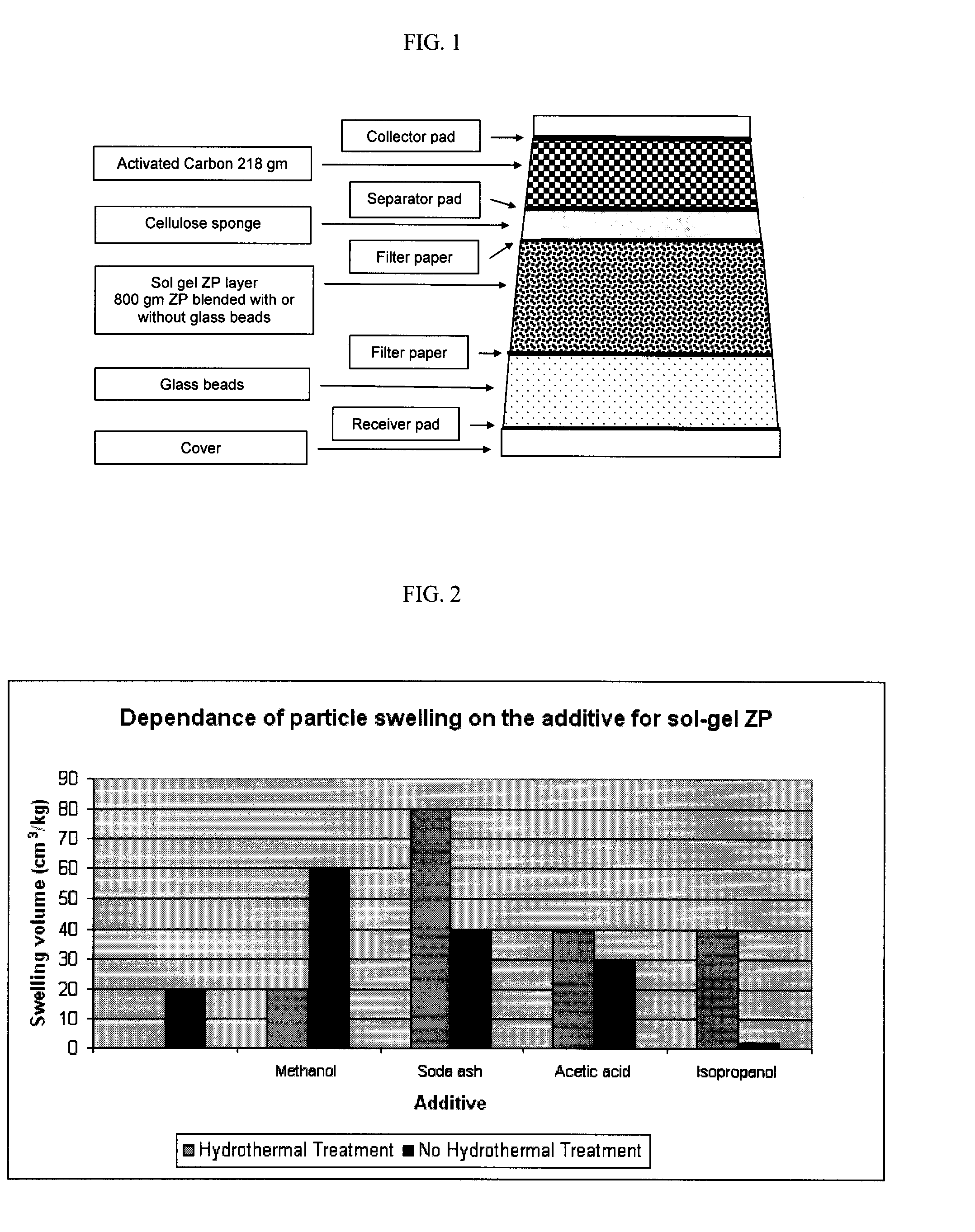

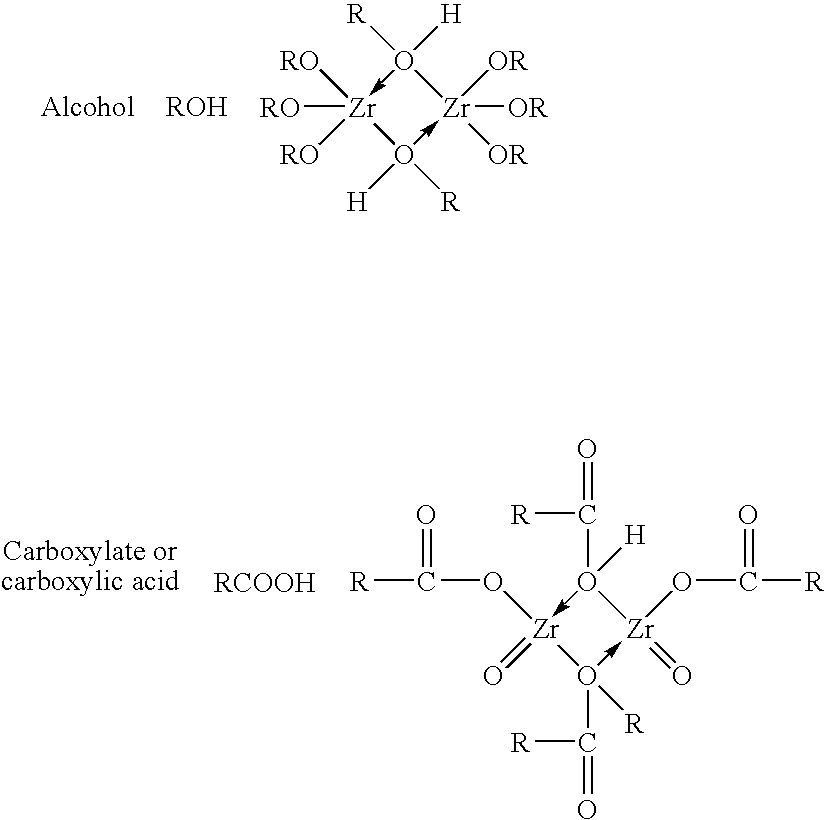

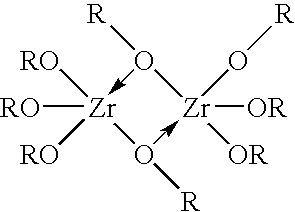

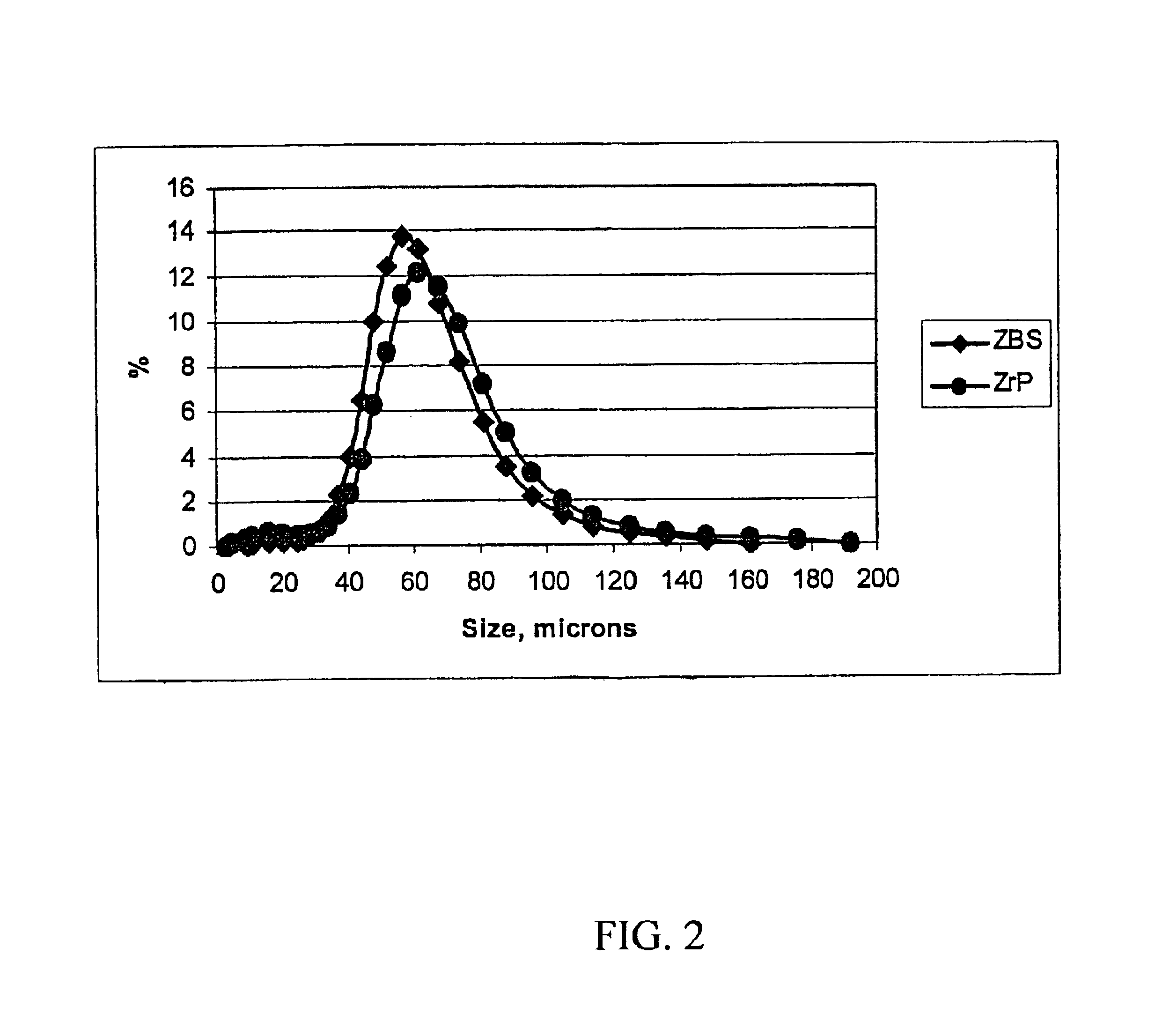

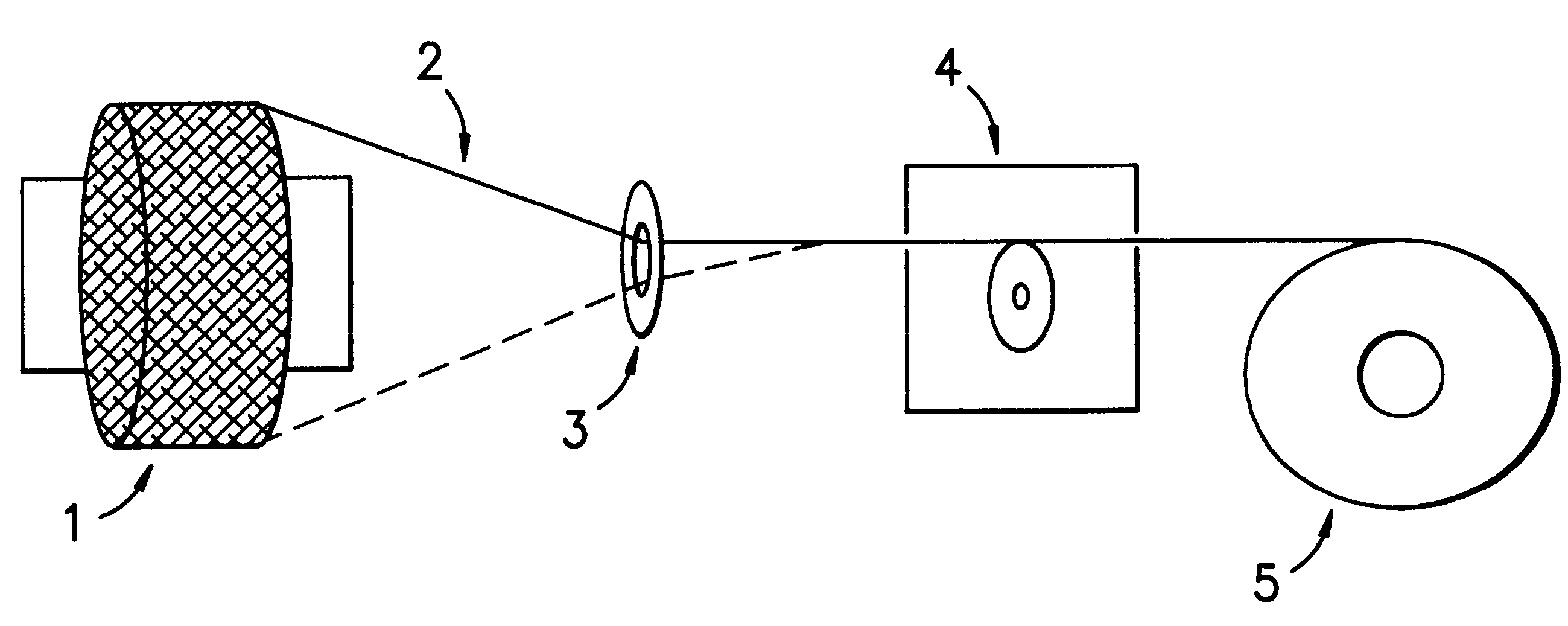

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one oxygen-containing additive to the solution, the oxygen-containing additive being selected to form a complex with zirconium ions in the solution of zirconium oxychloride and thereby reduce hydration of the zirconium ions, and combining this solution with phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:RENAL SOLUTIONS

Method and composition for removing uremic toxins in dialysis processes

ActiveUS7241272B2Improved dialysis procedureReduce impurityOther chemical processesOther blood circulation devicesToxinUrease

Owner:BAXTER INT INC

Zirconium Phosphate Particles Having Improved Adsorption Capacity and Method Of Synthesizing The Same

InactiveUS20100084330A1Avoid disadvantagesHigh porosityPhosphatesDialysis systemsPhosphoric acidOxygen

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one low molecular weight, oxygen containing, monofunctional, organic additive to the solution, and combining this solution with heated phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:FRESENIUS MEDICAL CARE HLDG INC

