Patents

Literature

135results about How to "Solve rigid problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

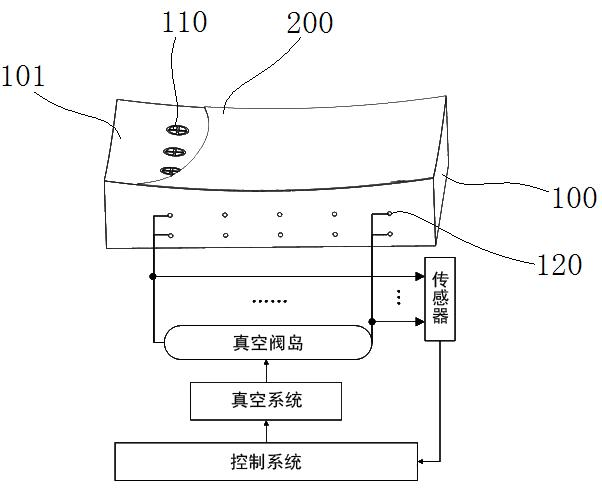

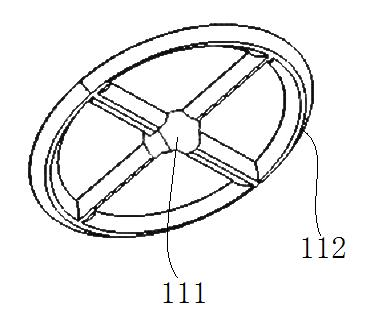

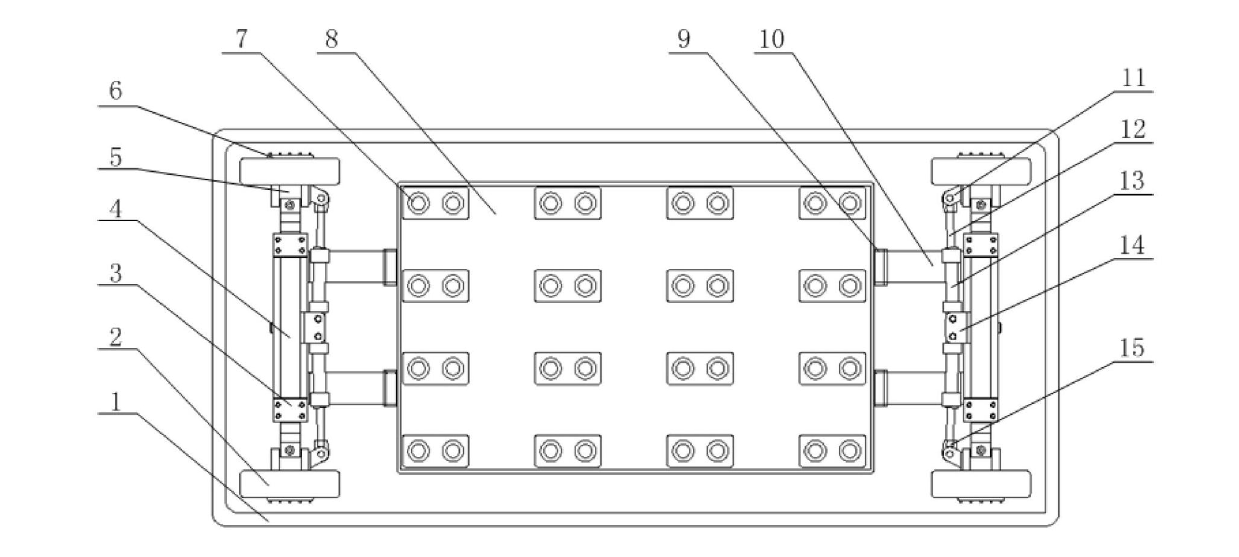

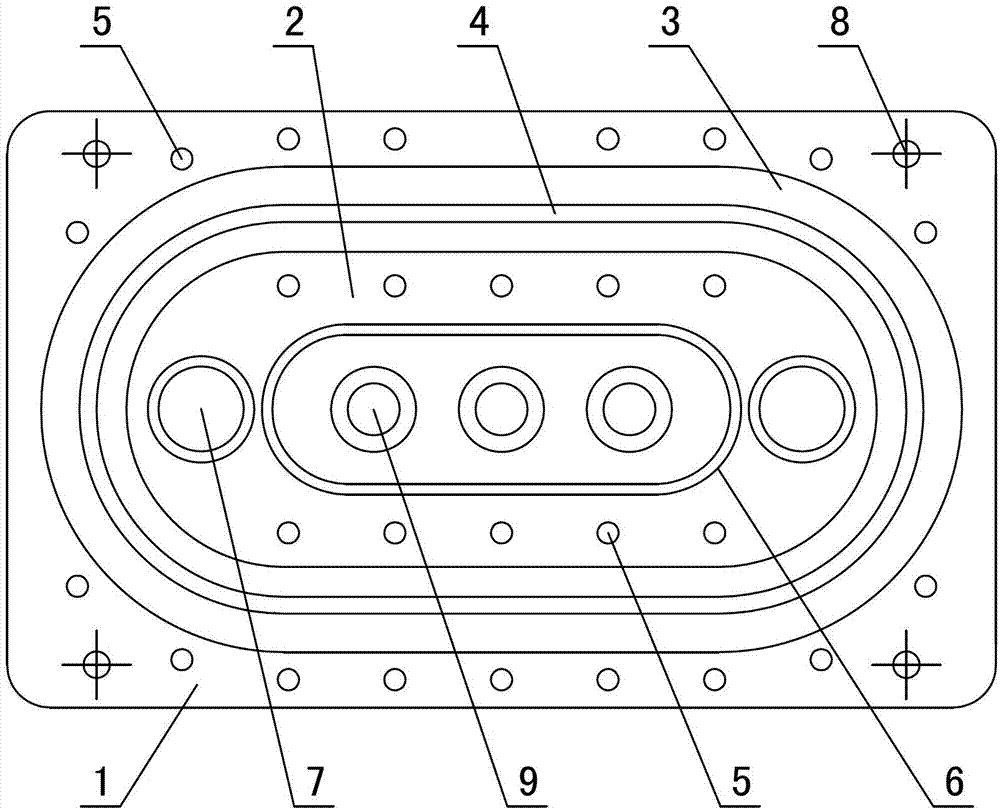

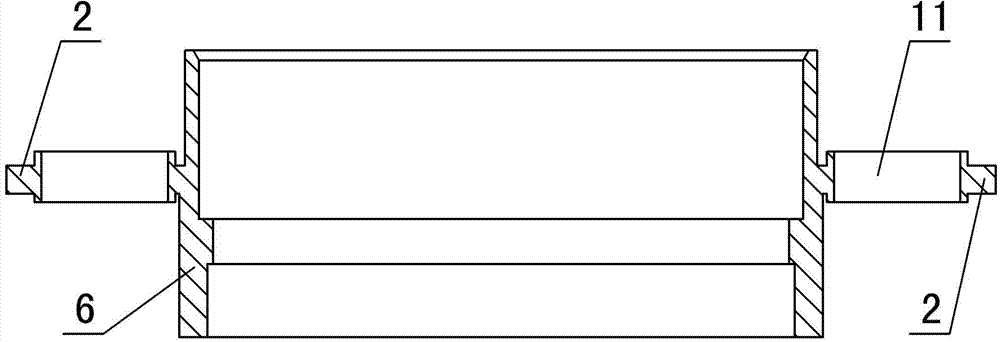

Multipoint profiling rigid clamp and method for processing thin-wall workpiece by using same

InactiveCN102179708ASolve rigid problemsSolve Vibration ProblemsPositioning apparatusMetal-working holdersControl systemSurface type

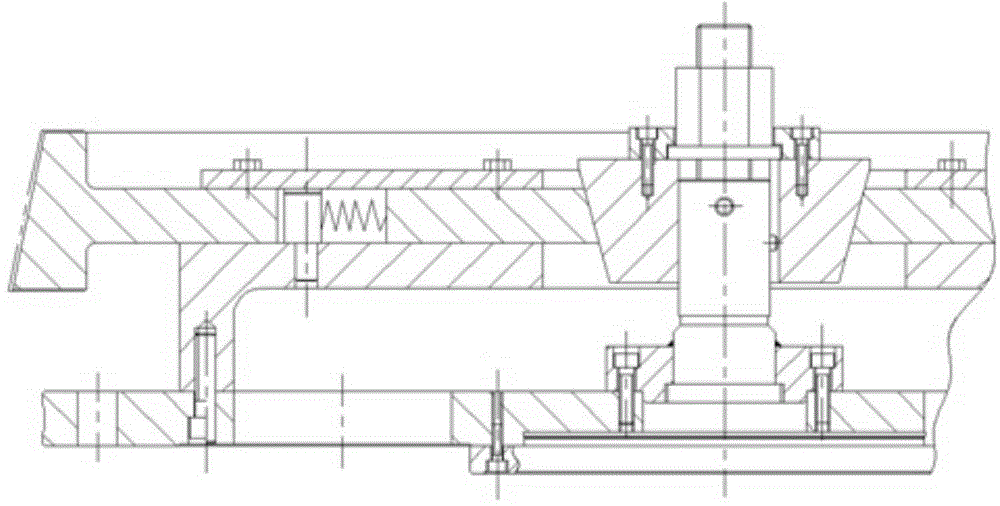

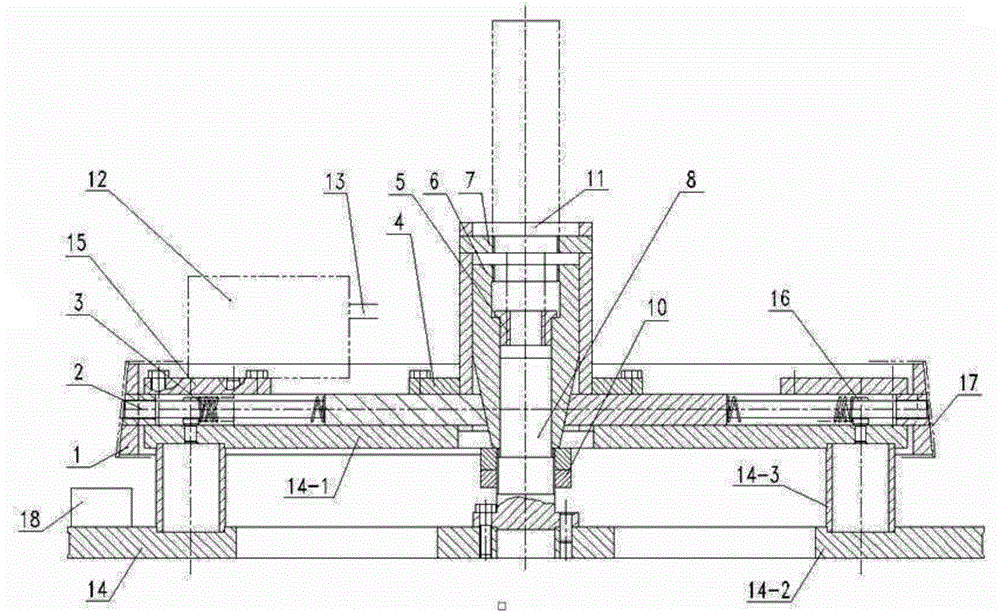

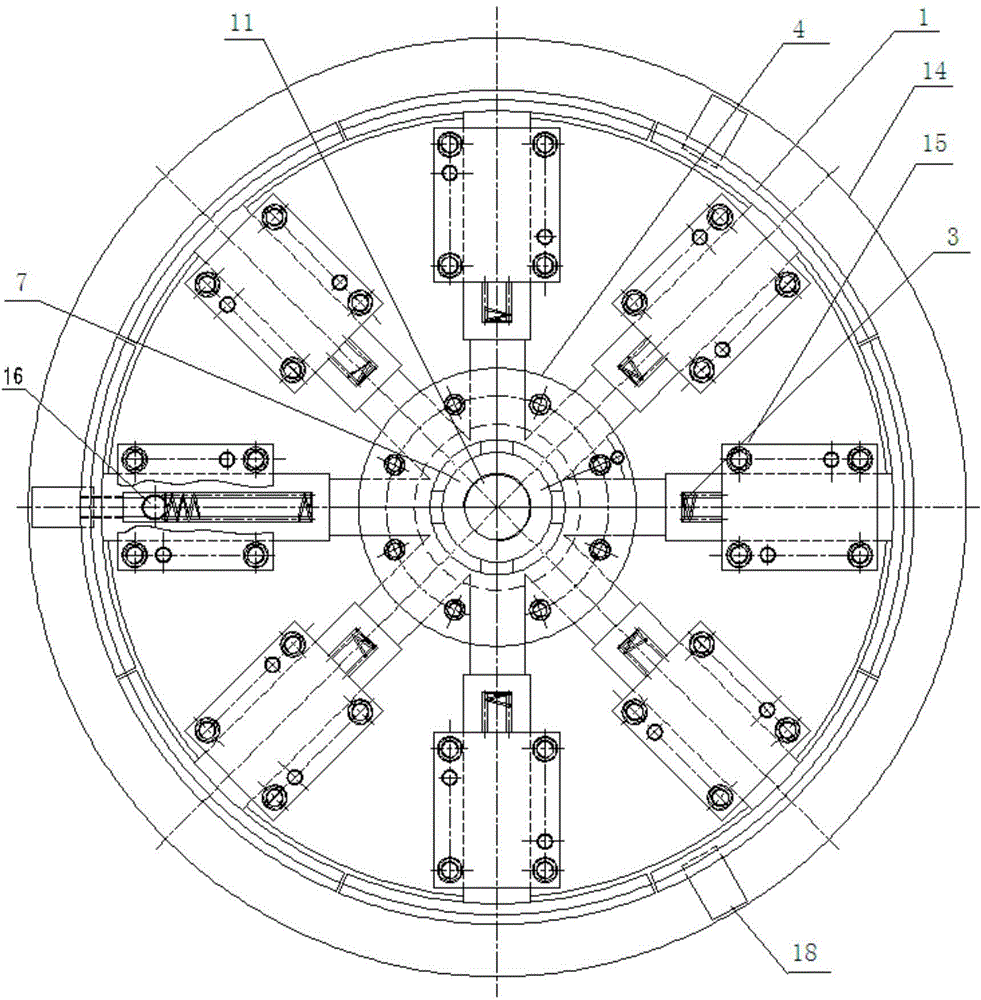

The invention discloses a multipoint profiling rigid clamp, comprising a clamp body. The clamp body is provided with a positioning surface for positioning a processed workpiece; the positioning surface is provided with a vacuum sucker; the clamp body is internally provided with a vacuum hole channel; one end of the vacuum hole channel is connected with the vacuum sucker, and the other end of the vacuum hole channel is connected with a vacuum valve island arranged at the outer part of the clamp body; the vacuum valve island is connected with a vacuum system connected with a control system; andthe vacuum hole channel is also connected with the control system by a vacuum sensor. A method for processing a thin-wall workpiece by using the multipoint profiling rigid clamp comprises the steps of: modeling, analyzing, determining and optimizing key positioning points, arranging the vacuum sucker, processing the positioning surface of the clamping body and finally carrying out processing on the thin-wall workpiece. The multipoint profiling rigid clamp is used for a high-speed milling finish processing stage of the complex profile of the thin-wall workpiece, the positioning surface of the clamp is consistent to the surface type of the processed workpiece, the uniform distribution of a clamping force is guaranteed and the clamping and the deformation of the thin-wall workpiece are avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

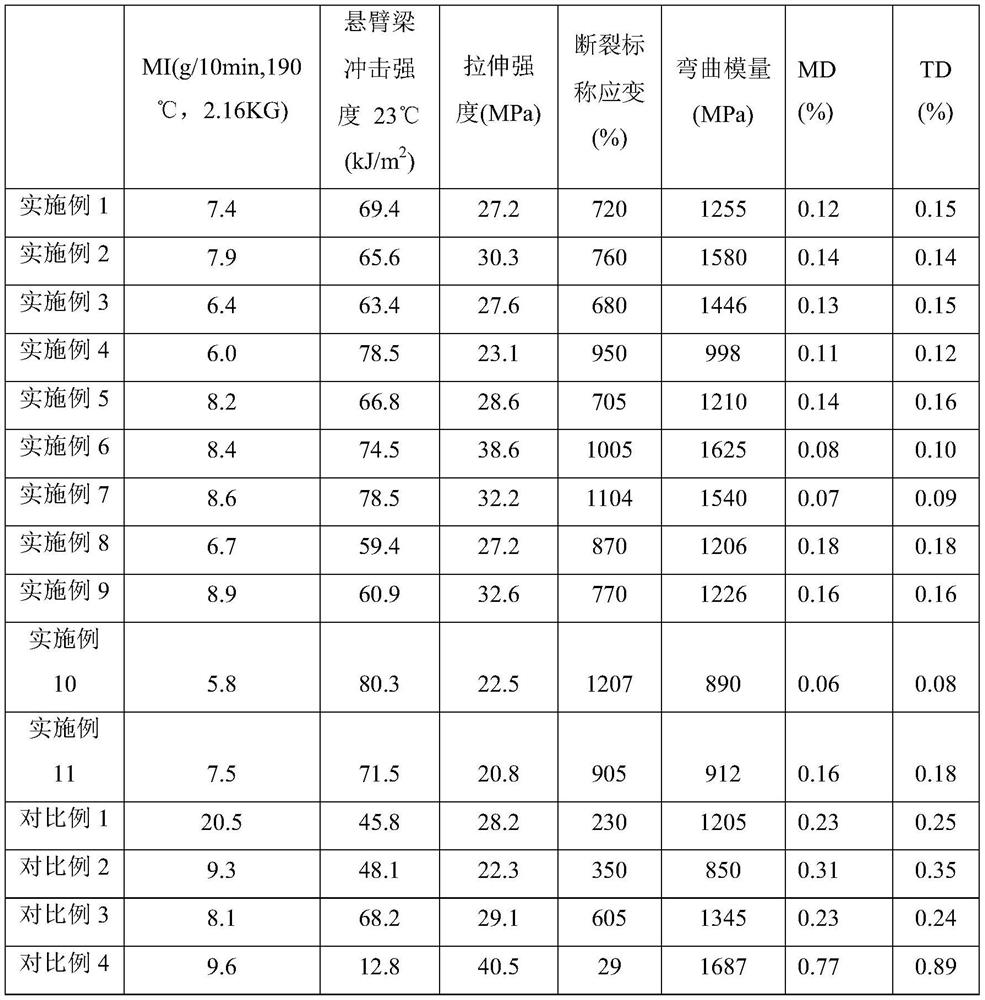

Degradable plastic composition as well as preparation method and application thereof

ActiveCN111995848ASolve rigid problemsImprove mechanical propertiesBio-packagingPolymer scienceUltimate tensile strength

The invention discloses a degradable plastic composition as well as a preparation method and application thereof. The degradable plastic composition comprises the following components in parts by weight: 70-99 parts of at least two degradable resins, 0-6 parts of a toughening agent, 0.5-5 parts of a compatilizer, 0.05-3 parts of a chain extender, 0.05-5 parts of an anti-hydrolysis agent, 0.05-5 parts of a nucleating agent and 0.05-3 parts of a slipping agent. By matching two or more degradable resins, the problem of poor toughness or rigidity of the existing single degradable resin is solved,so that the product has excellent comprehensive mechanical properties, excellent rigidity and toughness, high impact property, high nominal strain at break and higher flexural modulus and tensile strength.

Owner:联泓(江苏)新材料研究院有限公司

Device for wind tunnel dynamic derivative pitch vibration test

InactiveCN102998082ARealize measurementResolve interferenceAerodynamic testingEngineeringSinusoidal vibration

The invention provides a device for wind tunnel dynamic derivative pitch vibration test. The device comprises a support mechanism, a parallel-double-crank mechanism and a limit detection module, the support mechanism is a base body for mounting of the device, the parallel-double-crank mechanism realizes and transfers pitch sinusoidal vibration motion, and the limit detection module provides alarm for excess of mechanism rotational stroke. After vibration frequency and amplitude are set and a specific vibration curve is outputted by a servo motor, an aircraft model is driven to perform pitch vibration through the parallel-double-crank mechanism mounted on the support mechanism, and in the process, the limit detection module provides limit and protection for the mechanisms.

