Patents

Literature

77results about How to "Improve positional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

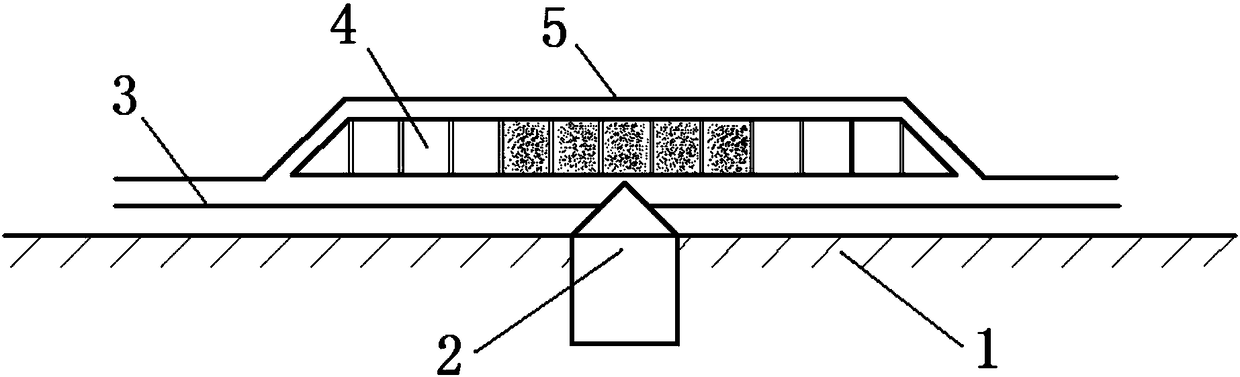

Writing device for color electronic paper

ActiveUS7292231B2Improve color accuracyImprove positional accuracyCathode-ray tube indicatorsSolid materialCMOS sensorElectric field

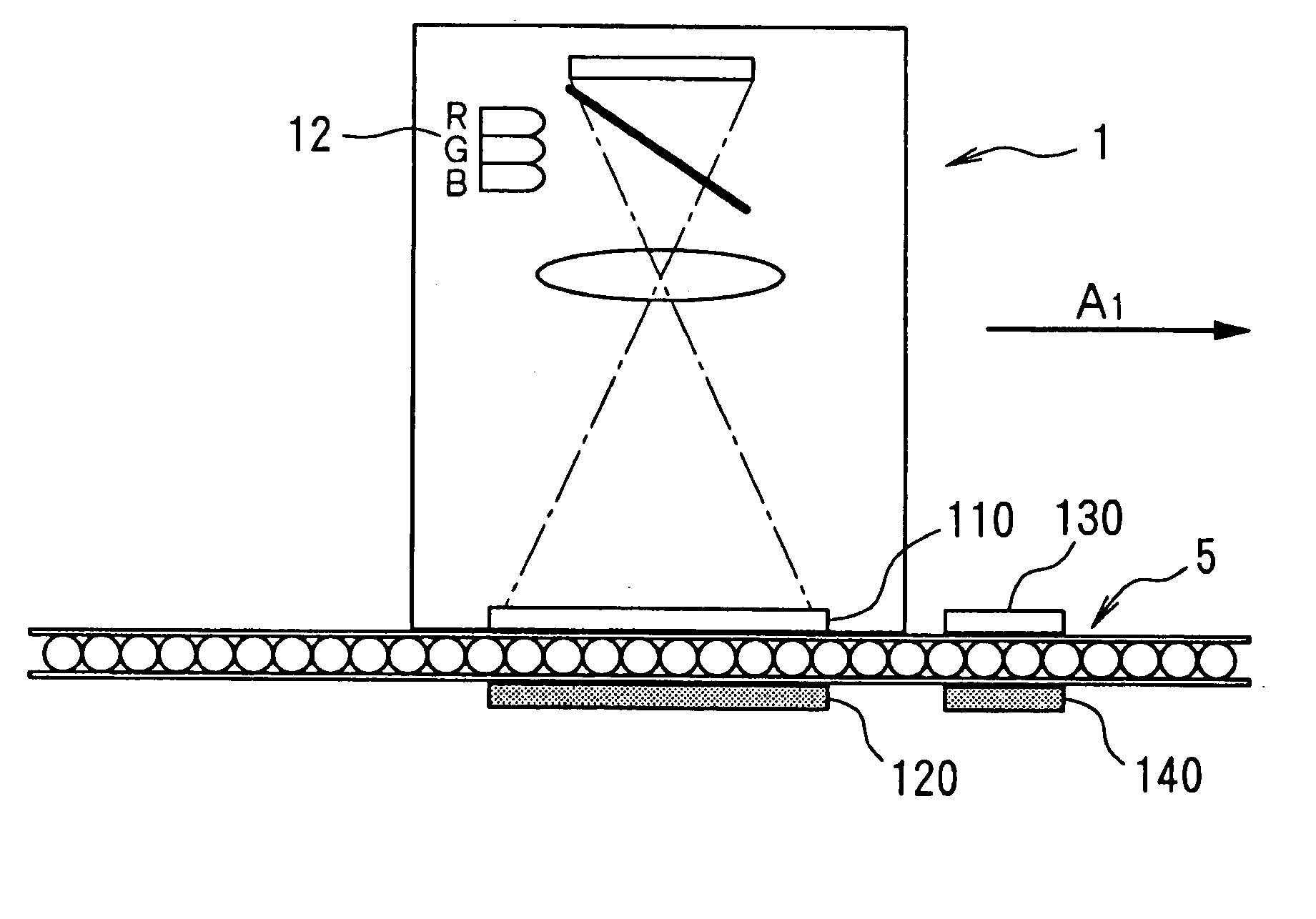

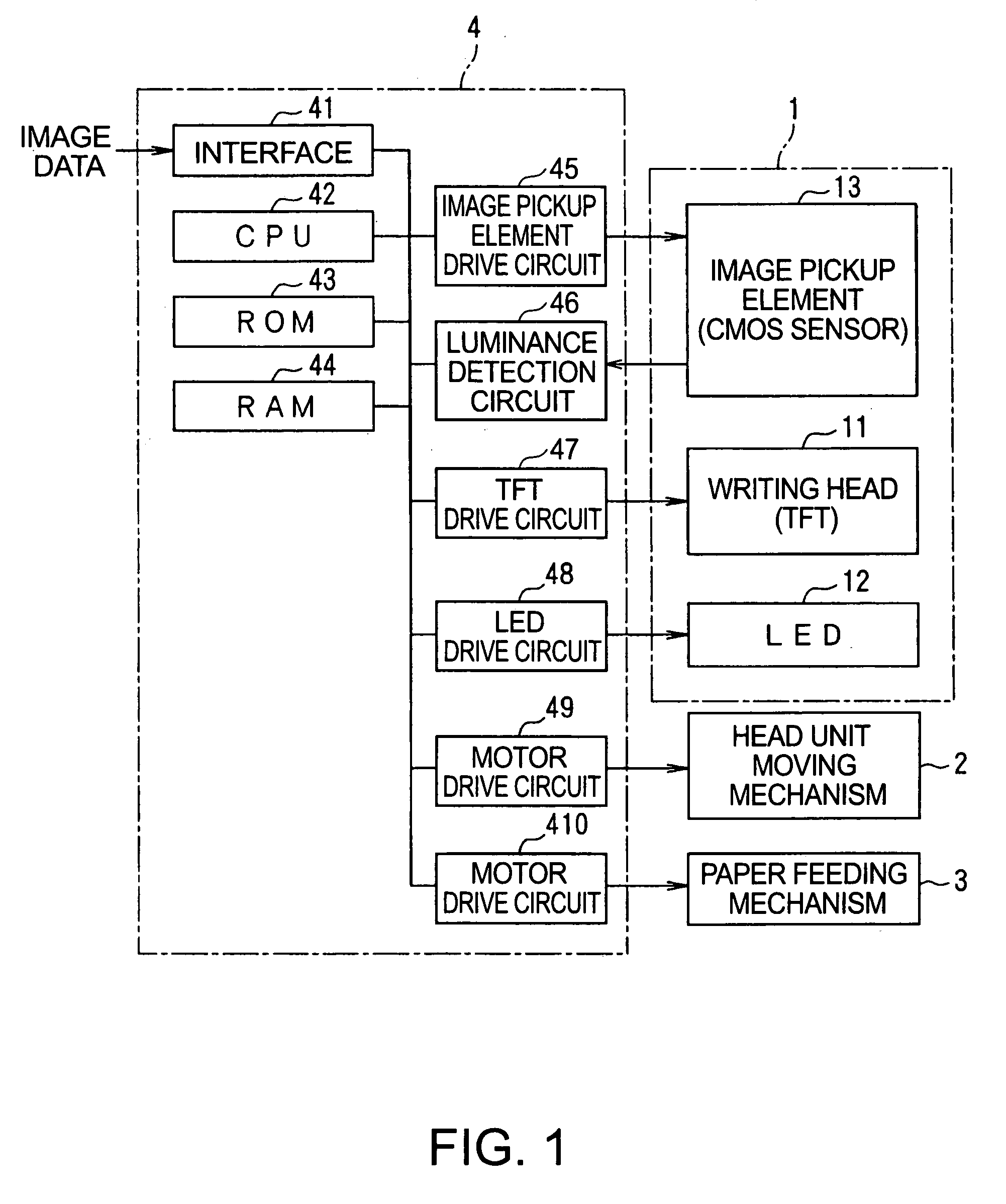

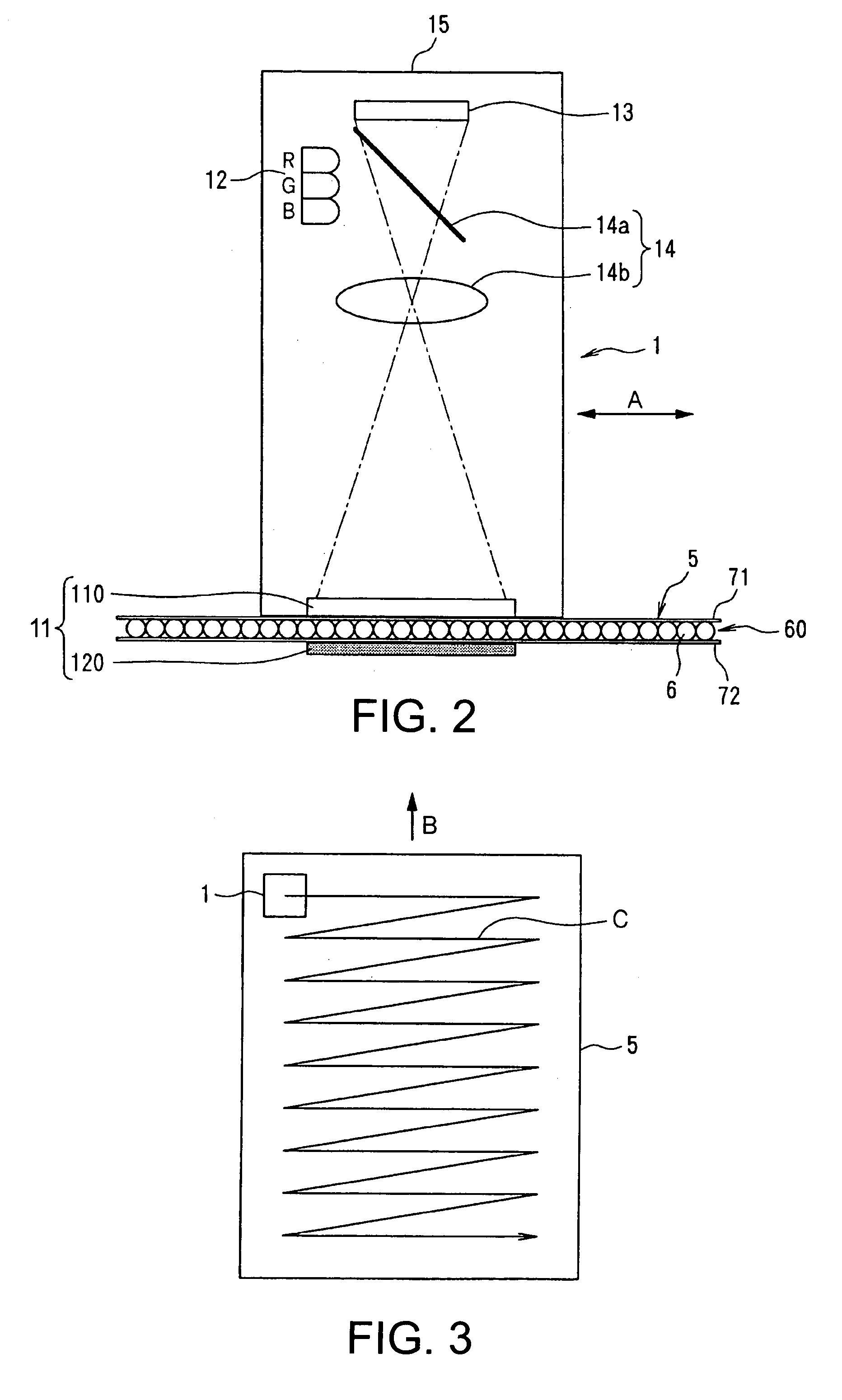

A writing device is provided for color electronic paper which is capable of performing full color display. The writing device includes a head unit, a head unit moving mechanism which moves the head unit in a first direction, a feeding mechanism which moves electronic paper, and a controller. The head unit includes a writing head, an LED which emits light of three primary colors, an image sensing element consisting of a CMOS sensor, and an optical system. The writing head includes an optically transparent head main portion provided with pixel electrodes, and a common electrode (counter electrode). In the controller, an arrangement of three types of microcapsules in a microcapsule layer is detected to perform electric field formation for each of the pixel electrodes based on a detection result.

Owner:E INK CORPORATION

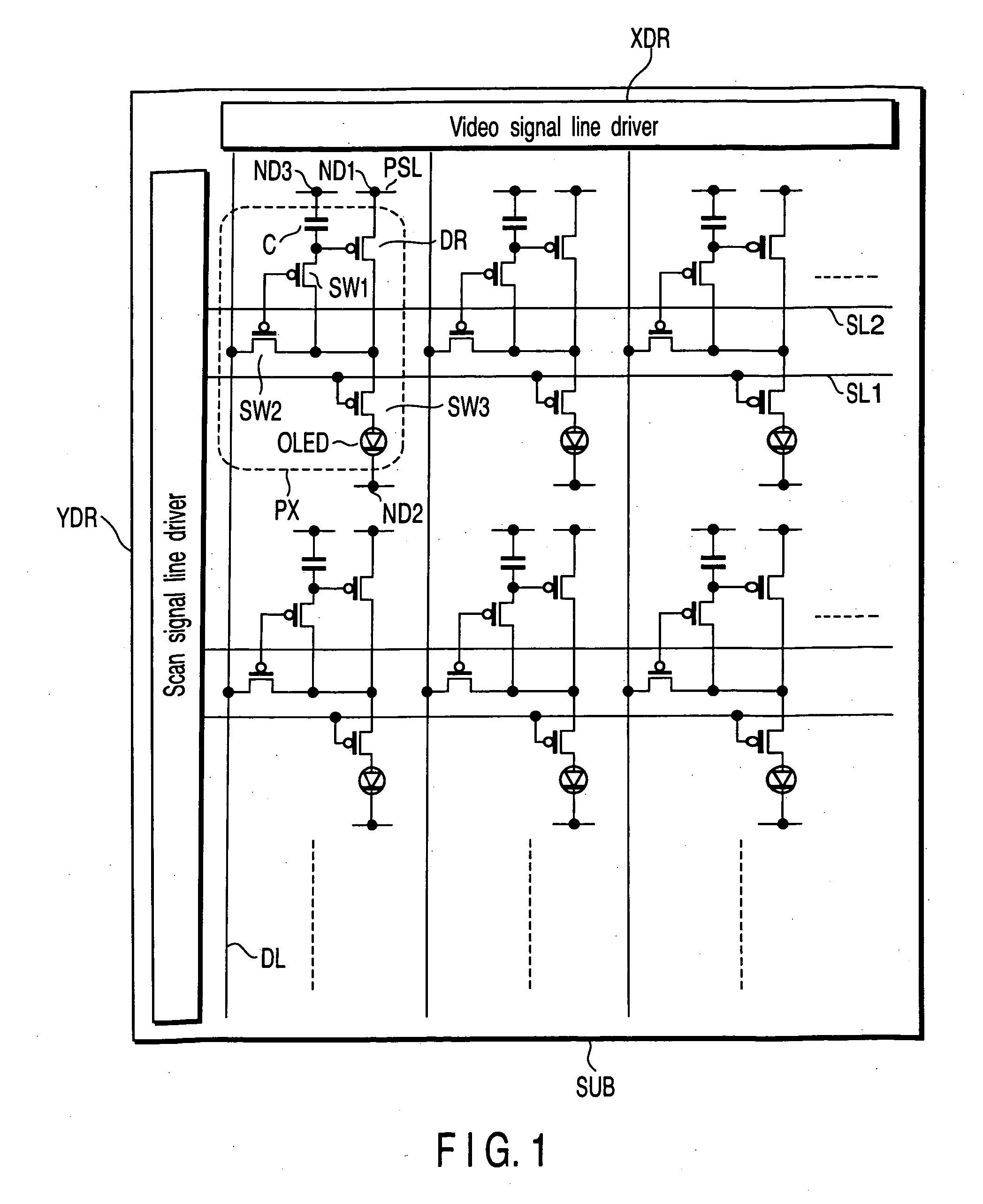

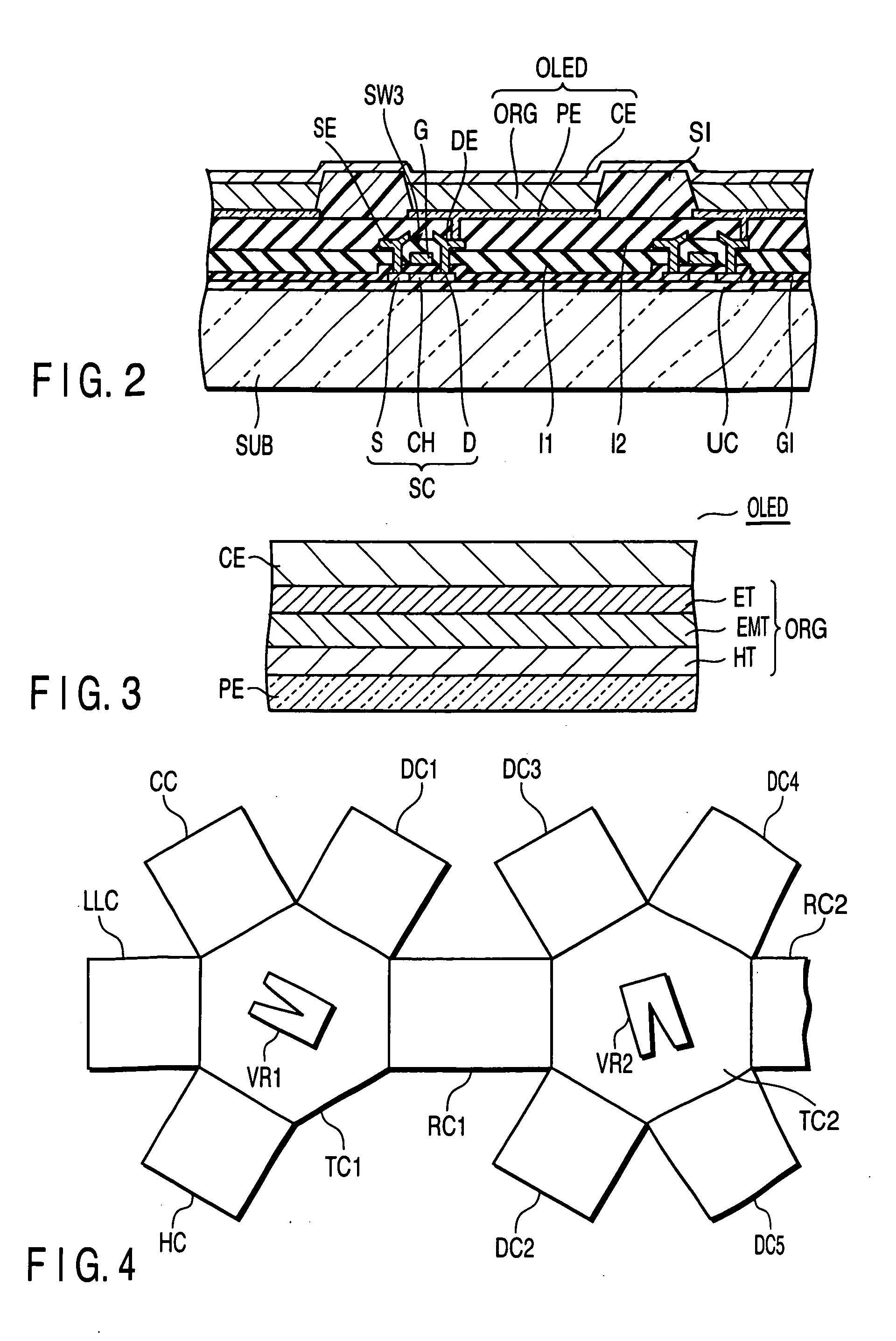

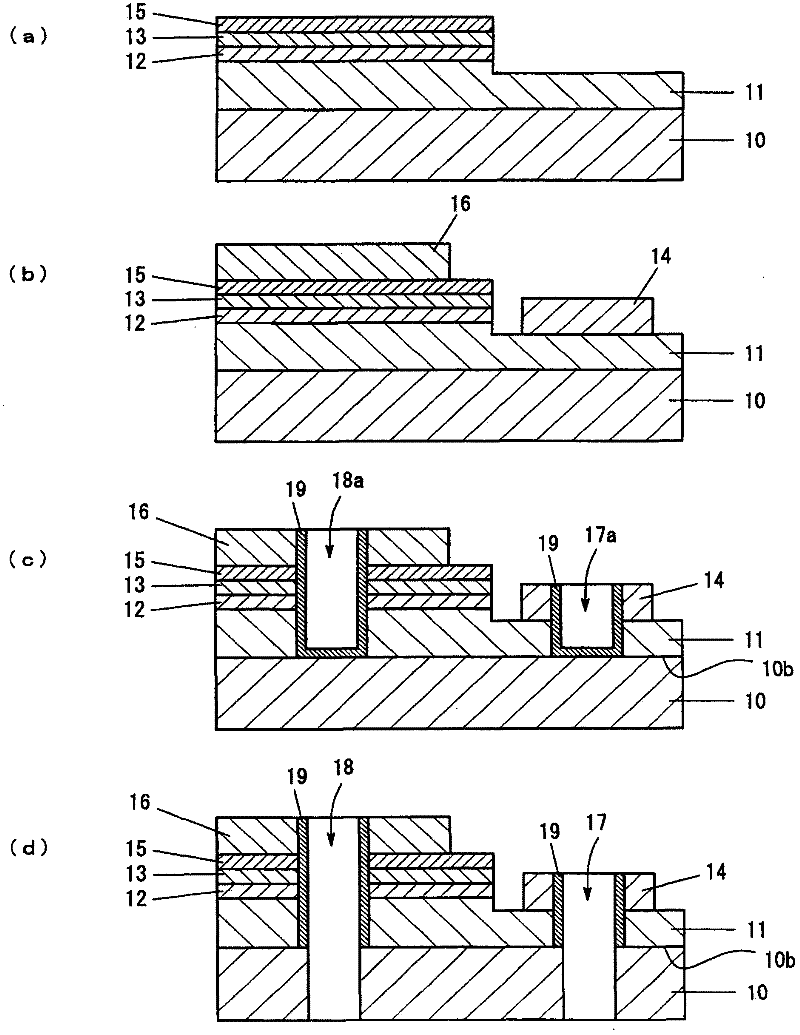

Method and apparatus for manufacturing display

ActiveUS20060057750A1Improve positional accuracySuppressing temperature of substrateThyristorElectroluminescent light sourcesMetal substrateDisplay device

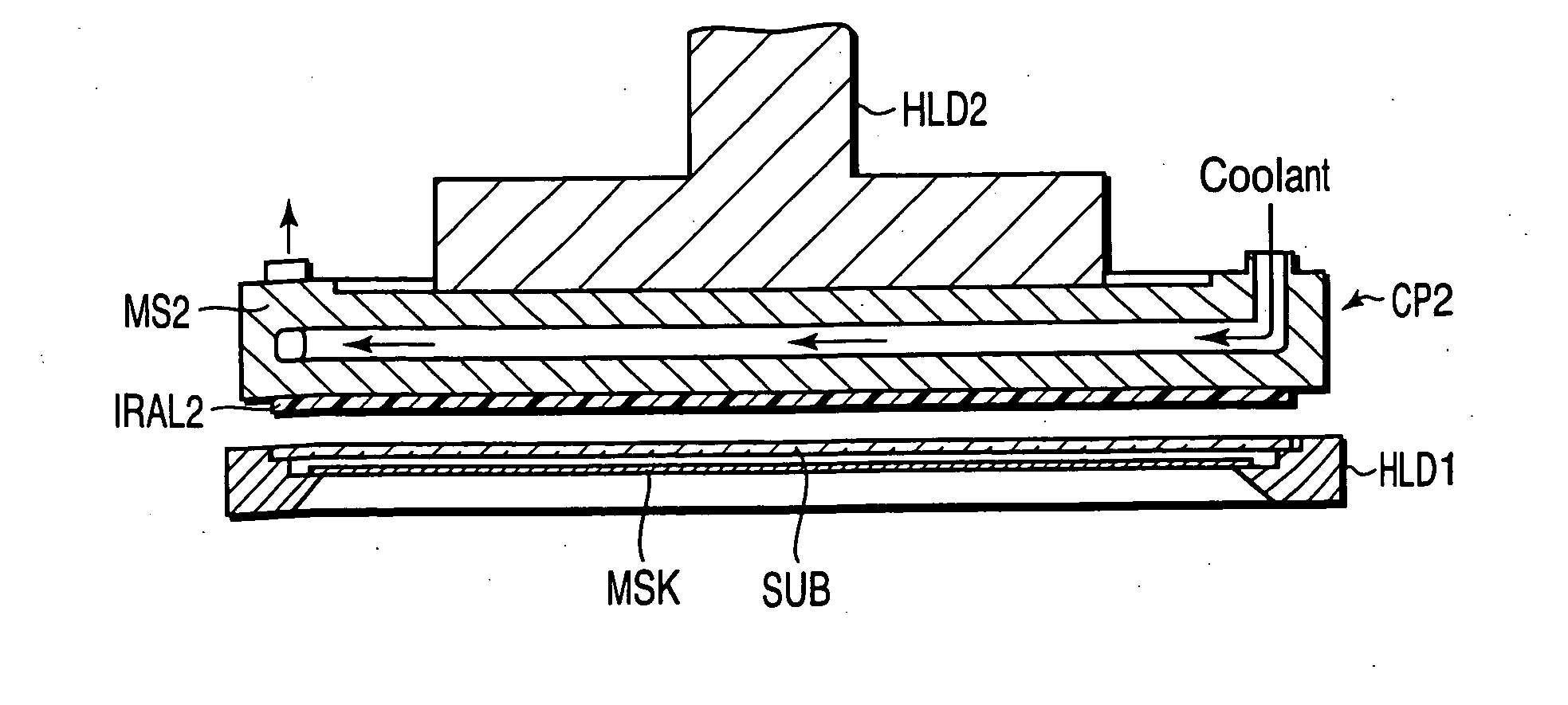

Provided is a method of manufacturing a display which includes an insulating substrate and a structure formed on the insulating substrate and including a display element, including forming a patterned layer as a portion of the structure on the insulating substrate by vapor deposition in vacuum using a mask, and cooling the insulating substrate before and / or during formation of the patterned layer by arranging a cooling plate which comprises a metal substrate and an infrared absorption layer covering a main surface of the metal substrate and being larger in infrared absorptance than the metal plate such that the infrared absorption layer faces the insulating substrate.

