Antibacterial spectacle lens and manufacturing process thereof

A production process and antibacterial eye technology, applied in the field of spectacle lenses, can solve the problems of no antibacterial property, light transmittance, etc., and achieve the effects of long-lasting and effective antibacterial function, high heat resistance, and low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

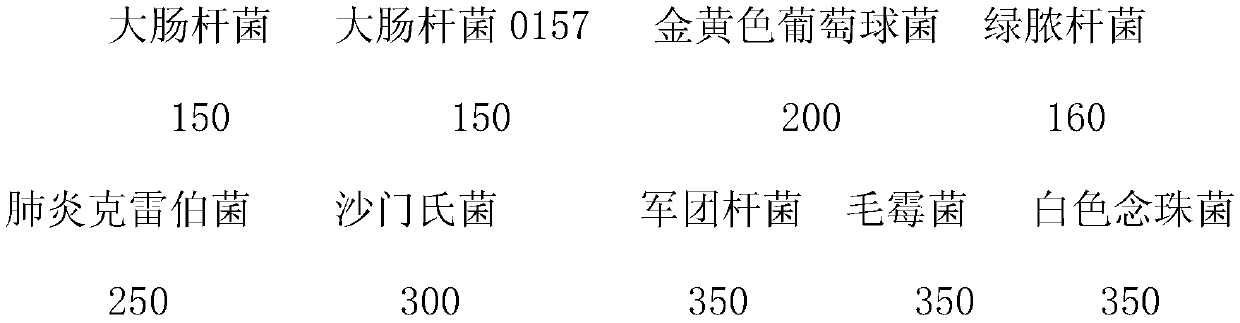

[0014] An antibacterial spectacle lens, which is formed by extrusion and solidification of the following components by weight percentage: 70-80 parts of propylene glycol diethylene glycol carbonate, 5-8 parts of polypropylene glycol, 2-3 parts of nano silicon dioxide, silver 0.5-1 parts of ions, 0.5-1 parts of zinc ions, 5-8 parts of organic solvents, 2-4 parts of glass particles. Polypropylene glycol is a plasticizer, and nano-silica can further increase the strength of the lens.

[0015] Optimized, the following components are extruded and solidified by weight percentage, 75 parts of propylene glycol diethylene glycol carbonate, 6.5 parts of polypropylene glycol, 2.5 parts of nano-silicon dioxide, 0.8 parts of silver ions, 0.8 parts of zinc ions, organic 6.5 parts of solvent, 3 parts of glass particles, using this component to process spectacle lenses, the antibacterial effect, the light transmittance of the lens and the cost performance are higher.

[0016] A kind of antib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com