Owner:MIANYANG WEIBO ELECTRONICS

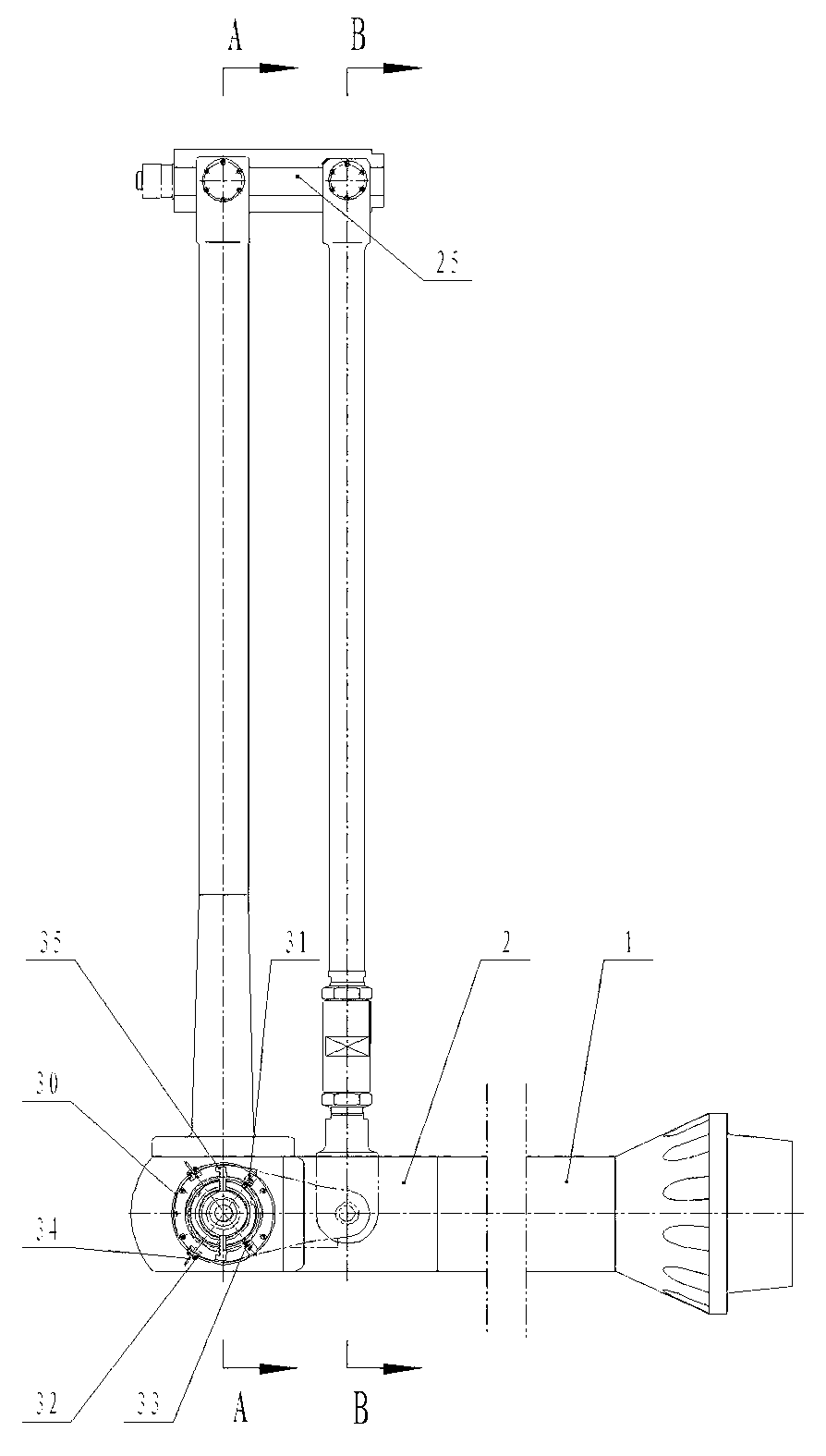

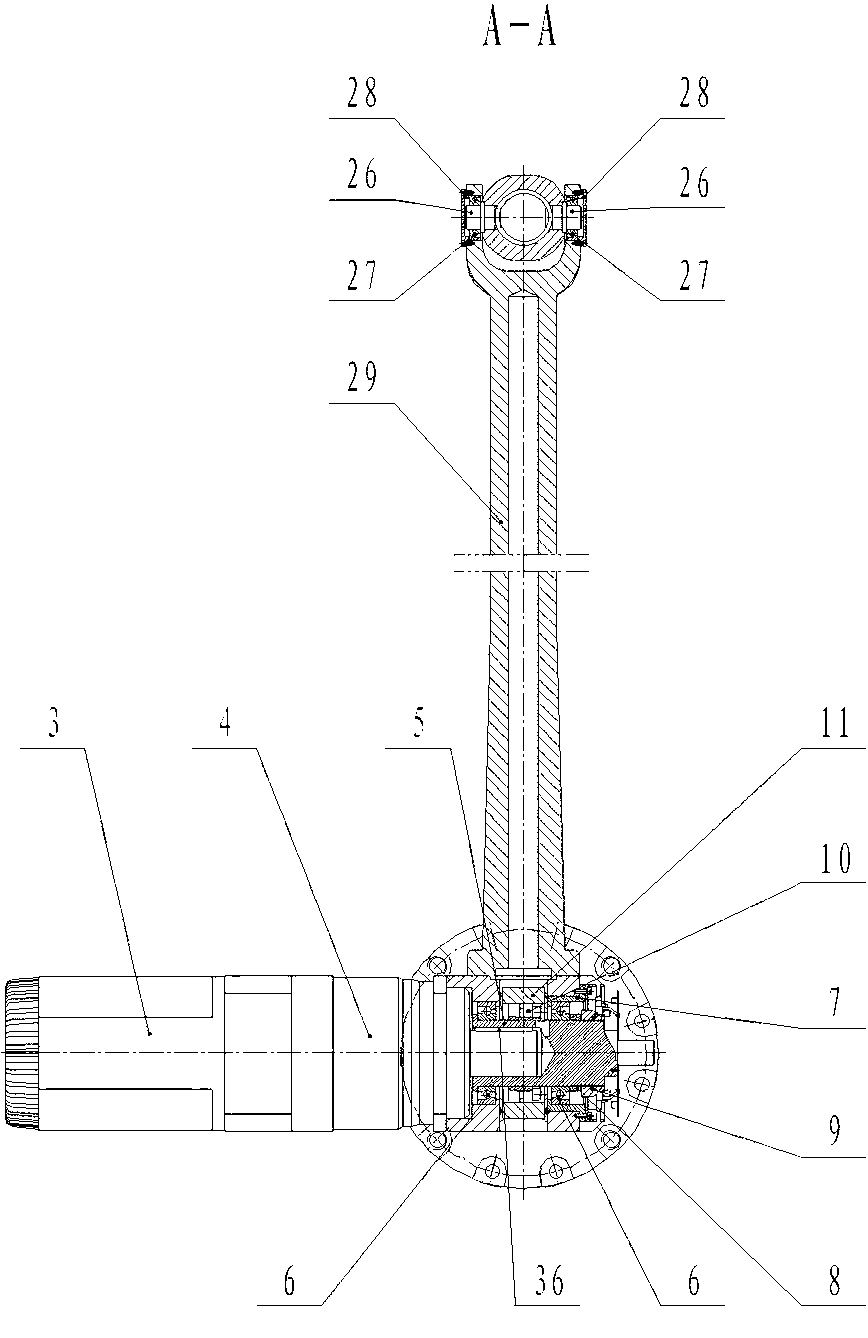

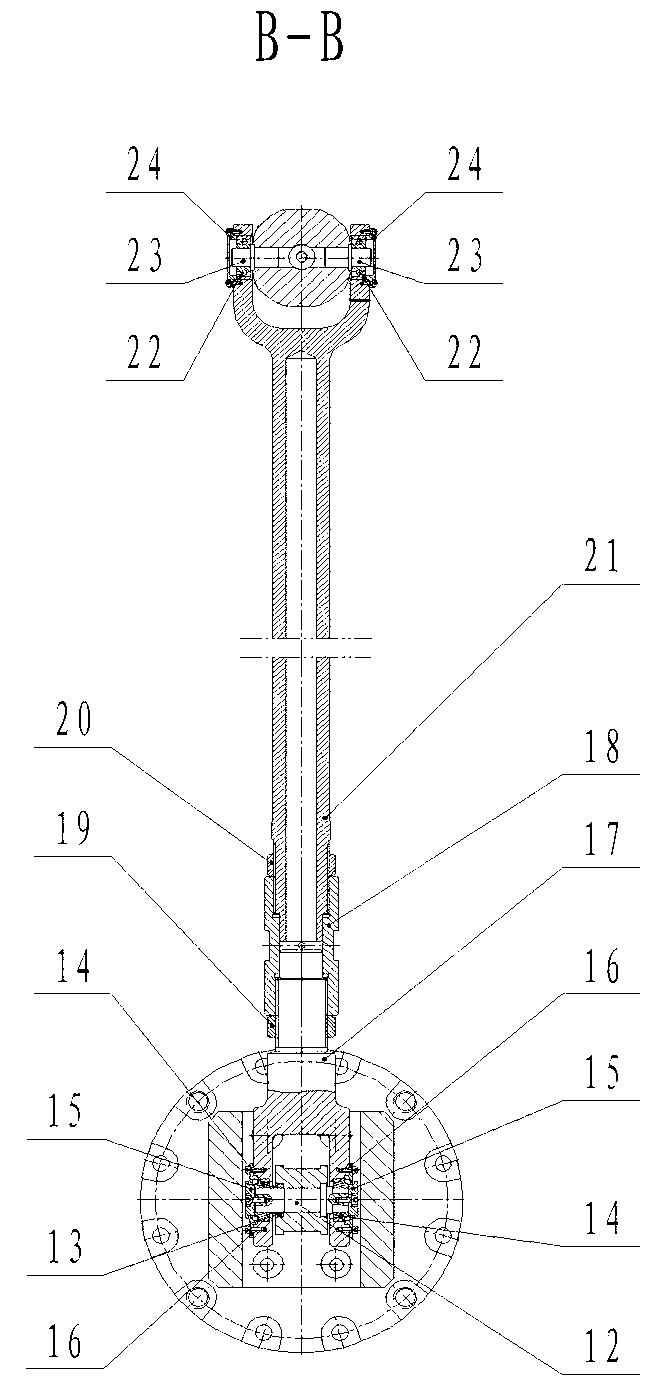

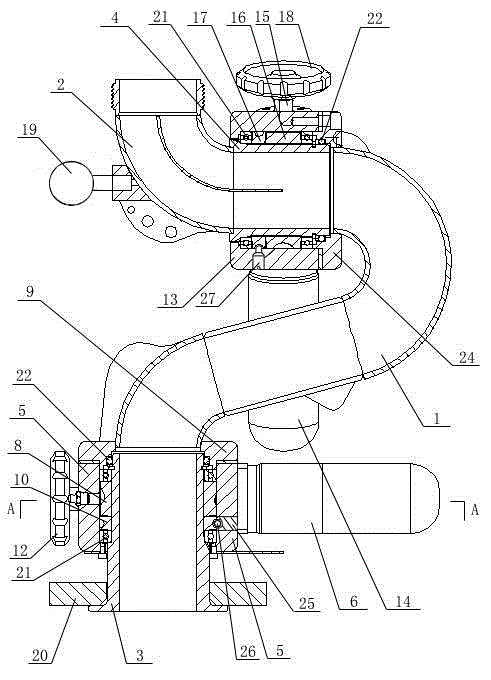

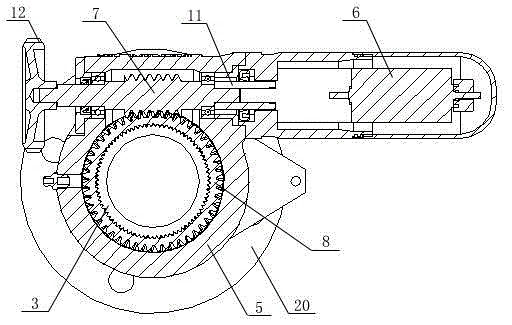

Servo control fire-fighting monitor

ActiveCN102940946ASolve process problemsSolve rigid problemsFire rescueElectric controlControl theory

The invention discloses a servo control fire-fighting monitor. The servo control fire-fighting monitor comprises a monitor body and a monitor head, a water inlet end of the monitor body is communicated with an entrance worm-wheel shaft through a horizontal servo control mechanism, a water outlet end is communicated with an exit worm-wheel shaft through a vertical servo control mechanism, and the exit worm-wheel shaft is fixedly connected with the monitor head. According to the servo control fire-fighting monitor, by means of the electric control, action commands are issued to servo motors in the horizontal and vertical directions respectively, the water outlet of the monitor head can perform corresponding angle adjustment, and due to the structural design of the horizontal servo control mechanism and the vertical servo control mechanism, the problems that in the existing fire-fighting monitor structure, the structural processability and rigidity are poor and the rotation accuracy is low when the monitor body rotates along the horizontal plane and rotates in a direction perpendicular to the horizontal plane are effectively solved.

Owner:VITALONG FIRE SAFETY GRP

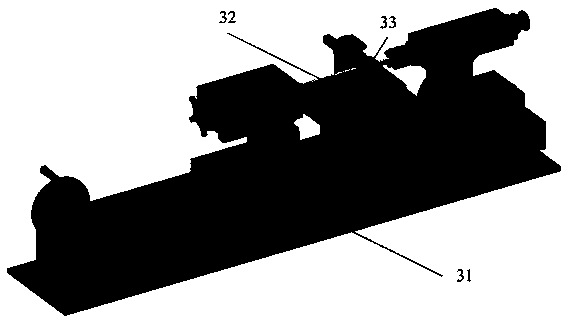

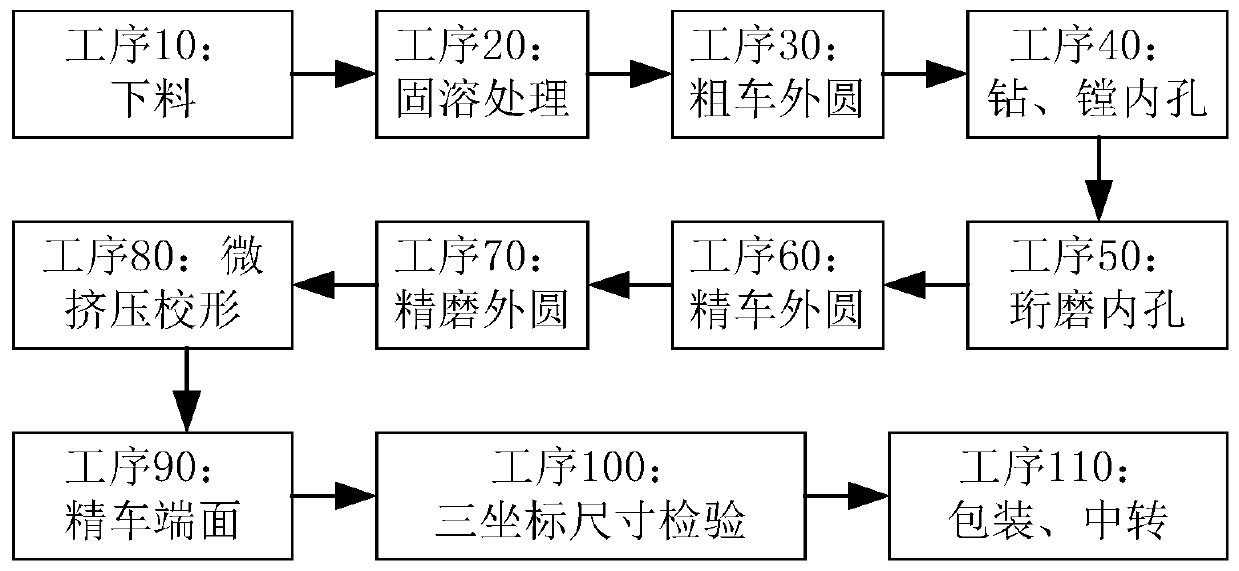

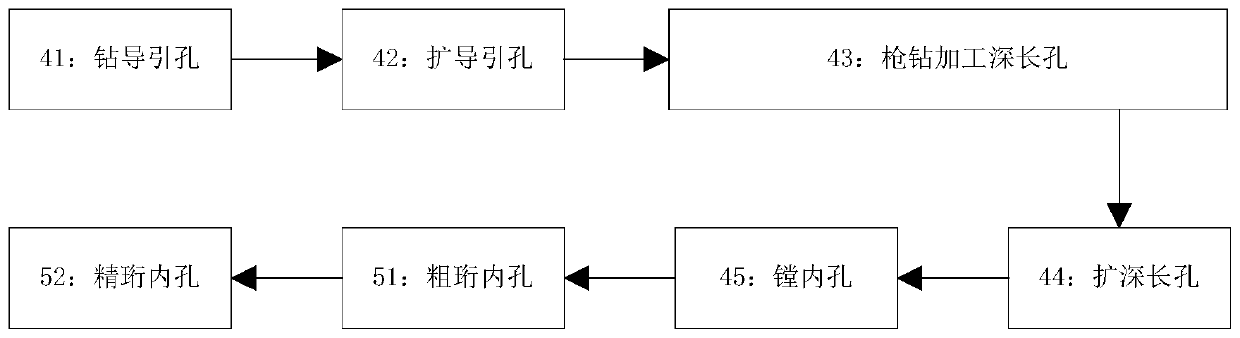

Thin-walled elongated pipe member whole precision processing method

The invention provides a thin-walled elongated pipe member whole precision processing method. The thin-walled elongated pipe member whole precision processing method comprises the following steps of S1, blanking; S2, hot working; S3, rough turning of the end face and the outer circle; S4, drilling and boring of an inner hole; S5, honing of the inner hole; S6, semi-finish turning and finish turningof the outer circle; S7, fine grinding of the outer circle; S8, micro-extrusion correction; S9, finish turning of the end face; and S10, inspection and packaging. By means of the method, the whole precision machining of thin-walled elongated pipe members which are made of austenitic stainless steel materials, have the maximum length being 575 mm, have the minimum pipe diameter being 24 mm, have the maximum draw ratio being 24 and have the thinnest wall thickness being 0.3 mm can be achieved, and the inner hole and outer circle precision reaches the IT5 stage, the coaxiality reaches 0.025 mm,the straightness reaches 0.025mm, the surface roughness reaches Ra0.8, and the method is a high-efficiency, precise and low-cost thin-walled elongated pipe member processing method.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST +1

Polyethylene resin and preparation method thereof

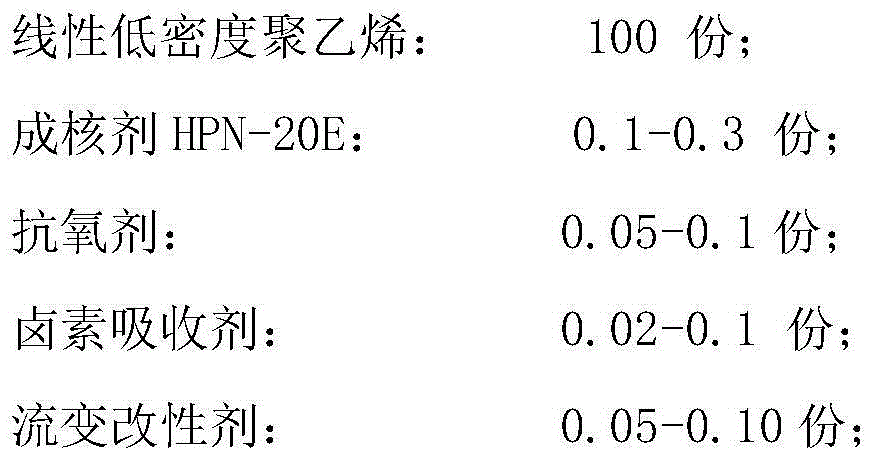

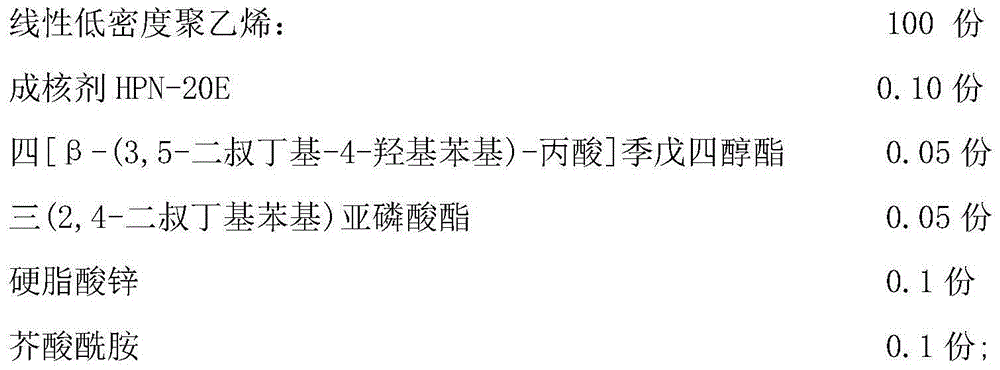

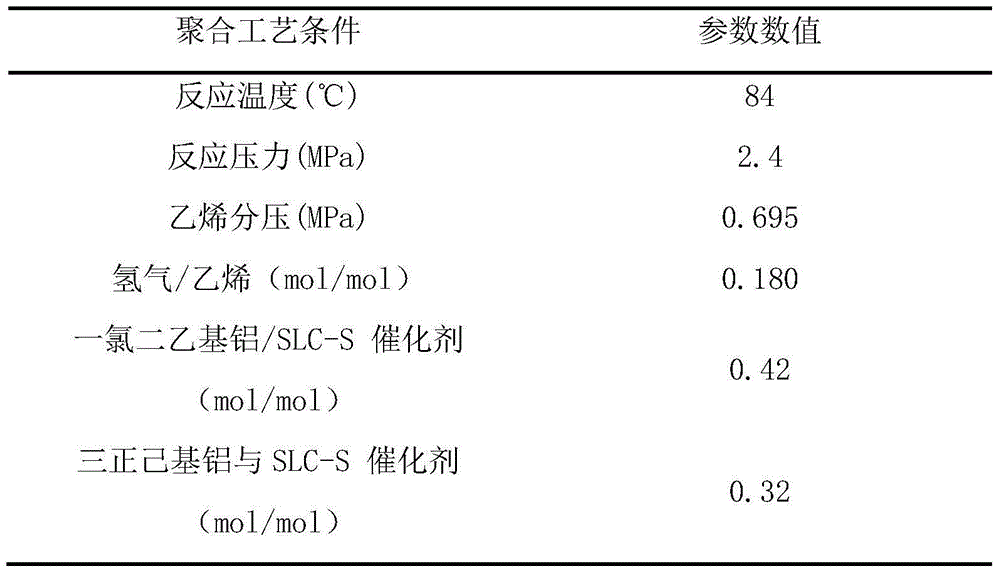

ActiveCN106317584ASolve rigid problemsSolve for uniformityLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene resin, which is prepared from the following components in parts by weight: 100 parts of linear low-density polyethylene, 0.1 to 0.3 part of nucleating agent HPN-20E, 0.05 to 0.1 part of antioxidant, 0.02 to 0.1 part of halogen absorber, and 0.05 to 0.10 part of rheology modifier. The linear low-density polyethylene is prepared by the following steps: preparing a Unipol gas phase technology polyethylene device; taking polyethylene gas with a volume percentage of 99.9% as the raw material, 1-butene as the co-monomer, hydrogen as the chain transfer agent, SLC-S as the catalyst, and aluminum diethyl mono-chloride and tri-n-hexyl aluminum as the co-catalyst; and carrying out gas phase polymerization to obtain the polyethylene resin; wherein the partial pressure of ethylene is 0.60 to 0.75 MPa, the mole ratio of hydrogen to ethylene is 0.100-0.225; and the polyethylene resin has the advantages of excellent rigidity and high transparency and can be used in the fields of film and injection molded products.