Owner:JAPAN DISPLAY CENT INC

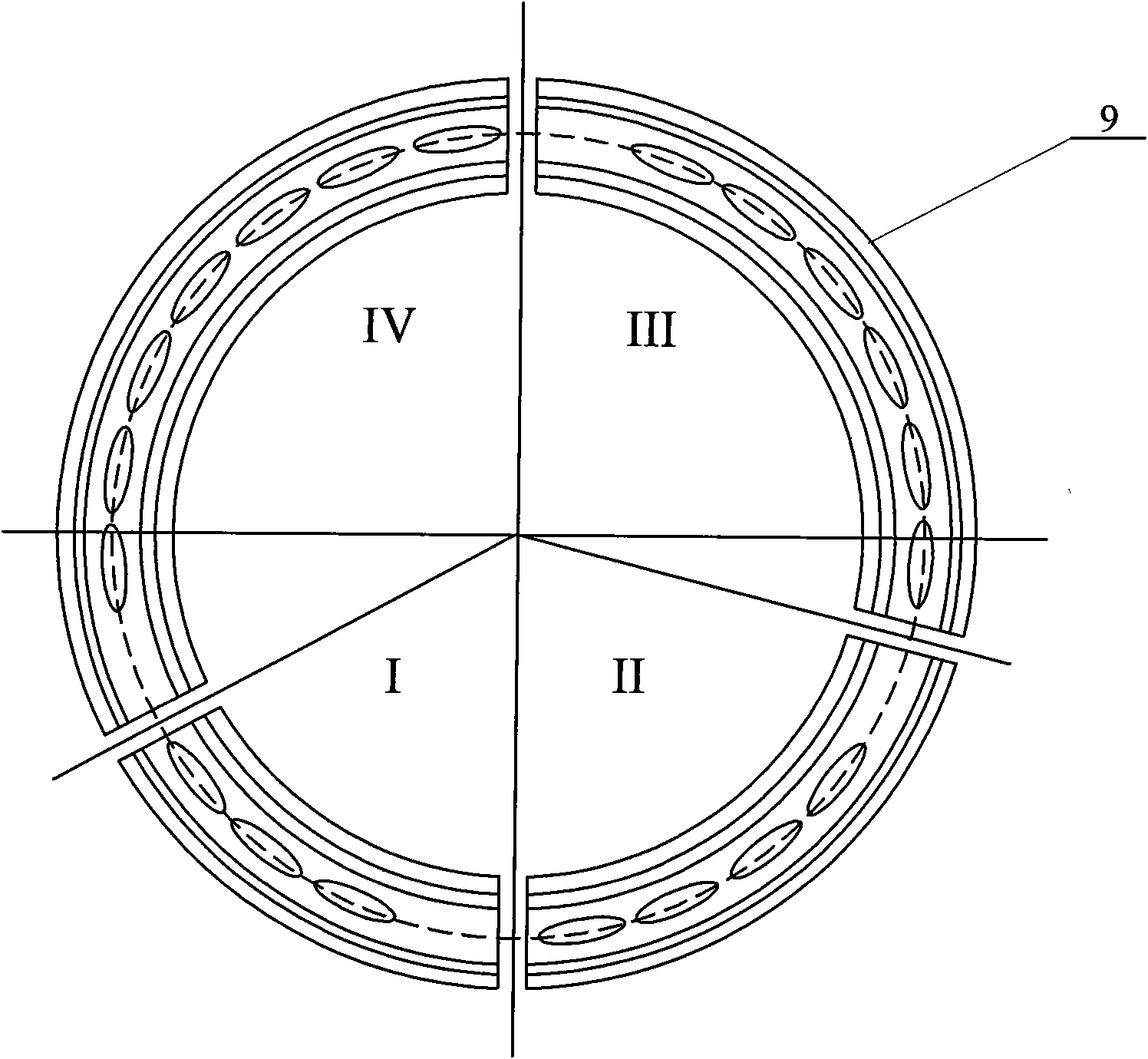

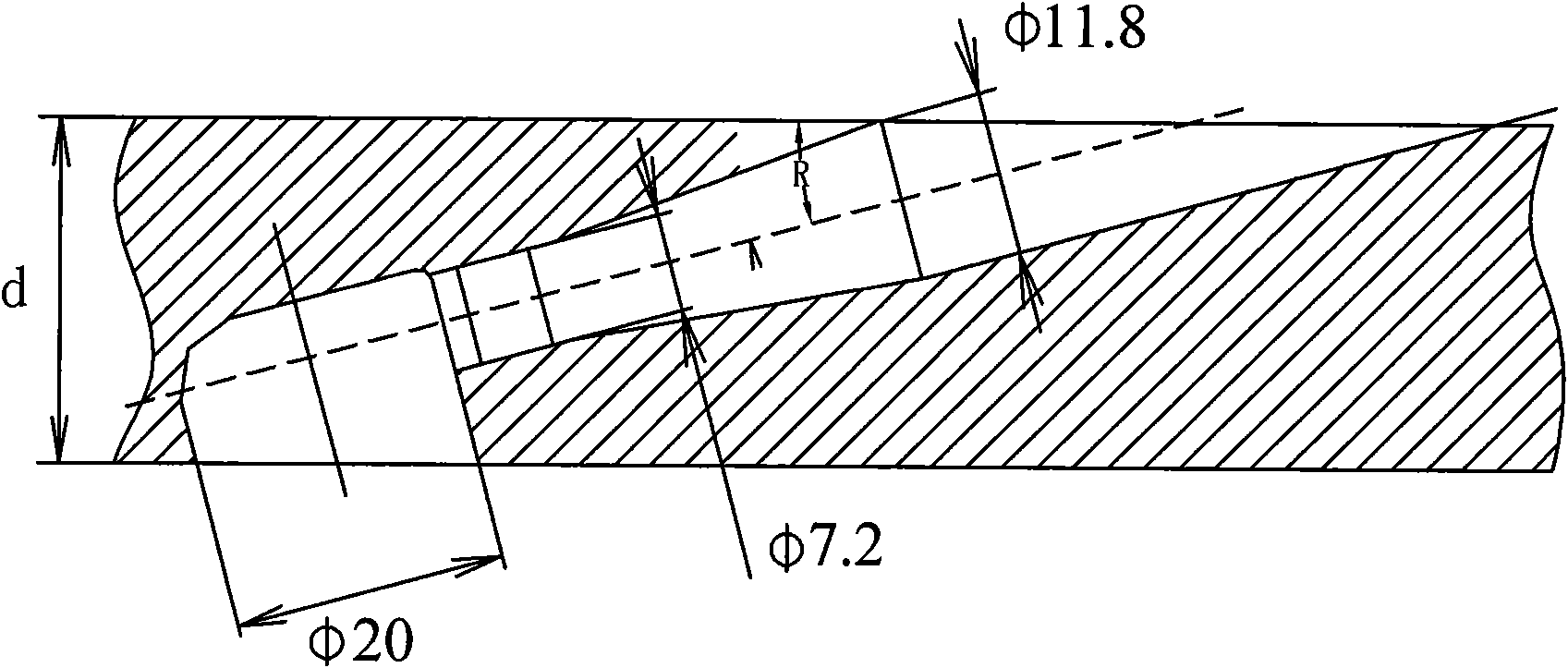

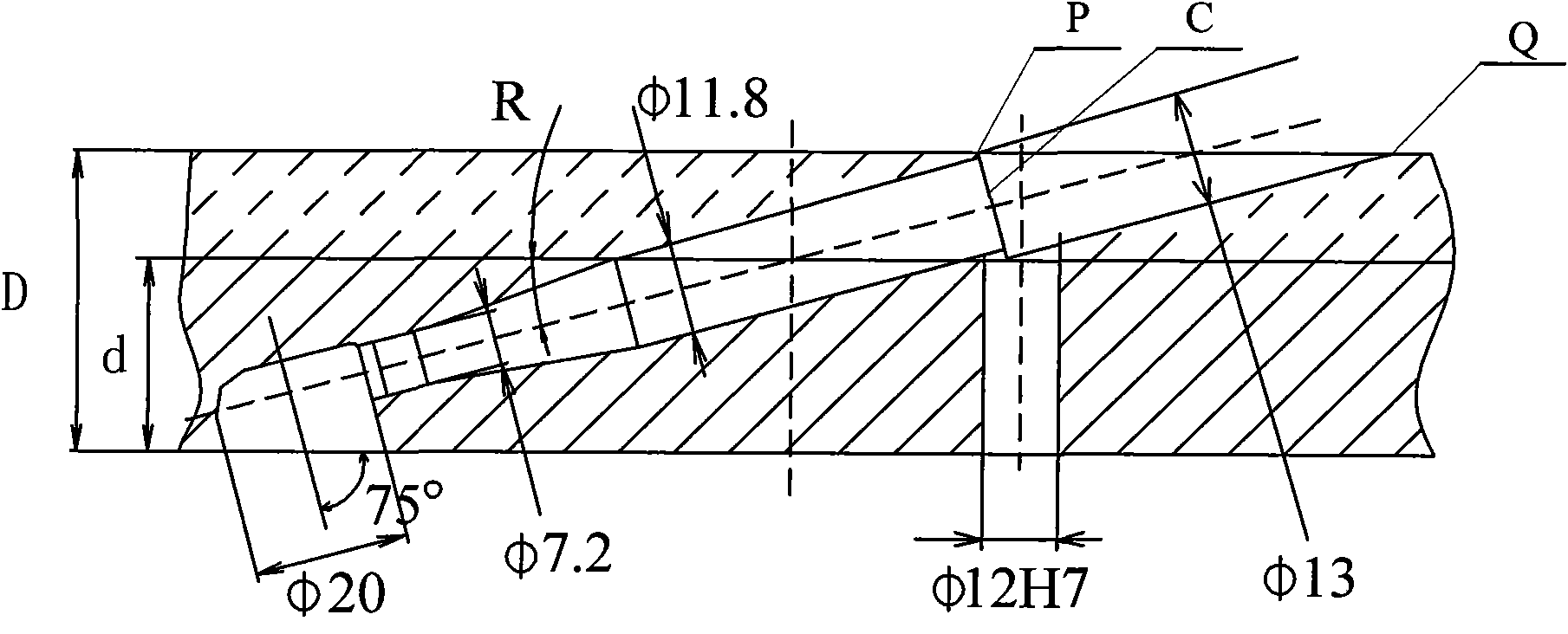

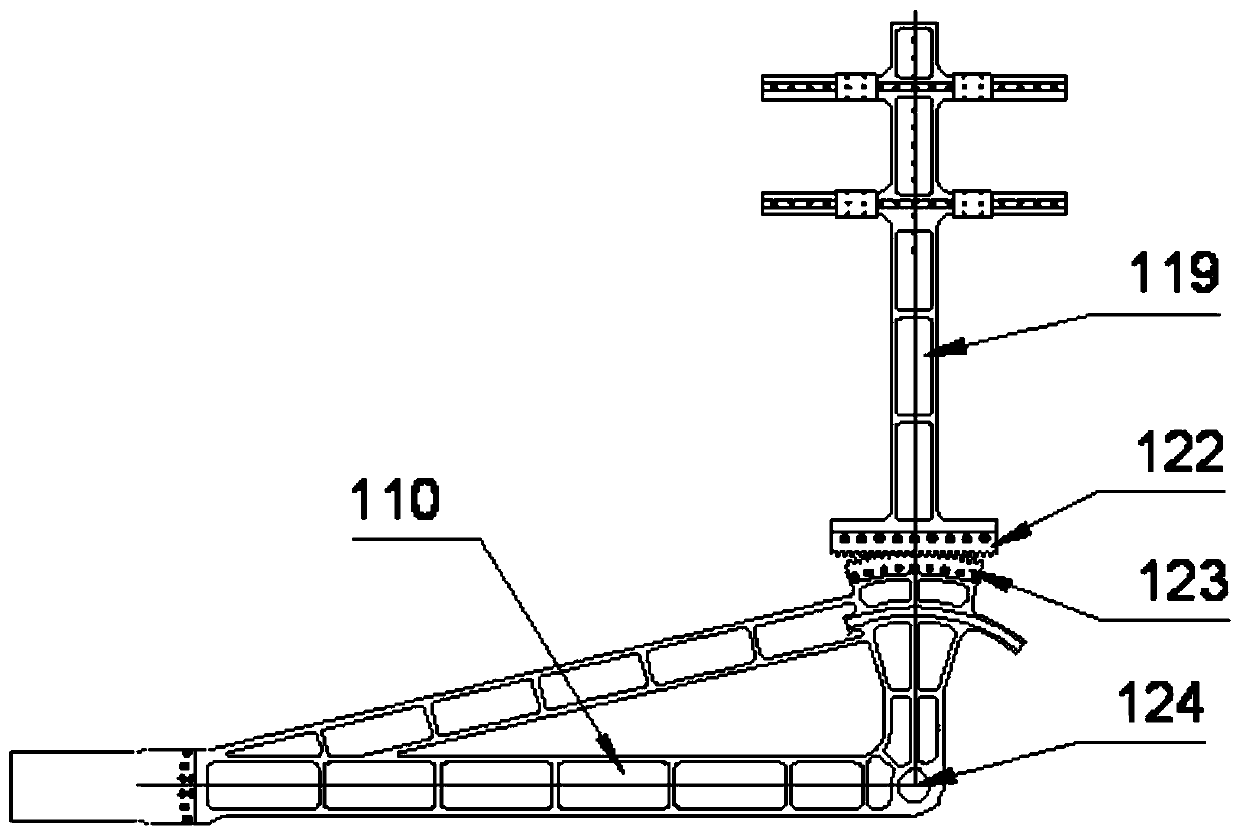

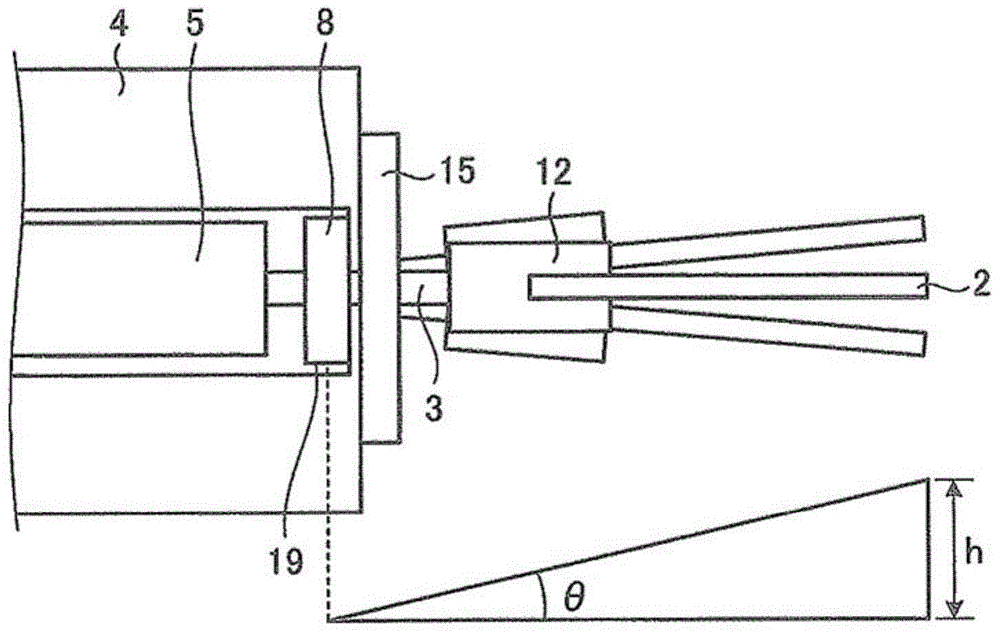

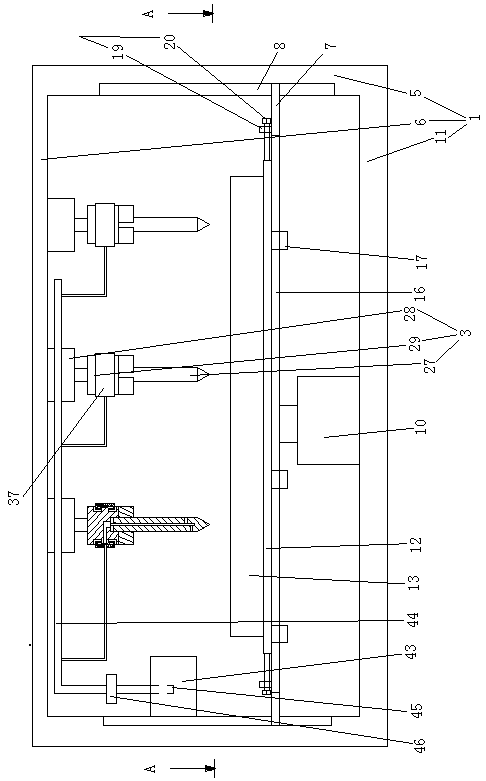

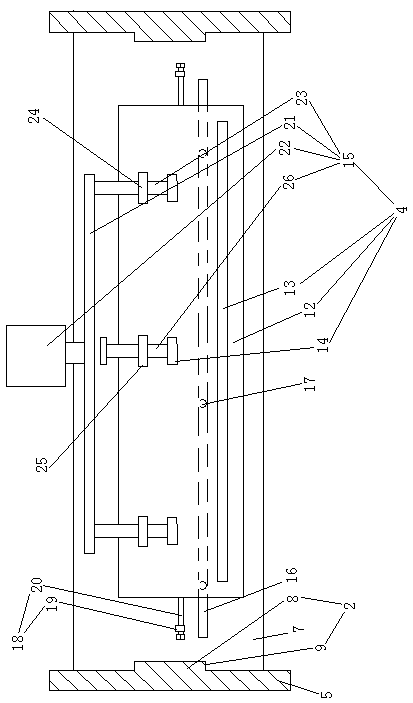

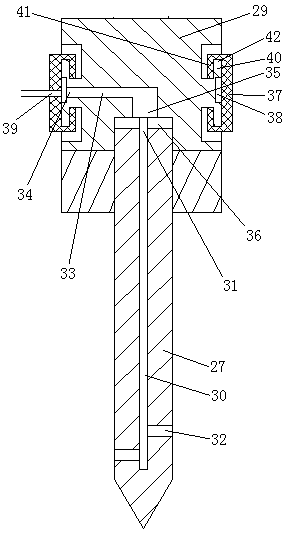

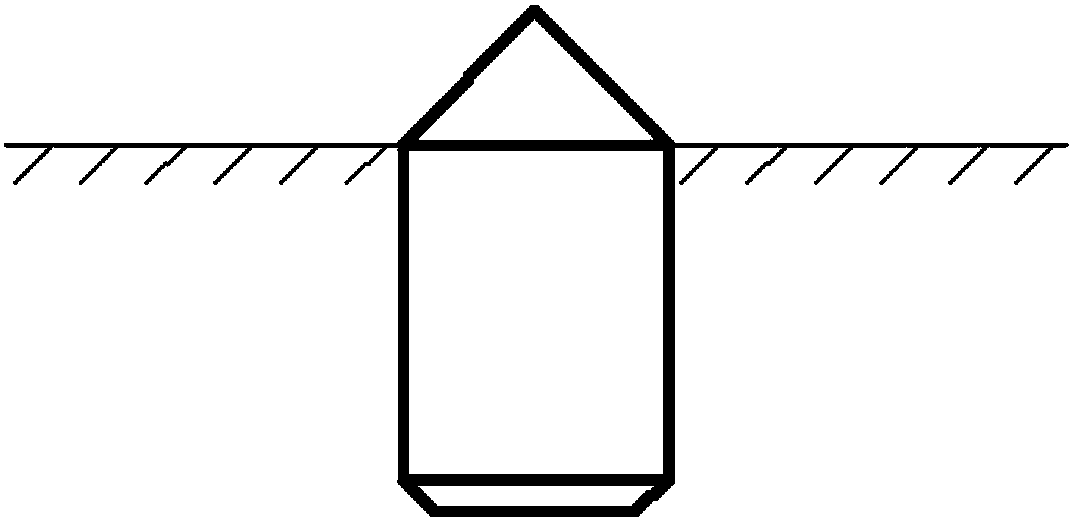

Special fixture for processing inclined conical nozzle steam passage and method thereof

InactiveCN101670527AGuaranteed accuracyImprove positional accuracyPrecision positioning equipmentPositioning apparatusDrill bitMilling cutter

A special fixture for processing an inclined conical nozzle steam passage and a method thereof relate to a fixture for processing the inclined conical nozzle steam passage and a method thereof. The invention solves the problem that at present, no special fixture for processing the inclined conical nozzle steam passage exists, and when a tapered hole of the nozzle steam passage is processed, a drilling bit is difficult to be centered. An indexing plate of the special fixture is provided with twenty indexing through holes along the periphery direction; the center of a stepped through hole and the center of the indexing through holes are on one periphery; a spotting spindle is mounted on the indexing plate in a plug-in manner; the processing method is as follows: using a milling cutter with diameter of 13mm to feed from a P point so as to process a plane C which is vertical to the central line of the tapered hole to be processed; and stopping feeding when the milling cutter mills to a Q point, wherein the center of a hole pitch circle having diameter of 13mm and milled by the milling cutter is the core-bit of the drilling bit. The special fixture solves the problem that at present, nospecial fixture for processing the inclined conical nozzle steam passage exists; and the inclined conical hole of the nozzle stream passage processed by the method has high position accuracy.

Owner:HARBIN TURBINE

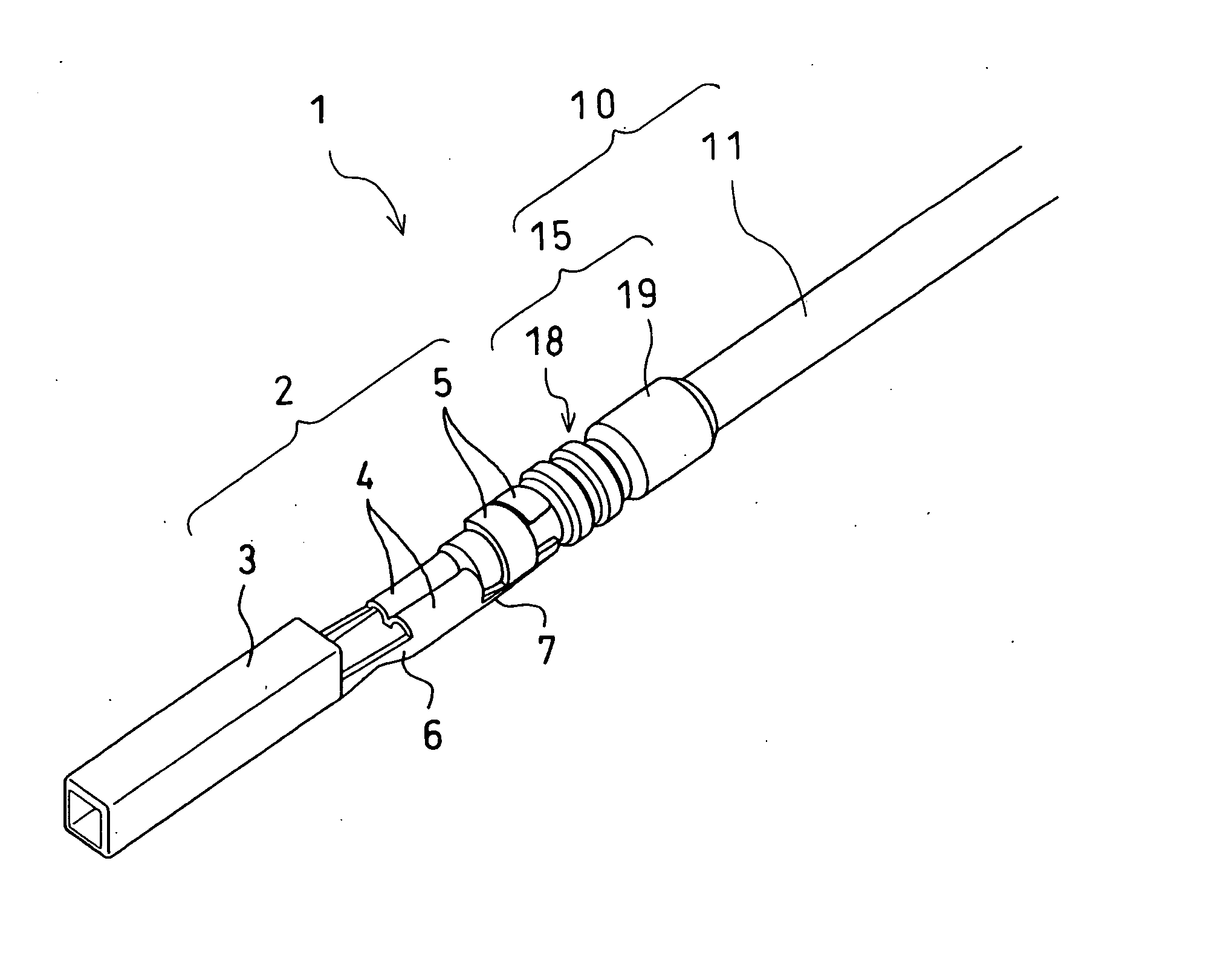

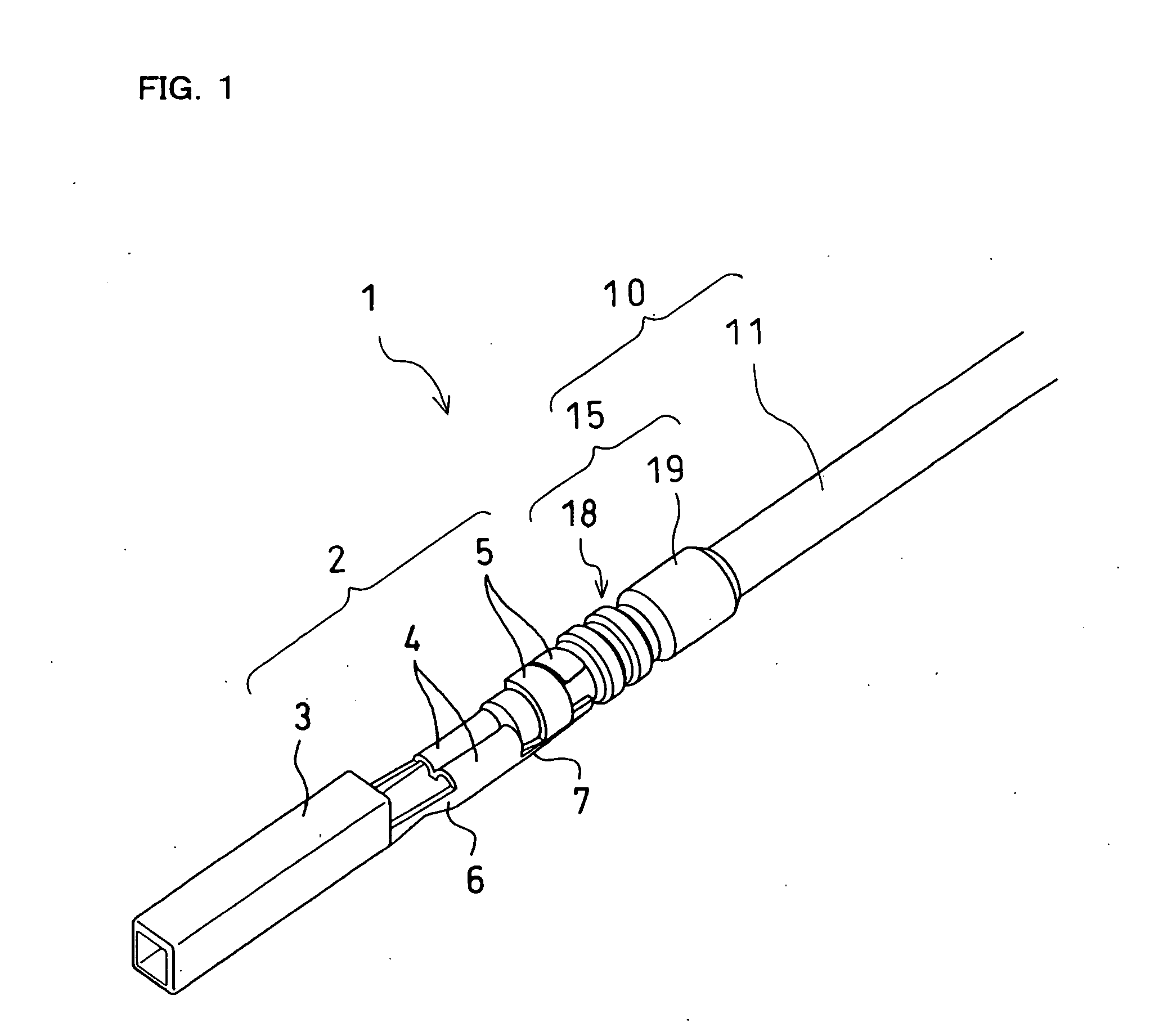

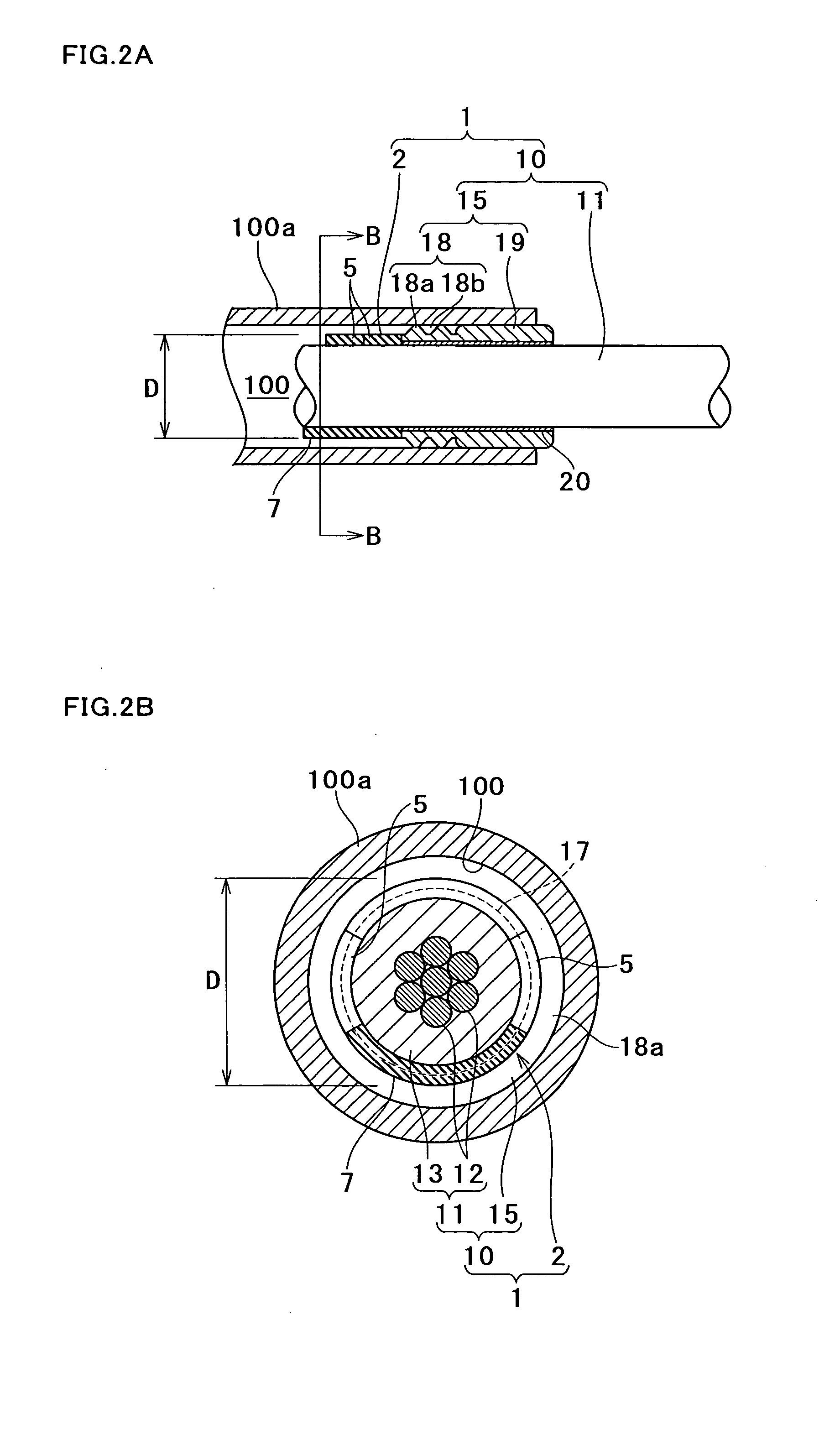

Cable with waterproof plug, connector cable with waterproof plug, manufacturing method of cable with waterproof plug, and connection structure between cable with waterproof plug and terminal

InactiveUS20050003709A1Reduce sizeImprove positional accuracySecuring/insulating coupling contact membersDustproof/splashproof/drip-proof/waterproof/flameproof connectionEngineeringElectrical and Electronics engineering

A cable with a waterproof plug includes a cable including a wire and an insulating coating covering the outer circumferential surface of the wire, and a waterproof plug made of an elastic material. The waterproof plug is formed integrally with the cable so as to cover the outer circumferential surface of the insulating coating in an annular region along the length of the cable. The waterproof plug is united to the cable with an adhesive component. By connecting a terminal to the cable at a position nearer to one end of the cable than the portion where the waterproof plug is formed, a connector cable with a waterproof plug is obtained. The cable may be substantially circular in cross section or substantially rectangular in cross section, such as an FFC or FPC.

