Patents

Literature

103results about How to "Reduce torsional deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

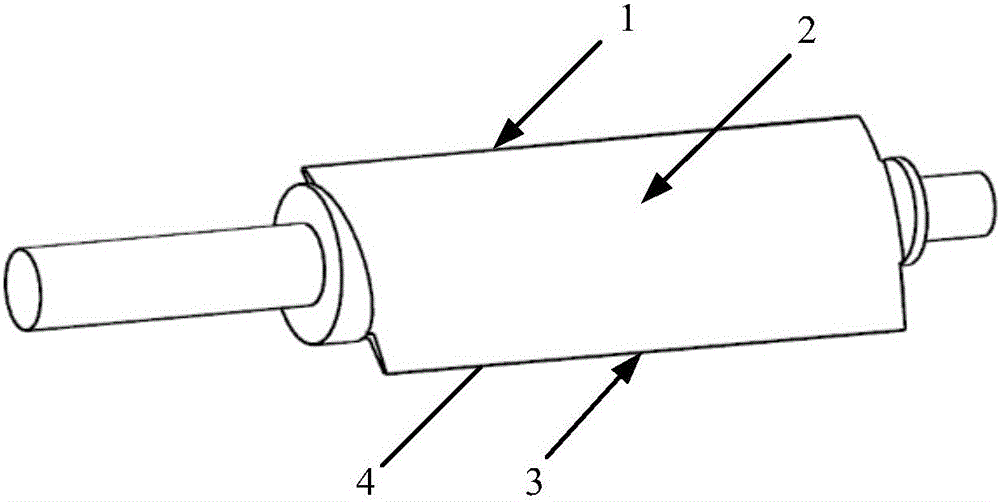

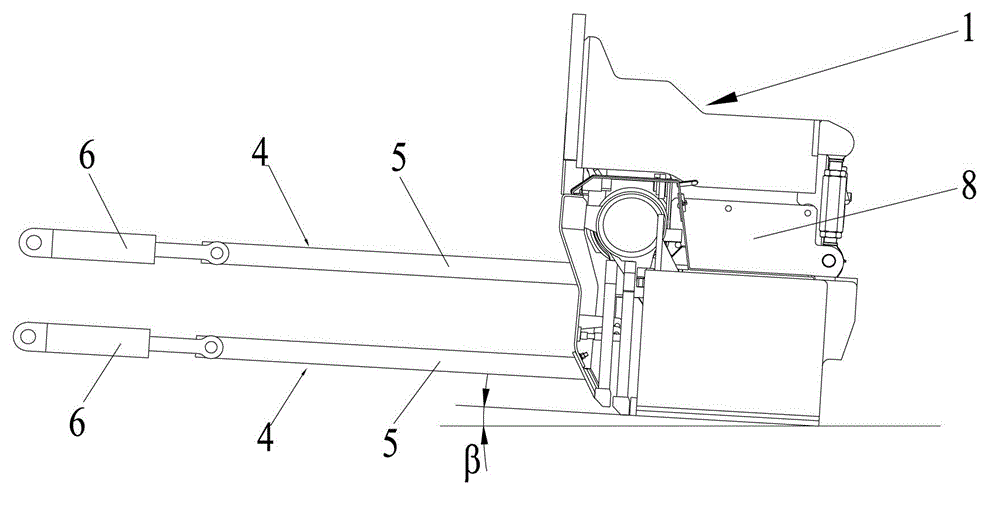

Spinning method

ActiveCN104858285AMeet SpinningFlexible settingsShaping toolsTorsional deformationMechanical engineering

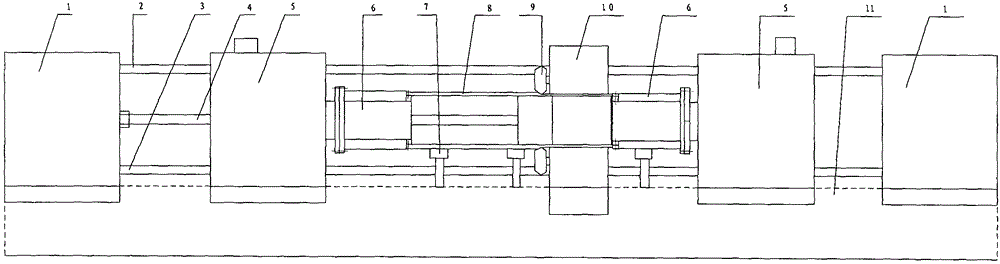

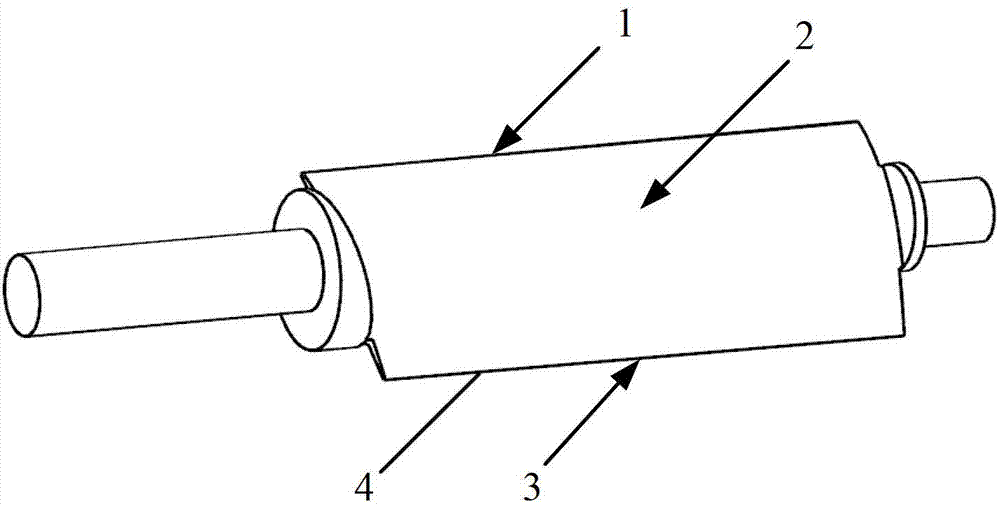

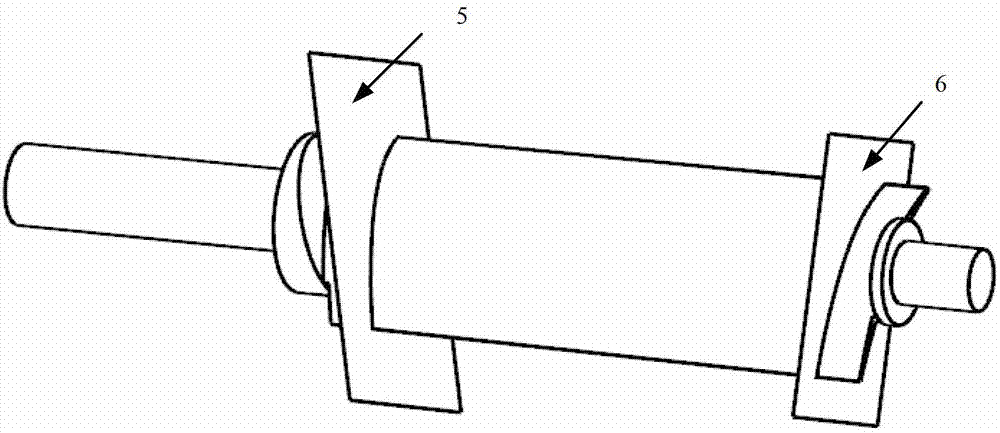

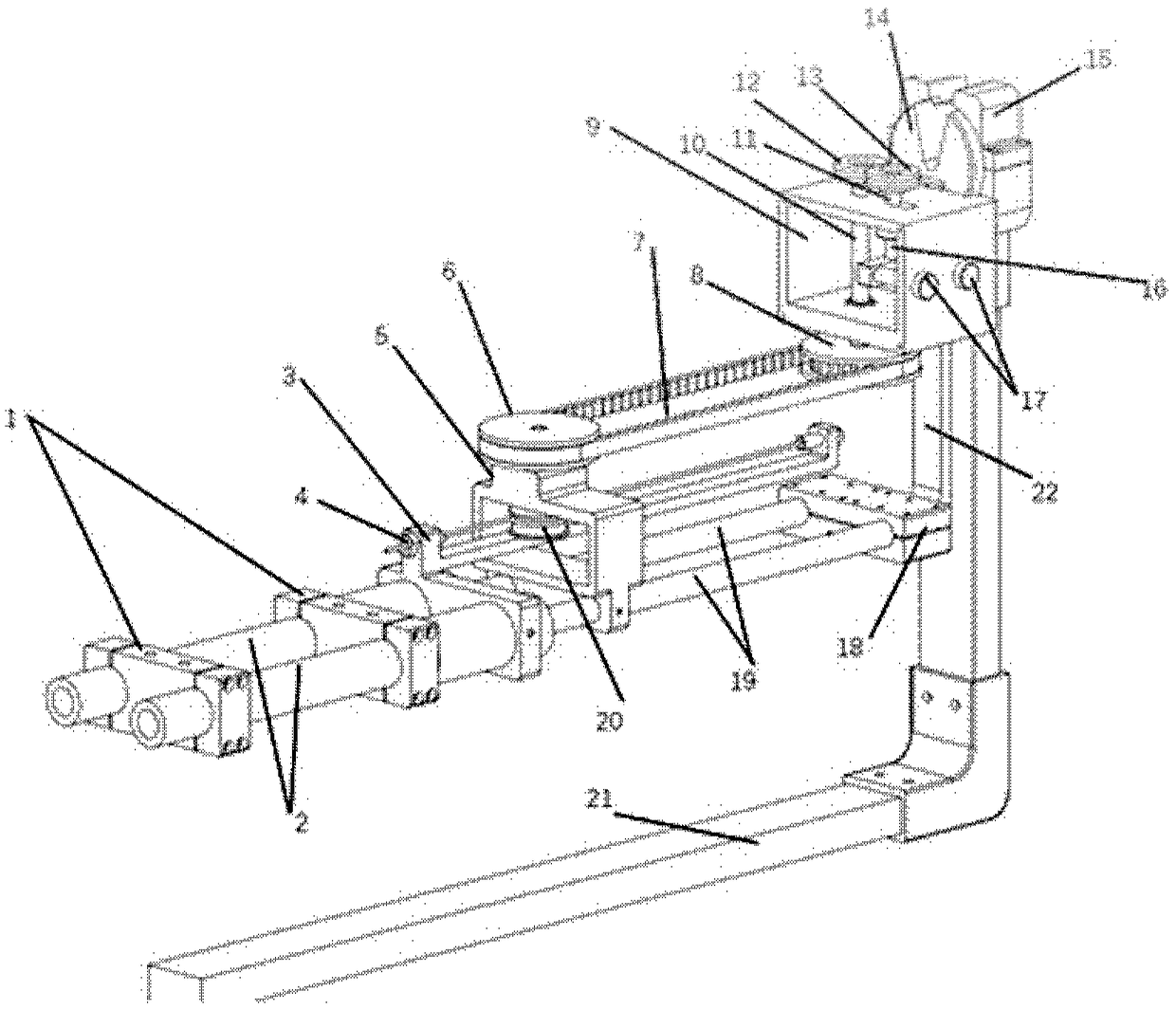

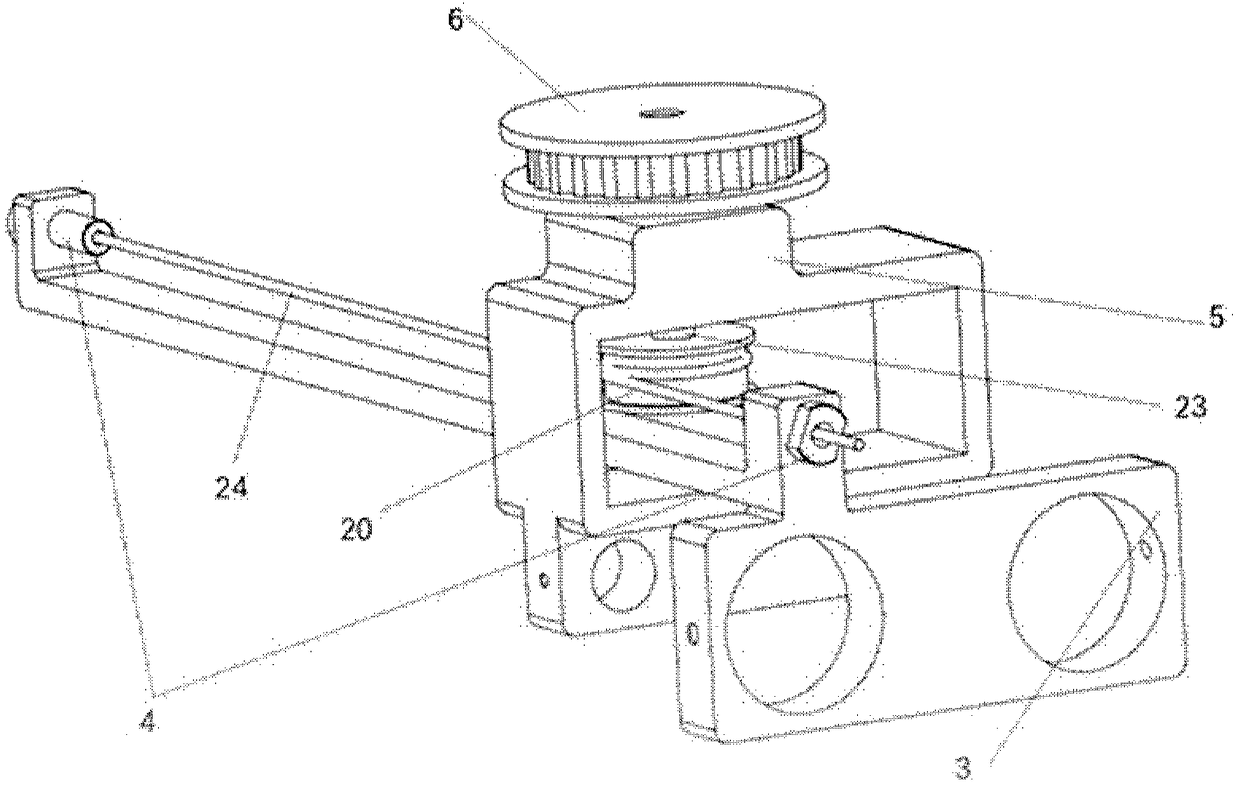

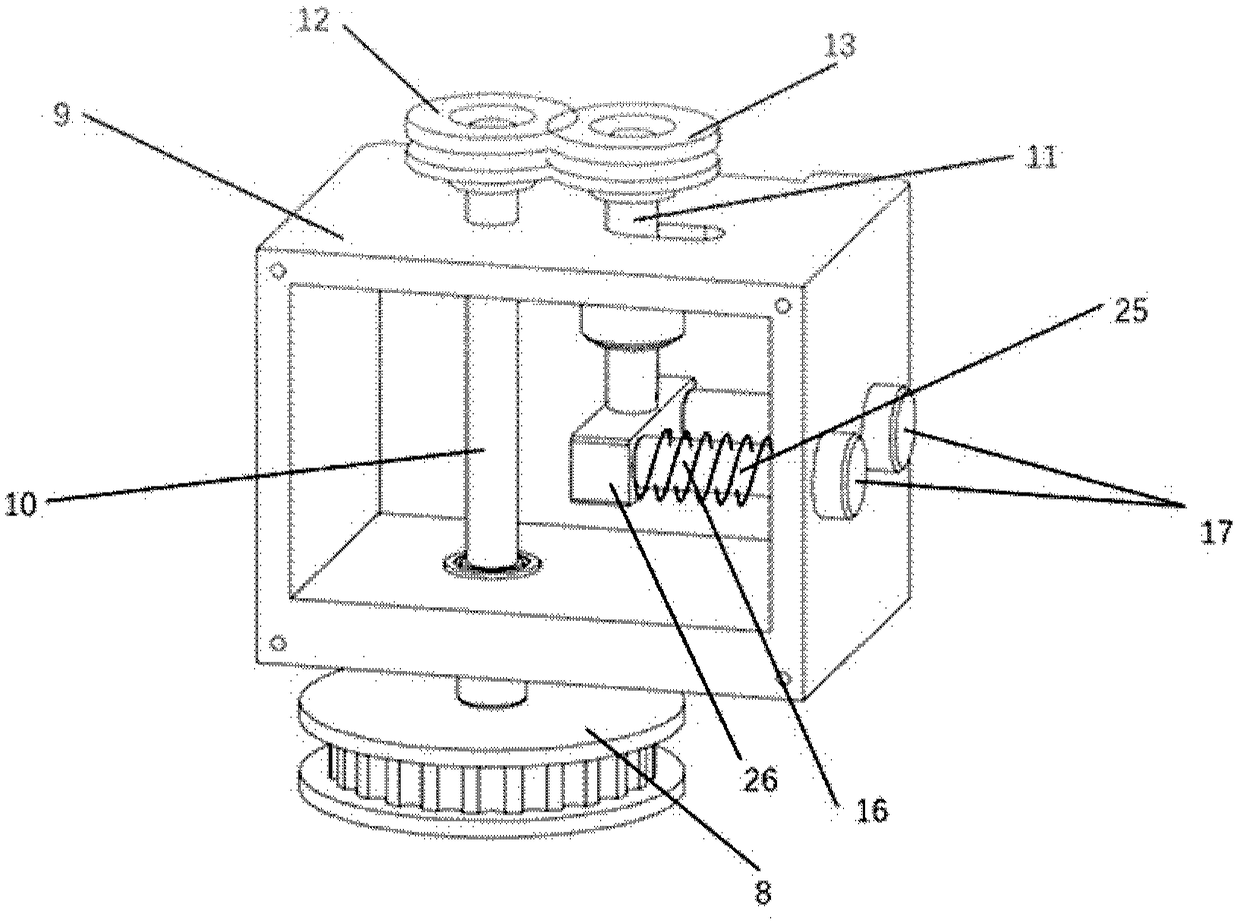

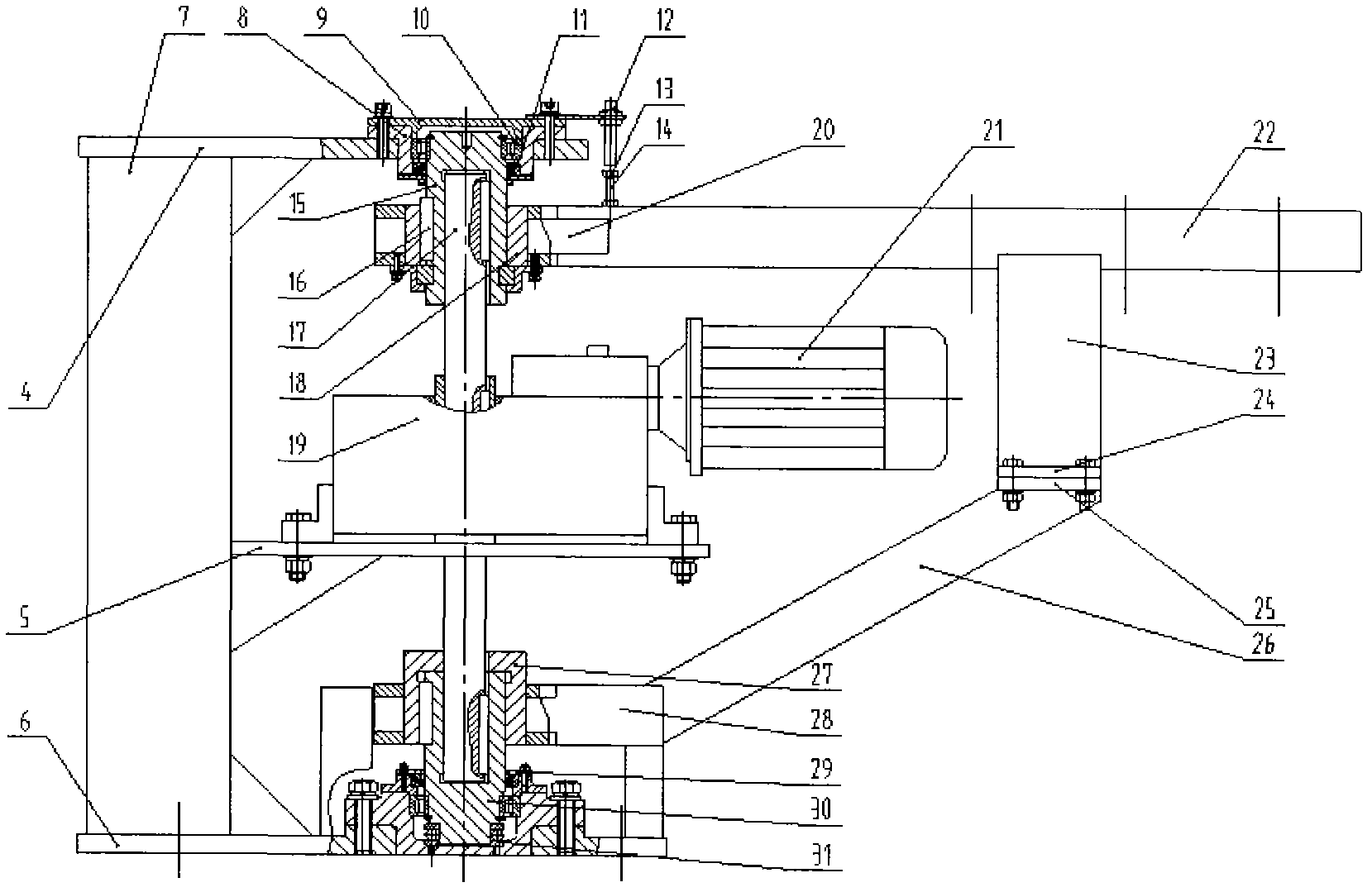

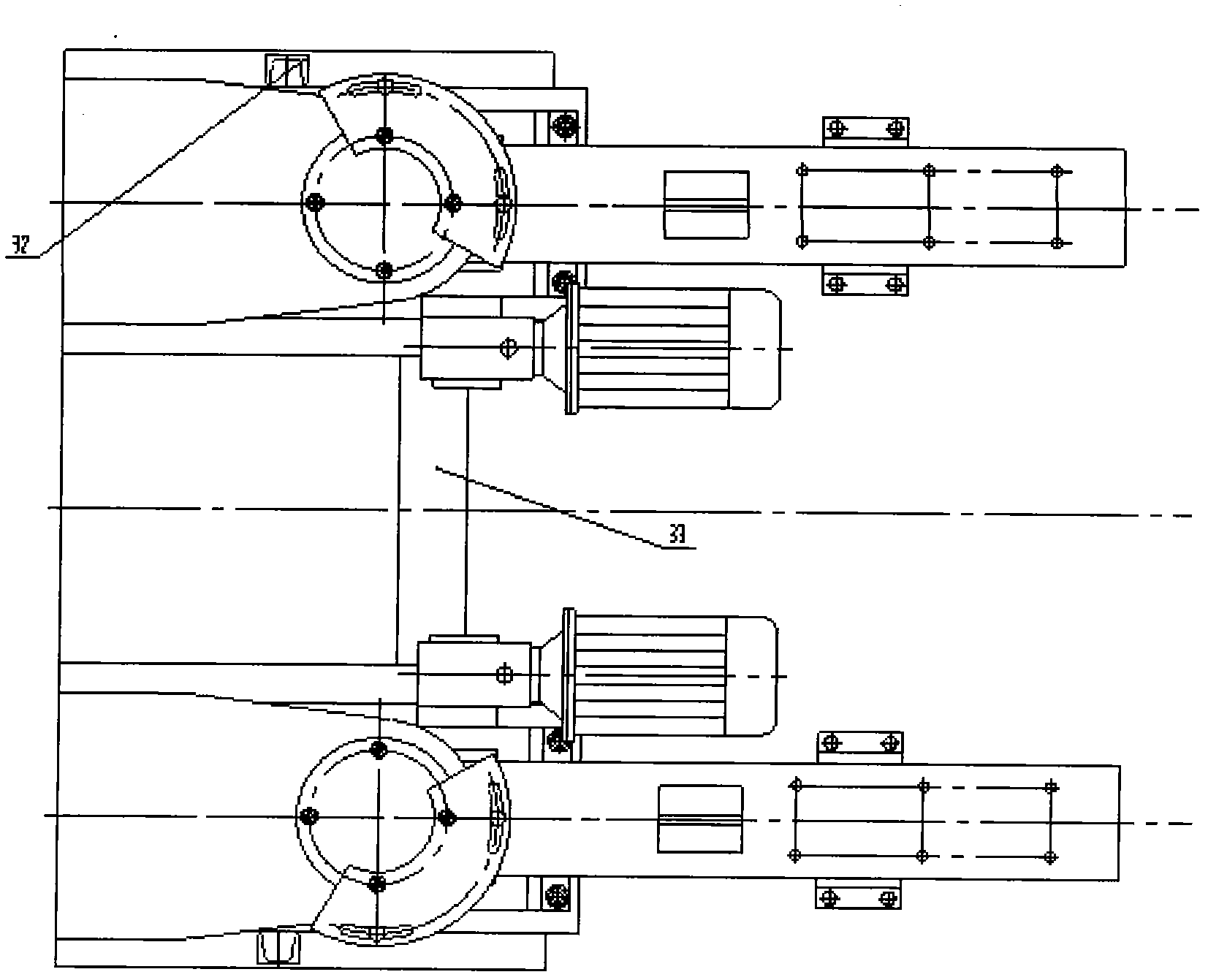

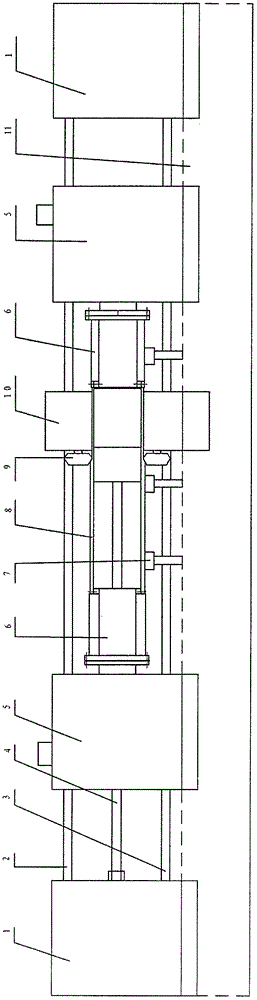

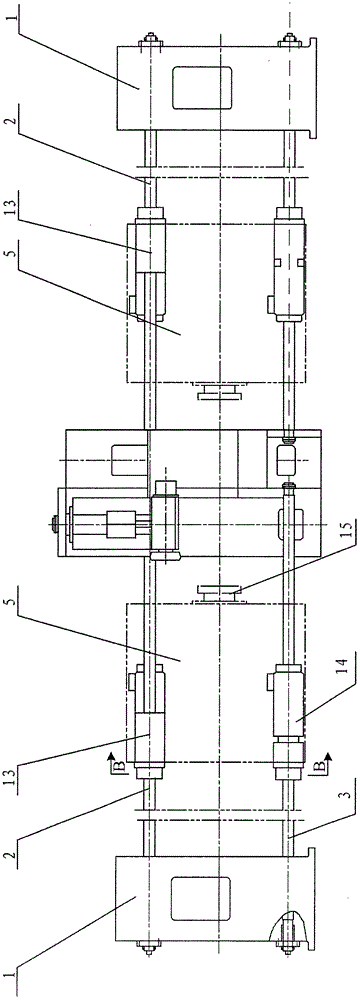

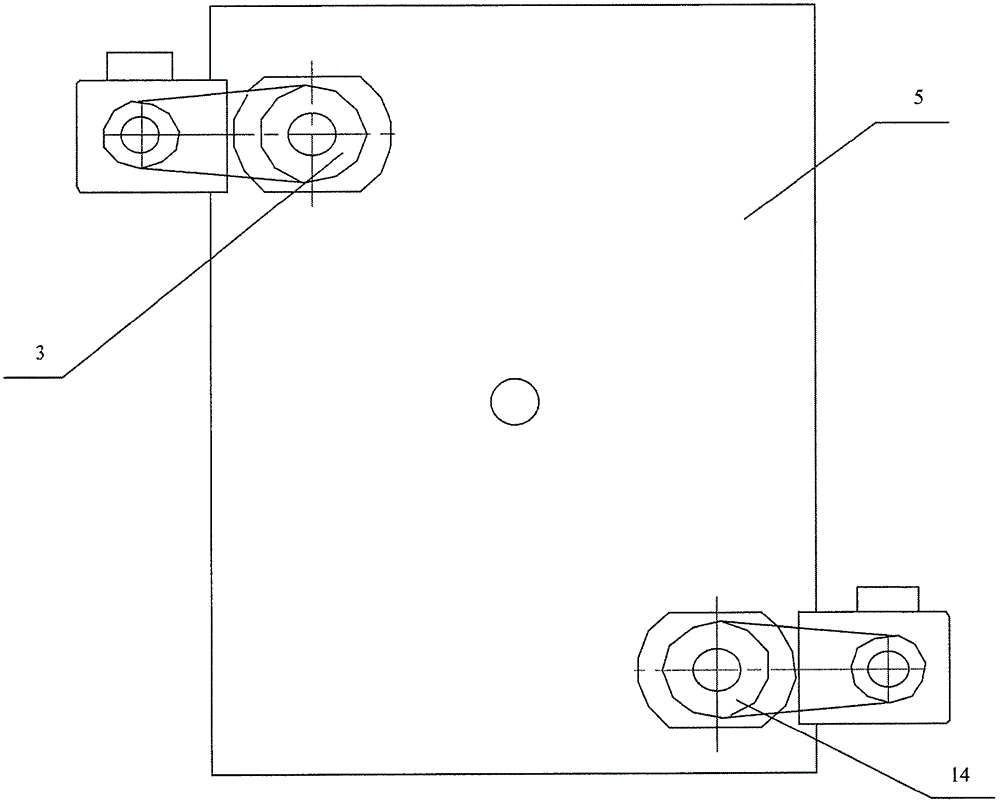

The invention provides a spinning method. The outside spinning technology is combined with synchronous rotation and the spinning technology of a short core mold to achieve integral spinning forming of super-long thin-wall cylindrical parts, and the therefore the technical problem that the common outside spinning technological method cannot be used for spinning the super-long thin-wall cylindrical parts is solved. According to the spinning method, the function of synchronous rotation of the two ends of workpieces is increased, the problem of torsional deformation of the super-long thin-wall cylindrical parts is solved, and therefore the precision of products is improved; the short core mold is adopted, so that the problems that core molds of the super-long thin-wall cylindrical parts lower heads and vibrate, the manufacturing cost is high, and demolding is difficult are solved, and integral spinning forming of the super-long thin-wall cylindrical parts is achieved.