Owner:CHINA PETROLEUM & CHEM CORP +1

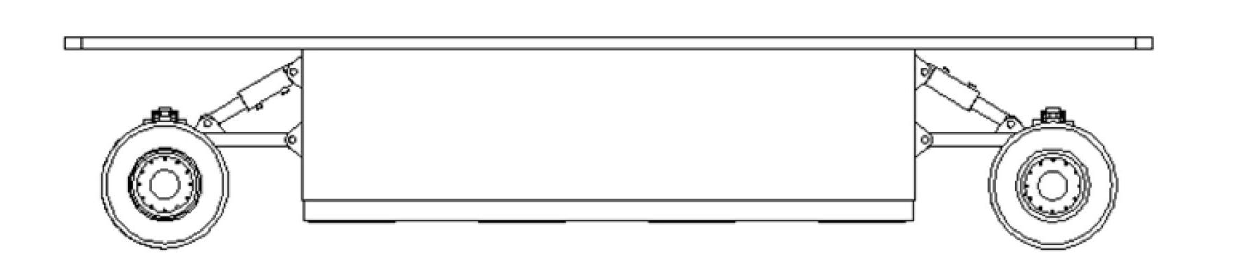

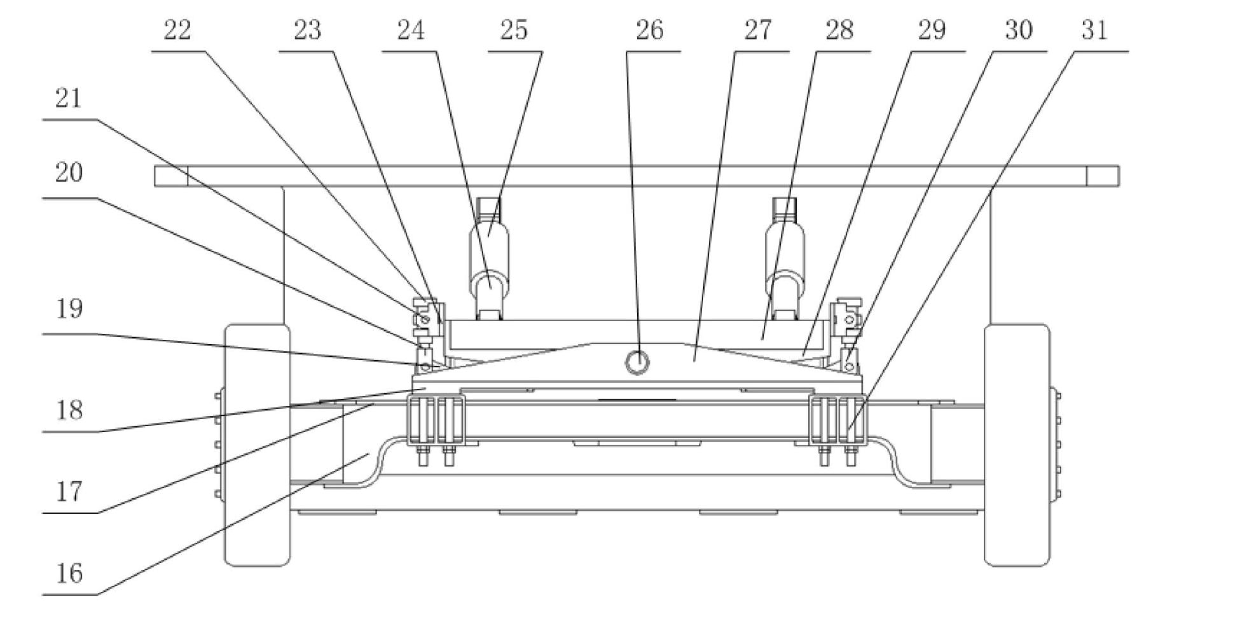

Movable and fixable mechanical equipment base

The invention provides a movable and fixable mechanical equipment base, which comprises a moving structure, a lifting structure, a fixing structure and a base plate. When the mechanical equipment base needs to be moved, electromagnets arranged on the base plate are powered off, and the moving structure descends through the lifting structure, so the stable moving of the mechanical equipment base is realized. When mechanical equipment base is moved to a proper position, the moving structure ascends through the lifting structure, the electromagnets uniformly distributed on the bottom of the base plate are in contact with magnetic plate materials of the ground, the electromagnets are electrified, and the fixation of the mechanical equipment base is fast and reliably realized. The four-wheel single driving structure is adopted, the stability is good, the rotation radius is small, and the obstacle climbing capability is high. The fast and firm fixation can be realized in an electromagnet fixation mode, and the moving looseness phenomenon cannot occur. The movable and fixable mechanical equipment base effectively solves the problems of poor shaft rigidity and poor stability caused by wheel type driving relying on motor braking fixation, meanwhile, the phenomena of moving difficulty and time and labor wasting during the mounting and the dismounting caused by the adoption of the screw bolt fixation are perfectly avoided, and the function of the upper layer mechanical equipment is preferably realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

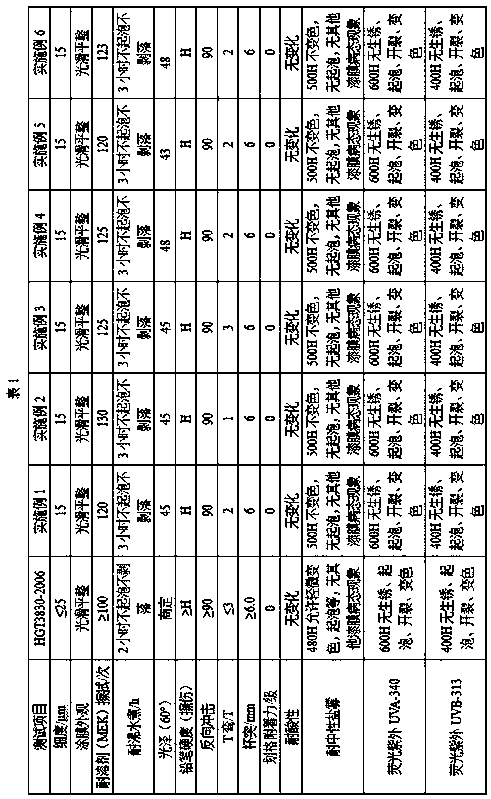

Finishing coat of waterborne coiled steel coating and preparation method of finishing coat

ActiveCN109468029AGood flexibilityOvercome resilienceAnti-corrosive paintsPolyester coatingsSolvent basedPolyester resin

The invention relates to the field of waterborne coatings and particularly discloses a finishing coat of a waterborne coiled steel coating and a preparation method of the finishing coat, wherein the finishing coat of the waterborne coiled steel coating comprises the following components: a waterborne polyester resin, a rust-proof sizing agent, an amino resin, an acid catalyst, a wetting agent, a levelling agent, a defoamer, an adhesion promoter, a wetting dispersant, an anti-settling agent, a PH regulator, a cosolvent and water. the provided finishing coat of the coiled steel coating is a waterborne product, the VOC (volatile organic compounds) content is very low, the environment pollution is small, the performance of a T-bend is greatly improved, the T-bend does not crack in winter and is anti-sticking in summer, and the physical and mechanical properties equivalent to those of the solvent based coating are achieved.

Owner:南通科顺建筑新材料有限公司

Automatic welding device

InactiveCN105643091ACorrection errorSolve rigid problemsNon-electric welding apparatusButt jointEngineering

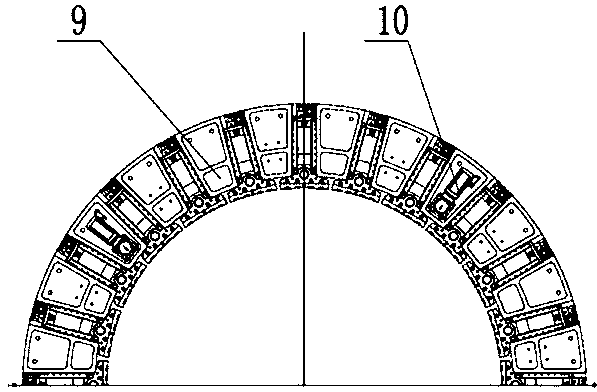

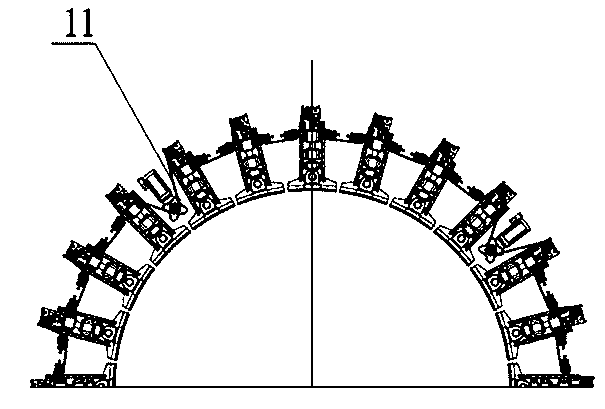

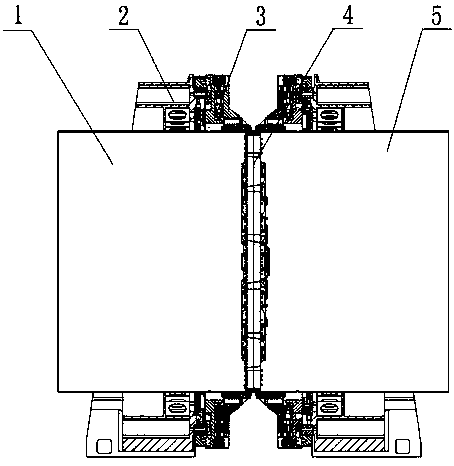

The invention relates to an automatic welding device. The automatic welding device comprises rigid supporting seats, multi-claw chuck mechanisms, built-in flexible pneumatic piston rings, a rotary table bearing, an annular guide rail and a rotary driving mechanism, wherein the built-in flexible pneumatic piston rings are matched with storage tank drum segments; the multi-claw chuck mechanisms are connected to the rigid supporting seats through the rotary table bearing and the annular guide rail; the flexible pneumatic piston rings and the multi-claw chuck mechanisms are matched with the storage tank drum segments needing butt joint and friction stir welding for circular seams so as to form a rigid body, and the rigid body is driven by the rotary driving mechanism to rotate relative to the rigid supporting seats. According to the automatic welding device disclosed by the invention, the problems that, in the prior art, storage tanks are structural parts with big sizes and thin walls, so that the rigidity of the storage tanks is poor, and the storage tanks are difficult to fix and position are solved, and the automatic welding device has the beneficial effects that the dynamic stability of the welding process of the circular seams is guaranteed, and the welding quality is improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

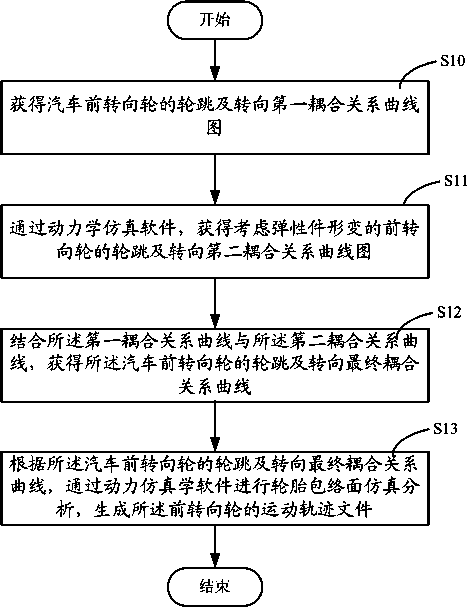

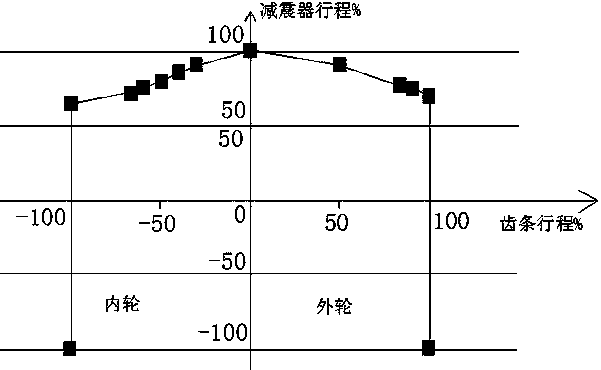

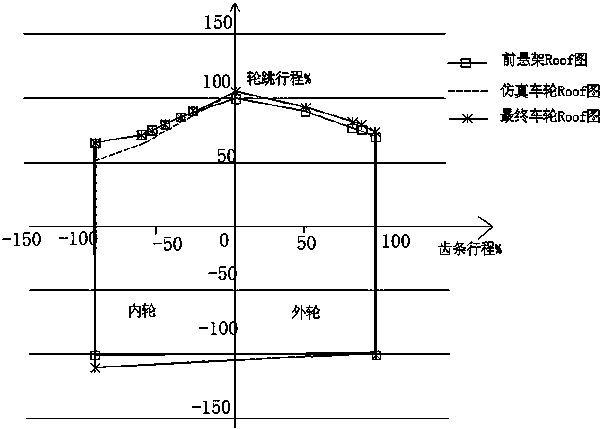

Method for simulating motion curve of automobile front steering wheel and manufacturing envelope surface

ActiveCN104216755AAccurately reflectReduce development costsSoftware simulation/interpretation/emulationSpecial data processing applicationsSteering wheelCoupling

The invention provides a method for simulating a motion curve of an automobile front steering wheel. The method comprises the steps that a wheel jumping and steering first coupling relation curve of the automobile front steering wheel is obtained; a wheel jumping and steering second coupling relation curve considering elastic piece deformation of the front steering wheel is obtained; a wheel jumping and steering final coupling relation curve of the automobile front steering wheel is obtained by combining the first coupling relation curve and the second coupling relation curve; a motion curve file of the front steering wheel is generated according to the final coupling relation curve. The invention further provides a method for manufacturing an envelope surface of the automobile steering wheel. The obtained motion curve of the front steering wheel can reflect a wheel track more accurately, and the reflection is more close to the actual situation; the obtained envelope surface has high reliability and safety.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

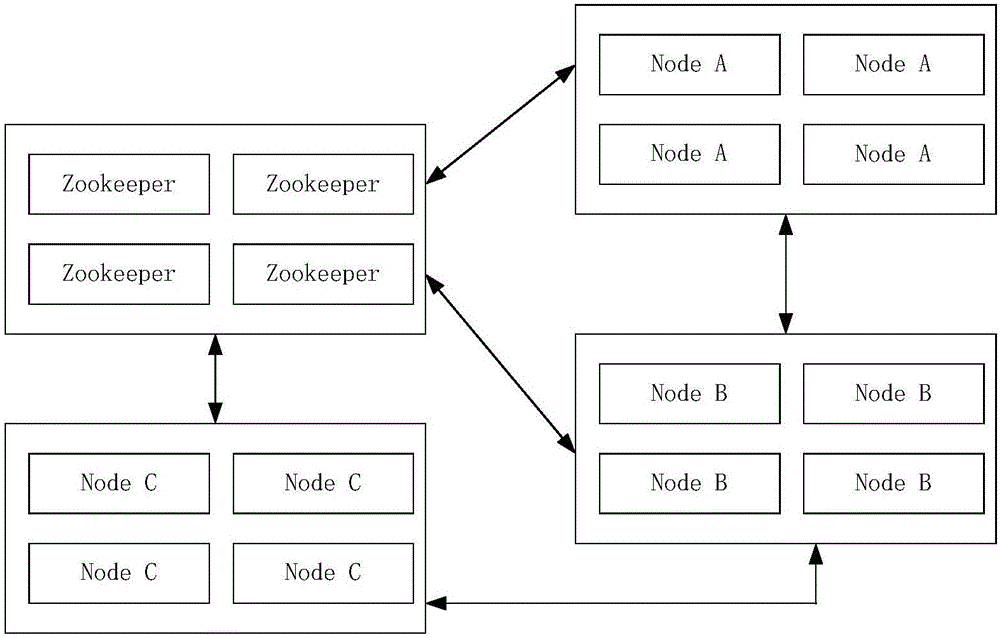

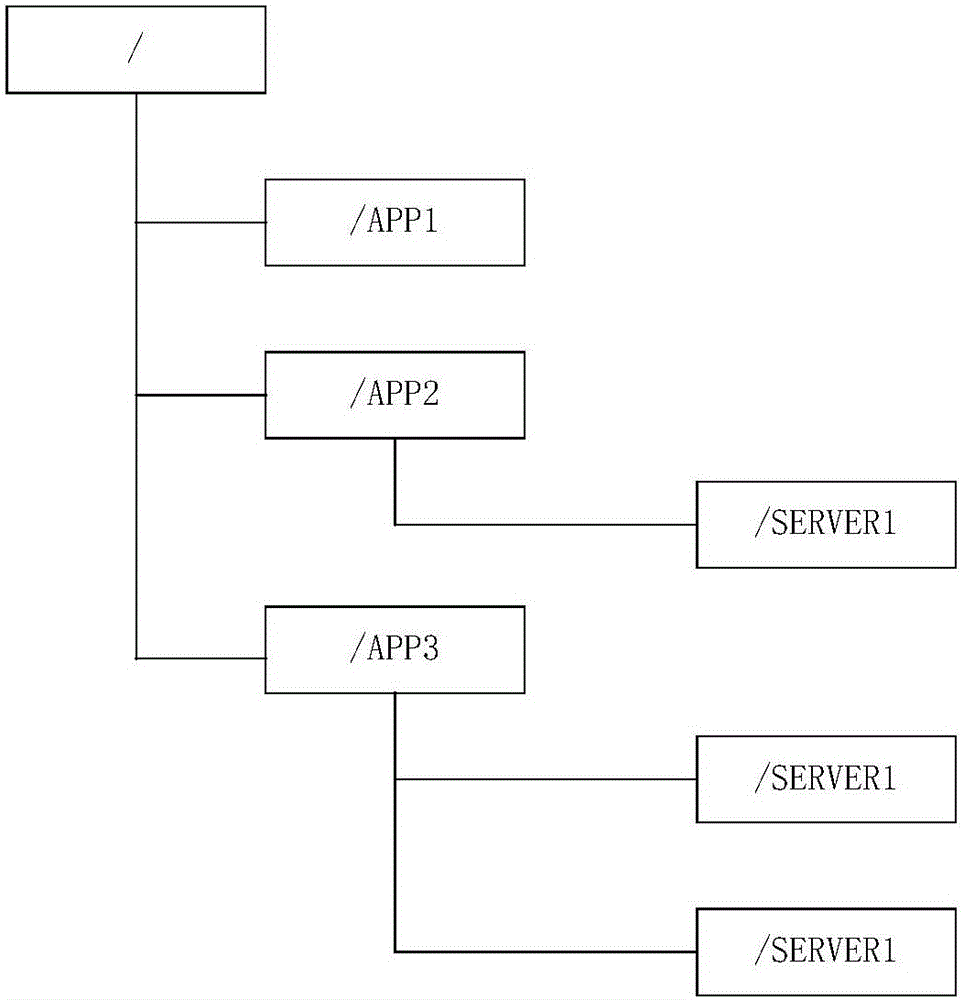

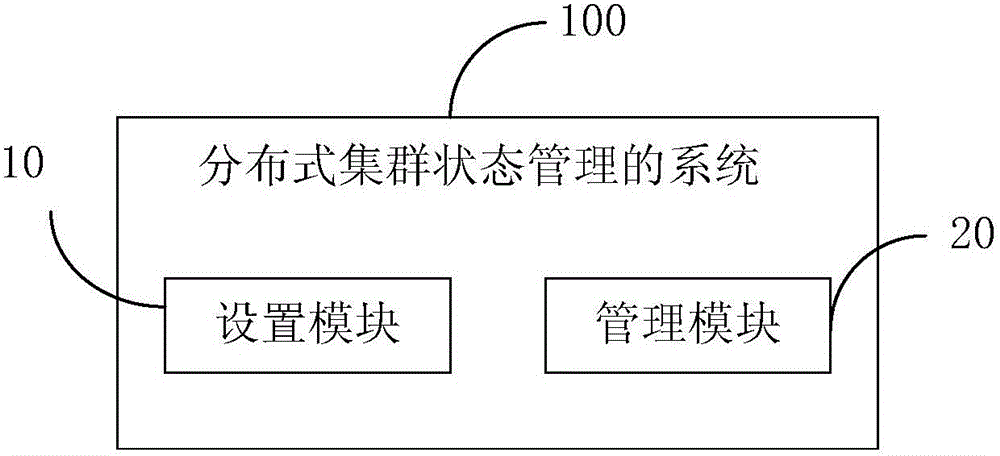

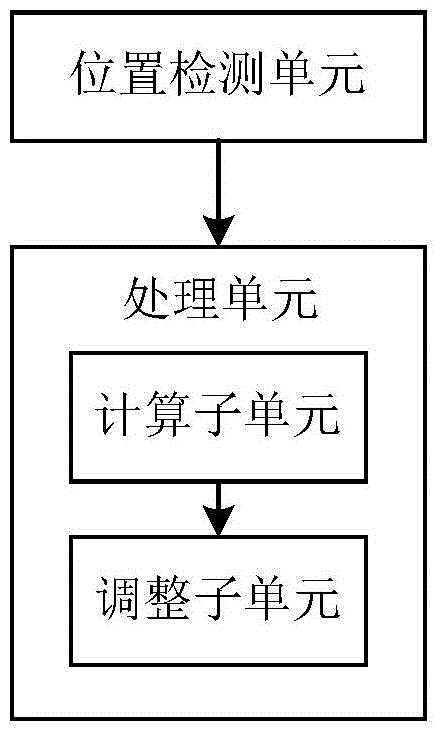

Distributed cluster state management method and system thereof

InactiveCN106027623ASolve the problem of high coupling and low flexibilitySolve rigid problemsData switching networksCluster stateManagement efficiency