Owner:JST MFG CO LTD +1

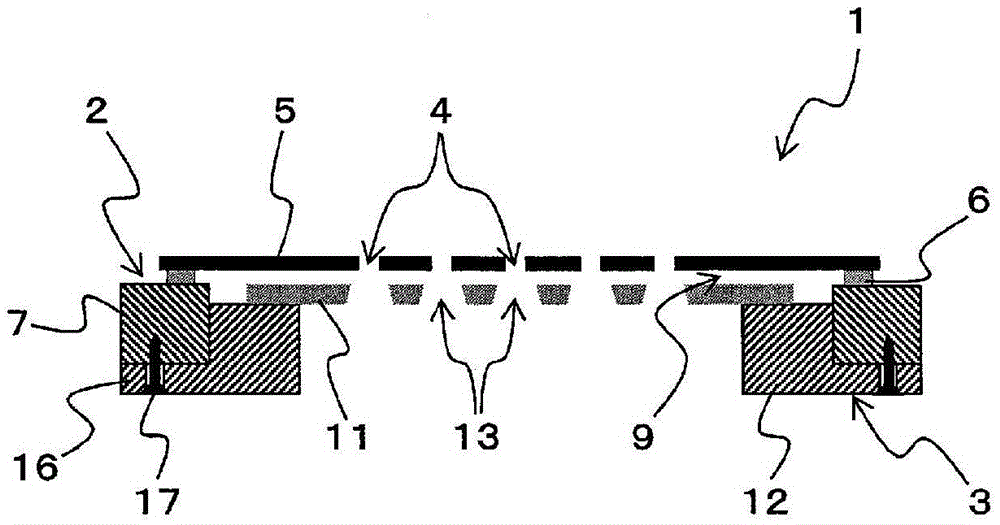

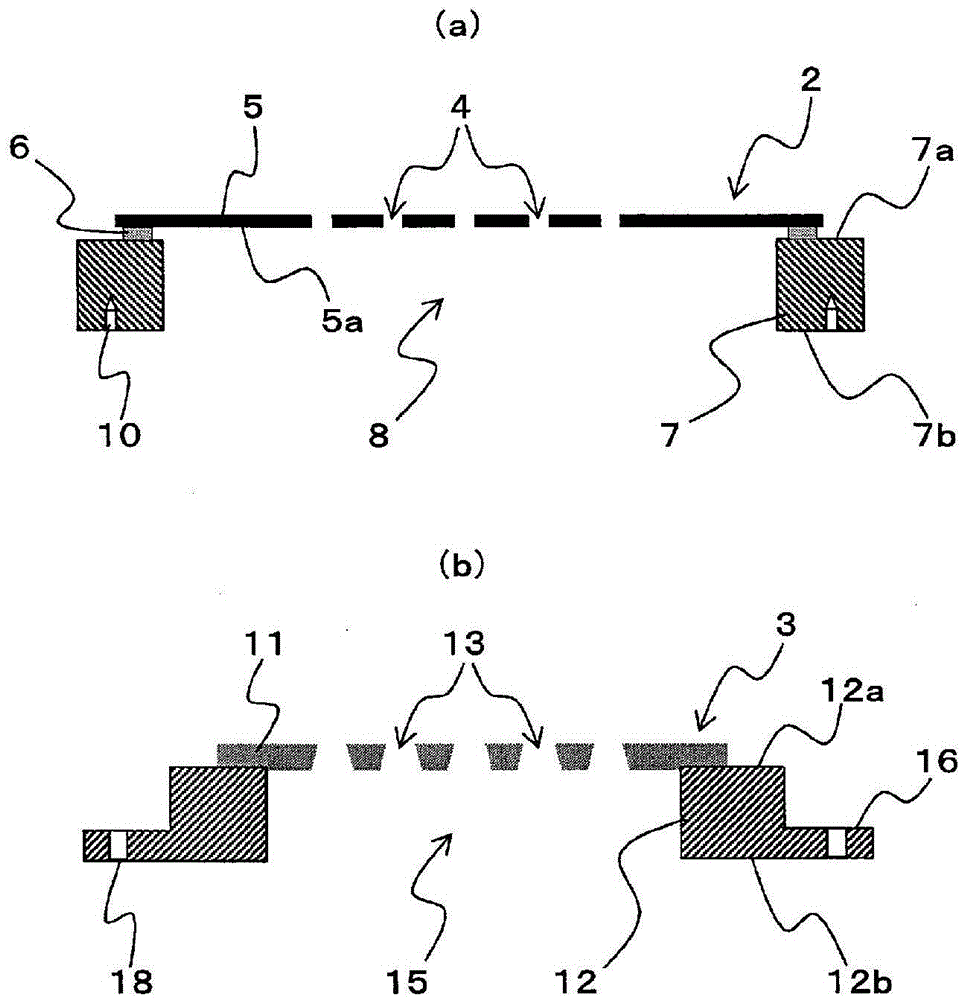

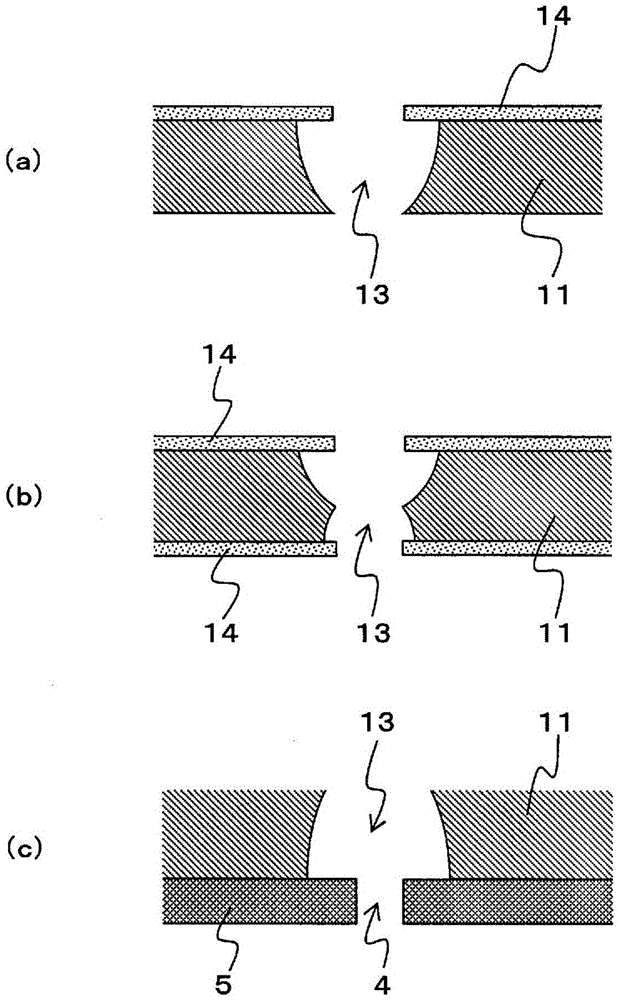

Film-forming mask and touch panel substrate

InactiveCN105555991AInhibit deformationImprove positional accuracyConductive layers on insulating-supportsVacuum evaporation coatingTouch panelSurface plate

The present invention provides a film-forming mask and a touch panel substrate. The film-forming mask comprises: a resin mask (5) on which is formed an opening pattern (4) corresponding to a thin-film pattern film-formed on a substrate; and a metal mask (11) of a magnetic metal member, which is provided on one side of the resin mask (5) with a gap (9) provided between the metal mask (11) and the resin mask (5), and in which are formed holes (13) of a size which encapsulate each of the openings of the opening pattern (4).

Owner:V TECH CO LTD

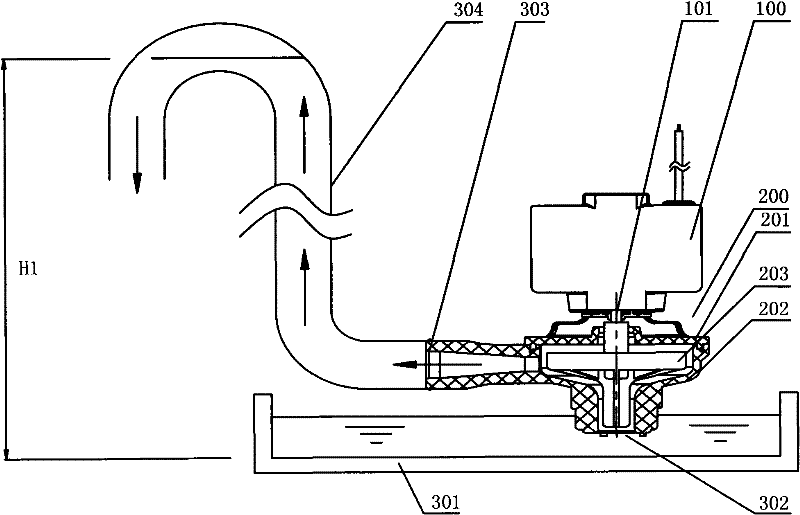

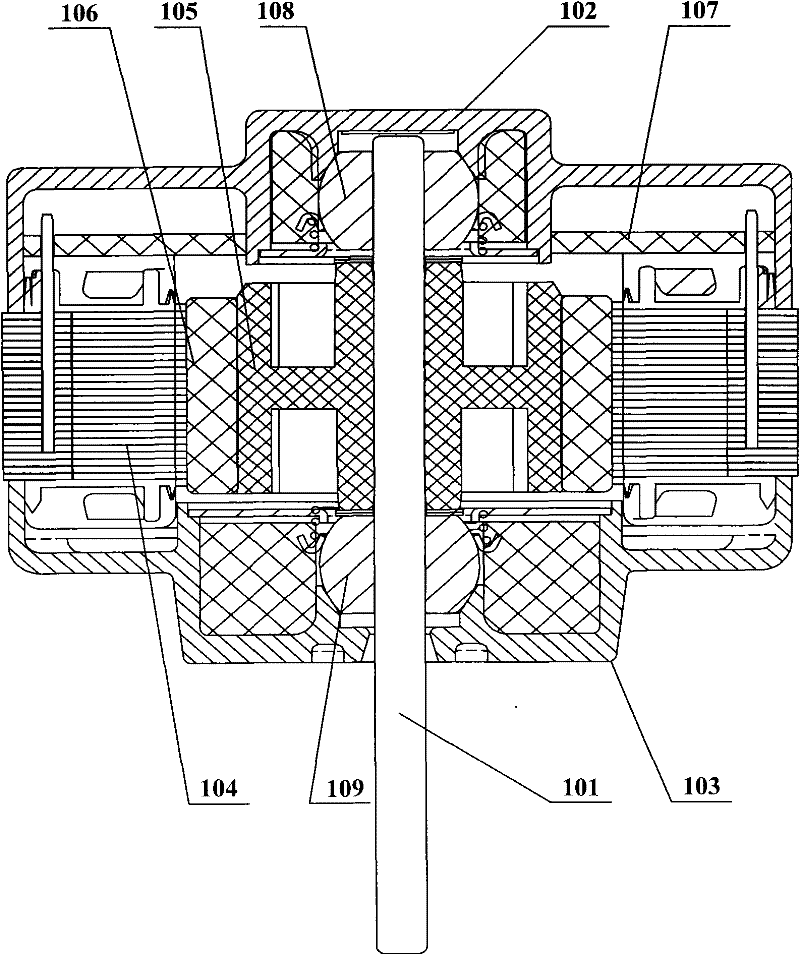

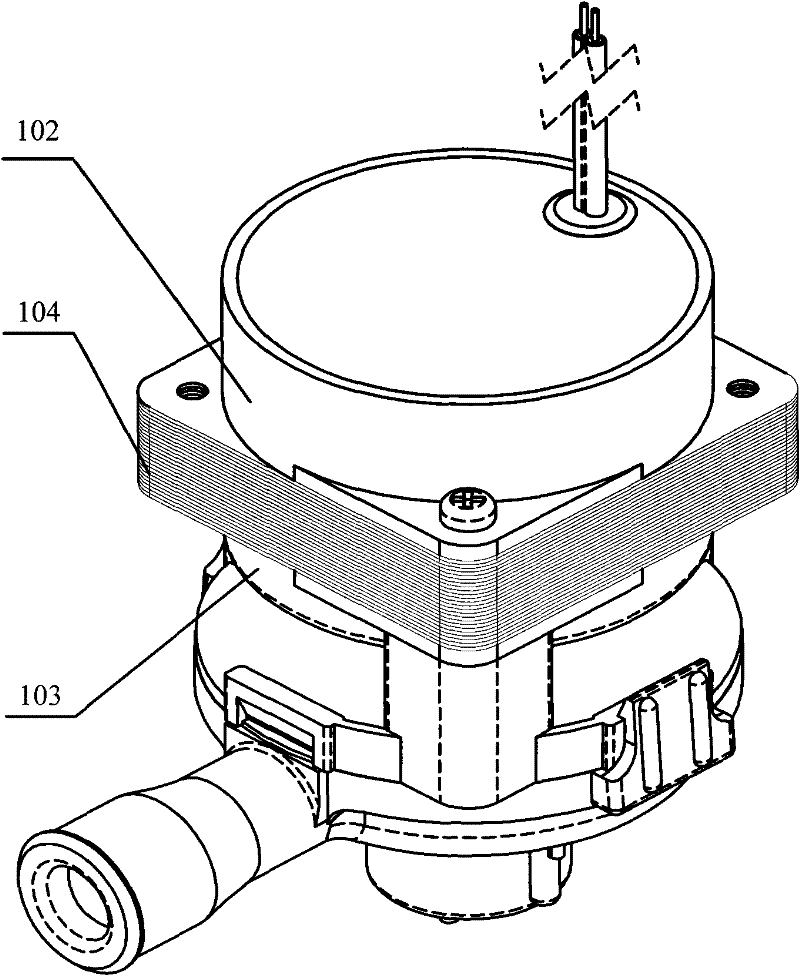

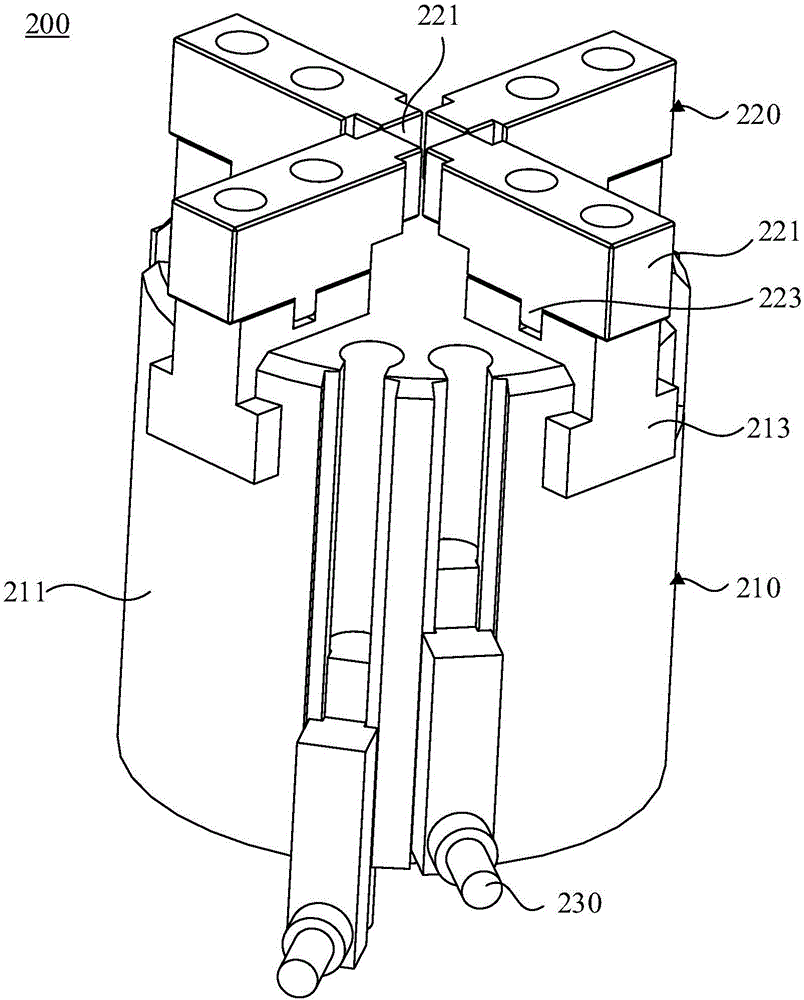

Direct-current brushless motor and drainage pump

InactiveCN102347676AImprove positional accuracyHigh control precisionPumpsPositive-displacement liquid enginesMotor shaftRotor magnets

The invention discloses a direct-current brushless motor and a drainage pump. The direct-current brushless motor comprises: an upper end cover, a lower end cover, a motor shaft, a stator assembly and a rotor magnet steel. The motor shaft is arranged through the upper end cover and the lower end cover. The rotor magnet steel is sleeved on an outside of the motor shaft. Outside edges of the upper end cover and the lower end cover are mutually fastened. Outer positioning structures which form mutual cooperation are respectively formed on the edges of the upper end cover and the lower end cover. The stator assembly is arranged in a cavity which is formed by fastening of the upper end cover and the lower end cover. Mutually cooperated inner positioning structures are formed on outer walls of the stator assembly and inner walls of the cavity. In the invention, the upper end cover and the lower end cover are directly fastened and positioned; the stator assembly is fixed in the end cover so that coaxiality of the stator and the rotor of the motor can be raised and position precision of the stator in the end cover can also be raised. Control precision of axial clearance and radial clearance can be improved. Uniformity of an electromagnetic air gap is good. Therefore, operation of the motor is stable, noise is low and vibration is small.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

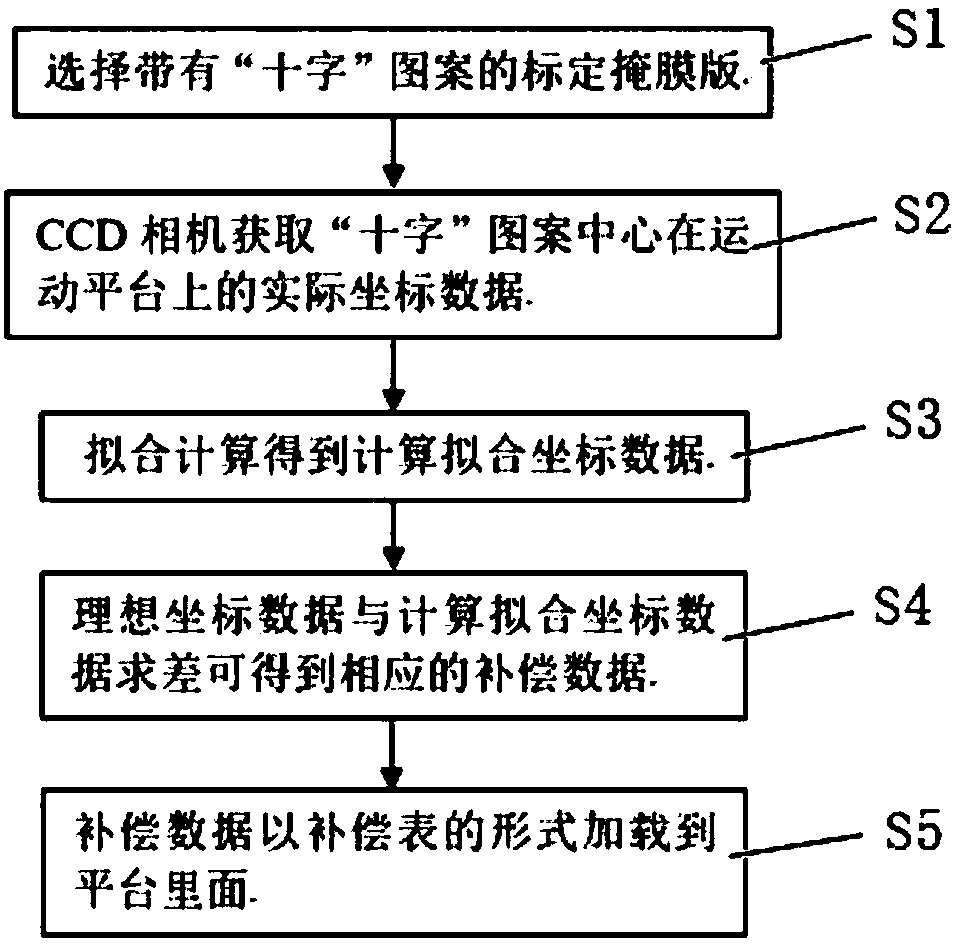

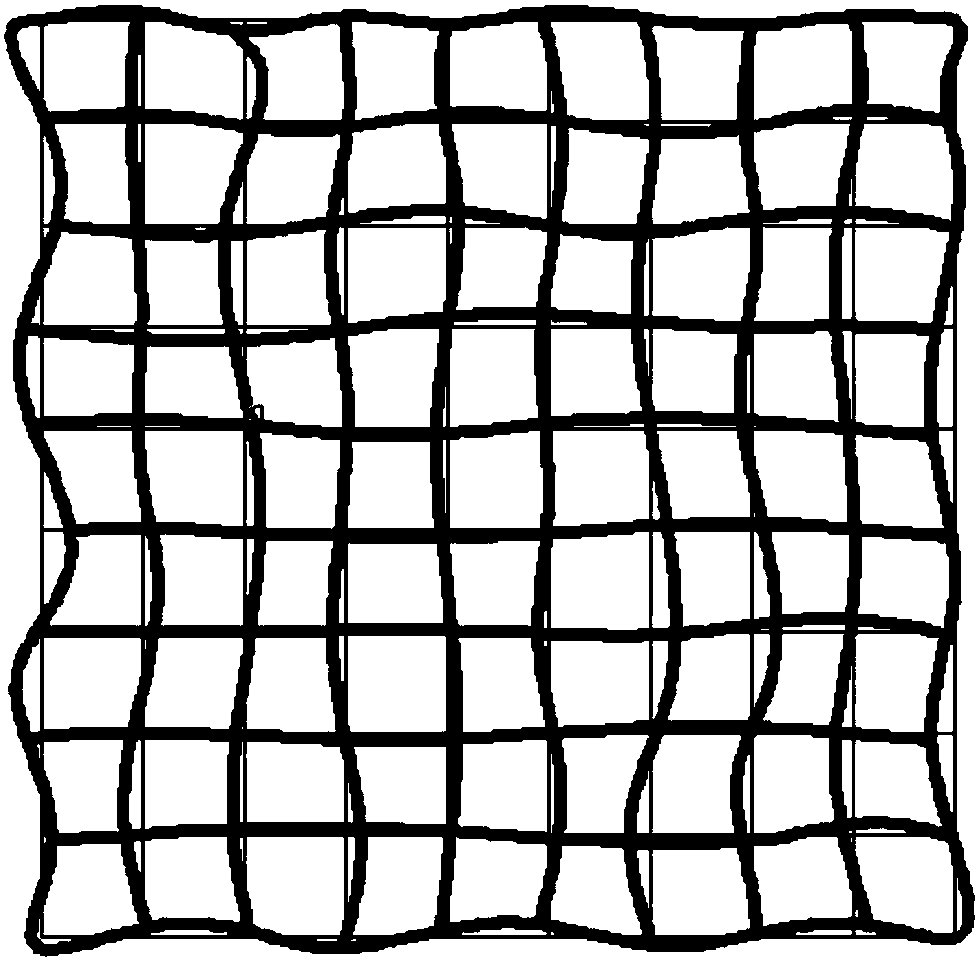

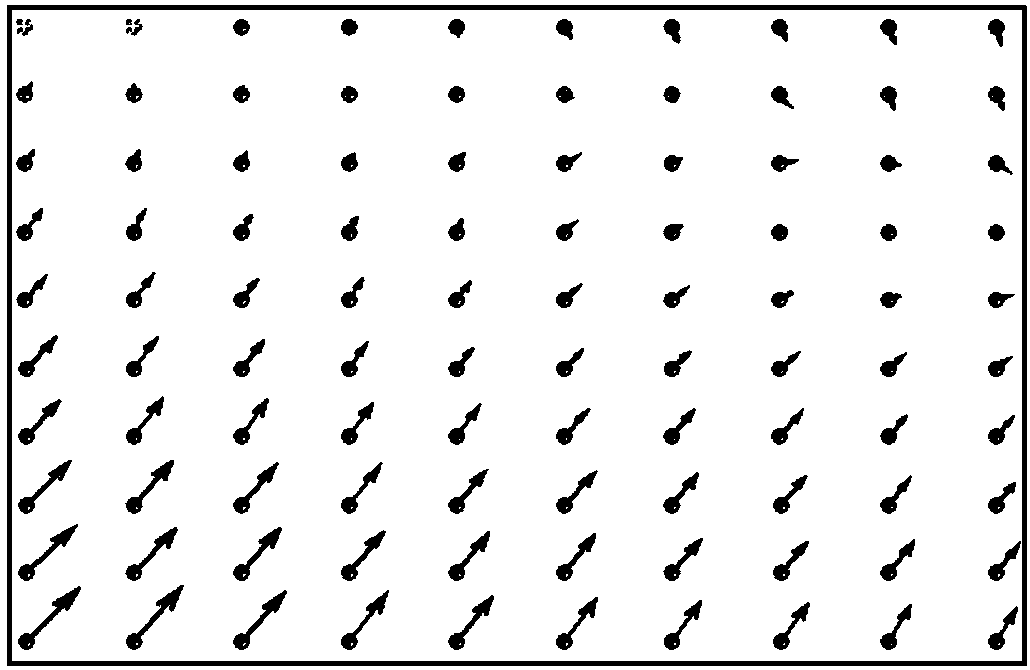

Position precision compensation method of ultra-precision two-dimensional motion platform system

InactiveCN108303023ALow costImprove positional accuracyUsing optical meansSystematic errorEngineering

The invention provides a position precision compensation method of an ultra-precision two-dimensional motion platform system. On the basis of processing by a fitting method, a placement error of a calibration plate and a systematic error of a platform are separated to realize position precision compensation of the platform. Therefore, a defect of the existing ultra-precision two-dimensional motionplatform system position precision compensation method is overcome; and thus harsh requirements on the ambient temperature and the placement position of the calibration plate are reduced.

Owner:HEFEI CHIP FOUND MICROELECTRONICS EQUIP CO LTD

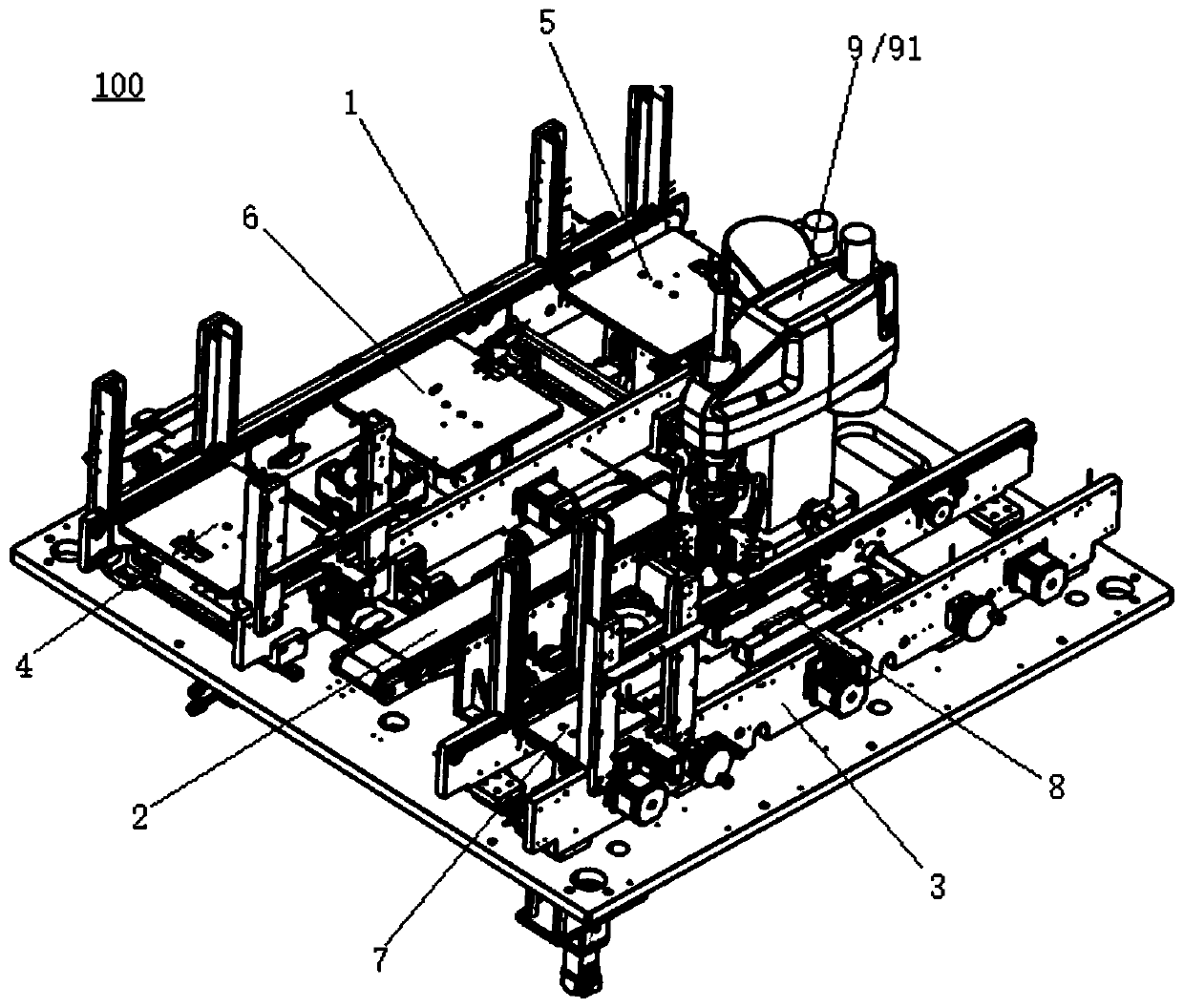

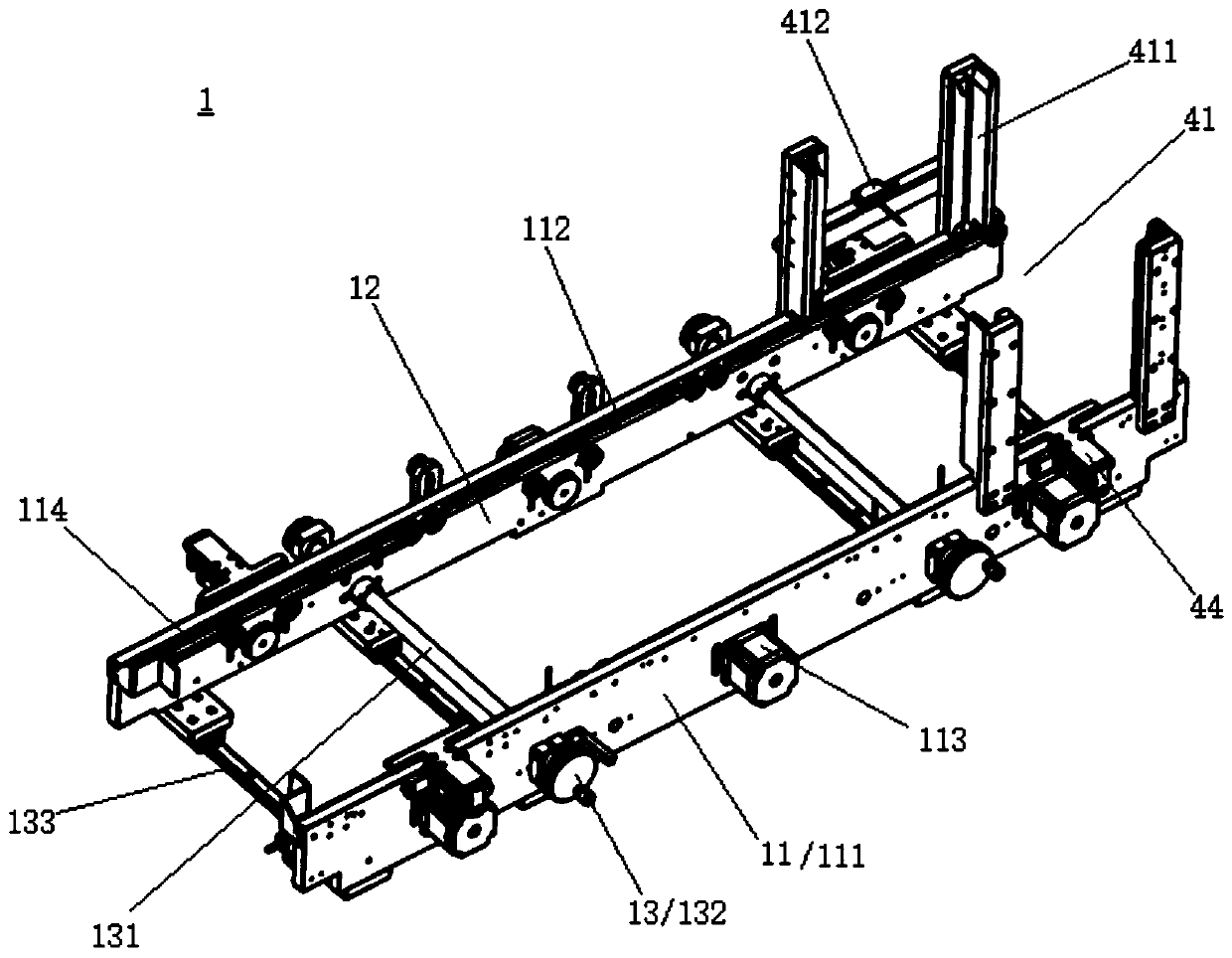

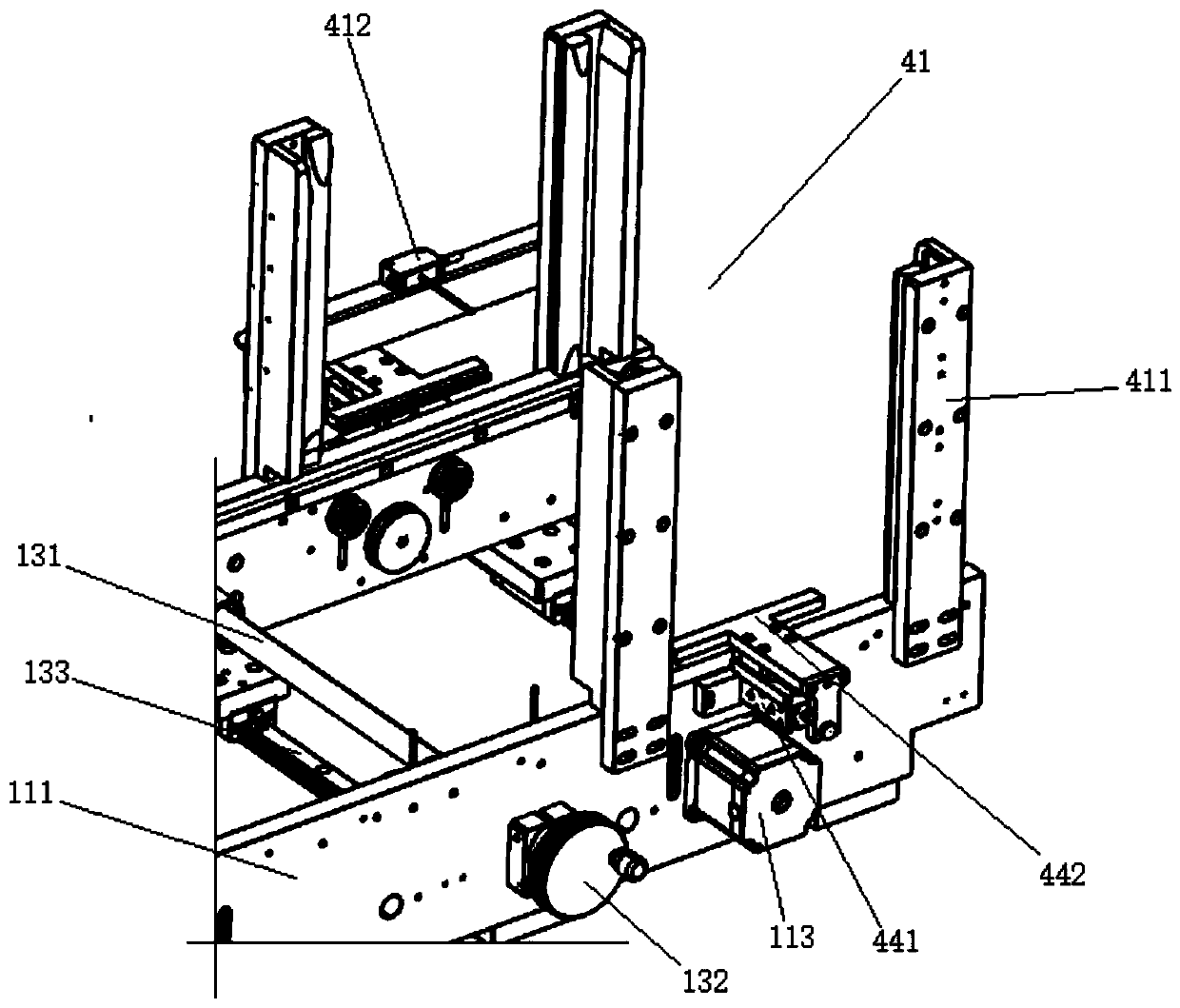

Automatic feeding mechanism for loading circuit boards and blanks on stacked trays

PendingCN111268420AImprove handling efficiencyImprove positional accuracyConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses an automatic feeding mechanism for loading circuit boards and blanks on stacked trays. The automatic feeding mechanism comprises a tray conveying line, a NG conveying line anda carrier conveying line which are arranged in parallel, a tray supply unit and an empty tray recovery unit which are arranged at the front end and the rear end of the tray conveying line correspondingly, a tray positioning unit which is arranged between the tray supply unit and the empty tray recovery unit, a carrier supply unit and a carrier positioning unit which are arranged along the carrierconveying line, and a product transfer device for grabbing multiple products from trays in the tray conveying line one by one to place into carriers in the carrier conveying line. One-by-one output ofthe stacked trays loaded with the blanks, automatic recovery of the empty trays and the automatic supply and feeding of the carriers can be achieved, the blanks are quickly placed in the carriers oneby one to realize automatic detection, and finally the carriers filled with qualified blank products are automatically output.

