Patents

Literature

605results about How to "Reduce rework rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

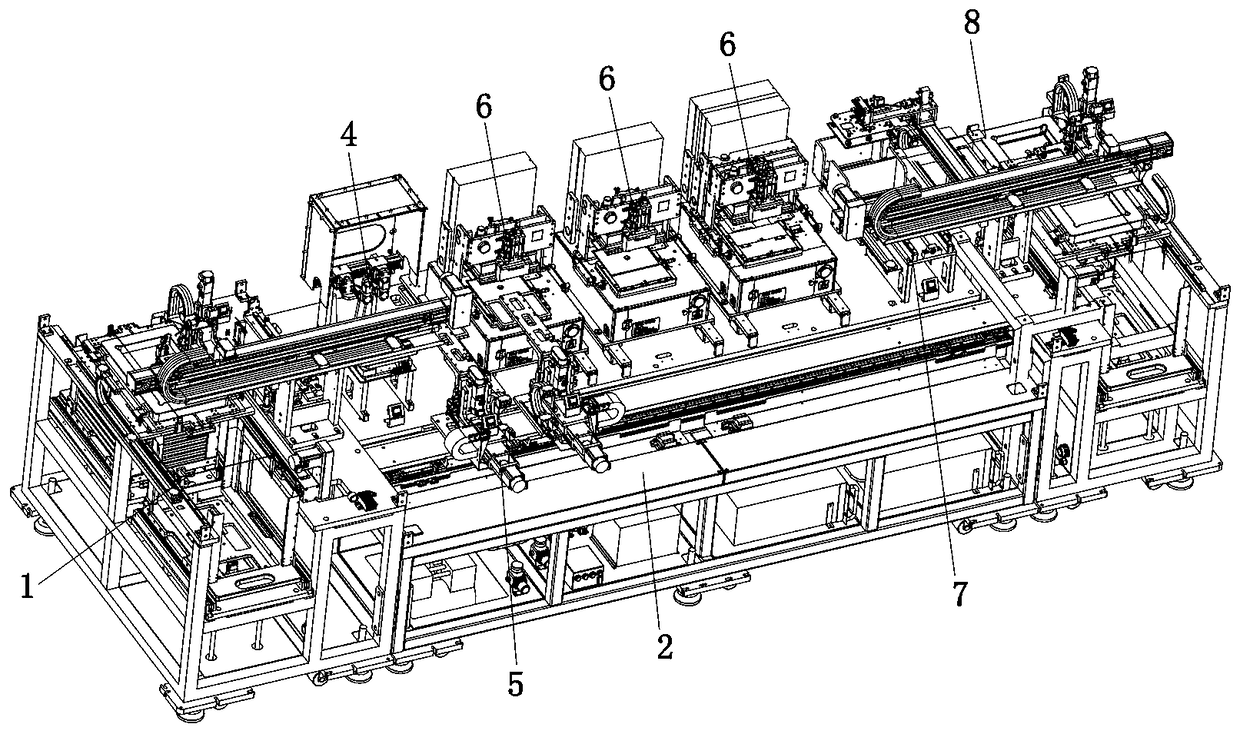

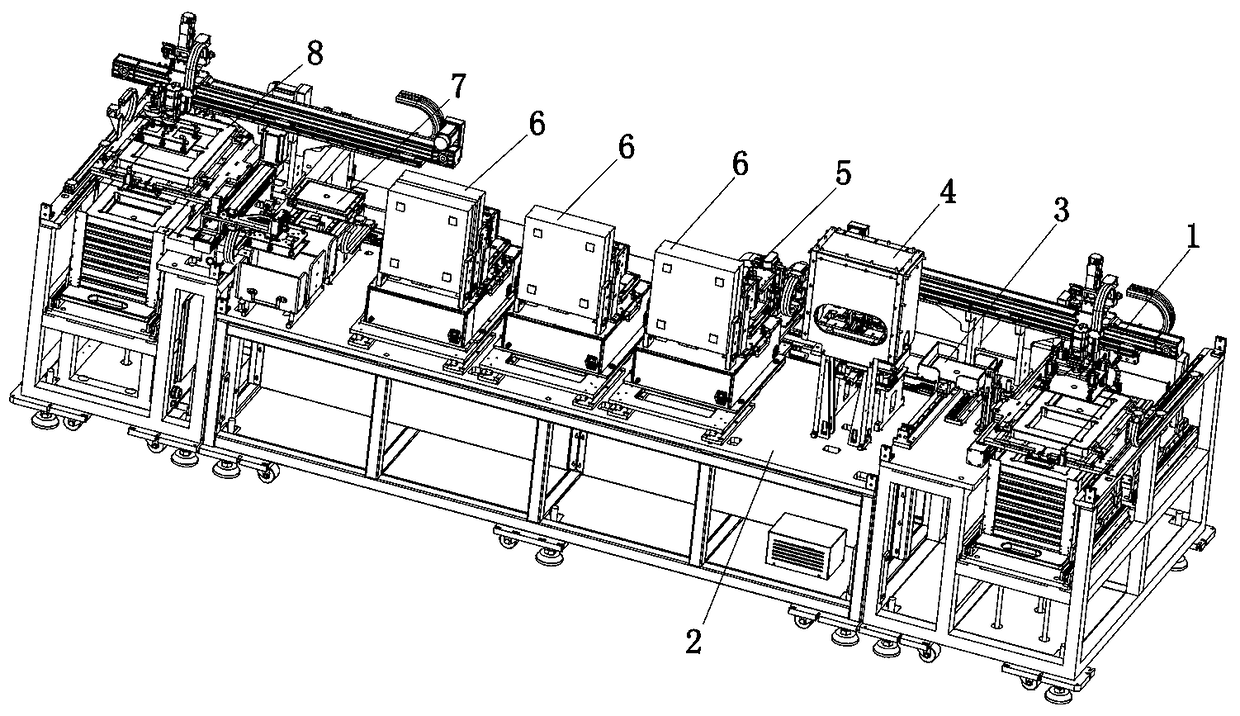

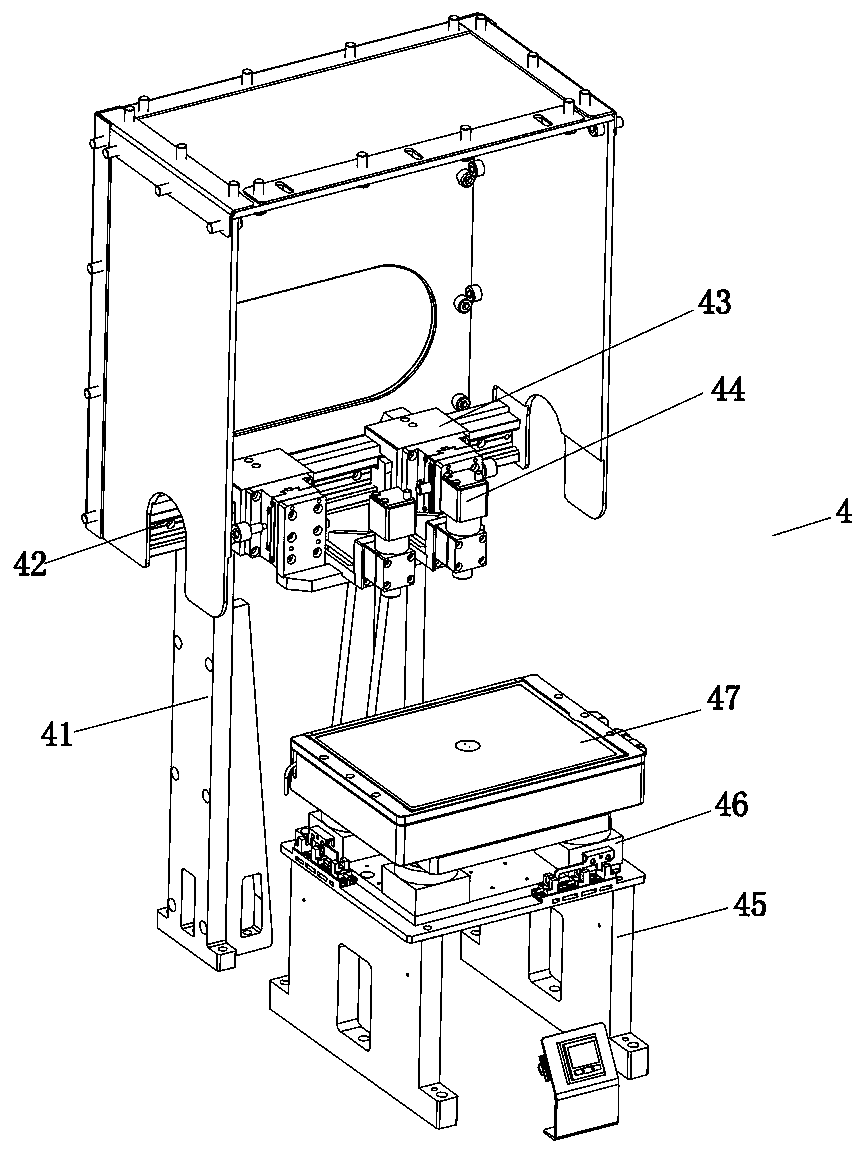