The present invention is applicable to the field of computer technology, and provides a distributed cluster state management method and a system thereof. The method includes the following steps: A. setting an in-memory database and a manager of the distributed cluster; B. through the The in-memory database stores information of each node of at least one of the distributed clusters, and maintains information of each node of at least one of the distributed clusters through a manager of the distributed cluster. Thus, the management efficiency of the distributed cluster is improved.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI +1

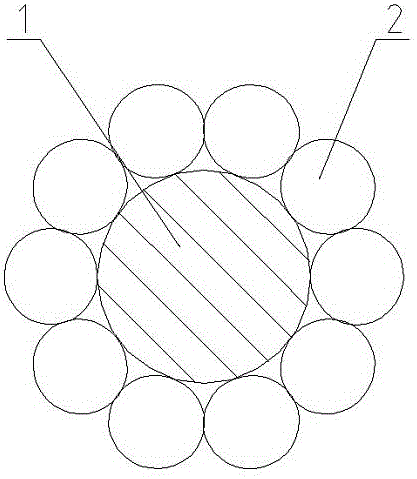

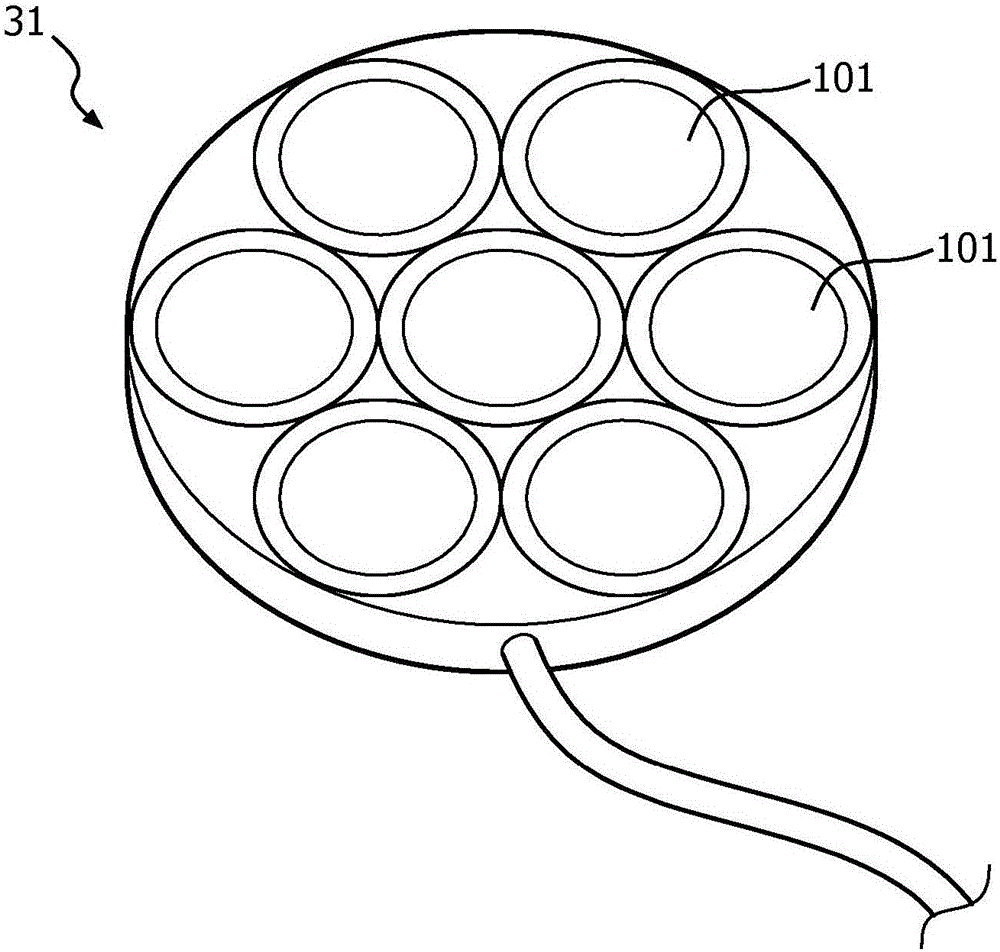

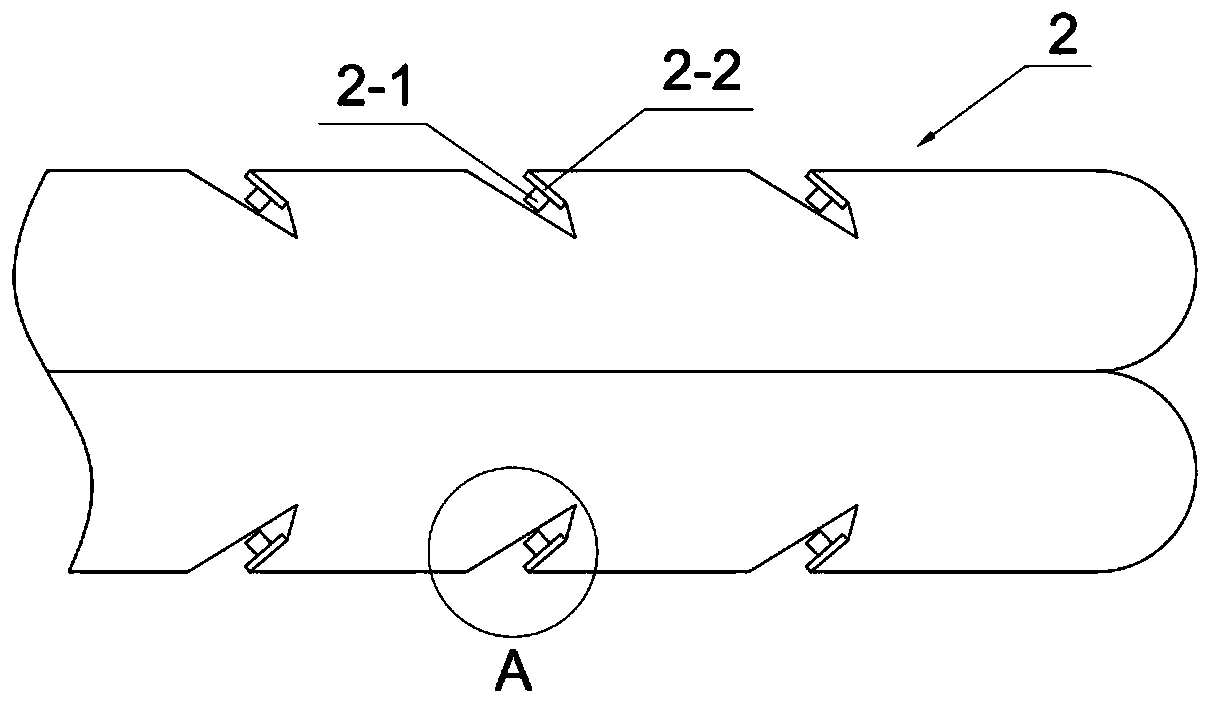

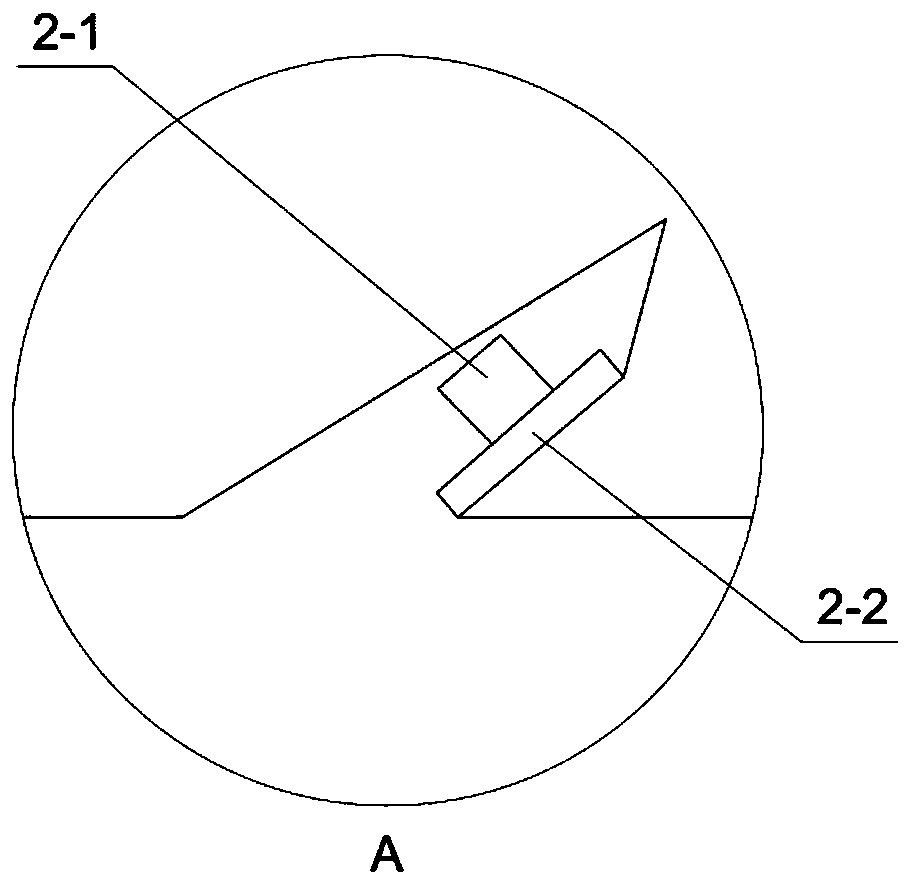

Twisted welding wire structure and manufacturing method thereof

InactiveCN106041351AThe solution is not easy to coilSolve rigid problemsWelding/cutting media/materialsSoldering mediaDiameter ratioEngineering

The invention relates to a twisted welding wire structure and a manufacturing method thereof, which belong to the technical field of metal welding. The twisted welding wire structure comprises a center wire (1), wherein multiple strands of peripheral wires (2) are spirally twisted on the periphery of the center wire (1), the diameter of the center wire (1) is not equal to that of each peripheral wire (2), and the diameter ratio of the peripheral wires (2) to the center wire (1) is 0.40 to 0.77. According to the twisted welding wire structure and the manufacturing method thereof, the problems that the diameter of a traditional welding wire is not big enough, the traditional welding wire is not likely to be wound when the diameter is increased, the rigidity is poor, energy consumption is high, deposition rate is high, welding quality is uneven and the like can be solved.

Owner:梁裕

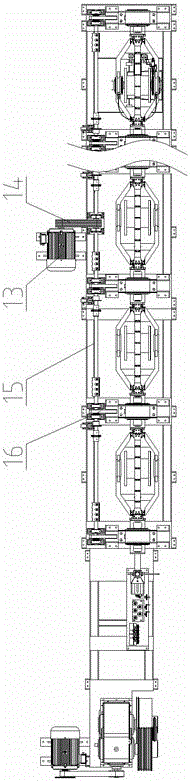

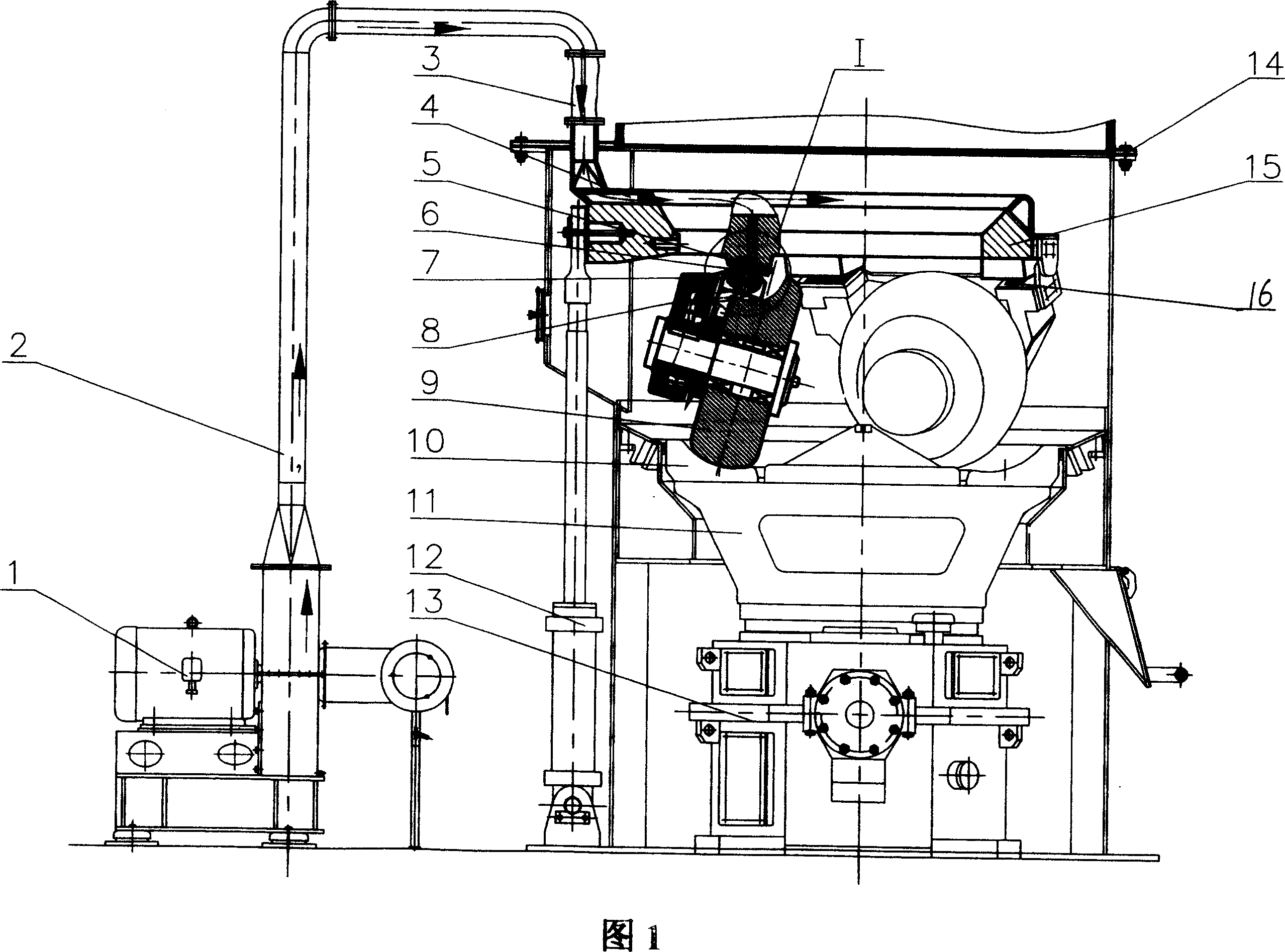

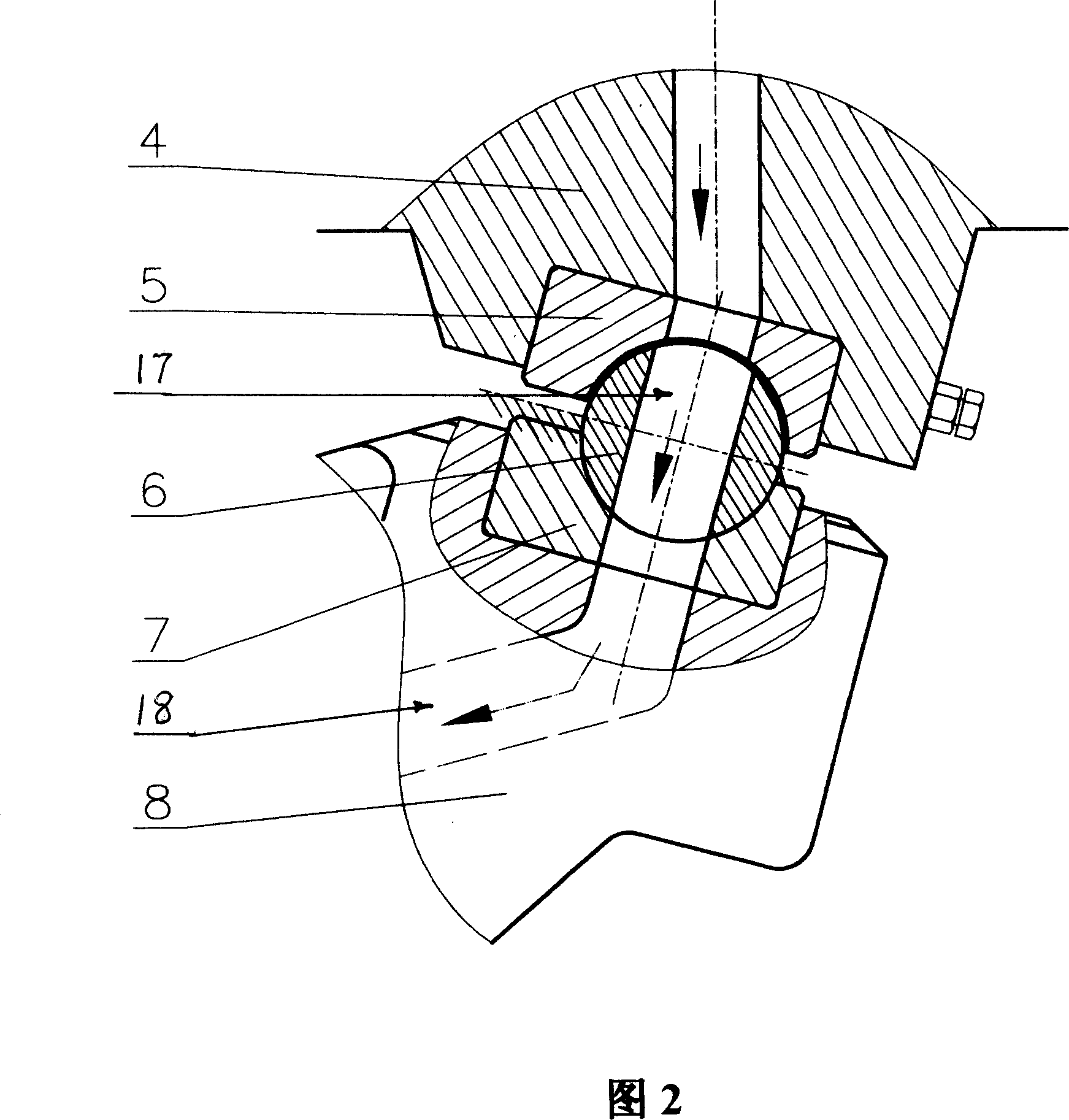

Enclosed air passage system for grinding roll

ActiveCN101007293ASolve seal failureSolve rigid problemsGrain treatmentsPositive pressurePulp and paper industry

Grinding roller sealed air duct system includes fan, external pipe lines, soft connectivity, pipe lines fixed on pressure framework, upper roller seat, sealing roller, lower roller seat, grinding roller frame and grinding roller; its characteristics is said upper roller seat, sealing roller and lower roller seat combine sealed air duct, the sealed air duct is connected with air holes of grinding roller frame. The fan transmits positive pressure wind into the sealed air duct combine by upper roller seat, sealing roller and lower roller seat through external pipe lines and pipe lines fixed on pressure framework, and blowout wind through the air holes of grinding roller frame and the chine between grinding roller frame, grinding roller and grinding roller frame driving rotating components.The invention solves the problem of grinding roller seal failure because of vibration joint wear, while solves the problems of the grinding leakage of loop pipe line and grinding roller frame air-supply line because of long-time mill vibration and dust wind erosion, or rigidity injury even breach lead by mill shape vibration. The invention not only saves a lot of investment, reduces costs, and is a highly reliable grinding roller sealed air duct system.