Owner:KUSN RUIBAODA ELECTRONICS

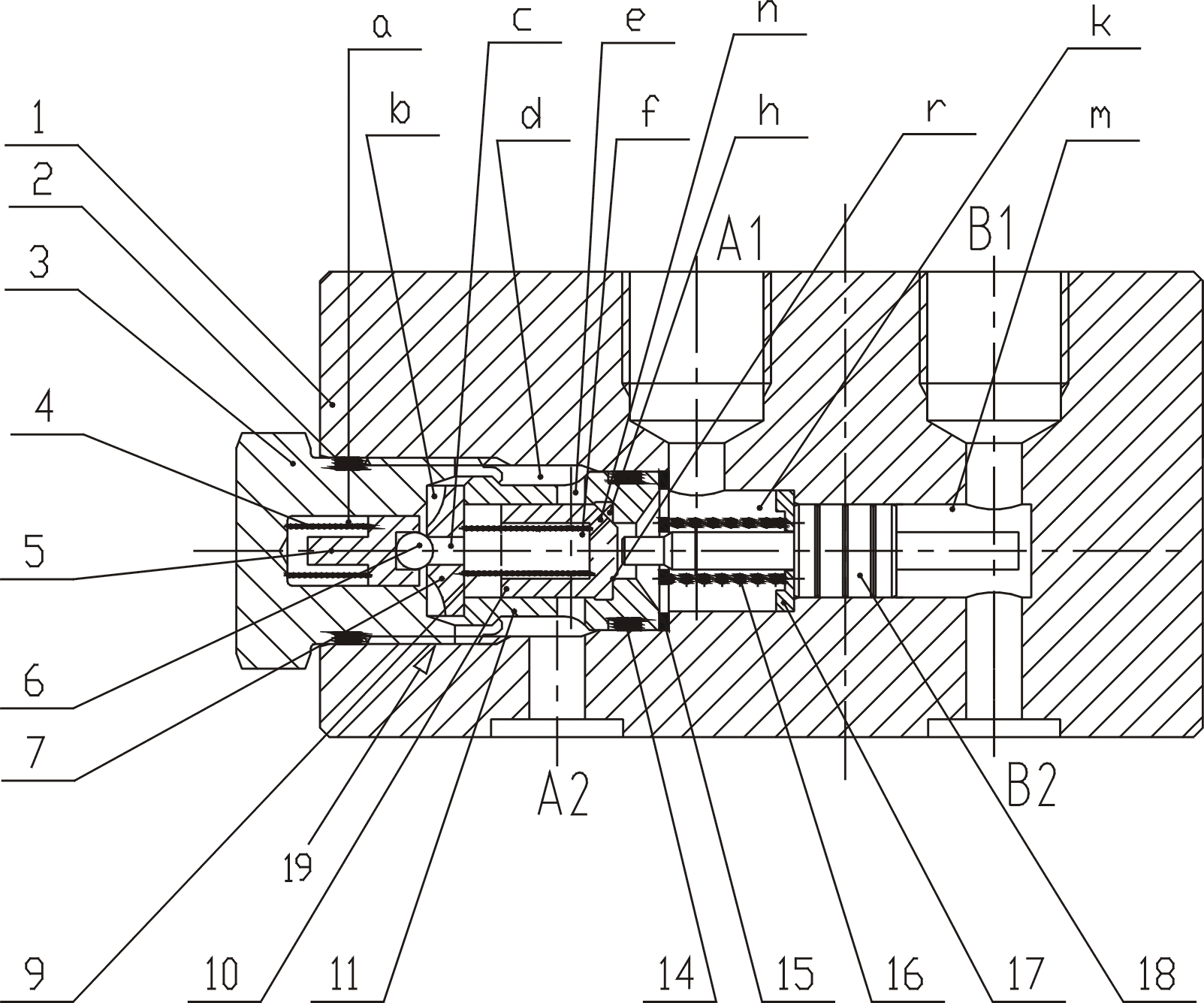

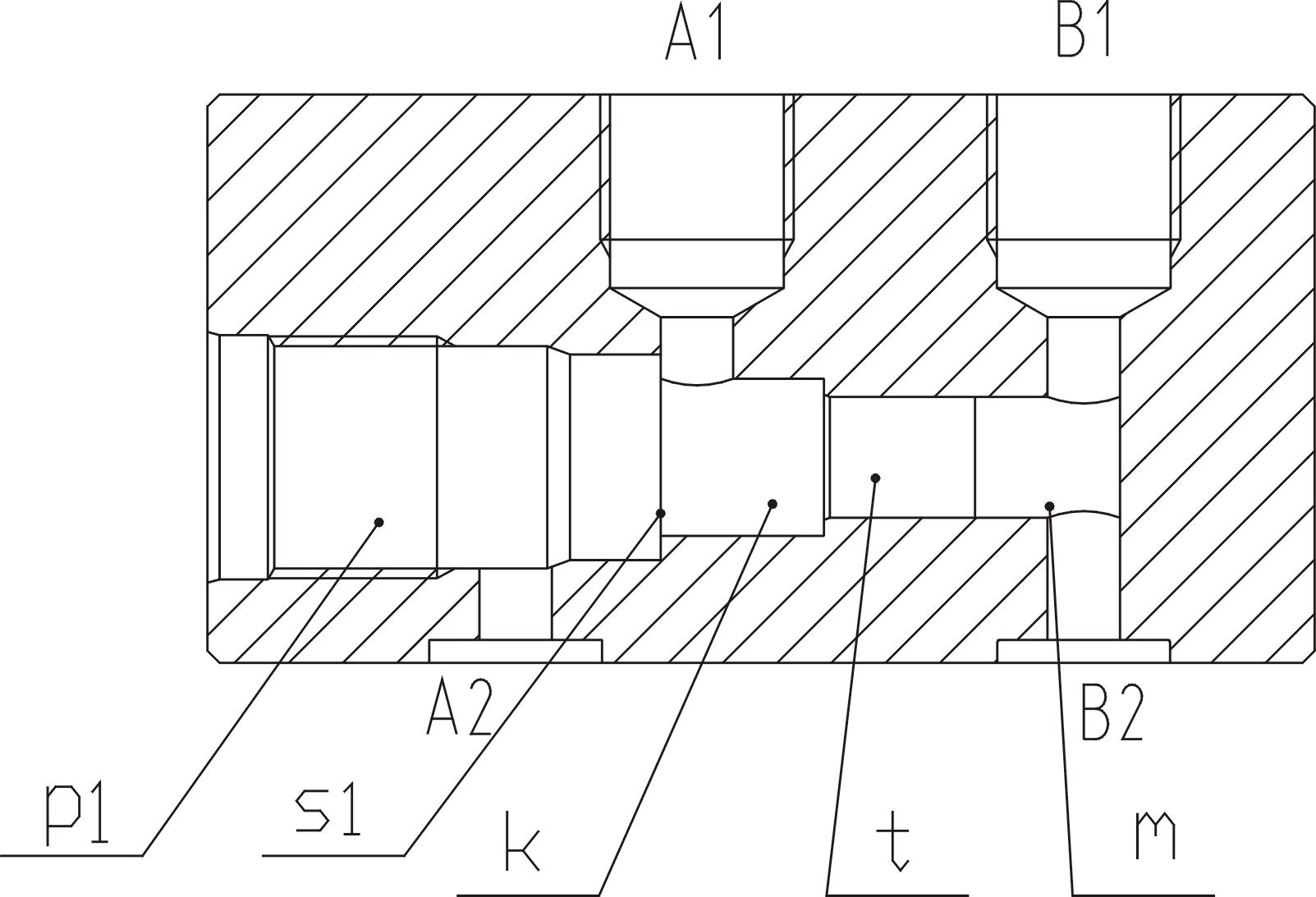

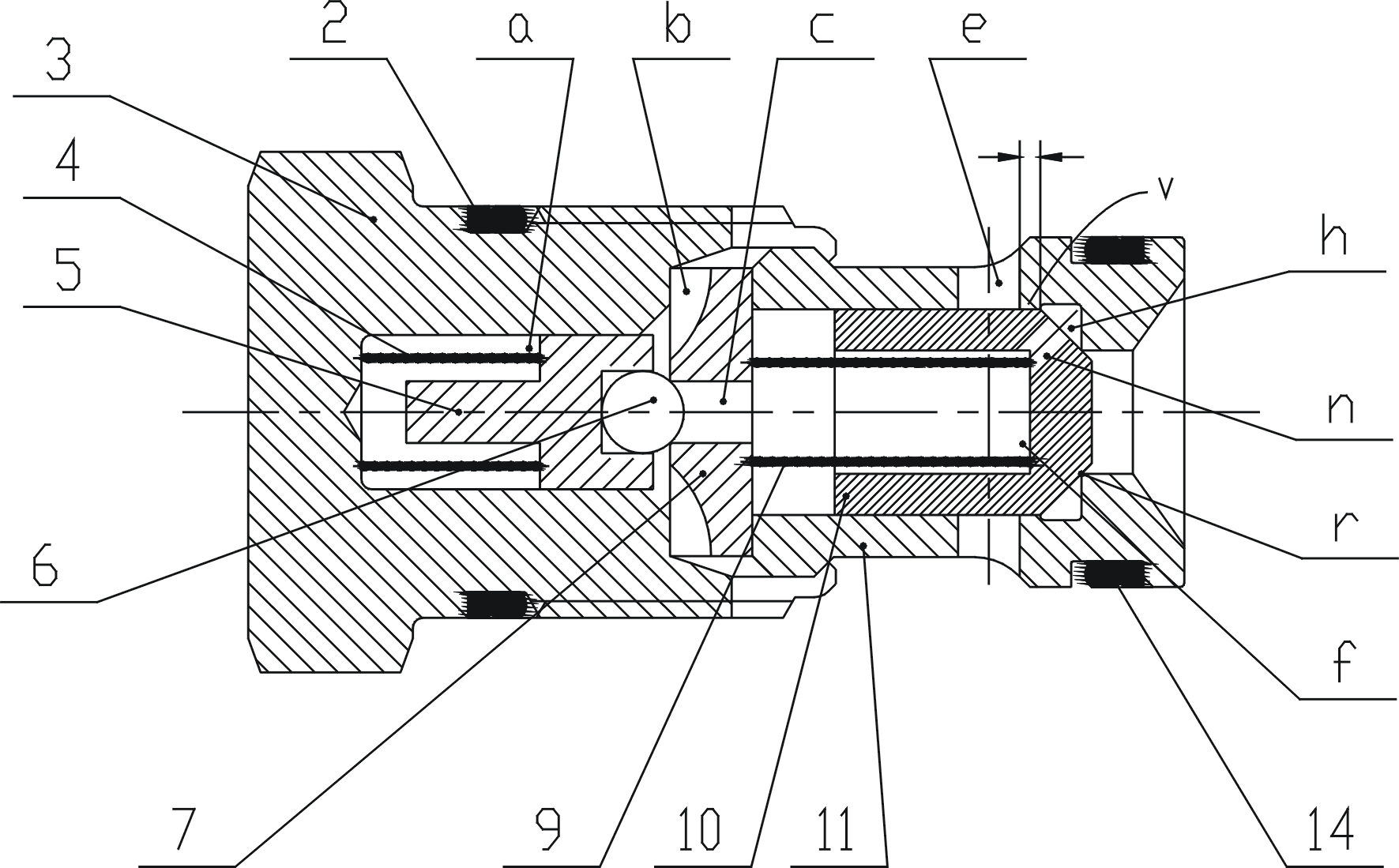

Pressure-reduction type balance hydraulic lock

InactiveCN102128284AImprove positional accuracySensitive movementOperating means/releasing devices for valvesValve members for absorbing fluid energyPistonFirst insertion

The invention discloses a pressure-reduction type balance hydraulic lock, comprising a valve body and a first mortise, wherein one end of the valve body is provided with an inner cavity, and the inner cavity is internally provided with a first insertion hole, a first oil cavity, a control piston mounting hole and a second oil cavity in sequence. A first oil port is communicated with the first oil cavity, a second oil port is communicated with the first insertion hole, and a third oil port and a fourth oil port is respectively communicated with the second oil cavity. The first mortise is arranged in the first insertion hole; the control piston is arranged in the control piston mounting hole, and a first limit cushion is arranged at the rear end of the control piston; and a third spring is arranged between the first limit cushion and a first porous plate. The lock disclosed by the invention has the advantages of reliability, high static safety and strong universality, and can overcome the phenomenon of high-frequency or low-frequency jitter.

Owner:蒋晓军

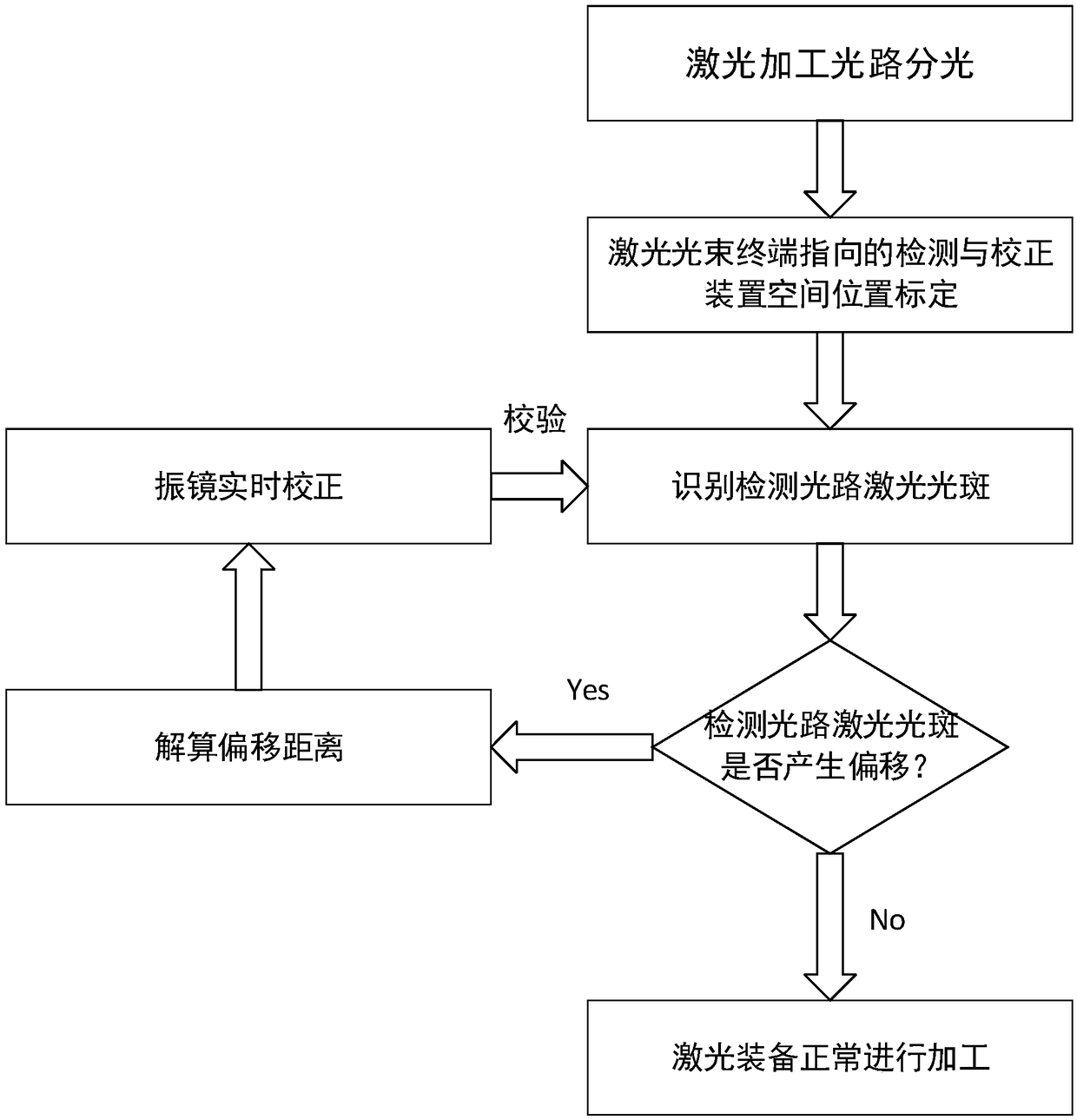

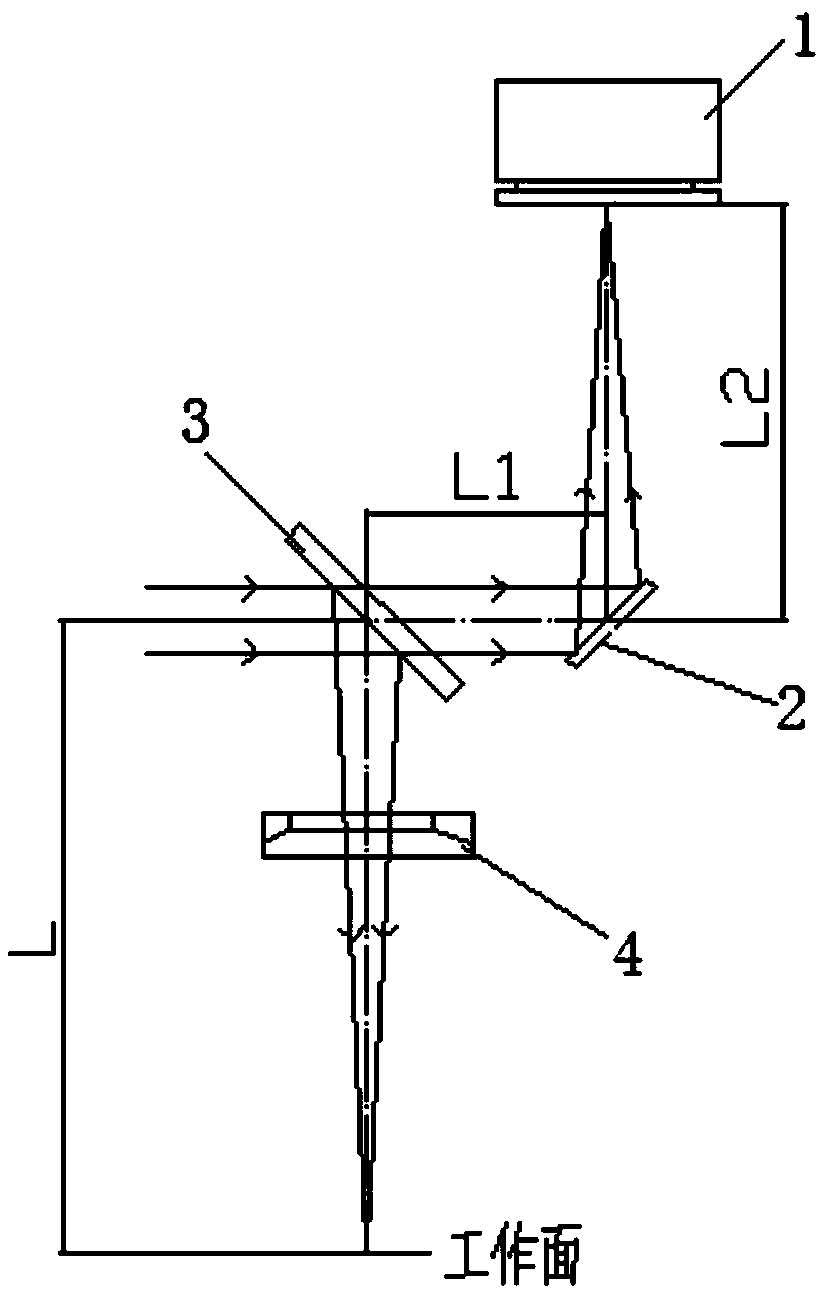

Laser beam terminal pointing detection and correction method and laser processing device

ActiveCN109483047AImprove positional accuracyHigh positioning accuracyLaser beam welding apparatusOptical pathCorrection method

The invention relates to a laser beam terminal pointing detection and correction method and a laser processing device. The laser beam terminal pointing detection and correction method and the laser processing device are used for solving the problem that in the process of laser processing, because of long time operation of laser equipment, a laser beam generates pointing offset at a processing terminal caused by emitting beam pointing offset of a laser device, temperature excursion and time excursion of a galvanometric scanner and the other reasons to affect the position accuracy of a machinedfigure. According to a principle of optical path conjugation, the spatial position of a detection and correction device of laser beam terminal pointing is arranged and calibrated, the light spot position offset amount in a view field is equal to the light spot position offset amount of the actual laser processing light spot position, so that the light spot offset situation of the laser processed surface is characterized through the light spot position of the detection device; and the laser beam terminal pointing detection and correction method and the laser processing device can be widely usedin laser fine surface manufacturing, hole making, fine cutting aspects of aerospace field, automobile field, 3C field, optoelectronic field, mold field and other fields.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

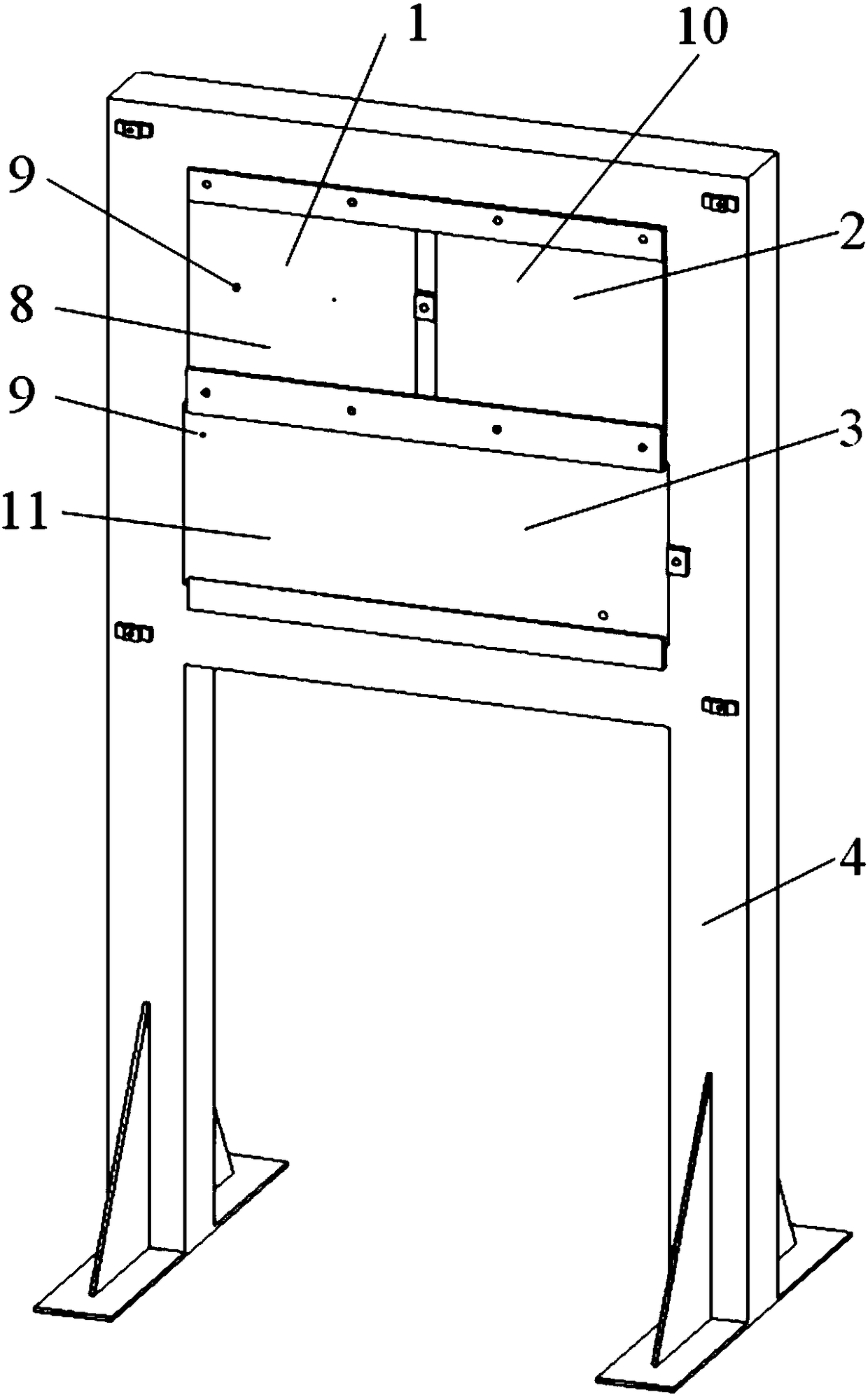

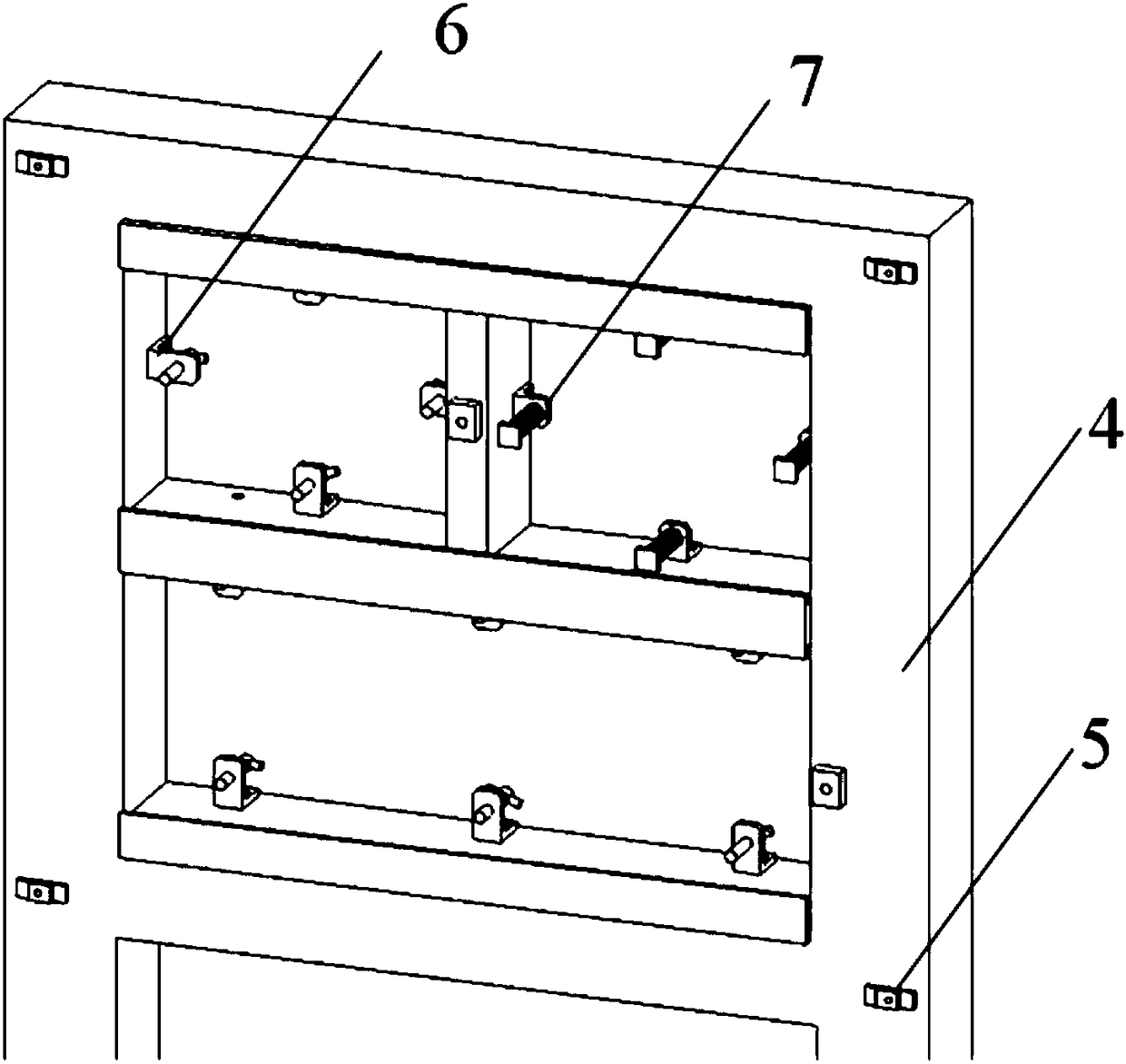

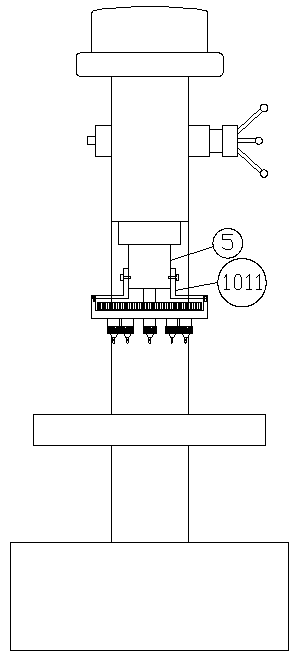

Testing and calibration integrated working table for automatic hole making system and calibration method of testing and calibration integrated working table

InactiveCN108544434AImprove positional accuracyGuaranteed accuracyMeasurement/indication equipmentsWork benchesSystem errorHole making

The invention discloses a testing and calibration integrated working table for automatic hole making system. The table includes a column frame which is divided into an upper layer and a lower layer, the upper layer is divided into two blocks through a division plate, one side of the division plate is provided with a vision camera calibration block which includes an alignment test plate fixedly connected between the side wall of the column frame and the division plate, positioning nails are fixed on the alignment test plate, and the other side of the division plate is provided with a normal sensor calibration block which includes a standard surface plate installed in the groove of the inner side wall of the column frame and the division plate; and the lower layer area of the column frame isprovided with a hole-making technology test module. The invention also discloses a calibrated method for an automatic hole-making system test. Firstly, the distance between the vision camera axis andthe hole-making cutting tool axis of the automatic hole-making system is calibrated, then, the distance between the normal sensor and the front end surface of a pressure foot of the automatic hole-making system is calibrated, and finally the hole-making and measurement are performed on a hole-making test plate. The problem that the prior art does not have the calibration function of the measurement system and the system error compensation cannot be realized is solved.

