Two-layer co-extruding plastic drainage pipe and preparation method thereof

A double-layer co-extrusion and drainage pipe technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of easy aging of rainwater pipes, high pipe cost, and inconvenient installation, and achieve light weight and reduce overall weight , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: D75 specification (outer diameter is 75mm)

[0024] The formula is as follows:

[0025] Outer layer: ASA or PMMA (green)

[0026] Inner layer: polyvinyl chloride resin (PVC SG-5) 100, composite stabilizer (Bear 318) 3.5, impact modifier (CPE) 3, stearic acid 0.2, calcium stearate 0.2, AC foaming agent 0.4, foam regulator ZB5304, calcium carbonate 10, PE wax 0.4, lead stearate 0.3

[0027] Extrusion process settings:

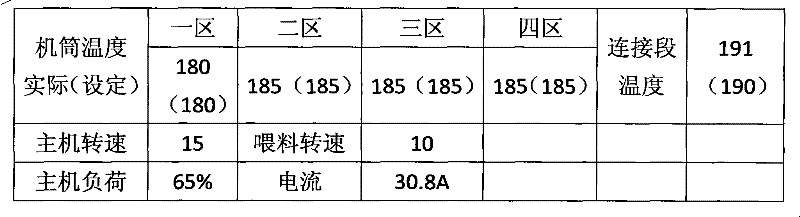

[0028] Outer layer (ASA or PMMA layer):

[0029]

[0030] inner layer:

[0031]

Embodiment 2

[0032] Embodiment 2: D110 specification (outer diameter is 110mm)

[0033] The formula is as follows:

[0034] Outer layer: ASA or PMMA (blue)

[0035] Inner layer: polyvinyl chloride resin (PVC SG-5) 100, compound stabilizer (Bear brand 318) 3.8, impact modifier (CPE) 4, stearic acid 0.3, calcium stearate 0.3, AC foaming agent 0.5, foam regulator ZB5305, calcium carbonate 15, PE wax 0.5, lead stearate 0.6

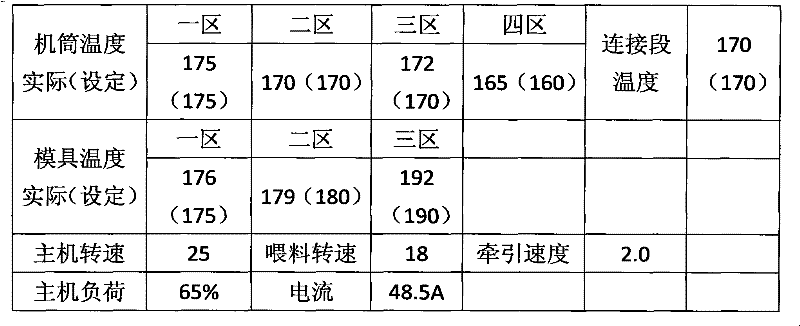

[0036] Outer layer (ASA or PMMA layer):

[0037]

[0038] inner layer:

[0039]

Embodiment 3

[0040] Embodiment three: D200 specification (outer diameter is 200mm)

[0041] The formula is as follows:

[0042] Outer layer: ASA or PMMA (red)

[0043] Inner layer: polyvinyl chloride resin (PVC SG-5) 100, composite stabilizer (Bear 318) 4.5, impact modifier (CPE) 6, stearic acid 0.5, calcium stearate 0.6, AC foaming agent 0.6, foam regulator ZB5308, calcium carbonate 30, PE wax 0.8, lead stearate 0.8

[0044] Extrusion process settings:

[0045] Outer layer (ASA or PMMA layer):

[0046]

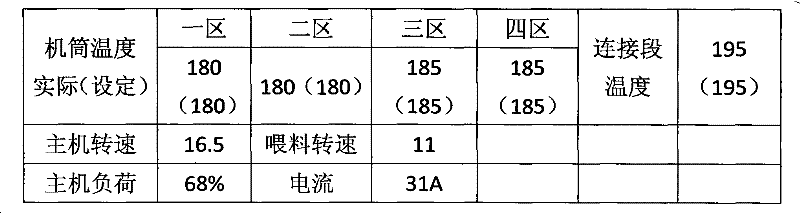

[0047] inner layer:

[0048]

[0049]

[0050] The outer layer of the drainpipe obtained through the above three embodiments is an anti-aging layer, which can solve the problem of aging resistance. The inner layer adopts the foaming process formula, which can not only reduce the overall weight, improve the impact resistance of the pipe, have the effect of sound insulation, but also reduce the cost of the drain pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com