Owner:沈阳吉大重型机械有限公司

Pure natural plant dyeing process of full-manual natural grass cloth

ActiveCN103451964ASoft textureImprove wrinkle resistanceBleaching apparatusDyeing processPulp and paper industryCrocus

The invention provides a pure natural plant dyeing process of a full-manual natural grass cloth. The process comprises the following steps of 1, preparing dyeing liquid through raw materials; sealing and storing; 2, soaking a grey grass cloth in water containing soda; transferring into a sealing container to naturally ferment for one week; 3, pulling out the cloth and cleaning through clean water and sulfuric acid; transferring into equipment to boil off; bleaching after boiling off; cleaning to remove impurities on the grey cloth; 4, adjusting the dyeing liquid; pouring into a dyeing machine to dye for the first time; and 5, adding a dye-fixing agent to the dyeing machine for solid wash, dyeing for the second time, drying after dyeing; arranging, sizing, and warehousing. According to the pure natural plant dyeing process of the full-manual natural grass cloth, gardenia jasminoides, coptis chinensis, saffron crocus, isatis root, persimmon and other plants are used for dyeing; the made clothes or household goods are soft, draped, straight, comfortable, antibacterial, health-care, warm in winter and cool in summer, high in wrinkle resistance and outstanding in air permeability, and have the effects of dissipating heat and clearing damp. The full-manual natural grass cloth is lightweight and anti-mildew, and is an outstanding pure natural green and health care fabric.

Owner:RONGCHANG YIHE TEXTILE CO LTD

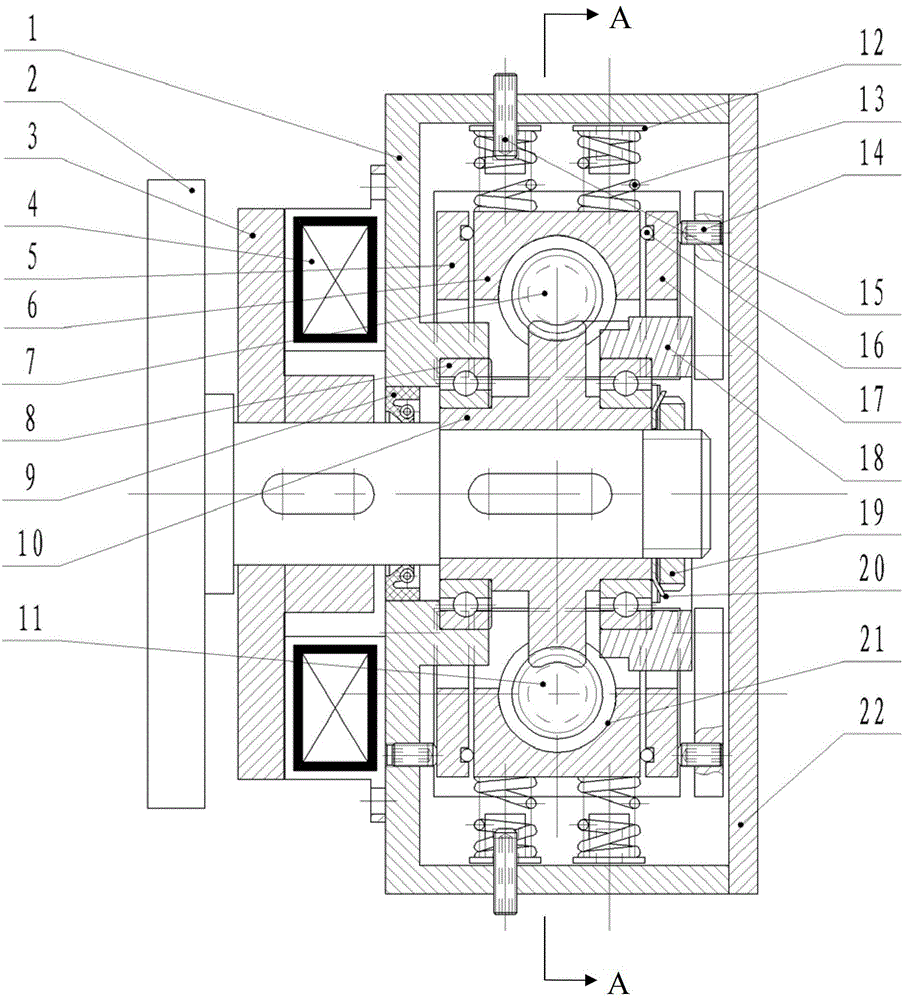

Automatic clearance-removing double-worm speed reducer

InactiveCN103335064ASolve the accuracy problemSolve rigid problemsToothed gearingsGearing detailsProcess systemsCoupling

The invention discloses an automatic clearance-removing double-worm speed reducer which comprises a shell body, an upper worm, a lower worm, worm boxes, a worm gear, a flanged shaft and a brake disc. The upper side and the lower side of the worm gear are provided with the upper worm and the lower worm respectively, wherein the upper worm is meshed with the upper side of the worm gear, and the lower worm is meshed with lower side of the worm gear. The upper side and the lower side of the worm gear are structurally symmetrical. The worms are installed on the worm boxes which can slide in the radial direction along the worm gear through two conical roller bearings, one end of the upper worm and one end of the lower worm penetrate out of the worm boxes and are connected with elastic couplings, the right end shaft head of the flanged shaft is directly installed in a worm hole and is compressed with a round nut through a tab washer, an oil seal is arranged between the flanged shaft and the shell body, the brake disc is installed on the right head shaft head of the flanged shaft, and an electromagnetic coil is fixed on the shell body. When the worm gear and the worms are designed and assembled, zero clearance in theory is ensured, the automatic clearance-removing double-worm speed reducer can automatically adjust and remove the clearance which exists when the speed reducer is used, the problems that machining precision of a spindle of a four-shaft or five-shaft semi-closed loop control system is not high and the rigidity of process systems of some machine tools is not enough due to backlash at the present stage can be solved, and the automatic clearance-removing double-worm speed reducer is higher in transmission accuracy due to the adoption of the double worms.

Owner:济南若泰数控科技有限公司

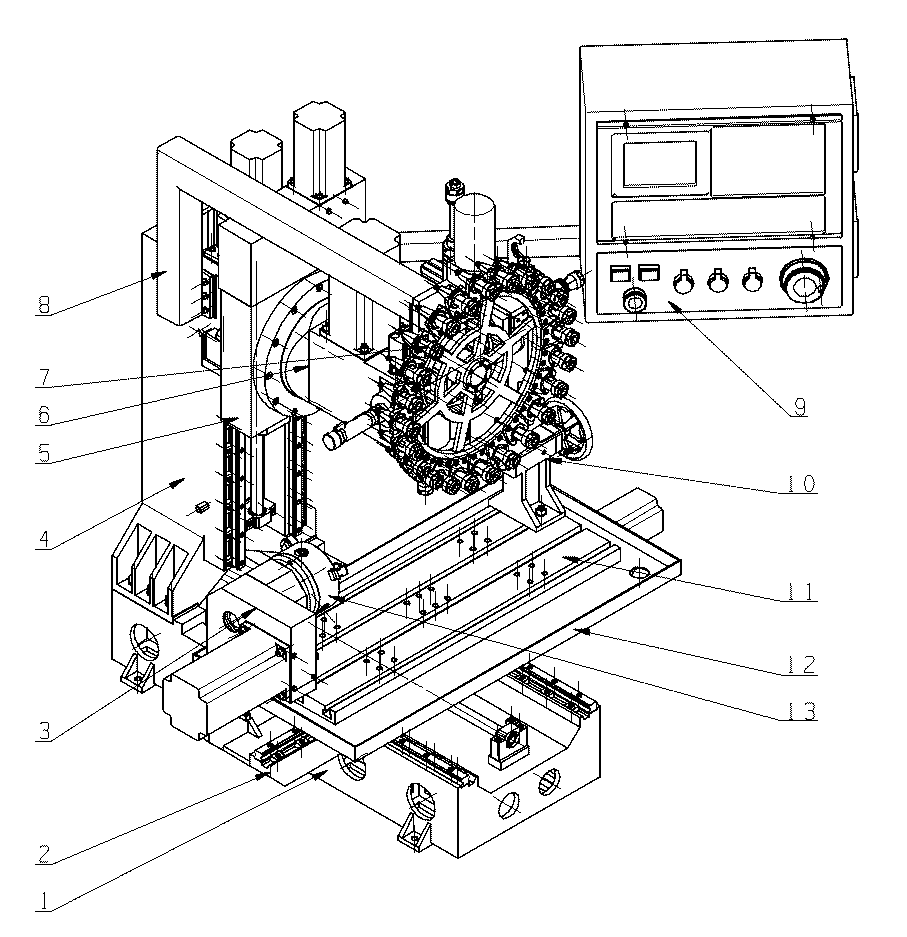

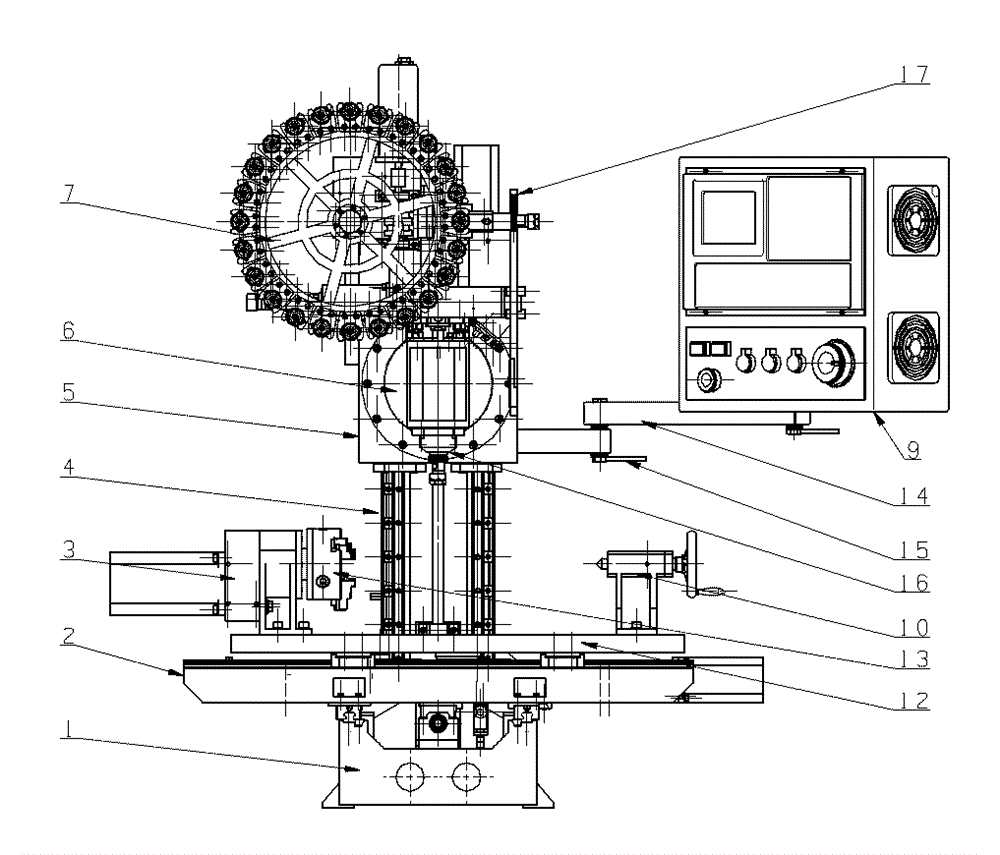

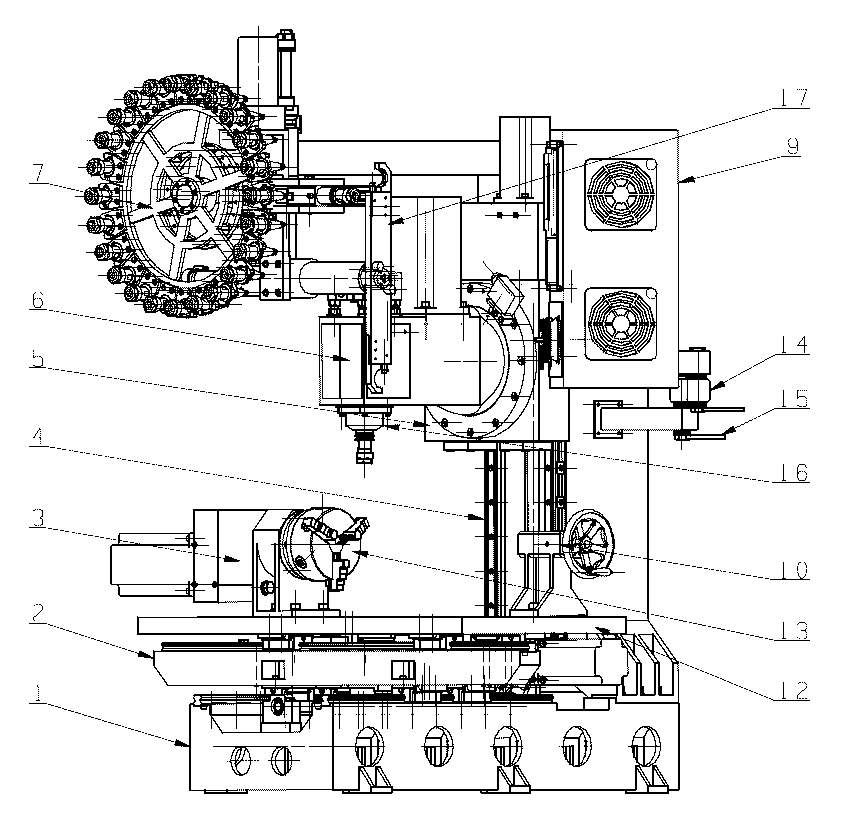

Miniature multifunctional combined machining center

InactiveCN104308668ASolve the accuracy problemSolve rigid problemsMetal working apparatusHobbingThree degrees of freedom

The invention discloses a miniature multifunctional combined machining center. The miniature multifunctional combined machining center comprises a tool magazine, a numerical control system, two spindles, three degree-of-freedom feed shafts and two degree-of-freedom rotating shafts, wherein the tool magazine is arranged on the front of a machine tool and at the highest point in right front of a spindle box, and an automatic tool exchange device mechanical arm of the tool magazine is longitudinally arranged on the right side of the machine tool; the numerical control system is arranged on the right side of the machine tool, is connected to the machine tool through a two-section connecting rod mechanism and can freely move in the movement range of the connecting rod mechanism; the connecting rod mechanism can be locked by a locking handle to fix the position of the numerical control system; the three degree-of-freedom feed shafts are respectively a shaft X, a shaft Y and a shaft Z; the two degree-of-freedom rotating shafts are respectively a shaft A and a shaft B; the shaft A also serves as a turning spindle and can be detached to increase the effective travel of a workbench and the shaft X of the machine tool. The miniature multifunctional combined machining center has the characteristics that the miniature multifunctional combined machining center is small in size and light in weight, can be placed at any place and can be used in a storied house; the miniature multifunctional combined machining center is low in power consumption and can be directly powered by a lighting source; the miniature multifunctional combined machining center is rich in functions and flexible and controllable in structure, comprises the tool magazine, can automatically exchange tools, can realize five-shaft linkage, and can complete turning, milling, boring, planing, grinding, slotting, drilling, tapping, hobbing and other machining processes.

Owner:续宗耀

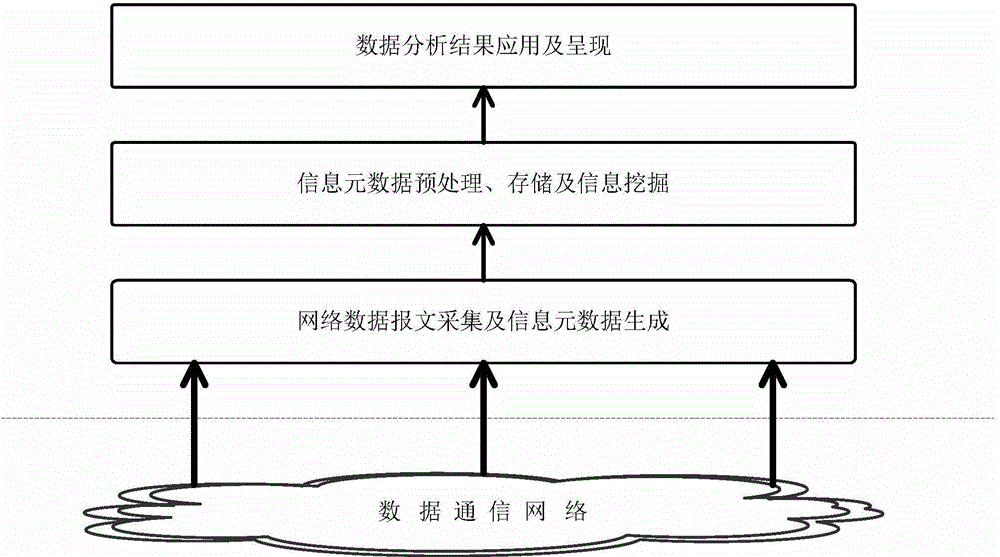

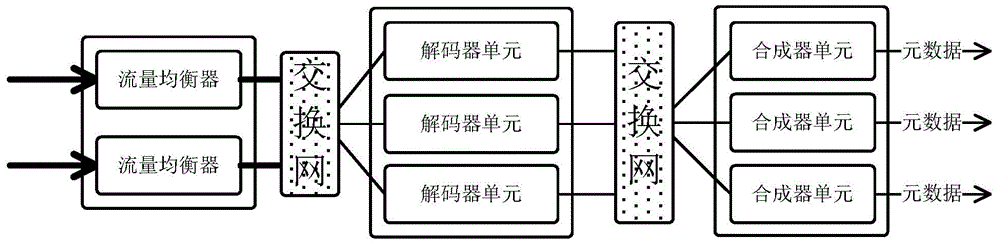

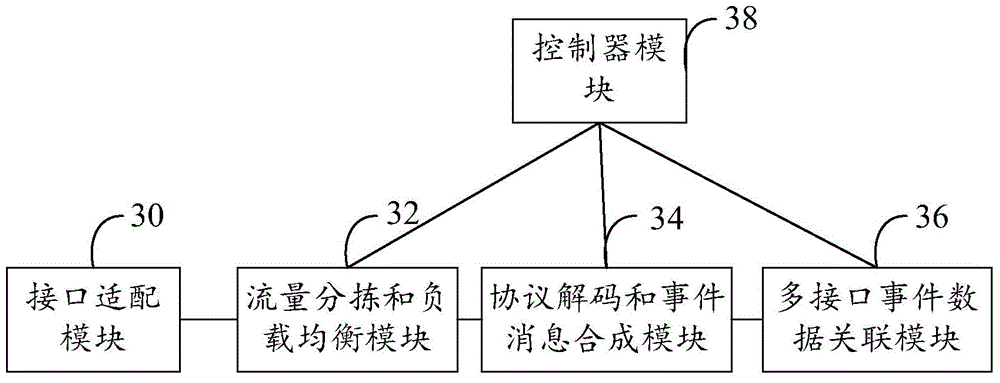

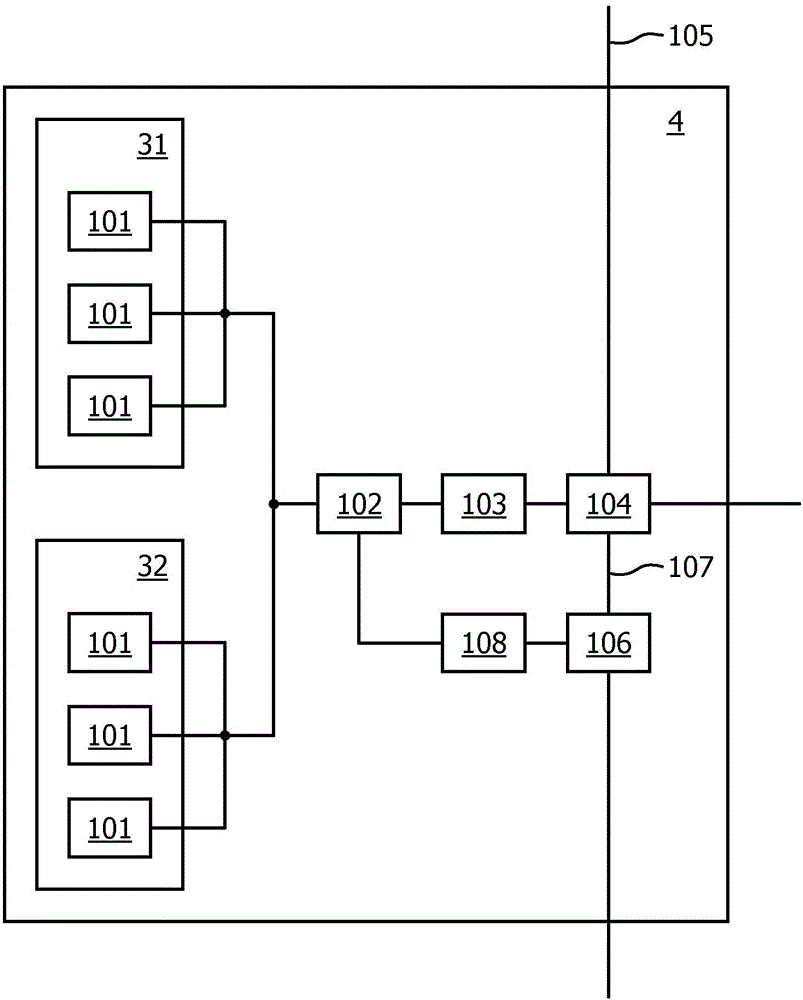

Network data acquisition system and network data acquisition method

ActiveCN105578488AFlexible deploymentSolve rigid problemsWireless communicationTraffic capacityData acquisition

The invention discloses a network data acquisition system and a network data acquisition method. The network data acquisition system comprises an interface adaption module, a flow sorting and load balancing module, a protocol decoding and event message aggregation module, a multi-interface event data association module, and a controller module. By adopting the technical scheme provided by the invention, the problems of the prior art such as rigidity and inflexibility of the data acquisition method of the data acquisition system can be solved, and the configurability and the customization of the data acquisition can be realized, and at the same time, the flexible deployment of the data acquisition system networking can be realized.