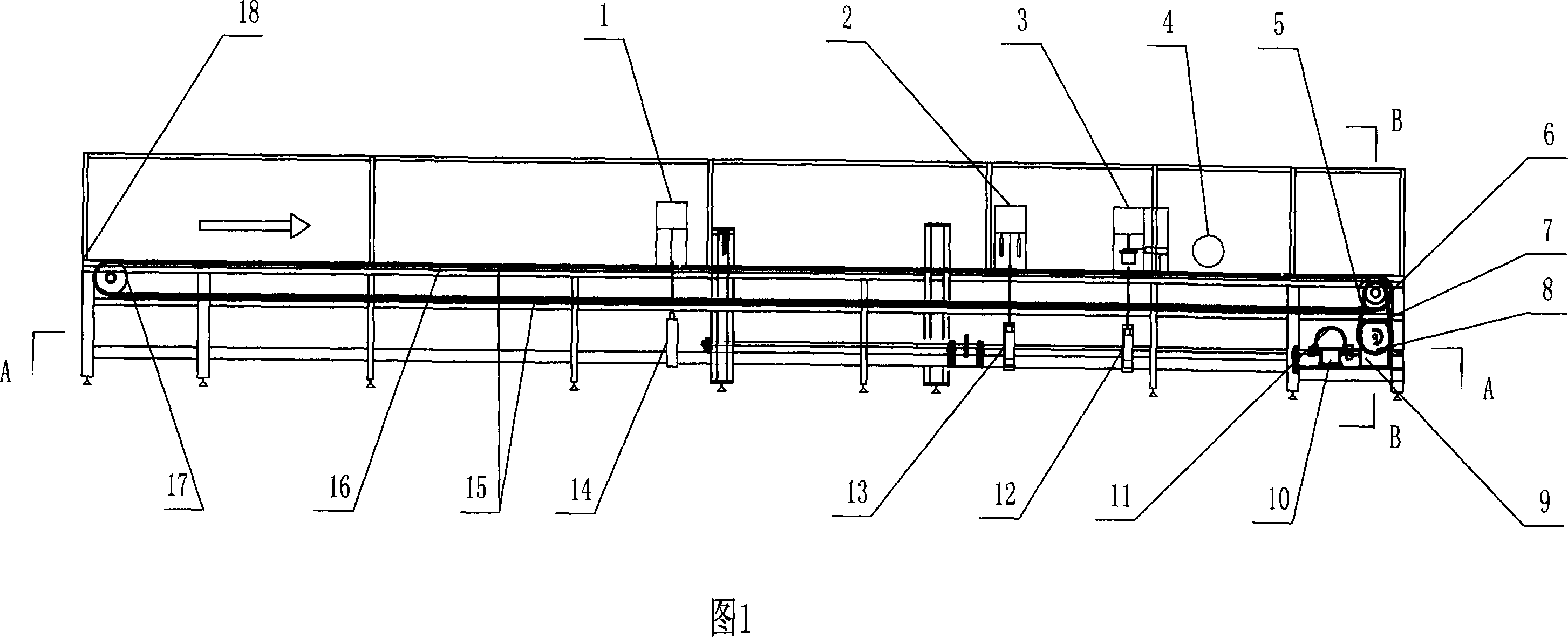

Three-station DITO full-automatic testing machine and testing process thereof

PendingCN109283417AIncrease fluid volumeImprove test efficiencyElectrical testingEngineeringAutomatic testing