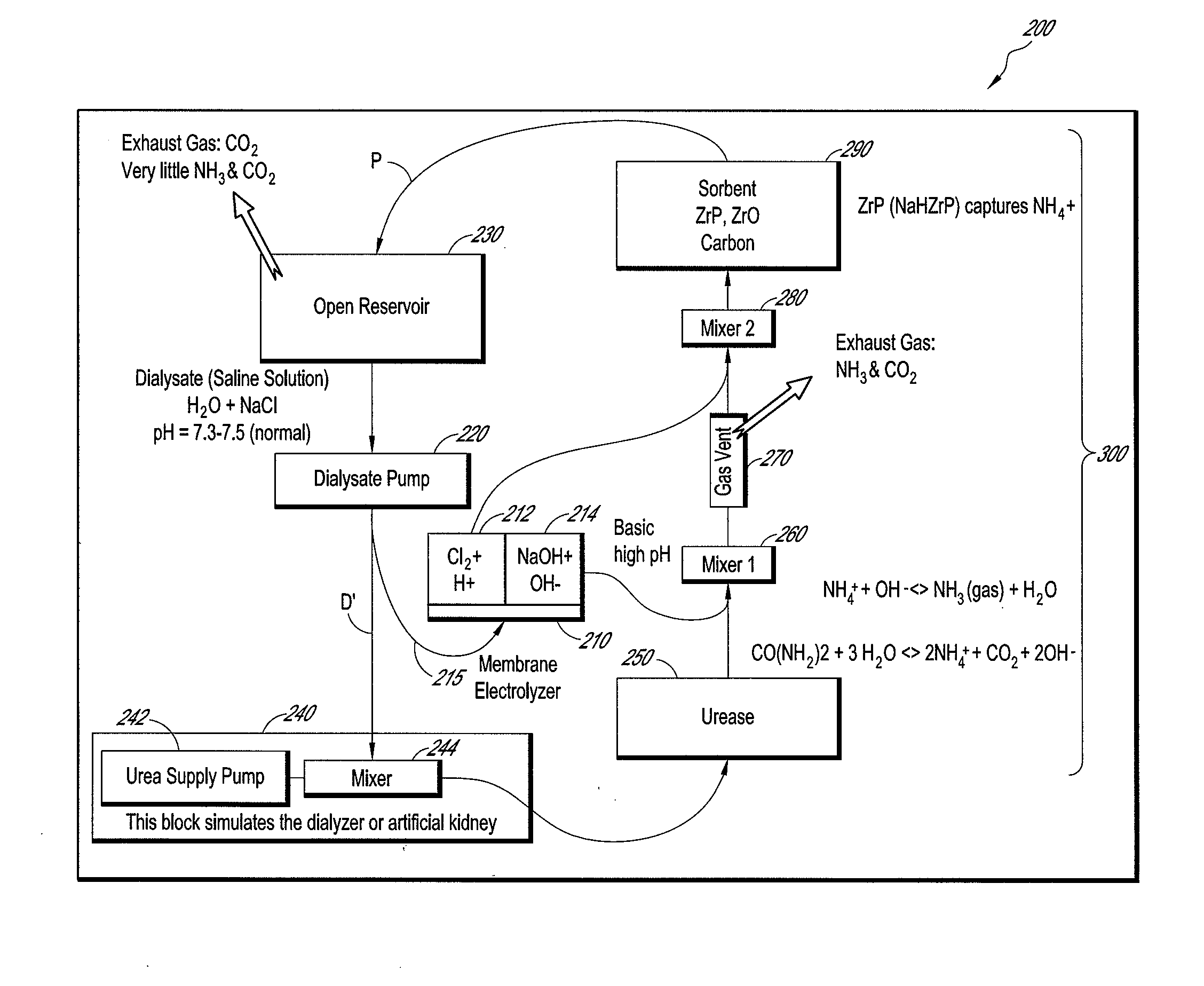

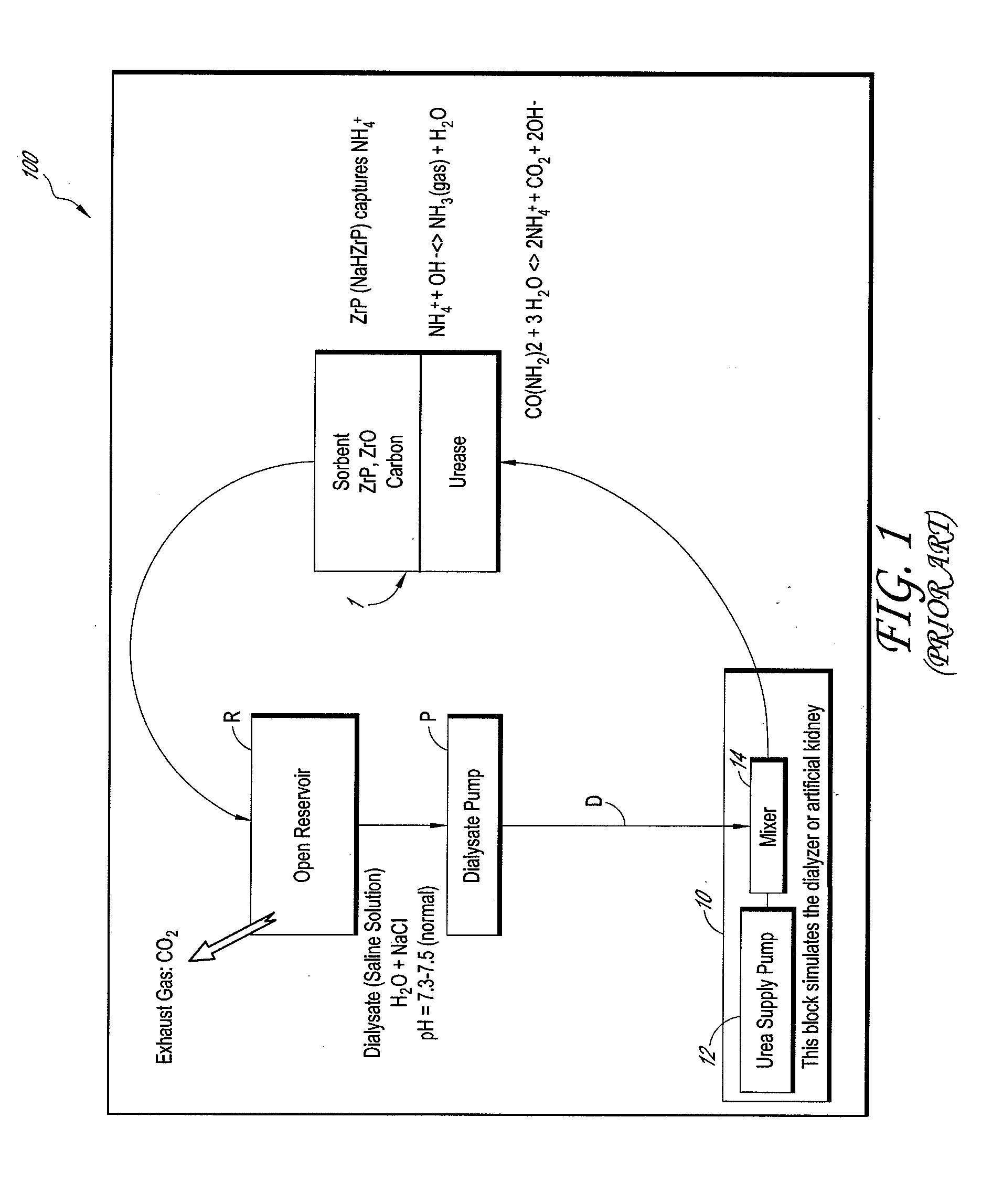

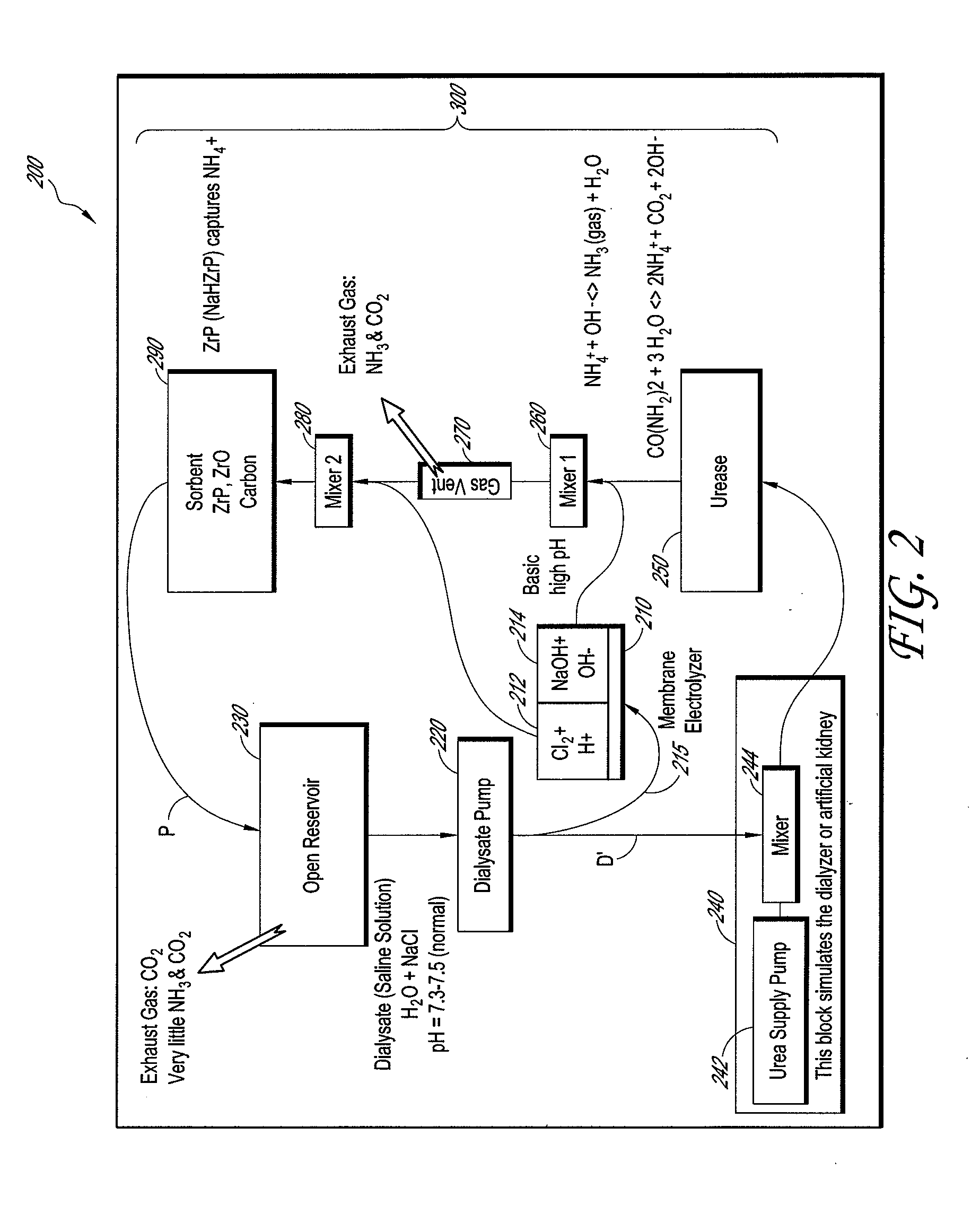

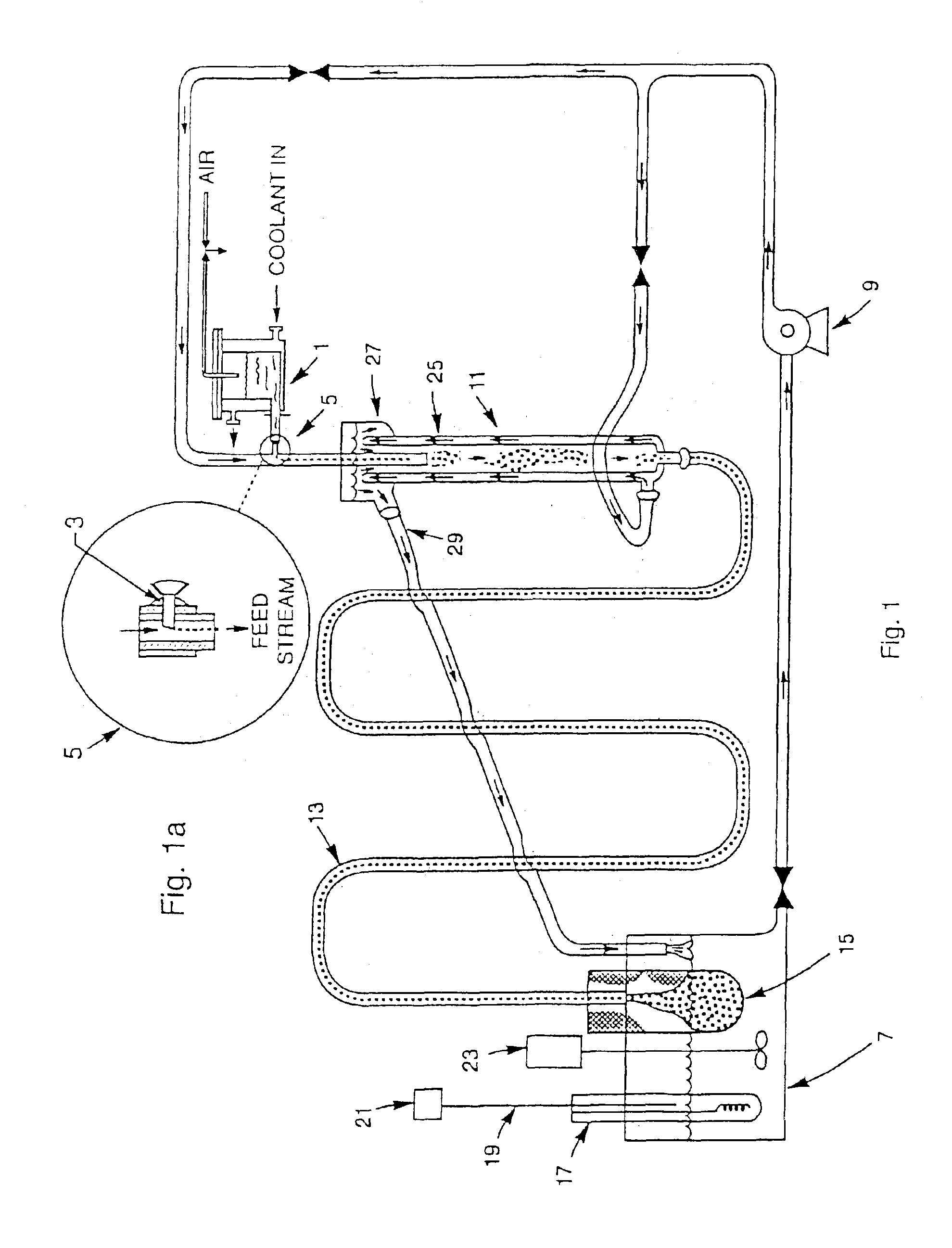

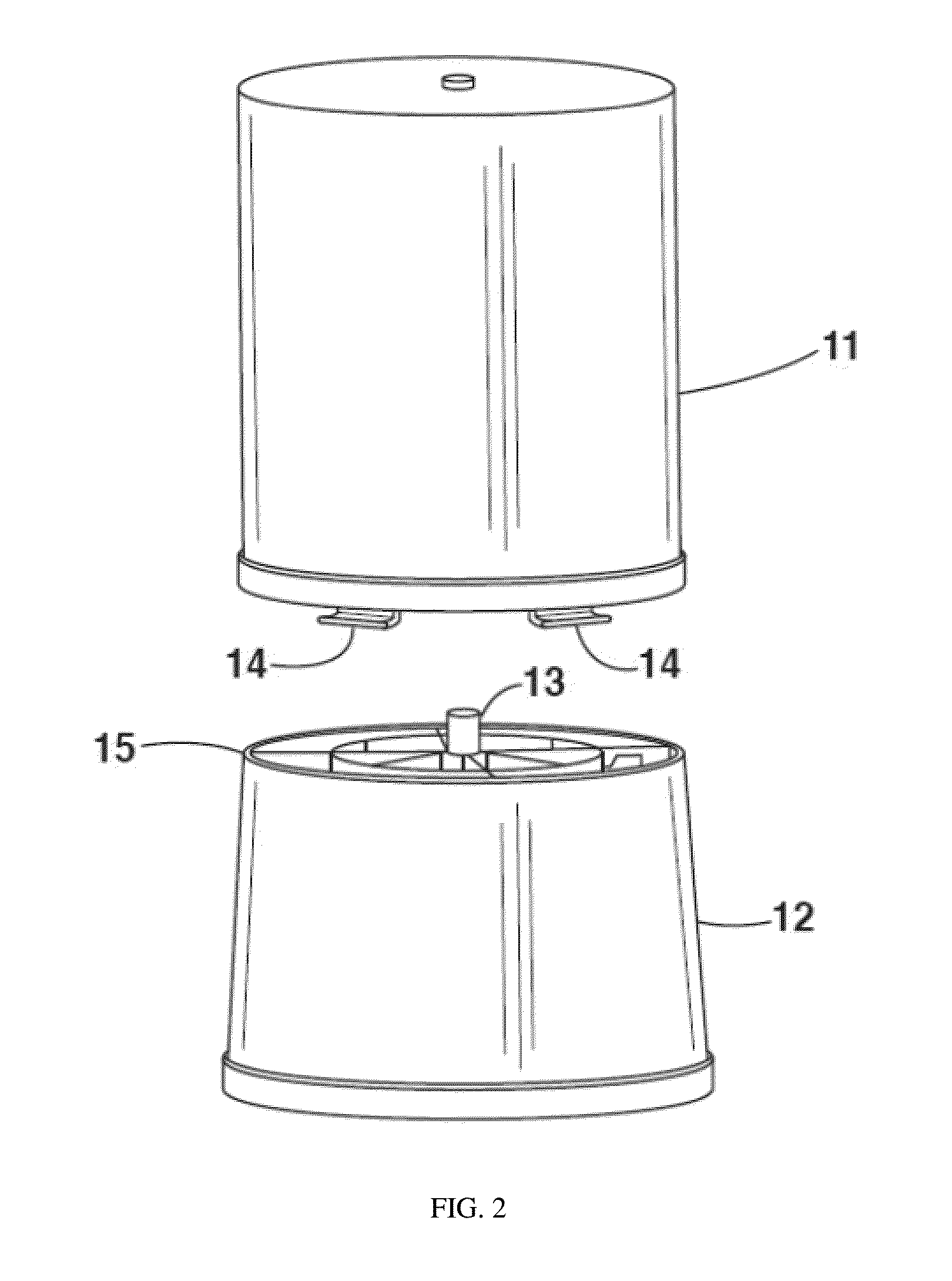

Membrane electrolyzer and hemodialysis system using the same

InactiveUS20110272352A1Raise the pHElectrolysis componentsApparatus sterilizationSorbentHaemodialysis machine