Owner:海鹰空天材料研究院(苏州)有限责任公司

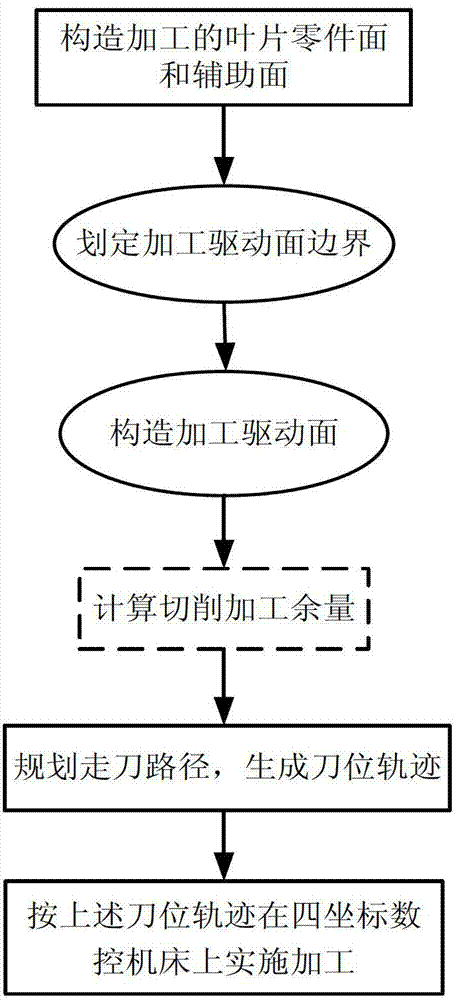

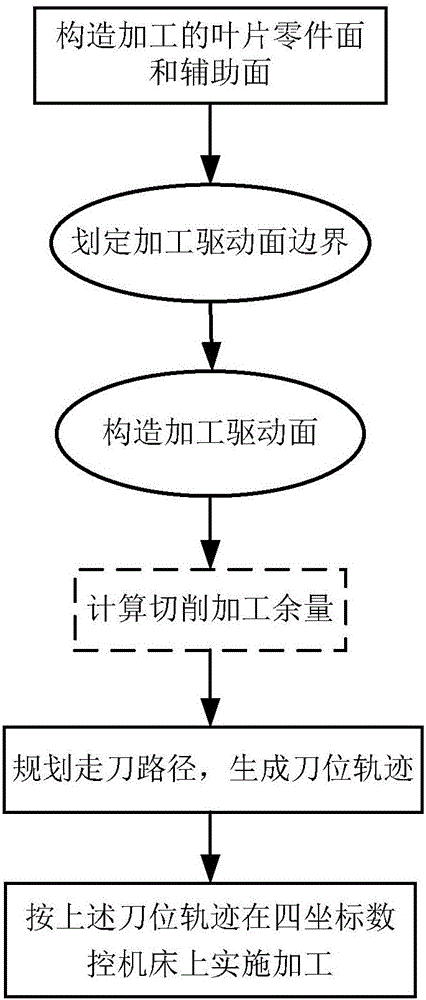

Precise milling processing method with variable inter-row allowance for thin walled blade of difficult-to-process material

ActiveCN102873384AThe direct effect is obviousImprove section positionMilling equipment detailsSpecial data processing applicationsNumerical controlTorsional deformation

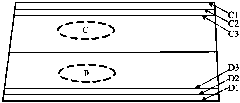

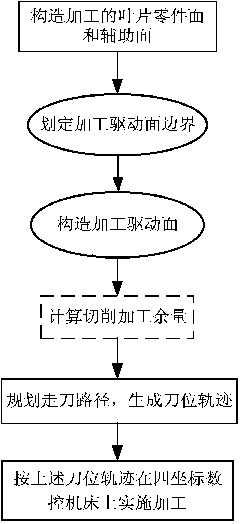

The invention provides a precise milling processing method with a variable inter-row allowance for thin walled blades of difficult-to-process materials; four driving curved surfaces are obtained by cutting a blade root boundary surface and a blade tip boundary surface into a blade back curved surface and a blade basin curved surface; parameter lines with equal u on the driving curved surfaces are used as processing paths; a cutting row allowance for each processing path is set respectively; and finally processing on the four driving curved surfaces are completed circularly. The invention facilitates the improvement of the blade cross section position accuracy, facilitates the improvement of the blade surface profile tolerance, and facilitates the reduction of the blade torsional deformation; when compared with traditional vertical cutting with a constant allowance and spiral milling methods, the invention can solve the technical problems of large torsional deformation, poor profile precision, difficultly-controlled cross section position accuracy error, and the like, and can realize the high-efficient precise numerical control processing of thin walled blades of difficult-to-process materials.

Owner:西安三航动力科技有限公司

Two-way allowance-variable milling method for blade

ActiveCN103990840AHigh precisionImprove positionMilling equipment detailsEngineeringDimensional modeling

The invention discloses a two-way allowance-variable milling method for a blade. The method is used for solving the technical problem that an existing allowance-variable milling method for the blade is low in accuracy. According to the technical scheme, firstly, a three-dimensional blade model is established in three-dimensional modeling software UG; both the two end faces of the blade are made deflect towards a blade body in the three-dimensional blade model, so that two deflection faces, namely, the blade root edge interface and the blade tip edge interface, are obtained; a driving face is determined by means of a section line lofting method; then, machining routes on the driving face are determined; allowance of each machining route is determined by means of a lever allowance fine tuning method; finally, circulation machining is conducted on the blade according to the set allowance, so that machining accuracy is improved for the blade. According to the method, when the blade with the length which is about 70 mm is machined, the surface tolerance of the blade can be controlled within the range of 0.06 mm to 0.1 mm.

Owner:西安三航动力科技有限公司

Method for controlling surface stress-strain field of casing part based on constant cutting force

ActiveCN109343472AImprove surface stress distributionImprove processing qualityComputer controlSimulator controlNumerical controlSurface stress

The invention relates to a method for controlling the surface stress-strain field of a casing part based on a constant cutting force, and belongs to the technical field of aerospace numerical controlmachining. The control method includes the following steps: (1) importing a part model into a computer; (2) importing an original numerical control program into the computer; (3) importing machine tool information into the computer; (4) setting cutter parameters; (5) simulating a cutting force; (6) analyzing simulation data; (7) judging the stability of the cutting process; (8) judging whether thecutting process belongs to local run-out; (9) adjusting the original numerical control program: (10) interrupting the original numerical control program adaptively; (11) optimizing the cutting parameters of the numerical control program by segments; (12) outputting an optimal numerical control program; and (13) applying the optimal numerical control program for processing verification. The methodof the invention can be applied to the surface stress-strain field control of various integral casing parts, and has huge economic and social benefits.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation

ActiveCN106001720AReduce bending deformationReduce torsional deformationWorkpiecesMilling equipment detailsPosition toleranceTorsional deformation

The invention provides a thin-walled vane nine-point control variable-allowance milling method based on Newton interpolation. Modeling is carried out by utilizing a three-dimensional modeling software, and an auxiliary surface and a boundary surface are formed, so that a driving surface is determined by utilizing a section line lofting process. Cutter machining paths are generated according to the driving surface, and the machining allowance of each cutter position point on each machining path is determined by adopting a Newton interpolation method. Finally, vanes are cyclically processed according to symmetrical milling rules. Compared with a traditional longitudinal fixed-allowance cutting and spiral milling method, the thin-walled vane nine-point control variable-allowance milling method has the advantages that technical problems, such as large torsional deformation, low contour precision, poor section position tolerance and difficult error control, in the machining process can be solved; and by adopting a Newton interpolation process allowance fine adjustment method, surface quality can be more comprehensively controlled, and problems, such as large bending deformation, poor section position tolerance and low surface contour precision, in the machining process can be effectively solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

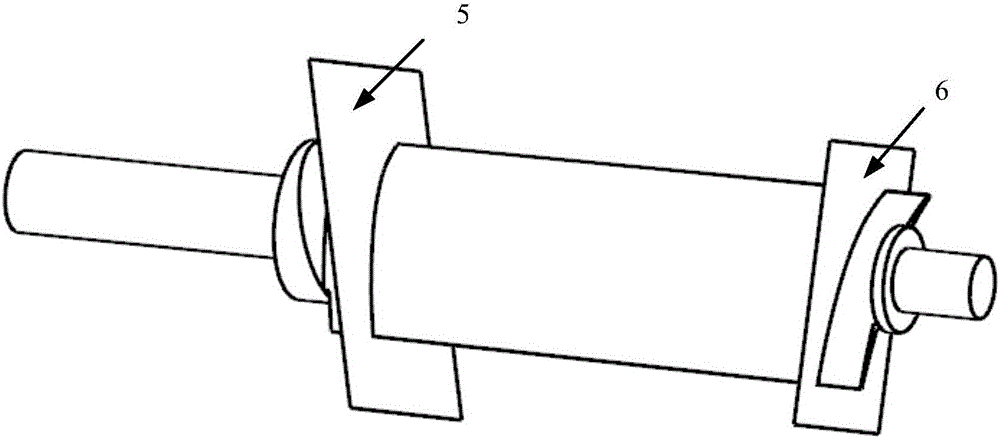

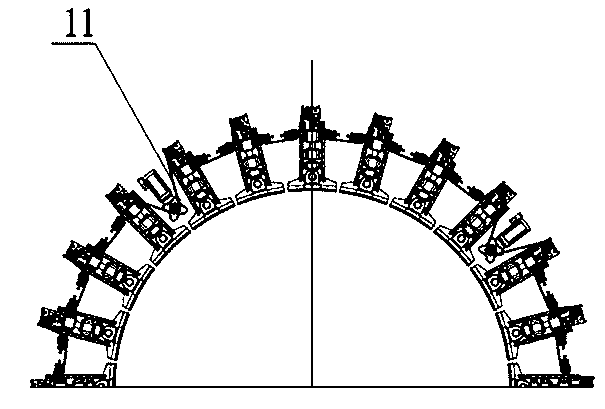

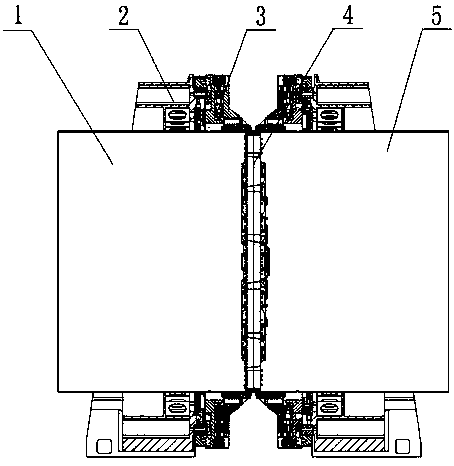

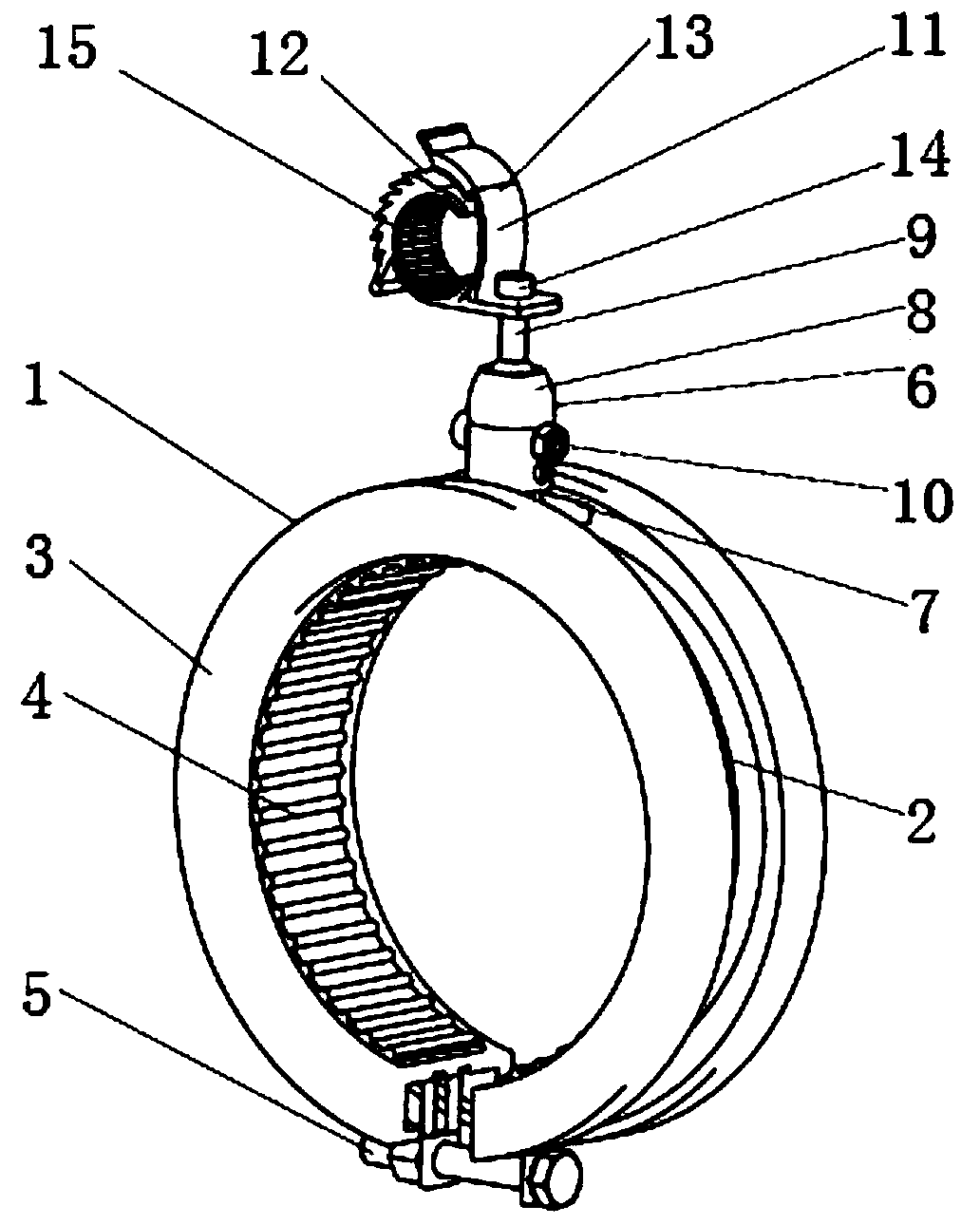

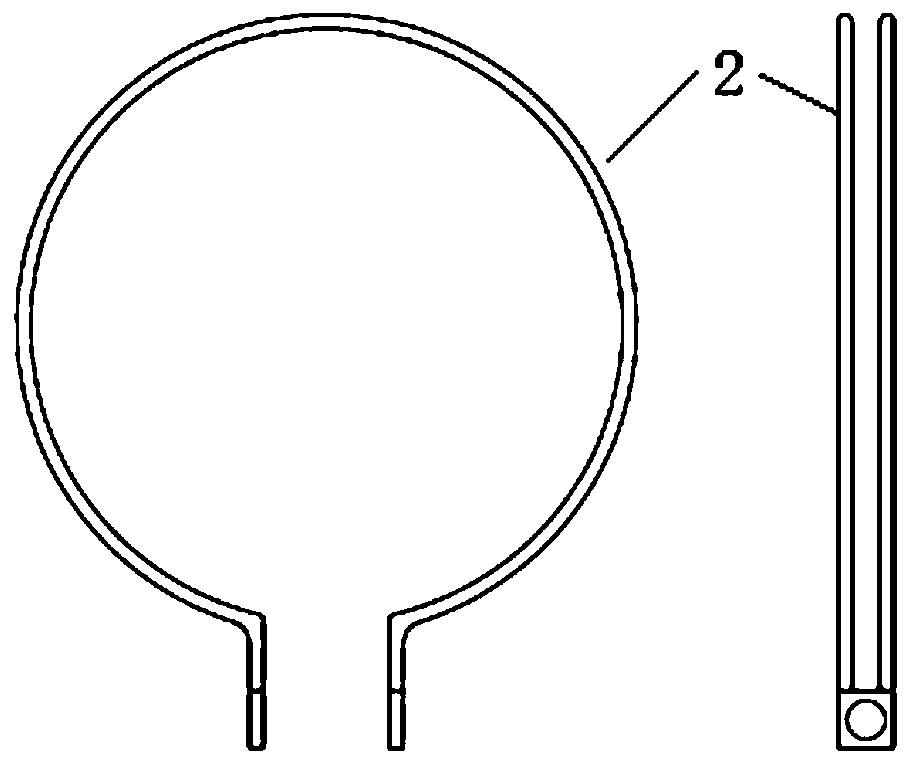

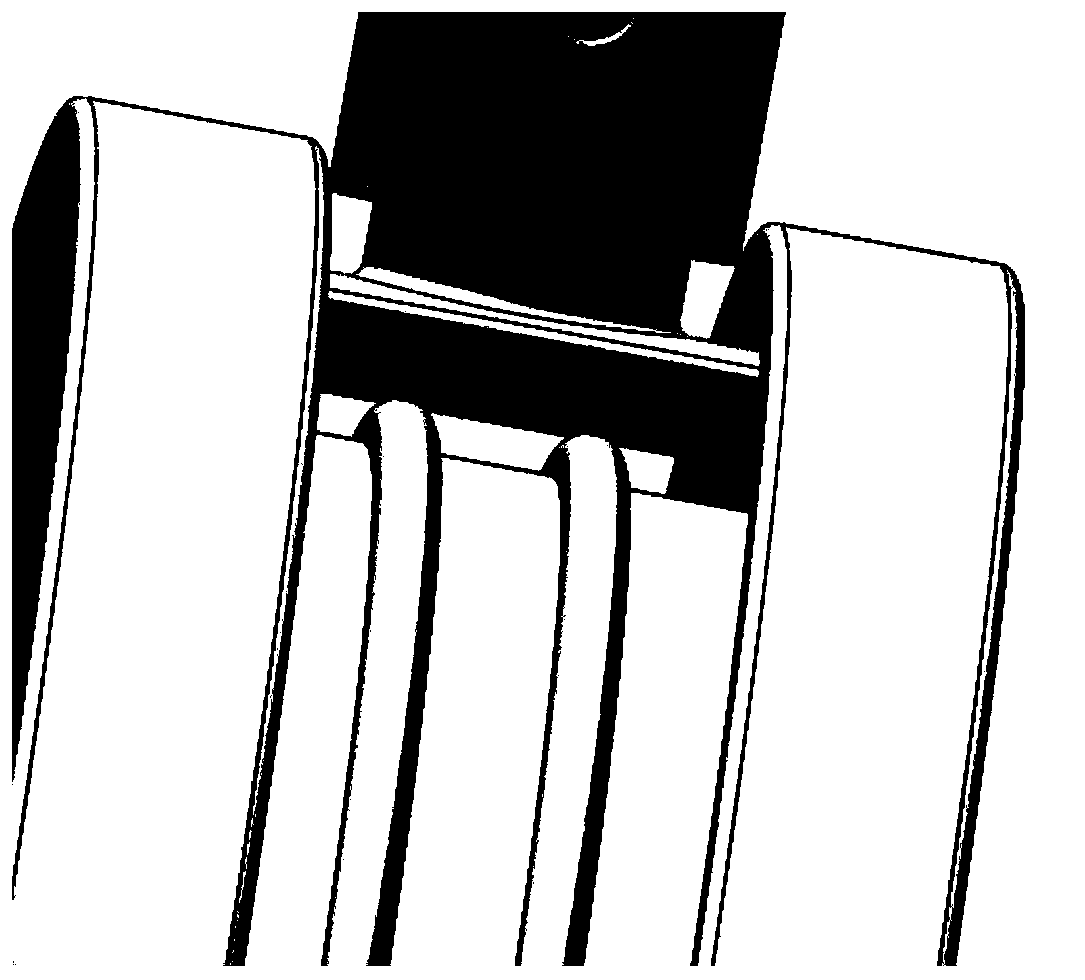

Automatic welding device

InactiveCN105643091ACorrection errorSolve rigid problemsNon-electric welding apparatusButt jointEngineering

The invention relates to an automatic welding device. The automatic welding device comprises rigid supporting seats, multi-claw chuck mechanisms, built-in flexible pneumatic piston rings, a rotary table bearing, an annular guide rail and a rotary driving mechanism, wherein the built-in flexible pneumatic piston rings are matched with storage tank drum segments; the multi-claw chuck mechanisms are connected to the rigid supporting seats through the rotary table bearing and the annular guide rail; the flexible pneumatic piston rings and the multi-claw chuck mechanisms are matched with the storage tank drum segments needing butt joint and friction stir welding for circular seams so as to form a rigid body, and the rigid body is driven by the rotary driving mechanism to rotate relative to the rigid supporting seats. According to the automatic welding device disclosed by the invention, the problems that, in the prior art, storage tanks are structural parts with big sizes and thin walls, so that the rigidity of the storage tanks is poor, and the storage tanks are difficult to fix and position are solved, and the automatic welding device has the beneficial effects that the dynamic stability of the welding process of the circular seams is guaranteed, and the welding quality is improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