Owner:XIAN UNIV OF TECH

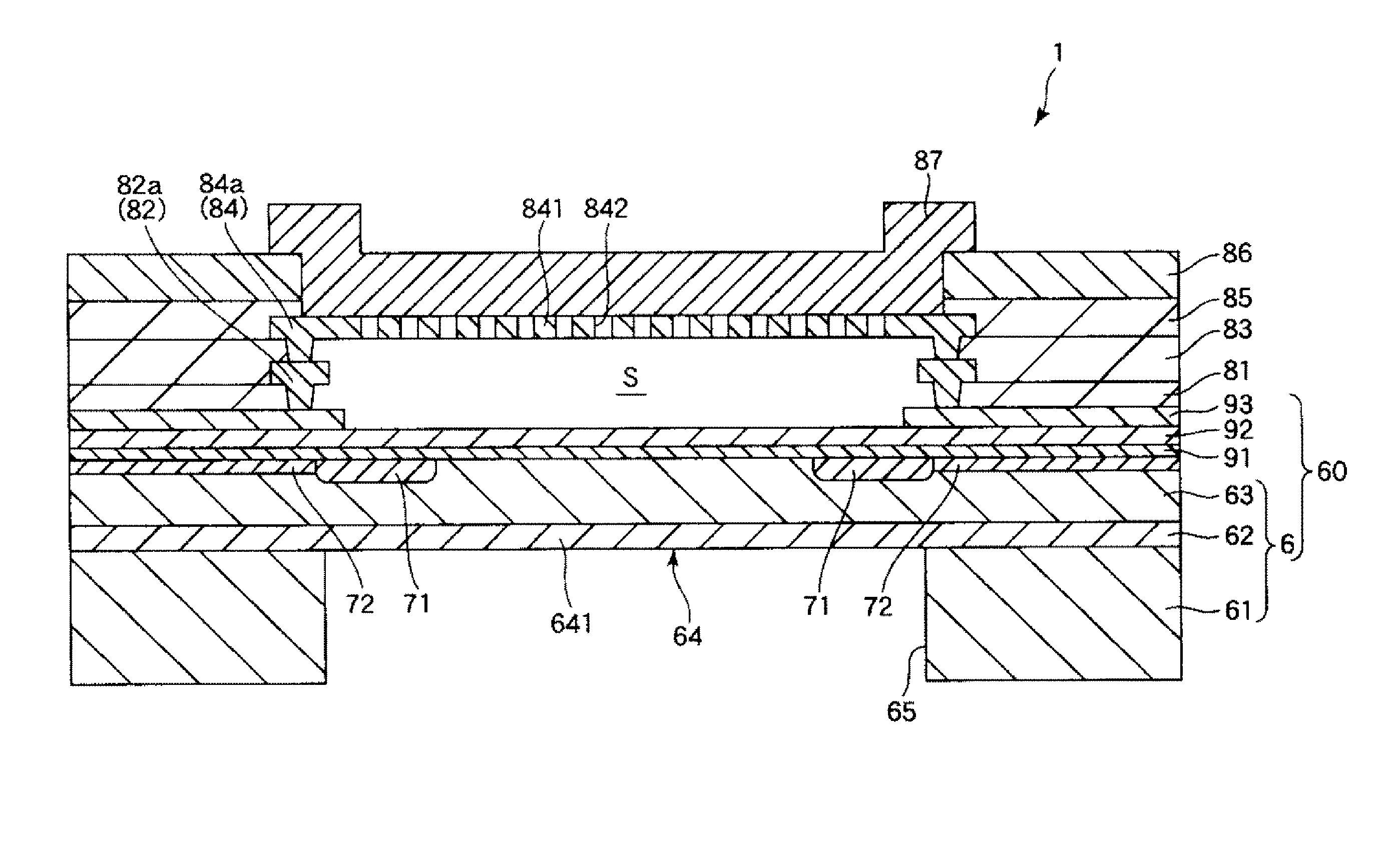

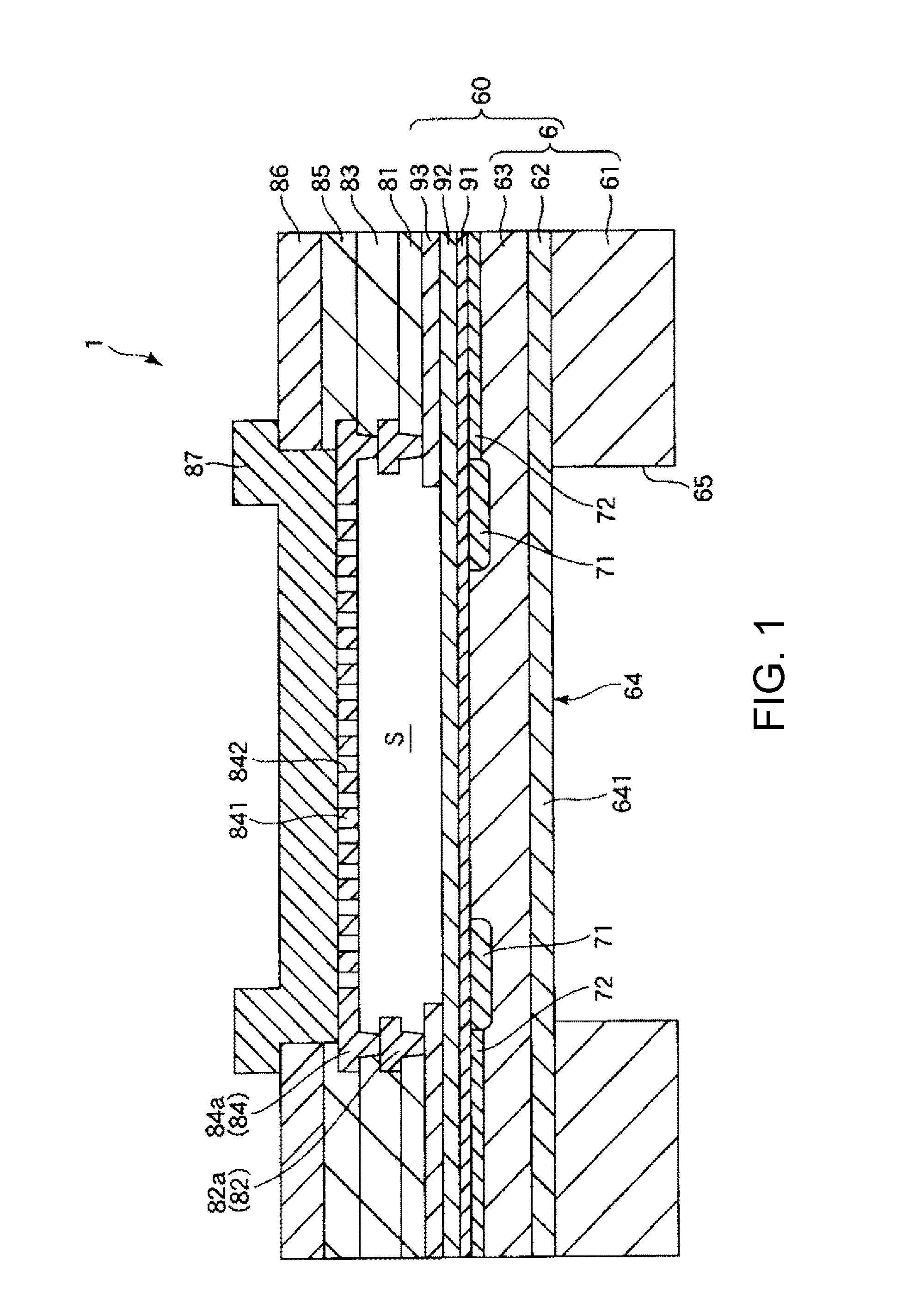

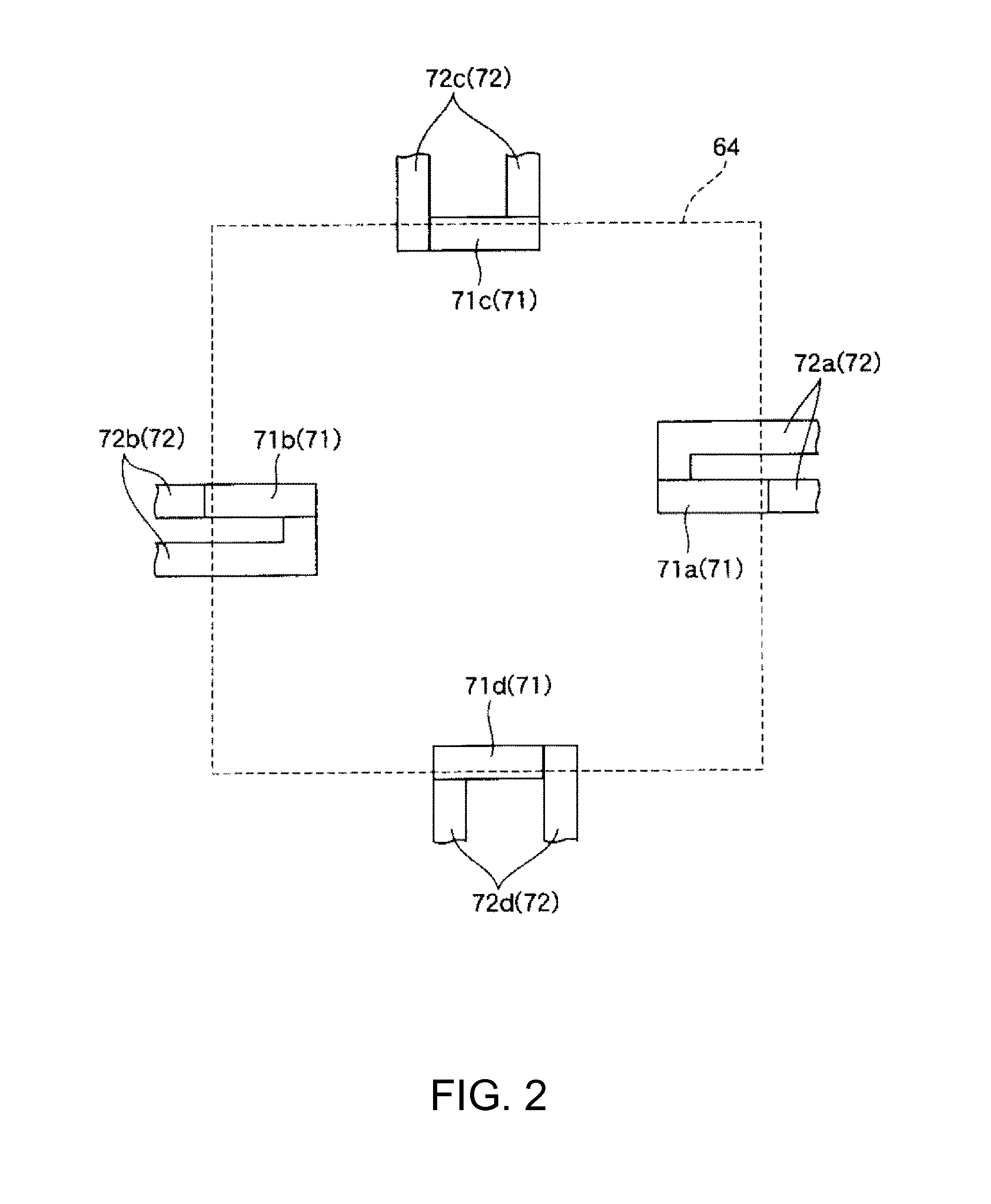

Physical quantity sensor, method for manufacturing physical quantity sensor, pressure sensor, altimeter, electronic device, and moving object

InactiveUS20150268114A1Improve positional accuracyReduce sizeFluid pressure measurement using pressure-sensitive liquidFluid pressure measurement using ohmic-resistance variationCmos processEngineering

A physical quantity sensor includes a substrate, a piezoresistive element, and a laminated structure. The substrate has a diaphragm portion deformed flexibly when receiving pressure. The piezoresistive element is arranged on one surface of the diaphragm portion. The laminated structure is arranged on the piezoresistive element side of the diaphragm portion and constitutes with the diaphragm portion a cavity portion that is a pressure reference chamber. The laminated structure is formed by using a CMOS process.

Owner:SEIKO EPSON CORP

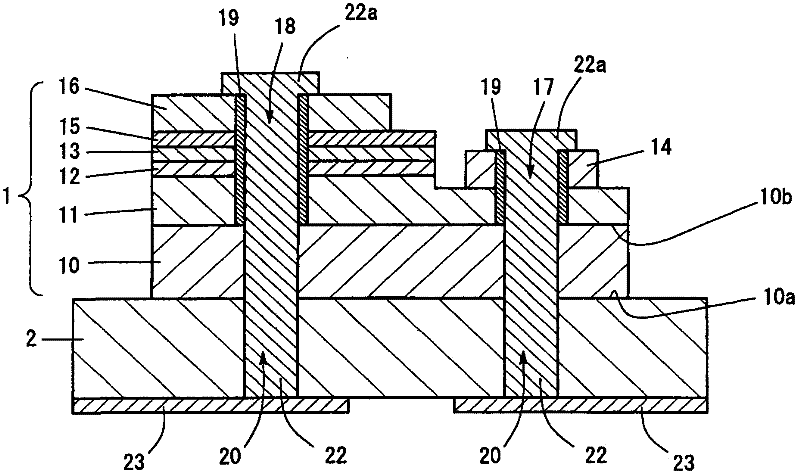

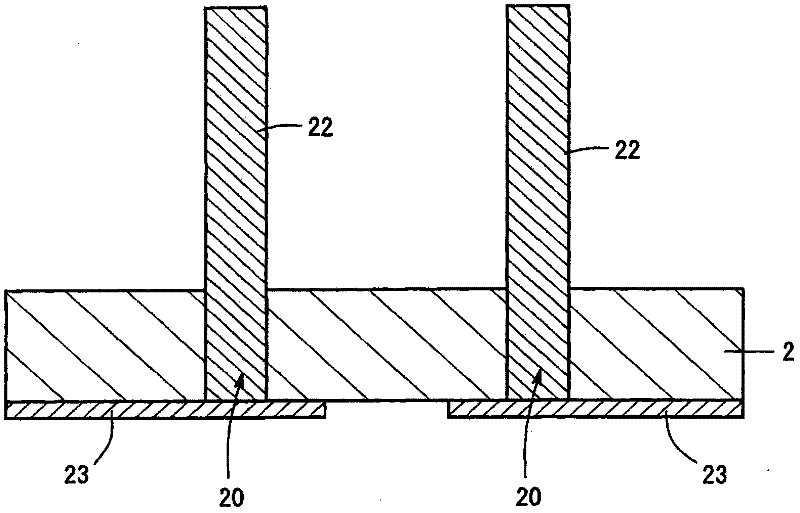

Light-emitting device and producing method thereof

InactiveCN102544258AImprove positional accuracyReduce areaSemiconductor devicesEngineeringMetallic Lead

The invention provides a light-emitting device. A light-emitting element facing upwards is disposed on a secondary mounting base, and the mounting does not require leads and is conducted with high position accuracy. The light-emitting device comprises a light-emitting element (1) facing upwards and a secondary mounting base (2). The light-emitting element (1) facing upwards is composed of III-group nitride semiconductor and is provided with through holes (17, 18). The secondary mounting base (2) has two rod-like electrodes (22) which are respectively inserted into the through holes (17, 18) of the light-emitting element (1). A front end part (22a) of the rod-like electrode (22) protrudes from the surface of a n pad electrode (14) and p pad electrode (16) of the light-emitting element (1), and is flattened and expanded, and is connected to the n pad electrode (14) and the p pad electrode (16) of the light-emitting element (1).

Owner:TOYODA GOSEI CO LTD +1

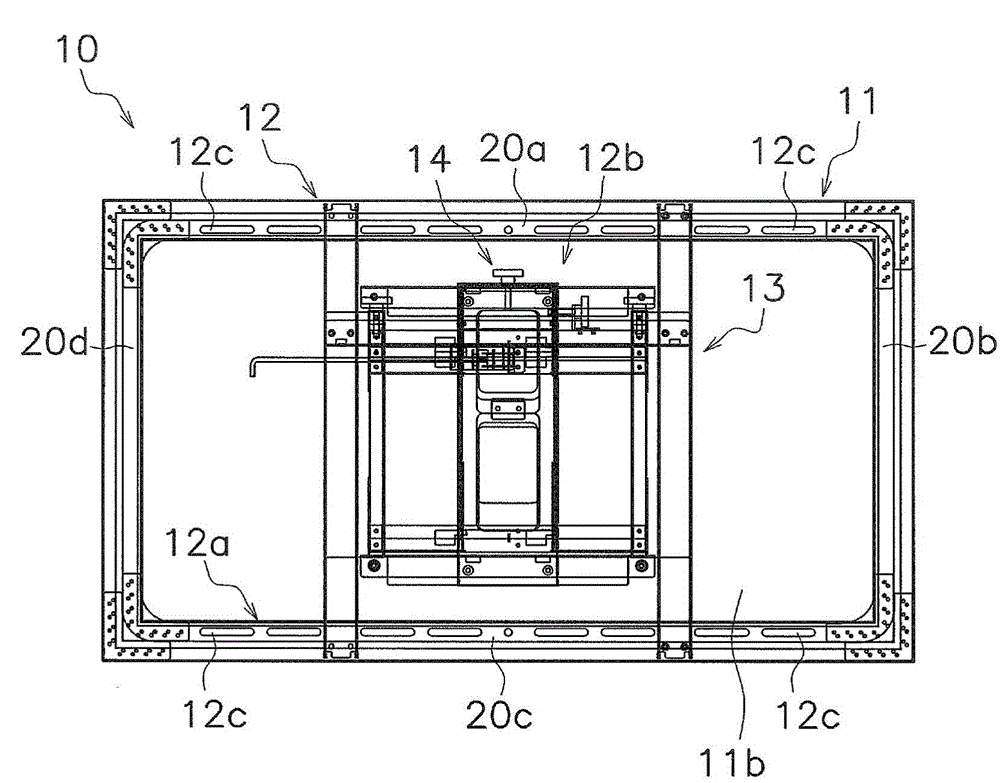

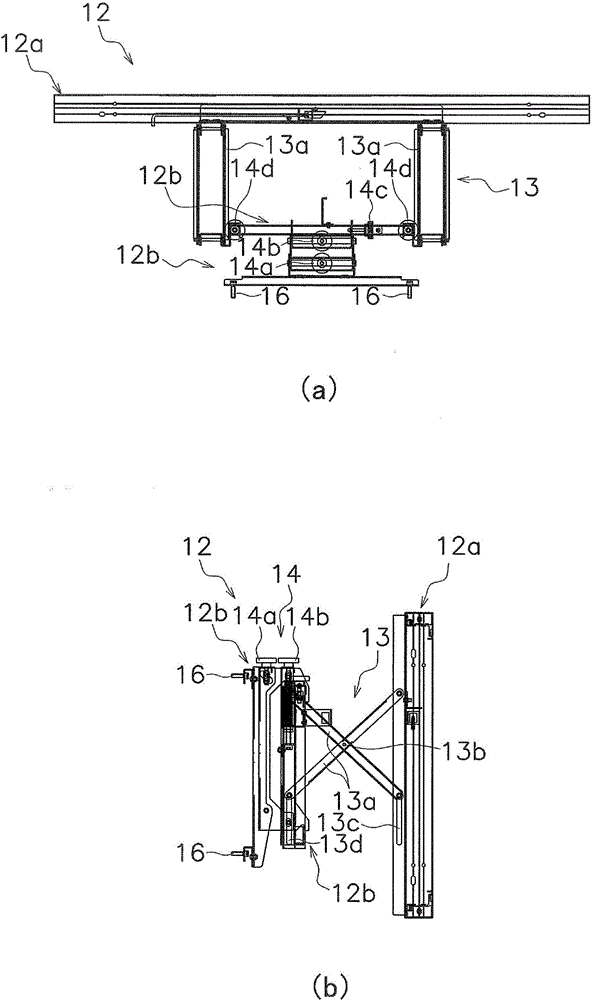

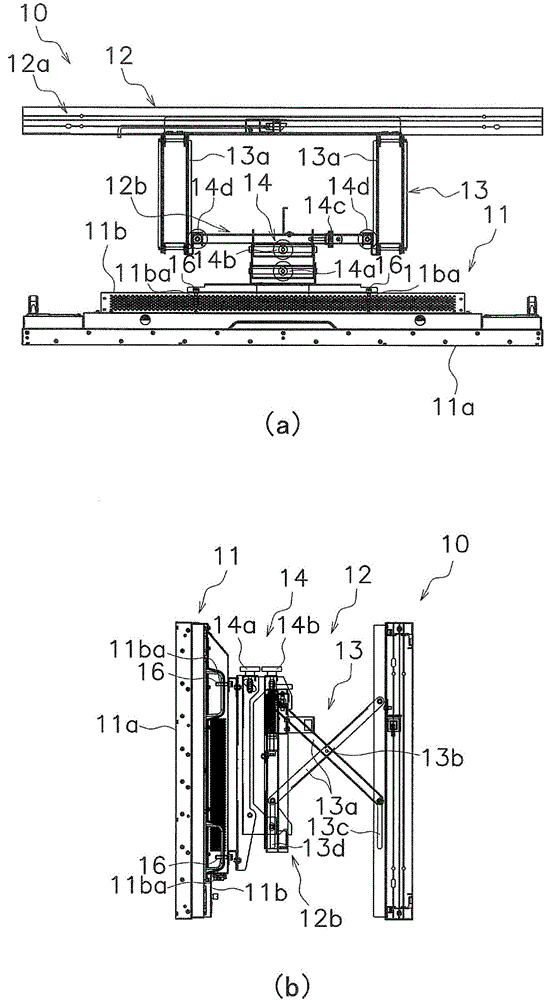

Display device attachment fitting and display device attachment jig

ActiveCN104972426AImprove positional accuracyHigh positioning accuracyTelevision system detailsWork holdersEngineeringMechanical engineering

An attachment fitting 12 comprises a frame body 12a, a fitting component 12b, and fixing bolts 17. The frame body 12a is externally the same size as a display device 11, and is attached to a wall surface 15, and has stiffness property enough to support the weight of the display device 11. The fitting component 12b is provided to the frame body 12a on the side where the display device 11 is attached, and supports the rear face 11b side of the display device 11. The fixing bolts 17 are provided to the side faces of the frame bodies 12a, and fix the frame bodies 12a to each other in a state of being in contact with the side faces of the frame bodies 12a included in attachment fittings 12 of display devices 11 attached at adjacent positions.

Owner:PANASONIC CORP

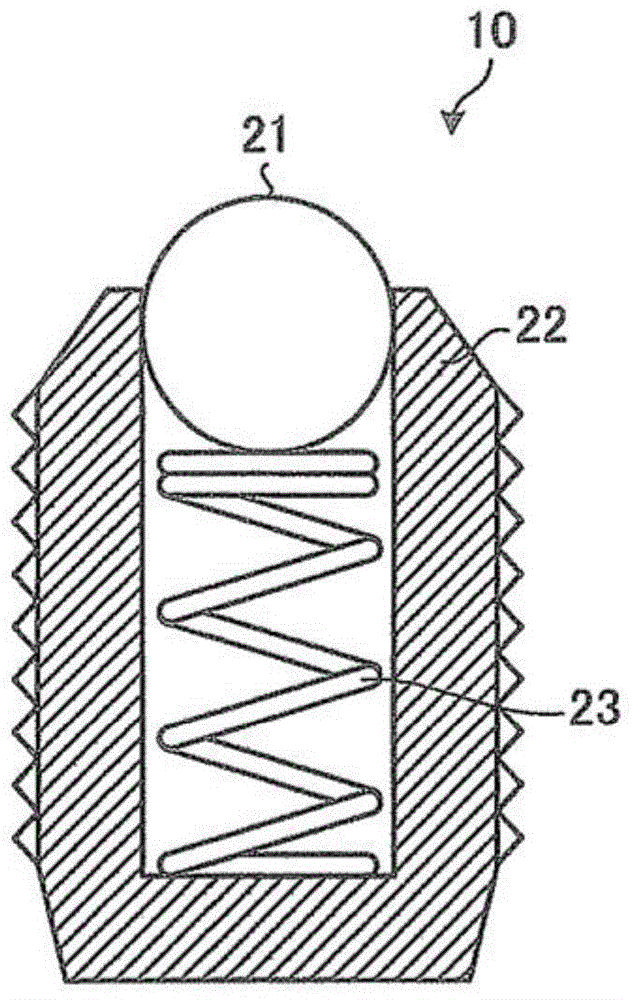

Precompression method and equipment

InactiveCN1796094AImprove positional accuracyQuality improvementShaping pressRadial positionEngineering

The present invention relates to a method for prepressing core tablet on the rotary core-covering tabletting machine and its device. It is characterized by that a prepressing device is added after first filling device and core-adding rotating disk and before second filling device so as to implement precompression location of core tablet and make the radial position of core tablet in the forming process be relatively fixed. Said prepressing device is formed from the components of prepressing wheel, prepressing wheel frame, fixed plate, regulating screw and spring, etc. The adoption of said method and device can ensure that the core tablet is positioned in the centre of medicine tablet so as to ensure the quality of core-covered tablet.

Owner:上海天和制药机械有限公司

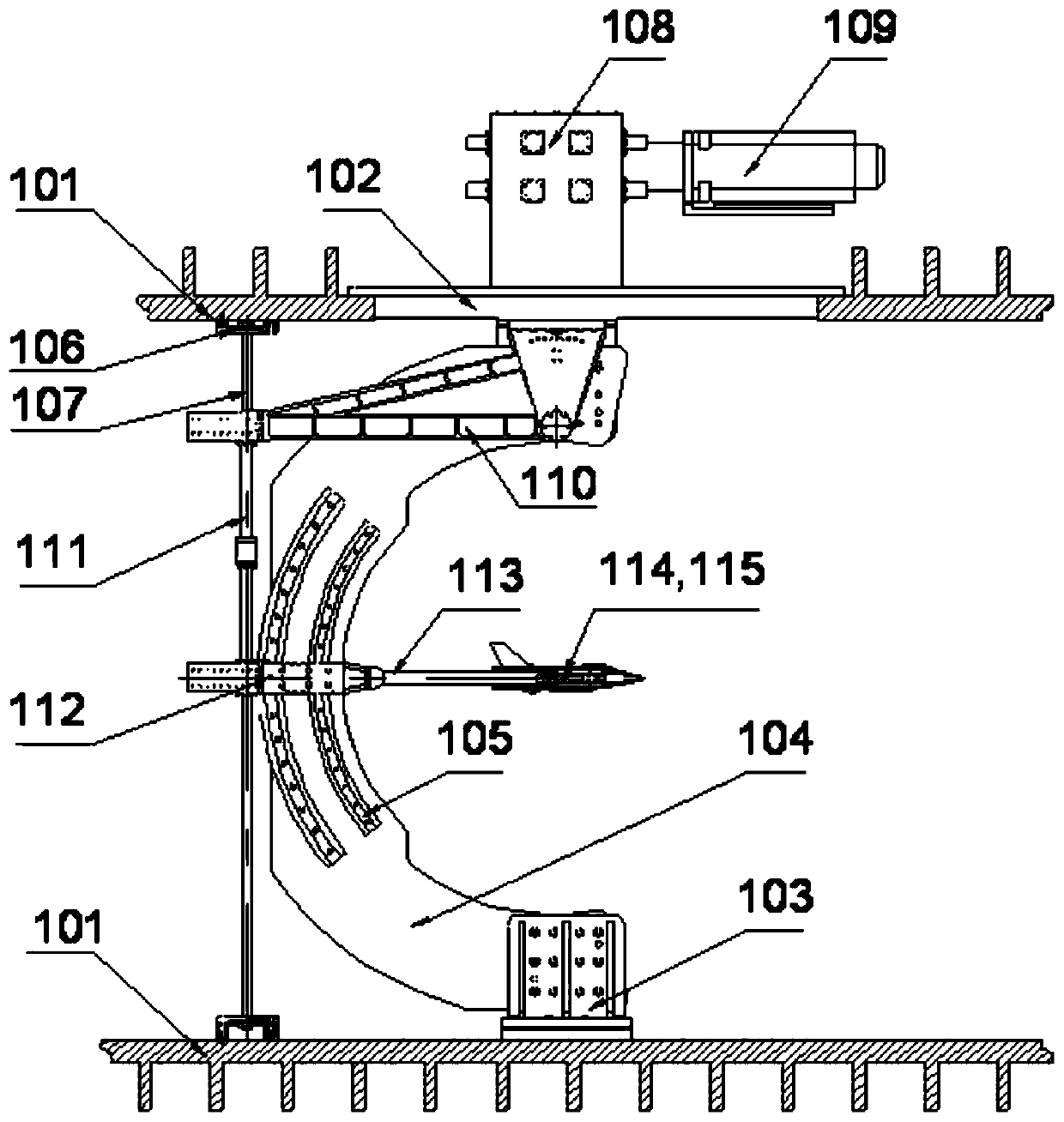

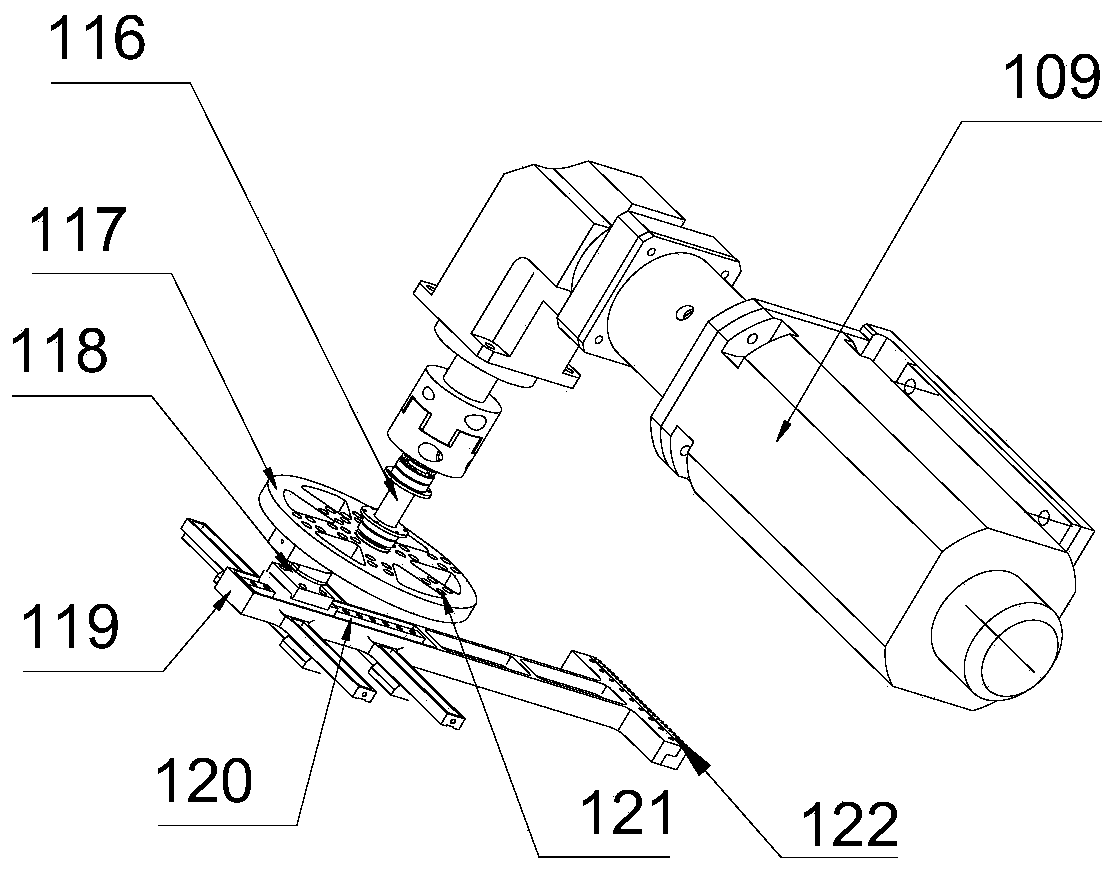

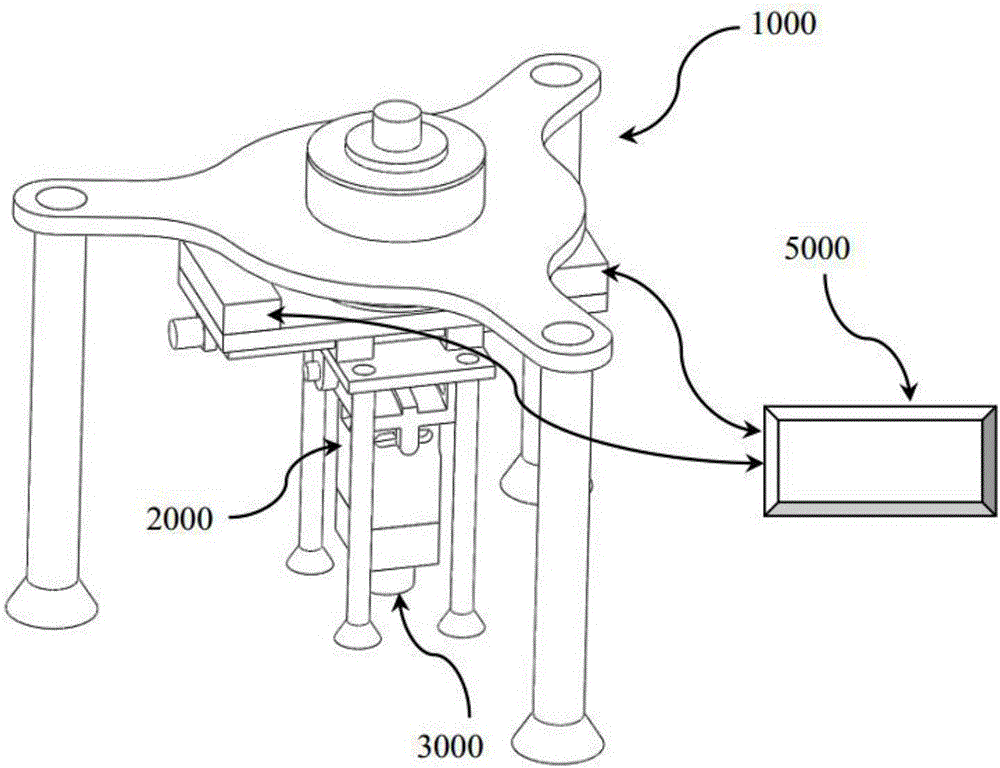

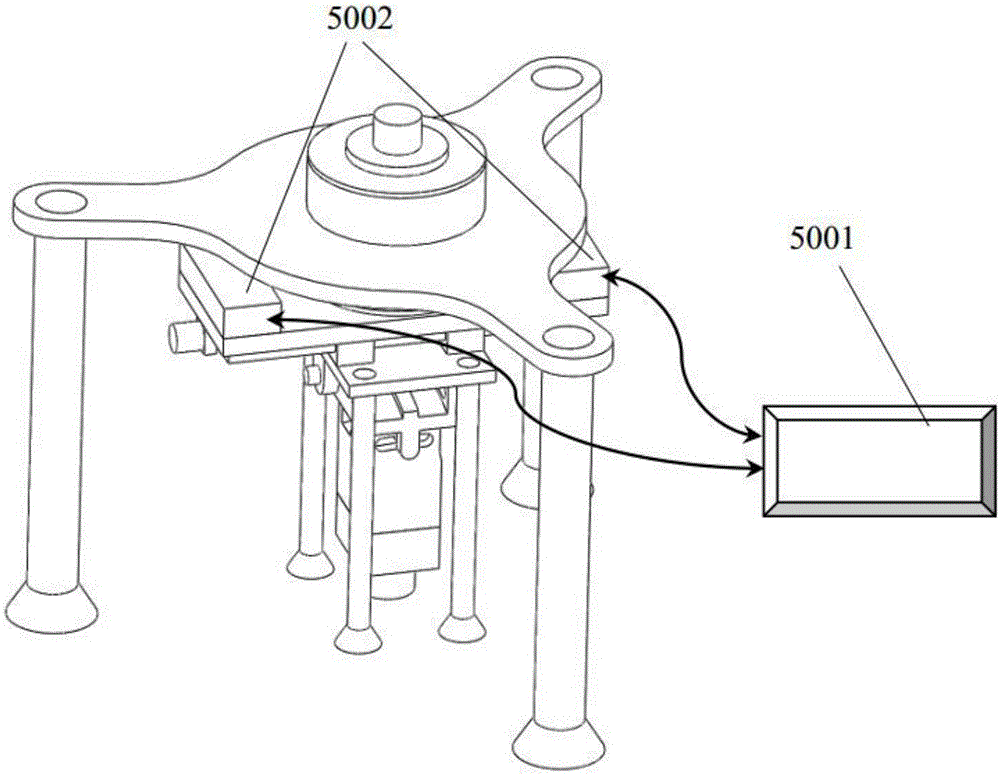

Test mechanism for rapidly changing model attitude angle

ActiveCN110207935AMeet high speedImprove positional accuracyAerodynamic testingDrive motorEngineering

