Preparation method of a green degradable high-barrier and high-transparency nano-cellulose composite film

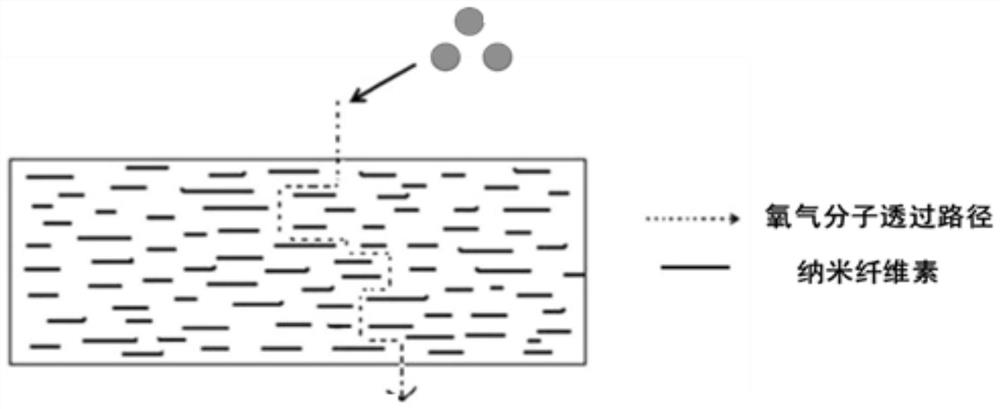

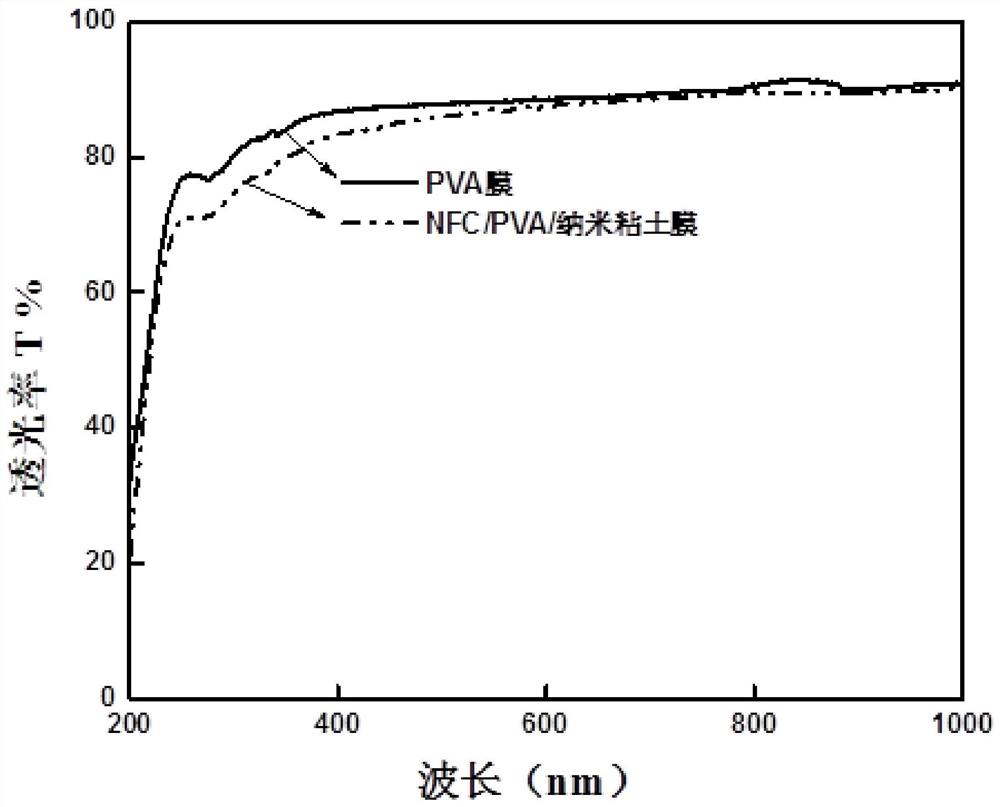

A nanocellulose, high-transparency technology, applied in the field of packaging materials, can solve the problems of unsatisfactory mechanical properties, insufficient transparency, and barrier properties to be improved, and achieves improved oxygen barrier properties and strength properties, excellent water resistance, and improved barrier properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a green degradable high-barrier and high-transparency nanocellulose composite film, comprising the following steps:

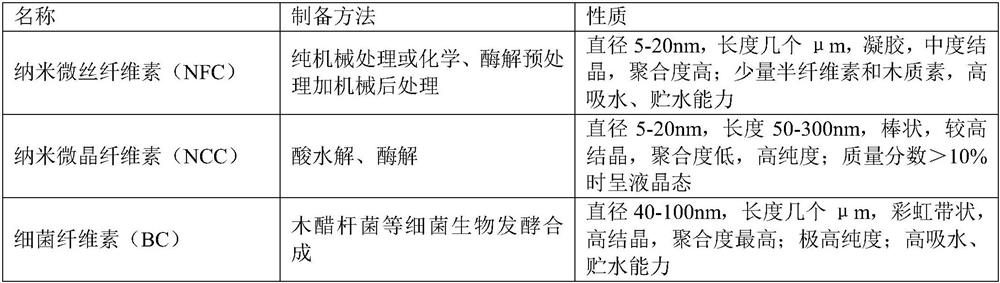

[0044] 1) Add nanocellulose gel with a concentration of 0.5-1.5wt% into water, prepare a nanocellulose solution with a concentration of 0.1-0.8wt%, and disperse at 10000-15000r / min for 5-15min.

[0045] 2) Adding nanoclay inorganic particles into water to prepare a nanoclay suspension with a concentration of 0.5-5 wt%, and dispersing at 10000-15000 r / min for 2-6 hours.

[0046] 3) Take solid PVA and dissolve it in water to prepare a PVA solution with a concentration of 5-10wt%, then add nanocellulose dispersion, heat and stir in a water bath at 90-100°C for 1-3 hours, then add nano-clay suspension, continue Stir and mix for 2-4 hours to obtain a nanocellulose / PVA / nanoclay composite liquid, wherein the mass ratio of PVA, nanocellulose and nanoclay is 70-98:1-15:1-15.

[0047] 4) Put the nanocellulose / PVA / nanoclay composite liquid a...

Embodiment 1

[0054] 1) Preparation of nanocellulose aqueous dispersion:

[0055] Get 200g concentration and be that the nano-cellulose (nanofibrillated cellulose) gel of 1% is added into the deionized water of 200g, be mixed with the nano-cellulose solution that concentration is 0.5%, adopt high-speed disperser at the number of revolutions of 10000r / min Disperse for 15 minutes.

[0056] 2) Preparation of nanoclay suspension: get 10g of nanoclay inorganic particles (bentonite) and add it to 200g of deionized water to prepare a nanoclay suspension with a concentration of 0.5%, and disperse at a speed of 10000r / min using a high-speed disperser Processing 2h.

[0057] 3) Preparation of nanocellulose / PVA / nanoclay composite liquid: take 8g of solid PVA (degree of polymerization between 600~2500, degree of alcoholysis between 80%~98%) and dissolve it in 100g of deionized water, Then add a certain proportion of nano-cellulose aqueous dispersion, place it in a 90°C constant temperature water bath...

Embodiment 2

[0061] A method for preparing a green degradable high-barrier and high-transparency nanocellulose composite film, comprising the following steps:

[0062] 1) Inoculate the Acetobacter xylinum strain into the seed medium, plug the bottle mouth with sterilized cotton, shake gently to disperse the seeds in the medium, and then culture it in a constant temperature incubator at 25°C for 3 days. Take the activated strain and insert it into the slant culture medium, shake and cultivate it in a constant temperature shaker at 30°C and 150rpm for 24 hours. Then take 15mL of cultured seeds and insert them into 200mL of fermentation medium, shake fully to separate the strains and fully disperse them in the fermentation medium, then vibrate and culture in a constant temperature shaker at 30°C and 150rpm for 7 days to obtain bacterial fibers plain film. Take out the bacterial cellulose membrane from the fermentation medium, filter it, wash it with deionized water, soak it in 4% NaOH soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com