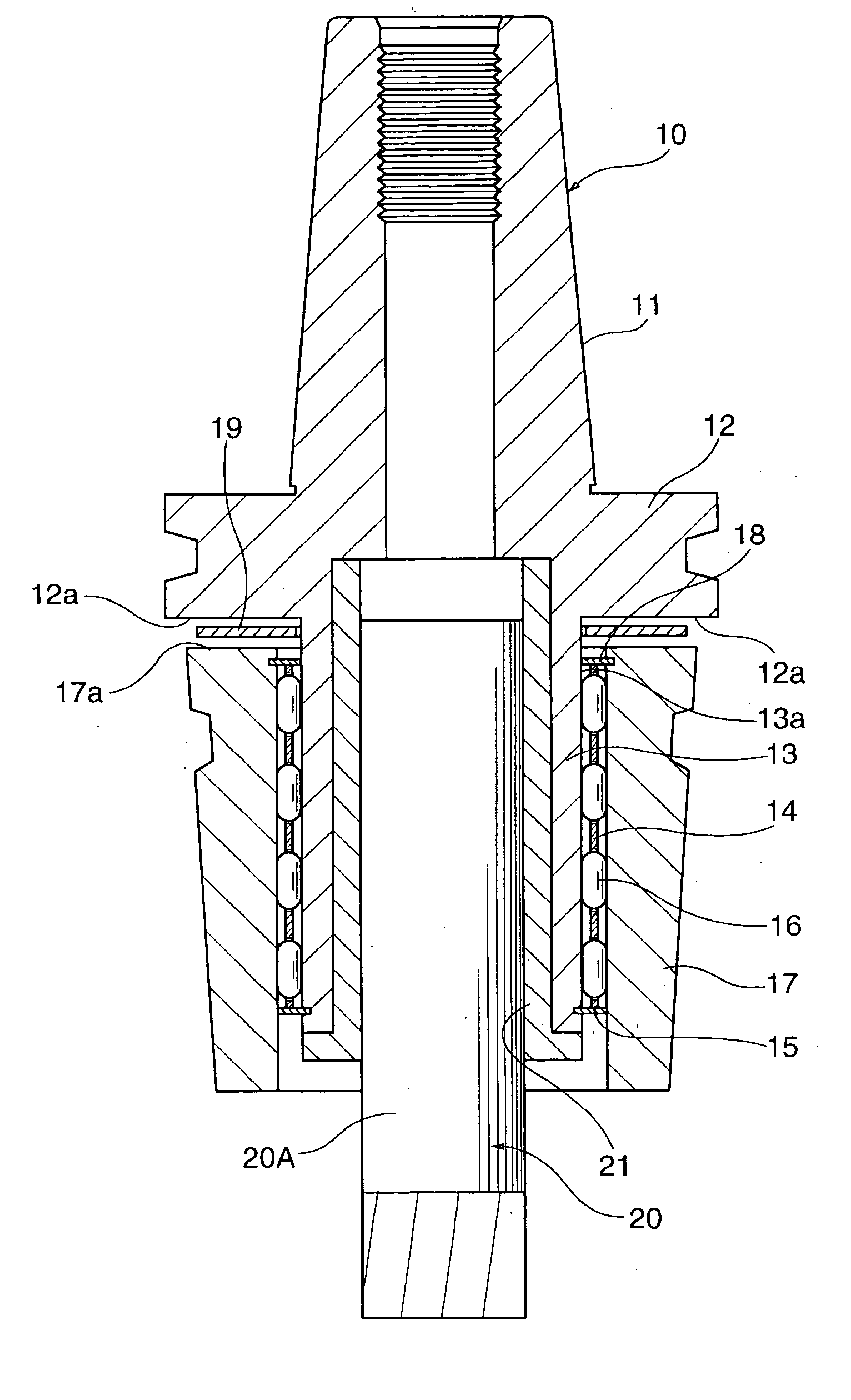

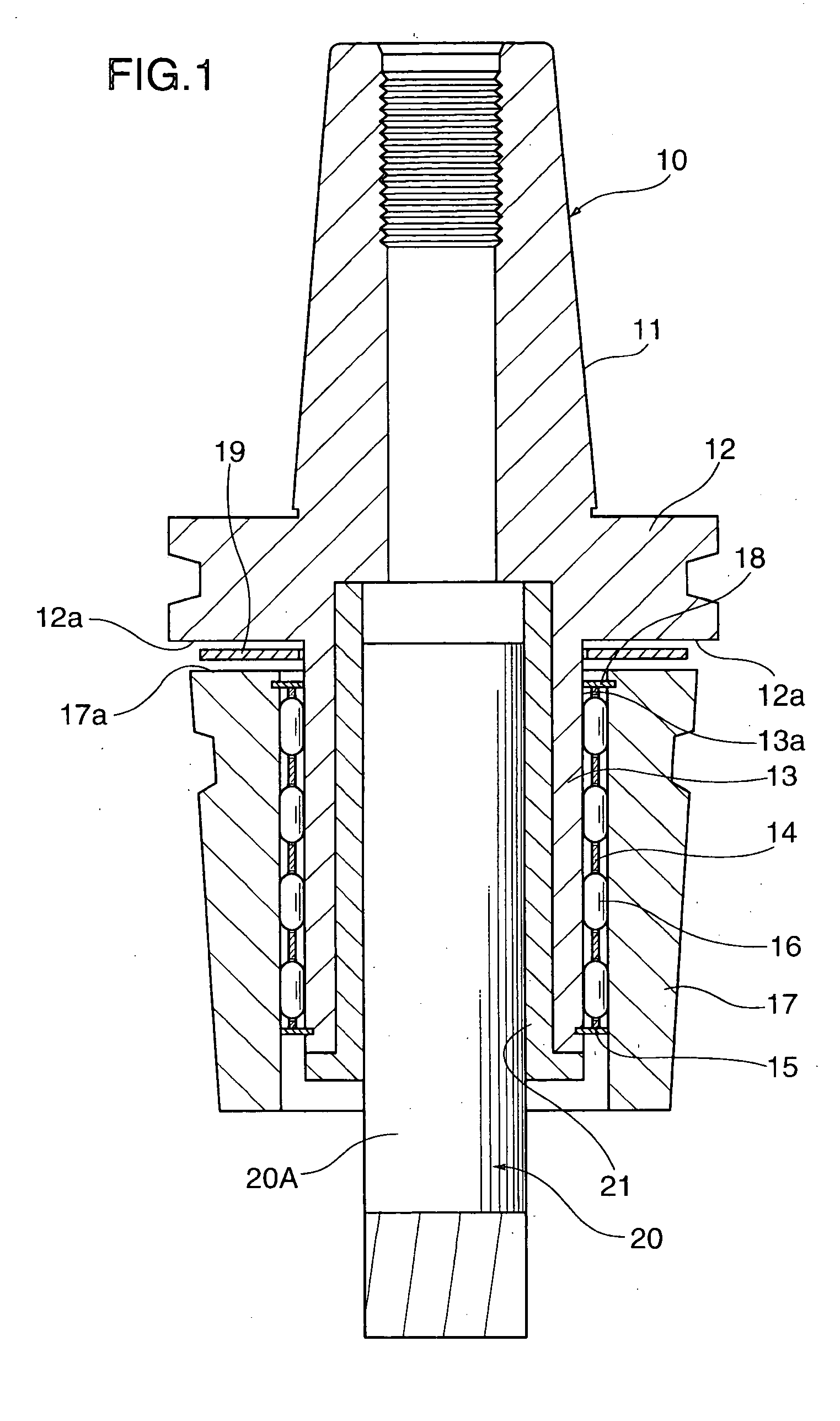

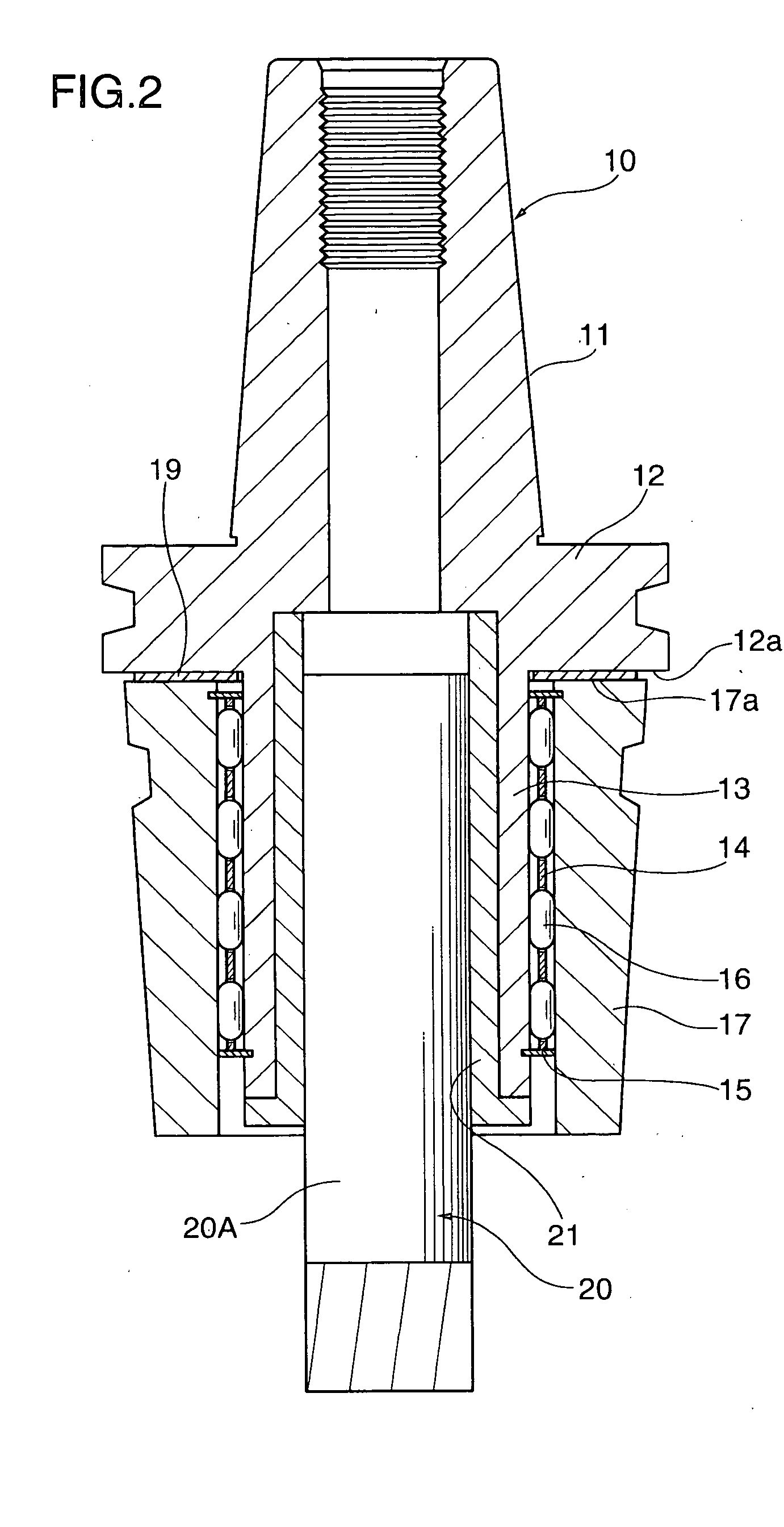

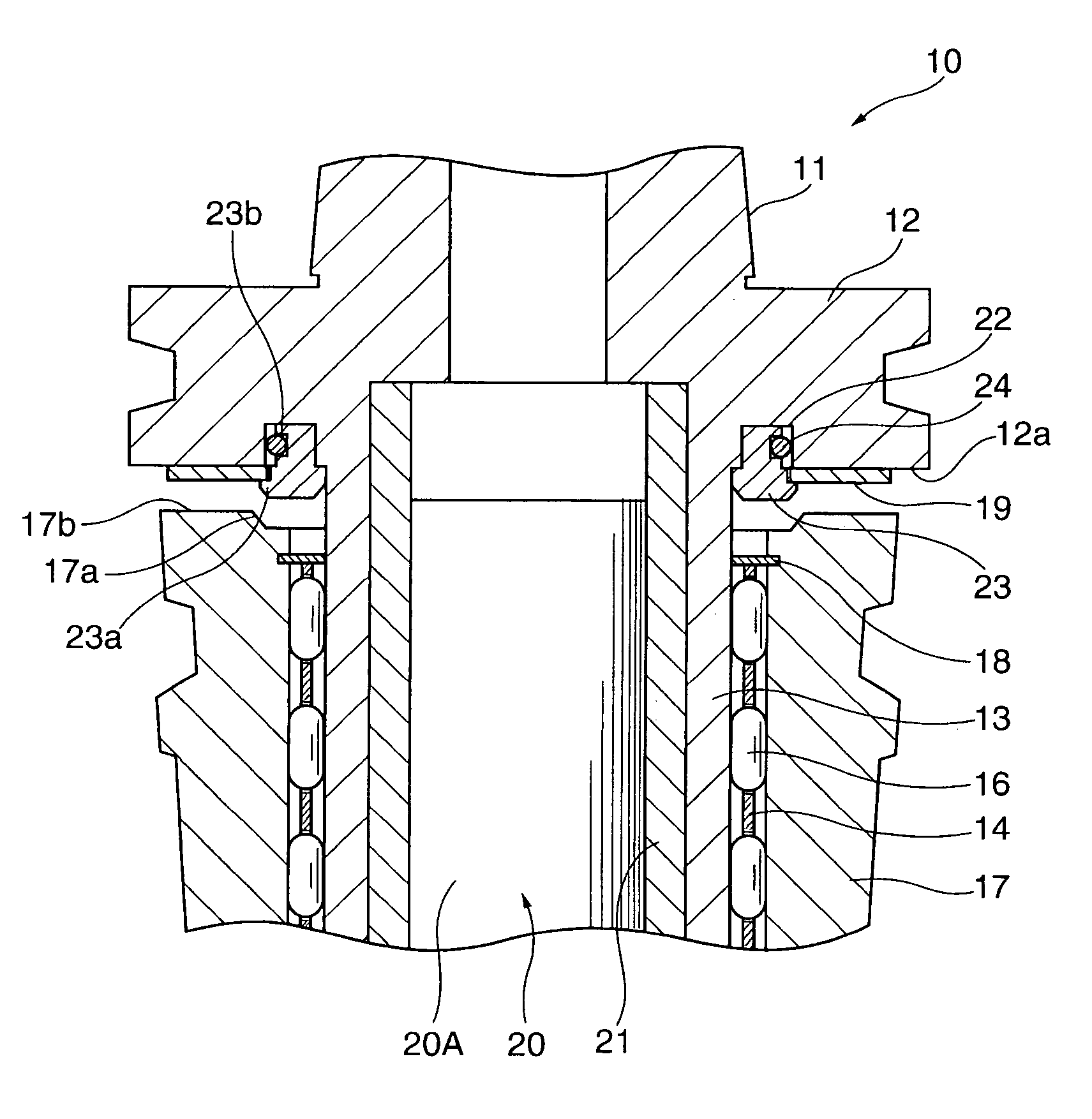

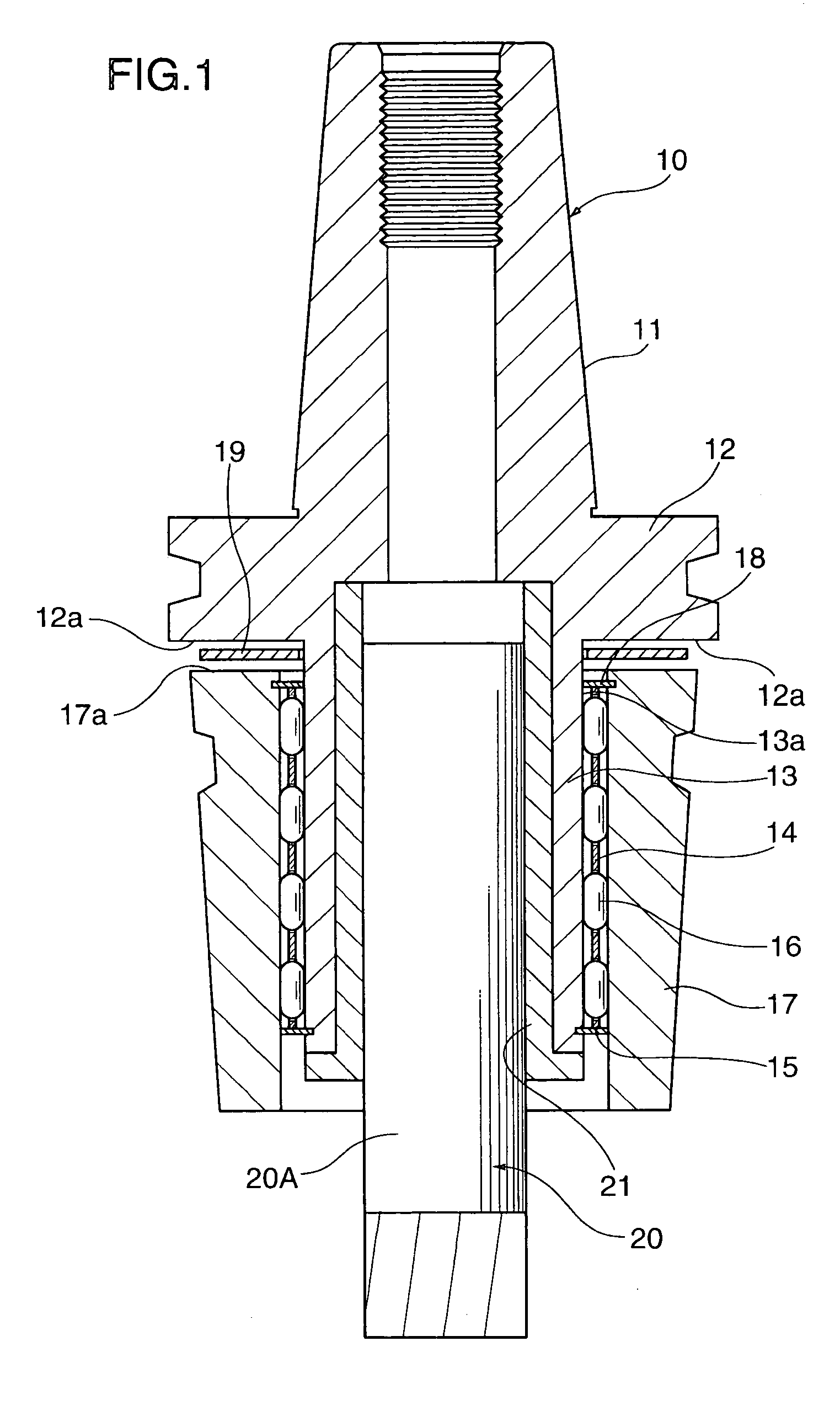

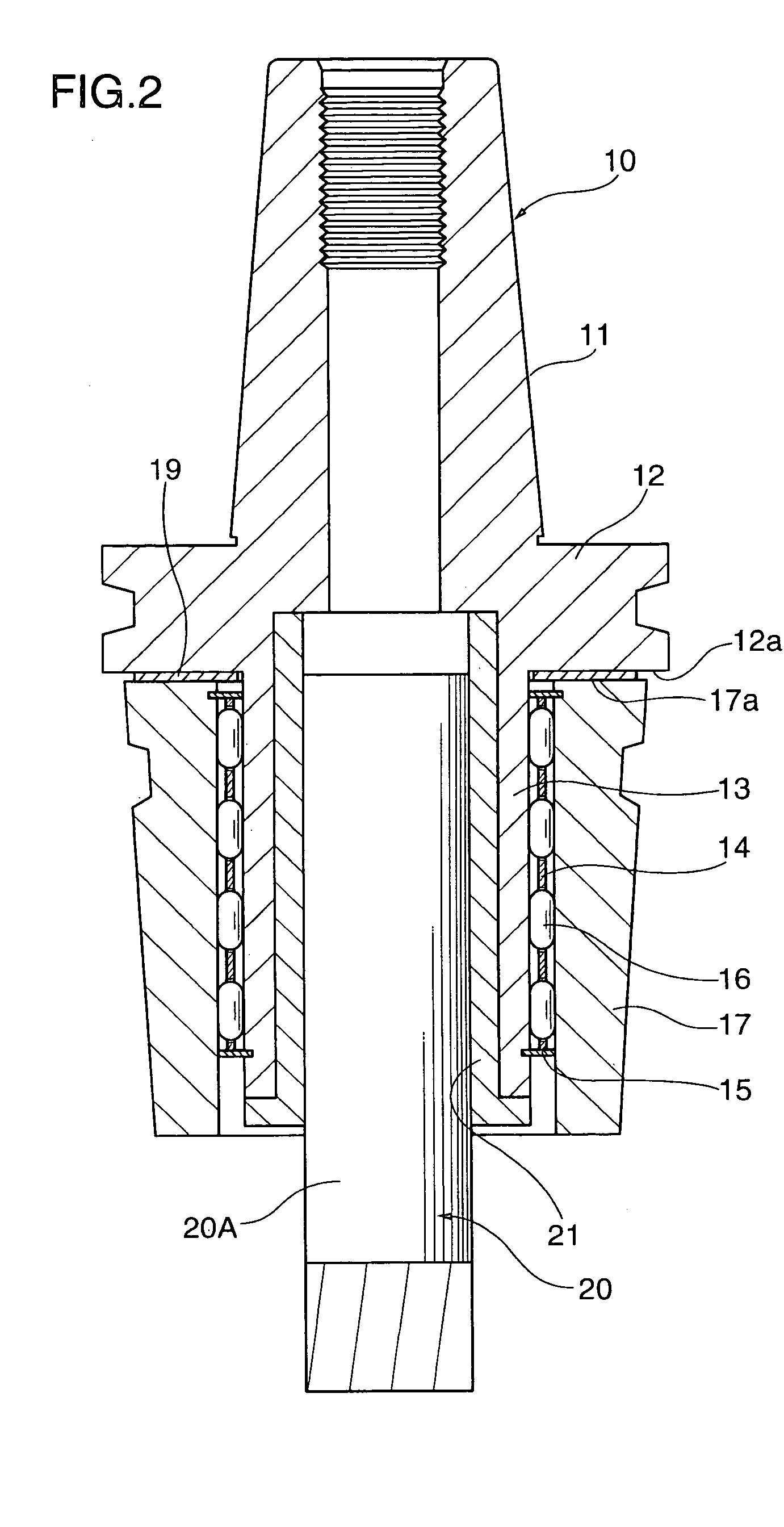

Chuck

ActiveUS20050073115A1Avoid torsional deformationReduce adverse effectsSleeve/socket jointsChucksFlangeEngineering

A chuck includes a holder body, a clamp sleeve, and a large number of needle rollers. The holder body has a shank portion, a flange, and a chuck sleeve. The clamp sleeve is fitted onto the outer circumference of the chuck sleeve such that the clamp sleeve is rotatable and axially movable relative to the chuck sleeve. The needle rollers are disposed between the chuck sleeve and the clamp sleeve over the entire circumference. The clamp sleeve is rotated to cause the needle rollers to revolve spirally along the outer circumferential surface of the chuck sleeve while rotating about their own axes in order to decrease and restore the diameter of the chuck sleeve. A thrust member is disposed between the end surface of the flange opposite the shank portion and a corresponding end surface of the clamp sleeve.

Owner:NIKKEN KOSAKUSHO WORKS LTD

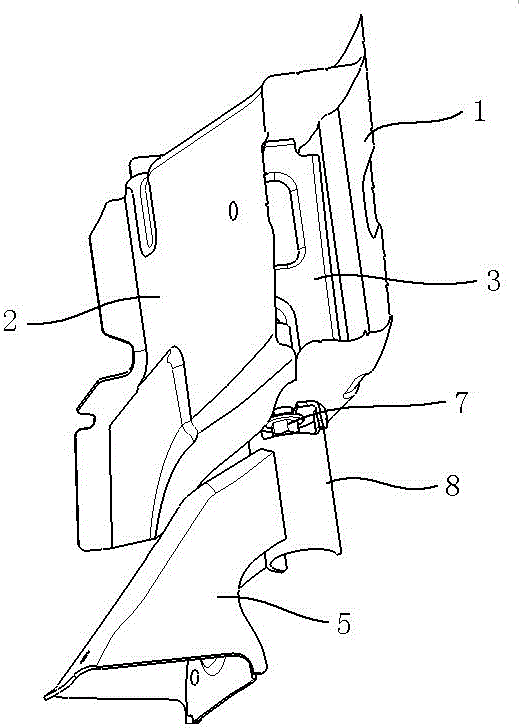

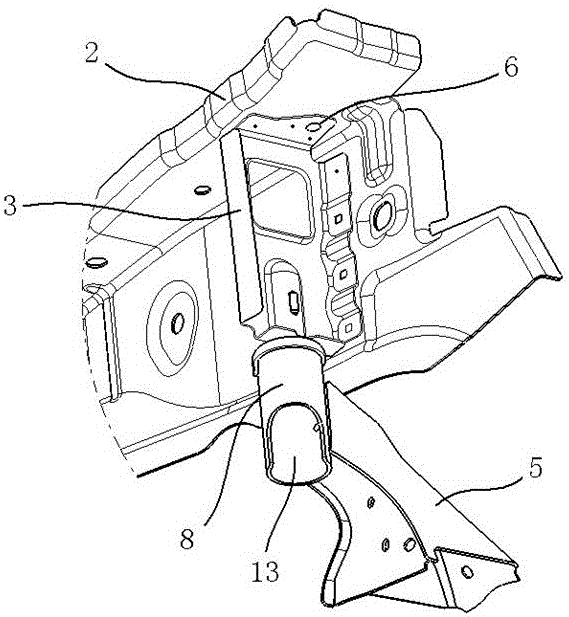

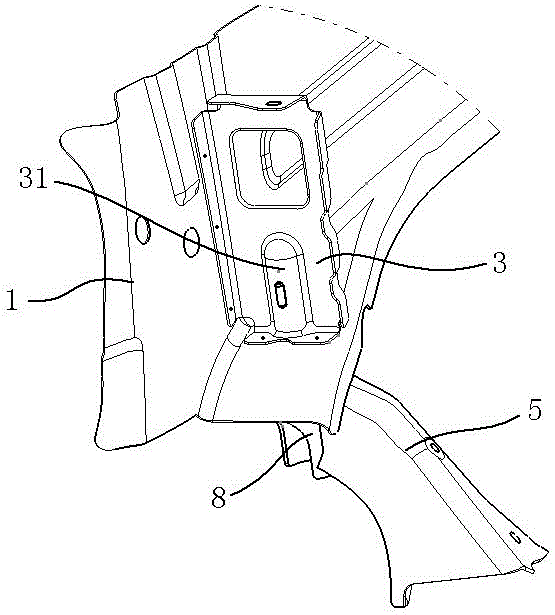

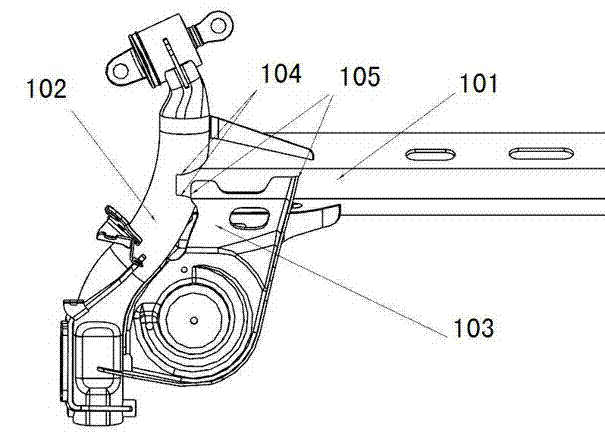

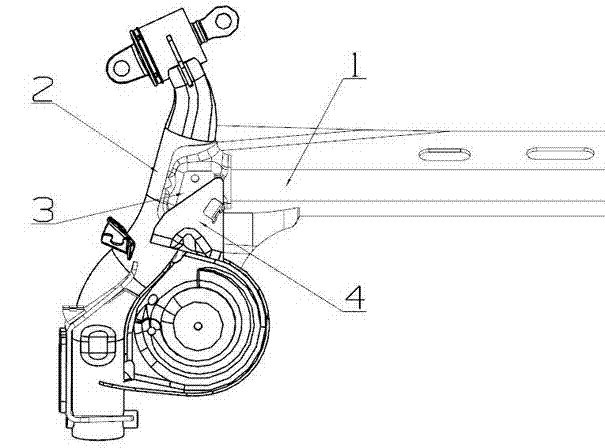

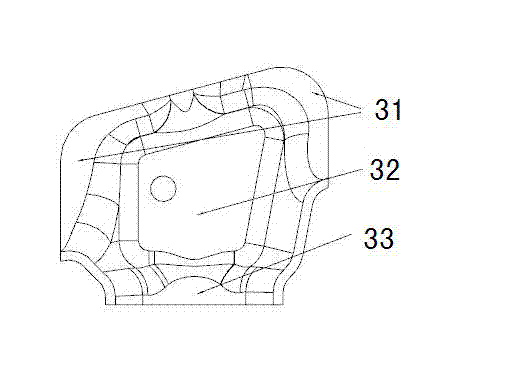

Auxiliary frame mounting point structure

The invention aims at providing an auxiliary frame mounting point structure. The auxiliary frame mounting point structure can realize drop in a collision process and reduce harm on a passenger in a passenger compartment. The auxiliary frame mounting point structure comprises an auxiliary frame provided with a mounting support and a longitudinal beam. The auxiliary frame mounting point structure is characterized inthat an internal screw thread sleeve with the bottom end open is fixed on the longitudinal beam; the mounting support is composed of a tubular support body with the two ends open and a cap body fixedly arranged at the top end of the support body, gaps corresponding in position are formed in the front end of the cap body and the front end of the upper part of the support body, a guide slot connected with the gaps is formed in the cap body, and the guide slot extends along the length direction of an automobile; and the auxiliary frame is fixedly connected with the longitudinal beam by utilizing a bolt which penetrates through the support body and the cap body and is screwed into the internal screw thread sleeve, and an anti-drop part with the diameter larger than the width of the guide slot is arranged at the bottom end of the bolt. The auxiliary frame mounting point structure has the advantages that the auxiliary frame can drop in the collision process and harm done to a passenger can be reduced.