Owner:NANJING ZHONGXING SOFTWARE

System and method for measuring a pulse wave of a subject

ActiveCN105813550ASolve rigid problemsPrecise positioningInertial sensorsEvaluation of blood vesselsSensor arrayPulse wave

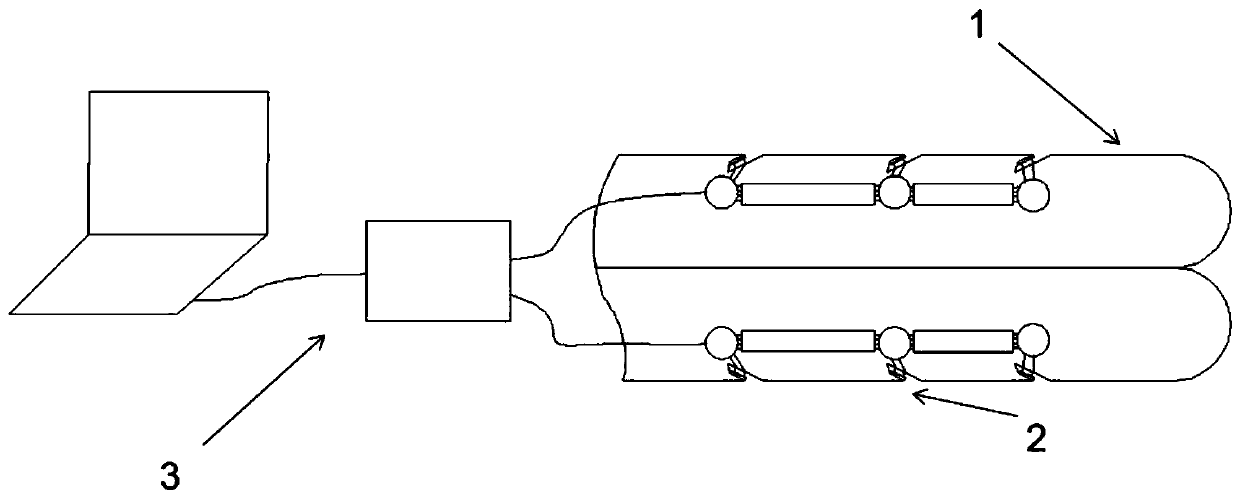

The present application relates to a system and method for measuring a pulse wave of a subject. The system comprises: a first sensor array and a second sensor array for respectively sensing a corresponding pulse wave of a first and a second artery of the subject, each of the first sensor array and the second sensor array comprising a plurality of sensors for respectively acquiring a plurality of first signals indicating a vibration of the skin; a deriving unit configured to derive, for each of the first sensor array and the second sensor array, a second signal representing the corresponding pulse wave from the plurality of first signals; and a first calculating unit configured to calculate a pulse transit time between the first artery and the second artery from the second signal derived for the first sensor array and the second signal derived for the second sensor array. An embodiment of this invention can improve accuracy of pulse wave measurement.

Owner:KONINKLJIJKE PHILIPS NV

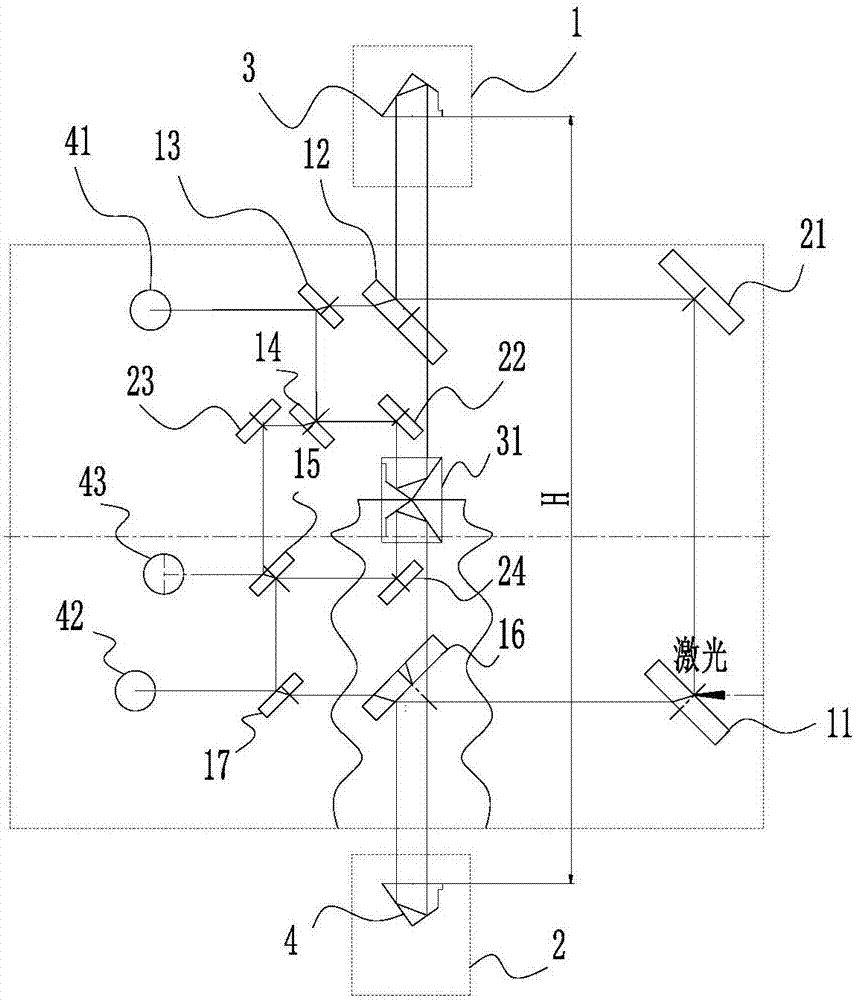

Absolute gravity measurement optical system and method with dual free falling bodies

ActiveCN107193050ASolve rigid problemsEliminate errorsGravitational wave measurementFree fallingAbsolute gravity

The invention discloses an absolute gravity measurement optical system with dual free falling bodies, which comprises a laser source, a falling body mechanism, an upper vacuum chamber, a lower vacuum chamber and an interferometer arranged between the upper vacuum chamber and the lower vacuum chamber, wherein the falling body mechanism comprises an upper falling body prism and a lower falling body prism which are exactly the same and are correspondingly arranged in the upper vacuum chamber and the lower vacuum chamber; the interferometer comprises a first interference system, a second interference system and a third interference system; after the laser source is incident to the interferometer and passes through the first interference system, the second interference system and the third interference system, three interference signals are generated for calculating the absolute gravity true value. The invention also provides a measurement method corresponding to the system.

Owner:北京奥地探测仪器有限公司 +1

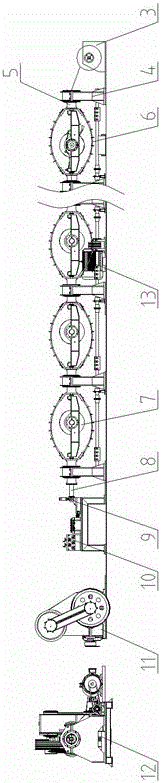

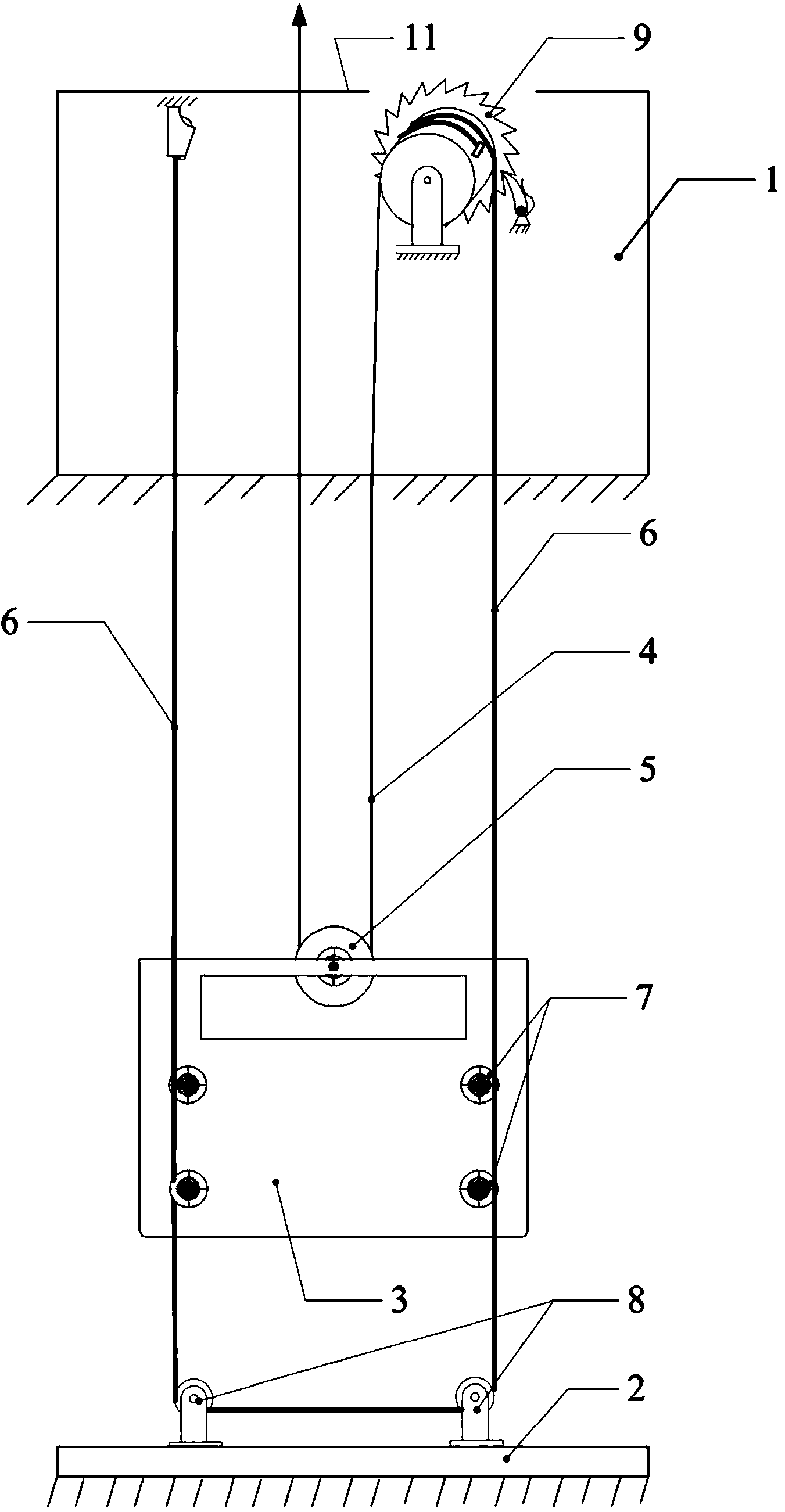

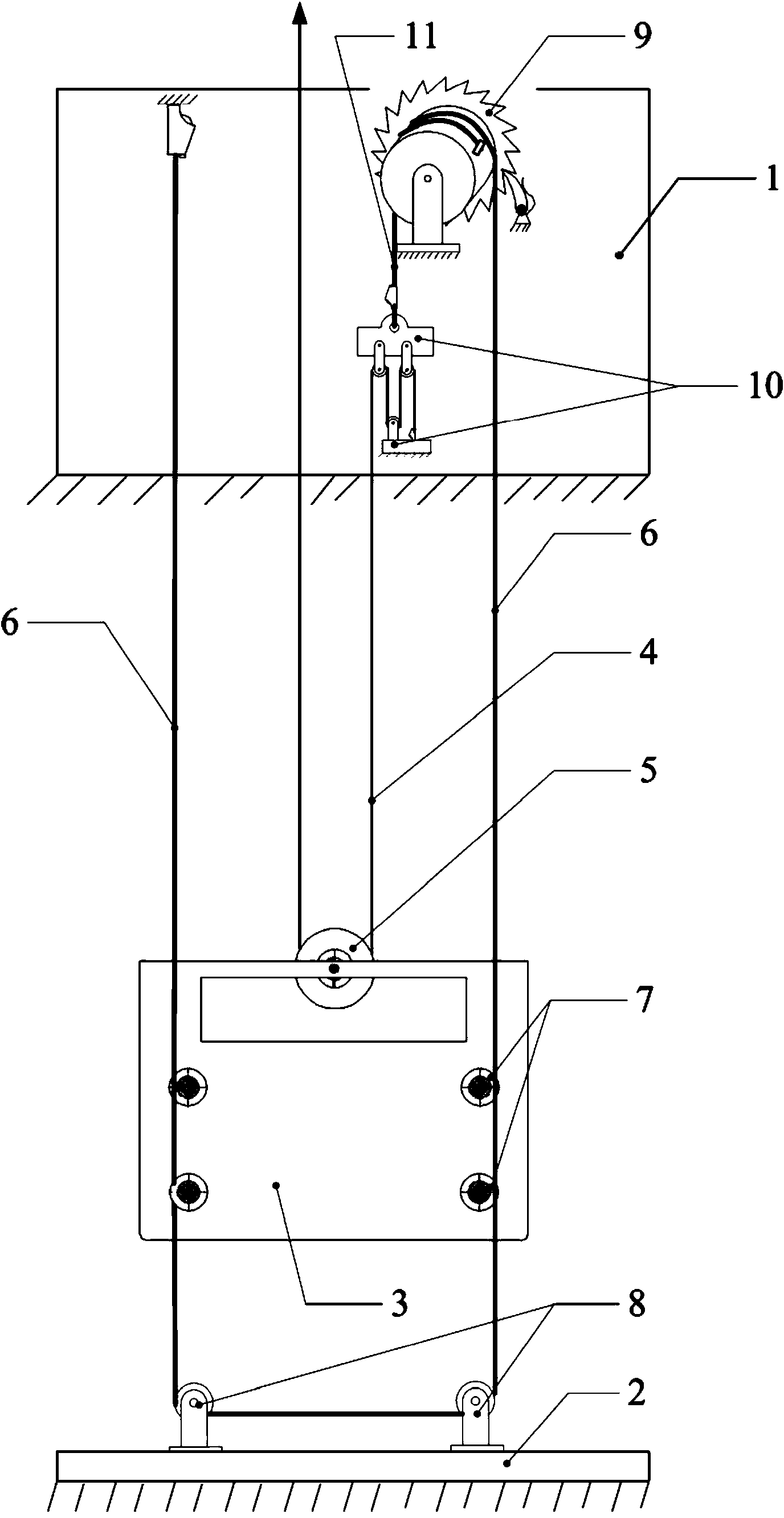

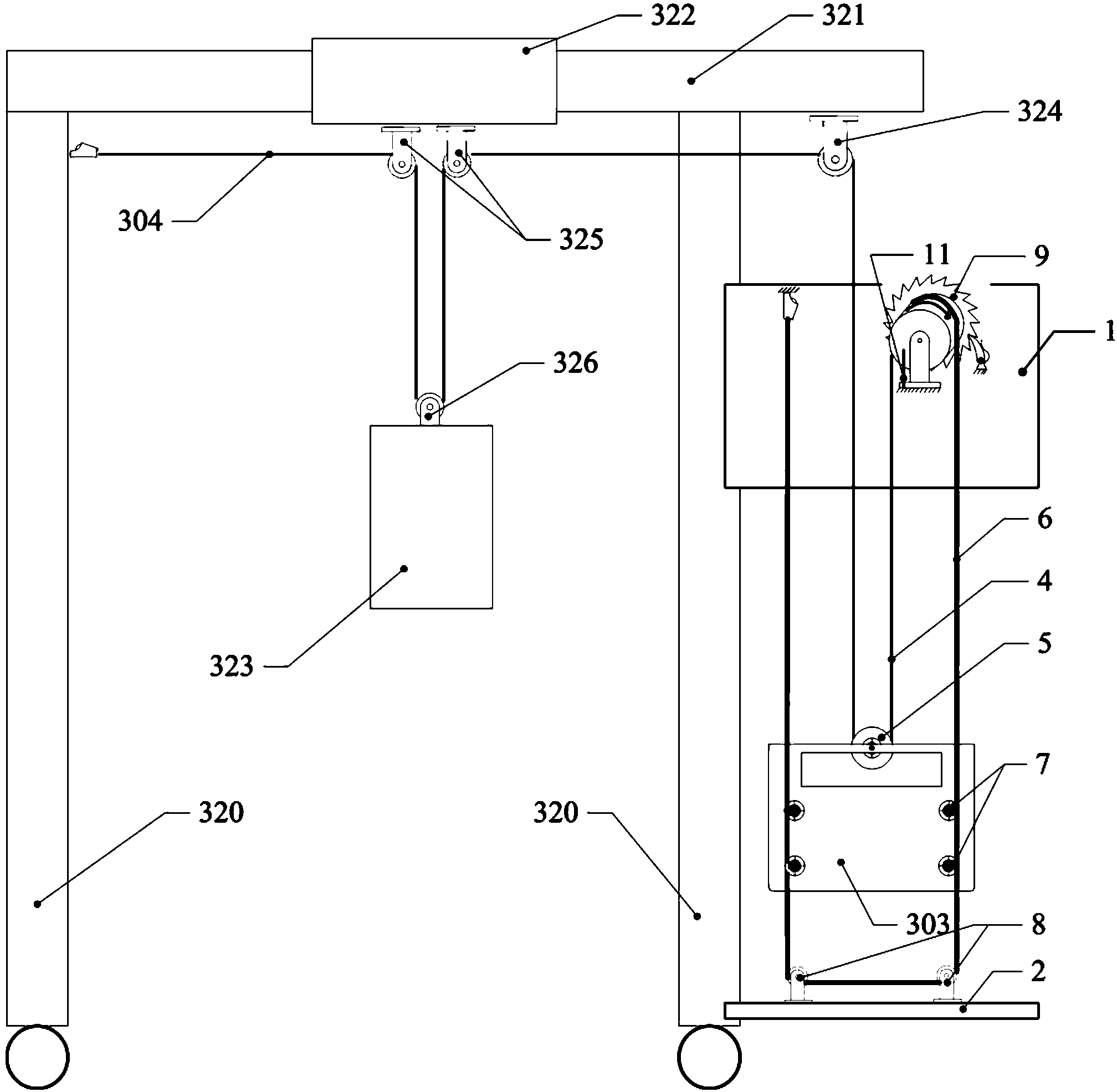

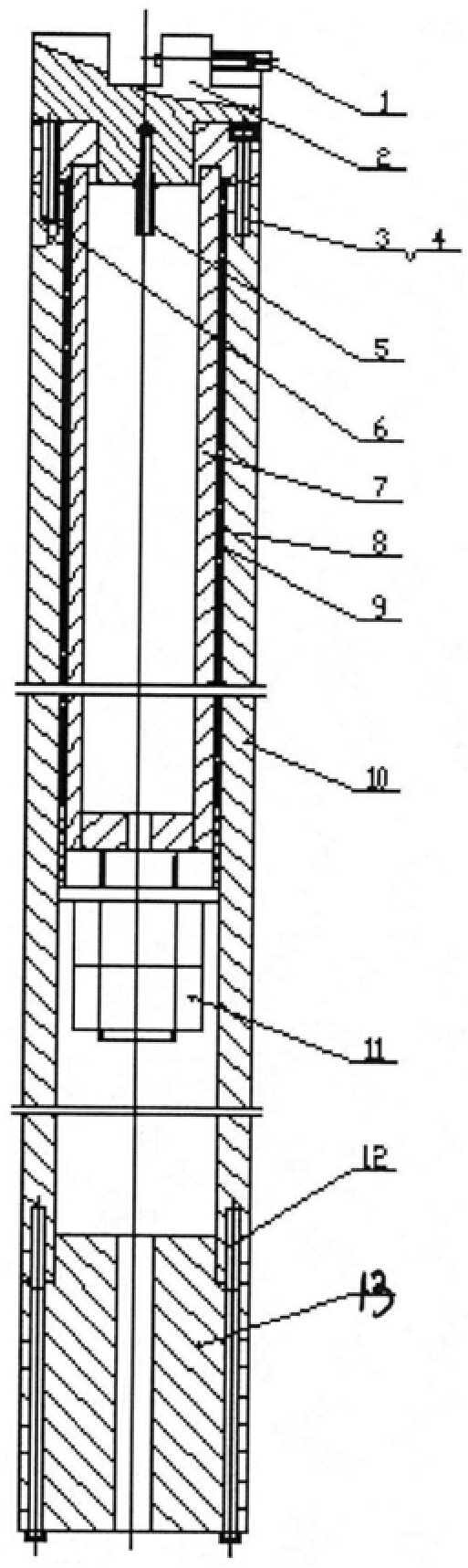

Entire flexible guide rail based on pulling force tension of lifting body and realization method thereof

InactiveCN103950808ARealize the rail function of counterweightSolve the flatnessElevatorsPull forceIndustrial engineering

The invention discloses an entire flexible guide rail based on the pulling force tension of a lifting body and a realization method thereof. The entire flexible guide rail comprises an entire guide rail steel wire rope; the entire guide rail steel wire rope forms flexible guide rails distributed in the lifting direction of the lifting body on the two sides of the lifting body through steering mechanisms; one end of the entire guide rail steel wire rope is fixed, the other end of the entire guide rail steel wire rope is pulled by the pulling force of the lifting body, and the entire guide rail steel wire rope is synchronously tensioned by the pulling force of the lifting body in the lifting process of the lifting body, so that the tensioning forces of the flexible guide rails on the two sides of the lifting body are the same. With the adoption of the technical scheme, the entire flexible guide rail can effectively solve the problem existing in an existing lifting body guide rail.