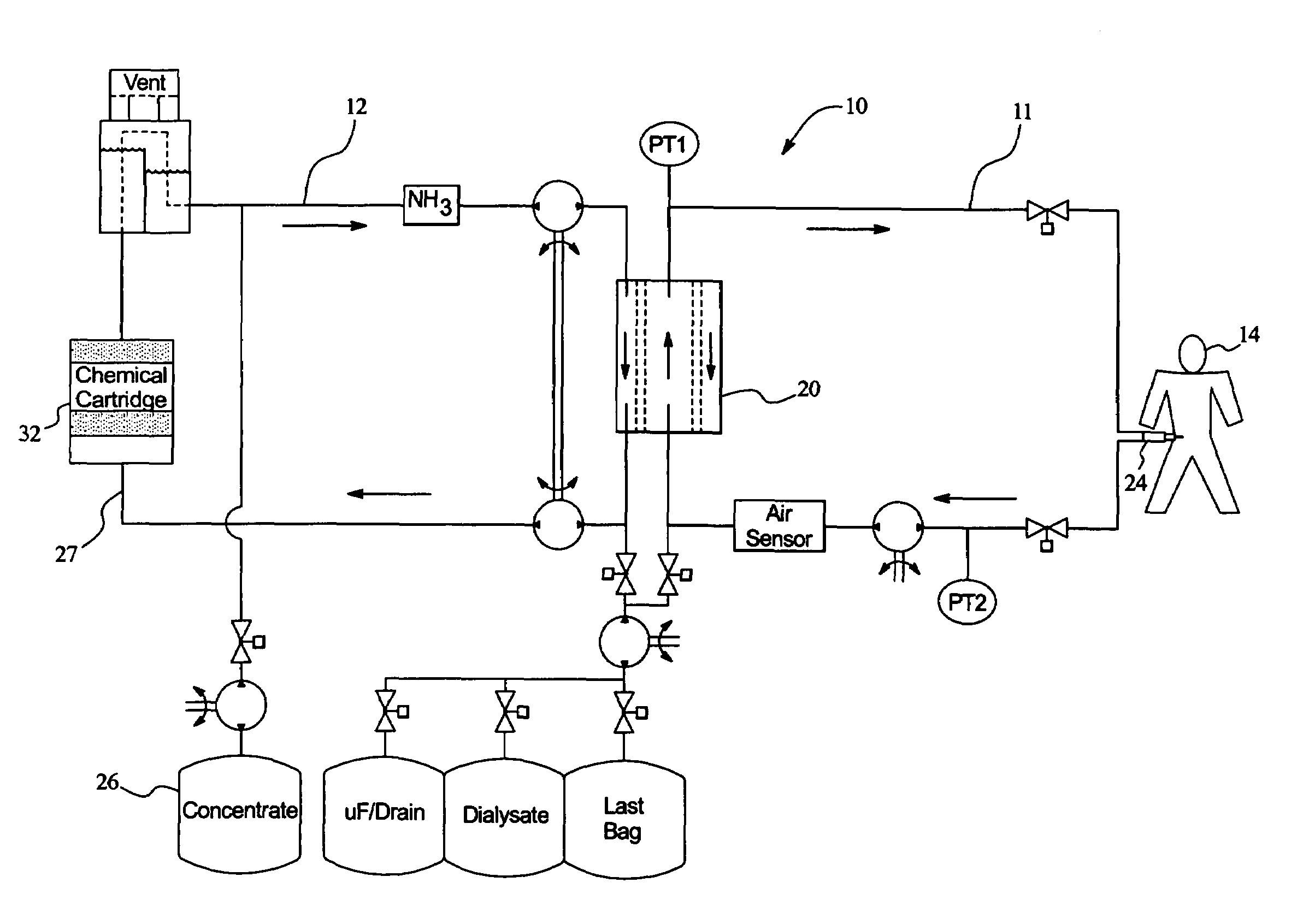

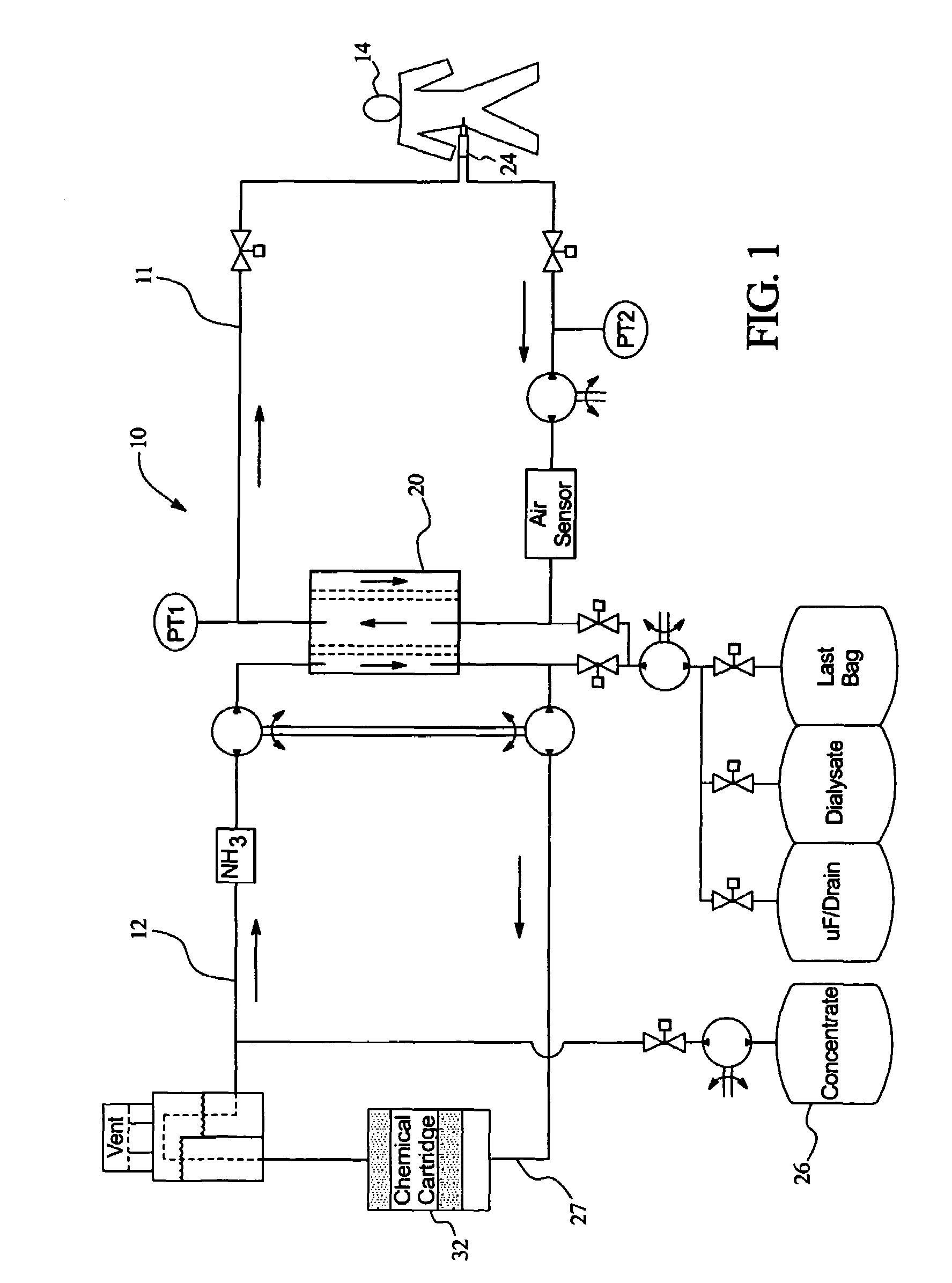

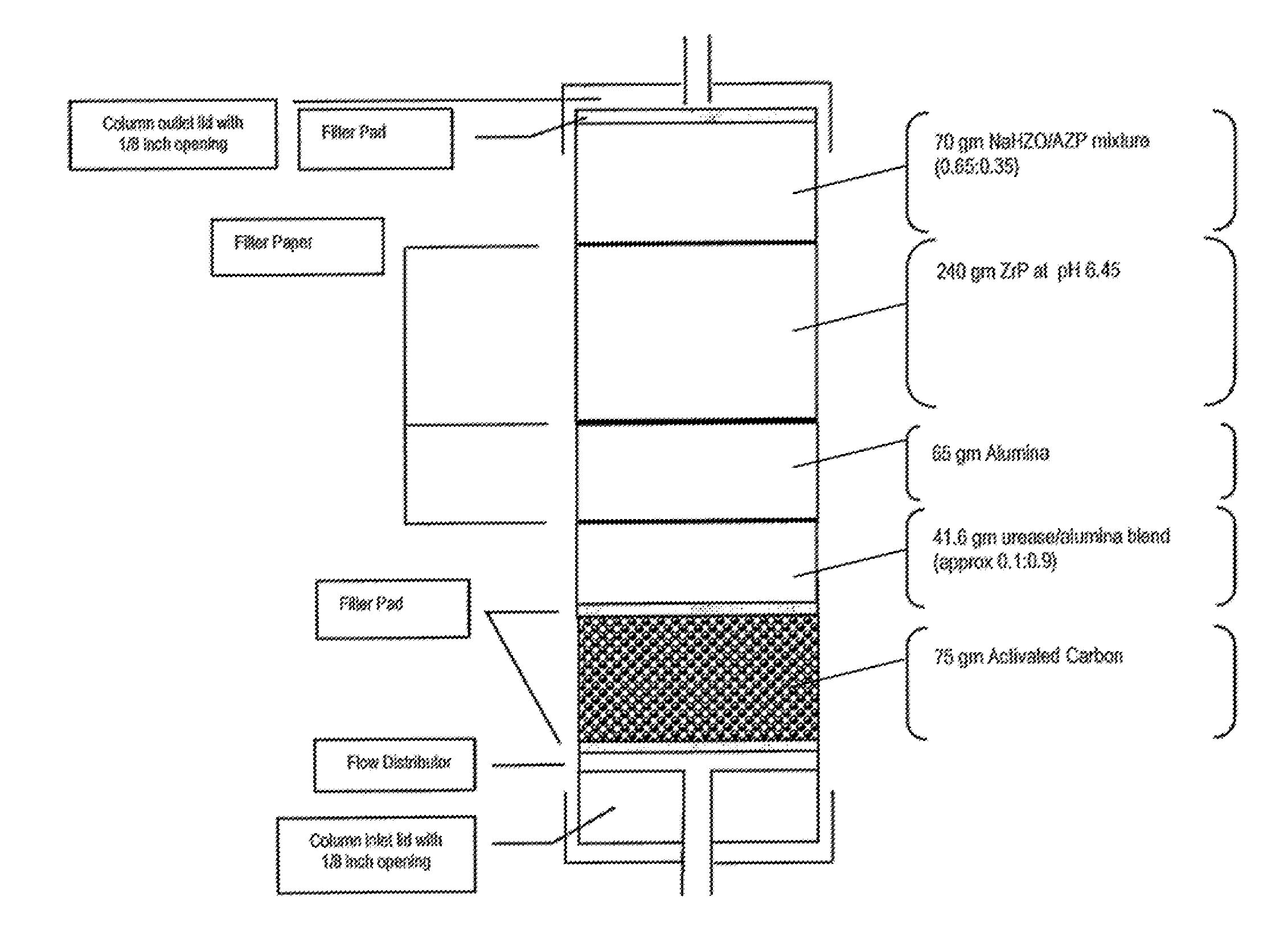

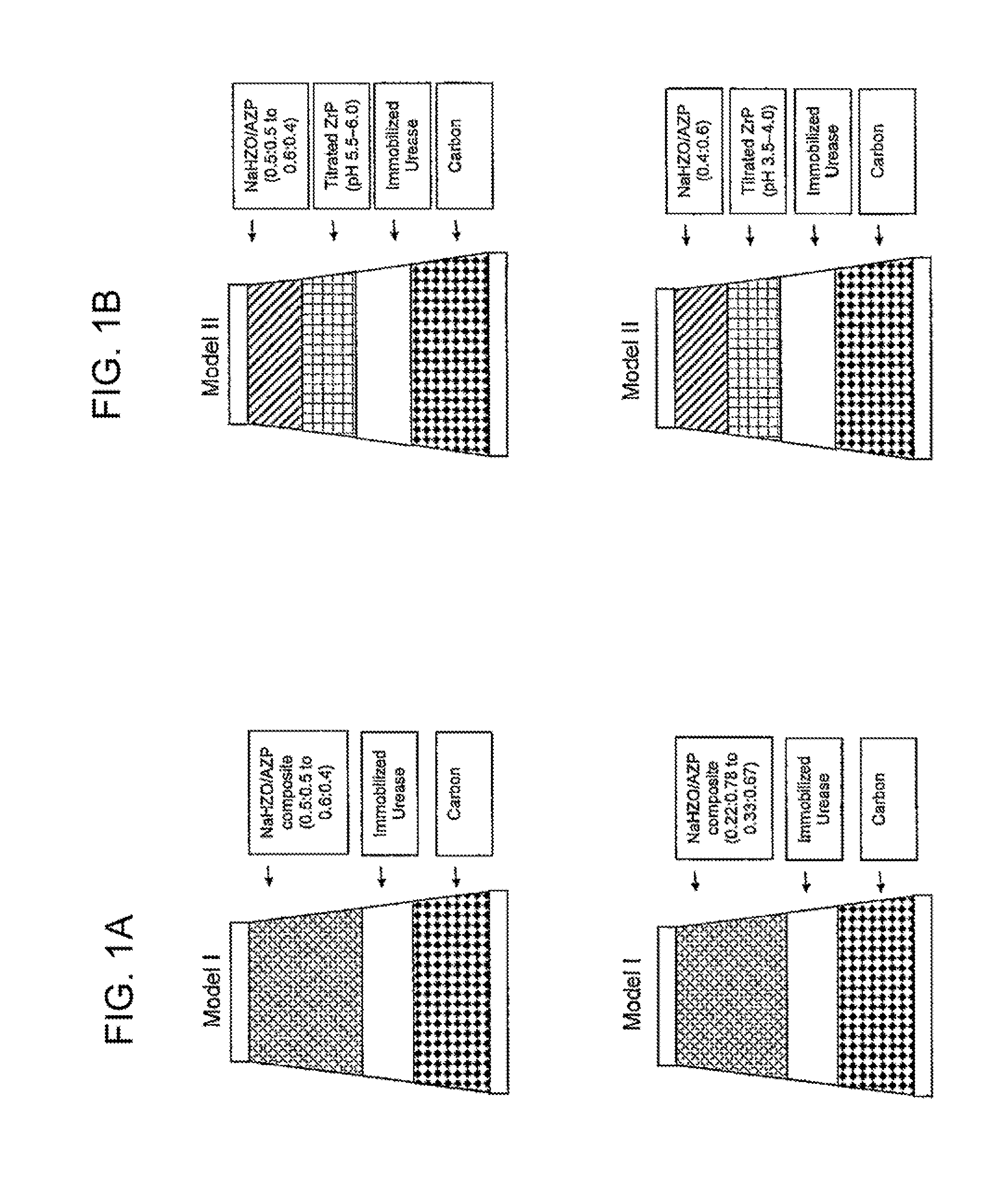

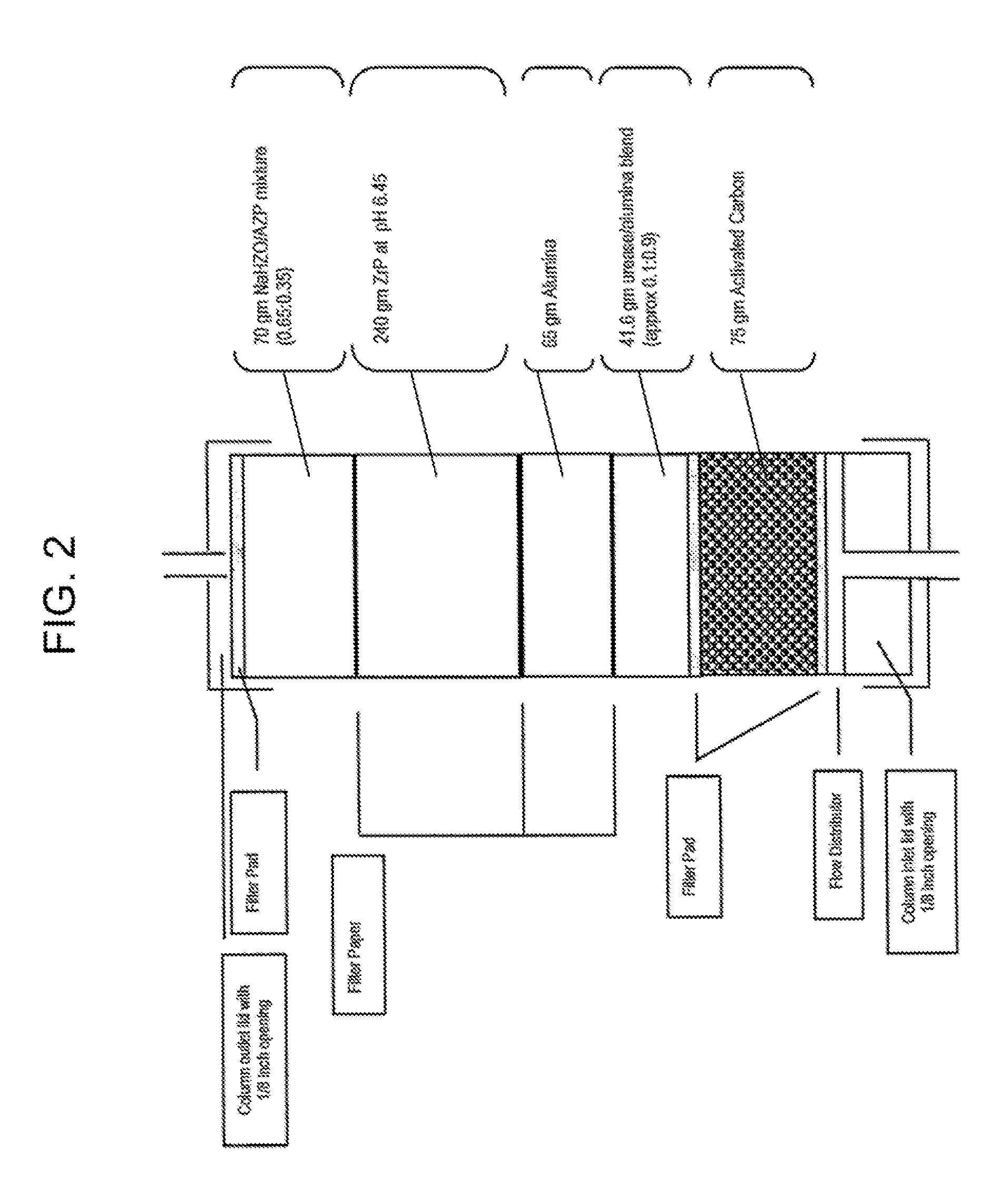

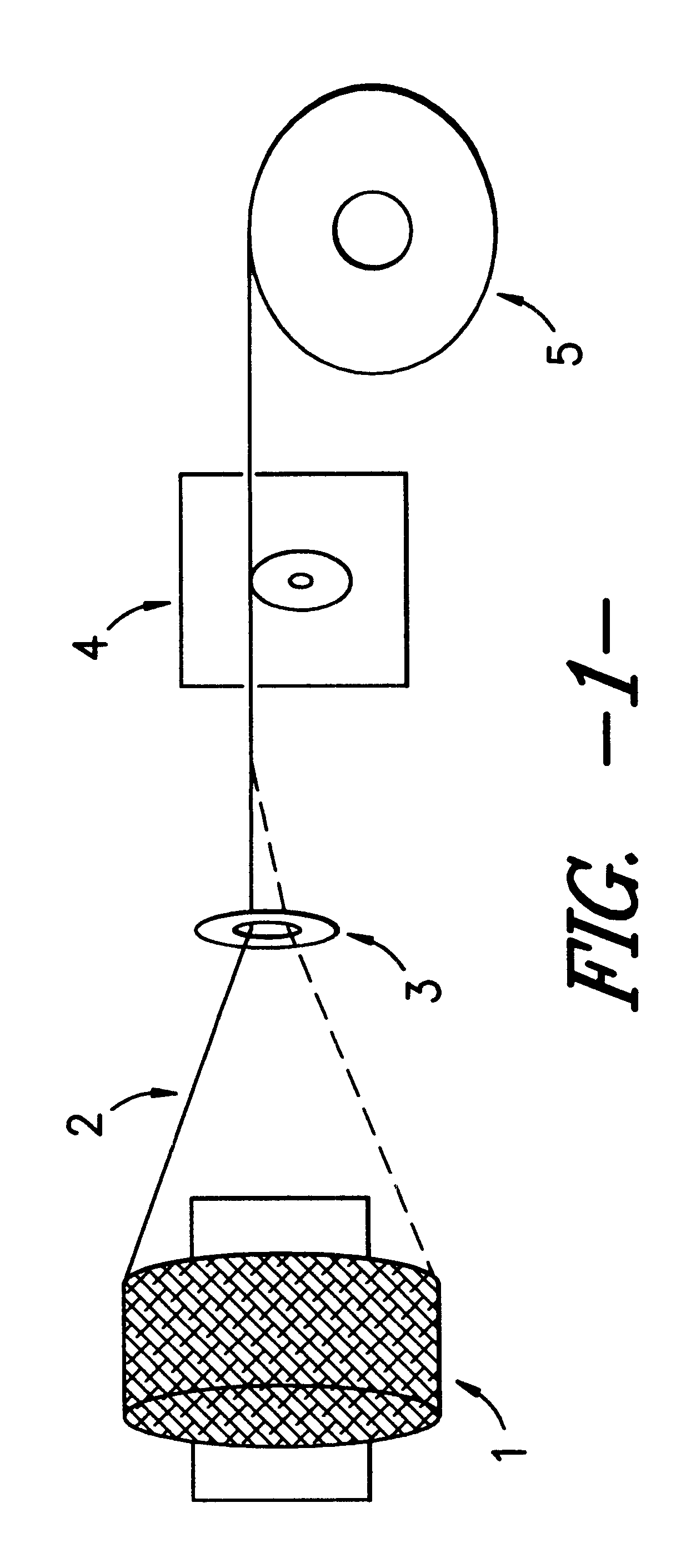

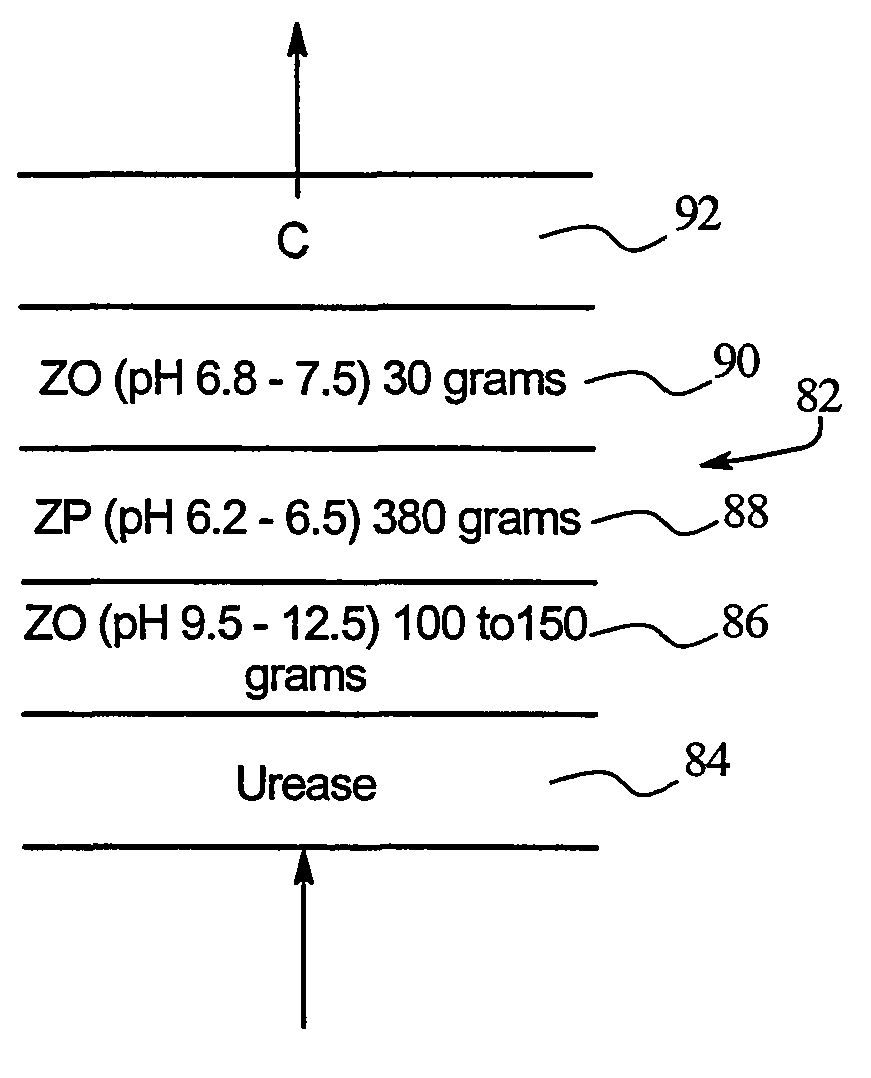

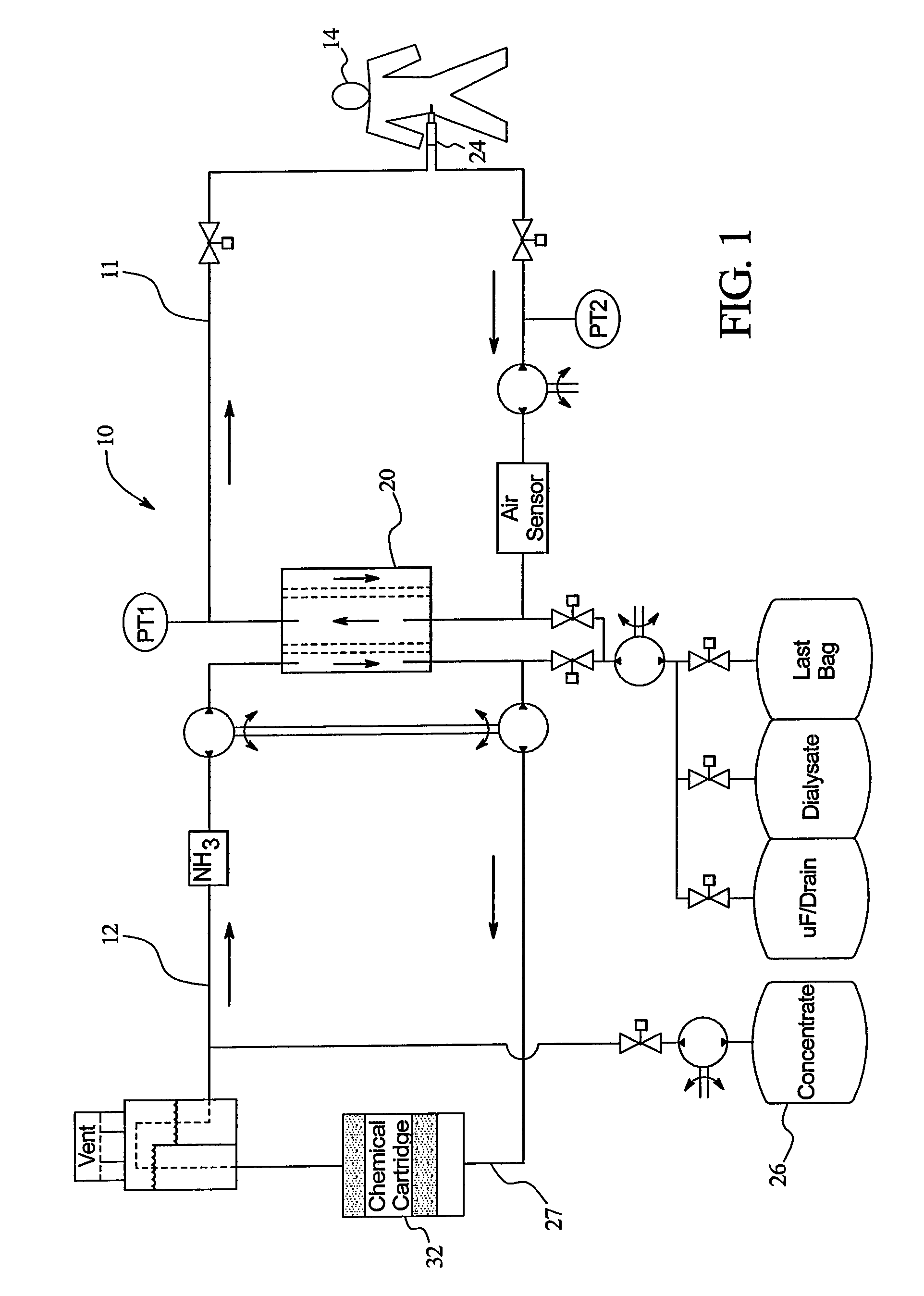

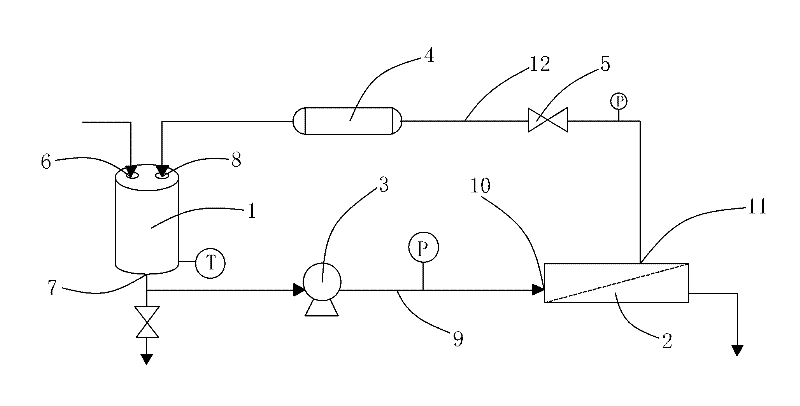

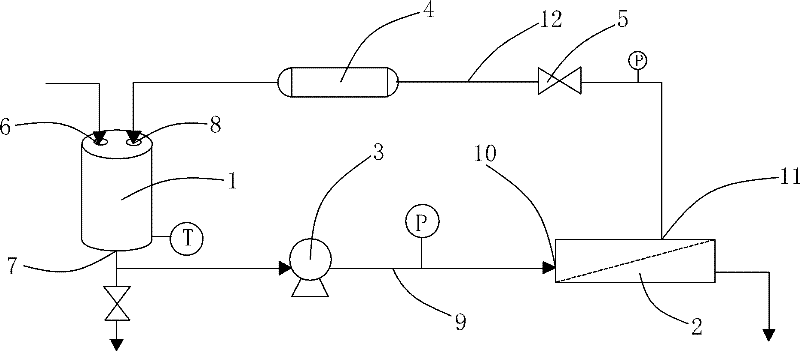

A sorbent hemodialysis system includes a dialyzer configured to receive a flow of clean dialysate from a reservoir and to output an unclean dialysate flow. The system also includes a sorbent component having a urease section and a sorbent section through which the unclean dialysate flow from the dialyzer passes, wherein the sorbent component removes urea from the dialysate. The system further comprises a membrane electrolyzer that receives at least a portion of said clean dialysate flow and separates the dialysate flow into an acidic component flow and a base component flow. A mixing conduit combines the base component flow from the membrane electrolyzer and an output dialysate solution from the urease section of the sorbent component to separate the dialysate solution into an ammonia gas amount and ammonia liquid amount. A gas vent is used to vent the ammonia gas amount, and the sorbent section with a suitable amount of zirconium phosphate (ZrP) removes the ammonia liquid amount from the unclean dialysate flow before flowing the clean dialysate to the reservoir. The system can further include a second mixing conduit upstream of the sorbent section of the sorbent component, the second mixing conduit combining the acidic component flow and the ammonia liquid amount in the dialysate solution to increase the pH of the dialysate solution to about 7.5 prior to returning to the reservoir.

