Swing arm drive device for spraying antifreeze on coal-carrying train

An arm drive, antifreeze technology, applied in the direction of injection devices, etc., can solve the problems of inability to use, difficult installation and disassembly, waste of antifreeze, etc., to ensure driving performance and reliability, easy installation and replacement of parts, and easy disassembly and the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

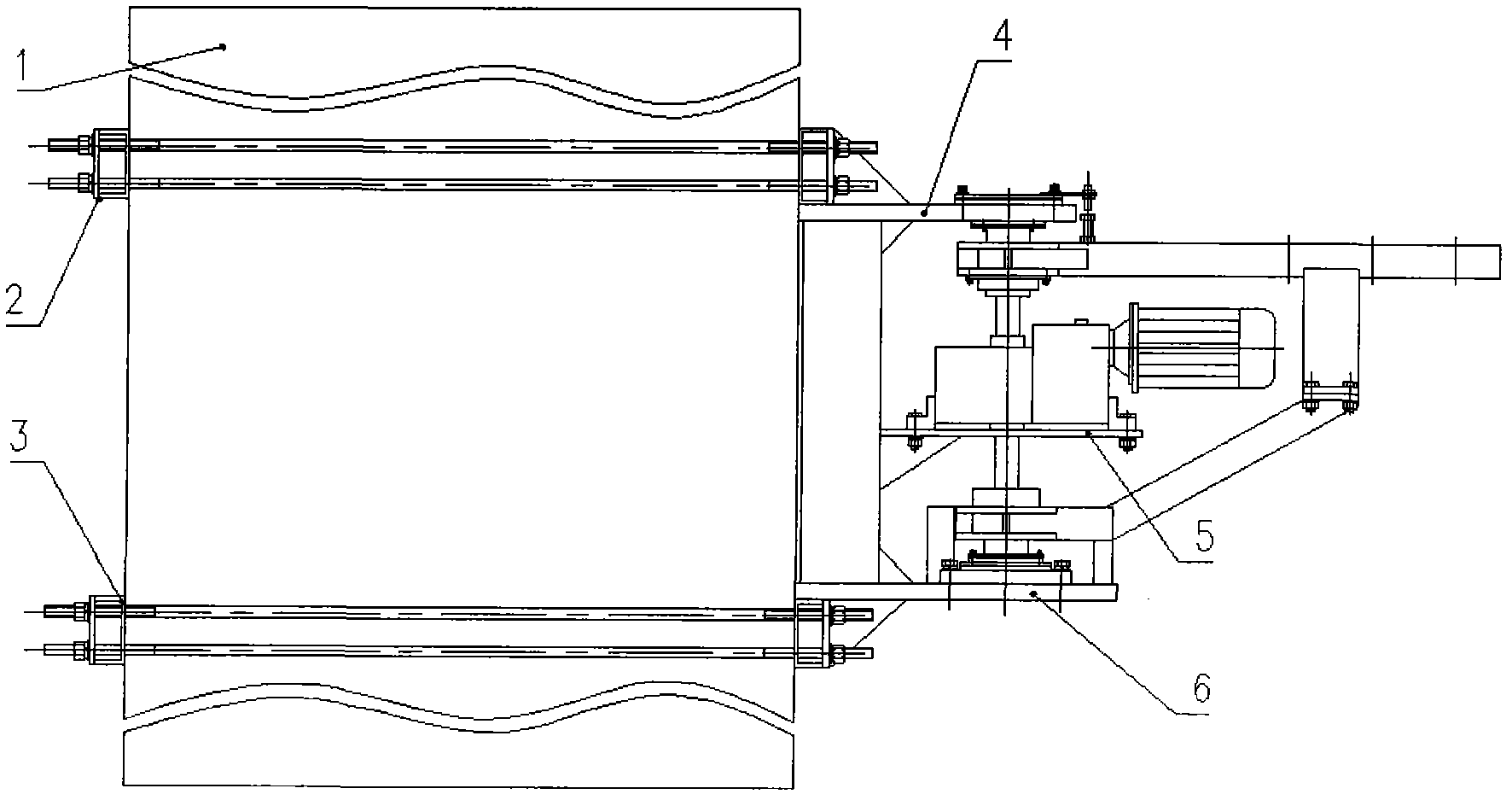

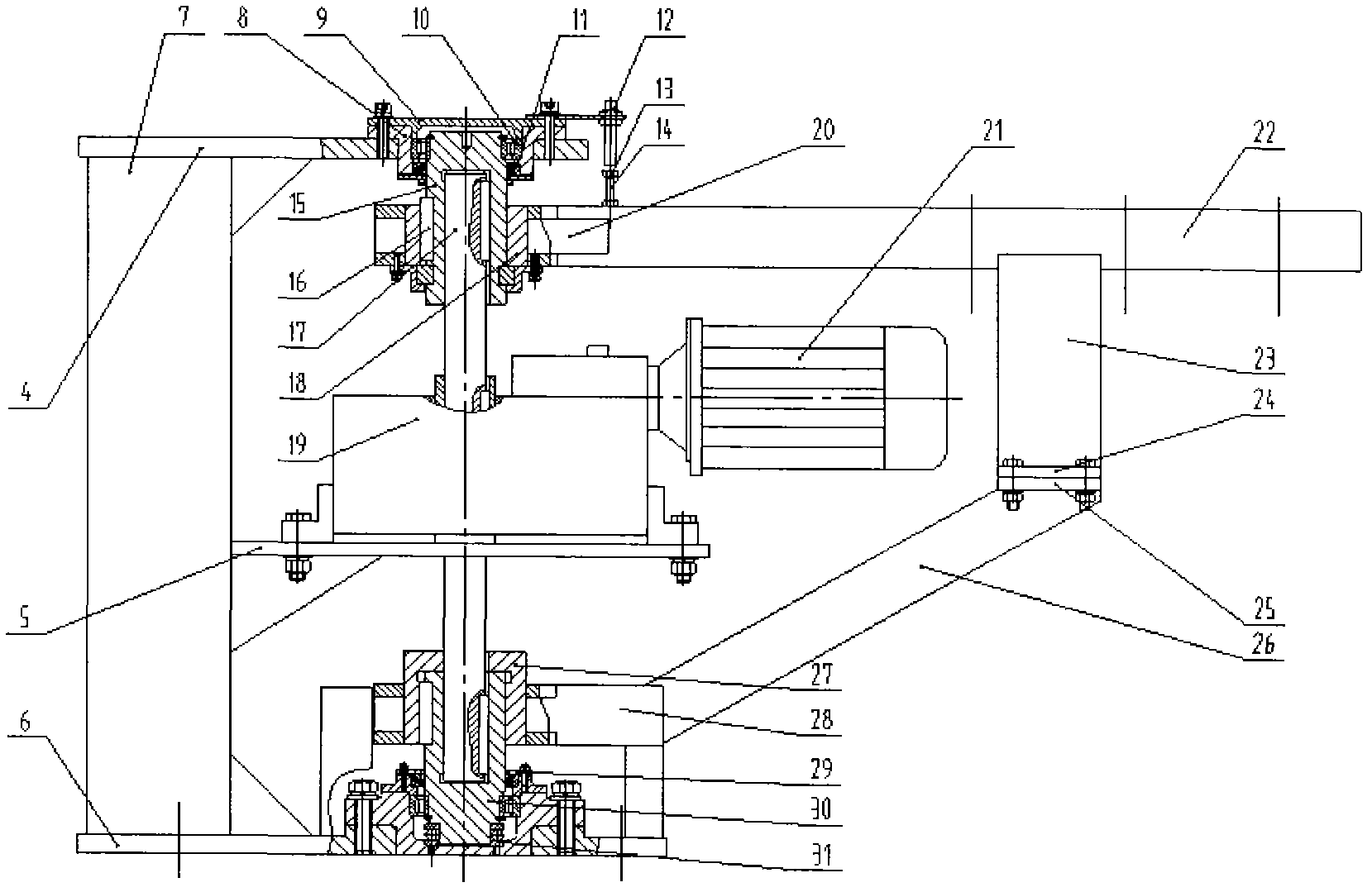

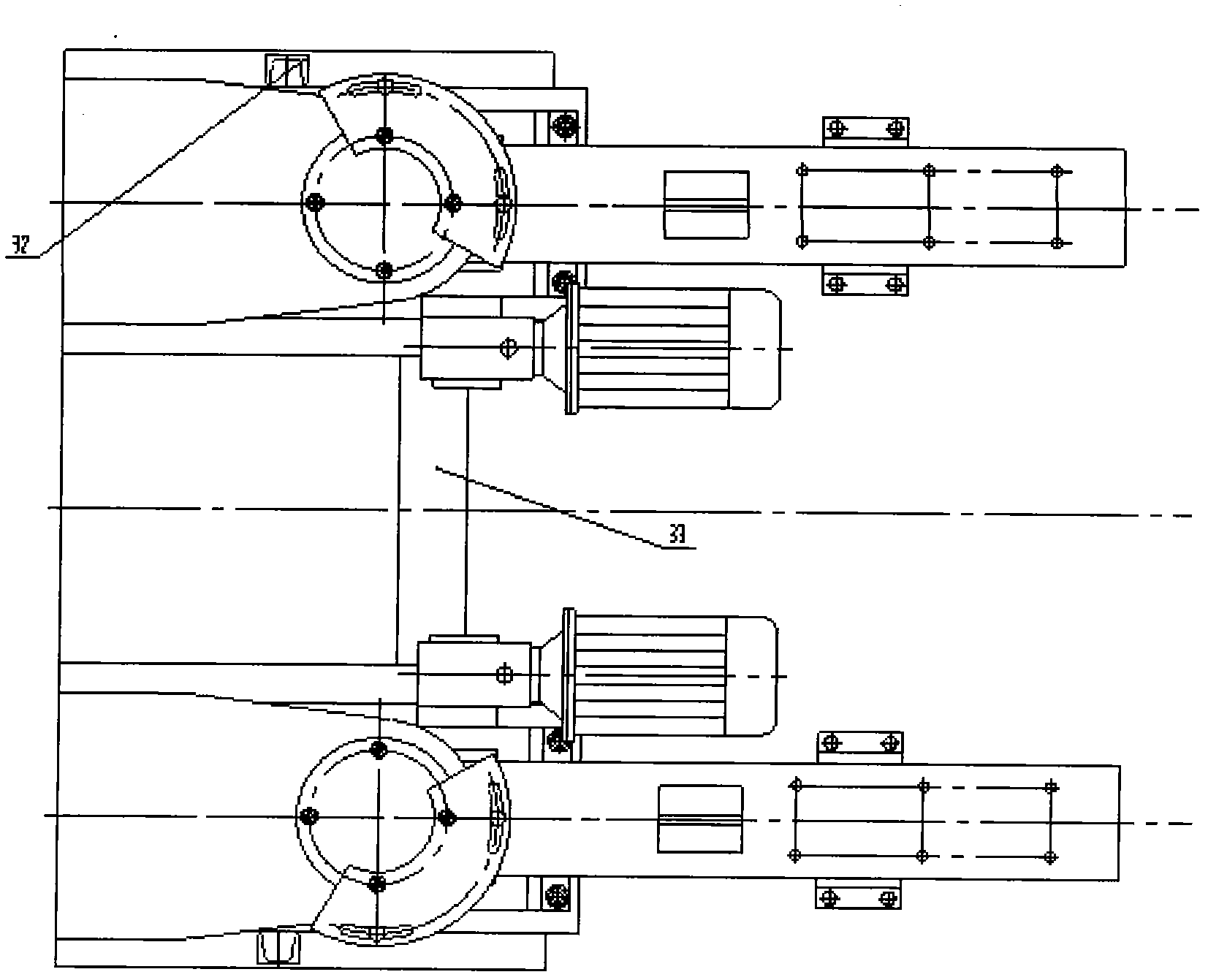

[0023] Such as figure 1 , figure 2 and image 3Shown: the present invention is used for the swing arm driving device of coal train antifreeze spraying, and the swing arm driving device is made up of square column 1, fastening device, slewing mechanism, upper arm assembly, driving mechanism, lower arm assembly, limit device Composition, the fastening device is to rely on the two vertical sides of the square column 1 perpendicular to the track surface, and the bolts are passed through the holes of the upper support plate 2 and the lower support plate 3, so that the support plate is fastened on the On the two vertical sides of the square column 1 perpendicular to the track surface, the upper support plate 4, the column channel steel 7, the motor support plate 5 and the lower support plate are welded vertically in sequence between the upper support plate 2 and the lower support plate 3 6. Ribs are welded on each support plate to strengthen the structural strength and firmness o...

Embodiment approach 2

[0025] Such as figure 1 As shown, the upper support plate 2 and the lower support plate 3 are removed, and the lower support plate 6 is directly installed on any horizontal platform, and the others are the same as the first embodiment.

Embodiment approach 3

[0027] Such as image 3 As shown, the connecting plate 33 is removed, and the two sets of symmetrical mechanisms are used separately, and the others are the same as those of Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com