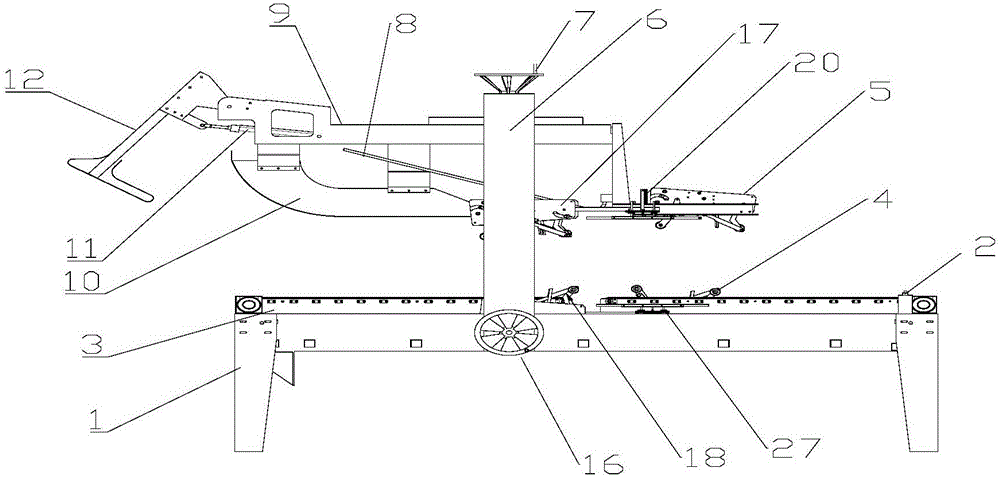

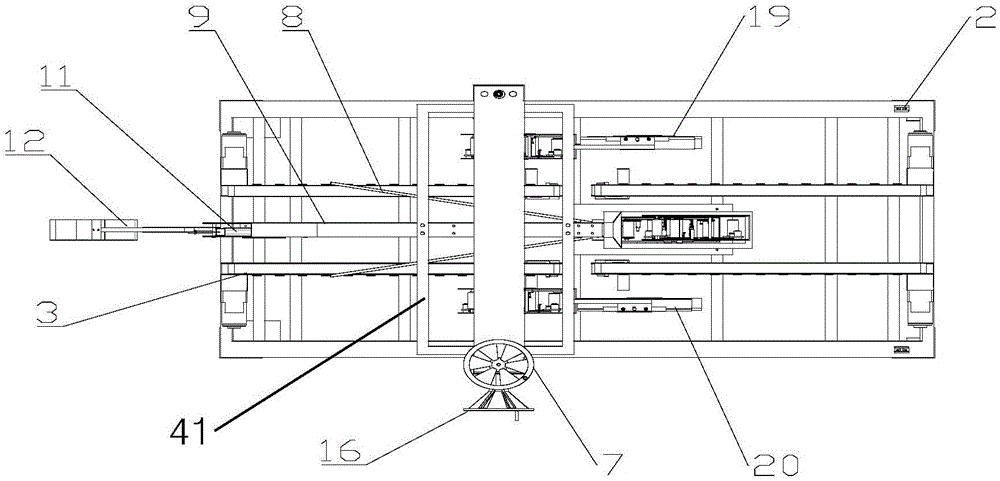

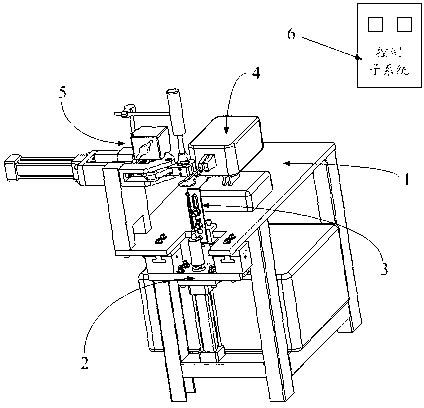

The invention discloses a three-station DITO full-automatic testing machine and a testing process thereof. The testing machine comprises a feeding part, a testing part and a discharging part. The testing machine disclosed by the invention comprises the following technical steps: product feeding, product taking and product detection, product photographing correction, product function testing, product transferring and defective product screening, product position correcting and discharging, and material tray discharging. According to the testing machine, a plurality of products are loaded in a centralized manner by adopting the material tray, and the loading part and the discharging part are connected to the front end and the back end of the tested part; the material trays of the feeding part and the discharging part are of a circulating flow type structure, meanwhile, the circulating type taking and placing of the products and the material trays are realized, and the material flowing volume is greatly improved through a laminating and conveying mode; and the test part adopts multi-test-station design, the time periods of testing and product taking and placing are effectively utilized, so that uninterrupted lead-out of the test products is realized, and the screen testing efficiency is greatly improved; and single-piece detection, defective product scanning by two-dimensional codes and the like are integrated to realize real-time screening of defective products.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Monocrystalline silicon wafer alcohol-free texturing process and texturing additive

ActiveCN104576831AReduce CODReduce the cost of cashmereAfter-treatment detailsFinal product manufactureAlcohol freePotassium hydroxide

The invention relates to a monocrystalline silicon wafer alcohol-free texturing process and a texturing additive. Firstly, a silicon wafer is placed in preprocessing liquid so as to be preprocessed for 60 s to 300 s, and the silicon wafer is then placed in texturing liquid for texturing. The monocrystalline silicon texturing process includes the steps that deionized water is heated to 70 DEG C to 90 DEG C, sodium hydroxide or potassium hydroxide is added, and monocrystalline silicon texturing corrosive liquid is acquired. When the texturing additive is adopted for texturing, isopropanol or ethyl alcohol is not needed, tiny, even and dense pyramid texturing faces can be acquired, texturing cost is reduced, and environmental pollution is avoided. The preprocessing process is added before the texturing step, the silicon wafer acquired after texturing can be cleaner, rework caused by white spot fingerprints and the like can be reduced, and certain practical value is achieved.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