Owner:C TECH BIOMEDICAL

Anion powder

InactiveCN102702833APurify waterPurifying airAntibacterial agentsCosmetic preparationsSolubilitySesquioxide

The invention discloses anion powder which includes the following components: by weight, 10-15 parts of coral fossil, 10-15 parts of tourmaline, 30-50 parts of opal, 5-10 parts of serpentine, 2-4 parts of medical stone, 2-4 parts of odd ice stone, 2-4 parts of radiobarite, 2-4 parts of king stone, 3-6 parts of shell, 15-25 parts of diatomite, 2-4 parts of iron sesquioxide, 2-4 parts of aluminium sesquioxide, 2-4 parts of zirconium oxide and 2-4 parts of zirconium phosphate. Air ions generated by the anion powder prepared is high in solubility and is not easy to modify at high temperature and long in effects, and original characters of products cannot be modified when used with other functional materials.

Owner:山东天宇圣邦涂料有限公司

Method of synthesizing zirconium phosphate particles

InactiveUS20060140840A1Avoid disadvantagesInhibition of agglomerationSemi-permeable membranesPhosphatesPhosphoric acidSolvent

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one oxygen-containing additive to the solution, the oxygen-containing additive being selected to form a complex with zirconium ions in the solution of zirconium oxychloride and thereby reduce hydration of the zirconium ions, and combining this solution with phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:RENAL SOLUTIONS

Non-chromium deactivation liquid for processing aluminium alloy and method of use thereof

InactiveCN101161861AReduce pollutionMeet WEESMetallic material coating processesTitanium zirconiumPhosphoric acid

The present invention relates to a chrome-free passivating liquid for treating aluminum alloy and a method for using the same; the components of the passivating liquid and the weight concentration of the elements thereof consist of fluorin titanate comprising Ti (IV) between 0.05 wt percent and 0.15 wt percent, fluorin zirconate comprising Zr (IV) 0.01 wt percent and 0.05 wt percent and organic phosphate compound comprising 0.02 wt percent to saturated concentration. The use method of the passivating liquid of the invention has the following procedures: after grease on the surface of the aluminum alloy is removed, the aluminum alloy is treated by alkali cleaning, deoxidation and activation; when the temperature is between 25 DEG C and 60 DEG C and the PH value is between 3 and 3.5, the aluminum alloy is treated by impregnating or spraying for 2 min to 5 min. In the passivating liquid of the invention, organic phosphoric acid is directly added to a titanium zirconium system; the formed zirconium phosphate composite structure can obviously improve the corrosion resisting property of a passivating film and the adhesive capactiy of polymer coating (primer) on the surface of aluminum alloy.

Owner:NORTHEASTERN UNIV

Acid zirconium phosphate and alkaline hydrous zirconium oxide materials for sorbent dialysis

ActiveUS8409444B2Avoid disadvantagesRestore balanceCation exchanger materialsSolvent extractionIon exchangeDialysis fluid

Owner:FRESENIUS MEDICAL CARE HLDG INC

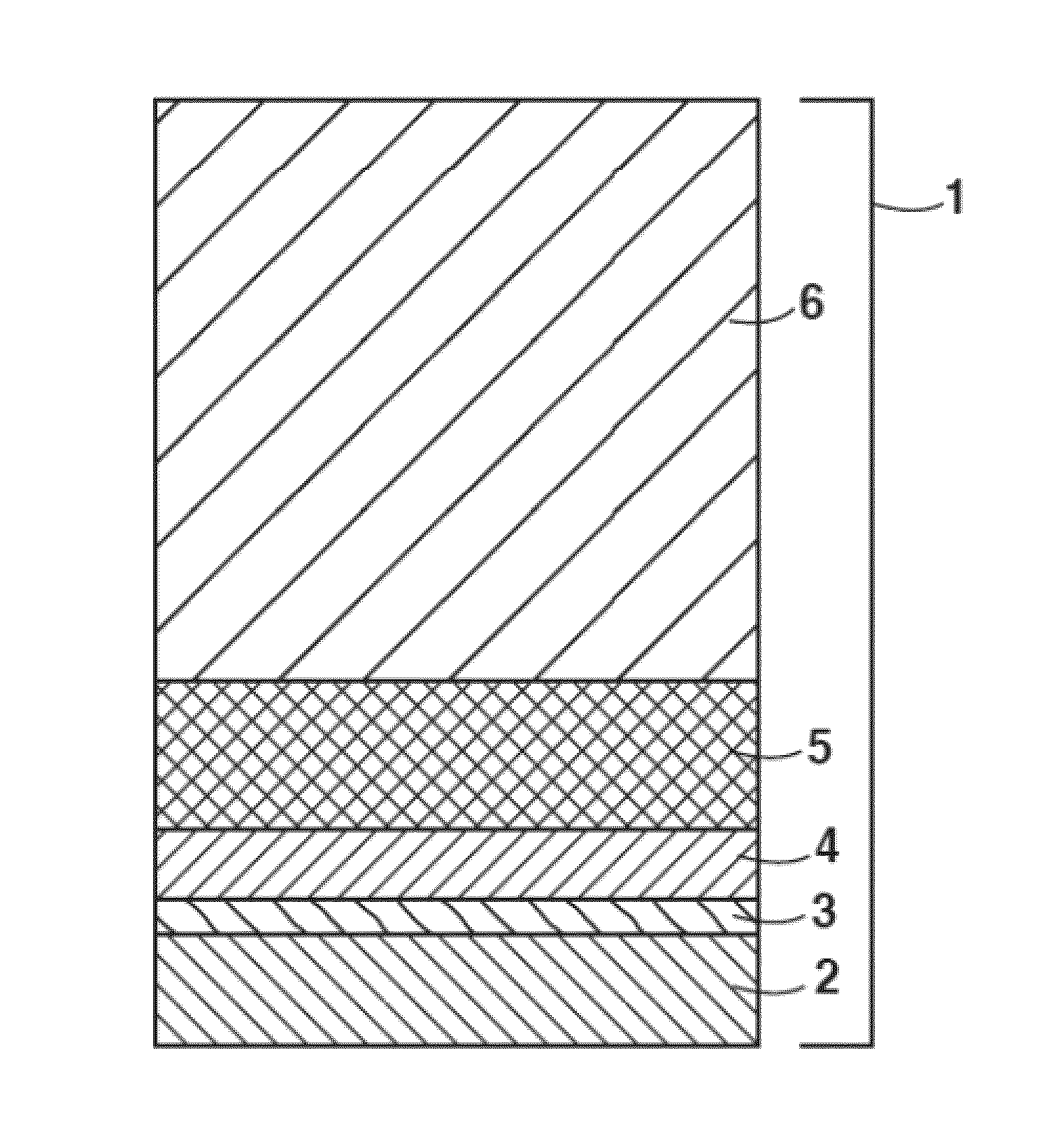

Anti-tack spandex fibers containing antimicrobial agents therein and fabrics made therefrom

InactiveUS6479144B2Easy to processImprove cohesionMonocomponent polyurethanes artificial filamentBiocideYarnFiber

Polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein are provided. This invention relates to polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein. Such formulations comprise antimicrobial compounds, such as, preferably, triclosan and / or silver-containing ion-exchange resins, such as zirconium phosphate, glass, and / or zeolite compounds. The inventive spandex yarns exhibit excellent antimicrobial qualities as well as surprisingly good anti-tack / frictional characteristics. As a result, antimicrobial spandex yams are provided which exhibit ease in processing, particularly in further knitting, weaving, etc., to produce fabrics therefrom. Such fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