Owner:CHERY AUTOMOBILE CO LTD

Chuck

ActiveUS7017919B2Avoid torsional deformationReduce adverse effectsSleeve/socket jointsChucksEngineeringFlange

A chuck includes a holder body, a clamp sleeve, and a large number of needle rollers. The holder body has a shank portion, a flange, and a chuck sleeve. The clamp sleeve is fitted onto the outer circumference of the chuck sleeve such that the clamp sleeve is rotatable and axially movable relative to the chuck sleeve. The needle rollers are disposed between the chuck sleeve and the clamp sleeve over the entire circumference. The clamp sleeve is rotated to cause the needle rollers to revolve spirally along the outer circumferential surface of the chuck sleeve while rotating about their own axes in order to decrease and restore the diameter of the chuck sleeve. A thrust member is disposed between the end surface of the flange opposite the shank portion and a corresponding end surface of the clamp sleeve.

Owner:NIKKEN KOSAKUSHO WORKS LTD

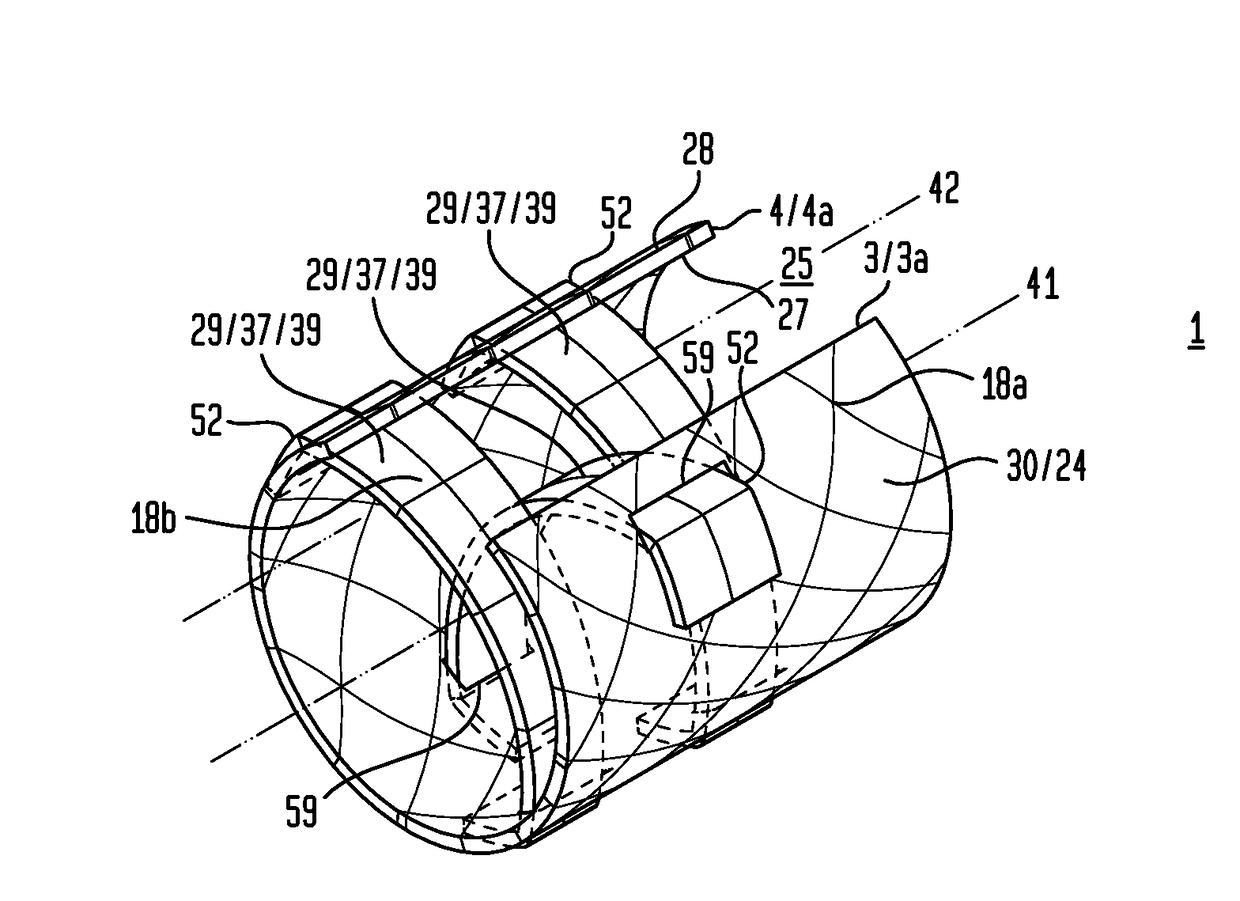

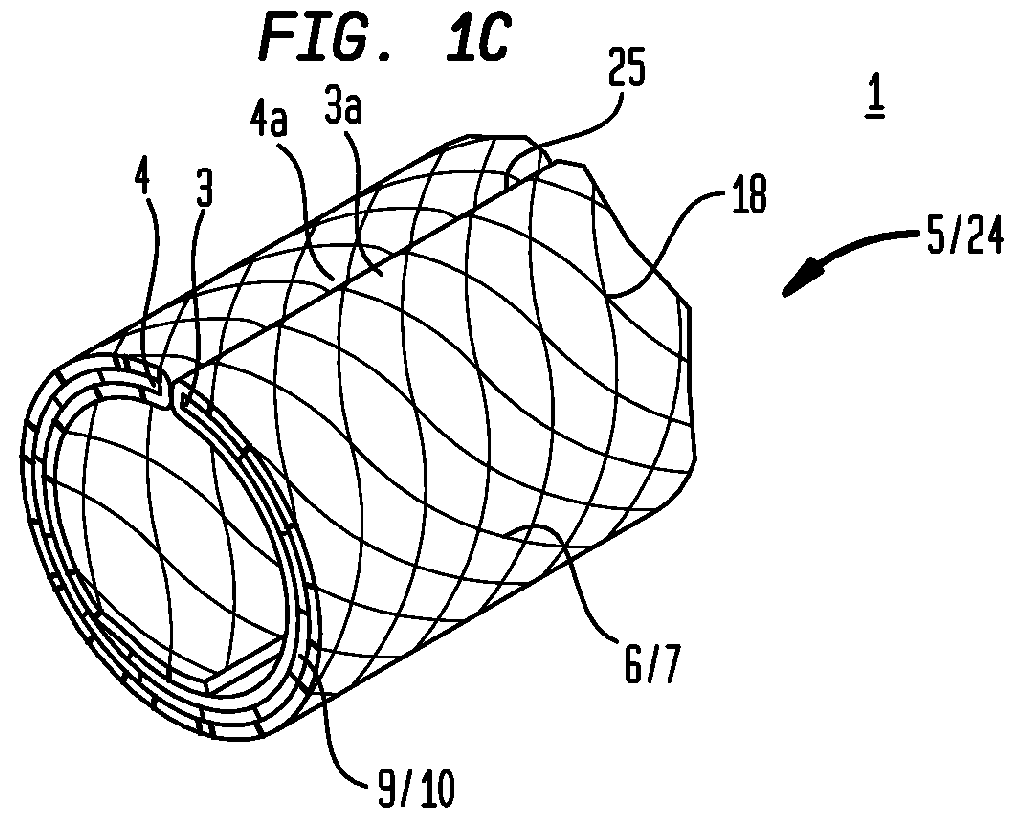

Rigid slit-tube laminate system

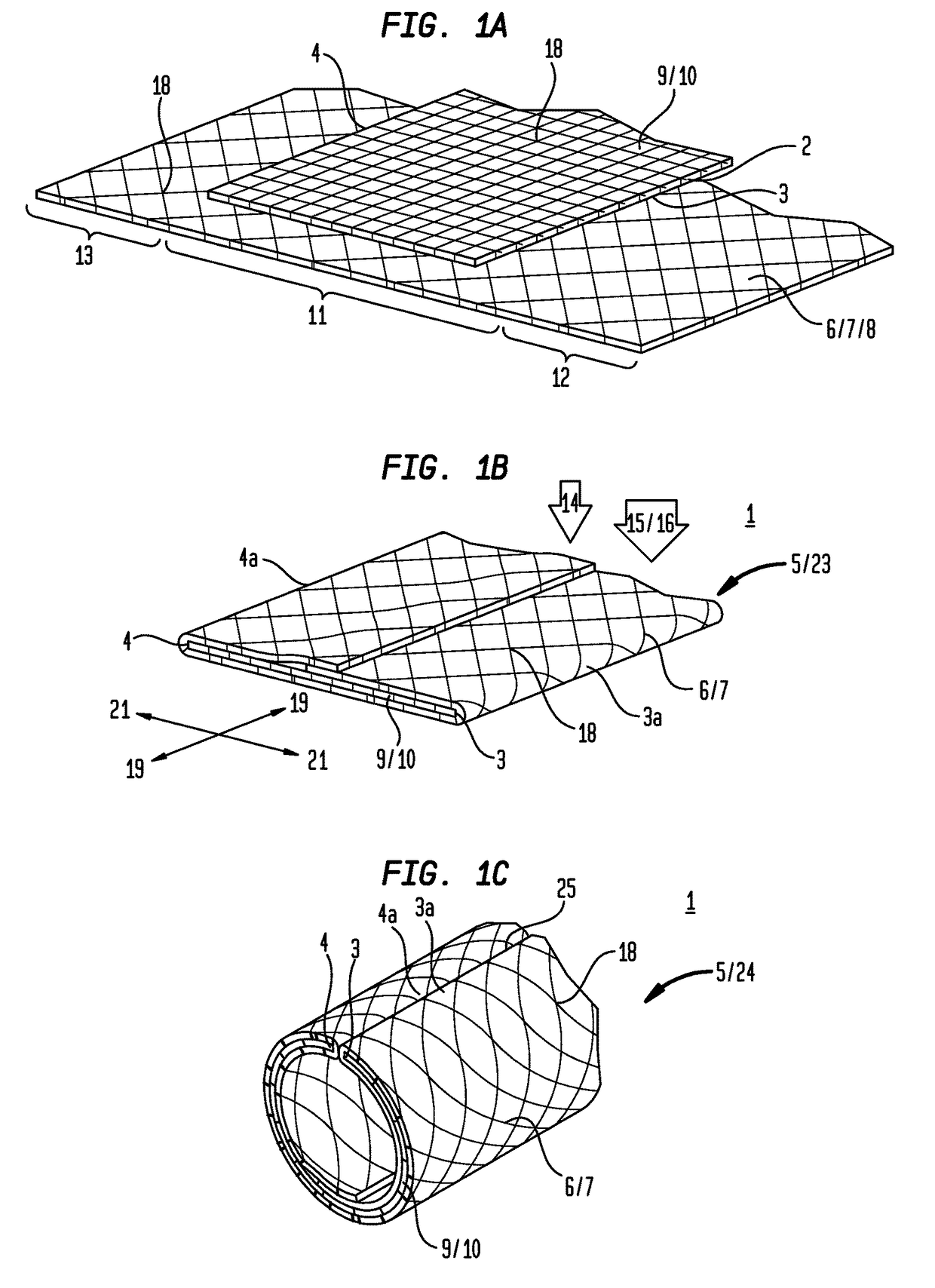

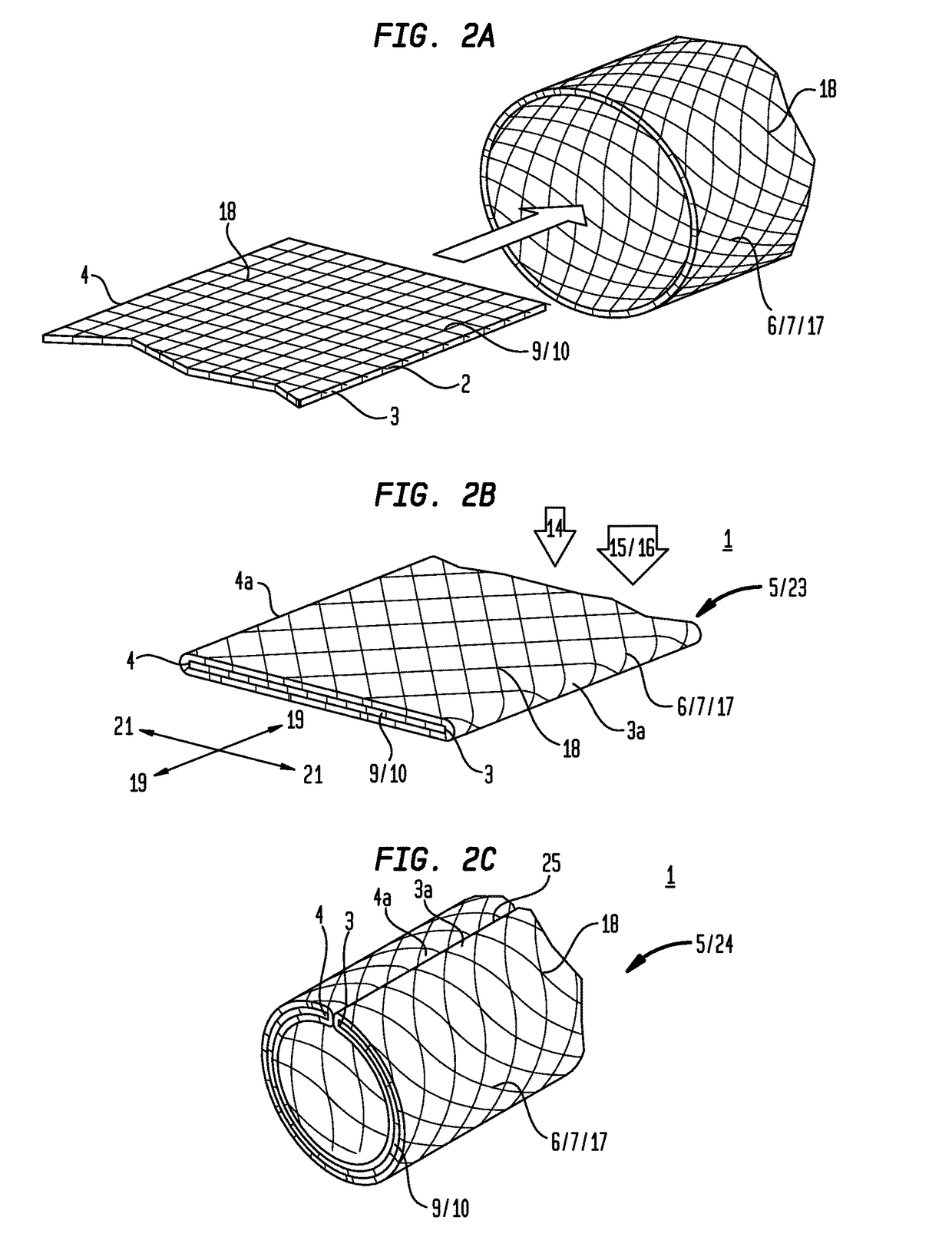

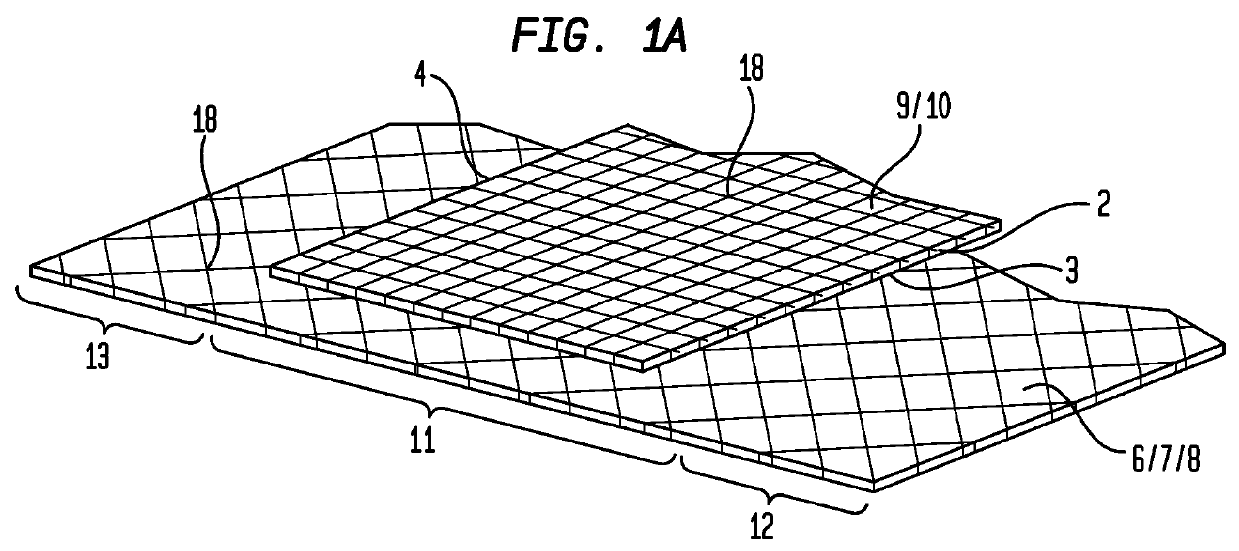

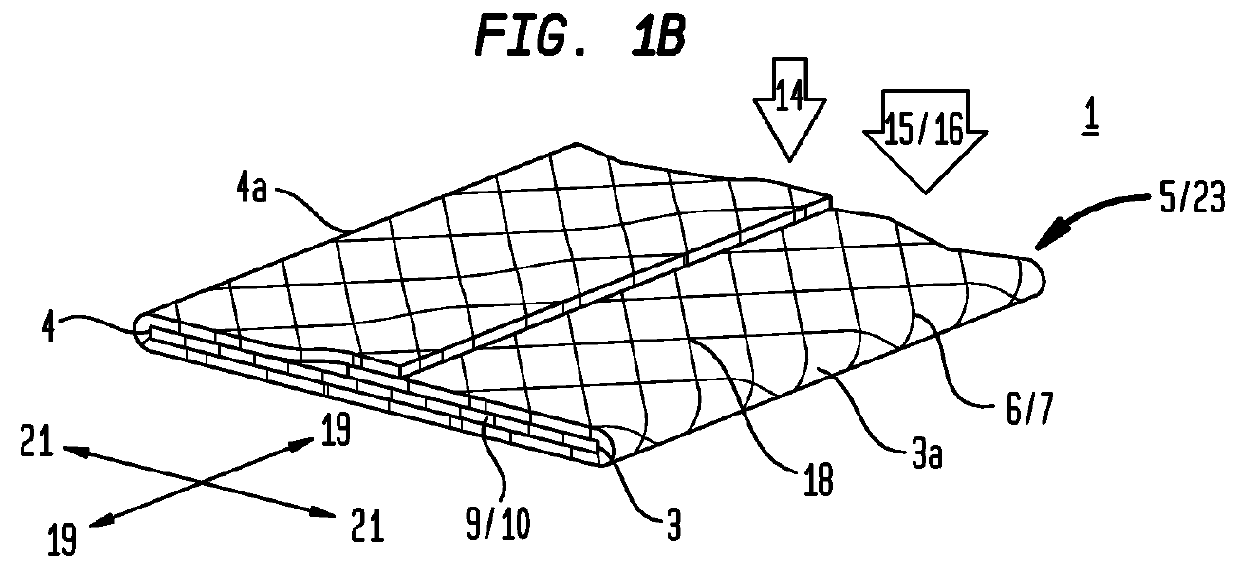

ActiveUS9840060B2Avoids and reduces fraying and detachmentReduce deflectionLaminationLamination apparatusEngineeringMechanical engineering

Laminate structures and methods of making laminate structures having overwrapped laminate edges which resist delamination and fraying or including one or more stabilizer laminates which afford greater radial and torsional rigidity in longitudinally slit tube structures.

Owner:TENDEG

Rigid Slit-Tube Laminate System

ActiveUS20160052225A1Avoids and reduces frayingAvoids and reduces and detachmentLaminationLamination apparatusEngineeringMechanical engineering

Laminate structures and methods of making laminate structures having overwrapped laminate edges which resist delamination and fraying or including one or more stabilizer laminates which afford greater radial and torsional rigidity in longitudinally slit tube structures.

Owner:TENDEG

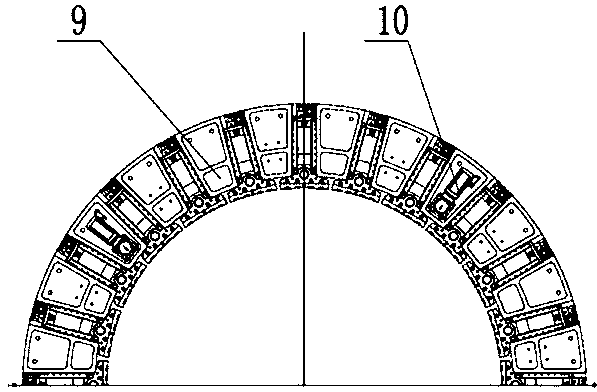

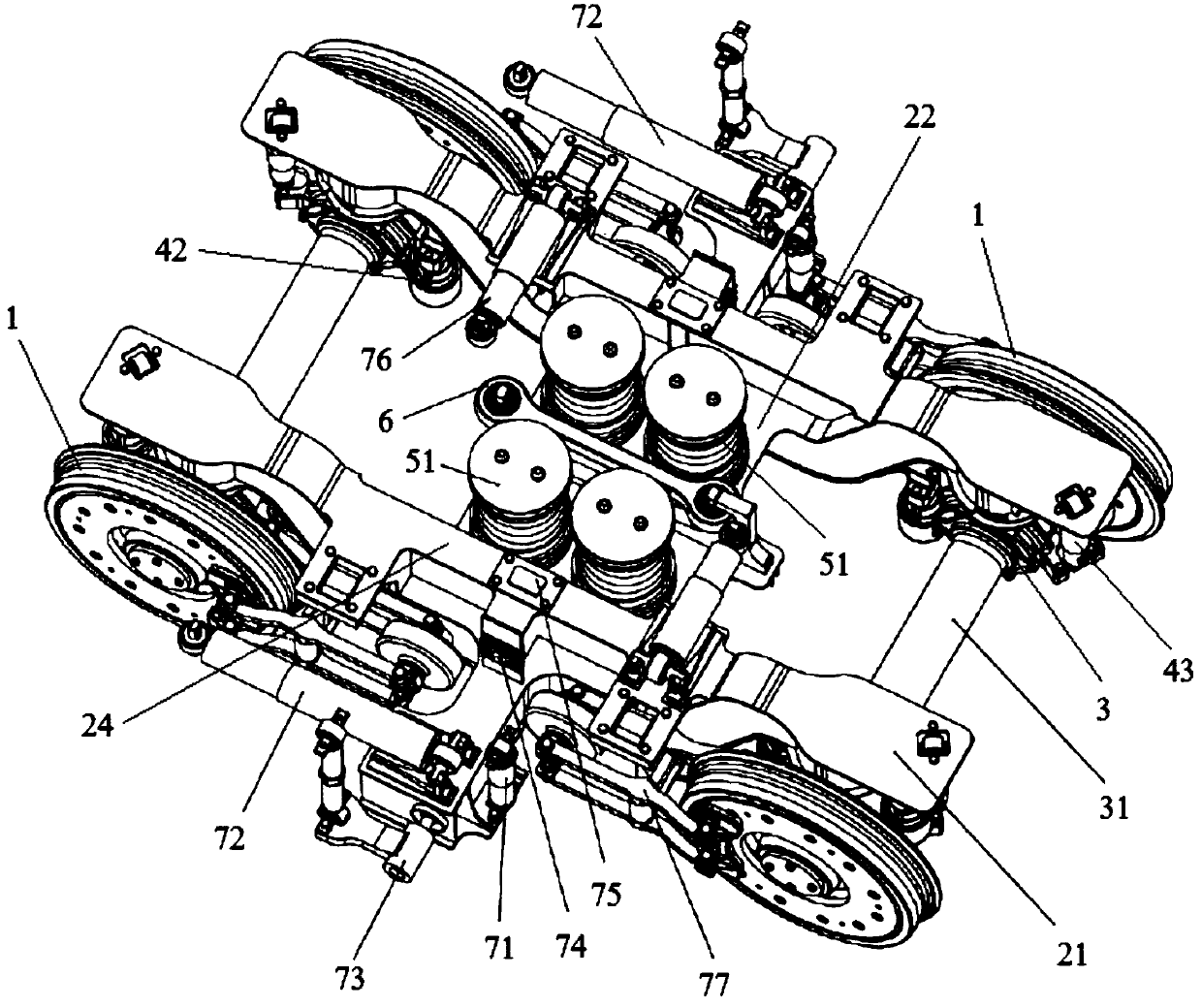

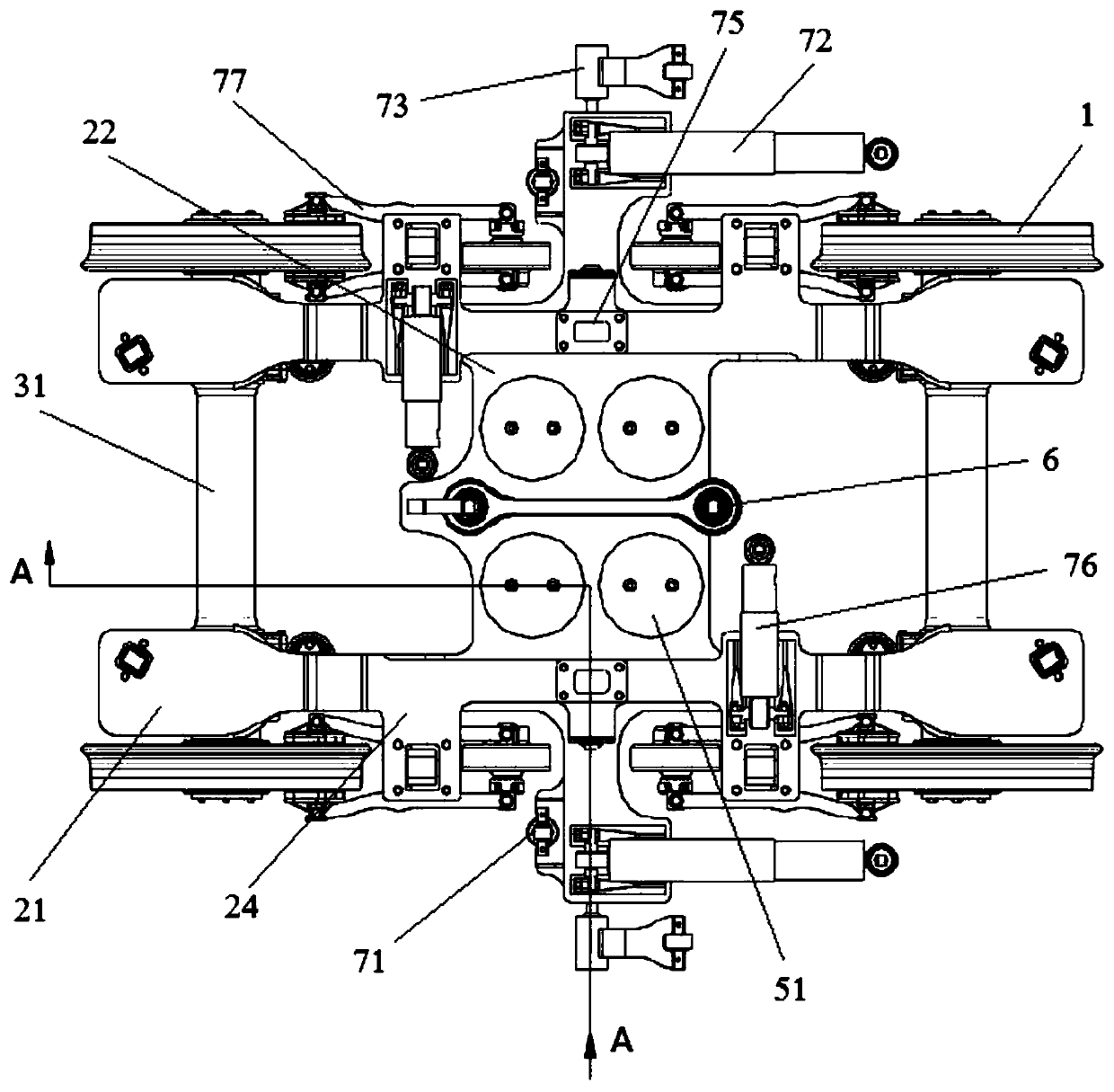

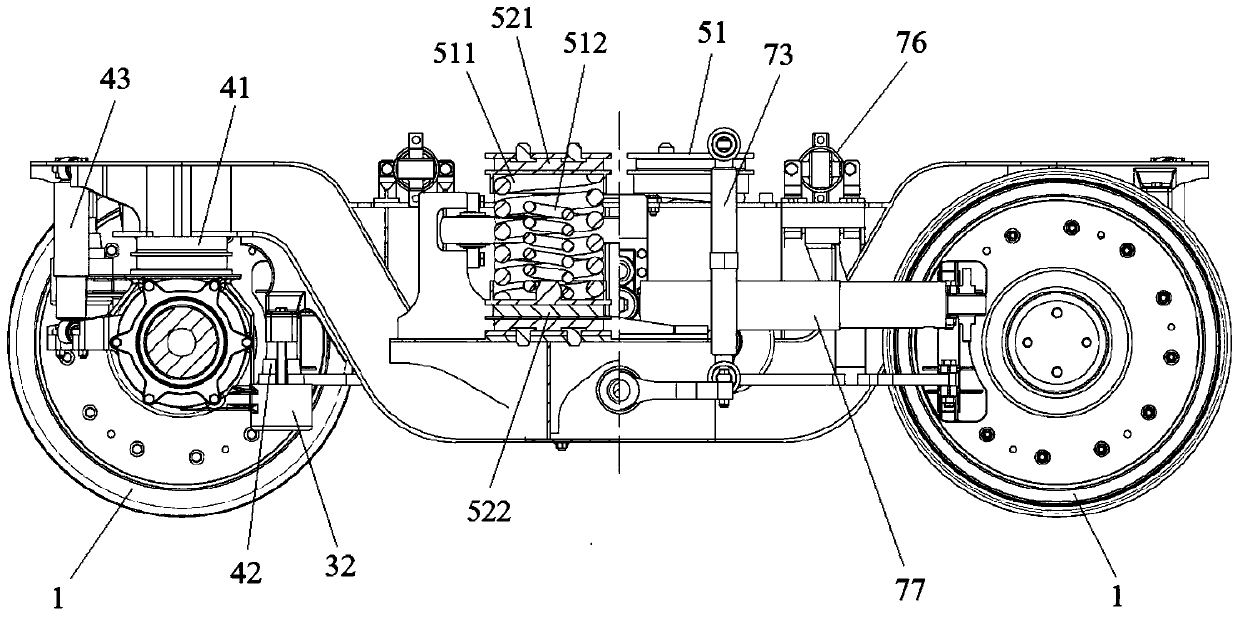

Railway vehicle bogie

PendingCN111301471ARun fastReliable speedBogiesBogie-underframe connectionsBogieTorsional deformation