Owner:上海港研实业有限公司

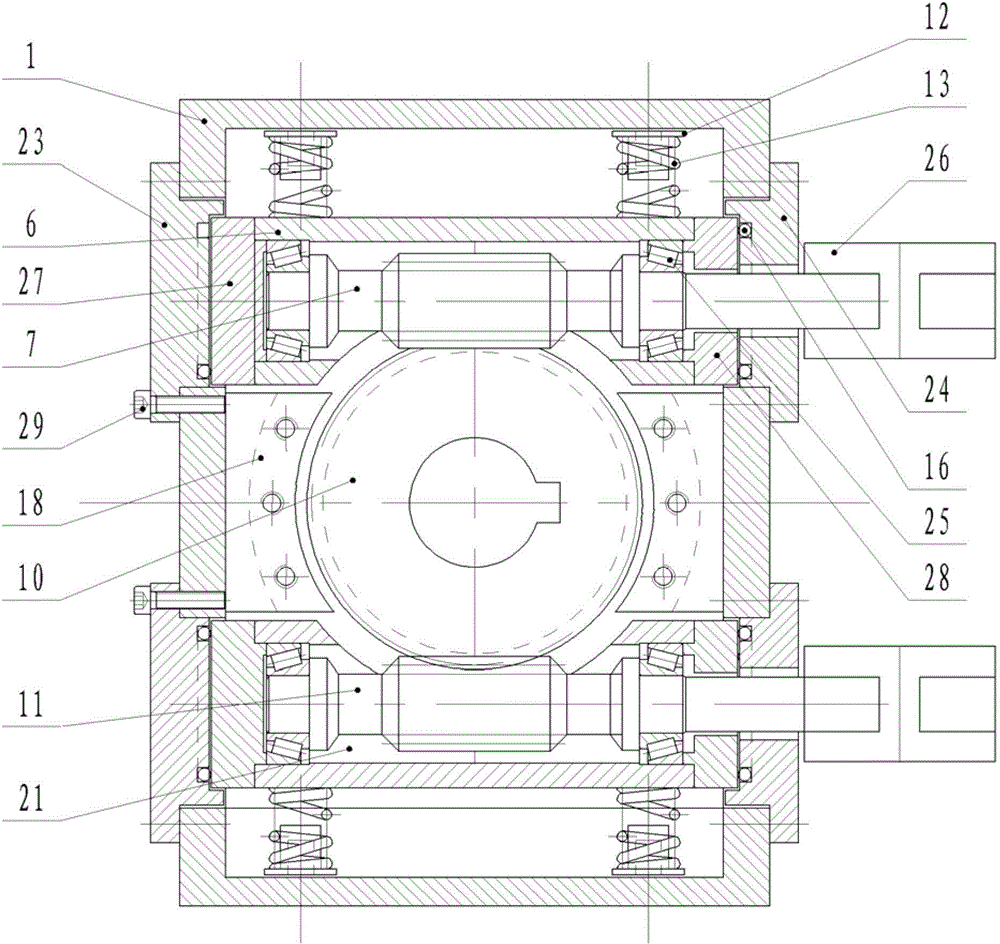

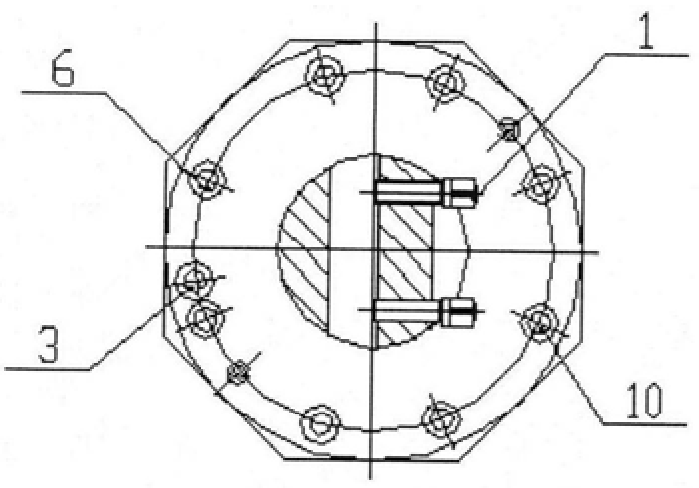

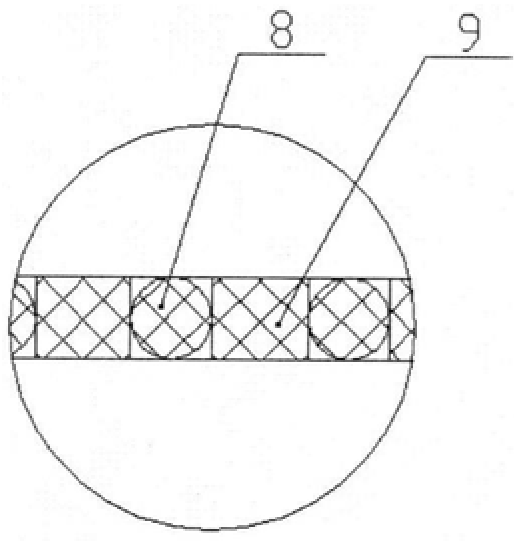

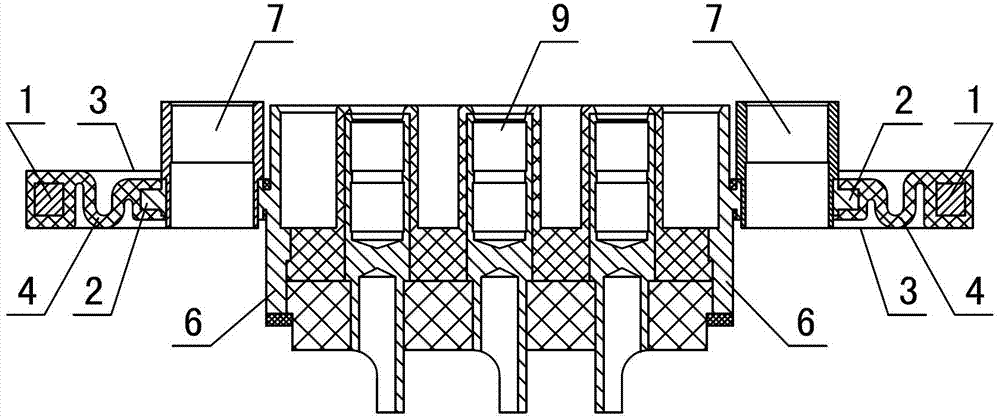

Vibration-absorbing tool holder

InactiveCN106507721BSolving resonance problemsChange the resonant frequencyBoring barsBoring/drilling machinesResonanceEngineering

The invention relates to a damping tool holder suitable for deep hole boring. The vibration-damping cutter bar includes an outer jacket and an inner sleeve. A tool seat and a nozzle connected to the coolant pipeline are arranged on the top of the cutter bar. An O-ring and an O-ring are arranged between the outer jacket and the inner sleeve. The vibration-damping layer formed by the flat washer 1 is connected with the adjustment nut 1 at the end of the vibration-damping layer formed by the O-ring 1 and the flat washer 1, and the adjustment nut 1 is placed in the jacket, which is a regular octagonal structure, at the end of the tool bar. The end is equipped with a counterweight, and the tool holder can be replaced with an extended tool holder. The vibration-damping tool rod of the present invention effectively solves the problem of the resonance of the tool rod, and the resonance frequency can be changed by adjusting the deformation of the vibration-damping layer by adjusting the nut, thereby reducing the resonance and improving the dimensional accuracy and surface quality of the product; the regular octagon of the jacket The structure greatly improves the rigidity of the tool holder. The invention adopts ordinary materials, has simple structure and low price, and can fully meet the complex damping requirements.

Owner:CAPITAL AEROSPACE MACHINERY

Multi-direction moving type connector seat

ActiveCN102931533ASolve the problem of poor anti-longitudinal vibration effectIncrease contactCoupling device detailsEngineeringShock resistance

The invention discloses a multi-direction moving type connector seat comprising a moving seat, and a connector assembly and a guide structure arranged on the moving seat, wherein the moving seat comprises a fixing plate with a hollow structure, and a moving plate arranged at the hollow position of the fixing plate, the connector assembly and the guide structure are arranged on the moving plate, an elastic strip which is fixedly connected with the moving plate and the fixing plate are arranged between the moving plate and the fixing plate, and an elastic telescopic strip is arranged on the elastic strip. The multi-direction moving type connector seat effectively solves the problems that the moving type connector in the prior art is poor in contact and shock resistance as the moving type connector in the prior art can not move longitudinally.

Owner:ZHEJIANG ZHONGHANG ELECTRONICS

Production technology for automobile spare tire cover plate with PP cellular board as base material

InactiveCN104986120ASolve the weight problemSolve rigid problemsSynthetic resin layered productsLaminationEngineeringRejection rate

The invention relates to a production technology for an automobile spare tire cover plate with a PP cellular board as a base material, and belongs to the technical field of automobile interior trim parts. The automobile spare tire cover plate with the PP cellular board as the base material is obtained through shell fabric preparation, shell fabric cutting, mold preheating, base material laying, pressing forming and postprocessing. The defects that existing spare tire cover plates are high in weight and not enough in rigidity are overcome, and the rigidity of the spare tire cover plate is improved, so that the bearing capacity of the spare tire cover plate is improved, and the weight of the spare tire cover plate is decreased so as to decrease the weight of an automobile body. Meanwhile, the production cost caused by the raw material cost is lowered. In addition, due to the fact that the production technology is simple, the rejection rate during production is lowered, raw materials are saved indirectly, and the cost for processing rejects is saved. The requirement of modern automobiles for high bearing capacity and low weight of the spare tire cover plate is met, the cost is low, the raw materials can be recycled, and the market consumption concept is met.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

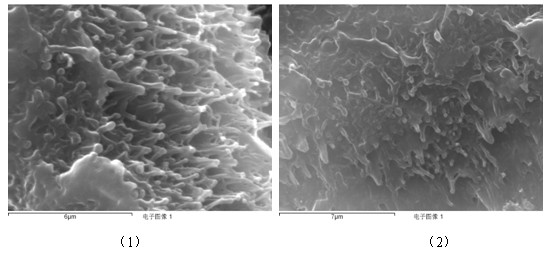

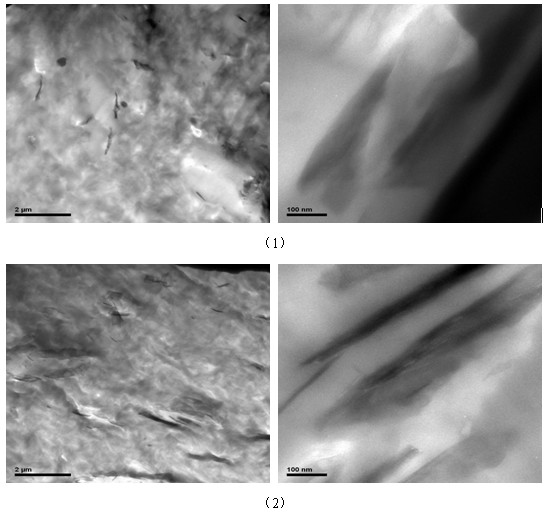

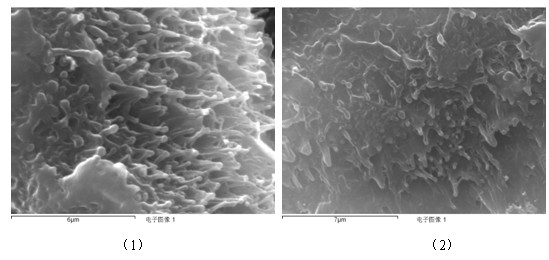

High-performance nano-composite material and preparation method thereof

The invention discloses a high-performance nano-composite material and a preparation method thereof. The high-performance nano-composite material comprises the following components in part by weight: 100 parts of high-density polyethylene, 2 to 10 parts of hydrotalcite and 20 parts of ethylene-acrylic acid copolymer. Ethylene and acrylic acid are used as a compatilizer and a toughening agent, so that the contradiction between the rigidity and the toughness of the composite material is resolved, and the toughness of the prepared high-density polyethylene / hydrotalcite nano-composite material can be greatly improved; in this way, the hydrotalcite which is not organically modified can be adopted, so that the production cost is reduced, and side reactions are avoided in melt blending; and the preparation method is simple and easy operate, and can be used for industrialized production, and the application value and application range of the high-density polyethylene / hydrotalcite nano-composite material are further developed.

Owner:贵州省复合改性聚合物材料工程技术研究中心

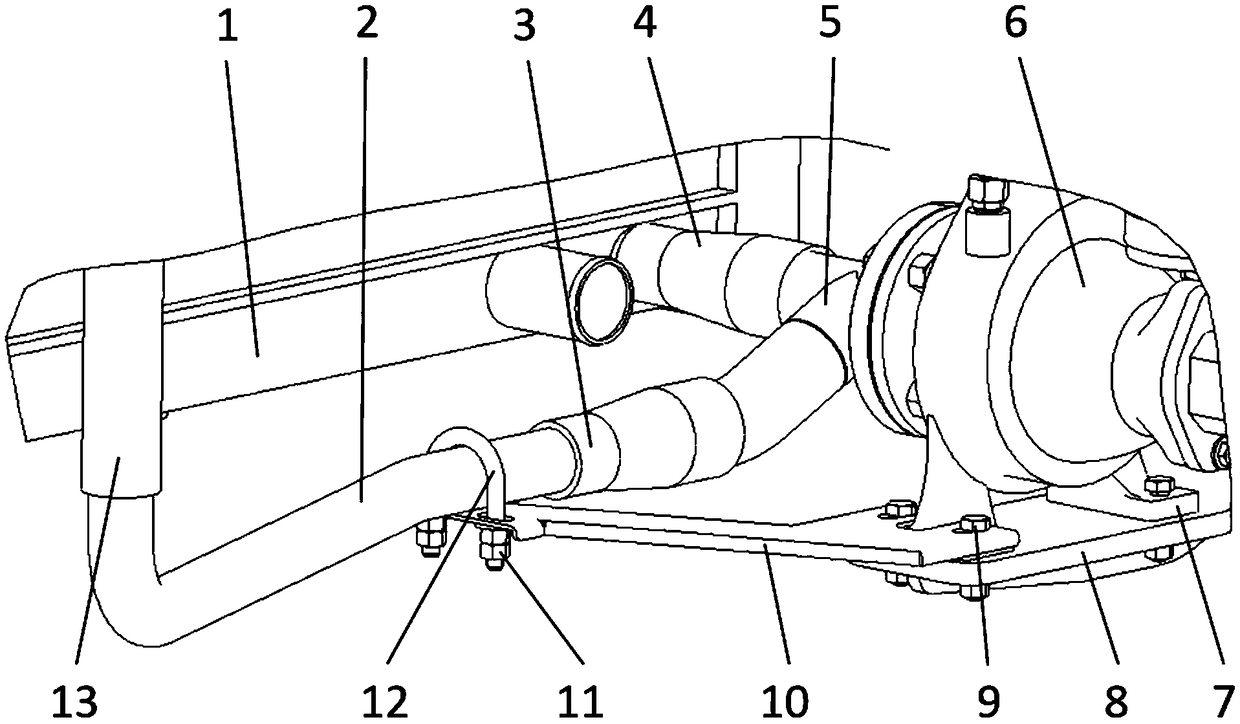

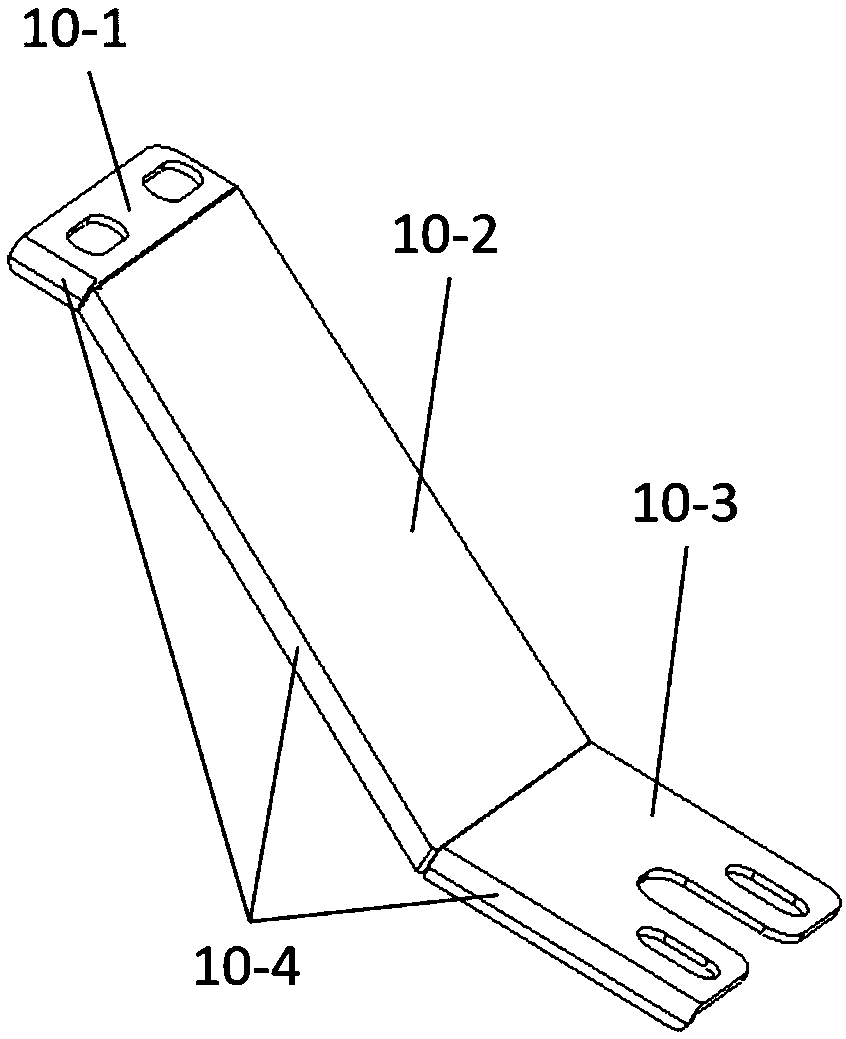

Damping fixing structure for suspended cooling metal pipe of articulated dump truck

PendingCN108638841ASolve the cooling problemSolve rigid problemsPropulsion coolingTruckPetroleum engineering

The invention discloses a damping fixing structure for a suspended cooling metal pipe of an articulated dump truck. A three-way metal pipe and mounting feet are arranged on a water pump, and the waterpump is fixed on a machine frame through the mounting feet; one path of the three-way metal pipe is connected with a radiator through a second rubber pipe, the other path of the three-way metal pipeis connected with one end of the suspended cooling metal pipe through a first rubber pipe, and the other end of the suspended cooling metal pipe is connected with a third rubber pipe which is fixed onthe machine frame. A fixed support comprises an upper mounting plane, a middle bent part and a lower mounting plane, and the fixed support is fixed on the machine frame through the lower mounting plane and supports and fixes the suspended cooling metal pipe through the upper mounting plane. Due to the fact that the metal pipe and the rubber pipes are connected in a staggered mode mutually, the problems of heat dissipation, rigidity and vibration resistance of a cooling pipeline are solved; and the fixed support is arranged and is consistent with the rubber pipes at the two ends of the suspended cooling pipeline in fixing source (the vibration frequency is the same), the position of the fixed support can be adjusted in the longitudinal direction and the horizontal direction, the problem offixation is solved, the cost is low, and the practicability is high.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