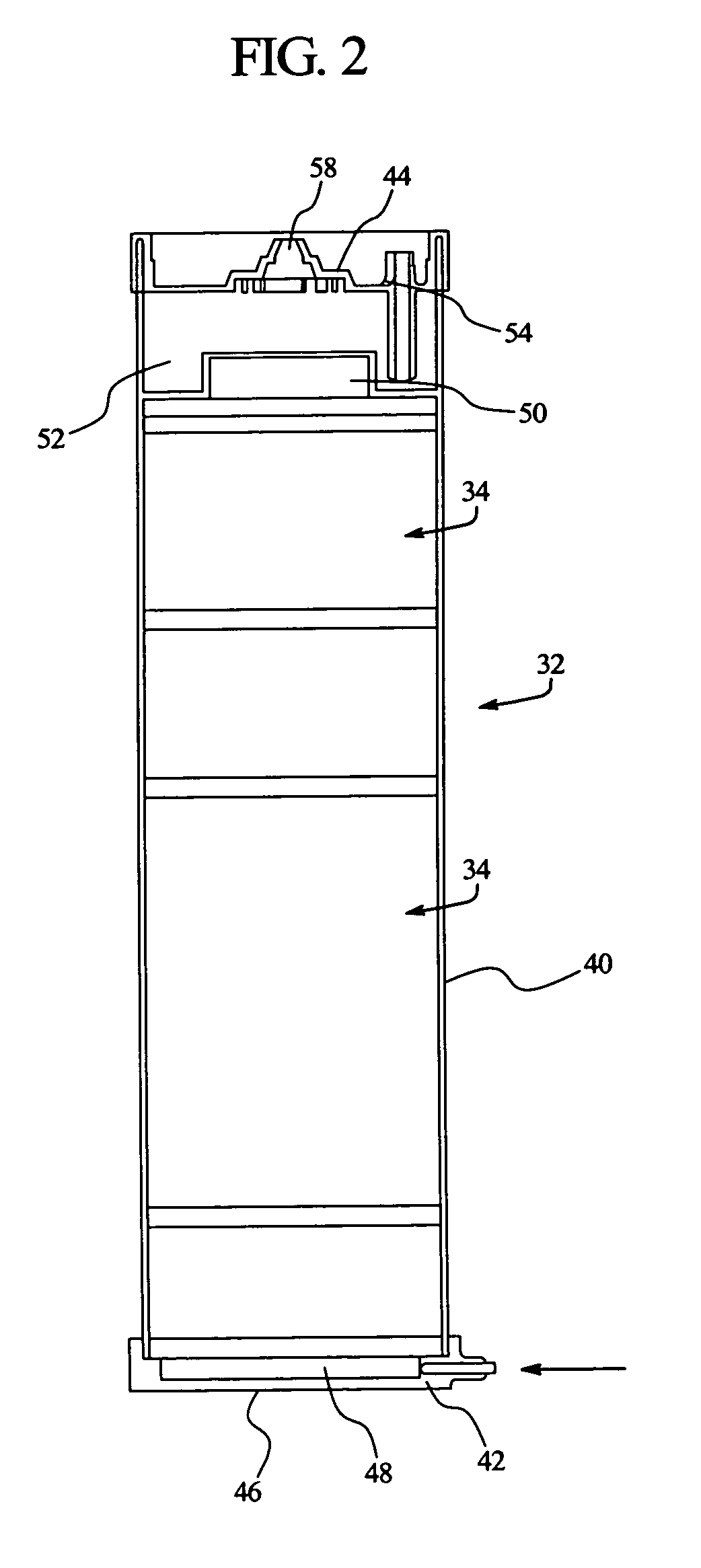

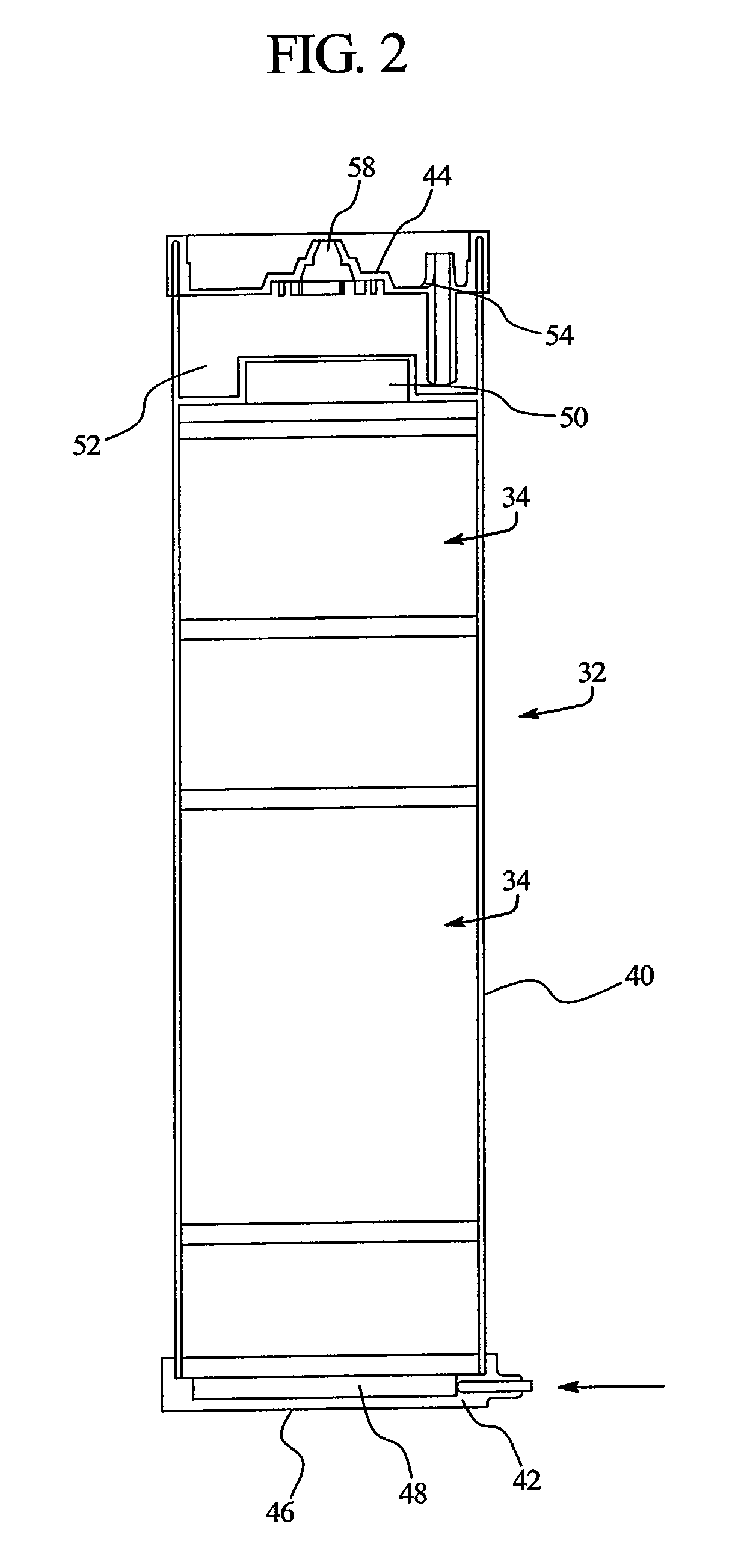

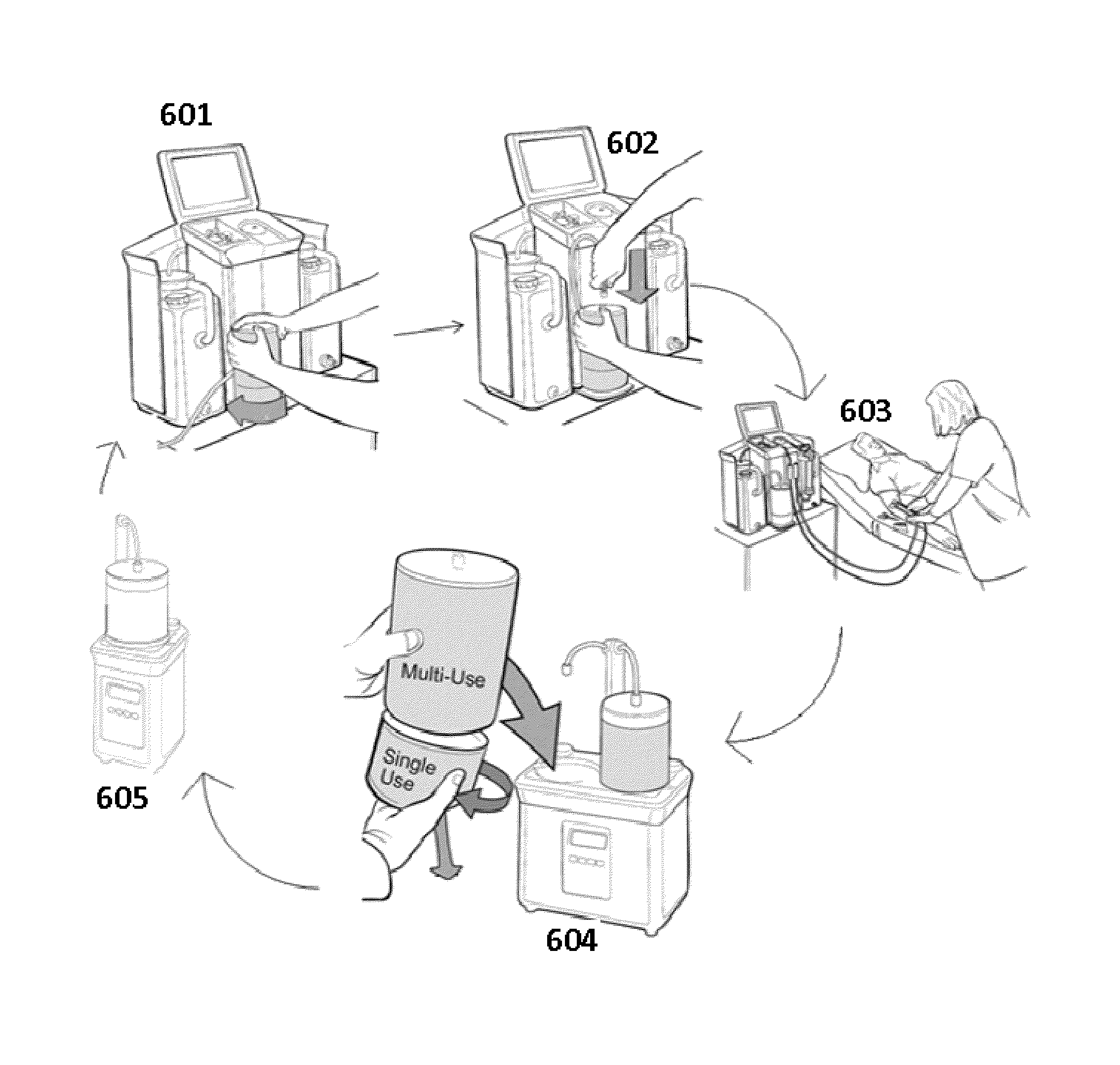

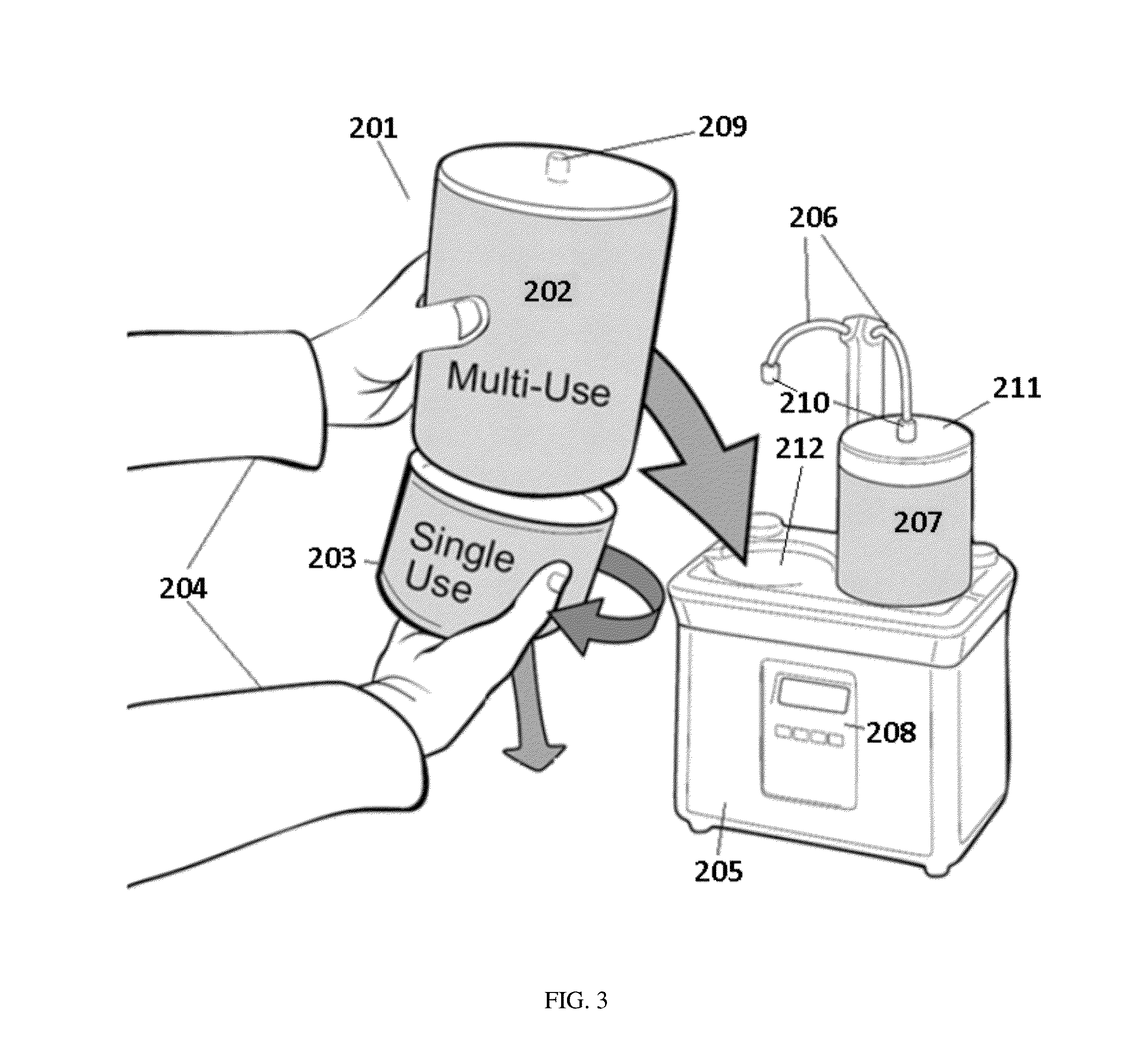

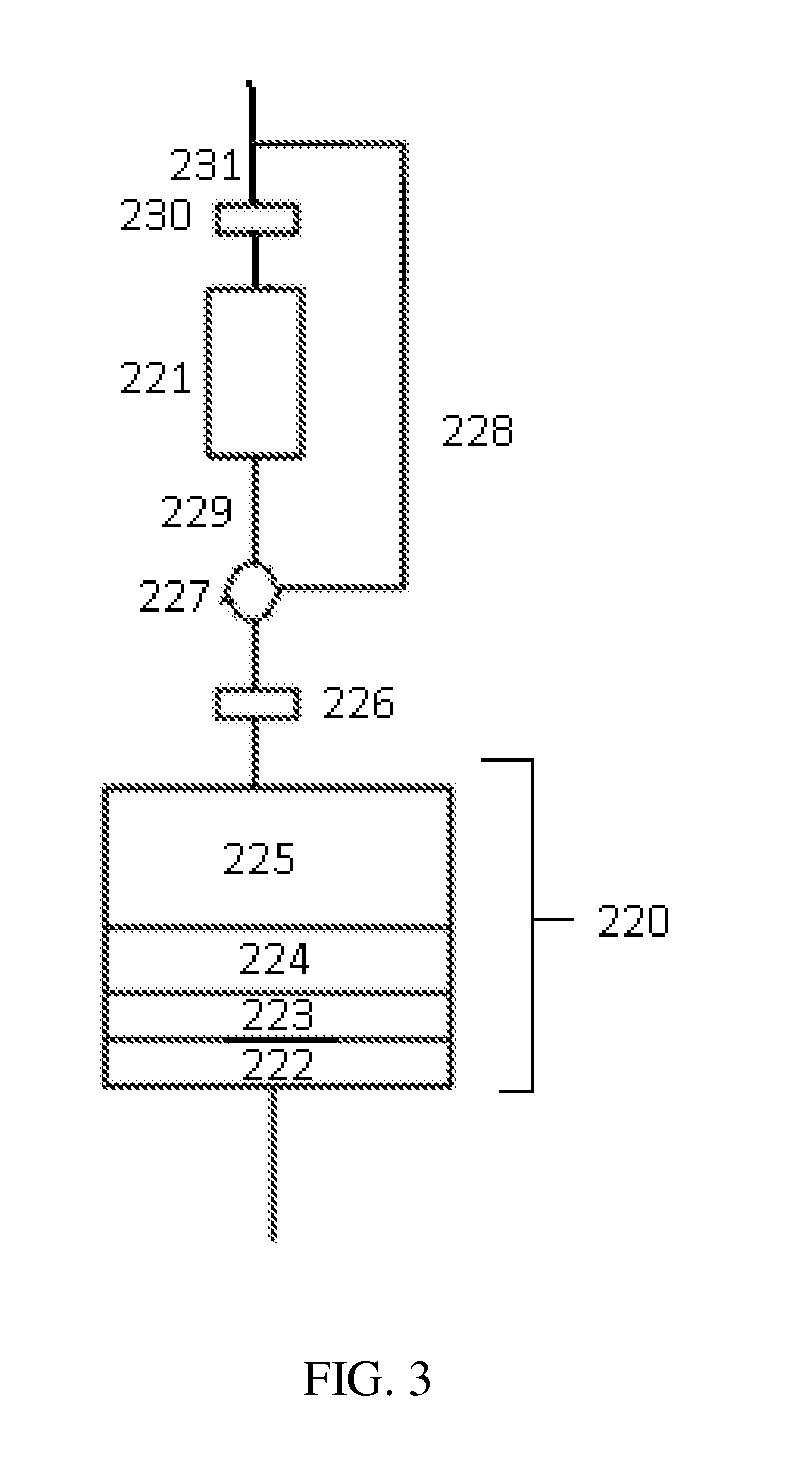

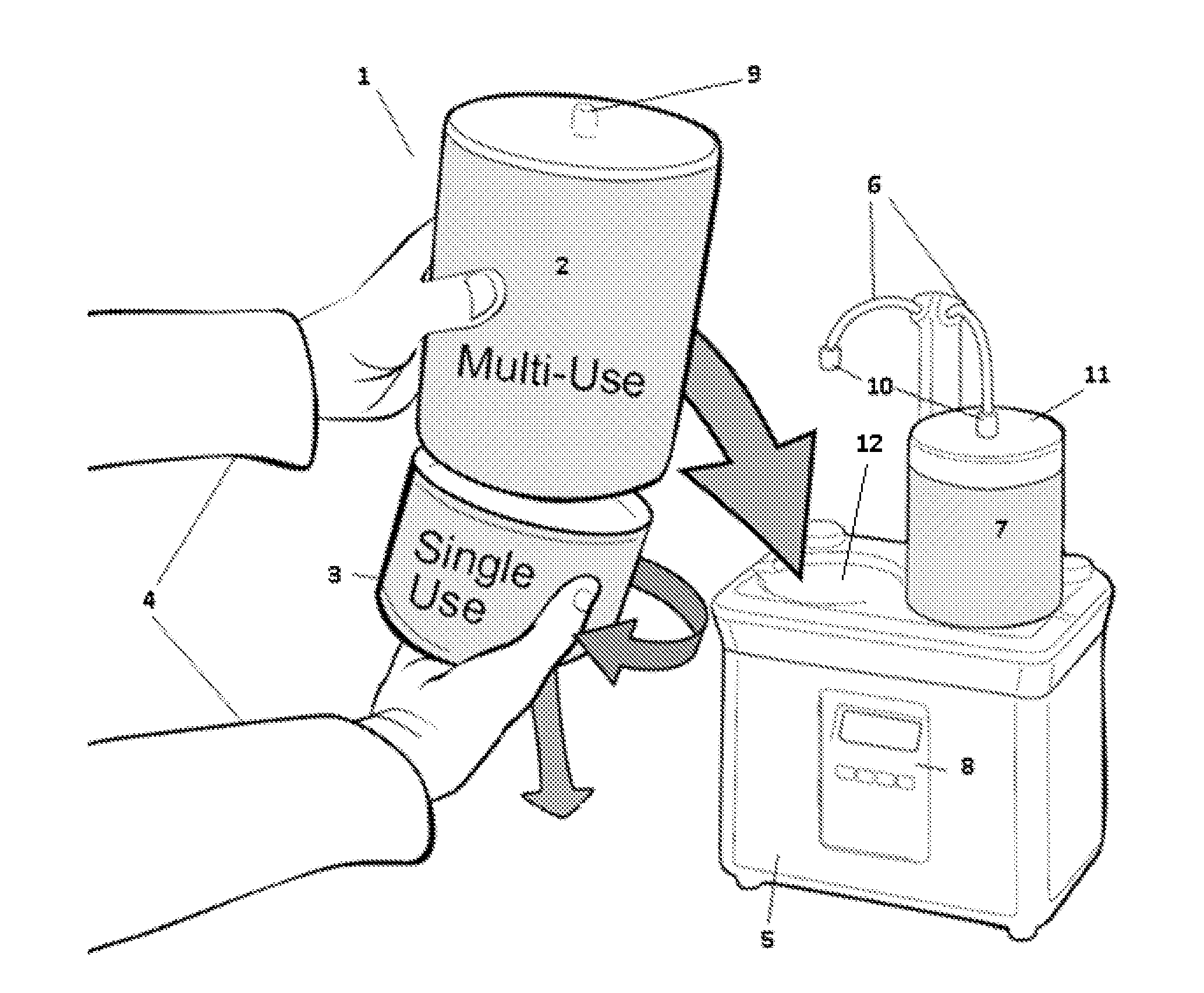

Module for In-Line Recharging of Sorbent Materials with Optional Bypass

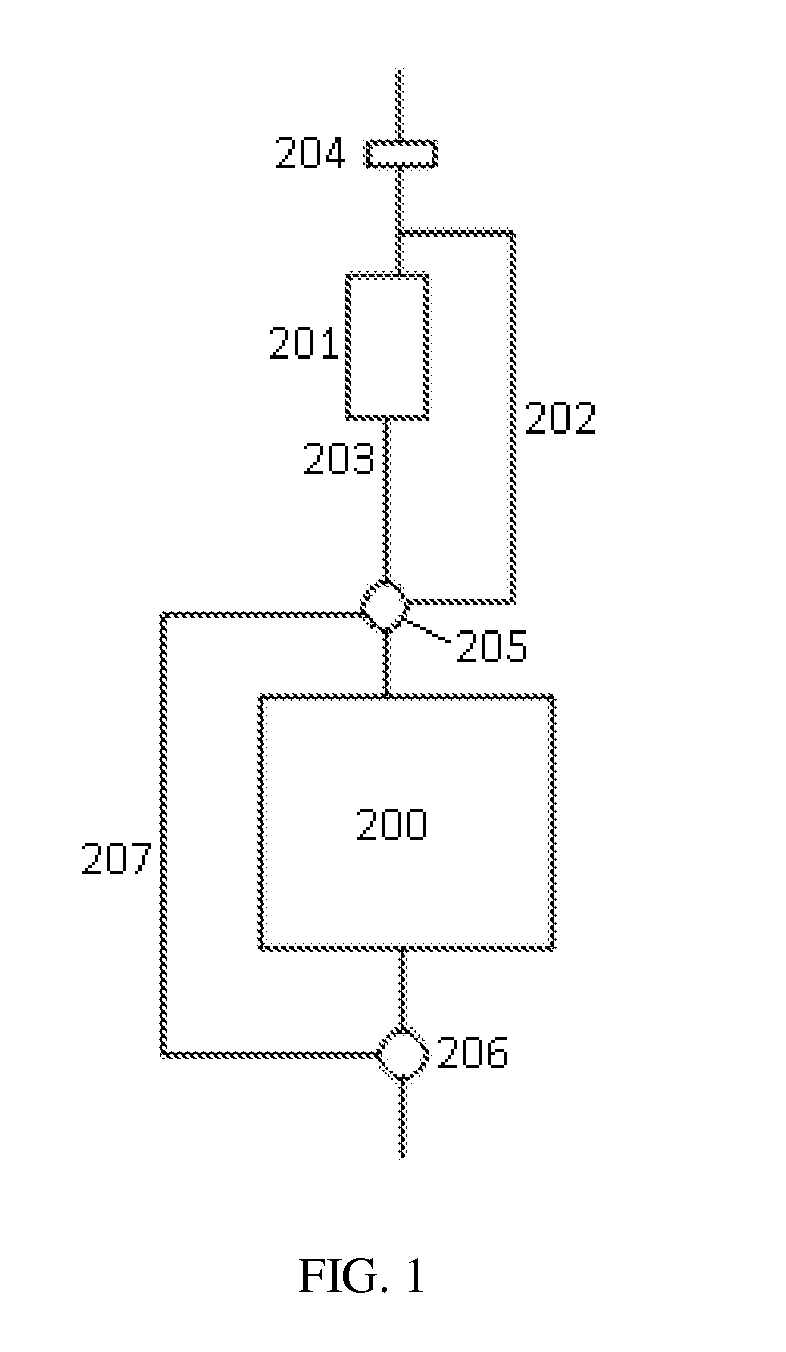

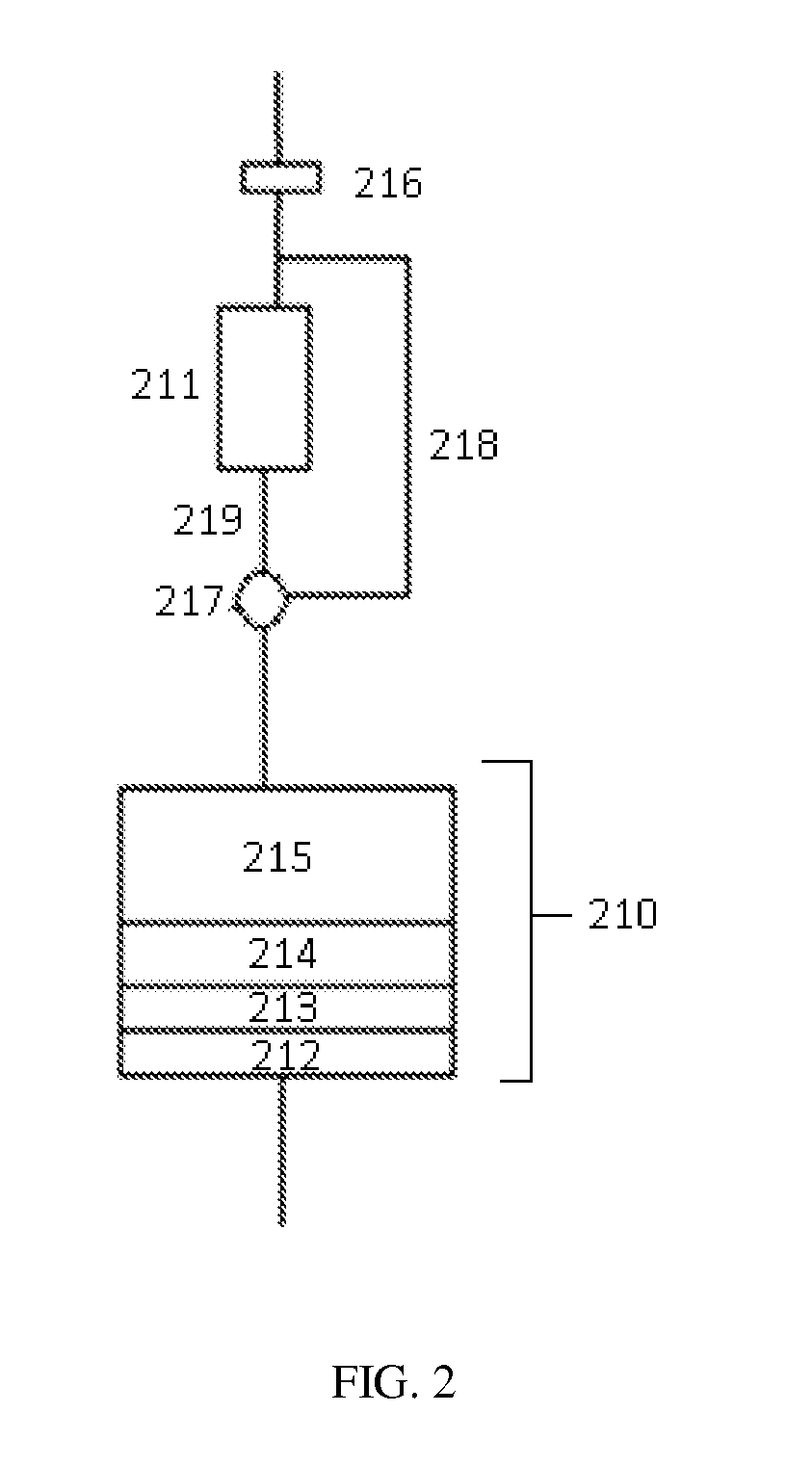

A module for optionally recharging sorbent materials in-line, including zirconium phosphate, with an optional bypass and conduits for a sorbent cartridge. The sorbent cartridge can have one or more modules contained therein having connectors connecting each of the modules. One or more of the modules can be reusable and the sorbent materials therein recharged.