The invention discloses a railway vehicle bogie. The bogie is arranged in an internal axle box manner, and frameworks are supported on the inner sides of wheel sets, so the axle length is effectivelyshortened, the unsprung mass and dead weight of the bogie are reduced, and the curve passing performance is improved; the arrangement of downward concave sections of side beams and the connection of cross beams to the downward concave sections can effectively reduce the height of the gravity center of the bogie and reserve a high longitudinal space for a vehicle body, and web plates and cover plates can be adopted to enhance the strength of the side beams and improve the bearing capacity of the side beams; two primary positioning components are adopted for positioning, so that the axle distance of the bogie can be further reduced; and a secondary suspension device is additionally arranged to improve the vertical and transverse performances of the bogie and increase the running speed of thebogie, and secondary spring sets are arranged in a centralized mode to reduce torsional deformation of the secondary spring assemblies. The bogie is compact and reasonable in structural arrangement,reliable in performances and beneficial to improving the running stability, stability and running speed of a vehicle.

Owner:SOUTHWEST JIAOTONG UNIV

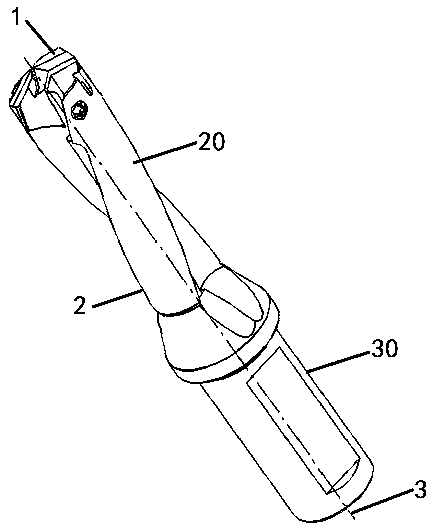

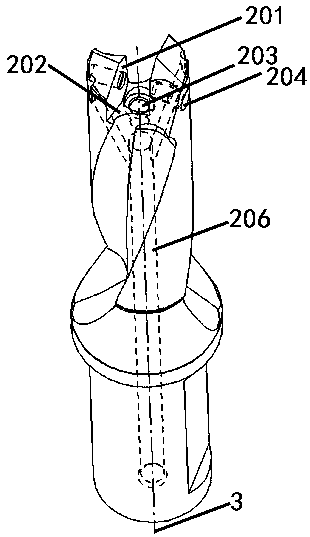

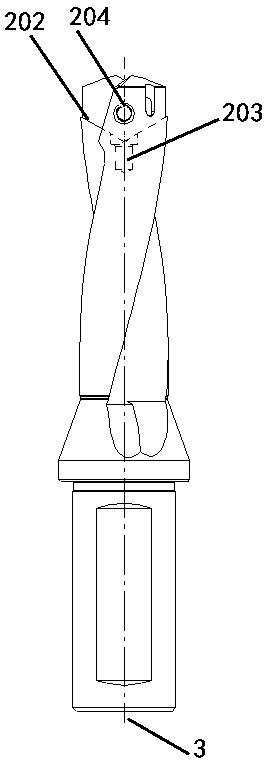

Rotary cutting tool with replaceable tool bit and rotary cutting method and tool bit mounting method thereof

ActiveCN107626960AEffective resistance to radial displacementNot easy to damageMilling cuttersTool bitCooling effect

The invention relates to a rotary cutting tool with a replaceable tool bit and a rotary cutting method and a tool bit mounting method thereof and belongs to the field of hole processing in machining industry. At present, a twist drill used for drilling is of an integrated structure, and the tool bit reaching the service life needs to be replaced integrally, so that the cost is relatively high. Ina drilling tool with the replaceable tool, as the tool bit is subjected to relatively great radial and axial actions in the drilling hole, the condition of no fine drilling as the tool bit shifts radially at the connection is avoided. According to the replaceable structure of the tool bit, the drilling tool at the connection of the tool bit is relatively weak, and the drilling tool matrix is weaker due to a design of a chip removal chute. According to the rotary cutting tool with the replaceable tool bit provided by the invention, the tool bit is detachably connected to a cutter bar and the connection of the tool bit and the cutter bar is a V-shaped locating surface, so that the rotary cutting tool is good in tool bit positioning and fixing effect, and is unlikely to shift. The strength ofthe cutter bar is improved due to different spiral angles of the chip removal chute; the cooling effect is enhanced by a design of a cooling guide slot, and the tool bit is simple to mount and detach.

Owner:ZHEJIANG XINXING TOOLS CO LTD

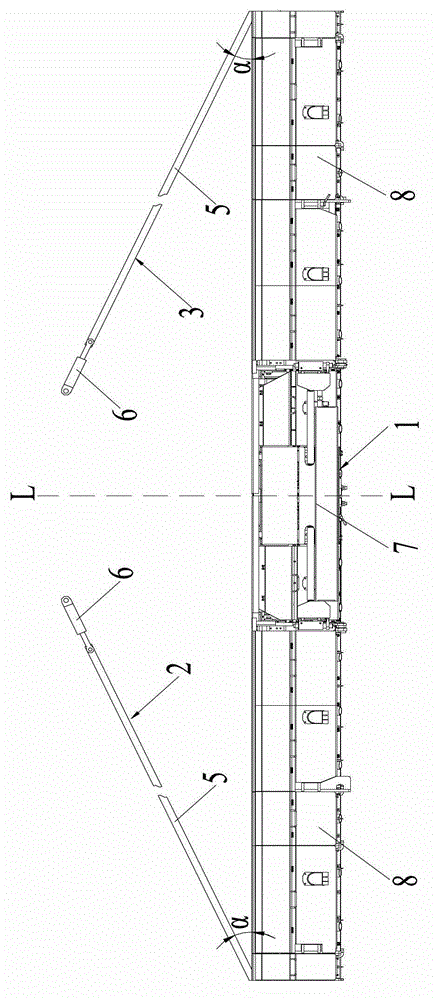

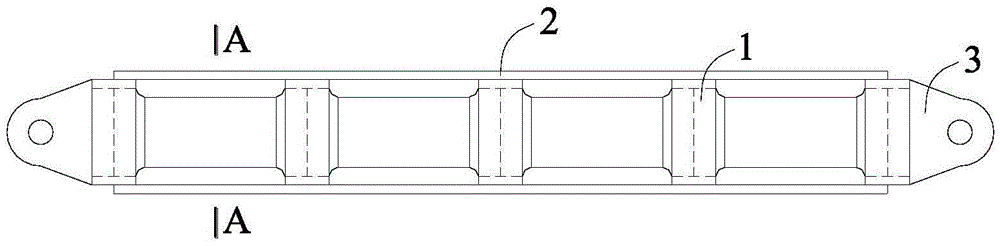

Screed and paver

The invention discloses a screed. The screed comprises a screed body (1), a left tension device (2) and a right tension device (3), wherein the left tension device (2) and the right tension device (3) are arranged symmetrically relative to a central line (L-L) of the screed body (1), one end of the left tension device (2) and one end of the right tension device (3) are respectively connected with an end portion of the screed body (1) at different height positions of the screed body (1), and the lengths of the left tension device (2) and the right tension device (3) both can be adjusted. The invention also discloses a paver. The torsional rigidity of the whole screed is good and the screed can not be twisted and deformed easily.

Owner:ZOOMLION HEAVY IND CO LTD

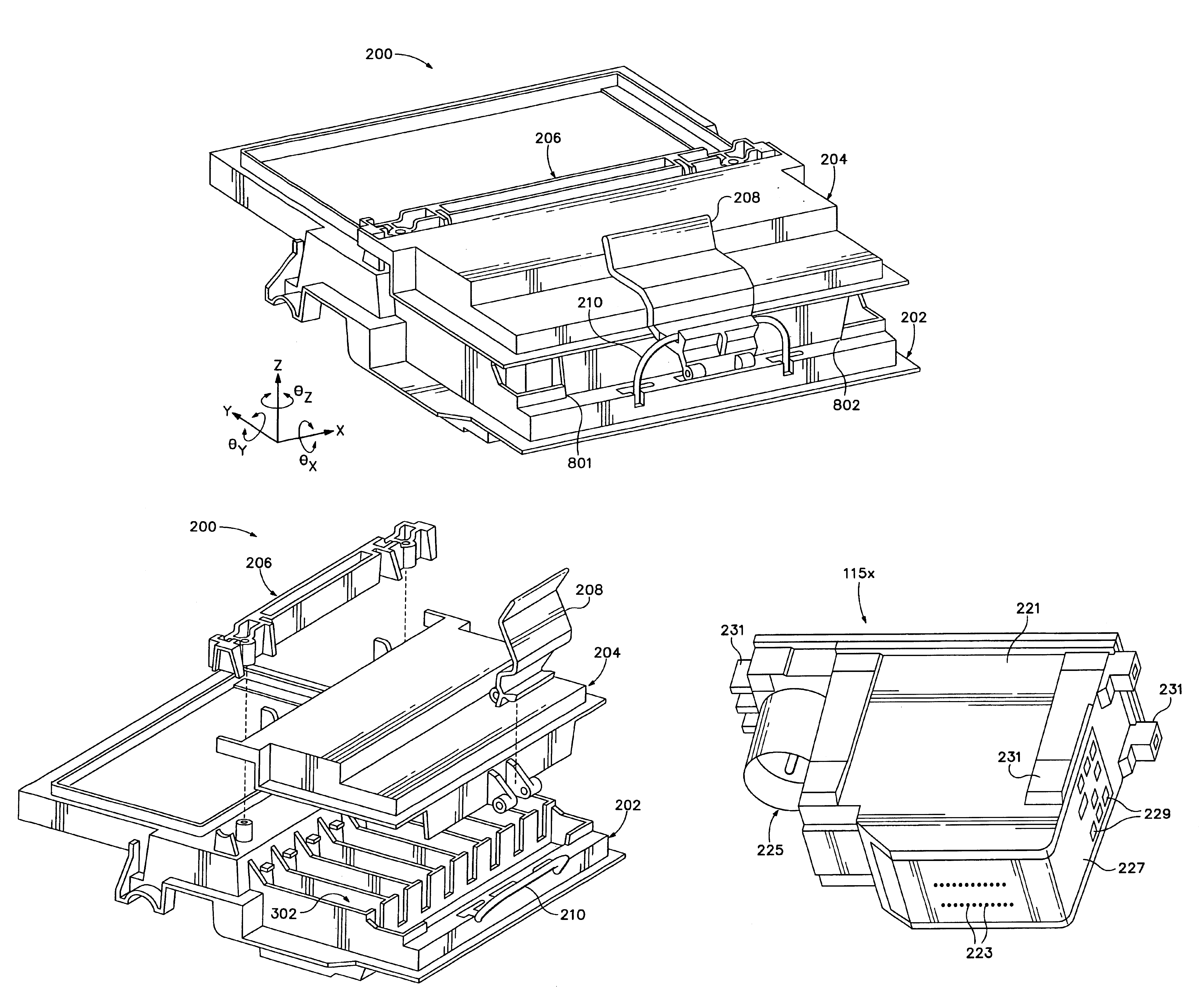

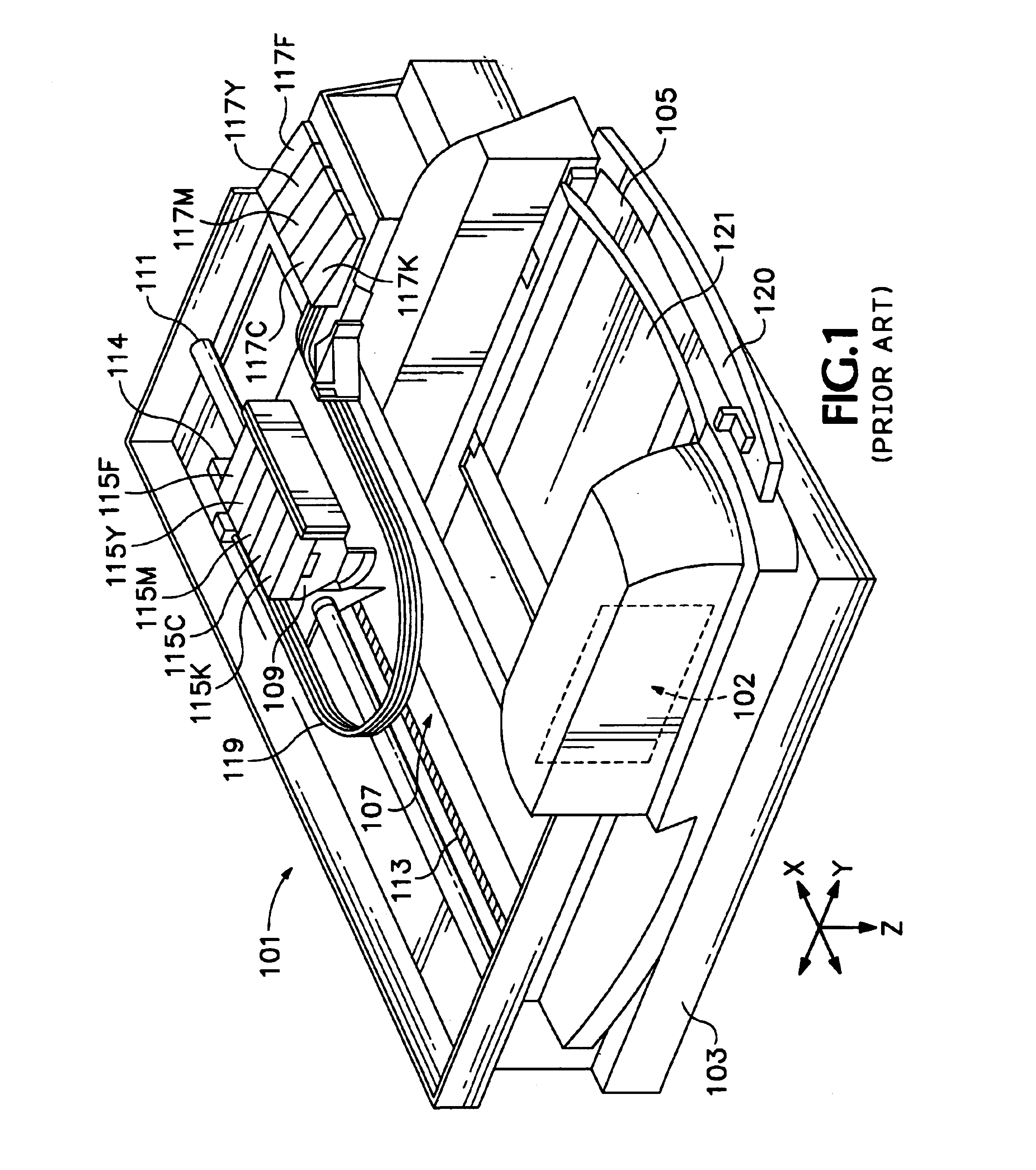

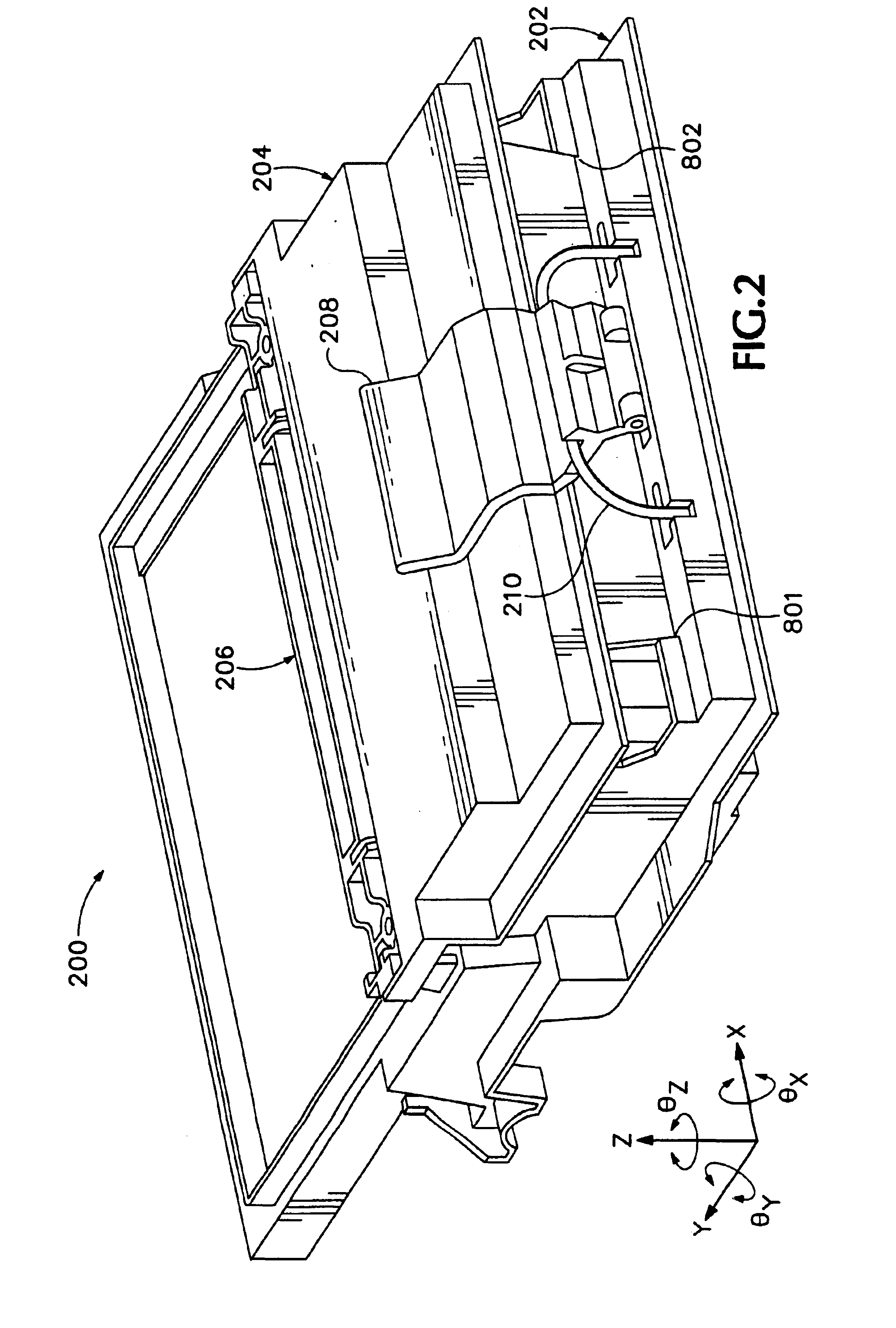

Carriage for ink-jet hard copy apparatus

InactiveUS6916084B2Reduce torsional deformationSmall footprintInking apparatusPower drive mechanismsInk printerEngineering

A carriage for an ink-jet printer constrains torsional deflections by providing carriage to writing-instrument latch interface features having a zero clearance interfit such that when opened, the writing-instrument latch allows individual writing-instruments to be accessed and when closed the writing-instrument latch reduces the carriage torsional deflections and increases the torsional stiffness of the carriage by providing a biasing force at each the interface feature.

Owner:HEWLETT PACKARD DEV CO LP

Robot operated flexible ureteroscope anti-bending mechanism

ActiveCN109008931ANo bendingNo reduction in working distanceEndoscopesSurgical robotsRobotic systemsMechanical engineering

The disclosure provides a robot operated flexible ureteroscope anti-bending mechanism comprising a sliding sleeve, a sliding sleeve fixing member, a polished rod, a distance measuring substrate, a distance measuring shaft, a distance measuring wheel, a first belt wheel, a linkage device and a clamping device; the sliding sleeve fixing member is nested on the sliding sleeve; the polished rod is nested in one end of the sliding sleeve, the polished rod is slidingly connected with the sliding sleeve, the distance measuring substrate is connected with the polished rod, the distance measuring shaftis connected with the distance measuring substrate, the distance measuring wheel is arranged on the distance measuring shaft in a sleeving manner and is connected with the distance measuring substrate, the first belt wheel is arranged on the distance measuring shaft in a sleeving manner and is connected with the distance measuring substrate, the linkage device is connected with the distance measuring wheel and the sliding sleeve, and the clamping device is connected with the first belt wheel via a synchronous belt. Via the mechanism disclosed in the disclosure, a flexible ureteroscope can beprevented from being bent during push processes, and the mechanism can be combined with a robot system; the mechanism is high in precision, stable in motion and high in safety and reliability.

Owner:TIANJIN UNIV

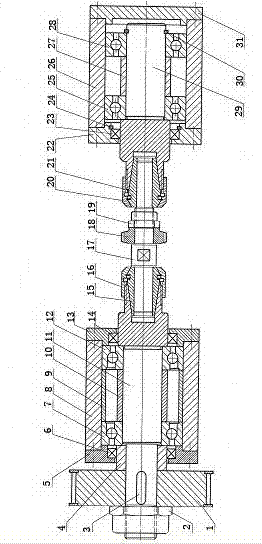

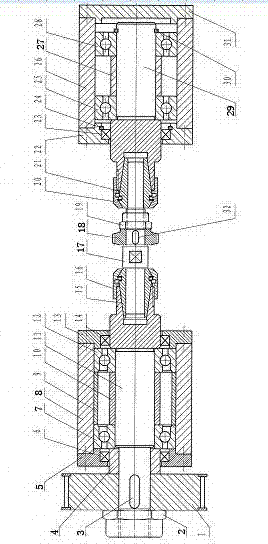

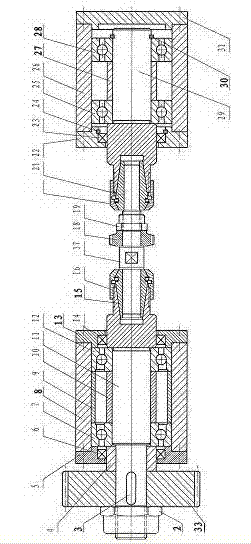

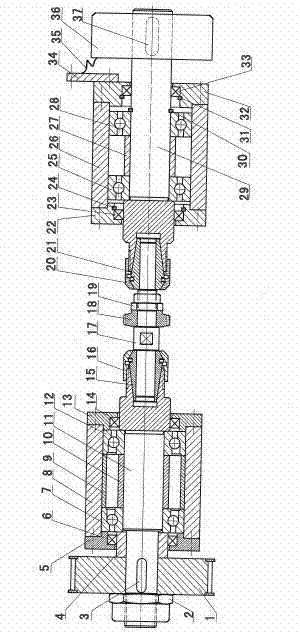

Quick-changing type hob main shaft of gear hobbing machine

ActiveCN103111637AEasy to replaceReduce torsional deformationGear-cutting machinesGear teethHobbingFriction torque

The invention provides a quick-changing type hob main shaft of a gear hobbing machine. The quick-changing type hob main shaft is simple in structure, can quickly replace a hob, and comprises a torque input component, a hob installation component and an auxiliary support component. According to a hob installation shaft, only the installation of the hob needs to be considered. The hob installation shaft is provided with no bearing and no torque transmission element, thereby being simple in structure, and convenient to machine. The hob and the hob installation shaft are convenient to replace, and the quick-changing type hob main shaft is suitable for single unit processing or small batch processing of various small module gears. An auxiliary support shaft only bears friction torque generated by a bearing and a sealing ring on the torque respect, and the friction torque is small, and therefore the auxiliary support shaft is small in torsional deformation.