Adjustable omnibearing automatic folding and carton sealing machine

The invention provides an adjustable omnibearing automatic folding and carton sealing machine. The adjustable omnibearing automatic folding and carton sealing machine comprises a carton sealing machine body, a carton clamping mechanism and a carton drive unit. The carton drive unit is transversely and symmetrically mounted on a rack and driven by a built-in motor. Machine cores are mounted above the carton drive unit, in the middle of the carton drive unit and at the symmetric positions of the two sides of the carton drive unit, and therefore middle sealing of carton tops and carton bottoms and corner sealing of cartons are achieved, and the sealing effect of packaging materials is improved. The carton clamping mechanism is mounted on a carton conveying belt, and a gear and gear racks are pushed by a both-way air cylinder to achieve actions of carton clamping, carton loosening and the like. The adjustable omnibearing automatic folding and carton sealing machine is simple in structure, ingenious in concept and high in work efficiency, and manpower is effectively saved. According to the rubber belt carton sealing machine, when the carton conveying speed is higher than the carton sealing speed, the cartons are clamped and loosened through the part of the carton clamping mechanism, and therefore the cartons are prevented from passing through a cover folding mechanism too densely.

Owner:JIANGSU UNIV OF SCI & TECH

High-efficiency soldering process of circuit board connector

ActiveCN102711391AImprove welding qualityIncrease productivityPrinted circuit assemblingElectronic componentIndustrial engineering

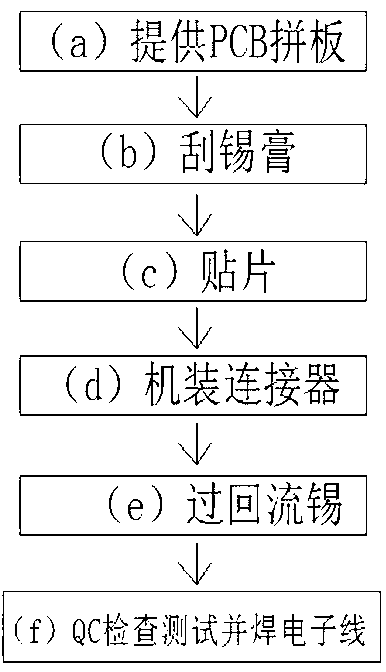

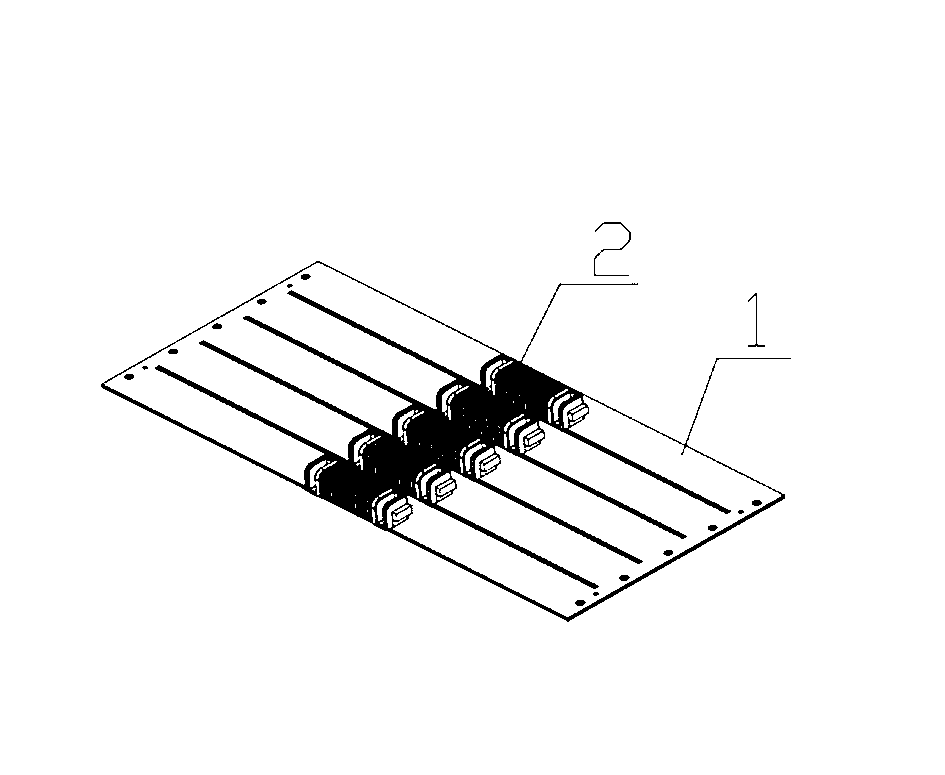

The invention discloses a high-efficiency soldering process of a circuit board connector in the field of soldering processes of electronic components on a circuit board. The high-efficiency soldering process comprises the following steps of: providing a PCB (Printed Circuit Board) jointed board; scraping soldering paste; mounting; mechanically installing a connector; carrying out reflow soldering; and carrying out QC (Quality Control) inspection testing and soldering an electronic wire. According to the high-efficiency soldering process, the step of manually soldering the connector is removed in the prior art, the PCB jointed board and the installed connector are placed in a soldering furnace of a reflux soldering machine for soldering, the original manual soldering is changed into the automatic soldering, thus the soldering quality of a soldering apparatus is improved, a series of procedures can be completed on the PCB jointed board, the production efficiency is increased, and the workers and the production cost which are required during production can be reduced.

