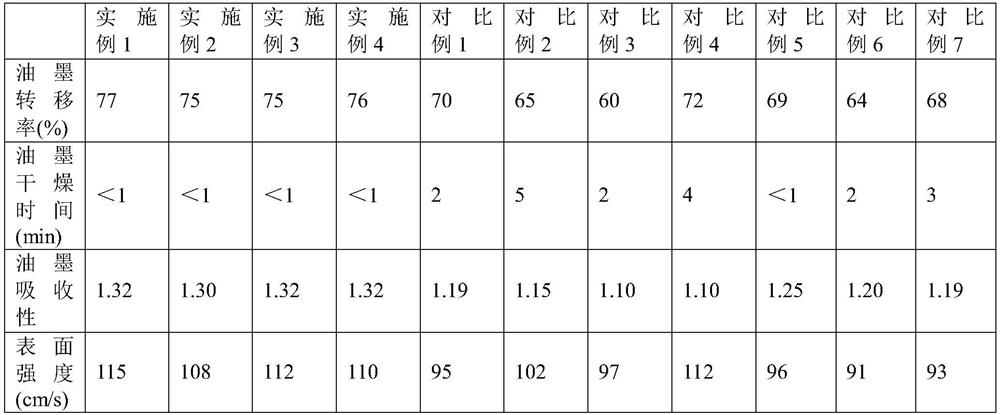

A thermal sublimation transfer paper coating with high ink transfer rate and fast ink drying rate and preparation method thereof

A technology of ink transfer and drying rate, applied in the field of papermaking, can solve the problems of difficulty in balancing the application performance of thermal sublimation transfer paper, and achieve the effects of excellent ink transfer rate, accelerated conduction speed and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation method of thermal lifting transfer paper coatings, including the following steps:

[0044] 1) Dissolve solid carboxymethylcellulose: formulated a carboxymethylcellulose solution having a concentration of 8-10% by weight.

[0045] 2) Preparation of modified kaolin: Pre-formulated a concentration of 45-55 wt% water washing kaolin dispersion, and water washing kaolin mass 1 / 140-1 / 160 cationic starch or polyacrylamide, continued to disperse 5-15 min to mix evenly.

[0046] 3) Preparation of insoluble starch dispersion: The formulation of 45-55 wt% of the insoluble starch dispersion, 4000 to 5000 r / min high speed dispersed 20-40 min.

[0047] 4) Preparation of nanochemical / carboxymethylcellulose / modified kaolin / insoluble starch mixture: Sequentially placed in the container in the container, mixed 20-40 min at 4000 to 5000 r / min, then The speed dropped to 800-1200r / min, first added a concentration of 0.5-1.5% by weight of nanocellulose hydrogel, then a...

Embodiment 1

[0050] 1) Dissolve solid carboxymethylcellulose: Take 12 g of solid carboxymethylcellulose in water in 88 g of water, and stir mixed with stirring in a constant temperature water bath in 65 ° C.

[0051] 2) Disperse kaolin and modify: Take 150 g of water washing kaolin inorganic particles to 150 g of water, formulated a high-speed dispersion at 4500R / min speed, mechanical dispersion treatment for 30 min under 4500r / min; then reduce the speed to 1500R / min, 1G of cationic starch, 30 min for mechanical dispersion.

[0052] 3) Dispersion insoluble starch: Take 150 g of insoluble starch organic powder to 150 g of water, formulated a concentration of 50% by weight of insoluble starch dispersion, using a high speed dispersing machine at 4500 r / min speed, mechanical dispersion treatment for 30 min.

[0053] 4) Preparation of nanochemical / carboxymethylcellulose / modified kaolin / insoluble starch mixture: the number of mass parts of each component is 55.0% of carboxymethylcellul...

Embodiment 2

[0056] 1) Dissolve solid carboxymethylcellulose: Take 12 g of solid carboxymethylcellulose in water in 88 g of water, and stir mixed with stirring in a constant temperature water bath in 65 ° C.

[0057] 2) Disperse kaolin and modify: Take 150 g of water washing kaolin inorganic particles to 150 g of water, formulated a high-speed dispersion at 4500R / min speed, mechanical dispersion treatment for 30 min under 4500r / min; then reduce the speed to 1 g of polyacrylamide is added to 1500R / min, and 30 min is added to mechanical dispersion.

[0058] 3) Dispersion insoluble starch: Take 150 g of insoluble starch organic powder to 150 g of water, formulated a concentration of 50% by weight of insoluble starch dispersion, using a high speed dispersing machine at 4500 r / min speed, mechanical dispersion treatment for 30 min.

[0059] 4) Preparation of nanochemical / carboxymethylcellulose / modified kaolin / insoluble starch mixture: each component mass: 50.0% carboxymethylcellulose, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com