The invention discloses a test mechanism for rapidly changing a model attitude angle. The test mechanism for rapidly changing the model attitude angle comprises a connecting cover plate and a lower connecting seat connected to a wind tunnel test section shell, a bent blade mechanism fixedly connected between the connecting cover plate and the lower connecting seat, an arc guide rail fixedly connected to the side of the bent blade mechanism, a guide rod fixedly connected to the test section shell by a connecting device behind the bent blade mechanism, a sinusoidal generator and a drive motor connected to the connecting cover plate, an upper swing lever connected to the lower side of the connecting cover plate, a push rod mounted on the guide rod, a lower swing lever connected to the arc guide rail, and a strut, a measuring balance and a model connected to the end of the lower swing lever. According to the invention, large pitching oscillation of the aircraft model can be realized by motor driving; the dynamic aerodynamic characteristics of the large pitching oscillation state of the aircraft can be measured by the measuring balance, so as to meet the test requirements of the high-speed wind tunnel; and the test mechanism for rapidly changing the model attitude angle has the characteristics of small snapback characteristics, convenient amplitude adjustment, high positioning accuracy, small support interference and the like.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

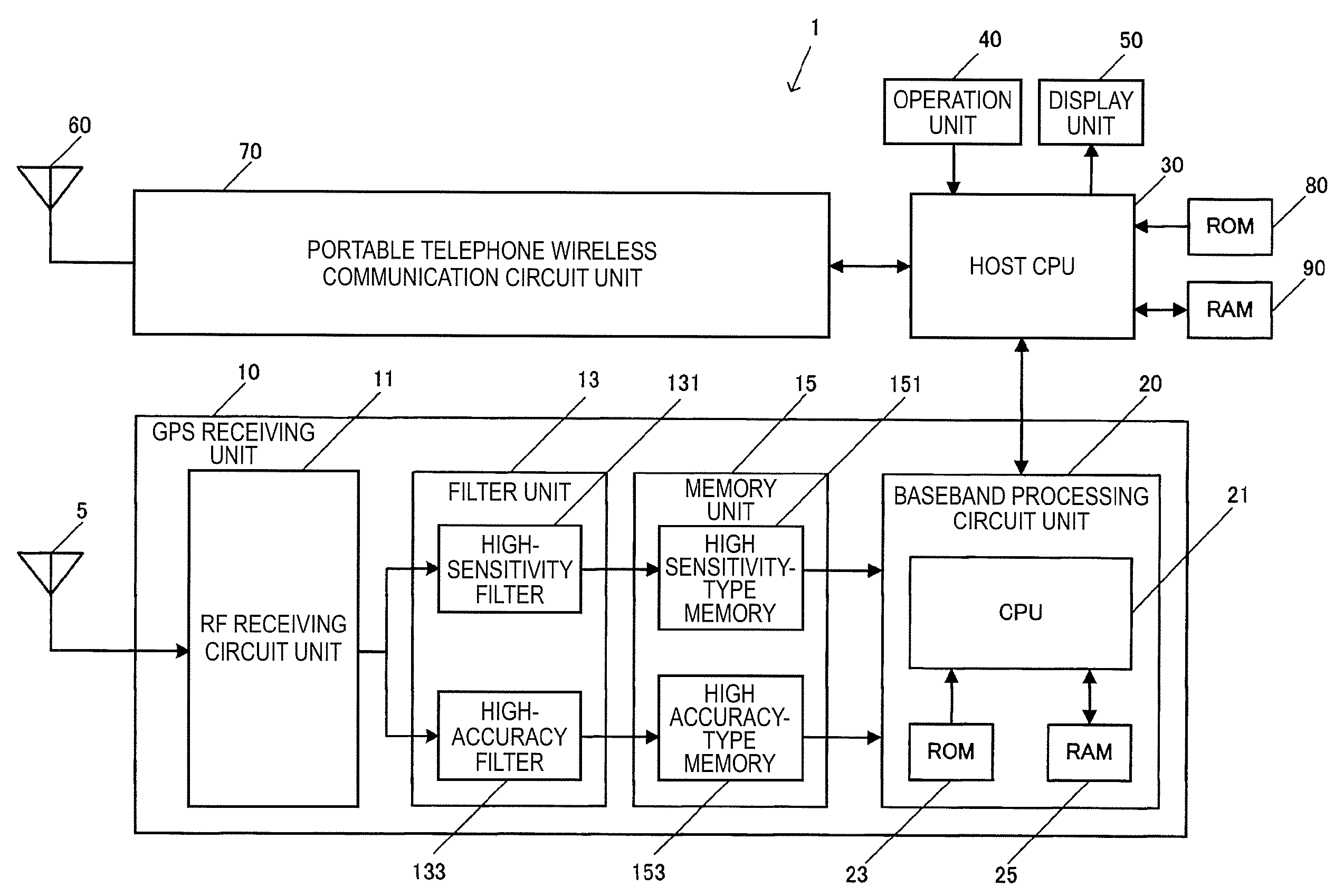

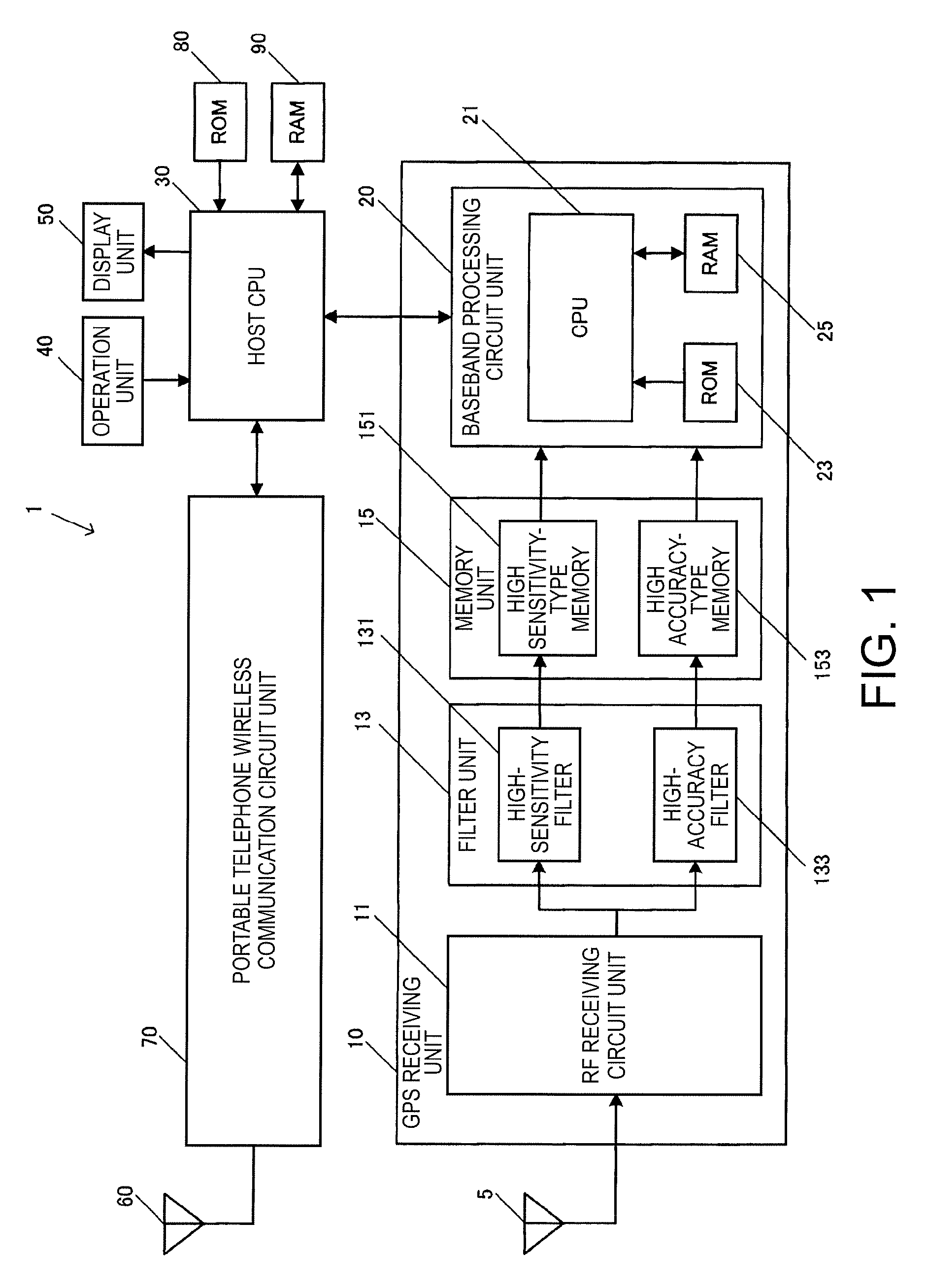

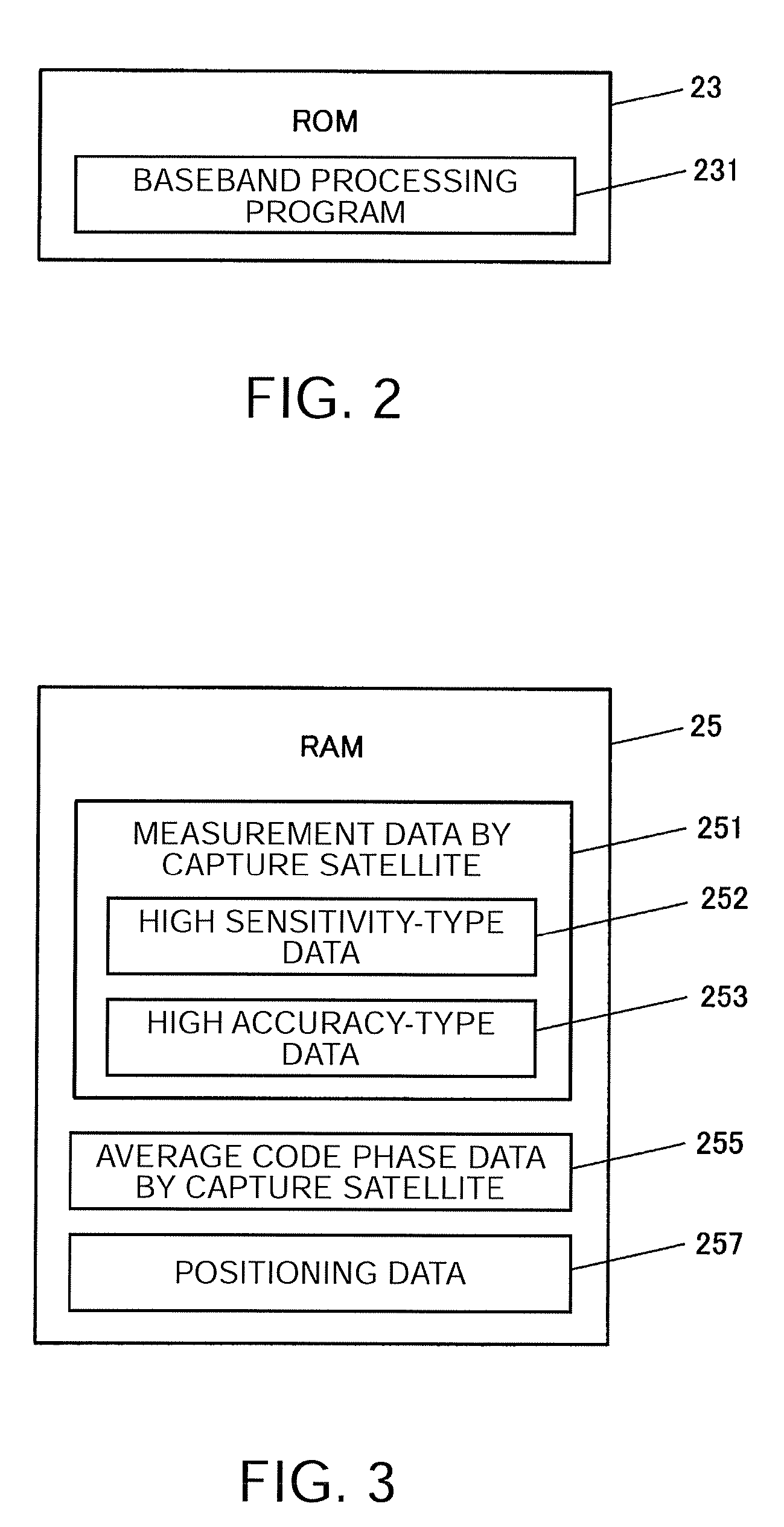

Pseudorange calculation method, position calculation method, computer-readable recording medium, and position calculation device

ActiveUS20090262019A1Improve positional accuracyHigh positioning accuracyBeacon systemsSatellite radio beaconingSatellitePseudorange

A pseudorange calculation method for calculating a pseudorange in a position calculation device includes: passing a received signal received from a satellite for position calculation through a first filter; passing the received signal through a second filter having a different phase characteristic from that of the first filter; calculating a first pseudorange on the basis of a signal acquired by passing through the first filter; calculating a second pseudorange on the basis of a signal acquired by passing through the second filter; and calculating a third pseudorange to be used for position calculation, on the basis of the first pseudorange and the second pseudorange.

Owner:SEIKO EPSON CORP

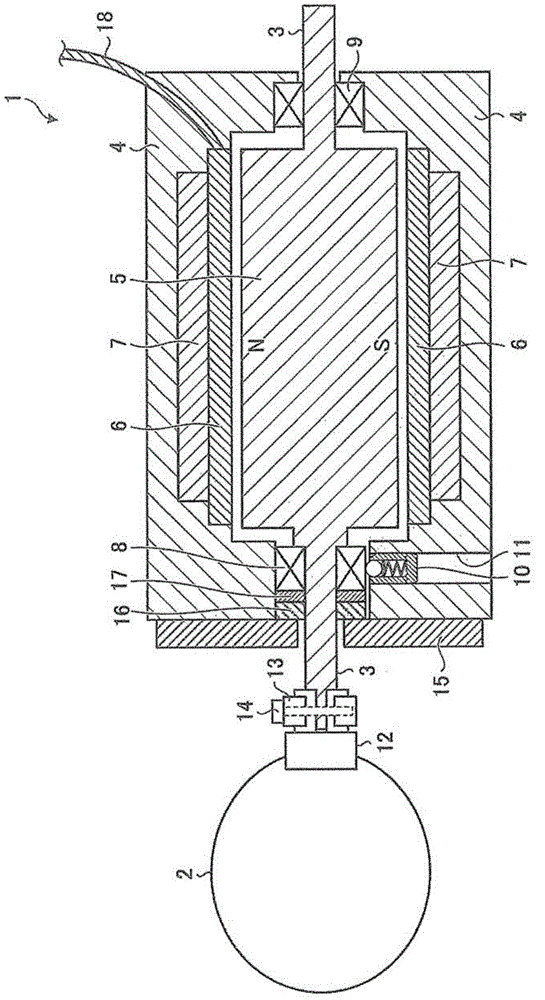

Galvano scanner and laser machining device

ActiveCN105209958AReduce face tilt resonanceImprove positional accuracyLaser beam welding apparatusOptical elementsEngineeringLaser

Provided is a galvano scanner comprising a rotating body that is provided with a rotation shaft (3) and is capable of rotating around the rotation shaft; a scan mirror (2) which is a mirror that deflects incident light and is connected to one end at the front side of the rotation shaft; a frame case (4) provided with an inner space in which the rotating body is rotated; a front-side bearing (8) which is a bearing provided at the front side end section of the inner space and rotatably supports the rotation shaft; and a ball plunger (10) which is a vibration suppression structure that suppresses vibrations of the front-side bearing caused by the driving of the rotation shaft. The vibration suppression structure has an abutting member that abuts an outer periphery side surface of the front-side bearing, and the abutting member is movable in accordance with displacement of the front-side bearing in an axial direction parallel to the rotation shaft.

Owner:MITSUBISHI ELECTRIC CORP

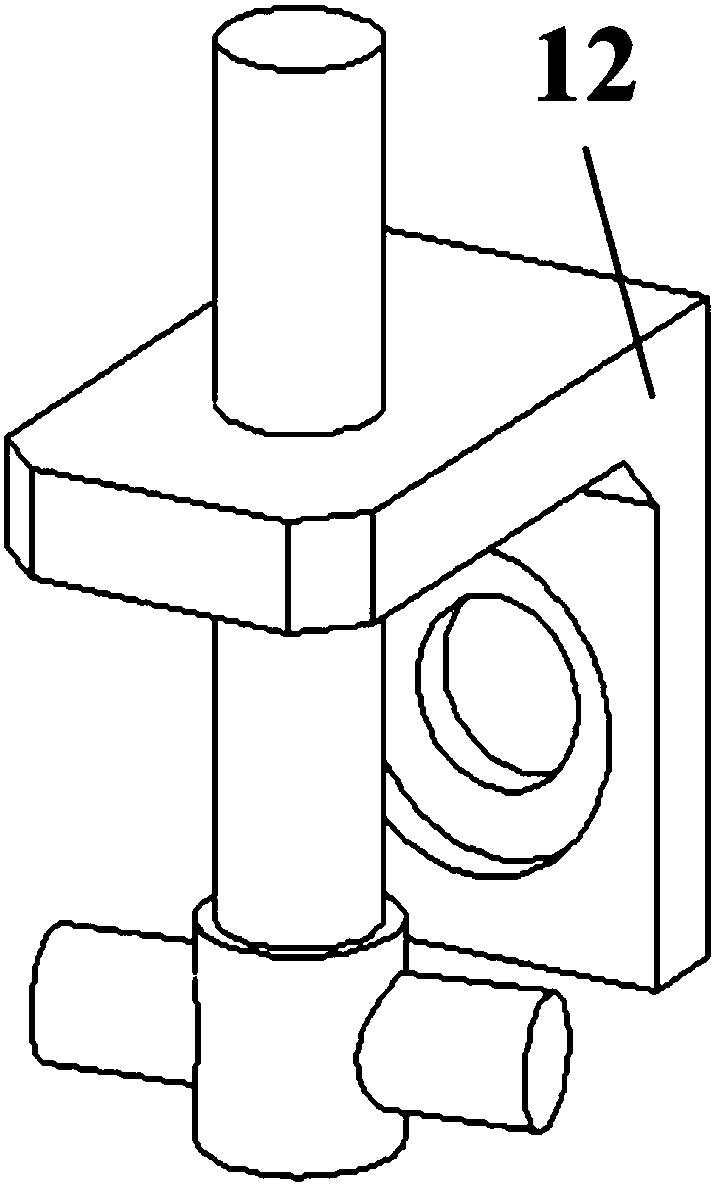

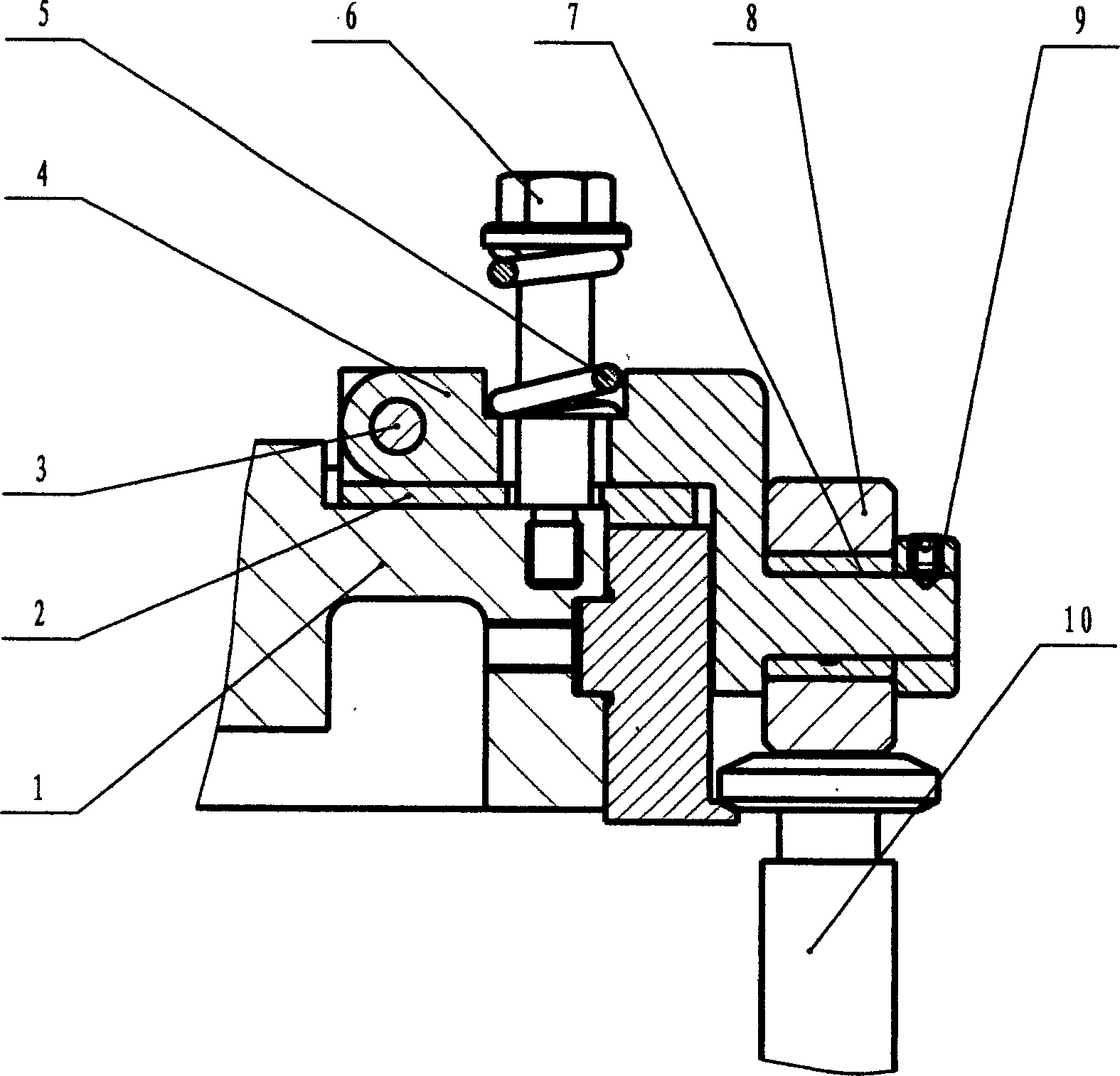

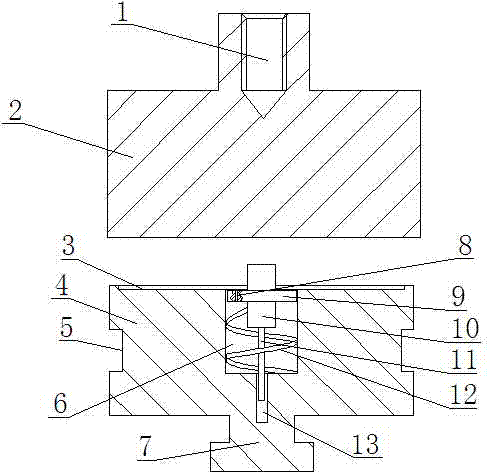

Welding device for positioning welding nut

InactiveCN103753075ASimple structureImprove positional accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a welding device for positioning a welding nut. The welding device comprises an upper pressure block (2) and a lower support block (4) which are arranged oppositely one above the other, wherein the upper end of the upper pressure block (2) is provided with a connecting post; a threaded connecting hole (1) is formed in the connecting post; the middle of the lower support block (4) is provided with a cylindrical spring cavity (6); a spring (12) is arranged in the spring cavity (6); the upper end of the spring (12) is connected with a positioning post (10); the middle of the positioning post (10) is provided with a baffle ring (9); the lower end face of the lower support block (4) is provided with a trapezoidal connecting block (7). The designed welding device for positioning the welding nut is simple in structure. Moreover, the welding nut can be positioned accurately, can be adjusted during compression, and is high in position accuracy, high in welding efficiency, good in effect and high in practicability.