Owner:湖南省麦克斯新能源有限公司

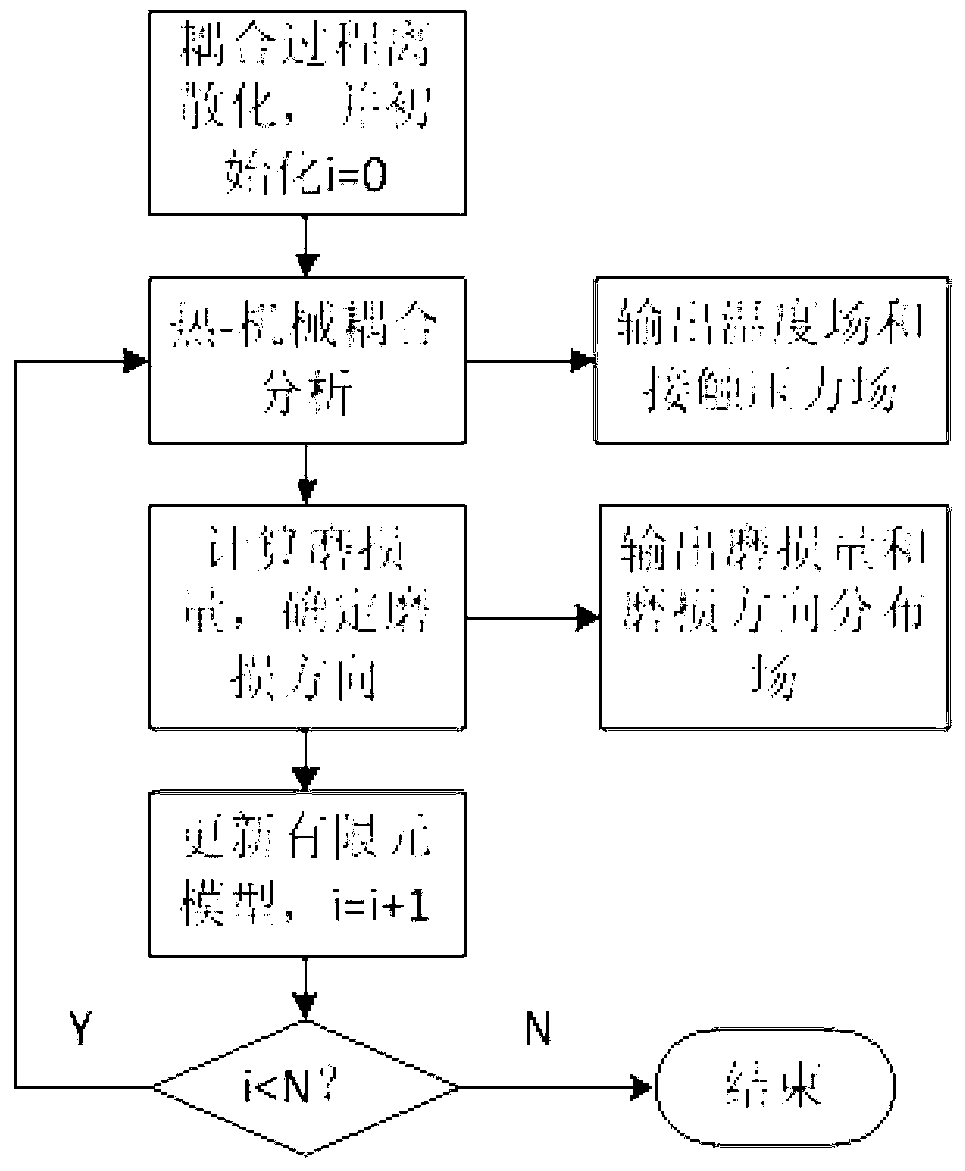

Heat-machinery-abrasion coupling analysis numerical simulation method based on finite element

InactiveCN103279627AControl increment step sizeHigh speedSpecial data processing applicationsElement modelContact pressure

The invention relates to a heat-machinery-abrasion coupling analysis numerical simulation method based on a finite element. The method includes the following steps: establishing a finite element model; discretizing a heat-machinery-abrasion coupling process; performing heat-machinery coupling analysis by commercial finite element software; outputting a temperature field of a contact pair and a contact pressure field; calculating abrasion loss, and determining abrasion direction; outputting node abrasion loss and abrasion direction; correcting node displacement, and updating the finite element model; judging whether all the increment steps are completed or not, if not, returning to a loop operation until all the increment steps are completed, and if yes, outputting contact pressure field distribution, temperature field distribution and abrasion loss distribution which correspond to contract nodes of all the increment steps. The commercial finite element software is taken as a platform, so that the method is simple and reliable; calculation of the abrasion loss is completed inside the finite element software, so that the method is rapid and efficient. The method can be widely applied to structural analysis relating to dry sliding friction.

