Envelope calcium chloride and preparation method thereof

A technology of coating calcium chloride and calcium chloride, applied in the application, animal feed, animal feed and other directions, can solve the problems of difficulty in promotion, poor effect, immature calcium chloride coating technology, etc., to improve bioavailability rate, low application cost, and the effect of reducing blood calcium and its secondary diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of coated calcium chloride, the concrete steps of its preparation method are as follows:

[0029] (1) Dissolve 600g of calcium chloride in water to prepare a saturated aqueous solution of calcium chloride, take 100g of silicon dioxide and put it into a granulation fluidized bed, atomize it with saturated aqueous solution of calcium chloride as the mother liquor, and spray it into Spray granulation is carried out from inside the fluidized bed to the surface of silica. During the spray granulation process, the inlet air temperature is 62°C, the outlet air temperature is 55°C, the atomization pressure is 0.2Mpa, and the speed of the peristaltic pump is 200r / min. Obtain first-level coated particles;

[0030] (2) Add 100g hydrogenated castor oil and 100g calcium palmitate (the mass fraction of palmitic acid is 43%) into the mixer, heat and melt at 80°C, then add the first-level coated particles, and mix for 10min; put the above mixture Put into a 75kW granulator with...

Embodiment 2

[0033] A kind of coated calcium chloride, the concrete steps of its preparation method are as follows:

[0034] (1) Dissolve 750g of calcium chloride in water to prepare a saturated aqueous solution of calcium chloride, take 100g of silicon dioxide and put it into a granulation fluidized bed, atomize it with saturated aqueous solution of calcium chloride as the mother liquor, and spray it into Spray granulation is carried out from inside the fluidized bed to the surface of silica. During the spray granulation process, the inlet air temperature is 65°C, the outlet air temperature is 53°C, the atomization pressure is 0.2Mpa, and the peristaltic pump speed is 200r / min. Obtain first-level coated particles;

[0035] (2) Add 50g of hydrogenated castor oil and 50g of calcium palmitate (the mass fraction of palmitic acid is 45%) into the mixer, heat and melt at 80°C, then add the first-level coated particles, and mix for 12min; put the above mixture Put into 75kW aperture and be in t...

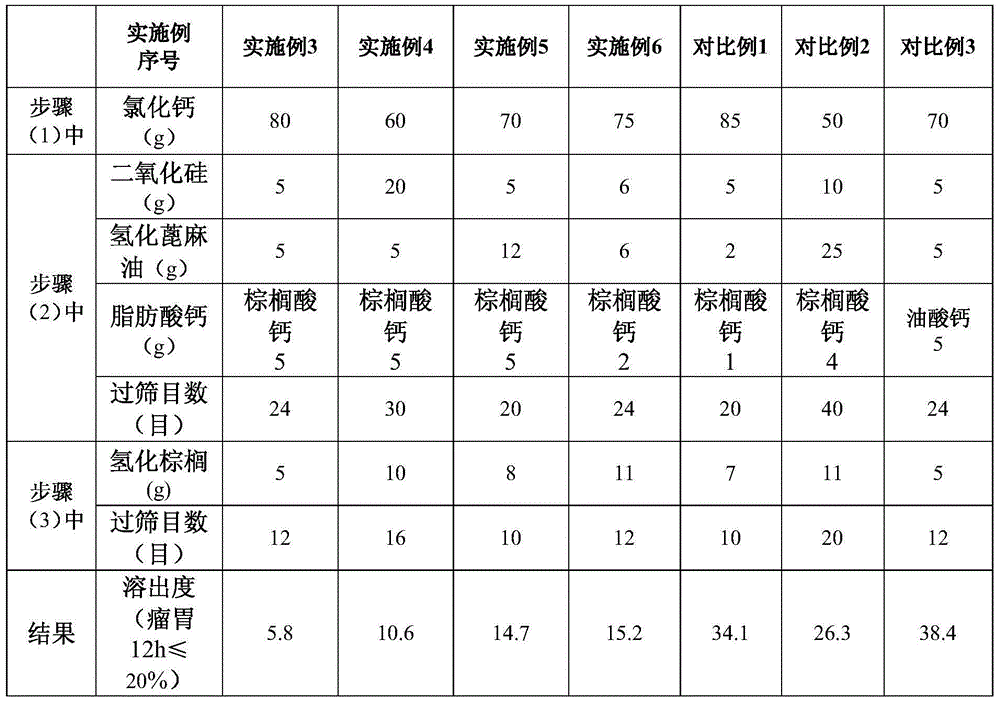

Embodiment 3~6 and comparative example 1~3

[0038] The coating calcium chloride preparation method of embodiment 3~6 and comparative example 1~3 is except that the parameter listed in table 1 is different with embodiment 1, all the other contents are identical with embodiment 1.

[0039] Adopt the same preparation method as Example 1, only some parameters in the preparation method are different; Comparative Example 1 and Comparative Example 2 are also basically the same as the preparation method of Example 1, only the raw material composition ratio of coated calcium chloride Different, Comparative Example 3 uses different raw material compositions, specifically as shown in Table 1, and the parts not mentioned in Table 1 are the same as in Example 1.

[0040] The coated calcium chloride obtained carries out the mensuration of dissolution rate, and detection method is:

[0041](1) Adjust the temperature of the dissolution tester to 37°C and the rotational speed to 100r / min, pour the artificially prepared simulated rumen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com