Positioning and punching method for composite material honeycomb sandwich part packing area

A technology of honeycomb interlayer and composite material, which is applied in the field of positioning and punching in the filling area of composite honeycomb interlayer parts, can solve problems such as positioning deviation, and achieve the effect of improving position accuracy, reducing rework and repair rate, and reducing positioning difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

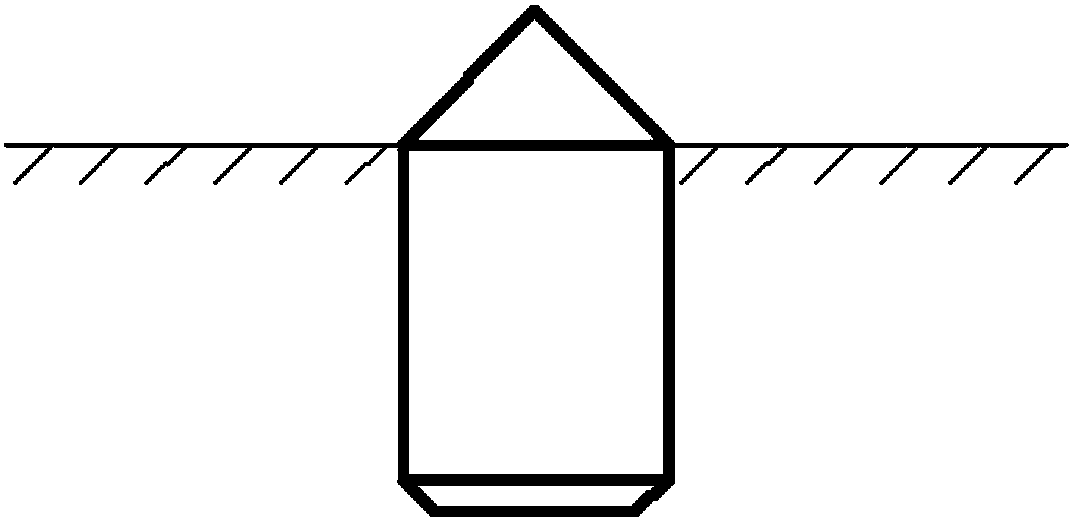

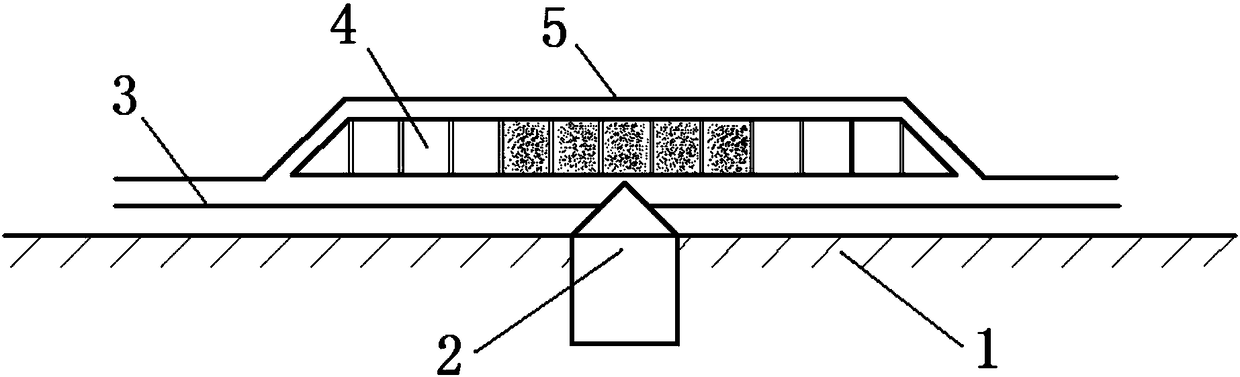

[0009] A positioning drilling method for the filling area of a composite honeycomb sandwich part, which is used to process a through hole with a diameter less than Φ50mm in the filling area. The method is provided with a tapered pin 2 at the theoretical drilling position of the tooling 1 and only the tapered pin is exposed. part, pave the mold surface prepreg 3 on the surface of the tooling 1, and then cut the raised mold surface prepreg 3 according to the tapered part; place the honeycomb interlayer 4, and use the tapered The part is filled with filler in the center, and its range is larger than the diameter of the through hole; laying the prepreg 5 on the non-mold surface, transferring it as a whole and curing it under heat and pressure; after the part is demoulded, drill according to the tapered hole formed at the bottom hole. The included angle at the top of the tapered pin 2 is 90 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com