Owner:常州安复环境工程有限公司

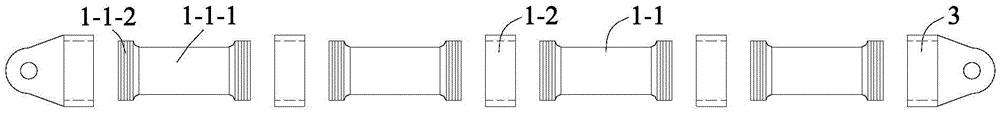

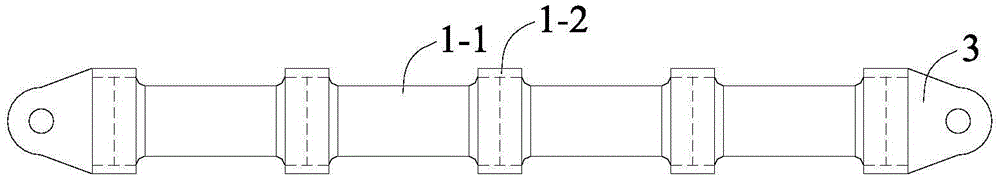

Modularized bamboo-shaped buckling restrained brace

ActiveCN105604205AIncrease production capacityRealize the designShock proofingBuckling-restrained braceEngineering

The invention discloses a modularized bamboo-shaped buckling restrained brace which comprises a core part, an outer restraining part and a structure connecting part. The core part comprises a plurality of circular energy dissipation sections and a plurality of elastic sleeves. Each circular energy dissipation section comprises a middle section and connecting sections at two ends. The core part is located inside the outer restraining part. The inner surface of the outer restraining part closely attaches to or is tangent to the outer surfaces of the elastic sleeves of the core part. One end of the structure connecting part extends into the outer restraining part, and the other end thereof extends out of the outer restraining part to be connected with a structure. The modularized bamboo-shaped buckling restrained brace has the advantages that the circular energy dissipation sections and elastic sleeves of the modularized bamboo-shaped buckling restrained brace can be produced in batch in factories, the circular energy dissipation sections and elastic sleeves can be selected and combined according to the length requirement of the buckling restrained brace, and accordingly the modularized production and design of the core part can be achieved.

Owner:CHINA JINGYE ENG TECH CO LTD +2

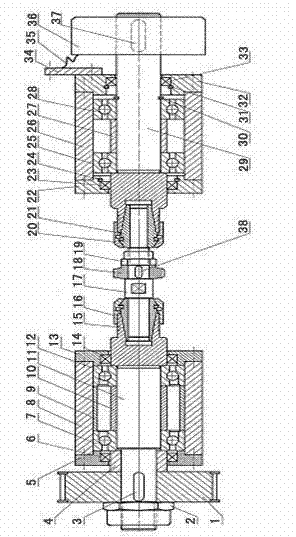

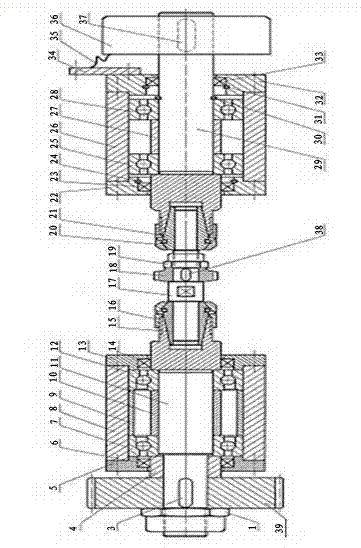

Quick-replacing-type hob main shaft of numerically-controlled gear hobbing machine

ActiveCN103111638AEasy to replaceReduce torsional deformationDriving apparatusHobbingFriction torque

The invention provides a quick-replacing-type hob main shaft structure of a numerically-controlled gear hobbing machine. According to the hob main shaft, the structure is simple and a hob can be quickly replaced. The hob main shaft comprises a torque input component, a hob installation component and an auxiliary supporting component. In terms of a hob installation shaft, what needs to be considered is hob installation, no bearings and no torque transmission parts exist on the hob installation shaft, so the structure is simple, machining is convenient, the hob and the hob installation shaft are convenient to replace, and the hob main shaft is suitable for single unit processing or small batch processing of various small module gears. In terms of torque, an auxiliary supporting shaft only bears friction torque produced by a bearing and a seal ring, and the friction torque is small, so torsional deformation of the auxiliary supporting shaft is small. A rotary encoder is installed on the auxiliary supporting shaft, the auxiliary supporting shaft and the hob installation shaft coaxially rotate, and so the rotation angle of the hob installation shaft (the hob) can be precisely detected.

Owner:常州辉展金属科技有限公司

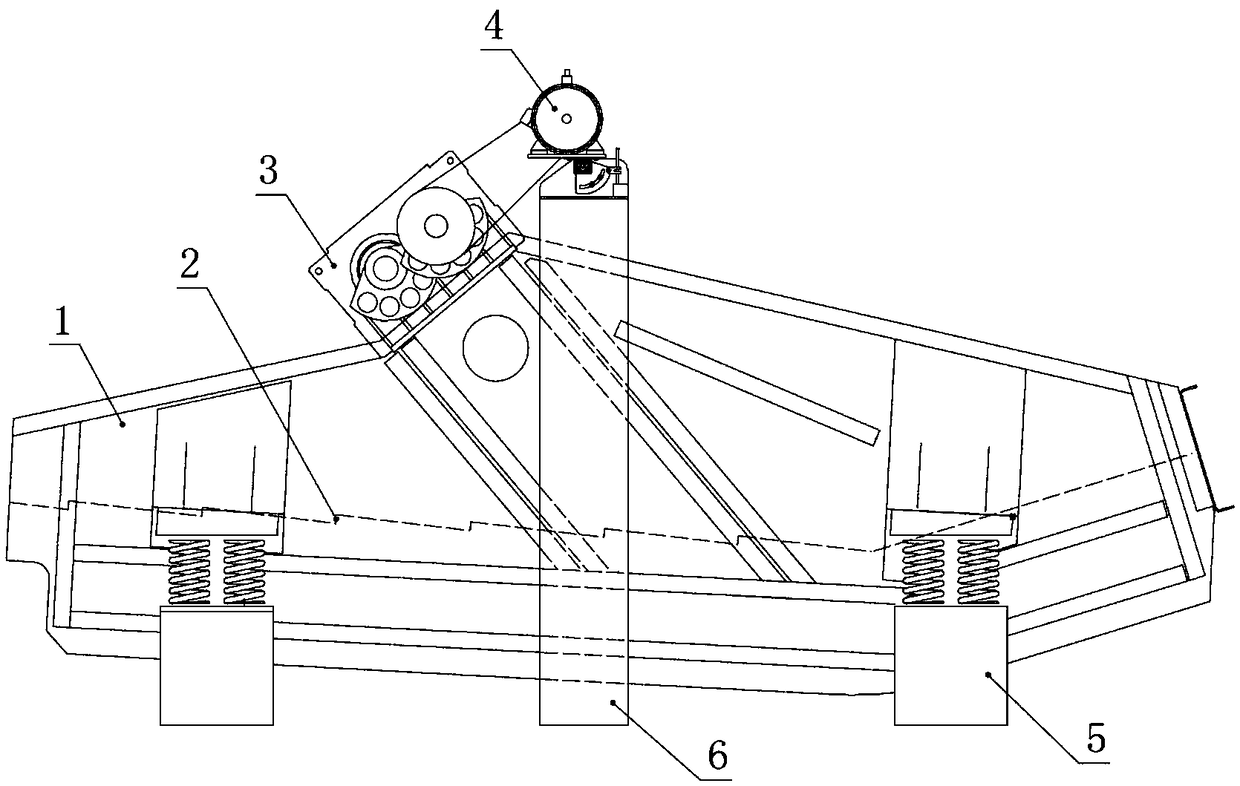

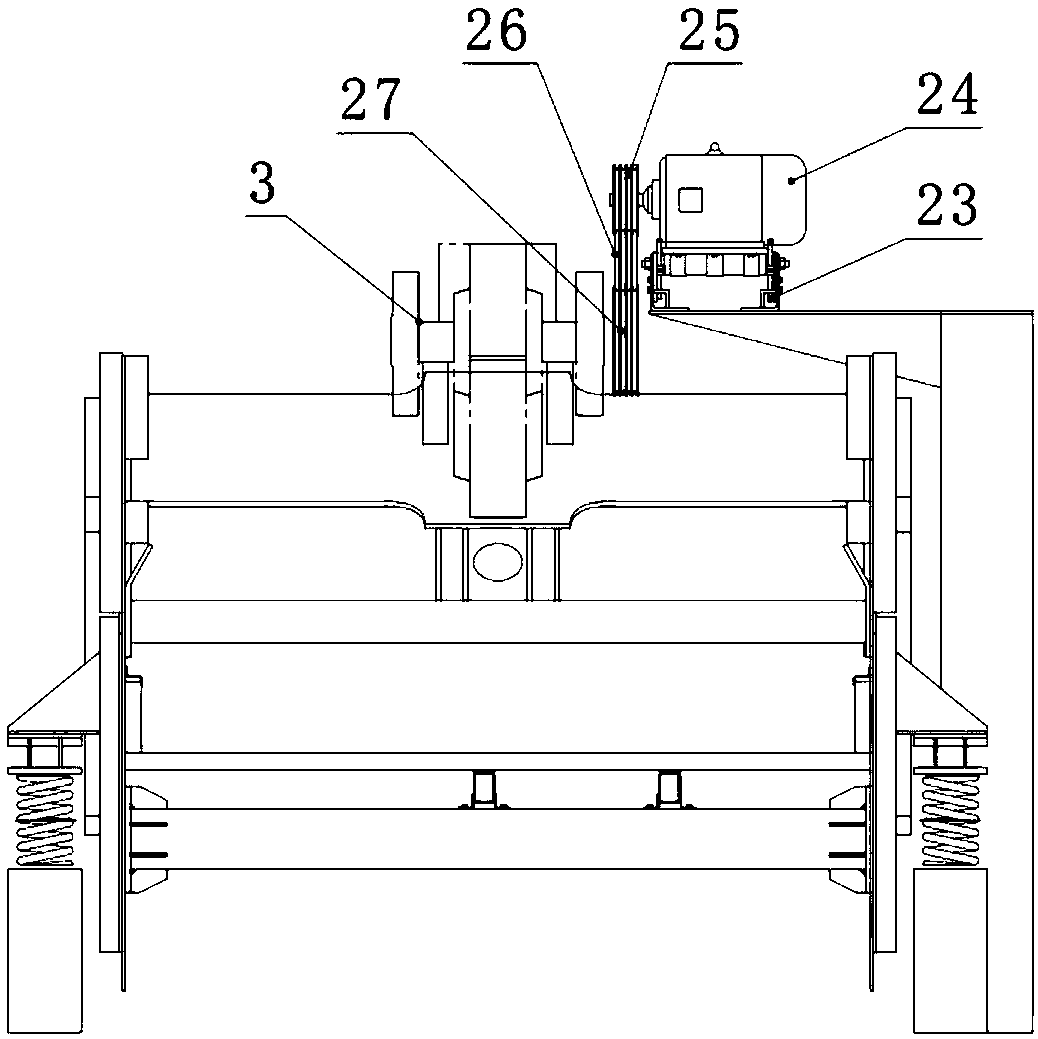

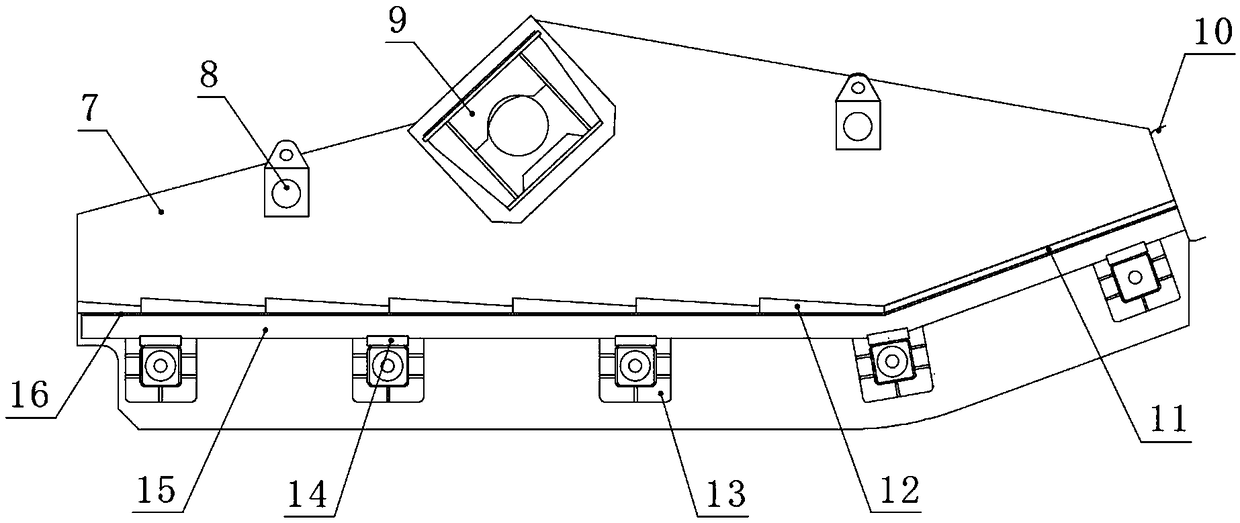

High frequency vibrating screen

ActiveCN108906600APromote looseImprove dehydration effectSievingScreeningButt jointVibration exciter

The invention discloses a high frequency vibrating screen which comprises a screen box, a screen plate, a box type vibration exciter and a driving system. The screen box comprises two side plates, a plurality of transverse beams and a driving beam, the two side plates are installed on a support through springs, the lower edges of the two side plates are connected through the multiple parallel transverse beams, the upper portions of the middles of the two side plates are connected through the driving beam, the box type vibration exciter is installed on the driving beam and is connected with thedriving system, the screen plate is fixed to the upper portions of the transverse beams and is formed by butt joint of a slope screen plate with a positive inclined angle and a step-shaped screen plate with a negative inclined angle, the slope screen plate is located on the back portion of the step-shaped screen plate, and a feeding baffle is arranged at the back end of the slope screen plate. According to the high frequency vibrating screen, the staged type screen plate formed by the slope screen plate and the step-shaped screen plate is adopted, the forced synchronization type box type vibration exciter is used as a vibration exciting source, coal slime scattering and layering and further dewatering can be promoted, material stacking and water running can be effectively prevented, the dewatering effect of the slime water is improved, the fault rate is low, and the screen machine running reliability is greatly improved.

Owner:TIANDI TANGSHAN MINING TECH +1

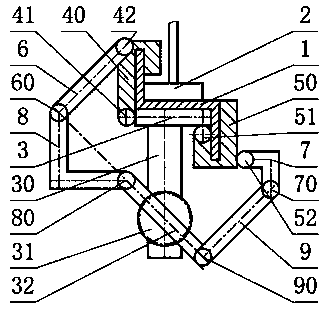

Swing arm drive device for spraying antifreeze on coal-carrying train

The invention relates to a swing arm drive device for spraying antifreeze on a coal-carrying train, belonging to the field of machinery design. The swing arm drive device for spraying the antifreeze on the coal-carrying train is characterized by being of a structure of changing a shaft diameter by means of shaft sleeves and arranging a drive mechanism in the middle of a shaft, and the swing arm drive device comprises a square upright, a clamp device, a slewing mechanism, a driving mechanism, a stop block, an upper arm assembly and a lower arm assembly. One shaft sleeve is designed at each end of the shaft of the swing arm drive device, and the drive mechanism is arranged in the middle area of a rotating shaft, thus the distance between an upper support plate and a lower support plate in a limited space is increased, and the force applied by the supported swing arm to the rotating shaft is reduced. According to the invention, the diameter of the rotating shaft is changed by means of the shaft sleeves, and the position of the drive mechanism is rationally arranged, therefore volume and weight of the swing arm drive device are reduced, cost is saved and field installation is convenient. The swing arm drive device for spraying the antifreeze on the coal-carrying train has the characteristics of lower horizontal rotating speed, smaller rotating driving torque and strong radial carrying capacity at two ends of the rotating shaft, is in particular suitable for support and horizontal rotating drive to the swing arm for spraying the antifreeze on the coal-carrying train.

Owner:TAIYUAN UNIV OF TECH

Torsion beam assembly

InactiveCN103568772AReduce torqueReduce torsional deformationInterconnection systemsEngineeringUltimate tensile strength

The invention provides a torsion beam assembly which comprises a spring base, a transverse beam and a longitudinal arm. The torsion beam assembly further comprises a reinforcing cover plate, the reinforcing cover plate is respectively connected with the transverse beam and the longitudinal arm, and the spring base is arranged on the reinforcing cover plate. The torsion beam assembly has the advantages that connecting strength of the transverse beam and the longitudinal beam can be enhanced through the reinforcing cover plate, the spring base can be arranged on the reinforcing cover plate, force is prevented from being directly transmitted to the transverse beam from the spring base, torsional force of the transverse beam is decreased, and torsion deformation of the transverse beam is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Detachable type mechanical arm cable-bunching device adopting peripheral slide spherical hinge connection

ActiveCN109877878AMeet the needs of different robot arm diametersWide applicabilityCable arrangements between relatively-moving partsManipulatorEngineeringRelative motion

The invention discloses a detachable type mechanical arm cable-bunching device adopting peripheral slide spherical hinge connection, and belongs to the field of robots. The cable-bunching device comprises a dual-cable hoop mechanism, a spherical hinge connecting mechanism and a cable-bunching clamp mechanism, wherein the dual-cable hoop mechanism comprises metal dual cables, a metal hoop and a hoop connecting bolt; the spherical hinge connecting mechanism comprises a hoop slide connector, a spherical hinge external connecting part, a spherical hinge internal connecting part and a spherical hinge connecting bolt; and the cable-bunching clamp mechanism comprises a ratchet wheel, a pawl and a ratchet wheel connecting bolt. According to the cable-bunching device provided by the invention, thediameter of the dual-cable hoop mechanism is adjustable to meet different mechanical arm diameter needs. The detachable type mechanical arm cable-bunching device is wide in applicability, is simple instructure and is firm; and meanwhile, the spherical hinge connecting mechanism and the cable-bunching clamp mechanism realize relative motion in the peripheral direction of a mechanical arm, and greatly reduces torsional deflection, caused by rotation of the mechanical arm, of cables.

Owner:SIASUN CO LTD

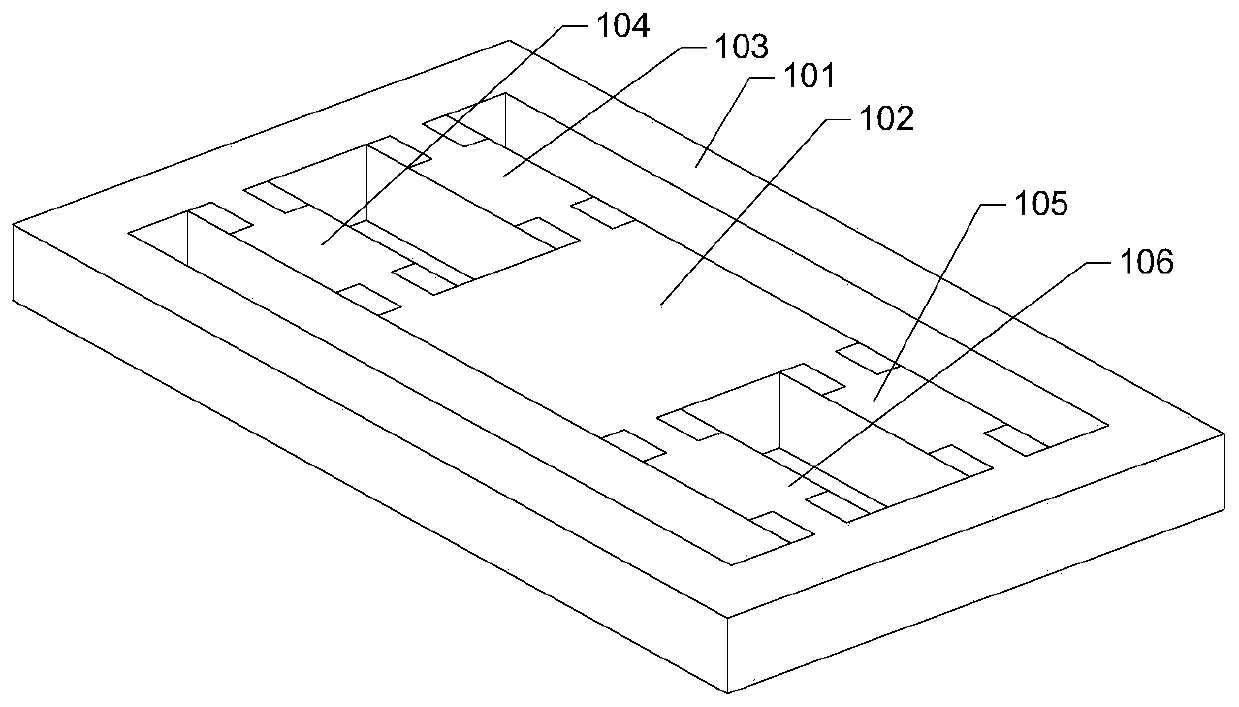

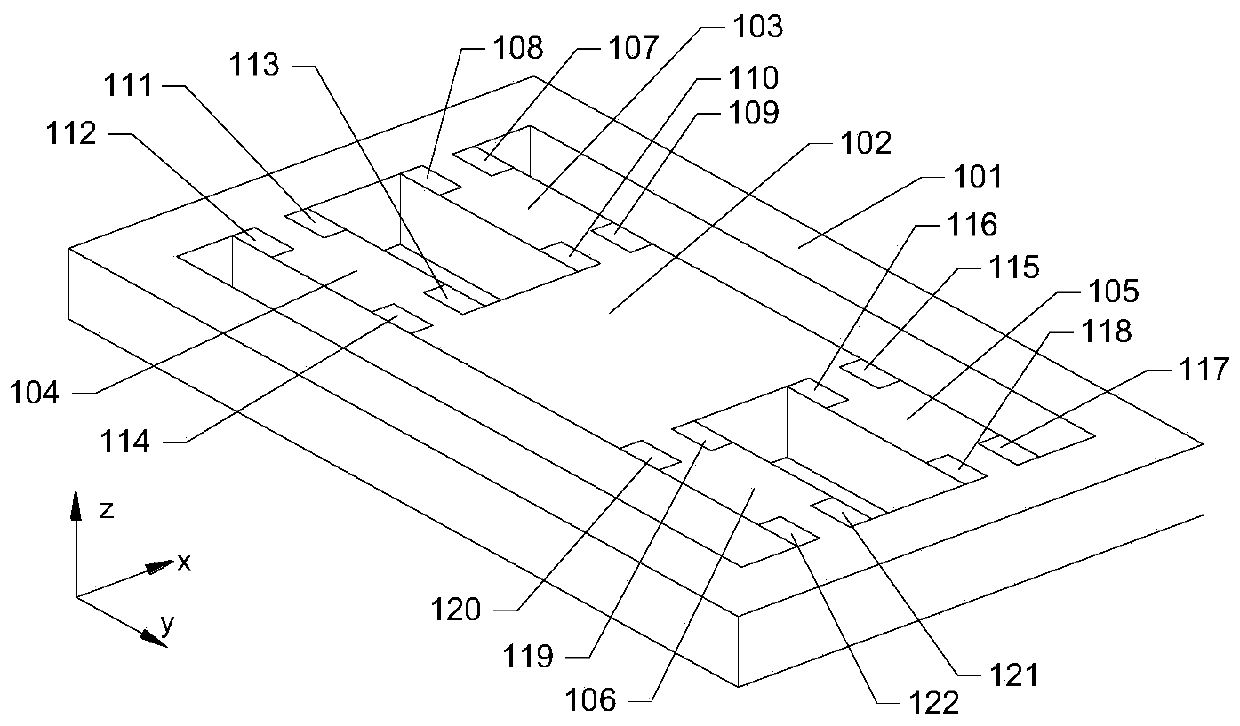

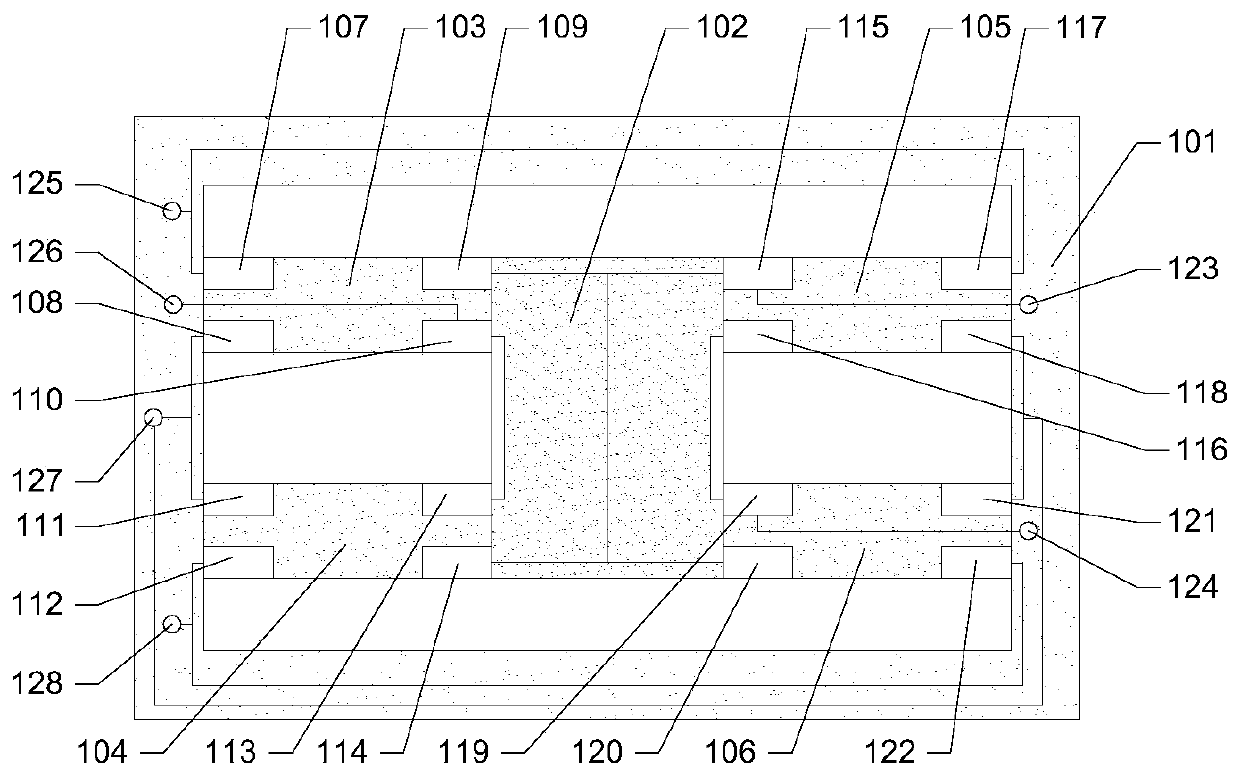

Piezoelectric accelerometer

ActiveCN110501521AImprove stabilityReduce torsional deformationAcceleration measurement using interia forcesAccelerometerTorsional deformation

The invention, which relates to the technical field of accelerometers, discloses a piezoelectric accelerometer which comprises a rectangular frame. A mass block is arranged in the rectangular frame. Abeam I, a beam II, a beam III and a beam IV are fixed to one group of parallel side surfaces of the mass block; the beam I and the beam II are symmetrical and arranged at the same side surface; the beam III and the beam IV are symmetrical and arranged at the other side surfaces parallel to the side surface where the beam I is located; and the beam I and the beam III are symmetric to each other and the beam II and the beam IV are symmetric to each other. Piezoelectric patches are arranged on the upper surfaces of the beam I, the beam II, the beam III and the beam IV; and metal electrodes are arranged at four corners of each piezoelectric patch. According to the invention, all beams are arranged at the two symmetrical sides of the mass block, so that the stability of the accelerometer is enhanced and the torsional deformation of the accelerometer under the working condition is reduced; the thickness of the mass block is consistent with the thickness of the beam, so that the stability ofthe accelerometer is enhanced and torsional deformation is reduced; and the high dynamic bandwidth can be obtained.

