Ag-carrying nano antibiotic material and its preparation method and use

A nano-antibacterial material, silver-loaded technology, applied in the direction of botany equipment and methods, applications, chemicals for biological control, etc., can solve the problems of poor heat resistance, poor safety and chemical stability, drug resistance, etc. Achieve excellent comprehensive performance, excellent antibacterial properties, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 20 grams of surfactant carboxymethyl cellulose to NH 4 h 2 PO 4 and ZrOCl 2 ·8H 2 The aqueous solution of O was stirred at room temperature for 10 minutes to form a co-precipitation, filtered, washed with water, and then the washed product ZrO(OH) 2 , performing centrifugal dehydration, then drying the obtained product at 80°C for 8 hours, calcining at 700°C for 1 hour, and jet crushing to obtain a nanometer mesoporous zirconium phosphate carrier;

[0022] Said NH 4 h 2 PO 4 and ZrOCl 2 ·8H 2 In aqueous solution of O, NH 4 h 2 PO 4 The content of ZrOCl is 1.0mol / L, ZrOCl 2 ·8H 2 O content is 0.5mol / L;

[0023] (2) The carrier obtained in step (1) is added with dispersant polyvinyl alcohol and water to obtain suspension A;

[0024] AgNO 3 , NH 3 ·H 2 O was mixed with water, and reacted at room temperature for 45 minutes to obtain the silver ammine ion aqueous solution B;

[0025] Mix A and B, add 10ml oxalic acid, the resulting nano-scale silve...

Embodiment 2

[0032] (1) Add 30 grams of surfactant to NH 4 h 2 PO 4 and ZrOCl 2 ·8H 2 The aqueous solution of O was stirred at 25°C for 20 minutes to form a co-precipitation, filtered, washed with water, and the washed product ZrO(OH) 2 , using a centrifuge to dehydrate for 20 minutes, then drying the obtained product at 90°C for 8 hours, calcining at 800°C for 1.5 hours, and jet crushing to obtain a nano-mesoporous zirconium phosphate carrier;

[0033] Said NH 4 h 2 PO 4 and ZrOCl 2 ·8H 2 In aqueous solution of O, NH 4 h 2 PO 4 The content of ZrOCl is 1.0mol / L, ZrOCl 2 ·8H 2 O content is 0.6mol / L;

[0034] Said surfactant is carboxymethyl cellulose (CMC);

[0035] (2) The carrier obtained in step (1) is added with a dispersant and water to obtain a suspension A;

[0036] AgNO 3 , NH 3 ·H 2 O was mixed with water, and reacted at room temperature for 50 minutes to obtain an aqueous solution B of silver ammine ions;

[0037] Mix A and B, add 20ml of oxalic acid, the resul...