Owner:MOZARC MEDICAL US LLC

Method and composition for removing uremic toxins in dialysis processes

ActiveUS7955290B2Reduce impuritySimple systemOther chemical processesOther blood circulation devicesToxinUrease

Owner:BAXTER INT INC

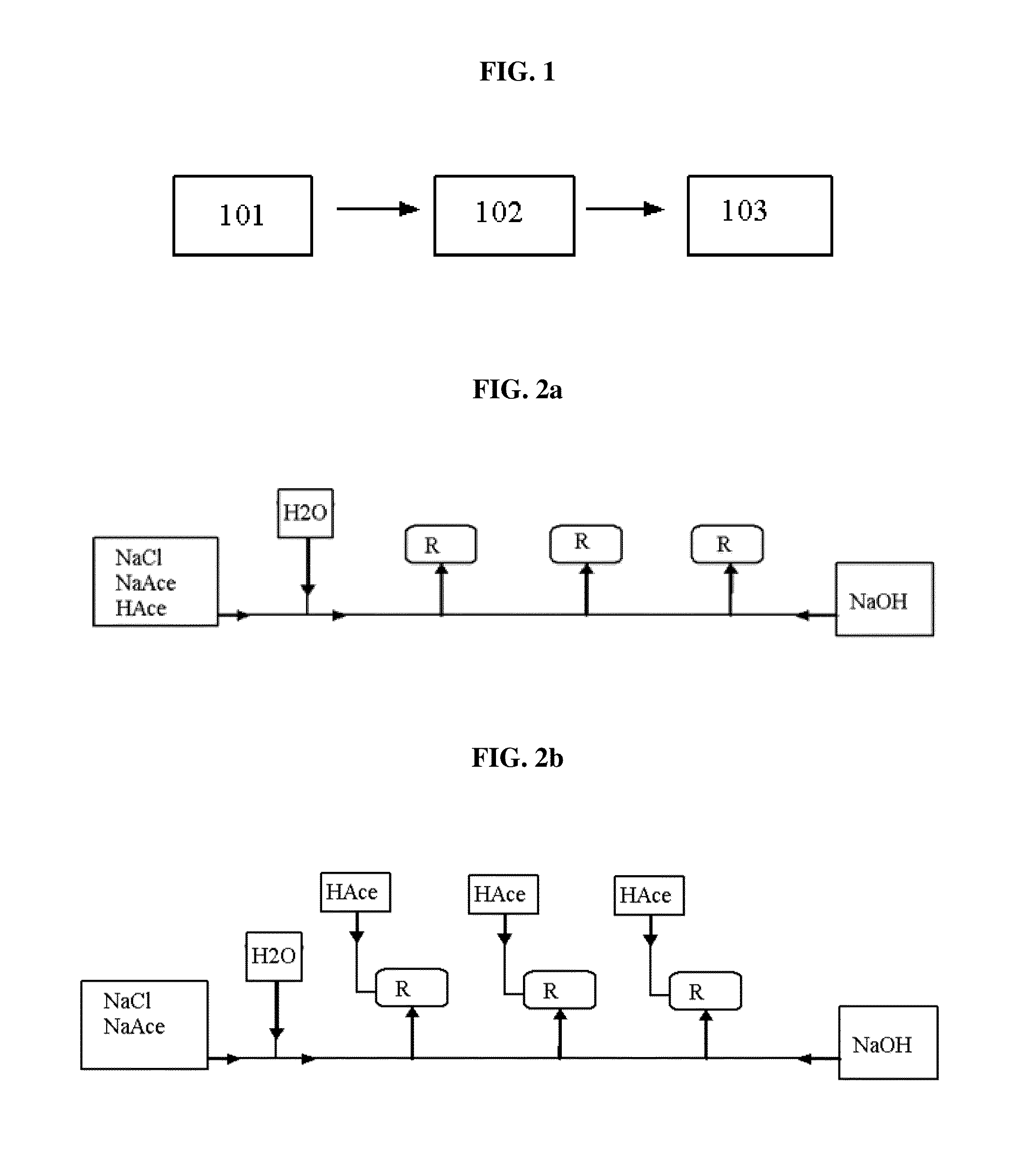

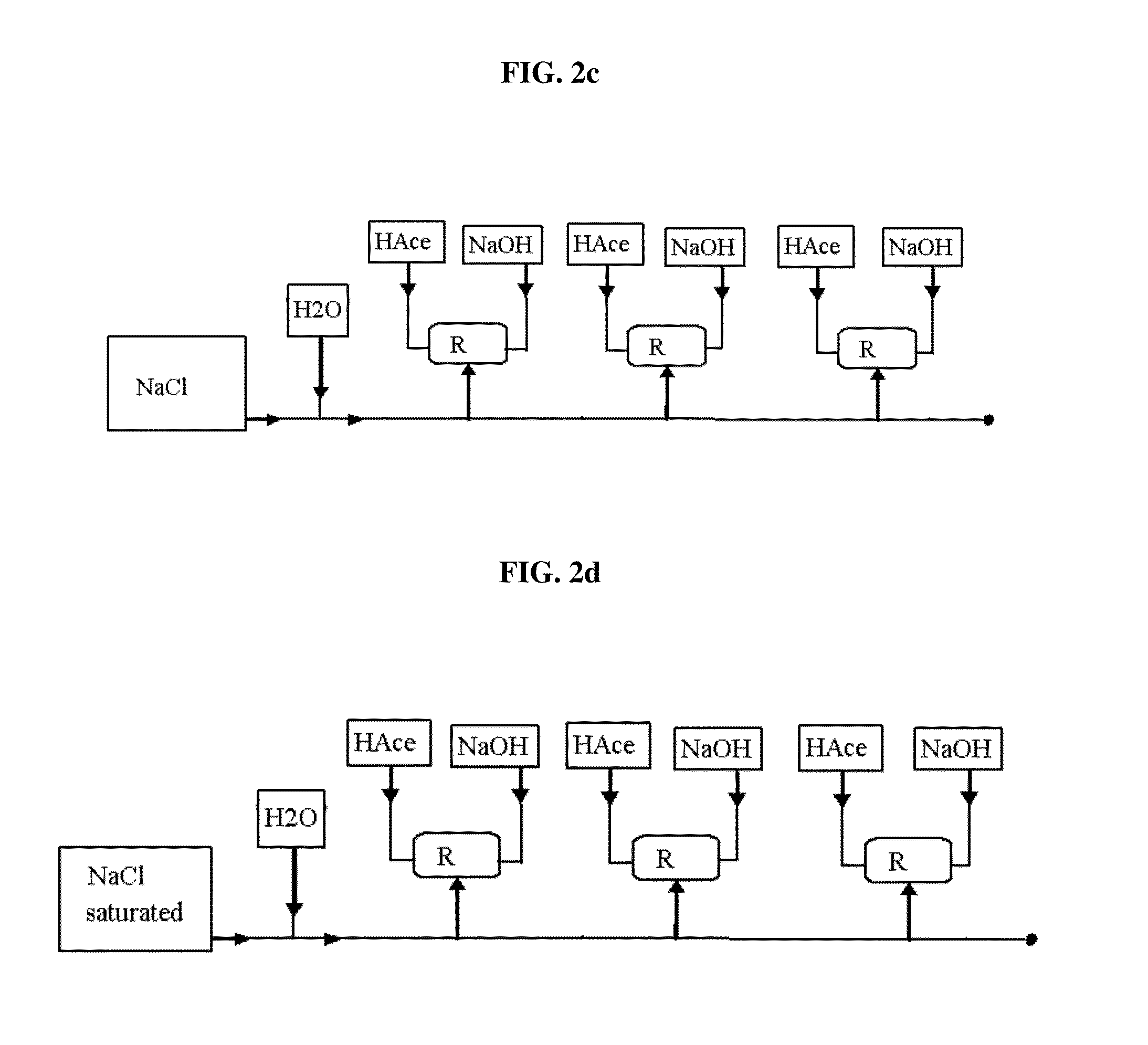

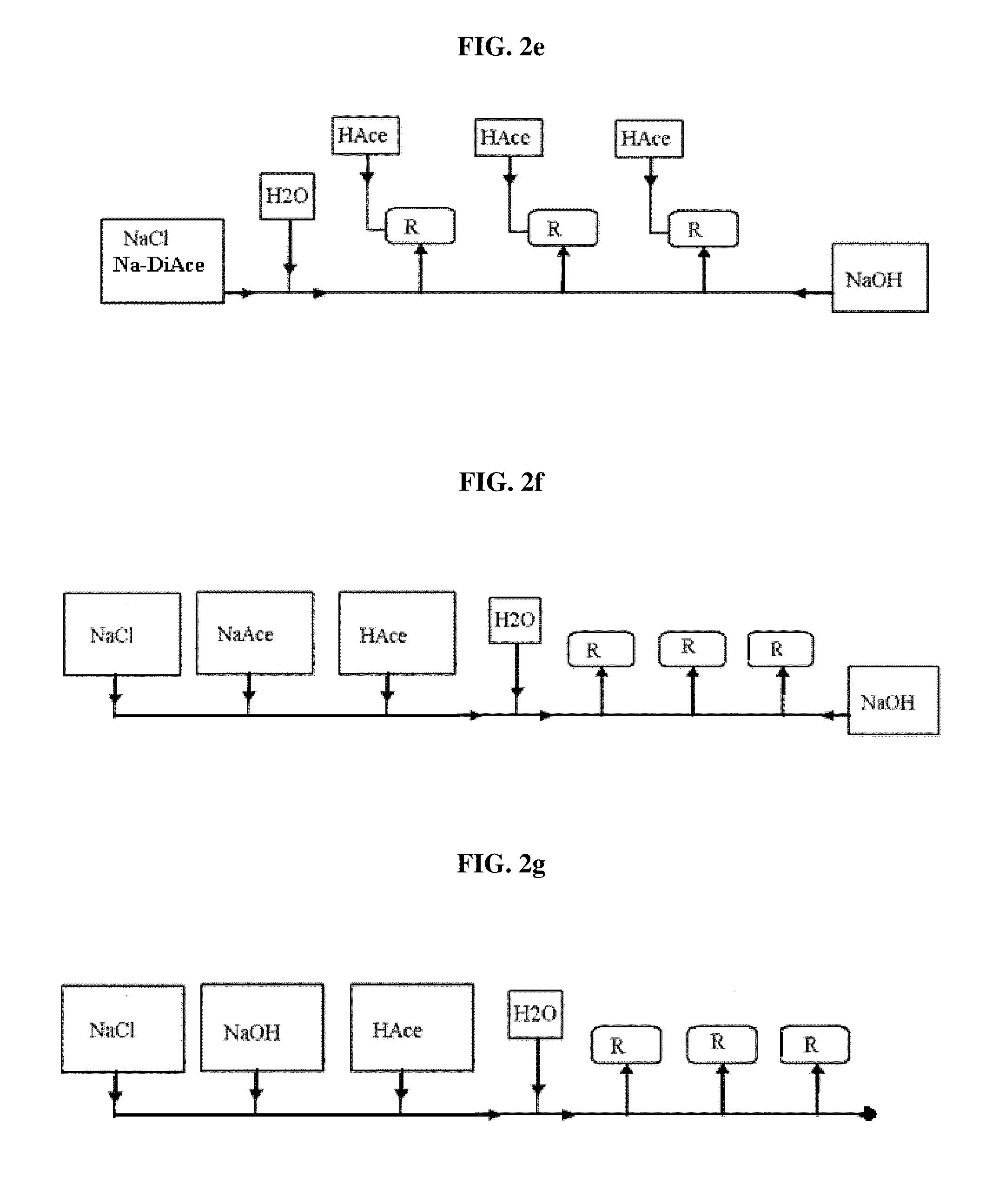

Zirconium phosphate recharging method and appartus

Methods and related apparatuses for sorbent recharging are provided. The methods and related apparatuses for recharging can recharge a specific rechargeable layer or module of a sorbent material such as zirconium phosphate in a sorbent cartridge. The methods and apparatuses include a fluid source containing at least one recharging fluid, wherein the fluid source is fluidly connectable to at least one rechargeable sorbent module for use in sorbent dialysis in a fluid flow path. The methods and apparatuses include passing a single solution through the zirconium phosphate for ion exchanges, resulting in zirconium phosphate to maintain a substantially consistent pH in a dialysate used during dialysis.

Owner:MOZARC MEDICAL US LLC

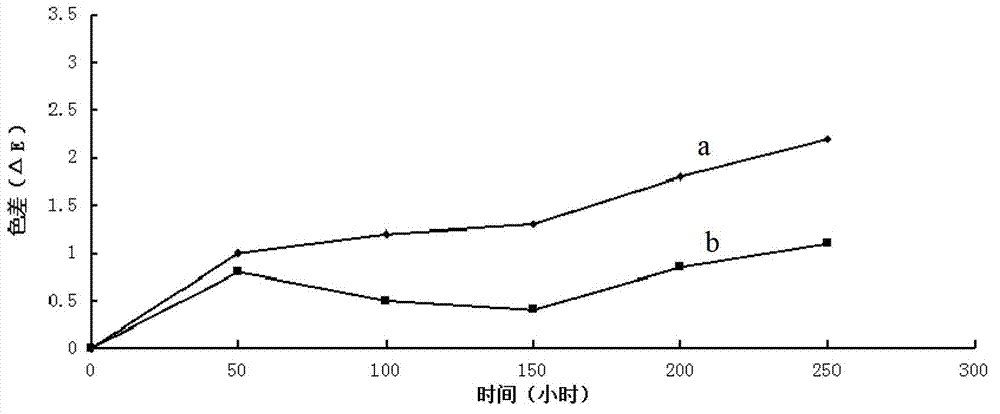

Fabrics having a topically applied silver-based finish exhibiting a reduced propensity for discoloration

InactiveUS20040106341A1Highly beneficial durabilityImprove performanceBiochemical fibre treatmentSynthetic resin layered productsTopical surfaceIon exchange

Improvements in the wash durability and discoloration levels for fabrics having topically applied silver-ion treatments (such as ion-exchange compounds, like zirconium phosphates, glasses and / or zeolites) are provided. Such solid compounds are generally susceptible to discoloration and, due to the solid nature thereof, are typically easy to remove from topical surface applications. The inventive treatment requires the presence of a specific polyurethane binder, either as a silver-ion overcoat or as a component of a dye bath mixture admixed with the silver-ion antimicrobial compound. In addition, specific metal halide additives (preferably substantially free from sodium ions) are utilized to combat the discolorations typical of such silver-ion formulations. As a result, wash durability, discoloration levels, or both, can be improved to the extent that after a substantial number of standard launderings and dryings, the inventive treatment does not wear away in any appreciable amount and the color of the treatment remains substantially the same as when first applied. The particular treatment method as well as the treated fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