Owner:武汉敏声新技术有限公司

Band sawing machine with saw band automation resetting function and control method thereof

InactiveCN103752945AAffect the service lifeAvoid damageMetal sawing devicesAutomatic control devicesEngineeringAutomation

The invention discloses a band sawing machine with a saw band automation resetting function and a control method thereof. The band sawing machine comprises saw bands, and a plurality of saw band resetting devices distributed in correspondence to the saw bands, wherein each saw band resetting device comprises a saw band monitor and a saw band lifting device. The control method of the band sawing machine has the saw band automation resetting function. According to the band sawing machine with the saw band automation resetting function and the control method thereof, before saw cutting work, the saw bands can be automatically installed on the band sawing machine, after the saw cutting work, the saw bands can be automatically demounted, and in the saw cutting work, upper and lower positions of the saw bands can be detected and the saw bands can be timely reset, and therefore the saw bands are enabled to keep working in the same horizontal plane, the probability that use life of the saw bands is influenced due to the fact that the saw bands swing up and down in running is reduced, production cost is reduced, labor intensity of work personnel is reduced, and installation speed of the saw bands is improved, production efficiency is improved, and furthermore damage to the saw bands, caused by sudden falling of the saw bands, is prevented, and the automation degree of the band sawing machine is improved.

Owner:郭益村

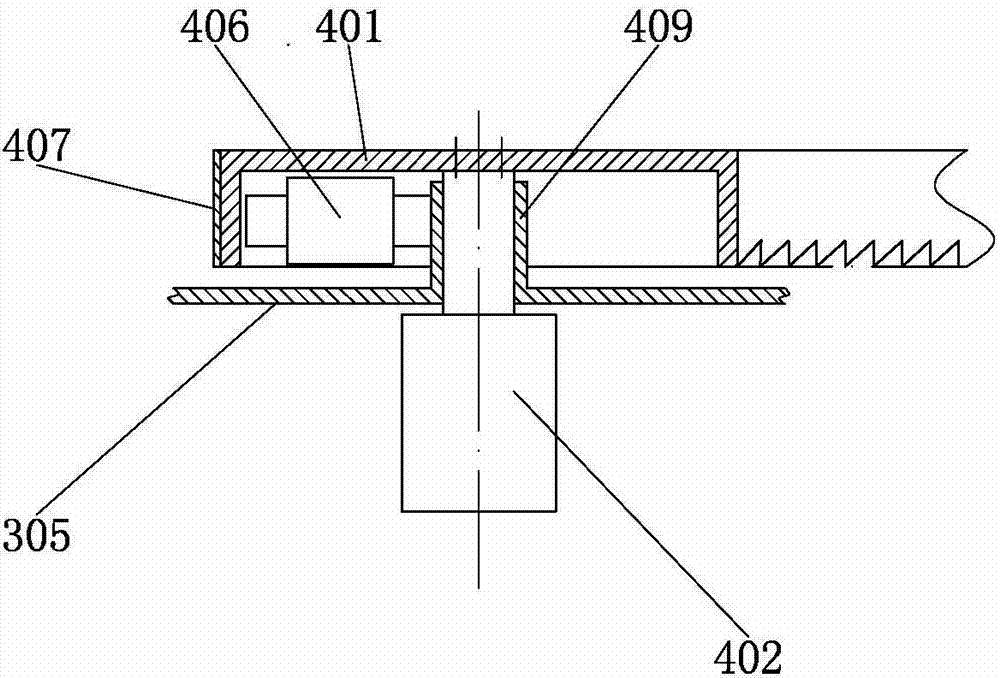

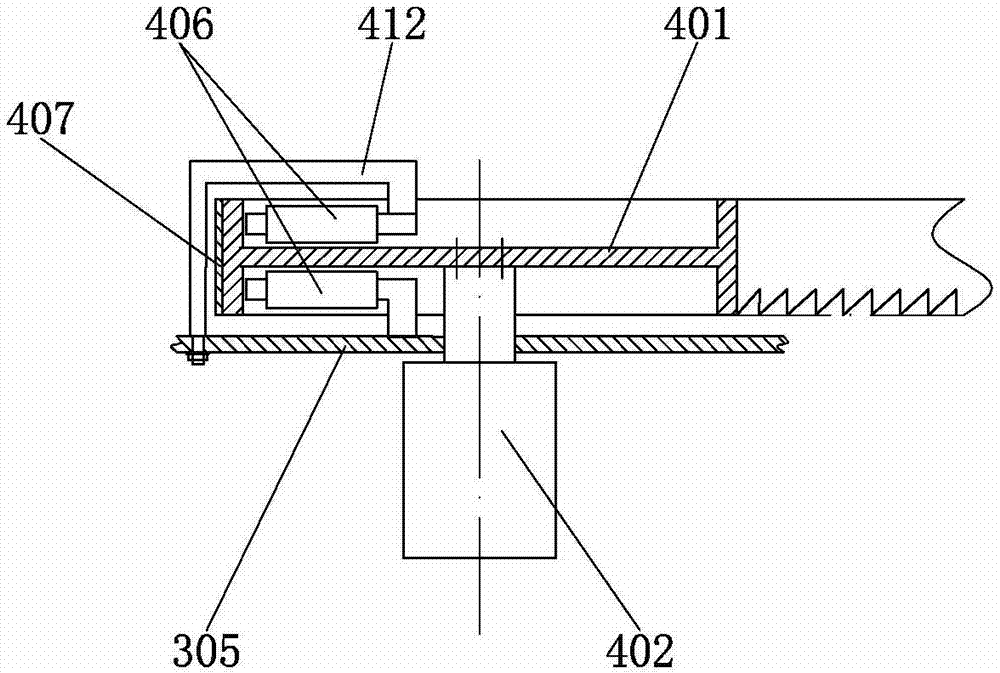

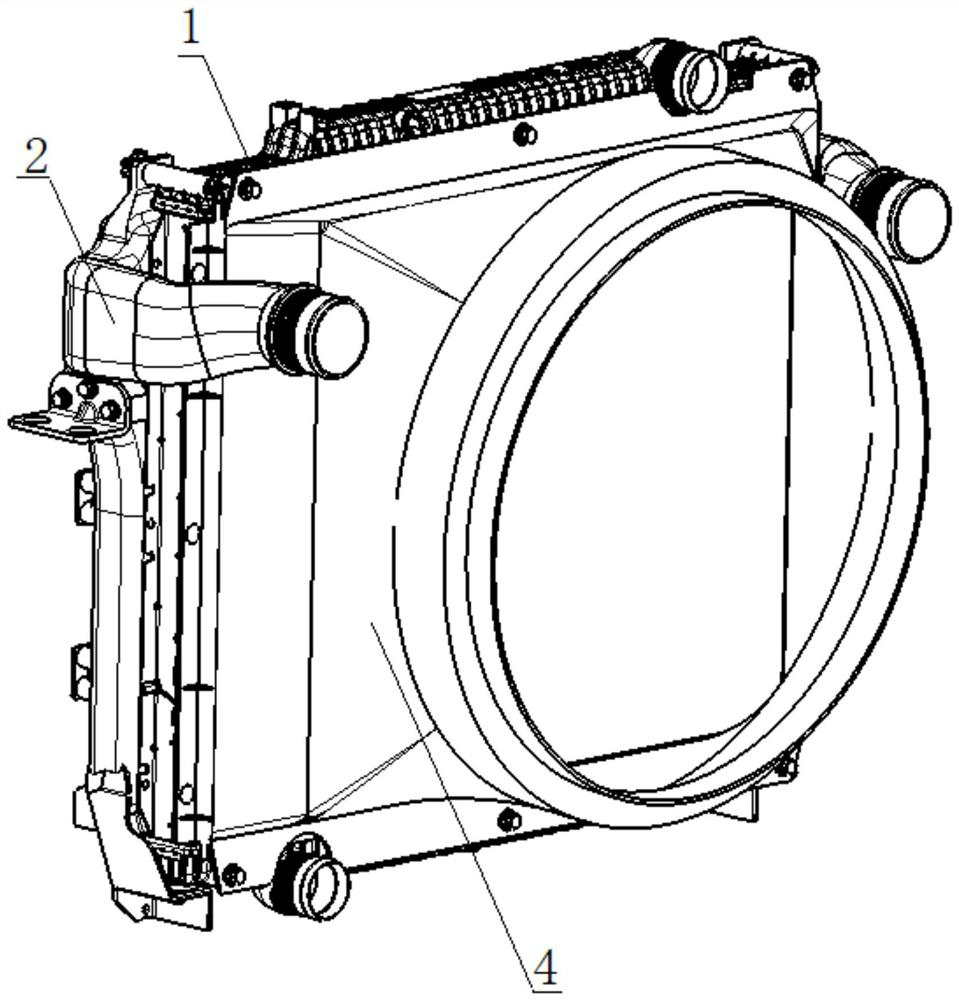

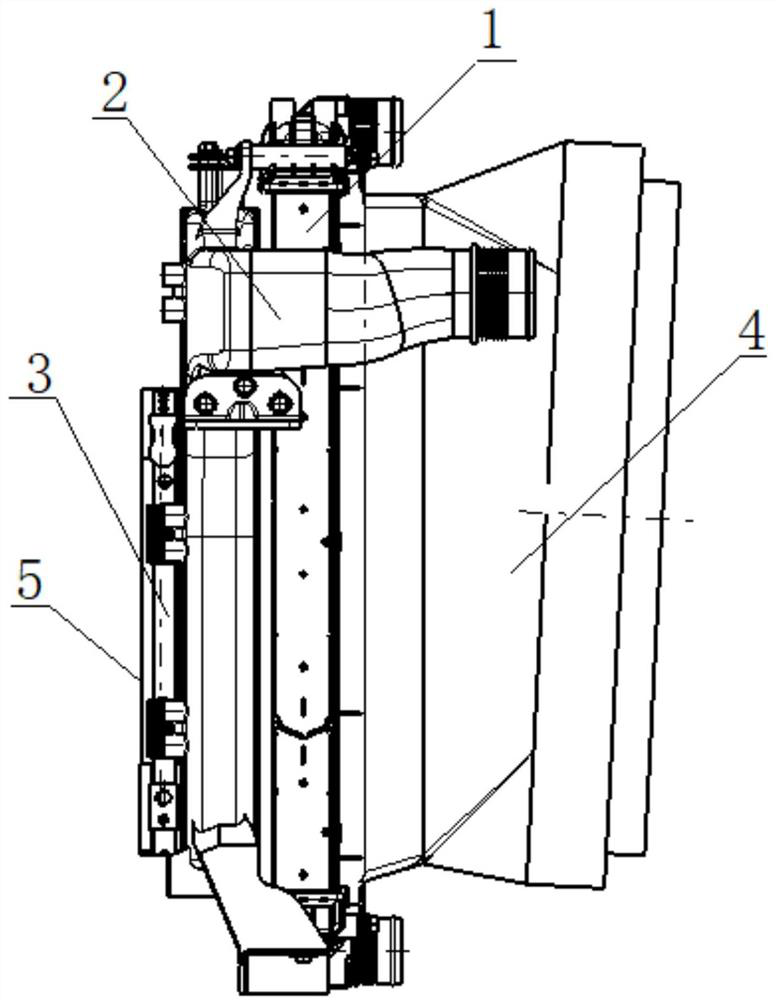

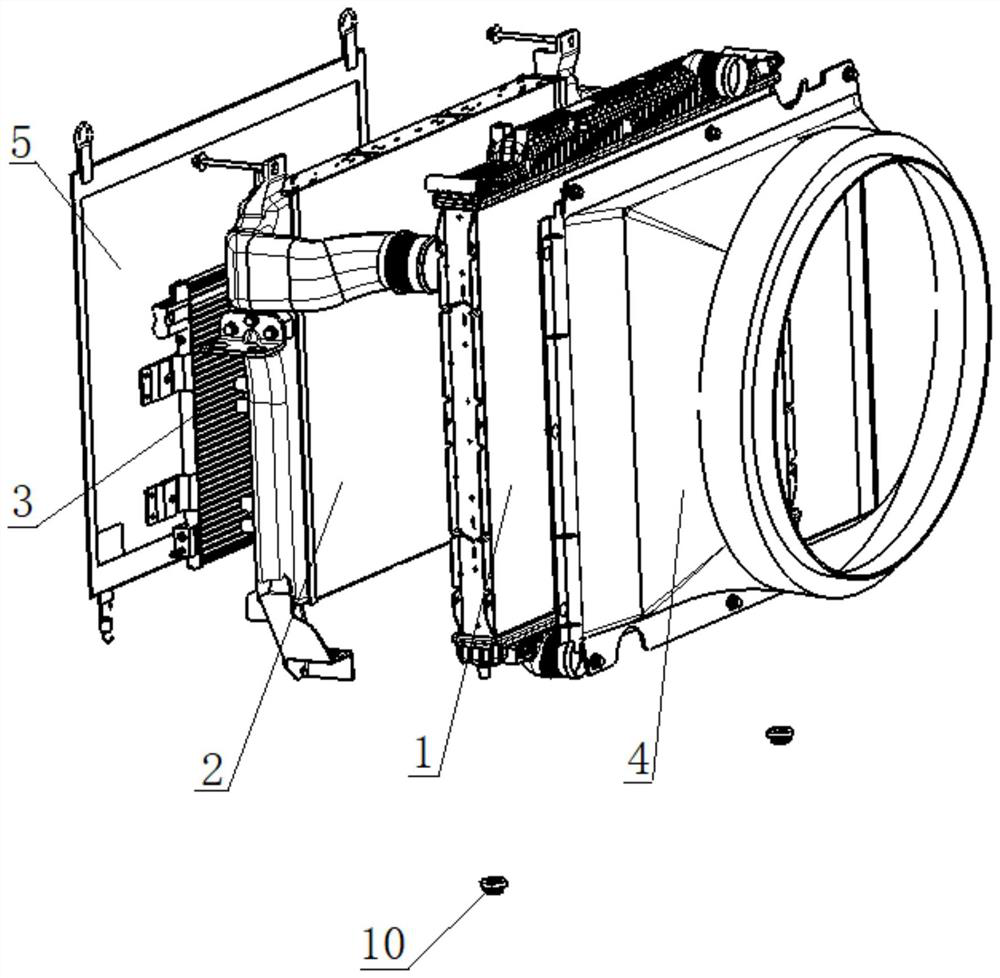

Guard-plate-free high-reliability commercial vehicle cooling module integrated structure

ActiveCN113043834AAchieve modularityImprove systematization abilityInternal combustion piston enginesRadiatorsThermal dilatationEngineering

The invention relates to the technical field of commercial heavy truck cooling systems, and discloses a guard-plate-free high-reliability commercial vehicle cooling module integrated structure which comprises a radiator, an intercooler, a condenser, a cooling fan protective cover and an insect-proof net, a water inlet chamber is arranged on the upper portion of the radiator, and a water outlet chamber is arranged on the lower portion of the radiator. The upper left portion of the side, close to the water inlet chamber, of the radiator is fixedly connected with the intercooler through a first bolt, the upper right portion of the side, close to the water inlet chamber, of the radiator is fixedly connected with the intercooler through a second bolt, and the lower left portion of the side, close to the water outlet chamber, of the radiator is connected with the intercooler through a metal shock pad. The lower right portion of one side close to the water outlet chamber is connected with the intercooler through a metal shock pad, the metal shock pad is fixedly connected with the water outlet chamber of the radiator through a plug pin, and the two sides of the radiator are each provided with a baffle for supporting the radiating core and releasing thermal expansion stress of the core. According to the guard-plate-free high-reliability commercial vehicle cooling module integrated structure, the reliability of the cooling module can be greatly improved, the lightweight requirement is met, and the weight and the cost are greatly reduced.

Owner:DONGFENG BEHR THERMAL SYST

Rapid bending forming bending machine for Z-shaped plate

The invention discloses a rapid bending forming bending machine for a Z-shaped plate, and belongs to the technical field of Z-shaped plate bending. The rapid bending forming bending machine comprisesa fixed die plate A, a fixed die plate B, an upgoing moving template, a downgoing moving template, an upgoing thrust rod, a downgoing tension rod, an upgoing L connecting rod, a downgoing L connectingrod, a coaxial gear and a coaxial connecting rod. The fixed did plate A and the fixed die plate B are used for locking a plate to be bent, the upgoing moving template is hinged to the fixed die plateB through an upgoing hinge A, and the downgoing moving template is hinged to the fixed die plate B through a downgoing hinge A. The coaxial gear and the coaxial connecting rod are installed on a machine frame. The upgoing moving plate and the downgoing moving plate move synchronously, and under the action of the coaxial connecting rod, Z-shaped bending of the plate can be completed rapidly. The rapid bending forming bending machine for the Z-shaped plate adopts a single power system and synchronous reverse bending plate.