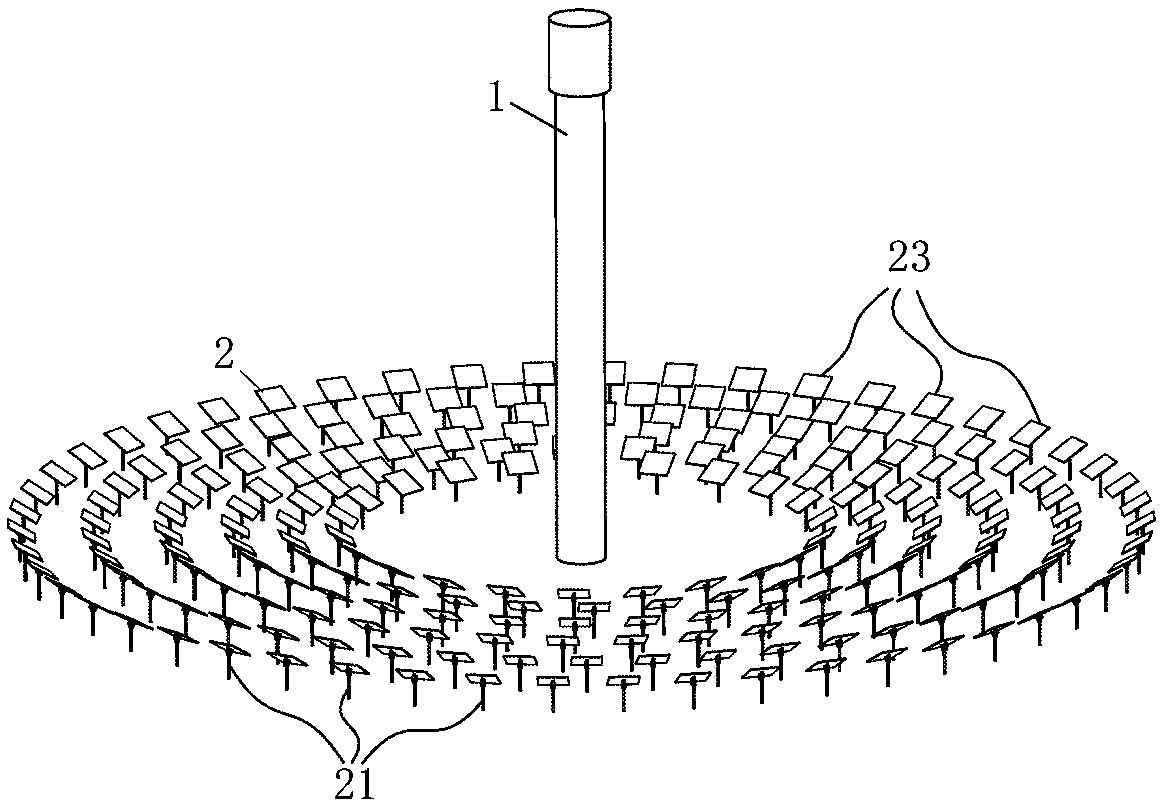

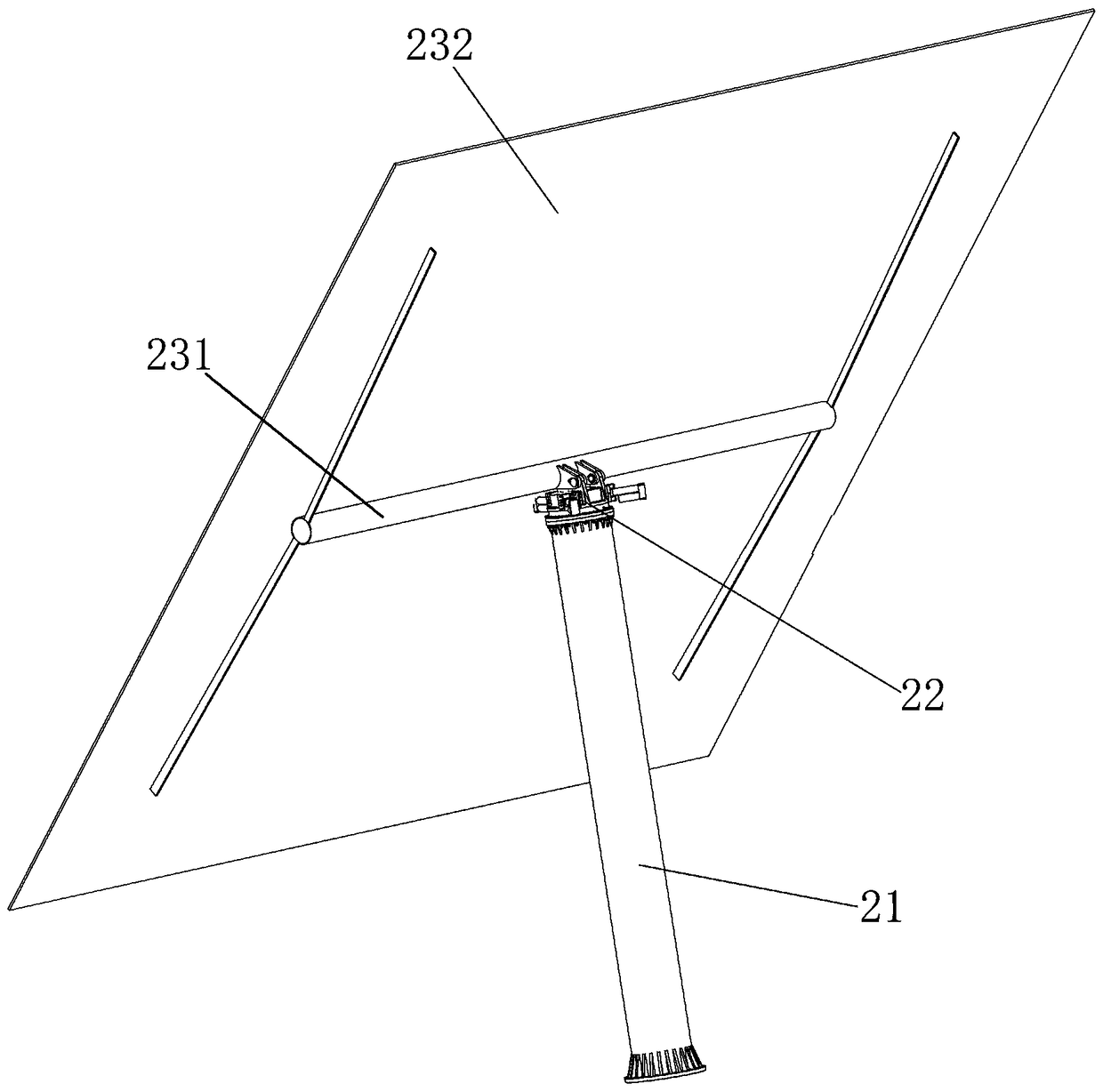

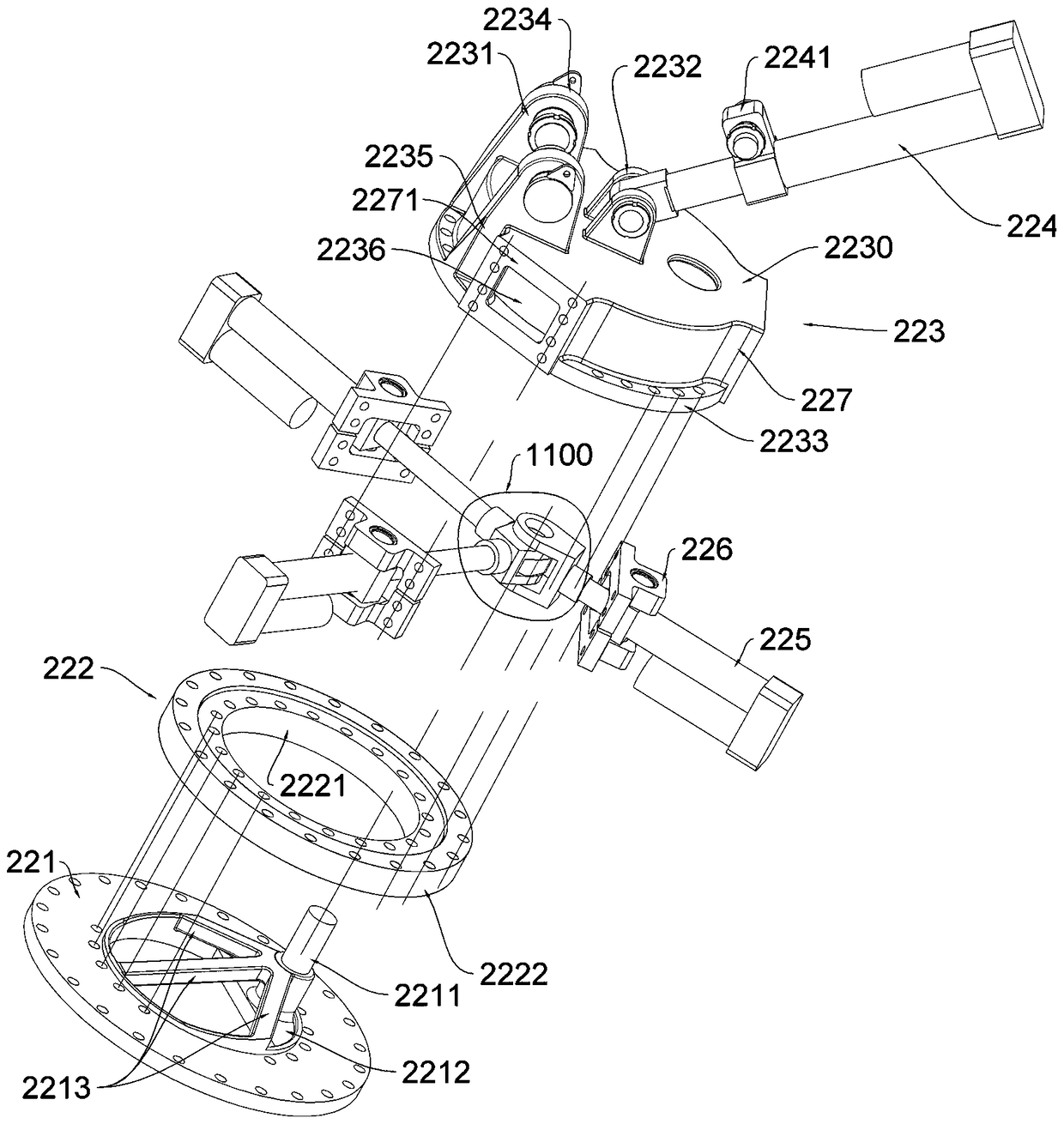

Tower type photo-thermal power generation system, heliostat, heliostat tracking driving device and heliostat rotating table

PendingCN108954861AHigh precisionImprove positional accuracyPhotovoltaic supportsSolar heating energyHinge angleEngineering

The invention relates to the field of photo-thermal power generation devices, in particular to a tower type photo-thermal power generation system, a heliostat, a heliostat tracking driving device anda heliostat rotating table. The heliostat rotating table comprises a rotating table body, a reflecting mirror hinge seat arranged on the rotating table body and a pitch angle oil cylinder hinge seat arranged on the rotating table body. The heliostat rotating table is of a casting formed integrated structure, and the reflecting mirror hinge seat and the pitch angle oil cylinder hinge seat are integrally formed with the rotating table body in a casting manner. The heliostat rotating table is integrally formed, and it is ensured that the position precision obtained after primary machining is improved while rigidity of the rotating table is ensured. Compared with a current assembly type heliostat rotating table, the heliostat rotating table is high in precision, and the problems that the installation precision and rigidity of the current heliostat rotating table are low are solved.

Owner:洛阳斯特林智能传动科技有限公司

Expansion device and processing method for facing of large-size medium-thickness cylindrical part

ActiveCN104353857ASolve self-importanceSolve rigid problemsExpansion mandrelsHydraulic cylinderEngineering

The invention relates to an expansion device and a processing method for facing of a large-size medium-thickness cylindrical part. The expansion device adopts the technical scheme that the expansion device comprises a base, a guide plate, an expansion block, a guide seat, an expansion jacking head, a conical head, a support plate, a guide column b, a loosening jacking head, a single-action hydraulic oil cylinder, a manual hydraulic cylinder and a high pressure hydraulic oil pipe, wherein the base is formed by welding an upper support plate, a lower support plate and support columns, the support columns are uniformly distributed along the circumference, the guide seat is fixedly arranged on the upper support plate of the base through a bolt, the guide seat is provided with an inner cavity, the guide column b is fixedly arranged on the lower support plate of the base through a bolt, and the guide seat, the guide column b and the base are coaxially arranged. By adopting the technical scheme, the expansion device has the advantages that the problems of large self weight, higher rigidity, and unreliable manual expansion of traditional thread in the large-size medium-thickness cylindrical part are solved; the manufacturing is simple, the time is shortened, the labor is saved, the fund is reduced, the implementation is easy, and the working efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Bus control manner self-growing soft robot based on flexible circuit

InactiveCN110861078ASolve rigid problemsSolve complexityProgramme-controlled manipulatorFlexible circuitsControl system

The invention relates to soft robots, in particular to a bus control manner self-growing soft robot based on a flexible circuit. The robot comprises a self-growing soft robot growing type main body, plane steering mechanisms and a bus type control system. The top end of the self-growing soft robot growing type main body is turned over towards the inner side to be wound in order, the self-growing soft robot growing type main body is inflated and turned over outwards to grow forwards, multiple wrinkle structures are symmetrically and evenly distributed on the outer side surface of the self-growing soft robot growing type main body along the two axial sides, the plane steering mechanisms are arranged in the wrinkle structures, the inner side of each plane steering mechanism is connected witha round controller, two adjacent round controllers are connected through the flexible circuit, maintaining and releasing of the wrinkle structures can be finished, turning of the self-growing soft robot growing type main body is achieved, and through the bus type control system, the problems that a control circuit is large in rigidity, complex in circuit and difficult to integrate are solved.

Owner:HARBIN INST OF TECH

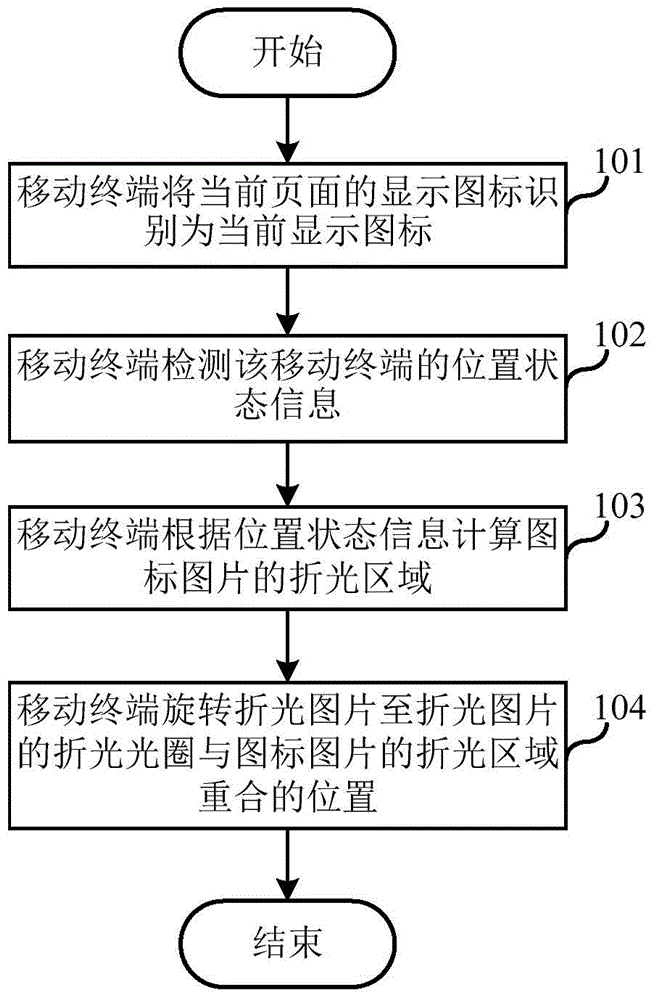

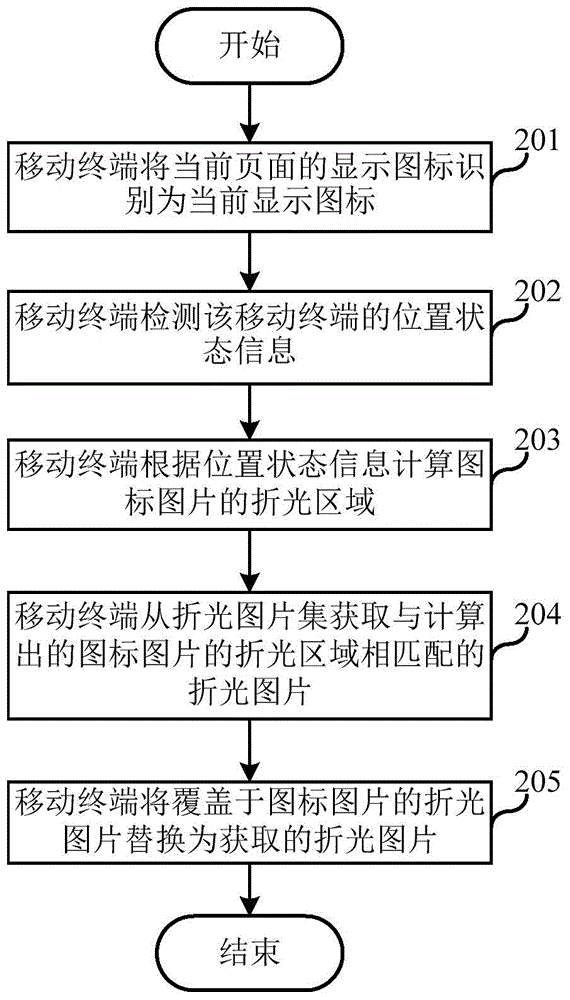

Mobile terminal and icon display method thereof

InactiveCN104951209AImprove experienceSolve rigid problemsInput/output processes for data processingComputer terminalComputer engineering

The invention discloses a mobile terminal and an icon display method thereof. The icon display method of the mobile terminal comprises the following steps that the mobile terminal detects position status information of the mobile terminal, and the mobile terminal adjusts the light refraction area of at least one current display icon of the mobile terminal according to the position status information. According to the mobile terminal and the icon display method thereof, the problem that a frame of a display icon of the mobile terminal is rigid is solved, and therefore user experience is improved.

Owner:SHANGHAI YUDE COMM TECH

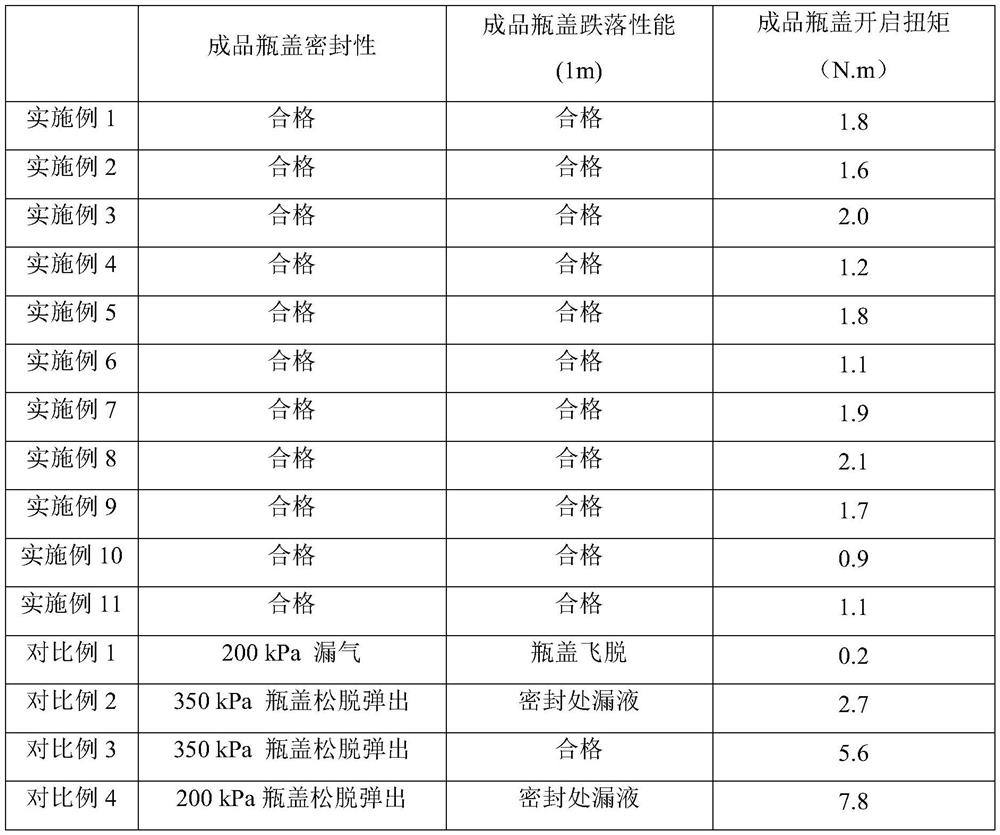

Method for preparing oral liquid plastic bottle

The invention relates to a method for preparing a medicine bottle and particularly discloses a method for preparing an oral liquid plastic bottle. The method for preparing the oral liquid plastic bottle includes the steps of mixing plastic particles with a nucleating agent in proportion to be then blended and modified by a twin-screw extruder to obtain a polypropylene composite modified material,and then allowing the polypropylene composite modified material to conduct molding, injection molding, blow molding and demolding processes to obtain a finished product of a medicine bottle, wherein the plastic particles include 80 parts of PP (polypropylene) and 15 parts of LDPE (low-density polyethylene). The method for preparing the oral liquid plastic bottle has the advantages of successfullysolving the shortcomings of insufficient rigidity and not impact resistance of ordinary PP materials with a uniform bottle wall by blending the PP with other plastic ingredients, providing materials that are heat resistant and convenient for production and processing, solving the problems of low gloss and transparency of PP materials and allowing the oral liquid plastic bottle to be neat through the addition of the nucleating agent, and allowing the oral liquid plastic bottle to replace a traditional glass bottle as an oral liquid medicine bottle.

Owner:慈溪市亿邦机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com