Owner:TSINGHUA UNIV

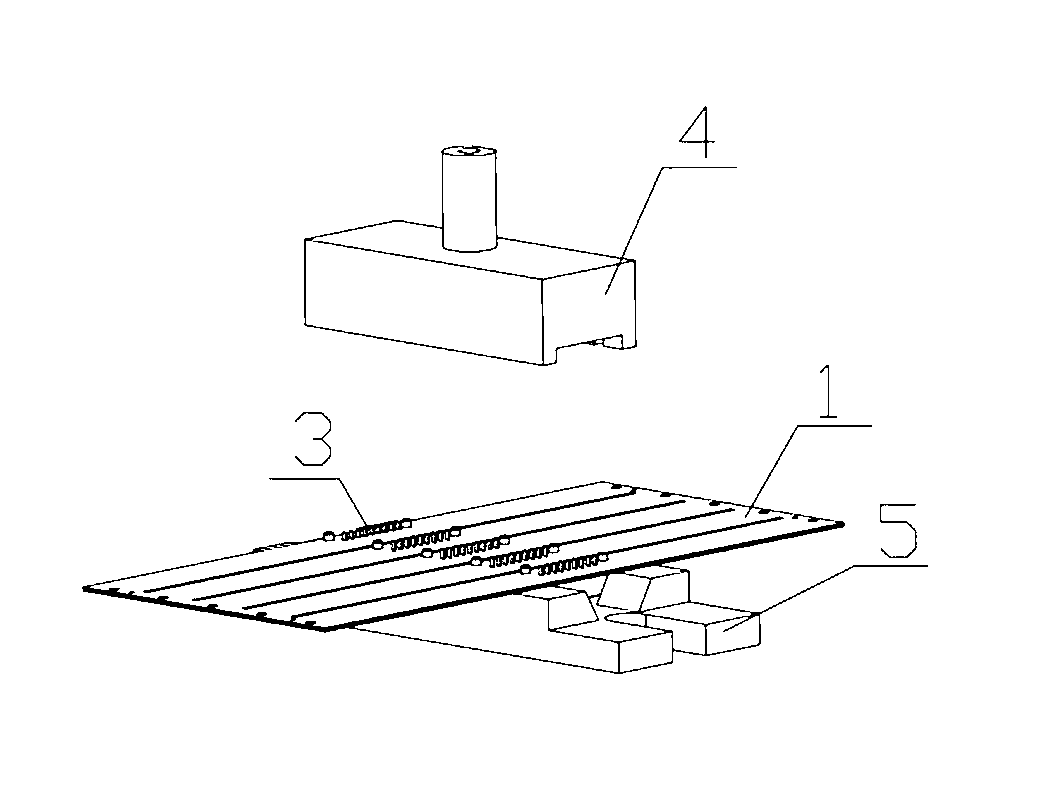

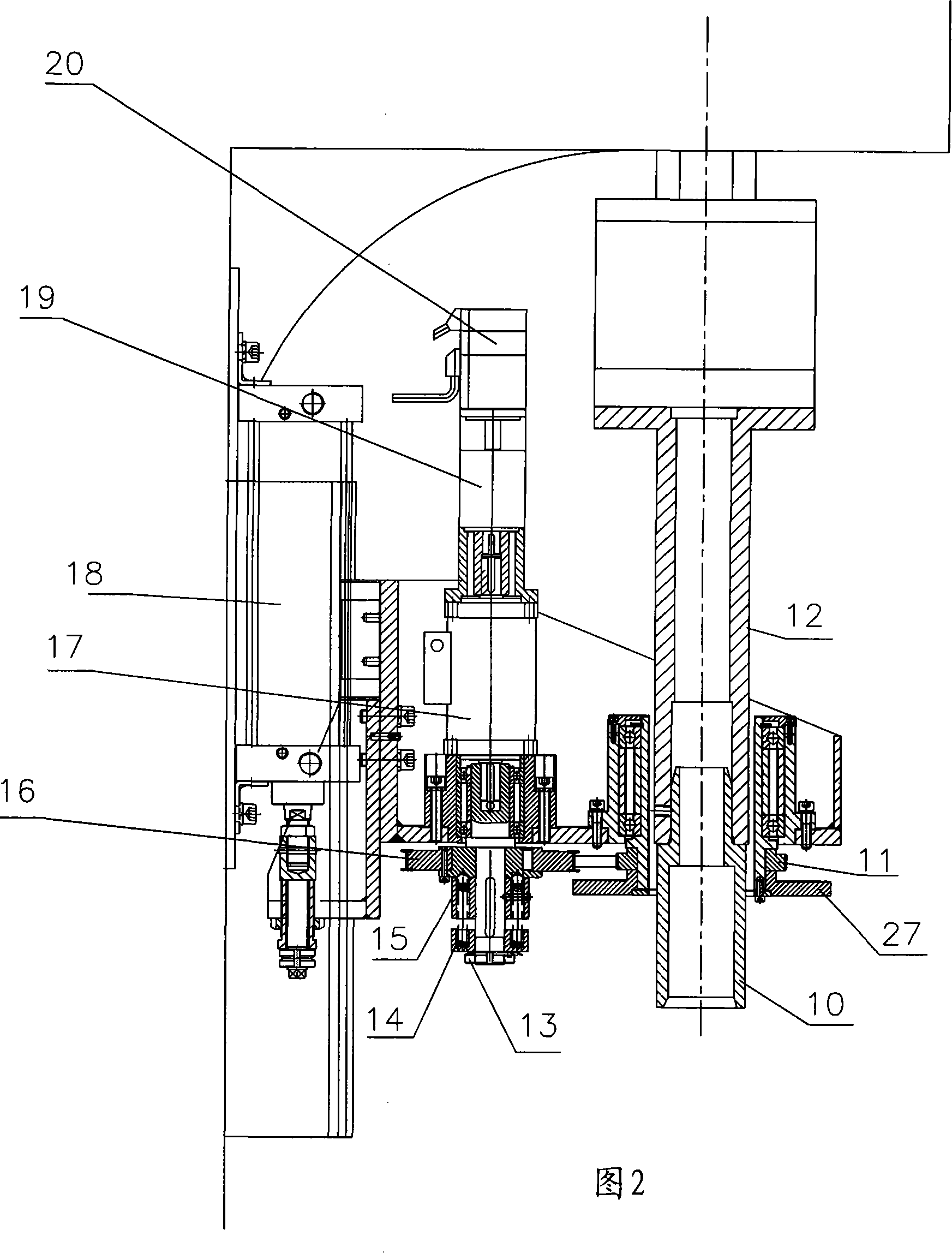

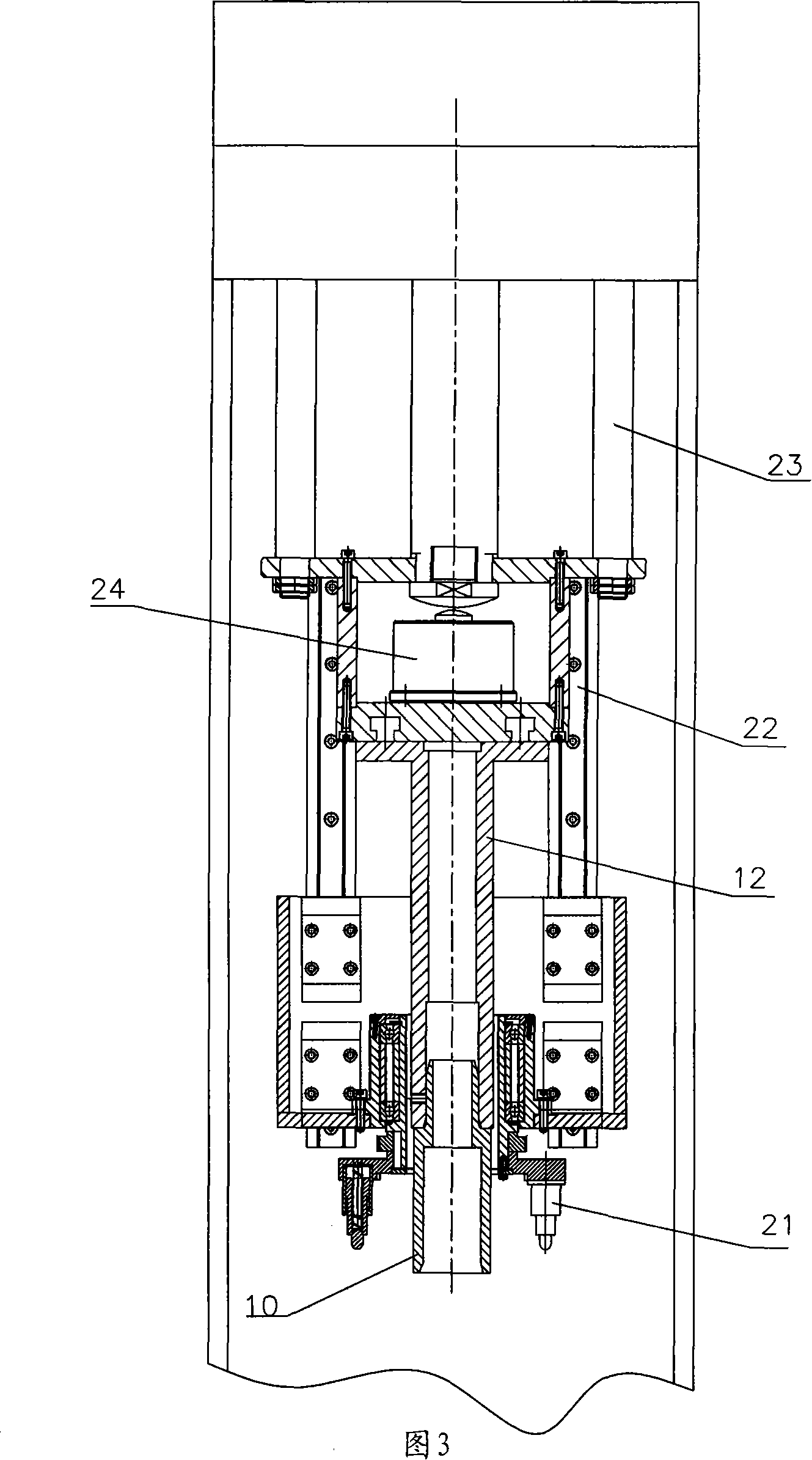

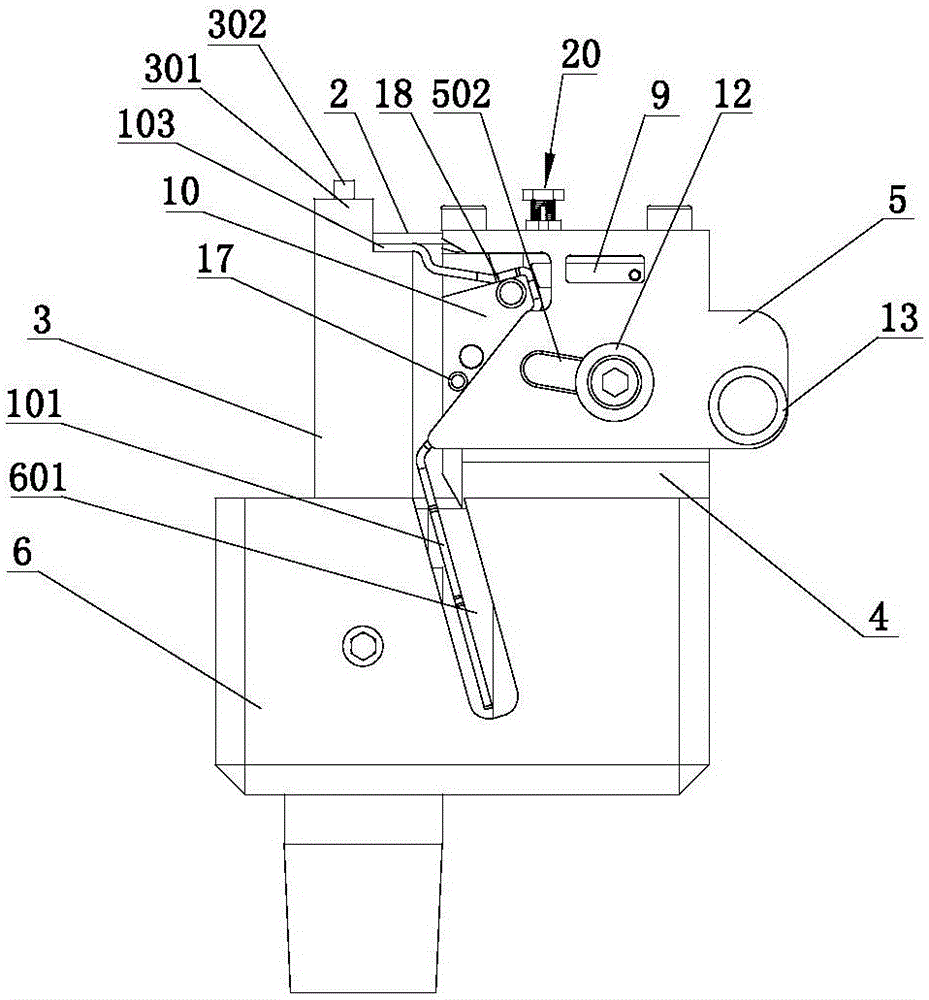

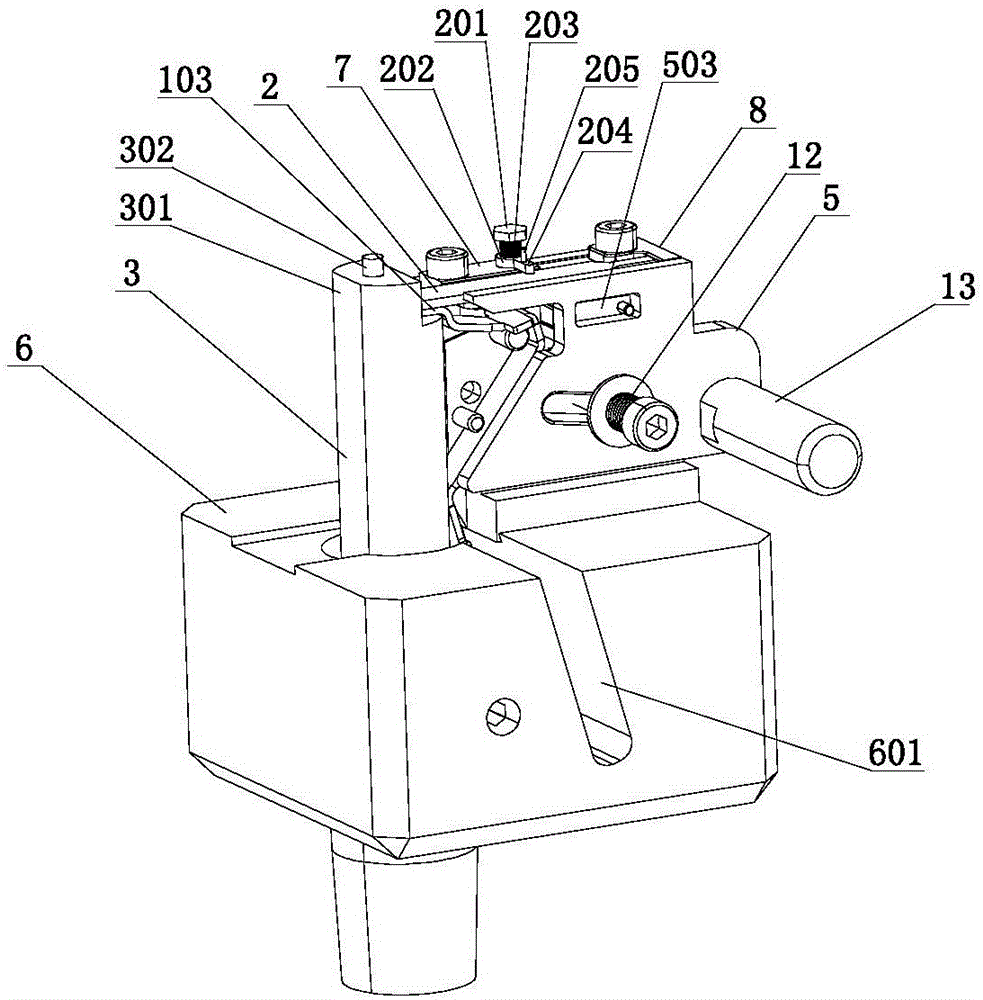

Drill welding system and drill welding method

ActiveCN103028832AClear structureReasonable settingWelding/cutting auxillary devicesAuxillary welding devicesRadial positionUltimate tensile strength

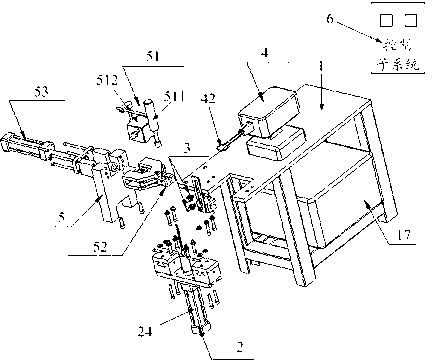

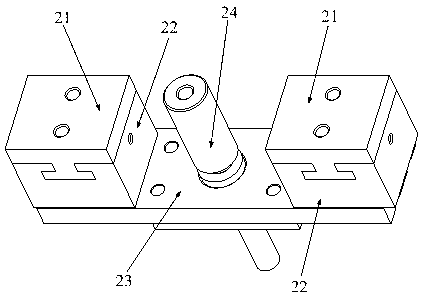

The invention discloses a drill welding system, the drill welding system comprises a cutter bar moving device, a welding and heating device, a tool bit adjusting device and a controlling subsystem, the cutter bar moving device is used for placing and moving the cutter bar placed a tool bit and welding materials on the top portion; the welding and heating device is used for heating the welding materials to melt to an end portion