Embodiment 3

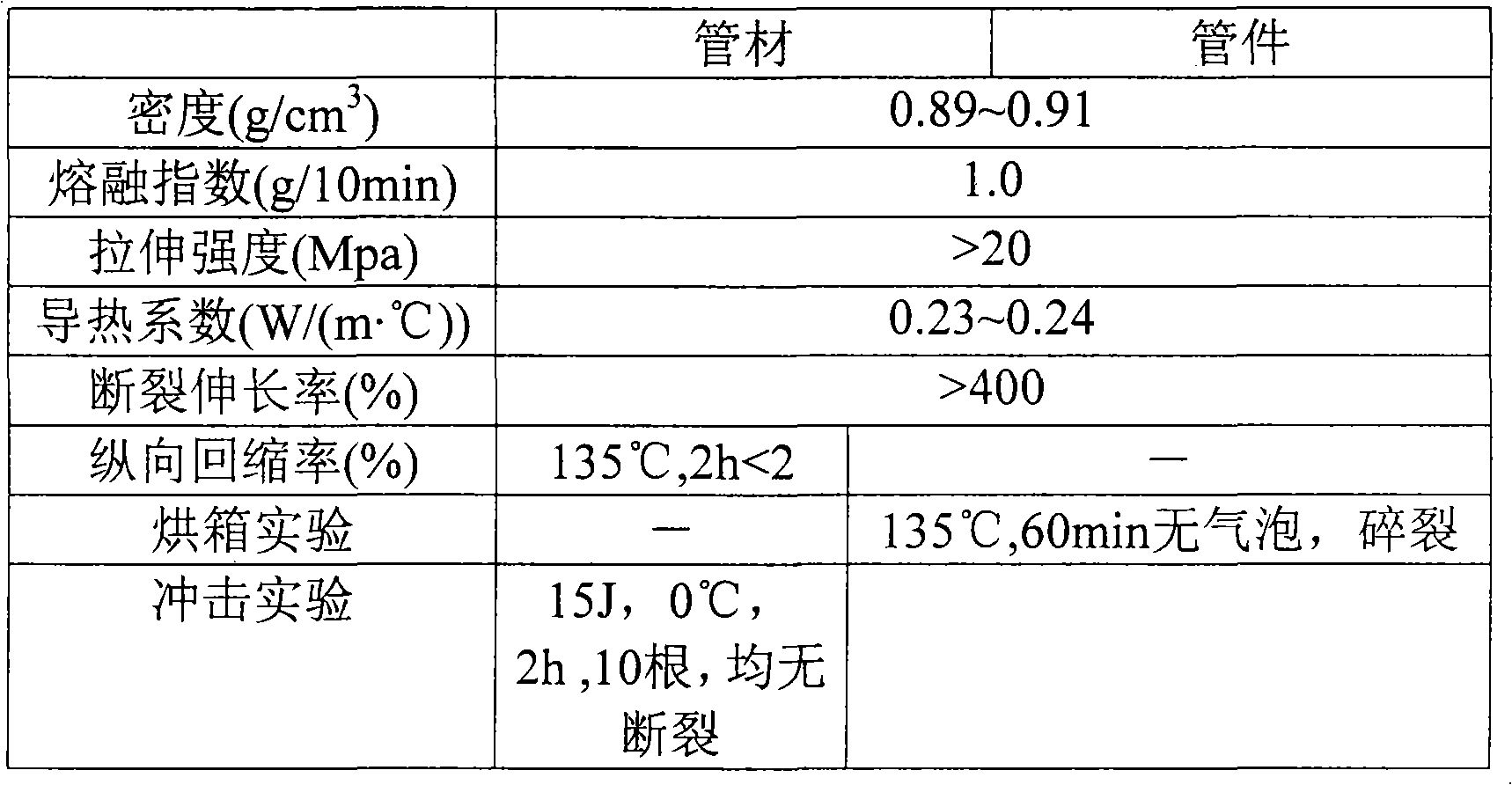

[0046] The antibacterial material and resin (PP-R) of Example 1 are mixed evenly in a low-speed mixer, and then according to certain process conditions, pipes and pipe fittings of various specifications are produced respectively through a pipe production line and an injection molding machine. The test results of the main technical performance are as follows:

[0047] Antibacterial evaluation:

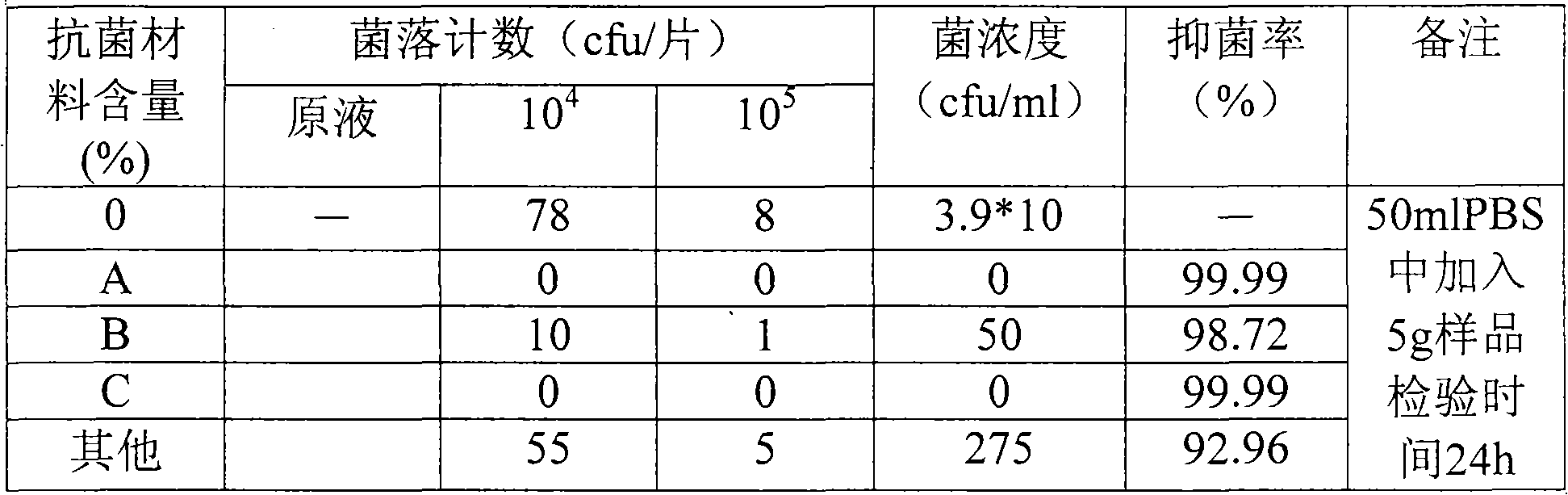

[0048] The antibacterial test was carried out by using the vibration test method of the first volume of the third edition of the "Disinfection Technical Specifications" of the Ministry of Health. We tested Gram-negative and positive bacteria, Escherichia coli and Staphylococcus aureus. The results are shown in Table 3. Visible The water supply pipe prepared by us has antibacterial effect and has advantages over other products in terms of high antibacterial efficiency.

[0049] Table 3 Antibacterial test results of antibacterial water supply pipes

[0050]

[0051] Evaluation of mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com