Owner:SICHUAN LANXUNBAOER ELECTRONICS TECH

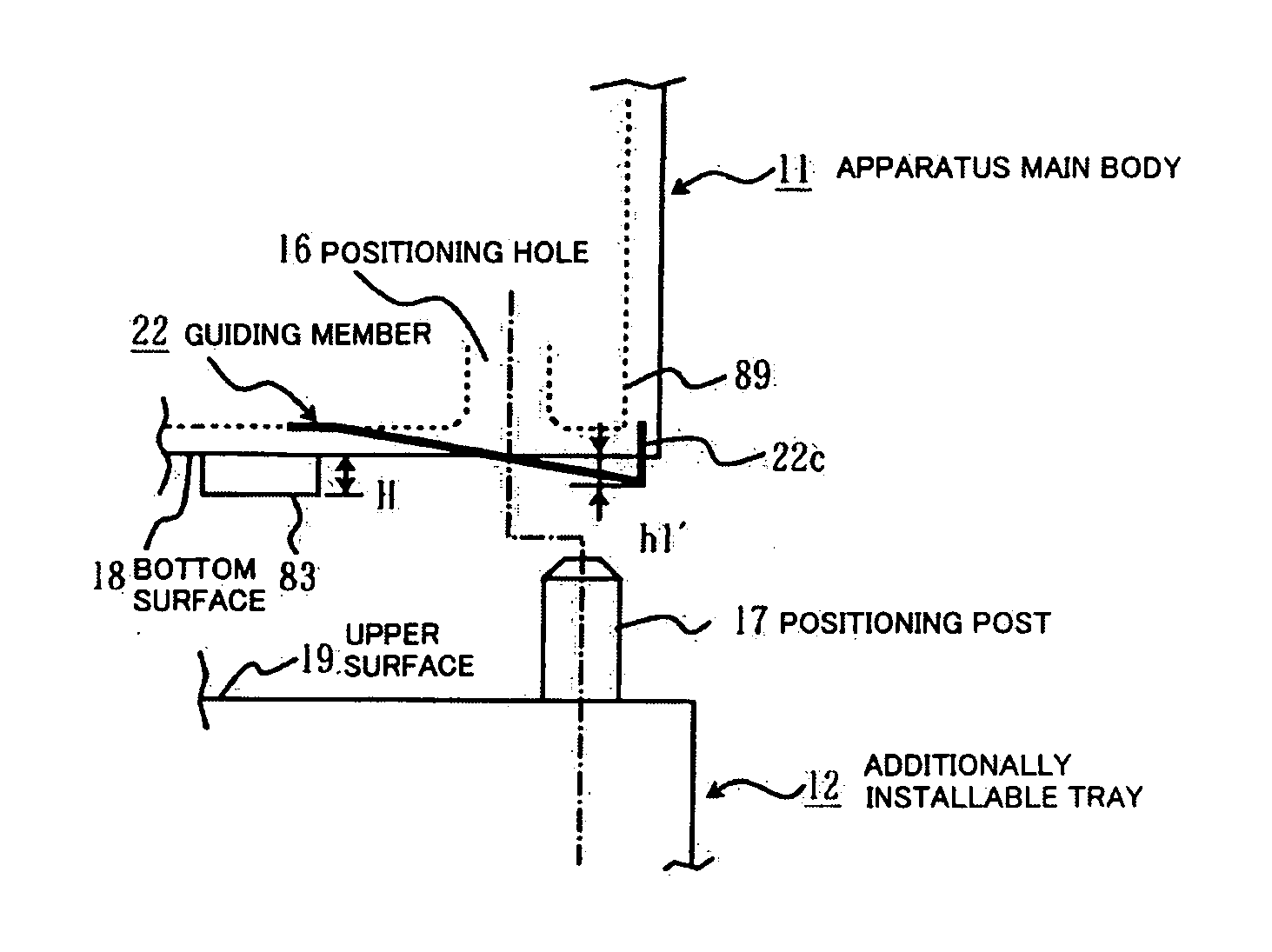

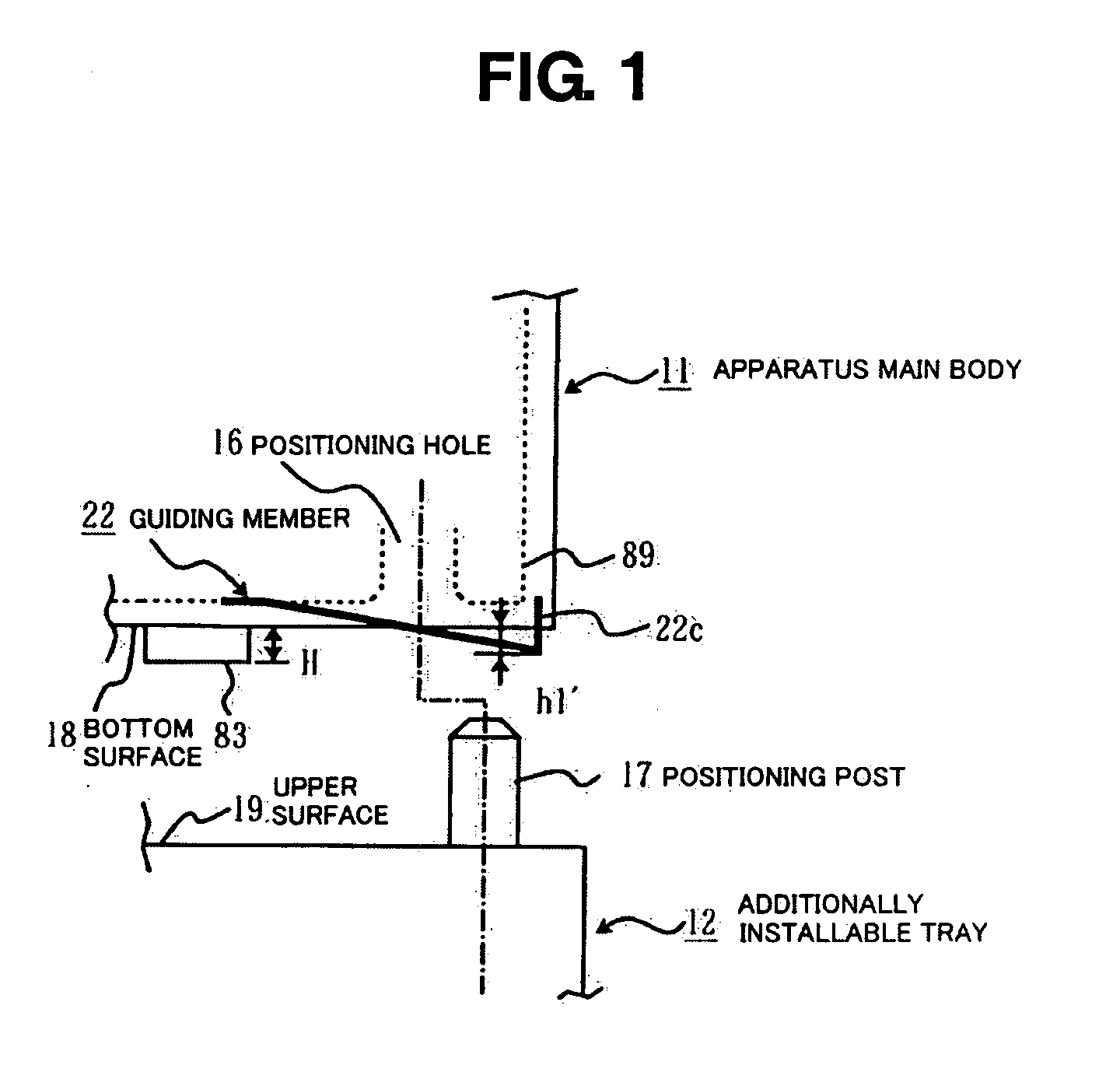

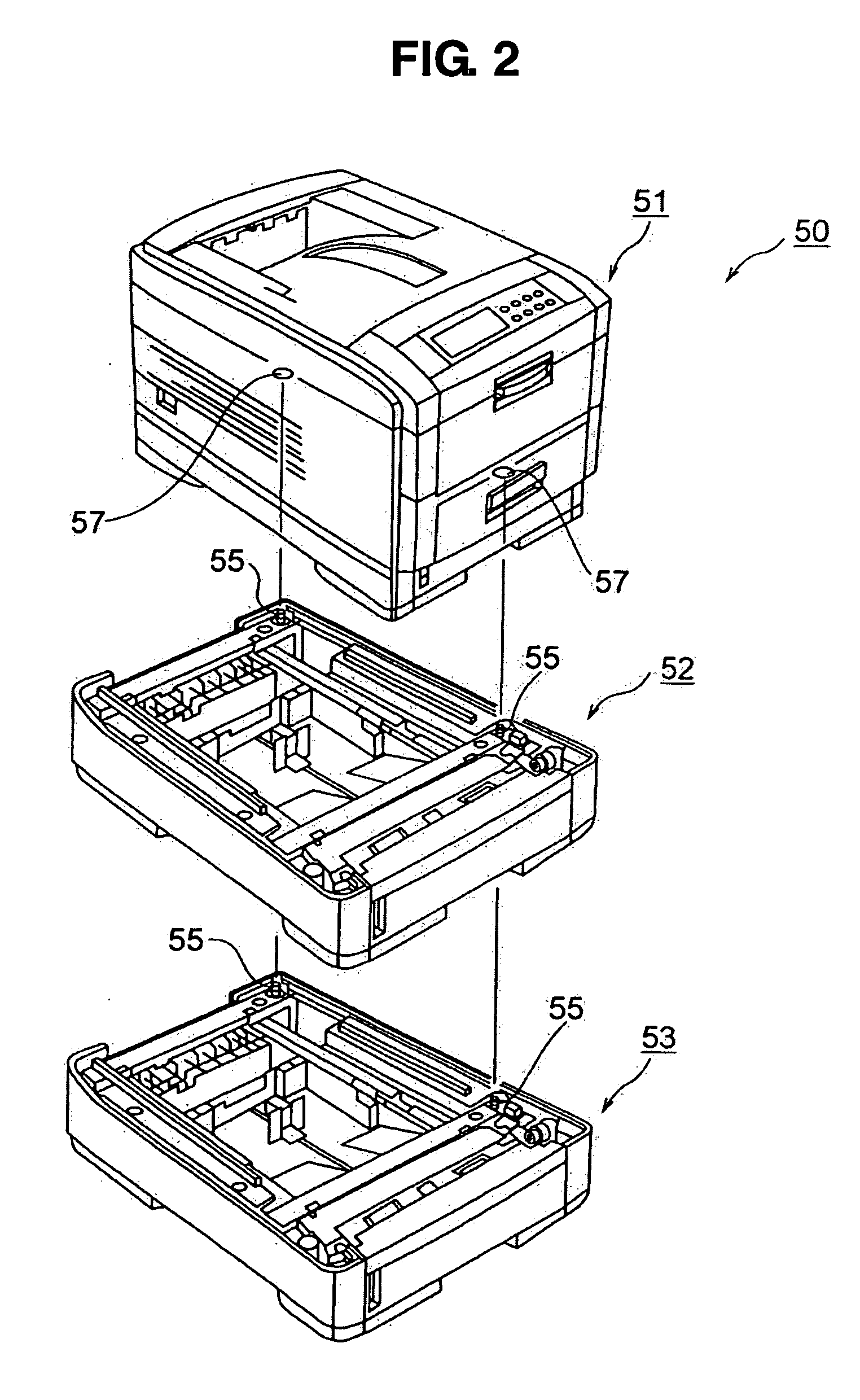

Image forming apparatus and additionally installable apparatus

InactiveUS20070212106A1Improve positional accuracySimple operationElectrographic process apparatusBiomedical engineeringImage formation

Owner:OKI DATA CORP

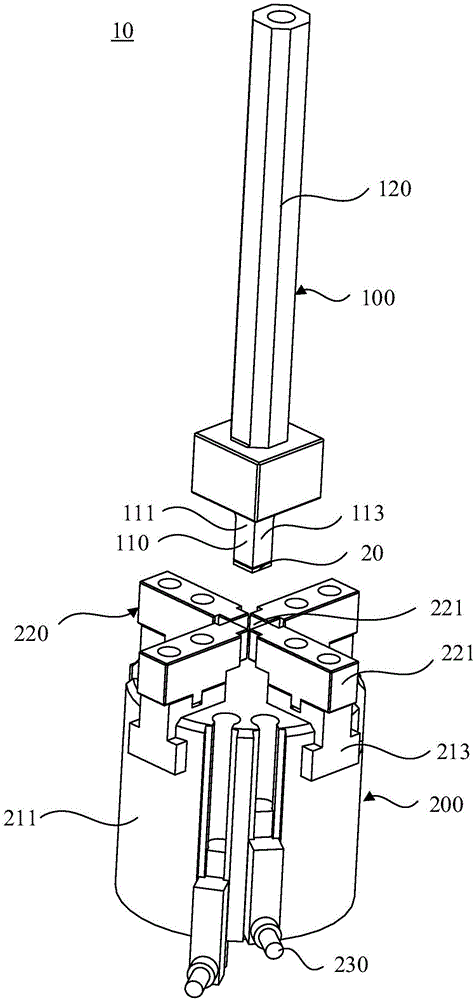

Corrector and correction assembly thereof

InactiveCN107175501AImprove positional accuracySimple and compact structureMetal working apparatusEngineeringMechanical engineering

The invention relates to a correction device and a correction component thereof. The correction component is used for correcting the position of auxiliary materials on a pick-up piece. The correction assembly includes a power part and a correction part, the power part includes a first body and a moving part, the first body is connected to the moving part, and the first body can drive the moving part to move; the correction part is fixedly connected to the moving part, and the correction part has a correction surface, The shape of the correction surface matches the shape of the auxiliary material; when the body drives the moving part to move, the moving part can drive the correction part close to the pick-up part, so that the correction surface contacts the auxiliary material. The above-mentioned correction device and its correction components have a simple and compact structure, take up little space, are easy to operate, and can effectively improve the positional accuracy of the assembly of auxiliary materials.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

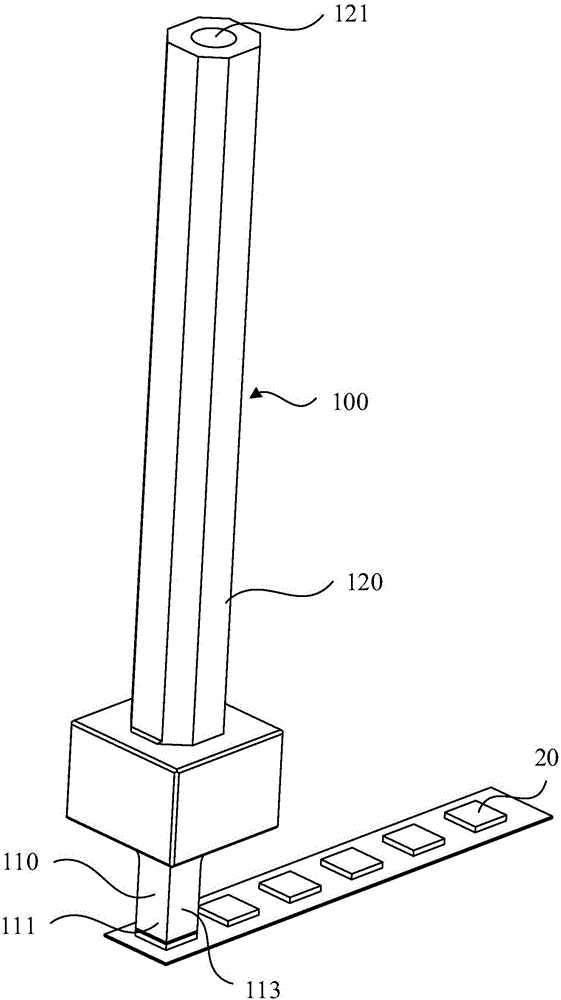

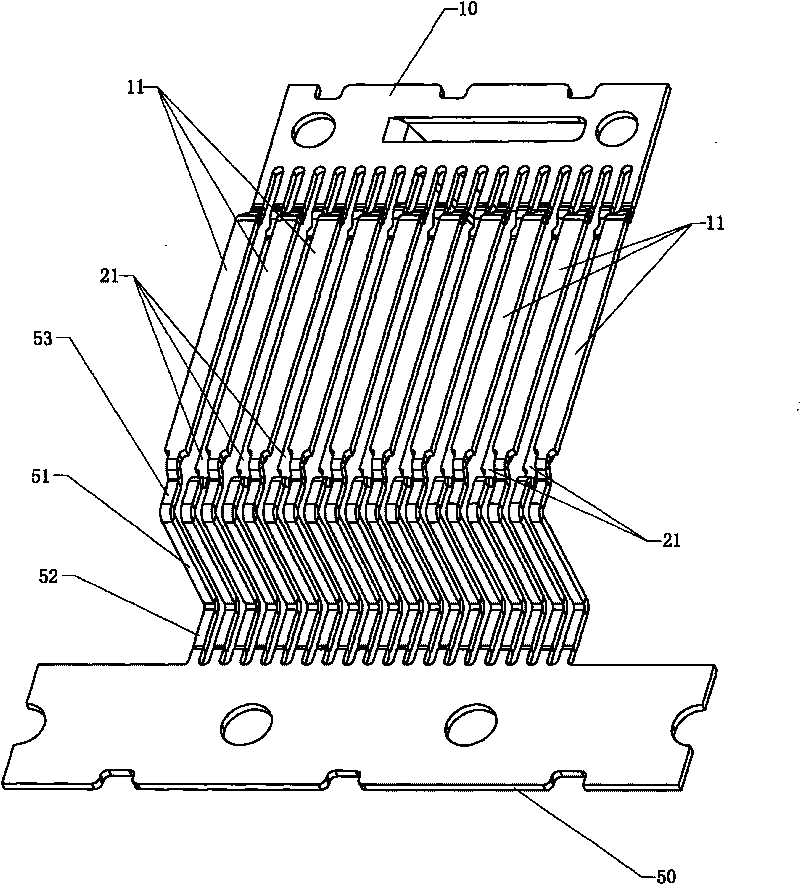

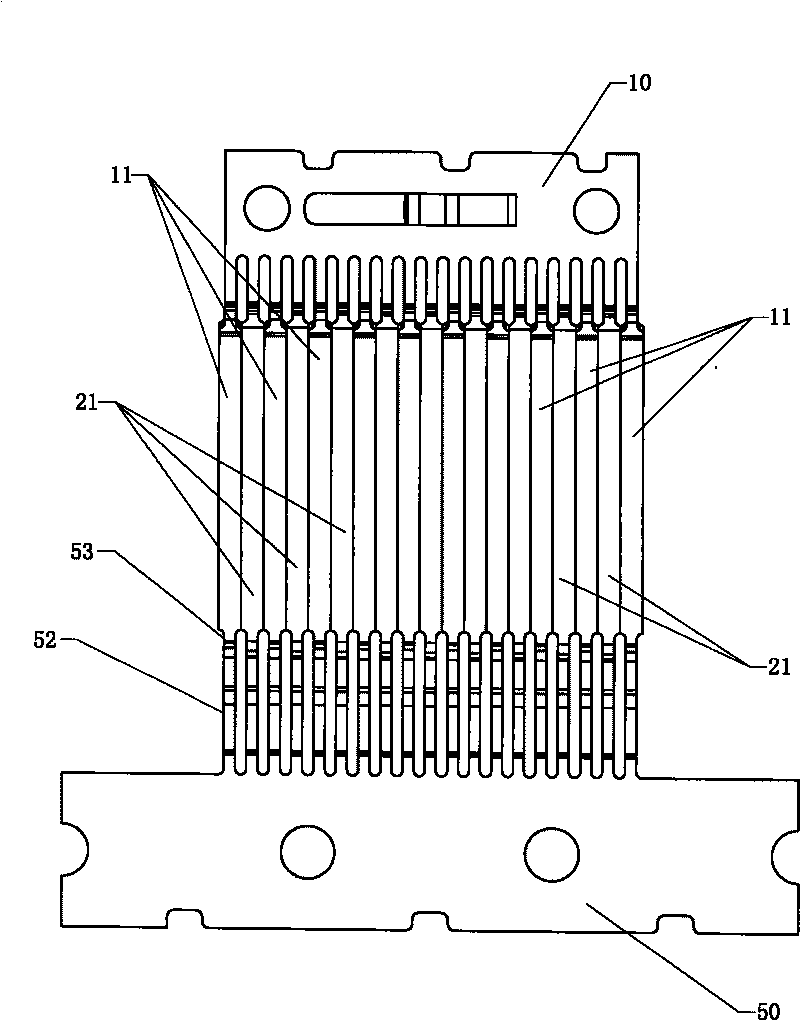

Manufacturing method of plug-in terminal of connector

ActiveCN101702484AImprove positional accuracyQuality improvementContact member manufacturingEngineeringElectrical and Electronics engineering

The invention provides a manufacturing method of a plug-in terminal of a connector, a first model and a second model are adopted, equal-height heaves are arranged on both opposite surfaces of the first model and the second model, the tail ends of all heaves of the first model are coplanar, and the tail ends of all heaves of the second model are coplanar; the first model and the second model are moved to the first row of conducting terminals and the second row of conducting terminals from two opposite directions, and the heaves of the first model are inserted between two adjacent conducting terminals of either of the first row of conducting terminals and the second row conducting terminals, and the heaves of the second model are inserted between two adjacent conducting terminals of the other one of the first row conducting terminals and the second row of conducting terminals; and a space formed between the first row of conducting terminals and the second row of conducting terminals is filled with insulating materials. The invention can effectively improve the position precision of the conducting terminals in the manufacturing process and the respective coplanarity both of the first row of conducting terminals and the second row of conducting terminals and correspondingly improve the quality of the connector and the plugged-in terminal. The method is simple in steps and easy to implement, and can improve the production efficiency and reduce the manufacturing cost by improving the product quality.

Owner:SHENZHEN JIANDUAN TECH

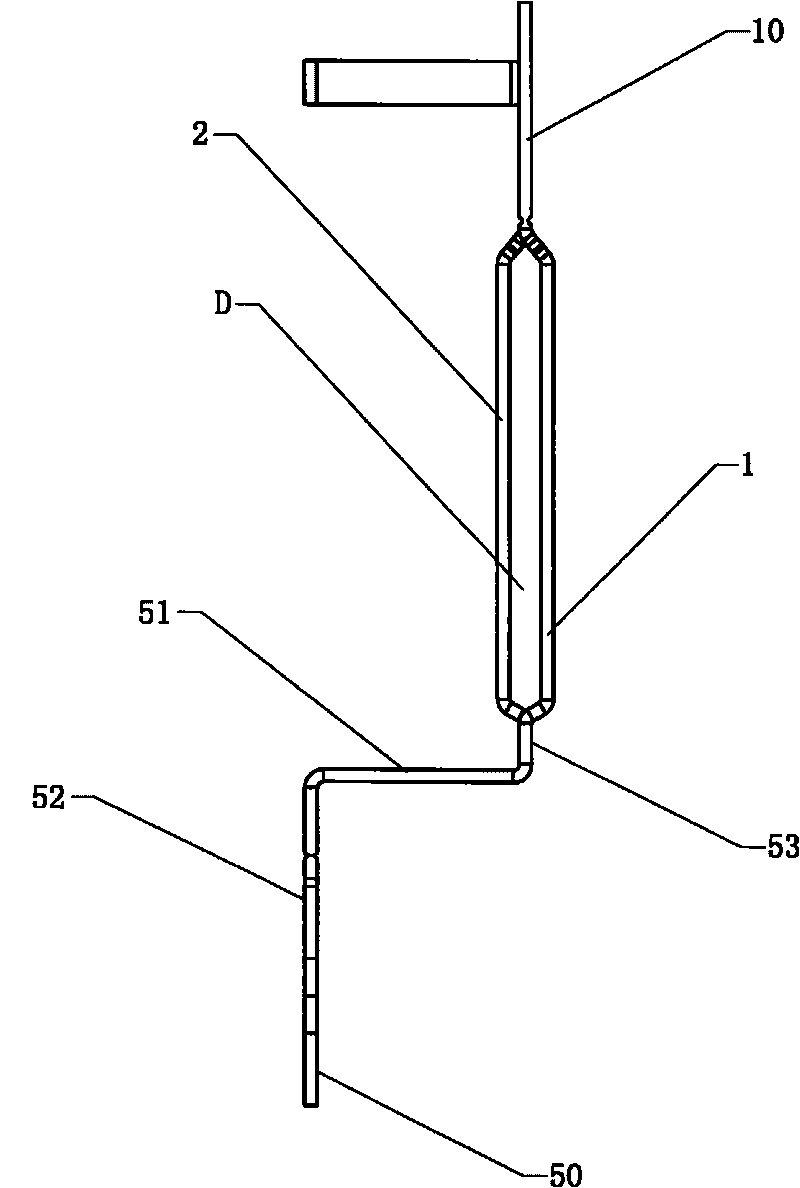

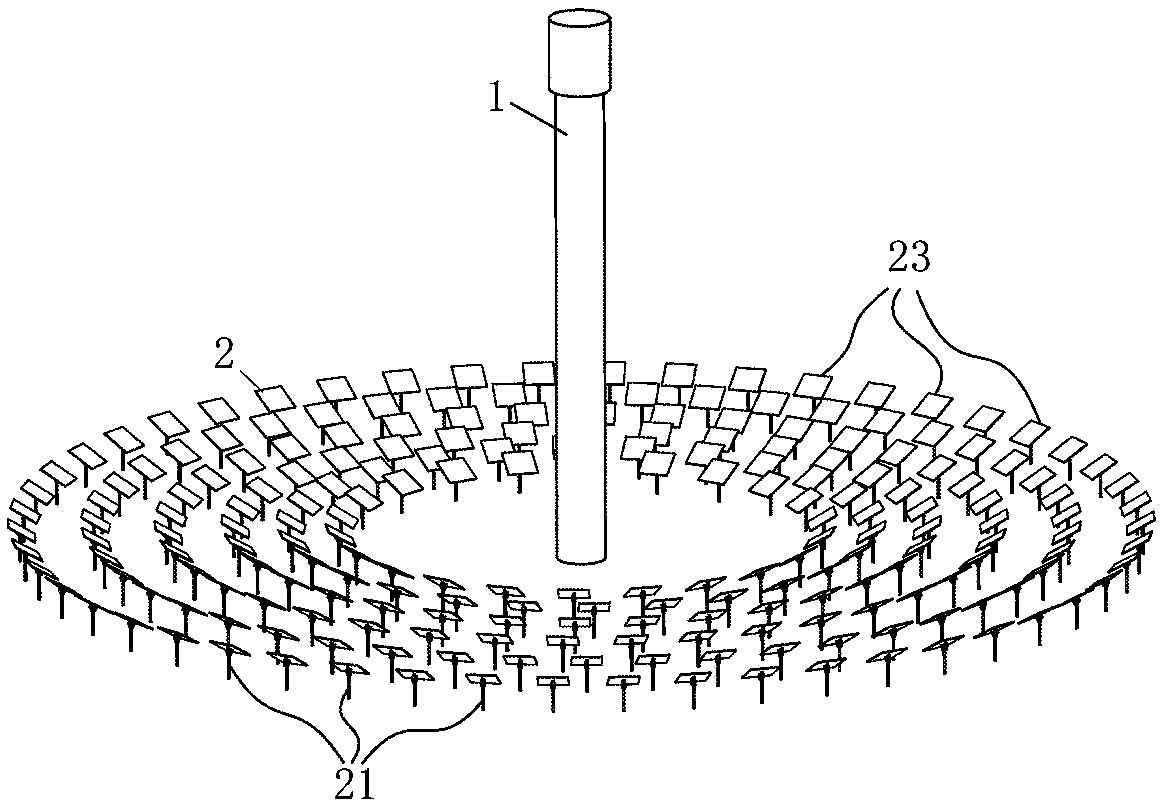

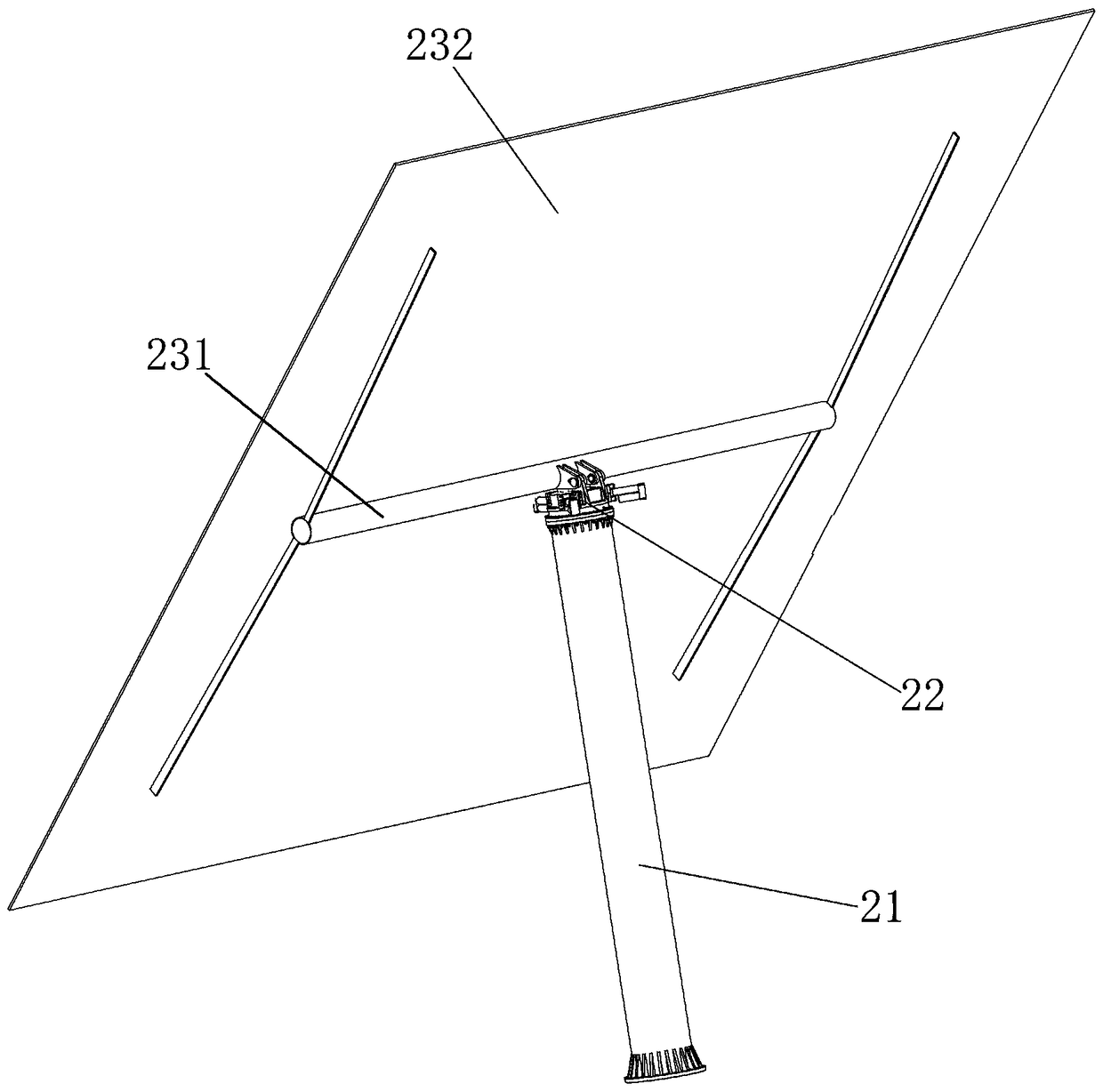

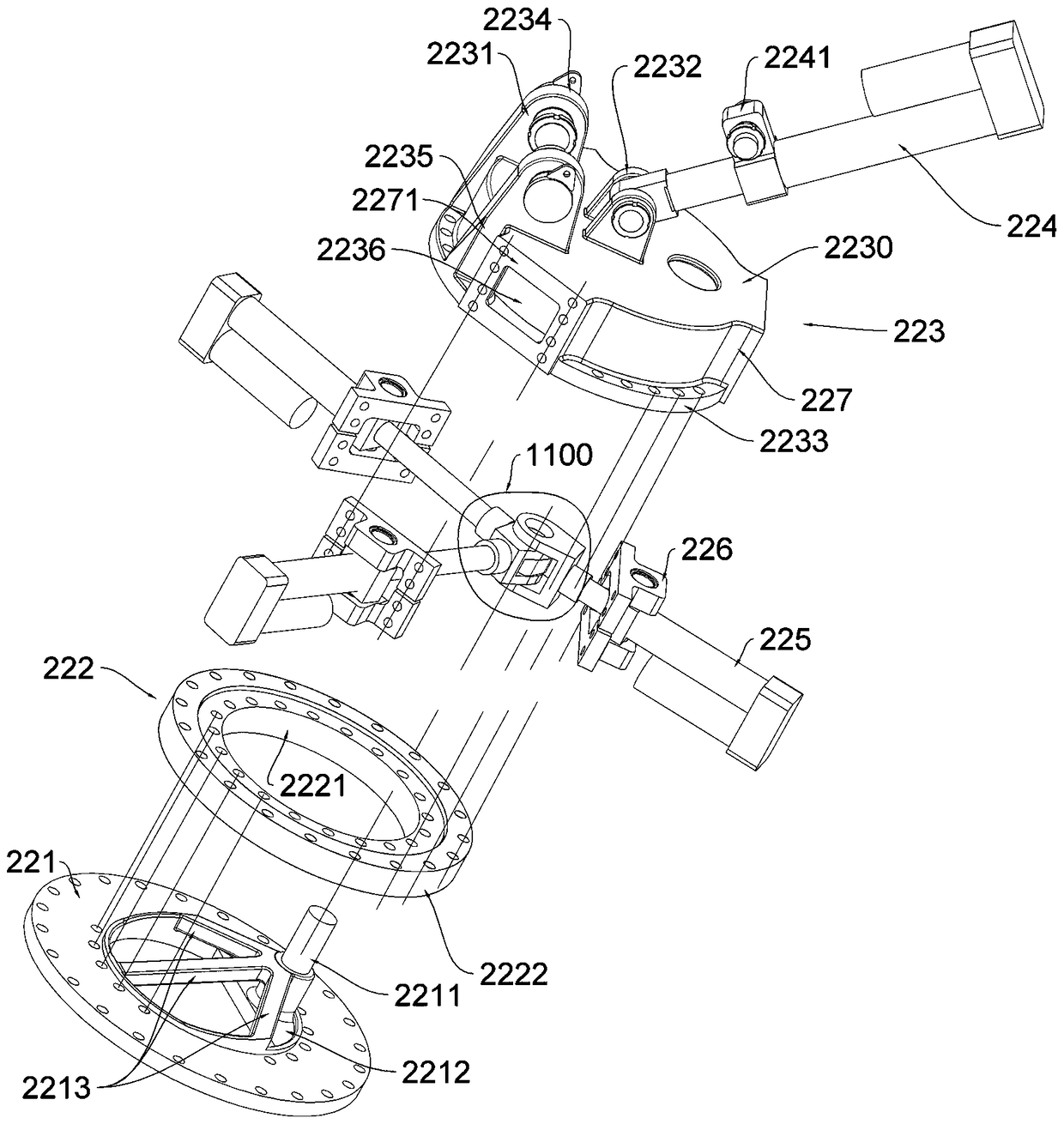

Tower type photo-thermal power generation system, heliostat, heliostat tracking driving device and heliostat rotating table

PendingCN108954861AHigh precisionImprove positional accuracyPhotovoltaic supportsSolar heating energyHinge angleEngineering

The invention relates to the field of photo-thermal power generation devices, in particular to a tower type photo-thermal power generation system, a heliostat, a heliostat tracking driving device anda heliostat rotating table. The heliostat rotating table comprises a rotating table body, a reflecting mirror hinge seat arranged on the rotating table body and a pitch angle oil cylinder hinge seat arranged on the rotating table body. The heliostat rotating table is of a casting formed integrated structure, and the reflecting mirror hinge seat and the pitch angle oil cylinder hinge seat are integrally formed with the rotating table body in a casting manner. The heliostat rotating table is integrally formed, and it is ensured that the position precision obtained after primary machining is improved while rigidity of the rotating table is ensured. Compared with a current assembly type heliostat rotating table, the heliostat rotating table is high in precision, and the problems that the installation precision and rigidity of the current heliostat rotating table are low are solved.