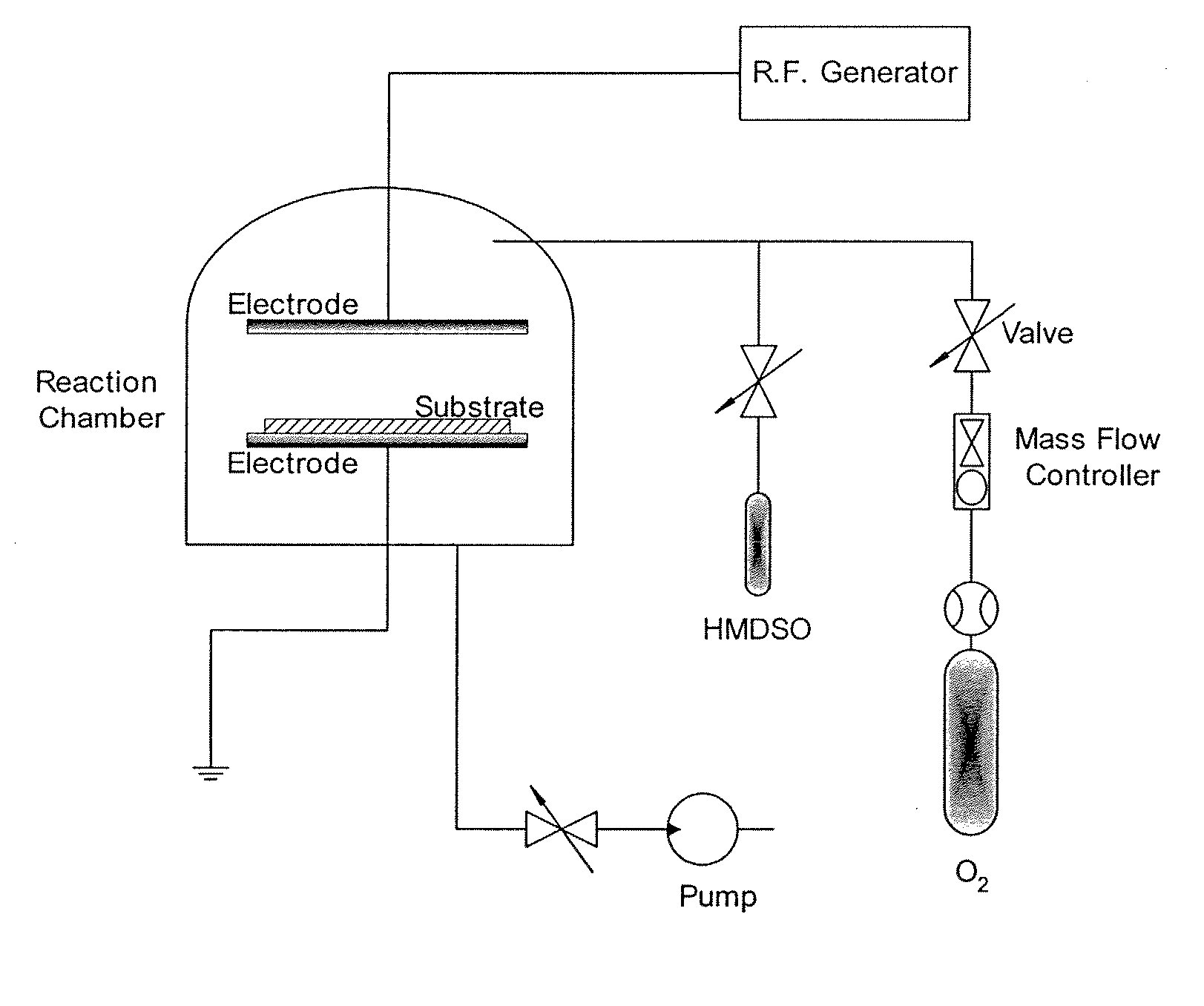

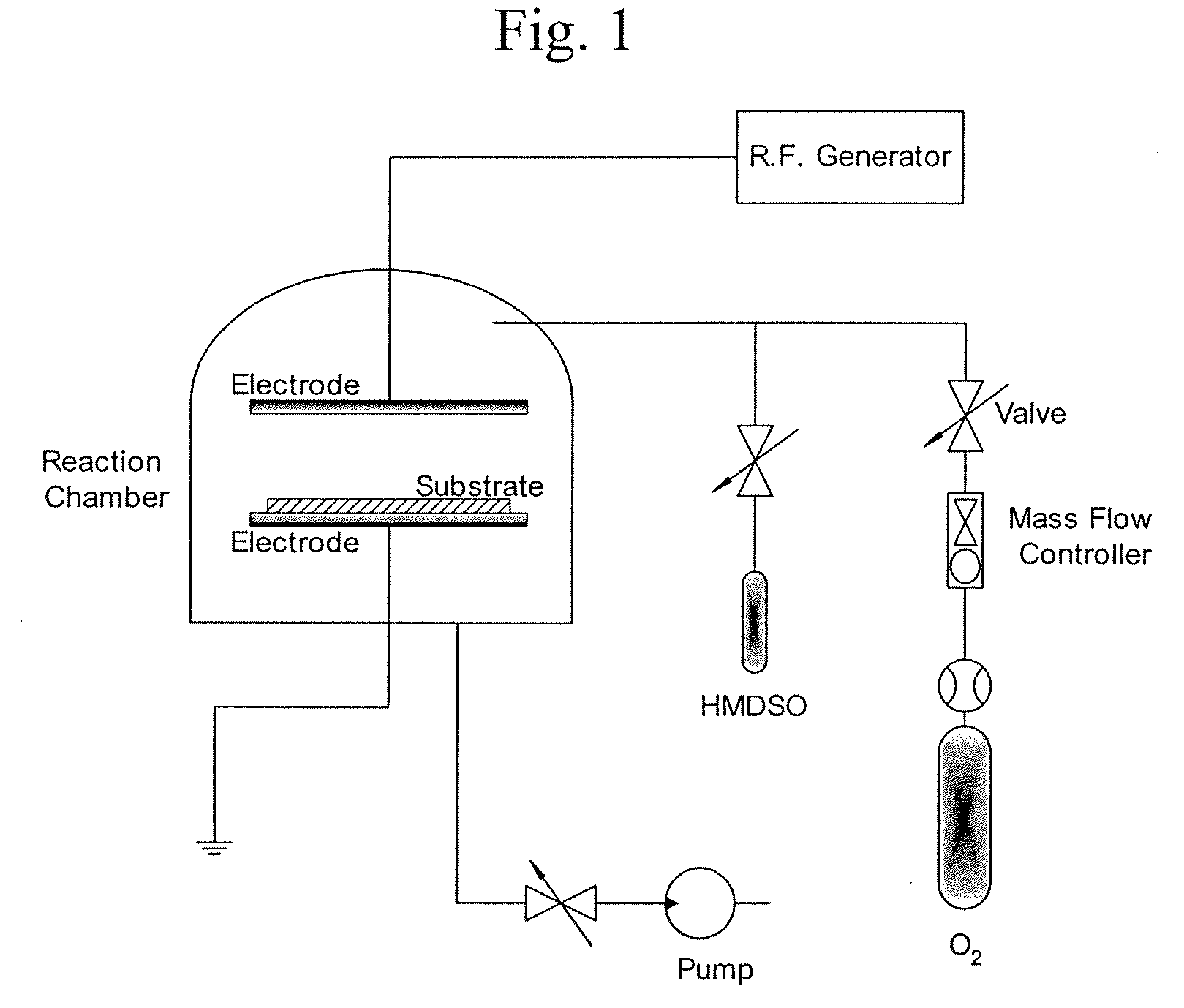

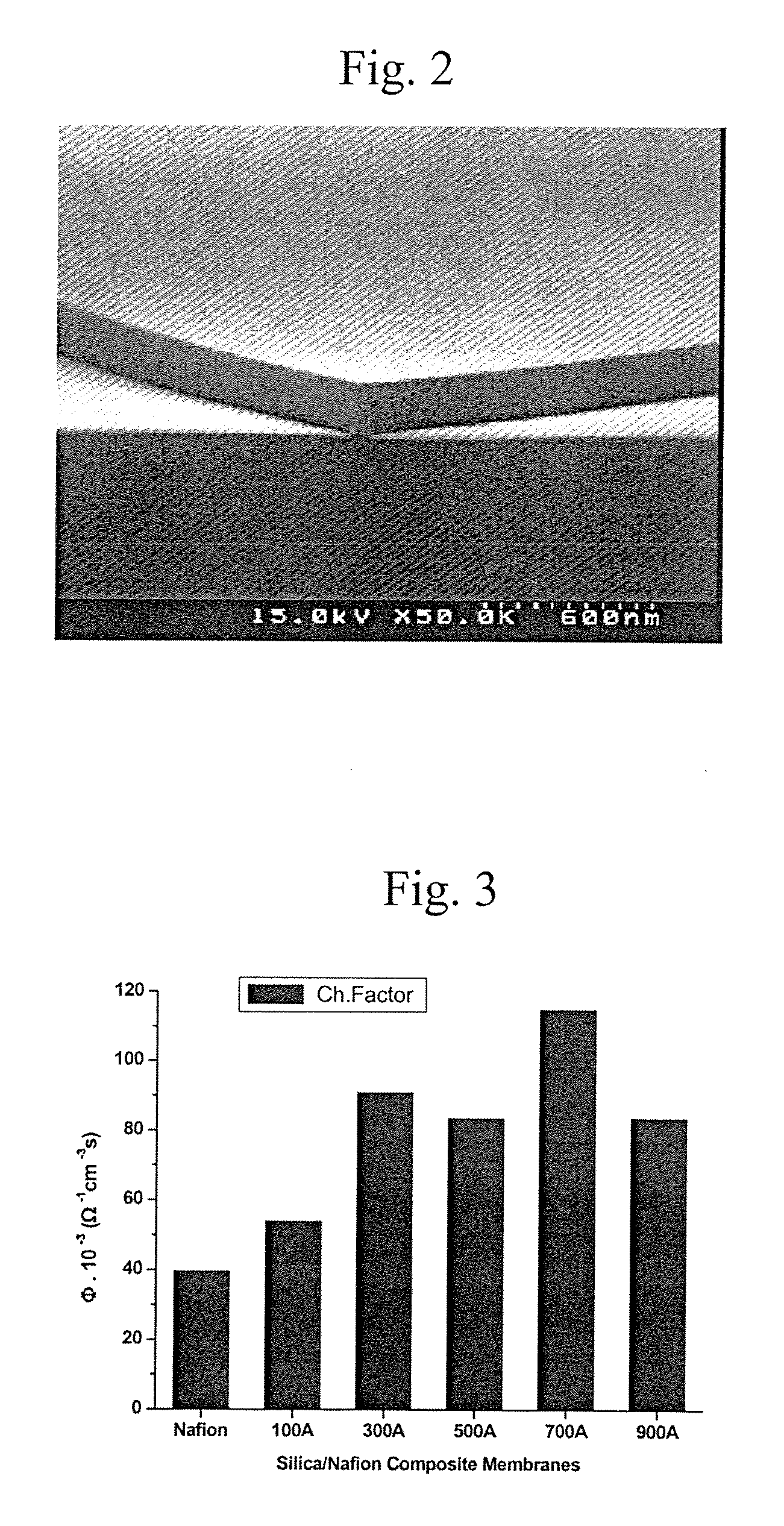

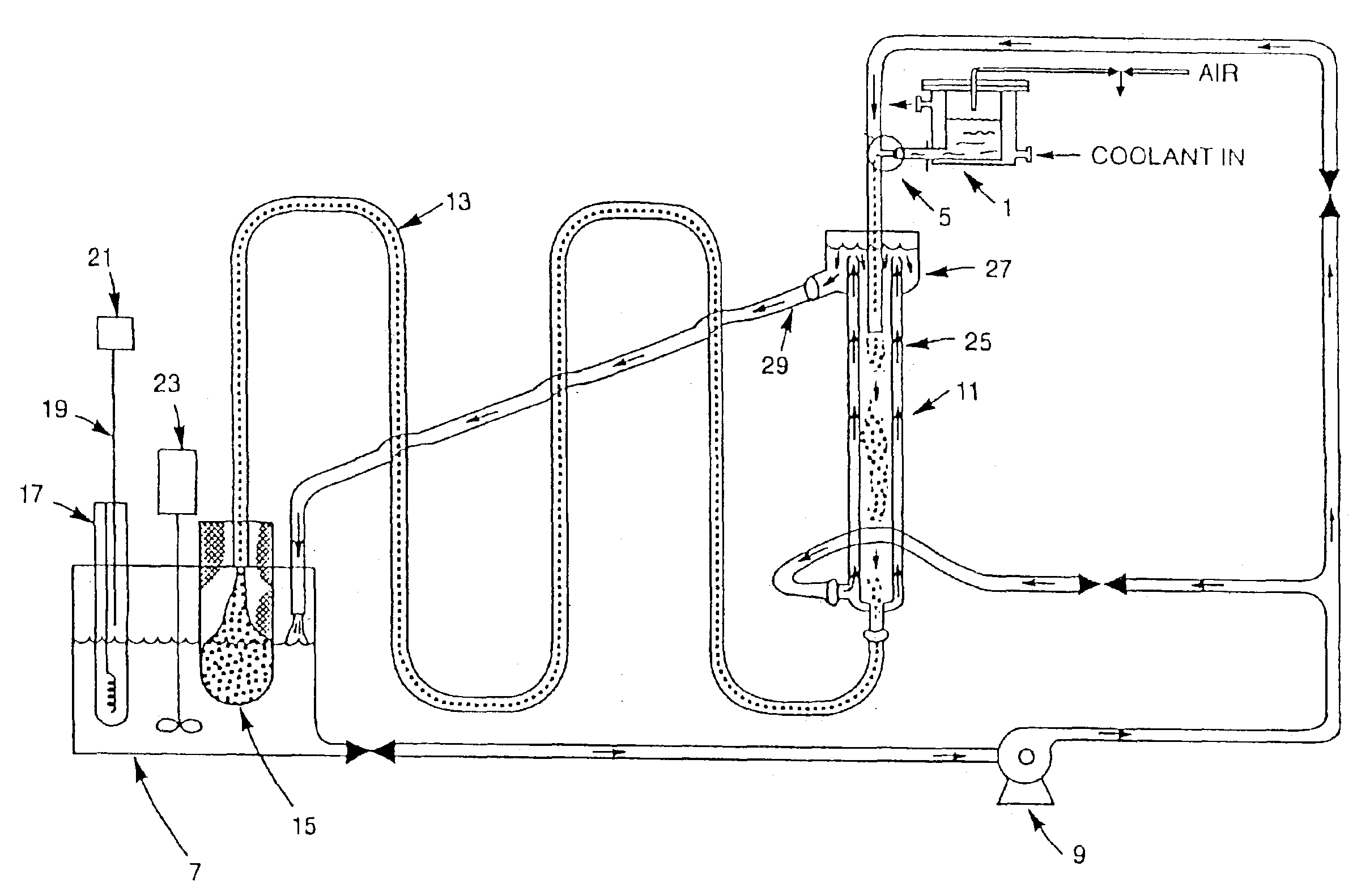

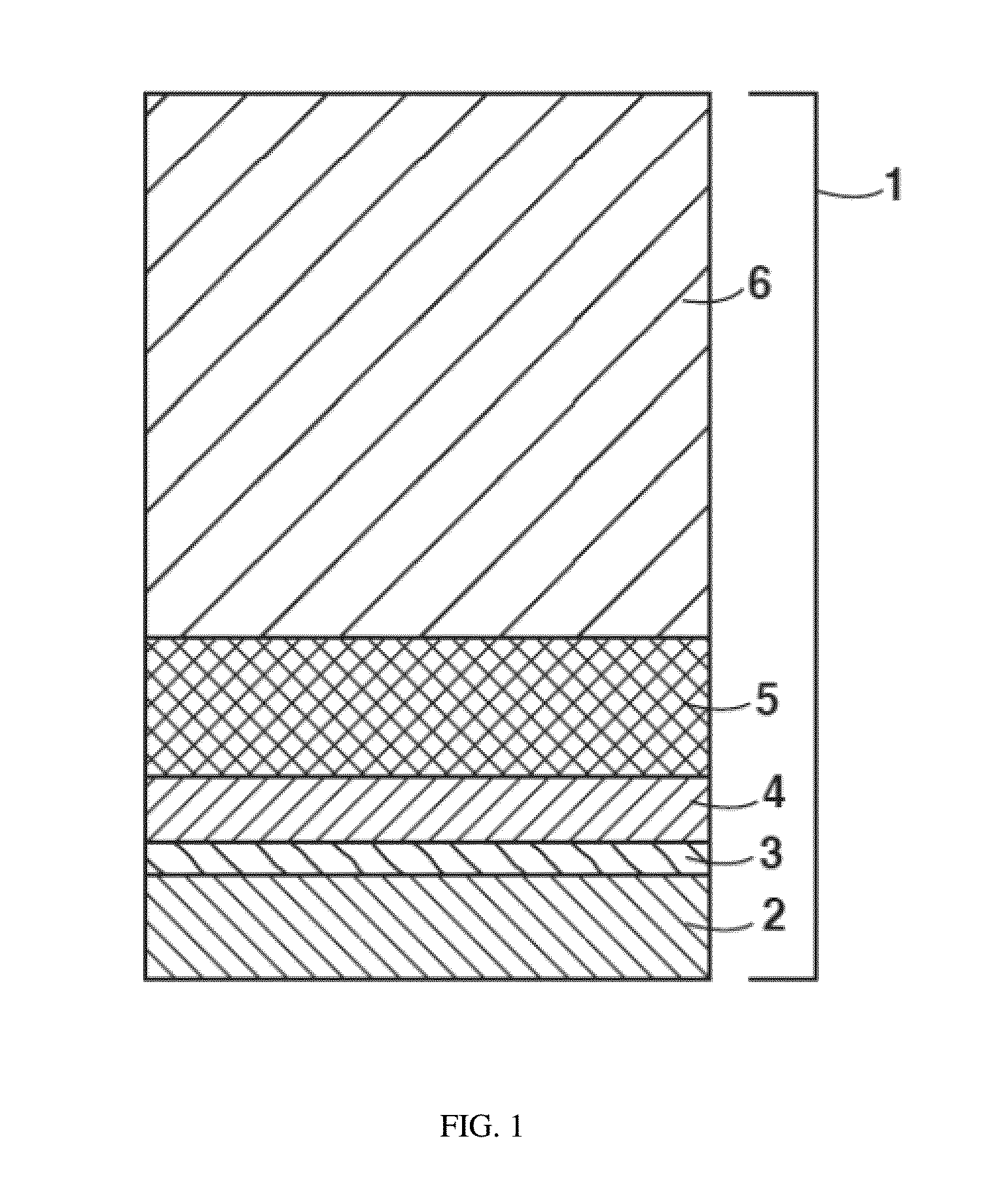

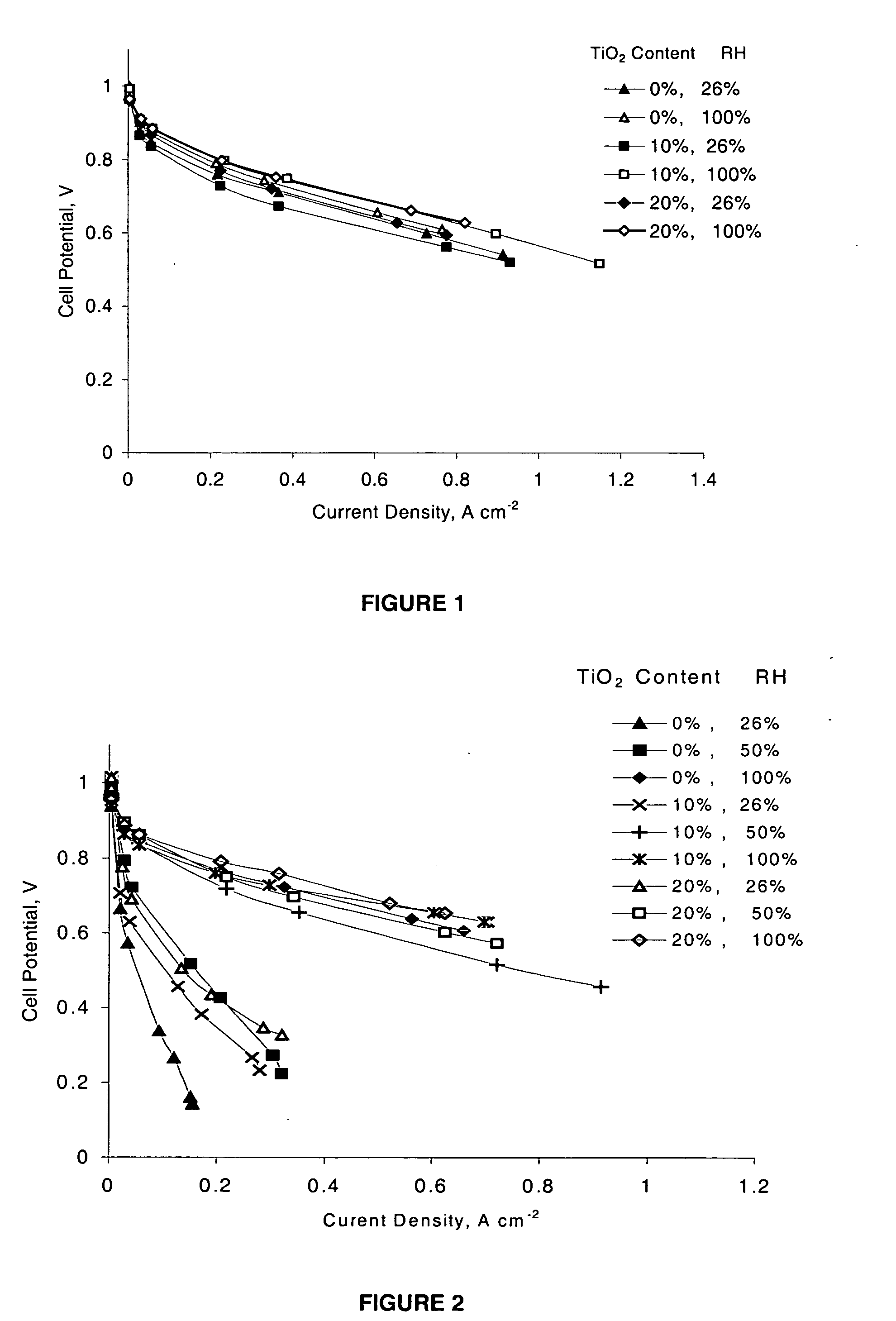

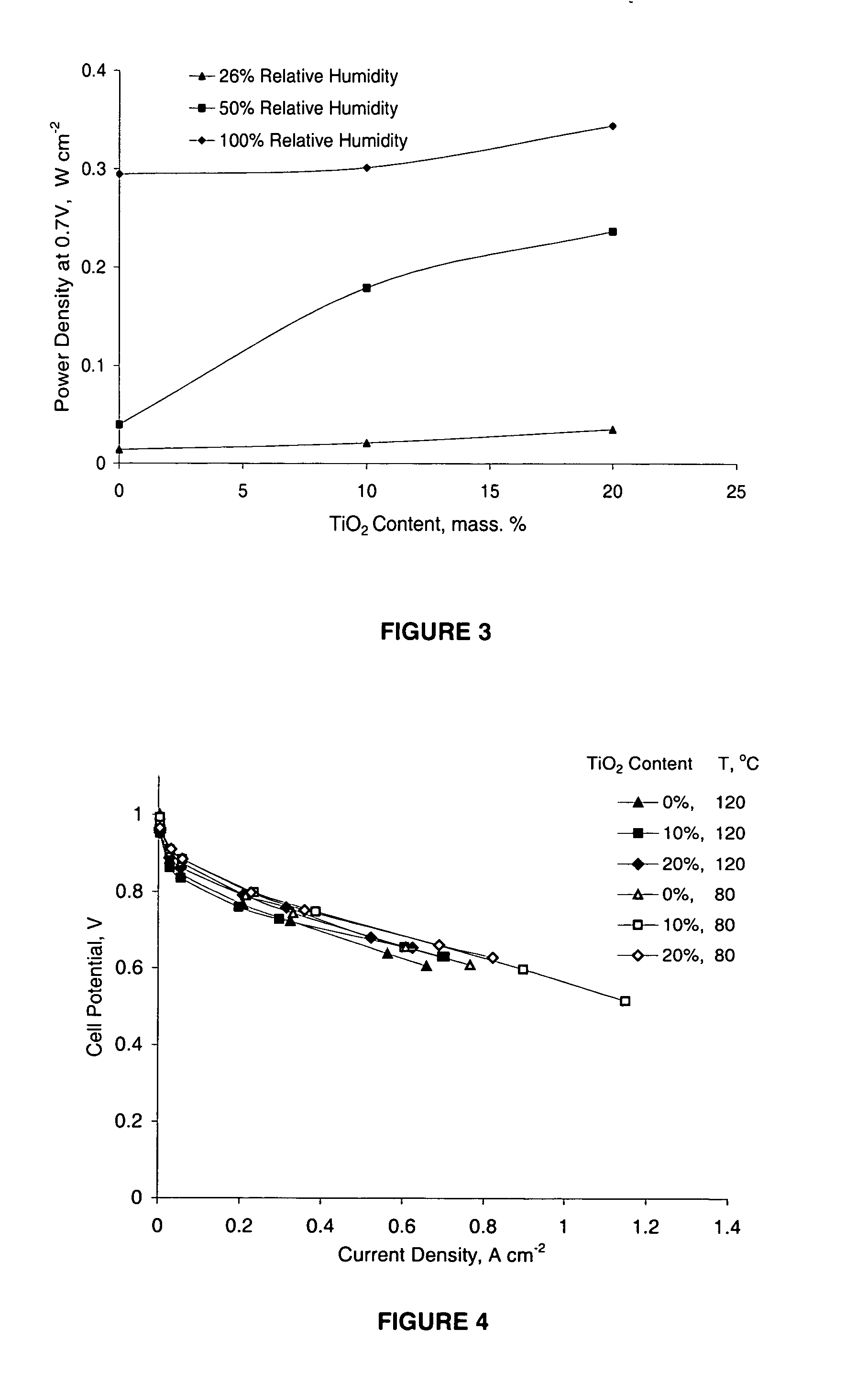

Method to manufacture composite polymer electrolyte membranes coated with inorganic thin films for fuel cells

InactiveUS20070231655A1Reduce conductivityLow methanol permeabilityMaterial nanotechnologyFinal product manufactureSilicon oxideMethanol crossover

The present invention relates to a method for manufacturing composite polymer electrolyte membranes coated with inorganic thin films for fuel cells using a plasma enhanced chemical vapor deposition (PECVD) method or a reactive sputtering method, so as to reduce the crossover of methanol through polymer electrolyte membranes for fuel cells and enhance the performance of the fuel cells. The manufacturing method of composite polymer electrolyte membranes coated with inorganic thin films for fuel cells according to the present invention is characterized to obtain composite membranes by coating the surface of commercial composite polymer electrolyte membranes for fuel cells with inorganic thin films using a PECVD method or a reactive sputtering method. The inorganic materials to form the inorganic thin films are chosen one or more from the group comprising silicon oxide (SiO2), titanium oxide (TiO2), zirconium oxide (ZrO2), zirconium phosphate (Zr(HPO4)2), zeolite, silicalite, and aluminum oxide (Al2O3). The present invention, by coating the polymer electrolyte membranes for fuel cells with inorganic thin films via a PECVD method or a reactive sputtering method, reduces the methanol crossover sizably without seriously reducing the ionic conductivity of polymer electrolyte membranes, thereby, when applied to fuel cells, realizes a high performance of fuel cells.