Owner:南通航力重工股份有限公司

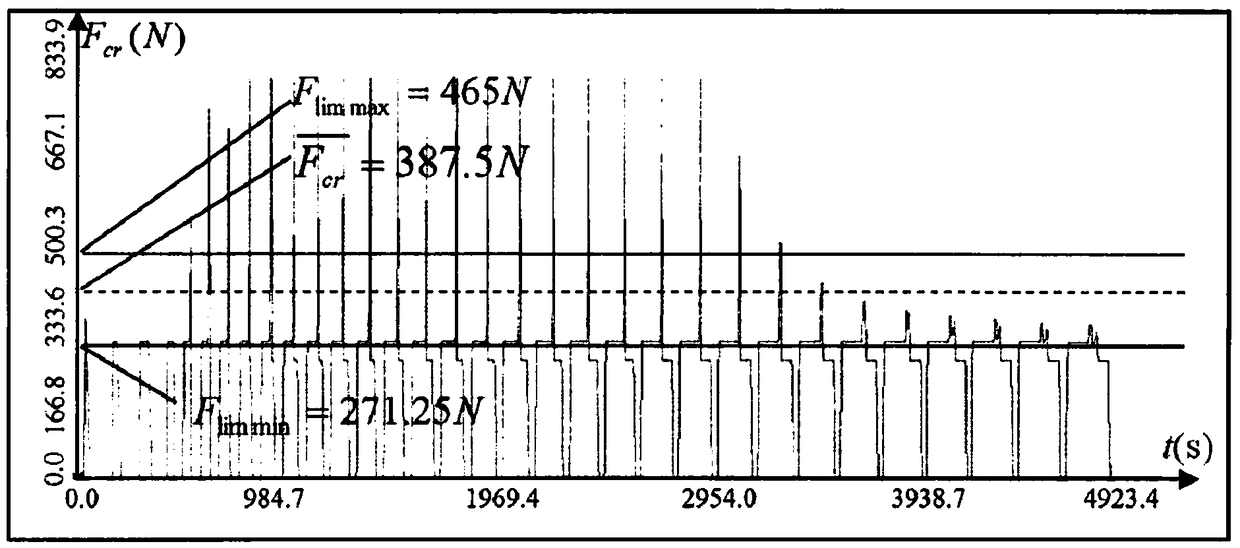

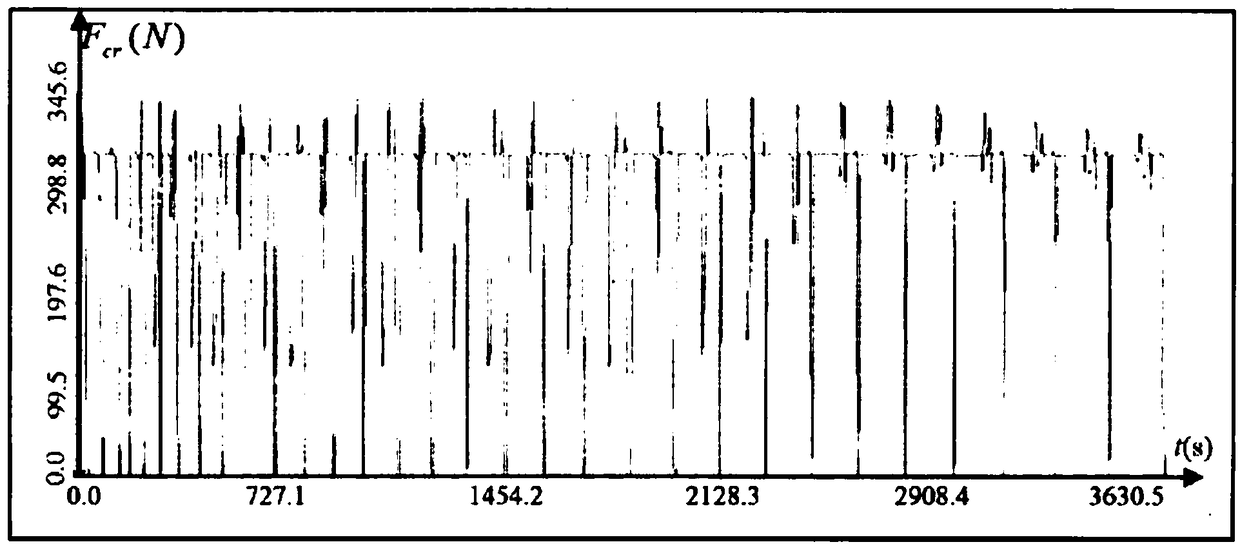

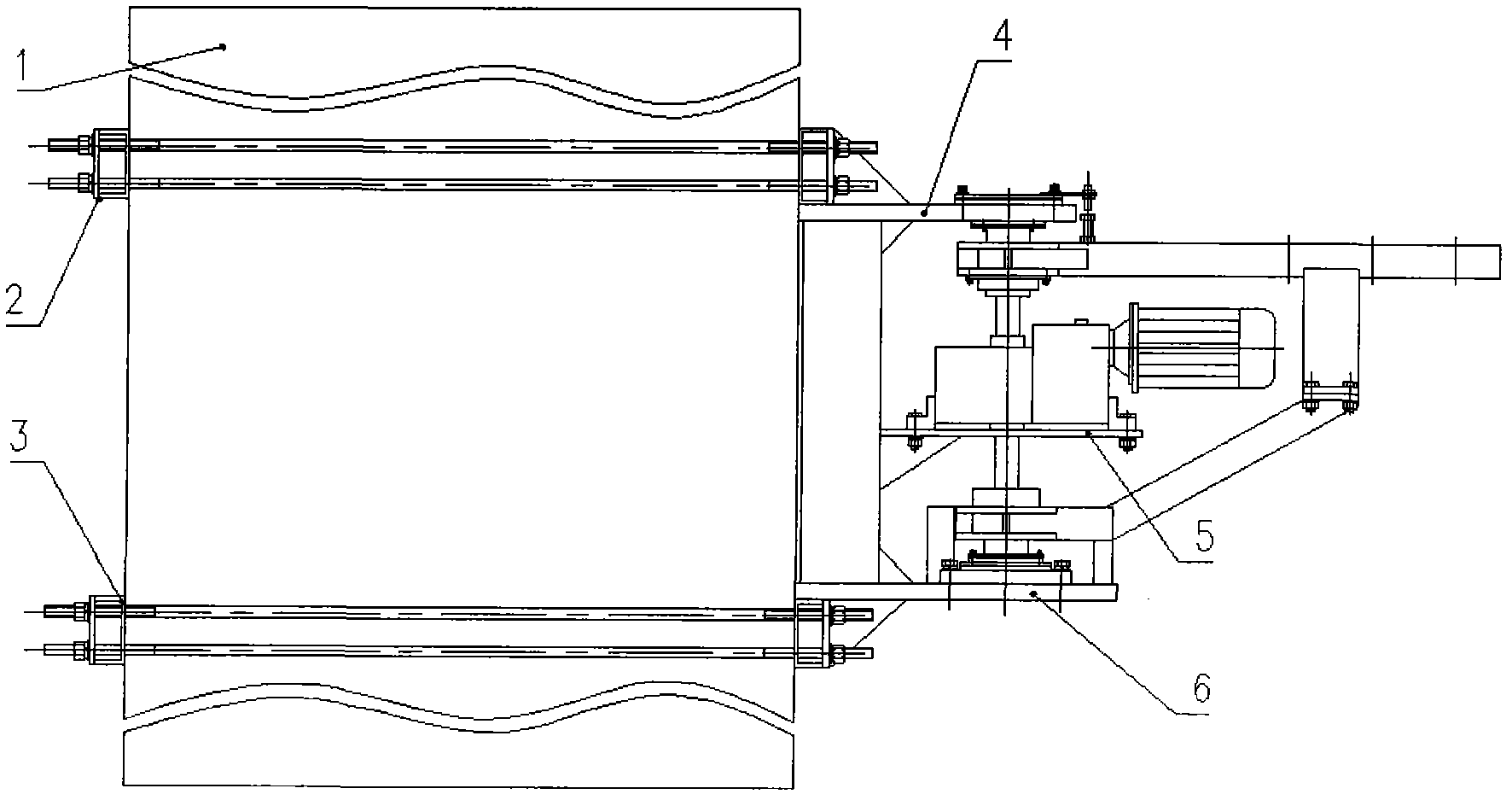

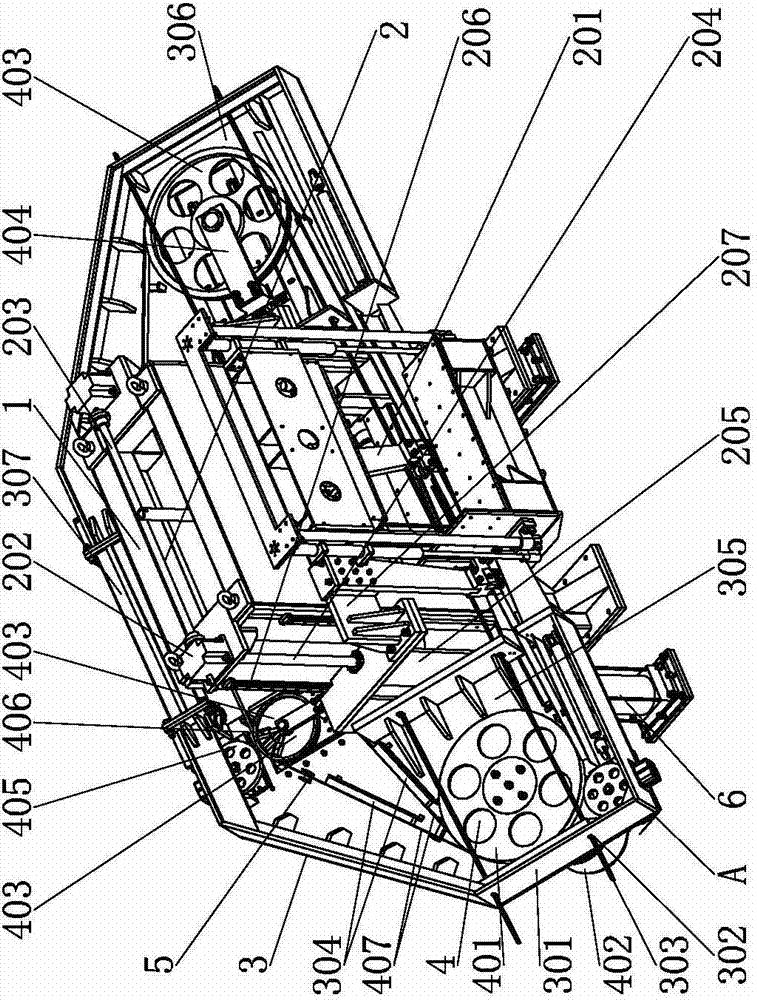

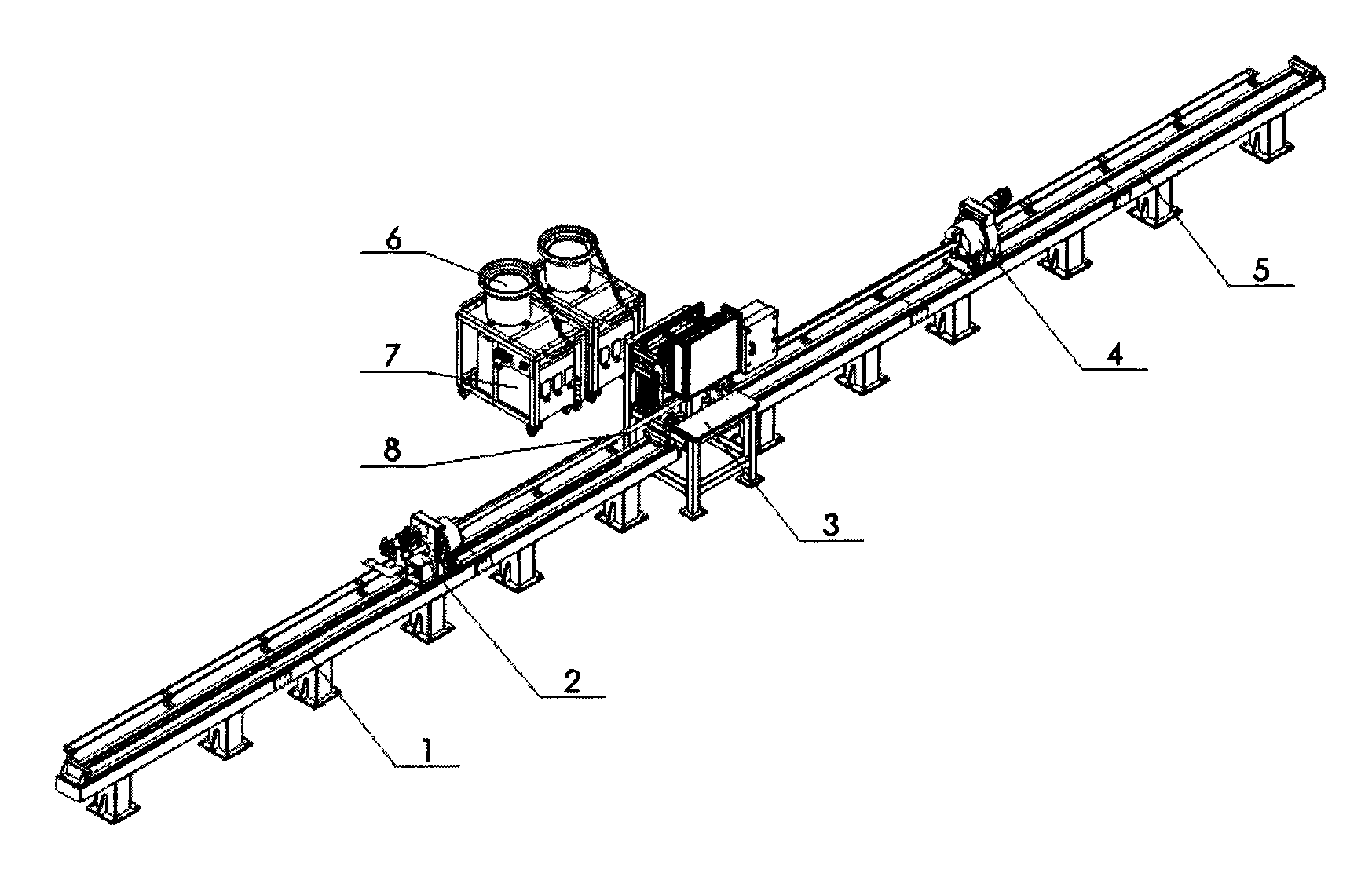

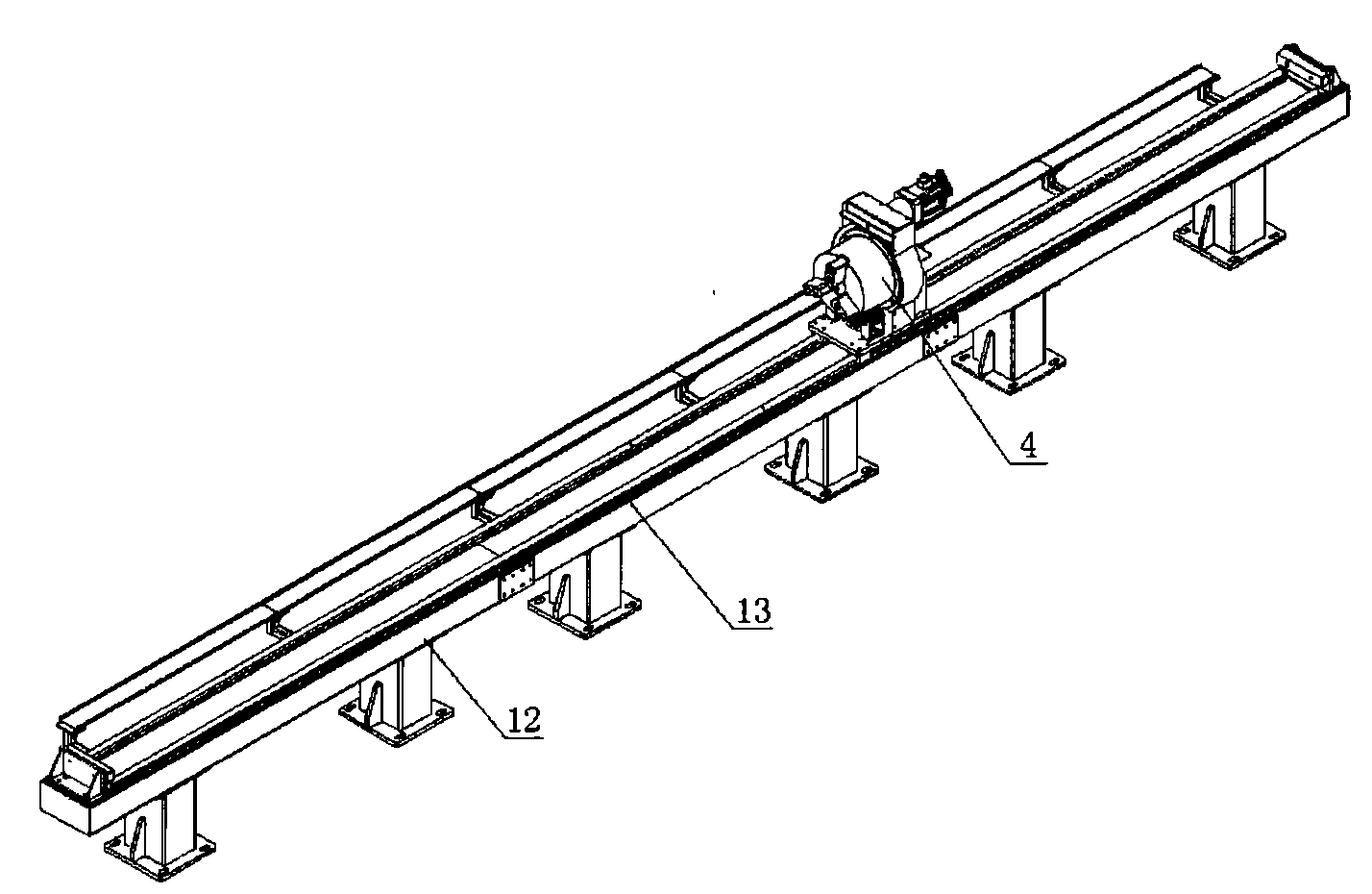

Full-automatic single-tube pin welding device

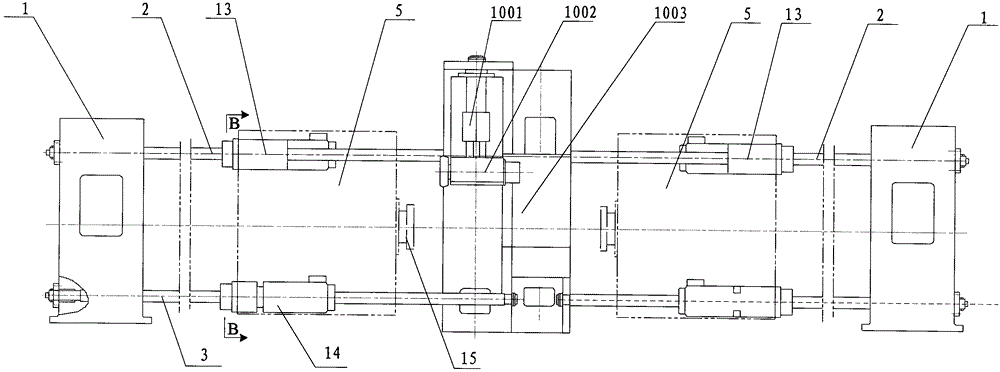

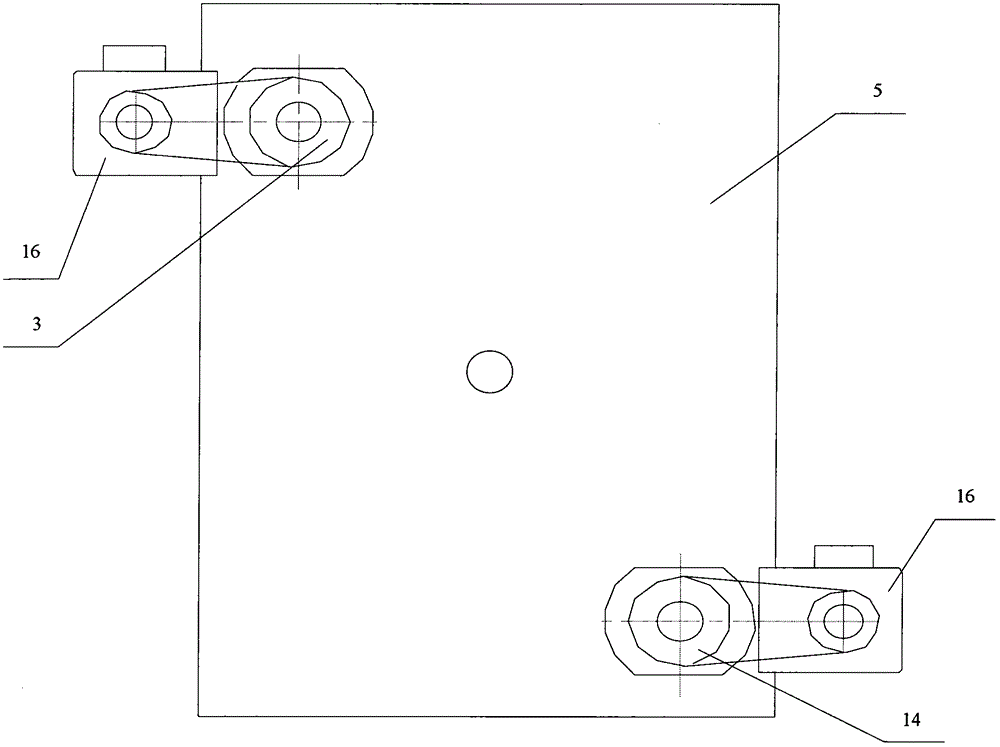

ActiveCN101422844BReduce torsional deformationHigh positioning accuracyWelding accessoriesStud weldingMachine tool

The invention relates to a full-automatic single tube and pin welding machine which belongs to the technical field of welding, and the welding machine comprises a machine bed at a driving end, a machine bed at a driven end, a driving feeding mechanism, a welding operation machine, a driven feeding mechanism, an automatic charging mechanism and a welding host. The driving feeding mechanism and thedriven feeding mechanism realize the horizontal feeding of a welded steel pipe along the longitudinal direction of the welding machine and the radial rotary feeding motion of the steel pipe, the welding operation machine is provided with a pneumatic welding fixture and two automatic stud welding guns, the pneumatic welding fixture realizes the holding and positioning of the steel pipe according to production tact in the welding process, and the horizontal distance between the two stud welding guns and the vertical distance between the automatic stud welding guns and the welded steel pipe are adjustable. The automatic charging mechanism realizes the automatic pin charging process. The welding machine has simple structure, the feeding motion of two degrees of freedom can be realized by a servo motor, the positioning precision is high, the clamping action of the welding fixture and the charging process are pneumatically controlled, and the operation is convenient. The welding machine cancomplete pin welding operation automatically or manually.

Owner:EUROCRANE

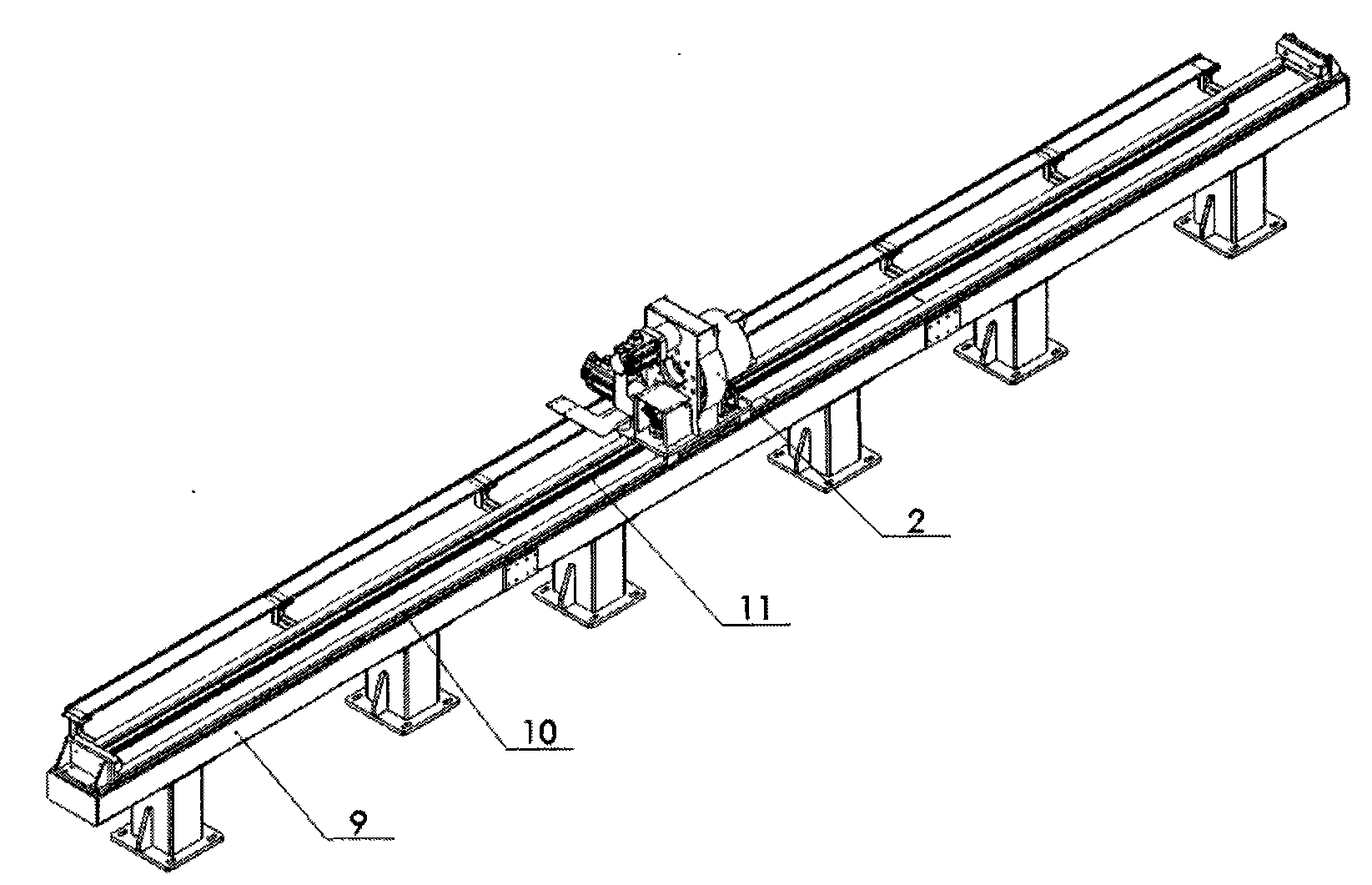

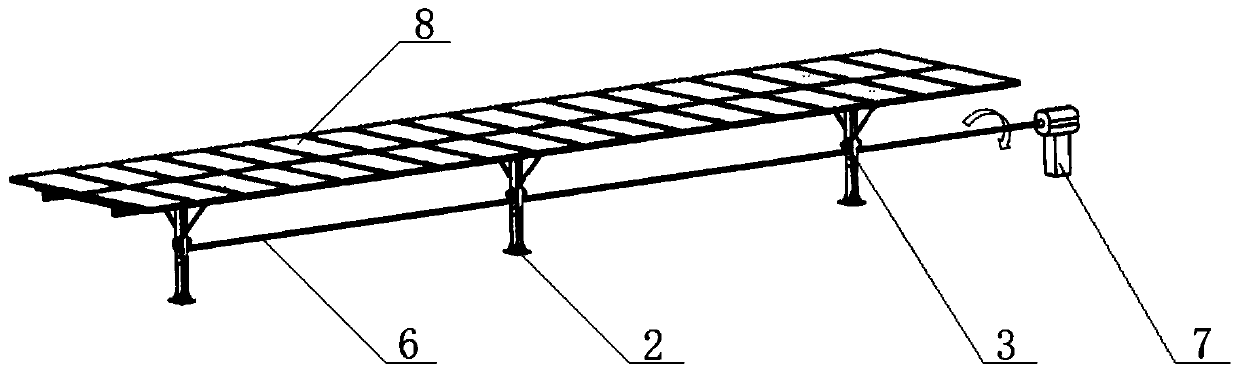

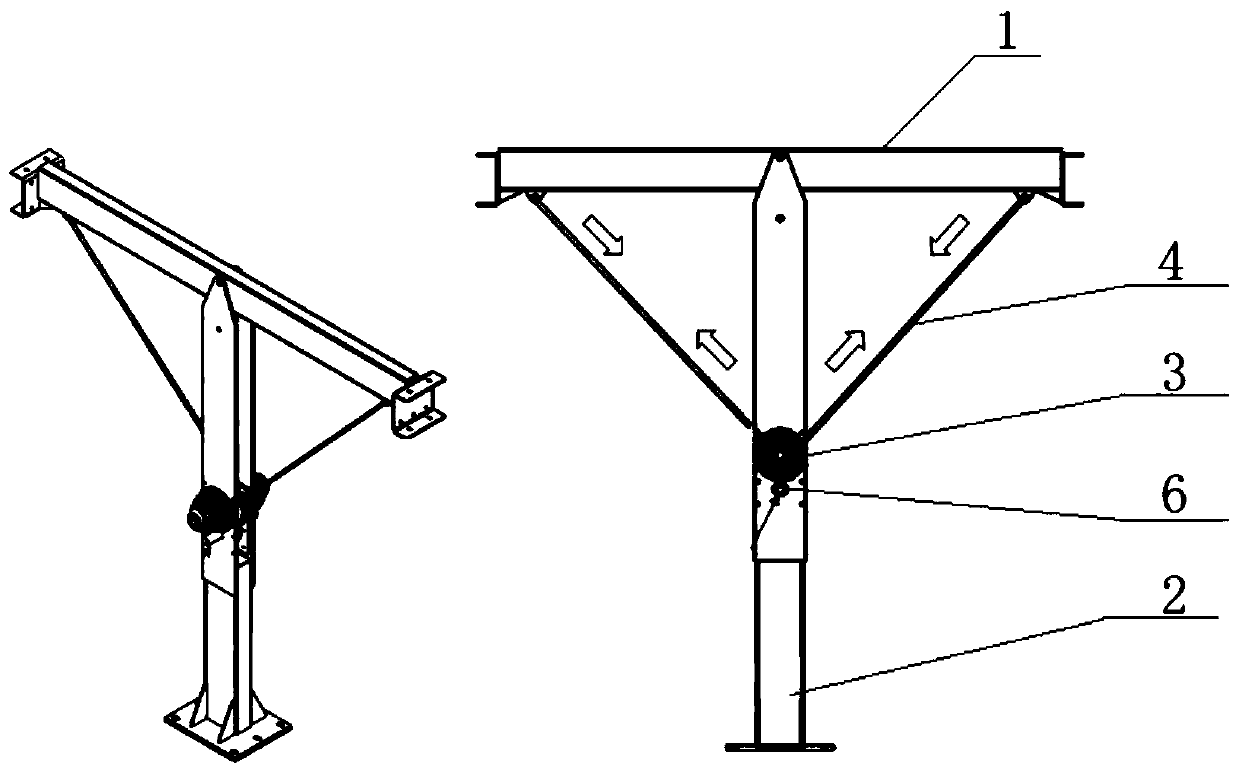

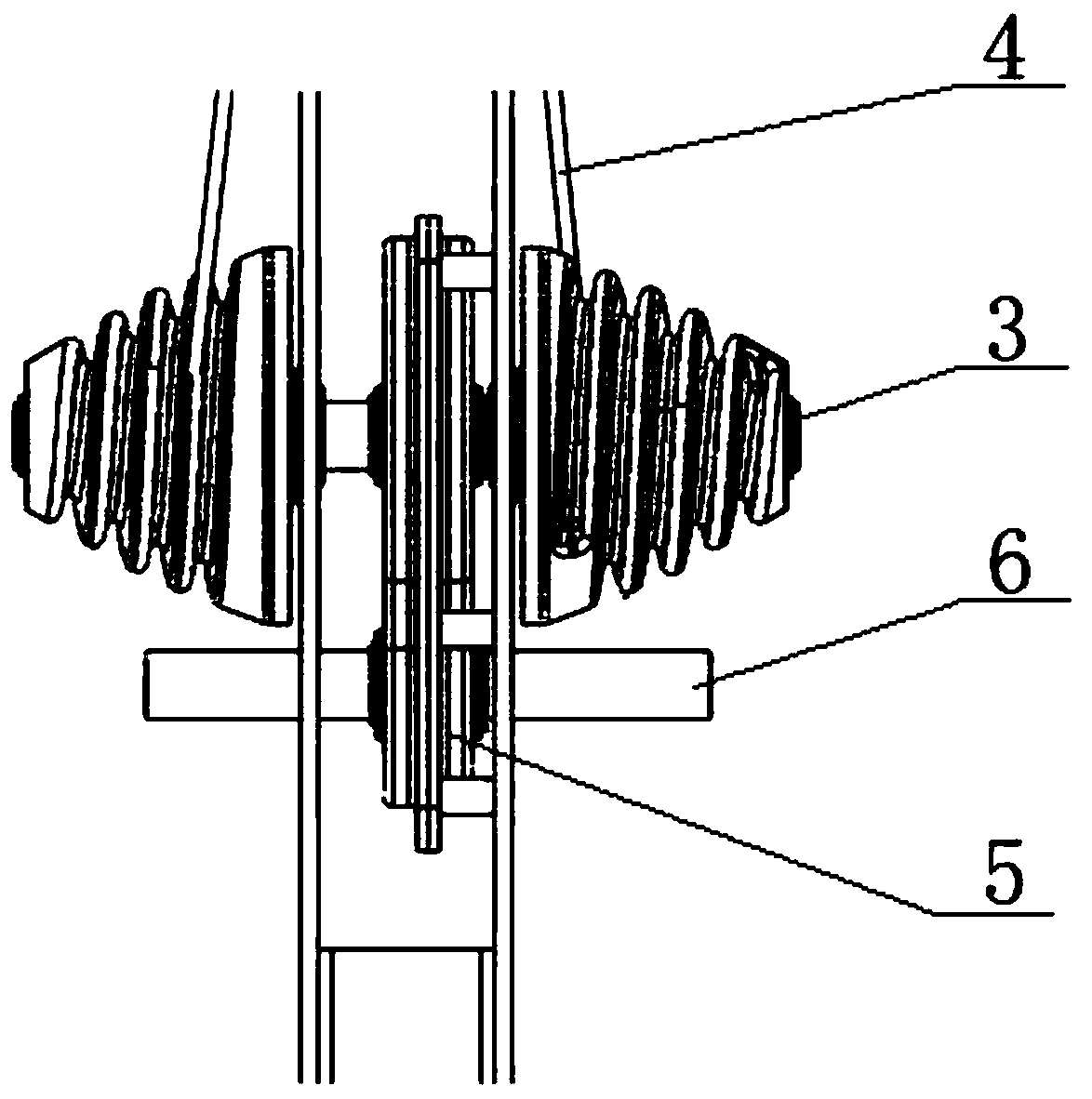

Flexible support photovoltaic tracking support with self-locking function

PendingCN110209206AGuaranteed Tracking AccuracyIncrease stiffnessControl using feedbackPhotovoltaic energy generationDrive shaftEngineering

The invention discloses a flexible support photovoltaic tracking support with a self-locking function. The flexible support photovoltaic tracking support comprises a photovoltaic module support frameused for fixing a photovoltaic module, a stand column used for supporting the photovoltaic module support frame, a transfer unit installed on the stand column, and a driving unit used for driving thetransfer unit to work. The transfer unit comprises a steel cable, a cable clamp, a differential winding wheel and a transmission case; the driving unit comprises a driving shaft and a drive and control device; and a self-locking structure is arranged between the driving shaft and the transmission case. Through multipoint cooperative driving, a driving load is uniformly applied to the tracking support to greatly reduce the torsional deformation of the whole structure, so that the tracking accuracy of the tracking support and the power generation efficiency of the photovoltaic module can be ensured; by adopting multi-point effective support, the vibration response of the structure under the action of wind load can be effectively reduced, and the safety and reliability of the tracking bracketare improved; and moreover, the position of each driving node is self-locked, so that the integral rigidity of the support structure and the stability and reliability of structure locking can be effectively improved.

Owner:SHANGHAI NENGYAO NEW ENERGY TECH CO LTD

A forward spinning method

The invention provides a forward-spinning spinning method. The outside spinning technology is combined with synchronous rotation, a short core mold, tension spinning and other technologies to achieve integral spinning forming of super-long thin-wall cylindrical parts, and therefore the technical problem that the common outside spinning technological method cannot be used for spinning the super-long thin-wall cylindrical parts is solved. According to the forward-spinning spinning method, the function of synchronous rotation of the two ends of workpieces is increased, the problem of torsional deformation of the super-long thin-wall cylindrical parts is solved, and therefore the precision of products is improved; the short core mold is adopted, so that the problems that core molds of the super-long thin-wall cylindrical parts lower heads and vibrate, the manufacturing cost is high, and demolding is difficult are solved. According to the forward-spinning spinning method, longitudinal drawing tension movement of the workpieces is increased, so that the super-long cylindrical parts are subjected to longitudinal force in the spinning process, the deforming and flowing of materials are facilitated, the problem that the ultra-long cylindrical parts bend and deform is solved, the product precision is improved, and integral spinning forming of the ultra-long thin-wall cylindrical parts is achieved.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com