Owner:洛阳斯特林智能传动科技有限公司

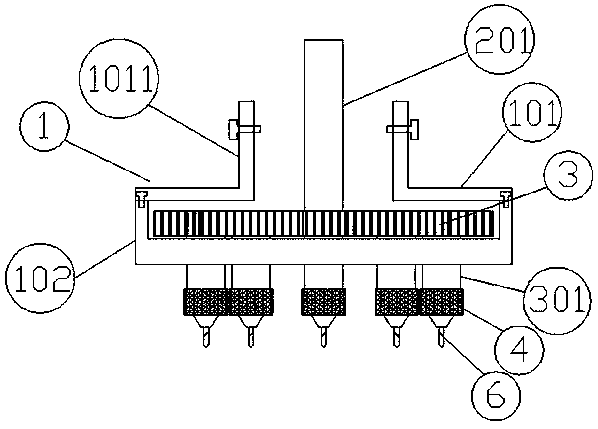

Wire rail perforating machine

InactiveCN110449624AImprove positional accuracyEasy to coolTransportation and packagingMaintainance and safety accessoriesDrill bitEngineering

The invention relates to a wire rail perforating machine. The wire rail perforating machine comprises a rack, wherein a drilling mechanism, a plurality of transversely-distributed drill bit assembliesand a wire rail fixing mechanism positioned below the drill bit assemblies are arranged on the rack; each drill bit assembly comprises a downward drill bit and a motor for driving the drill bit to rotate; the wire rail fixing mechanism comprises a supporting plate, a transverse straightening comparison strip arranged on the supporting plate, three pressing blocks which are transversely distributed and a pressing block driving mechanism which drives the pressing blocks to move in the longitudinal direction to be matched with the transverse straightening comparison strip to clamp the wire rail;the three pressing blocks are located on the same side of the transverse straightening comparison strip; and the drilling mechanism is used for driving the drill bit assemblies and the wire rail fixing mechanism to be separated and closed along the vertical direction. According to the wire rail perforating machine, the position precision of the punched hole is high, and the problems of labor consumption and low hole position precision existing in manually drilling by a bench drill can be solved.

Owner:浙江固德轴承制造有限公司

Positioning and punching method for composite material honeycomb sandwich part packing area

InactiveCN108068354AReduce the difficulty of positioningImprove positional accuracyDomestic articlesLine drawingsHoneycomb

The invention belongs to the field of aviation composite material part manufacturing, and particularly relates to a positioning and punching method for a composite material honeycomb sandwich part packing area. The size of small-diameter through holes, part of a composite honeycomb sandwich part, is 50 mm or less, a line drawing positioning is easy to be caused positioning deviation, so that a filling padding needs to be reworked after the part is drilled. According to the positioning and punching method for the composite material honeycomb sandwich part packing area, a conical pin is arrangedat the theoretical punching position of a tool, and only the conical part is exposed, and a veneering surface prepreg is laid on a molded surface of the tool, and then the convex veneering surface prepreg is cut off according to the conical part; a honeycomb sandwich layer is placed, and a packing is filled with the conical part as a center; a non-veneering surface prepreg is laid, the whole transfer is carried out, heating and pressurization solidification are carried out; and drilling is carried out according to conical holes formed in the bottom. The positioning difficulty of the packing area in the part manufacturing process is reduced, the position precision of the packing area is improved, the reworking repair rate is reduced, and the product quality is improved.

Owner:JIANGXI CHANGHE AVIATION IND

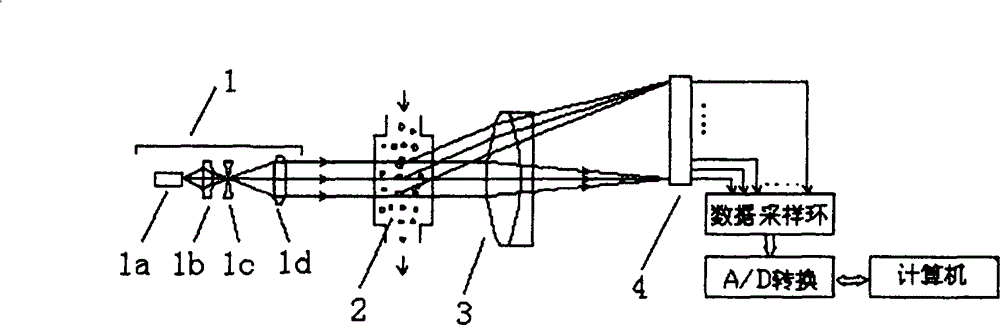

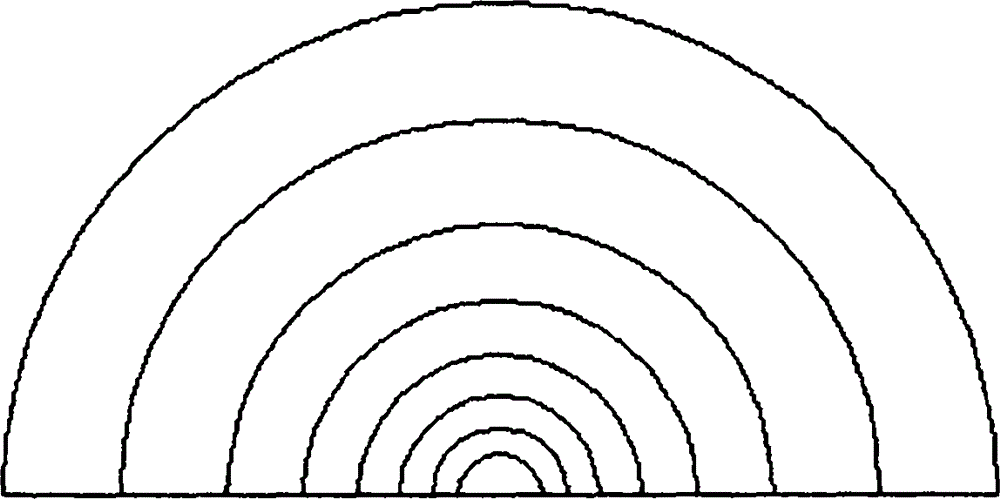

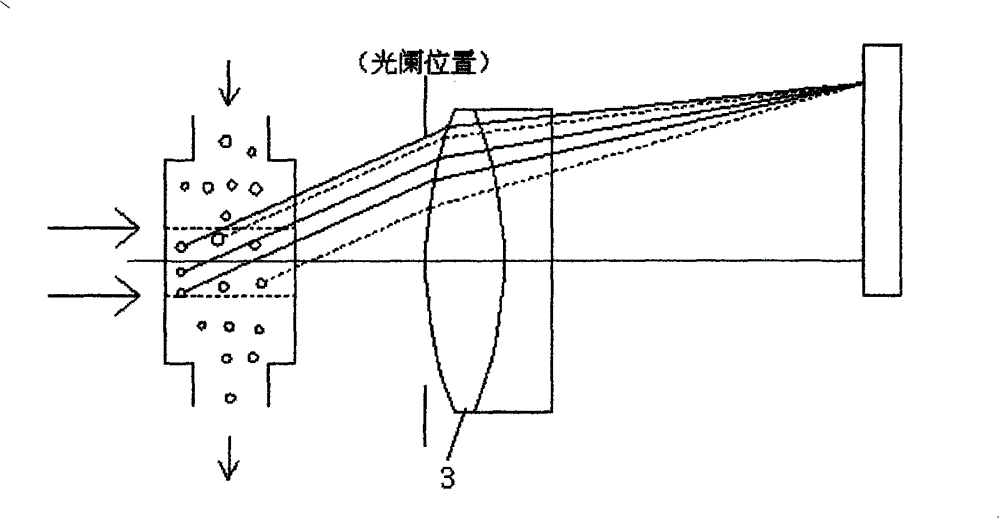

Design method of laser particle analyzer optical system

InactiveCN104568682AImprove positional accuracyHigh positioning accuracyParticle size analysisOptical pathOptoelectronics

Owner:THE 3RD ACAD 8358TH RES INST OF CASC

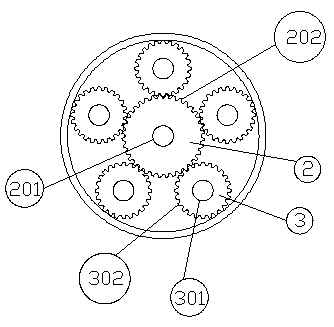

Multi-axis linkage drilling and cutting device

InactiveCN108637302AFast processing efficiencyImprove positional accuracyMilling machinesBoring/drilling machinesEngineeringDrill bit

The invention discloses a multi-axis linkage drilling and cutting device. The device is characterized by comprising a shell, a main power transmission mechanism, an auxiliary power transmission mechanism and an auxiliary chuck, and the shell can fix the main power transmission mechanism and the auxiliary power transmission mechanism; and the auxiliary chuck is arranged on the main power transmission mechanism or the auxiliary power transmission mechanism, and can move along with the main power transmission mechanism or the auxiliary power transmission mechanism, and the auxiliary chuck can fixa drill bit or a milling cutter; and the main power transmission mechanism can rotate to drive the auxiliary power transmission mechanism to rotate. The main power transmission mechanism can rotate to drive the auxiliary power transmission mechanism to rotate, then the auxiliary chuck on the main power transmission mechanism or on the auxiliary power transmission mechanism can be driven to rotate, then the drill bit or the milling cutter on the auxiliary chuck can be driven to work, so that simultaneous machining of a plurality of holes is realized, the machining efficiency is high, and position precision between the holes is high.

Owner:陕西图灵电子科技有限公司

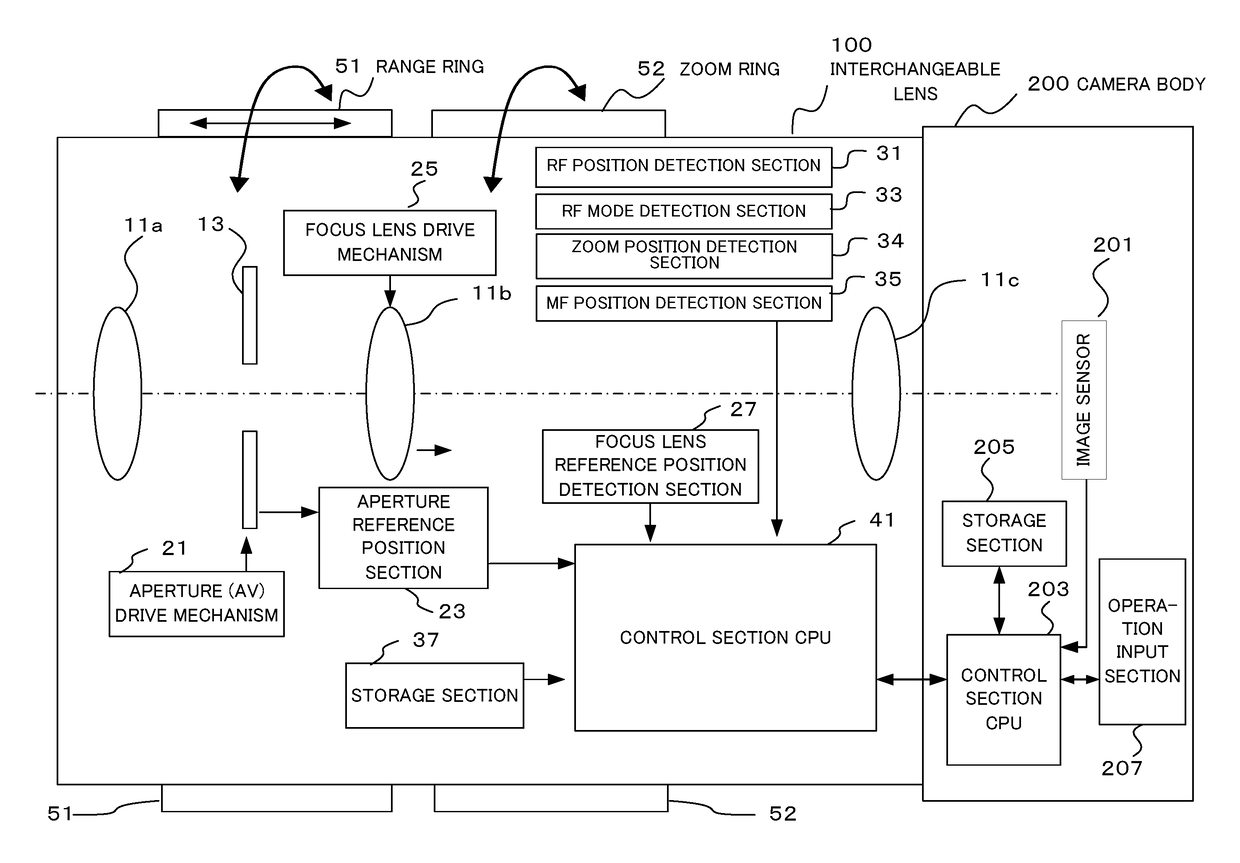

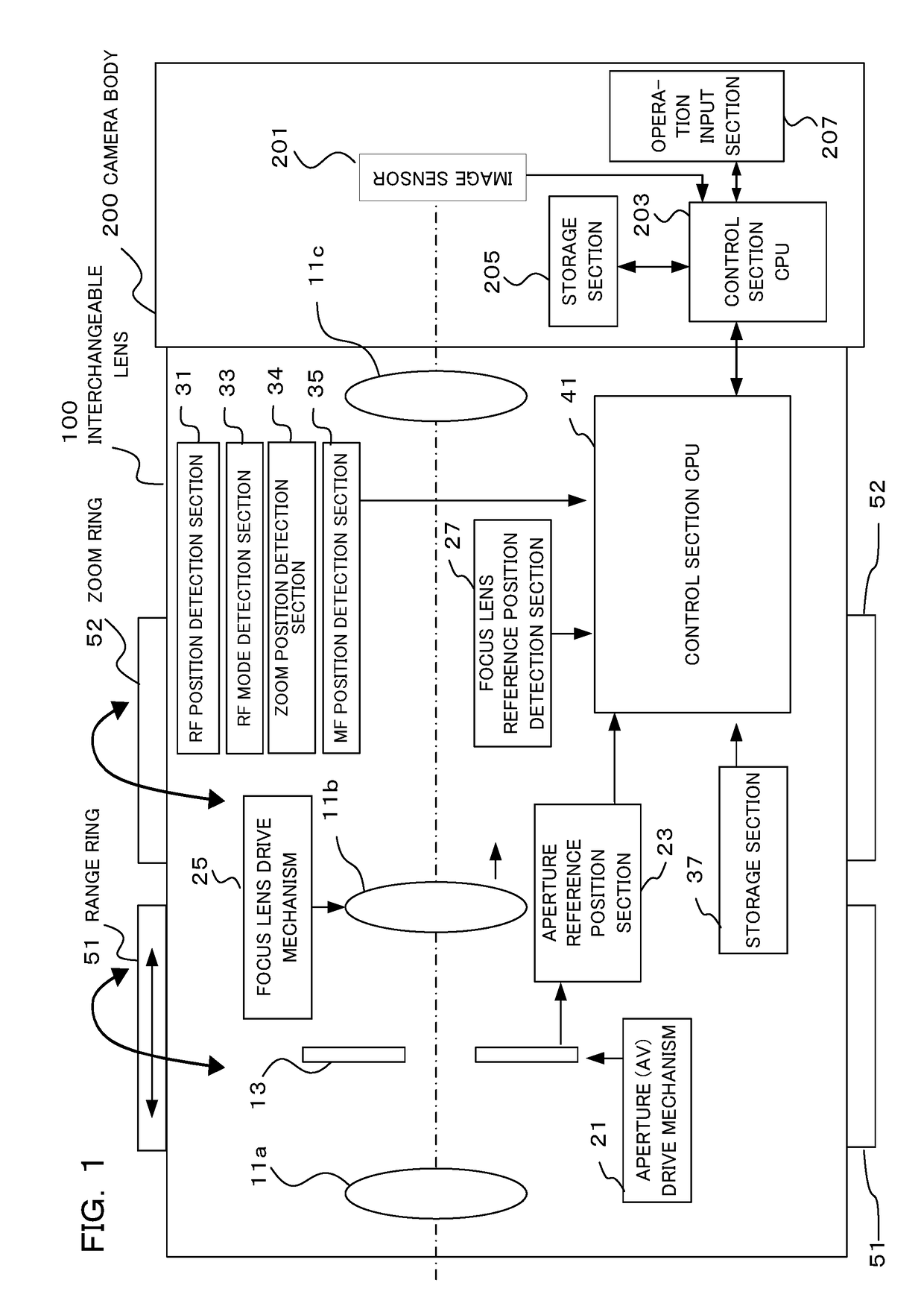

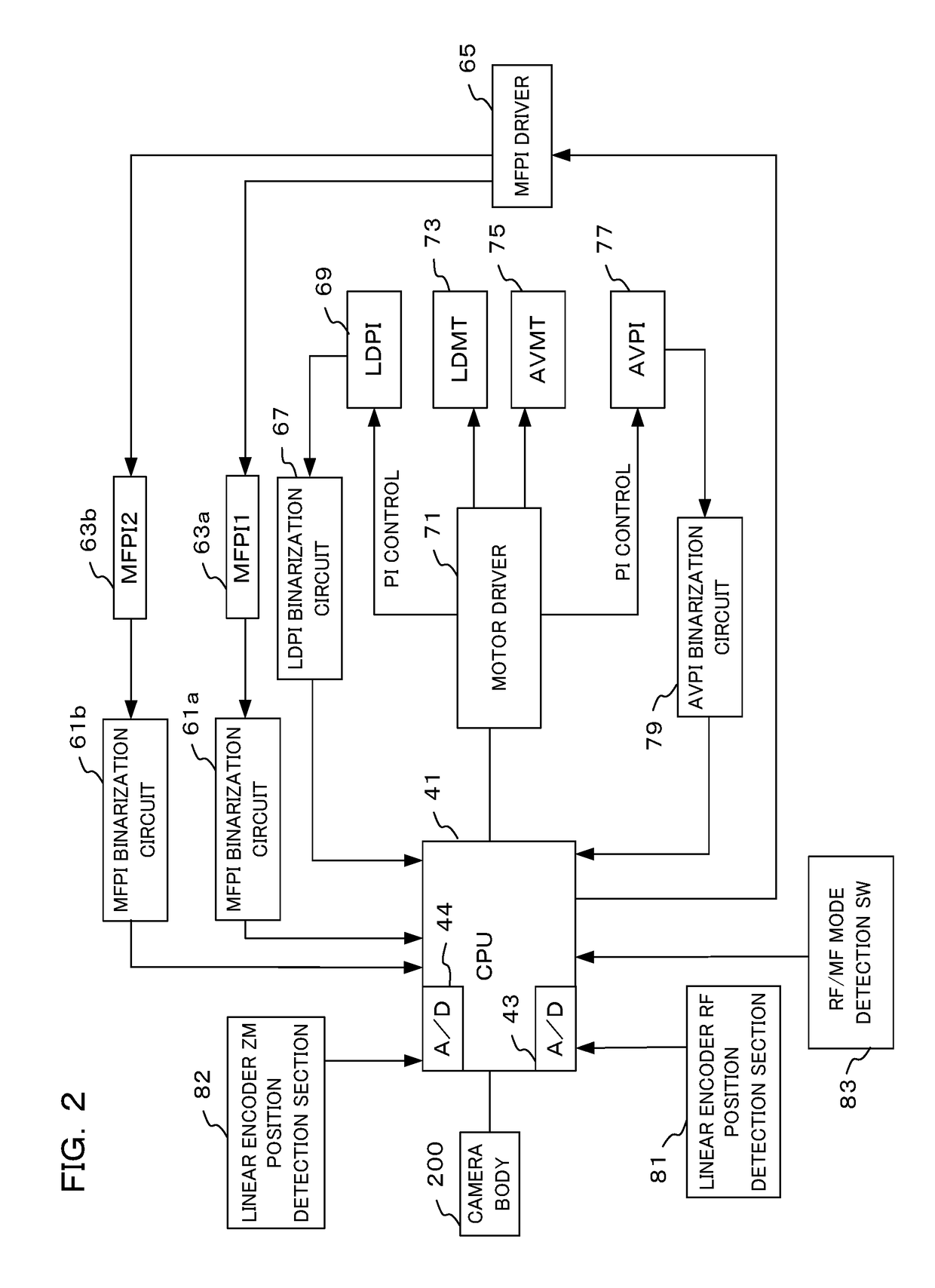

Imaging apparatus and position detection method

InactiveUS20180143399A1Improve positional accuracySimple methodTelevision system detailsColor television detailsEngineeringAnalog signal

Owner:OM DIGITAL SOLUTIONS CORP

Automatic moving type spiral hole milling manufacturing system

ActiveCN105772811AImprove positional accuracyAchieve translational movementMilling equipment detailsMaintainance and safety accessoriesEngineeringManufacturing systems

The invention provides an automatic moving type spiral hole milling manufacturing system. The automatic moving type spiral hole milling manufacturing system comprises an automatic moving mechanism composed of a crawling mechanism and a double-swinging platform. The crawling mechanism comprises an upper supporting plate, a lower supporting plate, bearings, a rotating shaft, a rectangular rotating plate, a first sliding rail, a first sliding block, a first drive device and three peripheral electric telescopic rods. The double-swinging platform comprises a first swinging shell, a second swinging shell, a first gear shaft, a third drive device, a second gear shaft and a fourth drive device. According to the automatic moving type spiral hole milling manufacturing system, the rotating shaft and a first screw pair are arranged between the upper supporting plate and the lower supporting plate of the crawling mechanism, random steering and horizontal moving of the crawling mechanism are achieved, and in addition, the hole machining position precision can be ensured through the double-swinging platform.

Owner:NANJING COLLEGE OF INFORMATION TECH

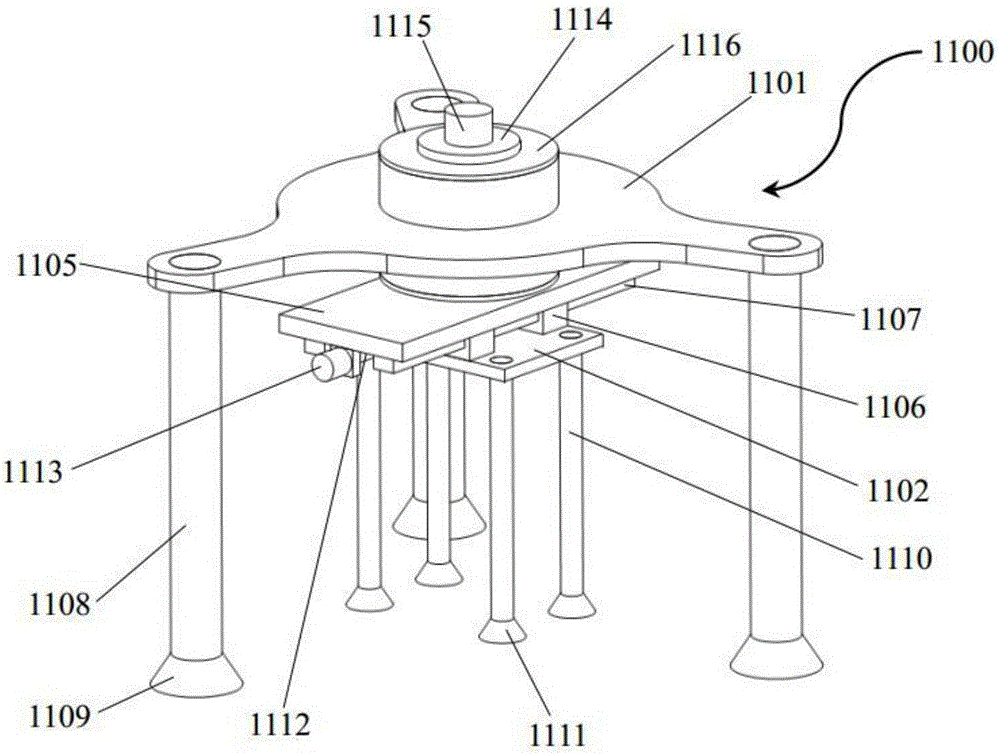

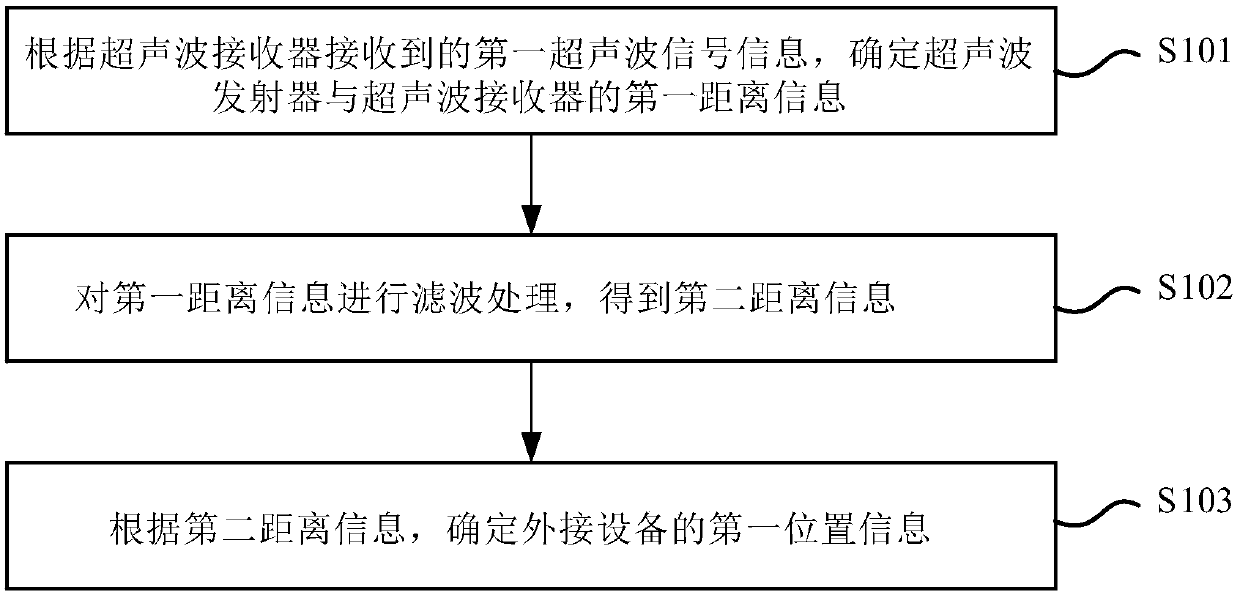

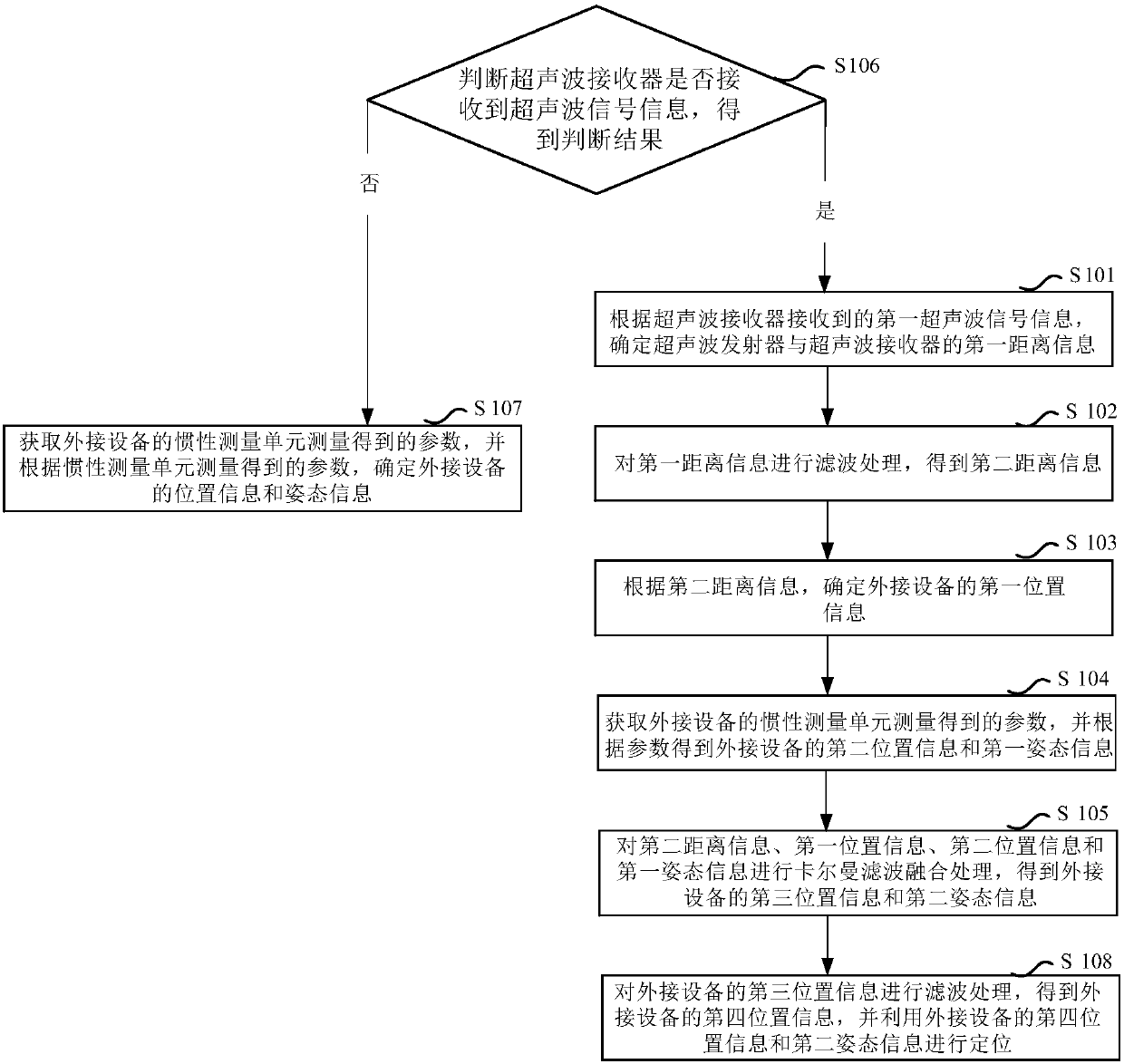

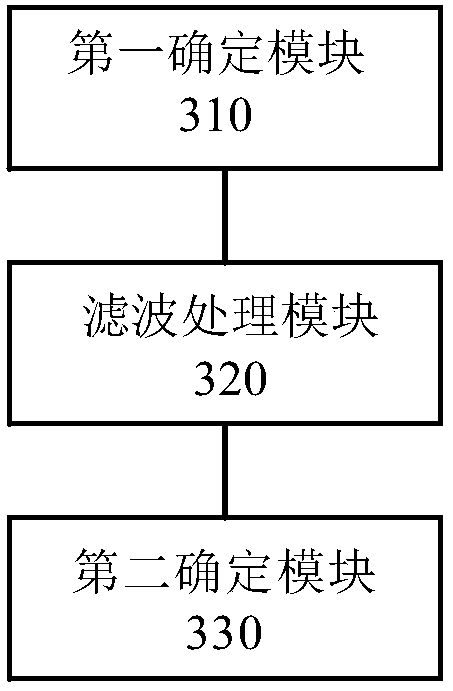

External equipment locating method and device, virtual reality equipment and system

ActiveCN108236782AImprove positional accuracySmooth motion trackPosition fixationNavigation by speed/acceleration measurementsUltrasoundVirtual reality

The invention discloses an external equipment locating method and device, virtual reality equipment and system. The external equipment is provided with an ultrasonic transmitter and the virtual reality equipment is provided with an ultrasonic receiver, or the virtual reality equipment is provided with the ultrasonic transmitter and the external equipment is provided with the ultrasonic receiver. The method comprises the following steps: according to ultrasonic wave signal information received by the ultrasonic receiver, determining first distance information of the ultrasonic transmitter and the ultrasonic receiver; carrying out filtering processing on the first distance information to obtain second distance information; and according to the second distance information, determining first position information of the external equipment. According to one embodiment of the invention, accuracy of a position, determined by distance value of the ultrasonic transmitter and the ultrasonic receiver, of the external equipment is improved, and the motion track of the external equipment is smoother.

Owner:QINGDAO PICO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com