Owner:KOREA INST OF SCI & TECH

Inorganic optical taggant and method of making

InactiveUS6899827B2Overcomes shortcomingDesired performanceCell electrodesMachines/enginesExplosive AgentsTitanium oxide

Owner:UT BATTELLE LLC

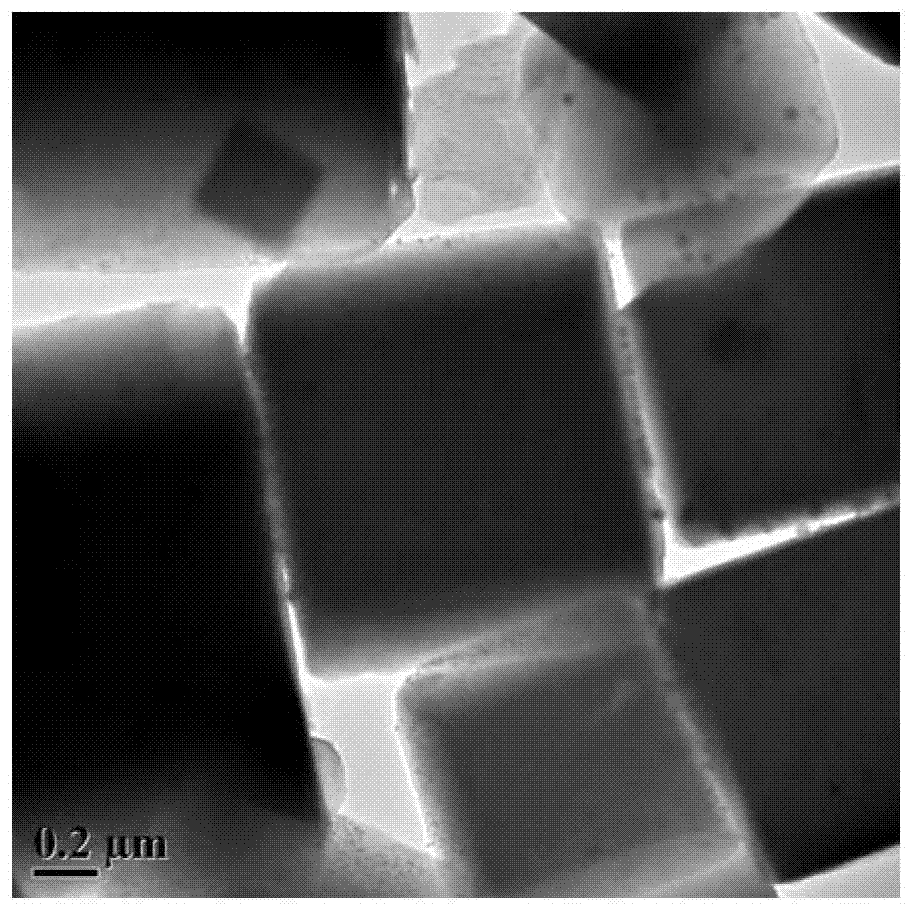

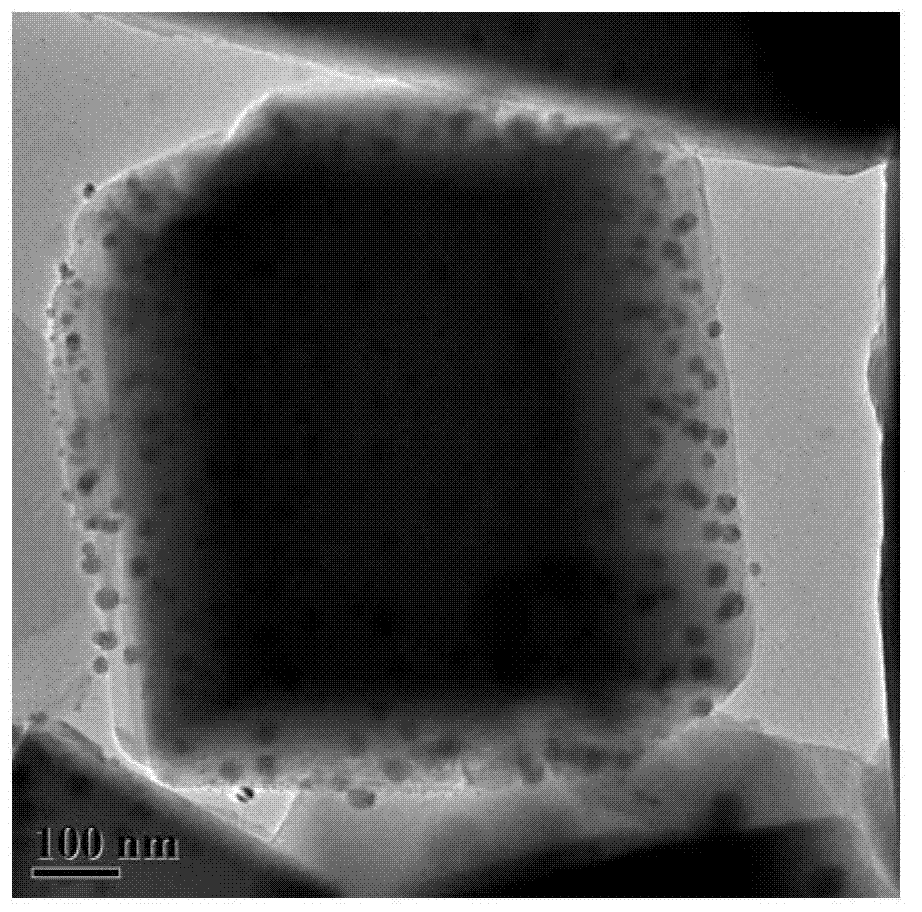

Method for preparing cubic zirconium phosphate silver-carrying antimicrobial powder

The invention relates to a method for preparing a zirconium phosphate silver-carrying antimicrobial powder, particularly a cubic zirconium phosphate silver containing antimicrobial powder. The cubic zirconium phosphate silver-carrying antimicrobial powder is in the microstructure of a cube, the silver is carried by the cube, and the side of the cube has a length of 400-1,000nm. The method comprises the following steps: preparing a cubic zirconium phosphate carrier, mixing the cubic zirconium phosphate carrier with the aqueous solution of zinc nitrate, stirring to generate a zinc-carrying intermediate; preparing the zinc-carrying intermediate into an aqueous dispersion solution, adding the silver nitrate solution so that the carrier contains 1.5-3.5% of silver ions, stirring, washing, filtering, drying and forging to obtain the final product. The carrier is prepared by adopting the atmospheric-pressure hydrothermal synthesis method, and the hydrofluoric acid used as the template agent in the old process is replaced by the sodium oxalate. The process is simple and convenient to operate, and the equipment has high selectivity. The product and the product producing process are truly safe and nontoxic, the enamel equipment can be used as the production equipment, and the production cost can be saved.

Owner:晋大纳米科技(厦门)有限公司

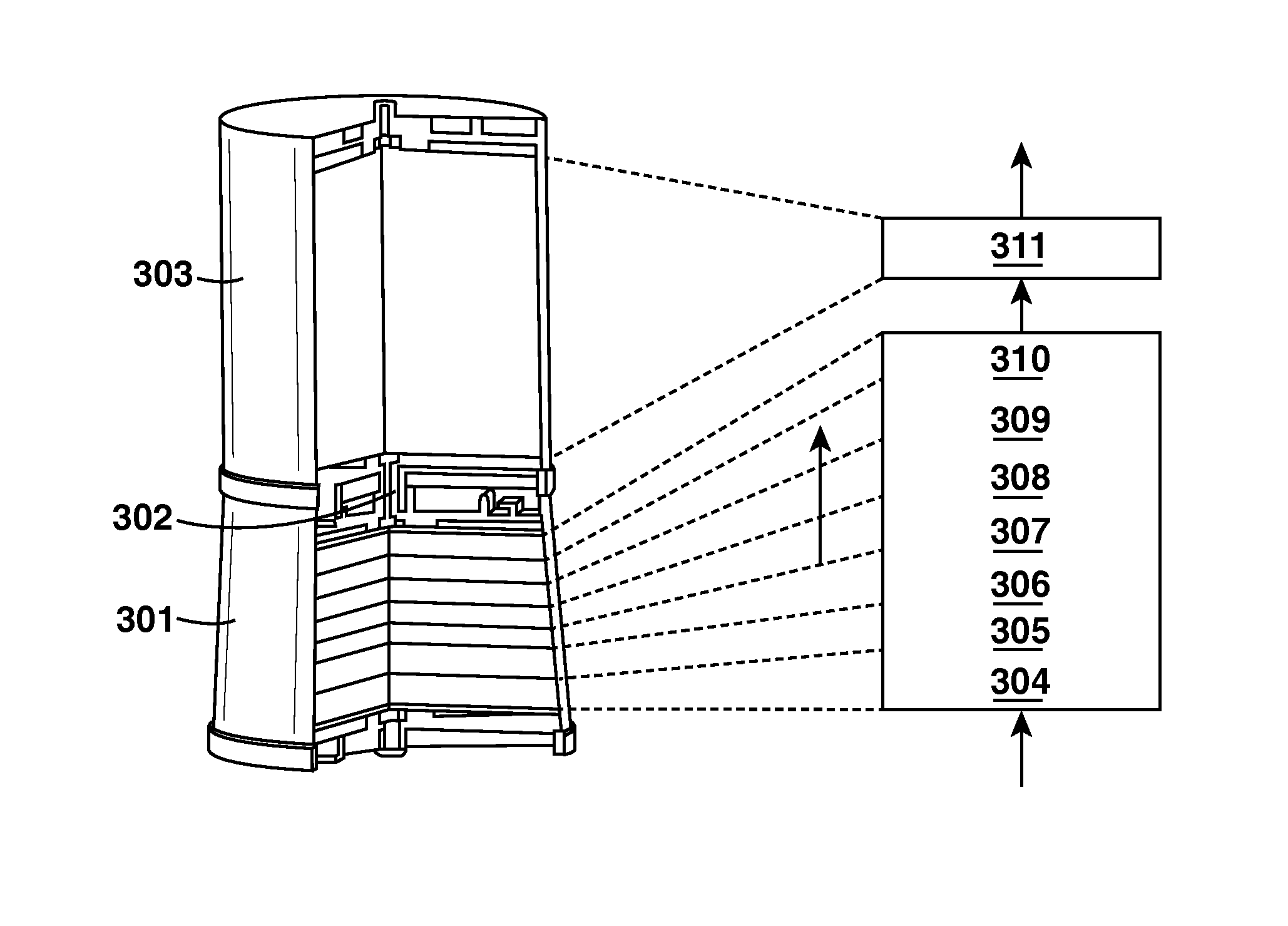

Multi-use sorbent cartridge

A sorbent cartridge comprising one or more detachable modules. The sorbent cartridge can have one or more modules contained therein having connectors connecting each of the modules. One or more of the modules can be reusable and the sorbent materials therein recharged. The sorbent cartridge can include a module containing an anion exchange resin, such as zirconium oxide, downstream of zirconium phosphate in the sorbent cartridge to recapture phosphate anions that leach out of the zirconium phosphate.

Owner:MOZARC MEDICAL US LLC

Composite membrane for fuel cell and fuel cells incorporating said membranes

A proton exchange membrane is provided which includes a proton exchange polymer, such as Nafion®, and agglomerates of metal oxide or metal phosphate particles. The particles and agglomerates are characterized in specific embodiments in having a high specific surface area. In one configuration an included particle includes a metal oxide or metal phosphate such as SiO2, ZrO2, GeO2, SnO2, TiO2 or a zirconium phosphate. A further detailed proton exchange membrane provided according to an embodiment of the invention is a membrane in which one surface is enriched in agglomerates of group IV metal oxide or phosphate particles. Inventive membranes demonstrate improvement in performance under dehydrating conditions compared to unmodified Nafion membranes.

Owner:PENN STATE RES FOUND

Functionalized polypropylene fibre and its preparation method

InactiveCN1766184AWith deodorizing functionSolve reunionMonocomponent polyolefin artificial filamentArtifical filament manufactureNatural substanceSilicon dioxide

The invention discloses a functional polypropylene fibre contained and fused a plurality of natural inorganic materials and polypropylene, which comprises: tourmaline, alumina, zirconium phosphate carried-Ag antibacterial agent, silicon dioxde, and titania. The preparation method comprises: breaking and mixing the materials, fusing and mixing said materials with polypropylene slice to obtain mother grain; then, using common fusion spinning method to treat said grain and slice. This product has well spinnability, high strength, and deodorization function.

Owner:上海依福瑞实业有限公司

Surface treated metallic implant and blasting material

InactiveUS20040158330A1Improve long-term stabilitySurface rougheningPigmenting treatmentImpression capsApatiteCrystalline materials

The invention relates to a metallic implant, which has vitreous-crystalline bioactive material on the surface thereof. According to the invention, a metallic implant base body arranged on the surface of the particles has a bioactive, vitreous-crystalline material consisting of 15-45 wt. % CaO, 40-45 wt. % P2O5, 10-40 wt. % ZrO2 and 0.7-3.5 wt. % fluoride, having apatite and calcium zirconium phosphate as main crystalline and a glass phase as an auxiliary component. Said vitreous crystalline material contains at least 35 wt. % main crystal phases and at least 5-15 wt. % auxiliary compounds. All of the percentage data is expressed in relation to the total weight of the vitreous crystalline material and the particle size of the vitreous crystalline material is between 60-350 mum.

Owner:HUMBOLDT UNIV BERLIN CHARITE UNIVSKLINIKUM CCM +1

Method and apparatus for zirconium oxide recharging

Methods and related apparatuses for sorbent recharging are provided. The methods and related apparatuses for recharging can recharge a specific rechargeable layer of a sorbent material such as zirconium oxide and / or zirconium phosphate in a sorbent cartridge. The methods and apparatuses include passing solutions containing aqueous basic solutions through the zirconium oxide. The apparatus allows for recharging the zirconium oxide, and also for recharging zirconium phosphate, wherein the sorbent materials are contained in reusable sorbent modules.

Owner:MOZARC MEDICAL US LLC

Preparation method of nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent

ActiveCN102239887AImprove antibacterial propertiesControl non-cohesiveBiocideDisinfectantsDisplacement reactionsZirconium oxychloride

The invention discloses a preparation method of a nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent. The preparation method comprises the following steps of 1, a nanoscale zirconium phosphate carrier preparation step specifically comprising that enough sodium dihydrogen phosphate aqueous solution is added into zirconium oxychloride aqueous solution to undergo areaction to produce nanoscale zirconium phosphate carriers, 2, an ultrafiltration step specifically comprising that the nanoscale zirconium phosphate carriers obtained from the step 1 are added into an ultrafilter membrane system for ultrafiltration and when a result of a detection adopting silver ions shows that there is not chloride ions in filtrate, the ultrafiltration is completed, 3, an antimicrobial metal ion adsorption and displacement step specifically comprising that nanoscale zirconium phosphate carrier sol precipitates are dissolved in pure water and then antimicrobial metal ion aqueous solution is added into the nanoscale zirconium phosphate carrier sol precipitate aqueous solution to undergo complete adsorption and displacement reactions, and 4, an inorganic antimicrobial powder preparation step specifically comprising that reaction products obtained from the step 3 are filtered by a pump and washed to form filter cakes and the filter cakes is dried by an oven, crushed slightly and calcined to form finished products. The preparation method removes an inorganic salt by-product from a zirconium phosphate synthesis process through adopting an ultrafilter membrane thus enables zirconium phosphate carriers to be utilized directly for adsorption and displacement of metal ions without high-temperature calcination.

Owner:SANDA FILM SCI & TECH XIAMEN

Fabrics having a topically applied silver-based finish exhibiting improved wash durability

InactiveUS20040106340A1Highly beneficial durabilityImprove performanceBiocideBiochemical fibre treatmentTopical surfaceIon exchange

Improvements in the wash durability and discoloration levels for fabrics having topically applied silver-ion treatments (such as ion-exchange compounds, like zirconium phosphates, glasses and / or zeolites) are provided. Such solid compounds are generally susceptible to discoloration and, due to the solid nature thereof, are typically easy to remove from topical surface applications. The inventive treatment requires the presence of a specific polyurethane binder, either as a silver-ion overcoat or as a component of a dye bath mixture admixed with the silver-ion antimicrobial compound. In addition, specific metal halide additives (preferably substantially free from sodium ions) are utilized to combat the discolorations typical of such silver-ion formulations. As a result, wash durability, discoloration levels, or both, can be improved to the extent that after a substantial number of standard launderings and dryings, the inventive treatment does not wear away in any appreciable amount and the color of the treatment remains substantially the same as when first applied. The particular treatment method as well as the treated fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

Reserve zirconium phosphate module for use in sorbent dialysis

A reserve zirconium phosphate module for continuing dialysis in the event the capacity of the original zirconium phosphate module is exceeded. The sorbent cartridge can have a sensor for detecting when the capacity of the zirconium phosphate material has been exceeded, and a valve assembly for diverting the flow of spent dialysate into the reserve module when needed. Any of the modules of the sorbent cartridge can be reusable and the sorbent materials therein recharged.

Owner:MOZARC MEDICAL US LLC

Method of zirconium phosphate recharging

Methods and related apparatuses for sorbent recharging are provided. The methods and related apparatuses for recharging can recharge a specific rechargeable layer of a sorbent material such as zirconium phosphate in a sorbent cartridge. The methods and apparatuses include passing solutions containing combinations of acids, bases and salts through a module containing a rechargeable sorbent material such as zirconium phosphate in order to replace ions bound to the zirconium phosphate with hydrogen and sodium ions. The method allows for a customizable zirconium phosphate, with control over the ratios of sodium to hydrogen on the recharged zirconium phosphate.

Owner:MOZARC MEDICAL US LLC

Ag-carrying nano antibiotic material and its preparation method and use

InactiveCN101305735AAging resistantHigh temperature resistantBiocideDisinfectantsAntibiotic YSilver ion

The invention discloses an silver-supported antibacterial nano-material and the preparation method and the application thereof. The preparation method comprises the following steps: (1) adding surfactant to a water solution of NH4H2PO4 and ZrOCl2*8H2O, co-precipitating, filtering, rinsing, dewatering, drying and pulverizing to obtain a nano-scale mesoporous zirconium phosphate carrier; and (2) adding dispersant and water to the carrier prepared in the step (1) to obtain a suspension A; mixing AgNO3, NH3*H2O and water to obtain a sliver-ammine complex ion water solution B; mixing the suspension A and the sliver-ammine complex ion water solution B, adding acid to inhibit the hydrolysis so that the generated nano-scale silver ions cluster is adhered to the carrier; and filtering, rinsing, dewatering, drying, sintering and pulverizing to obtain nano-scale silver ion antibacterial powder. The antibacterial nano-material has excellent antibacterial performances such as persistent effect, stability, high temperature resistance, etc. and can be applied in the fields such as building materials, public facilities, medical facilities and appliance, daily products, etc.

Owner:SHANGHAI SONGMING COMML CONSULTANT & SERVICE

Antimicrobial and odor adsorbing textile

The antimicrobial and odor adsorbing fabric substrate has a surface and at least a portion of the surface is coated with a finish. The finish contains a compound selected from the group consisting of silver particle-containing compounds, silver ion-containing compounds, silver ion-generating compounds, and any combinations thereof, a hyperbranched polyethyleneimine derivative, potassium citrate, inorganic chloride, a polyurethane binder, and a cross-linking agent. The silver-ion containing compound is selected from the group consisting of silver zirconium phosphate, silver zeolite, silver glass, and any mixtures thereof or a conductive silver containing nanoparticle. The hyperbranched polyethyleneimine derivative is of the formula:(R)x−h-PEI−(A)y where R is a non-hyperbranched hydrocarbon group and the hydrocarbon group has at least one linear portion. The linear portion has between 5 and 30 carbon atoms, x is a number from 1 to 10,000, h-PEI is a hyperbranched polyethyleneimine, A is an organic compound having from 1 to 4 carbon atoms, and y is a number from 0 to 500.

Owner:MILLIKEN & CO

Nano-silver antibacterial melt-blown non-woven fabric and production method thereof

ActiveCN104047114AHigh strengthAvoid breakingFilament forming substance formingArtificial thread manufacturing machinesPolyesterNonwoven fabric

The invention relates to nano-silver antibacterial melt-blown non-woven fabric and a production method thereof. The nano-silver antibacterial melt-blown non-woven fabric is characterized in that the fabric contains hybrid nanoscale antibacterial powder, a non-woven fabric base stock can be polypropylene, polyester or polyphenylene sulfide, the hybrid nanoscale antibacterial powder is formed in a way that nanoscale zirconium phosphate and silver nitrate are exchanged in water to form silver phosphate, zinc oxide needs to be added in the exchange process, and the antibacterial powder has the proportion of ingredients as follows: 2-5 percent of the silver nitrate, 90-95 percent of the zirconium phosphate and 1-5 percent of the zinc oxide. The nano-silver antibacterial melt-blown non-woven fabric has excellent inhibition and stop effects on escherichia coli, staphylococcus aureus, Candida albicans and the like, and can filter various particles with the pm (particulate matter) over 2.5 in current air haze, the filter efficiency is over 95 percent, and the antibacterial ratio is over 99 percent; the fabric is tested by sgs (Societe Generale de Surveillance); the prepared nano-silver antibacterial melt-blown non-woven fabric is good in strength, not easy to break, soft and comfortable.

Owner:李文博 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com