Design method of laser particle analyzer optical system

A technology of laser particle size analyzer and optical system, which is applied in particle size analysis, scientific instruments, particle and sedimentation analysis, etc. It can solve the problems of low measurement accuracy and large difference in focus position, and achieve the effect of improving position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

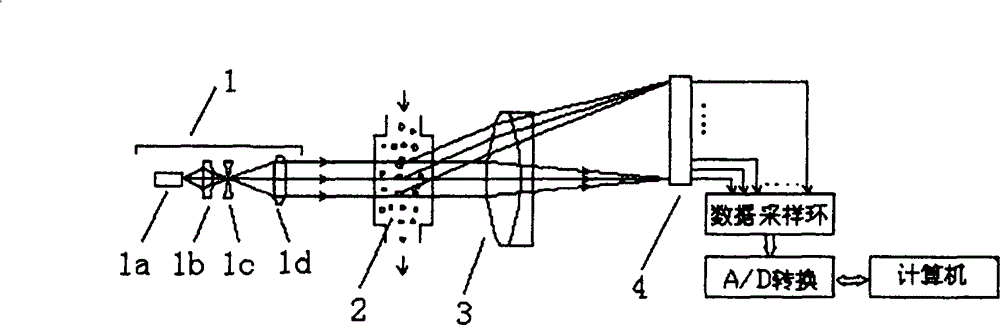

[0019] The design method of the optical system of the laser particle size analyzer of the present invention will be introduced below with reference to the accompanying drawings and embodiments.

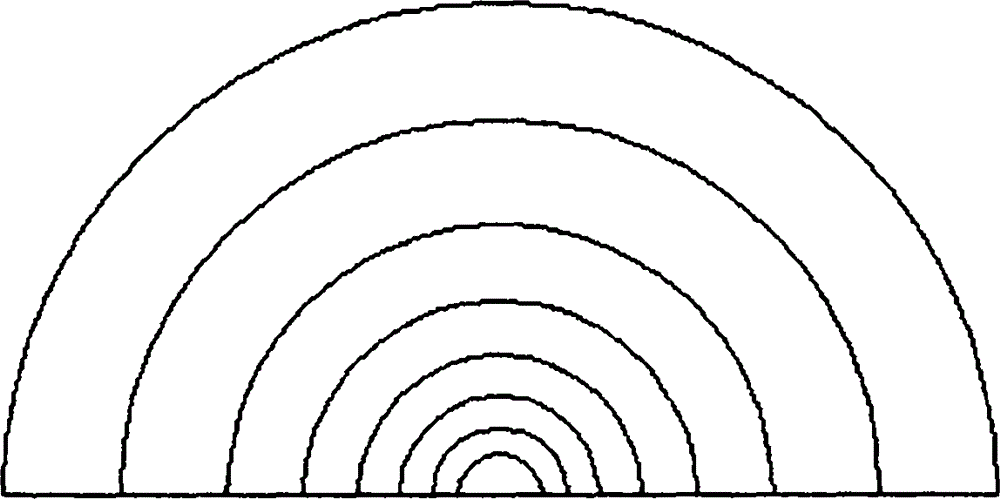

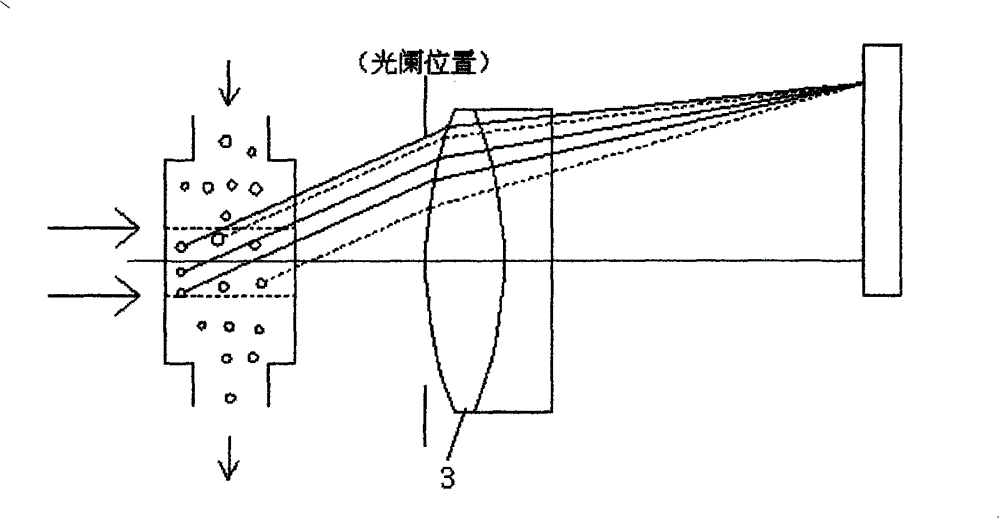

[0020] The optical system of the laser particle size analyzer of the present invention includes a diaphragm, a lens and a ring photodetector, which are arranged one after another along the optical path, and the diaphragm is zoomed in multiple positions within the range of the sample cell of the measurement window of the laser particle size analyzer. The light in the same direction scattered by the particles in the sample cell is focused on the same half ring of the ring photodetector with the smallest position difference.

[0021] When using the method of the present invention to design the optical system of the laser particle size analyzer, it is necessary to control the positions of the chief ray, upper ray, lower ray, left ray, and right ray of each field of view on the ring photodetecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com