Automatic welding device

A technology for automatic welding and driving motors, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

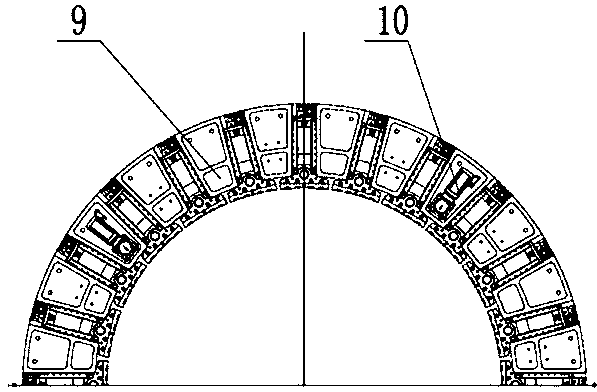

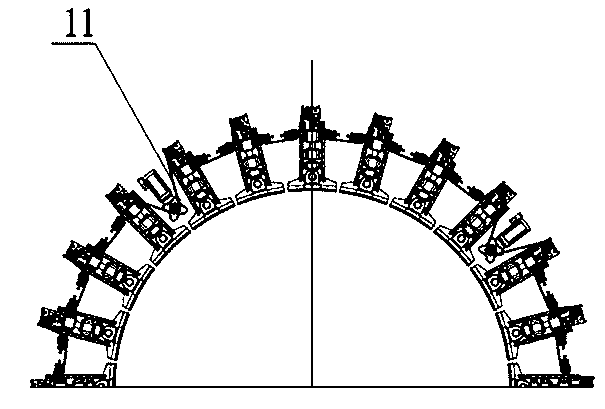

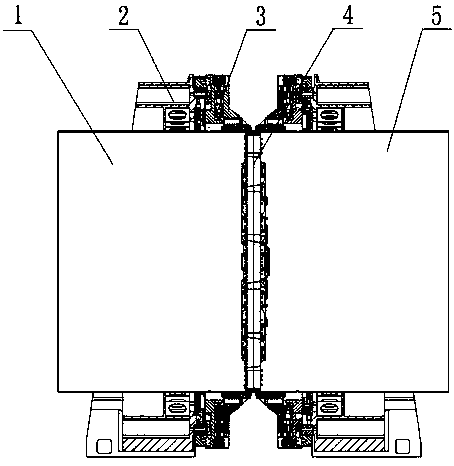

[0023] as attached figure 1 And attached figure 2 As shown, the overall use function of the automatic welding device, such as the left cylinder section 1 of the storage tank and the right cylinder section 5 of the storage tank, are two cylinder sections that need to be butt jointed for circular seam friction stir welding, and the left and right chucks 3 pass through the turntable bearing 6 and The ring guide rail 7 is connected to the rigid support 2, and the pneumatic expansion ring 4 cooperates with the chuck 3 to clamp the left cylinder section 1 of the storage tank and the right cylinder section 5 of the storage tank to form a rigid body, which is driven by the rotary drive mechanism 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com