of the cutter bar; the tool bit adjusting device is used for adjusting the axial position and radial position of the tool bit and the cutter bar, thereby guaranteeing the concentricity and compactness of the cutter bar and the tool bit; the cutter bar moving device, the welding and heating device and the tool bit adjusting device are respectively connected with the controlling subsystem, the cutter bar moving device used for a controlling positioning pre-added drill returns to seat after sequentially passing the welding and heating device and the tool bit adjusting device. The invention further provides a drill welding method. The drill welding system and drill welding method has the advantages of improving accuracy as well as speed of welding, greatly improving the quality of welding and productivity and lowering the labor intensity of workers. The drill also has high concentricity and firm connection.

Owner:SHANGHAI KUNJEK HANDTOOLS & HARDWARE

Semi-fixing abrasive grain grinding tool and method of producing the same

InactiveCN101134298AHigh bonding strengthImprove material removal rateAbrasion apparatusGrinding devicesWear particleAdhesive

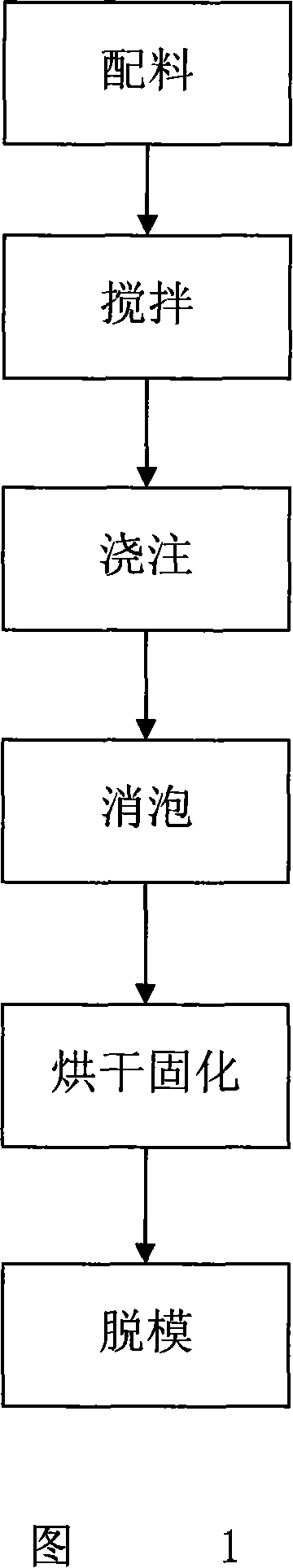

The present invention is one kind of grinding tool with semi-fixed abrasive particle and its making process. The grinding tool consists of abrasive grain in 80-90 wt%, adhesive 1-10 wt% and additive 5-15 wt%. Its making process includes the following steps: 1. mixing abrasive grain, adhesive and additive, sieving and mixing with water; 2. molding the mixture in a mold; 3. eliminating bubbles from the molded grinding tool; and 4. stoving the grinding toll in a stove for curing and demolding to obtain the grinding tool with semi-fixed abrasive particle. The present invention has high processing precision and high processing efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

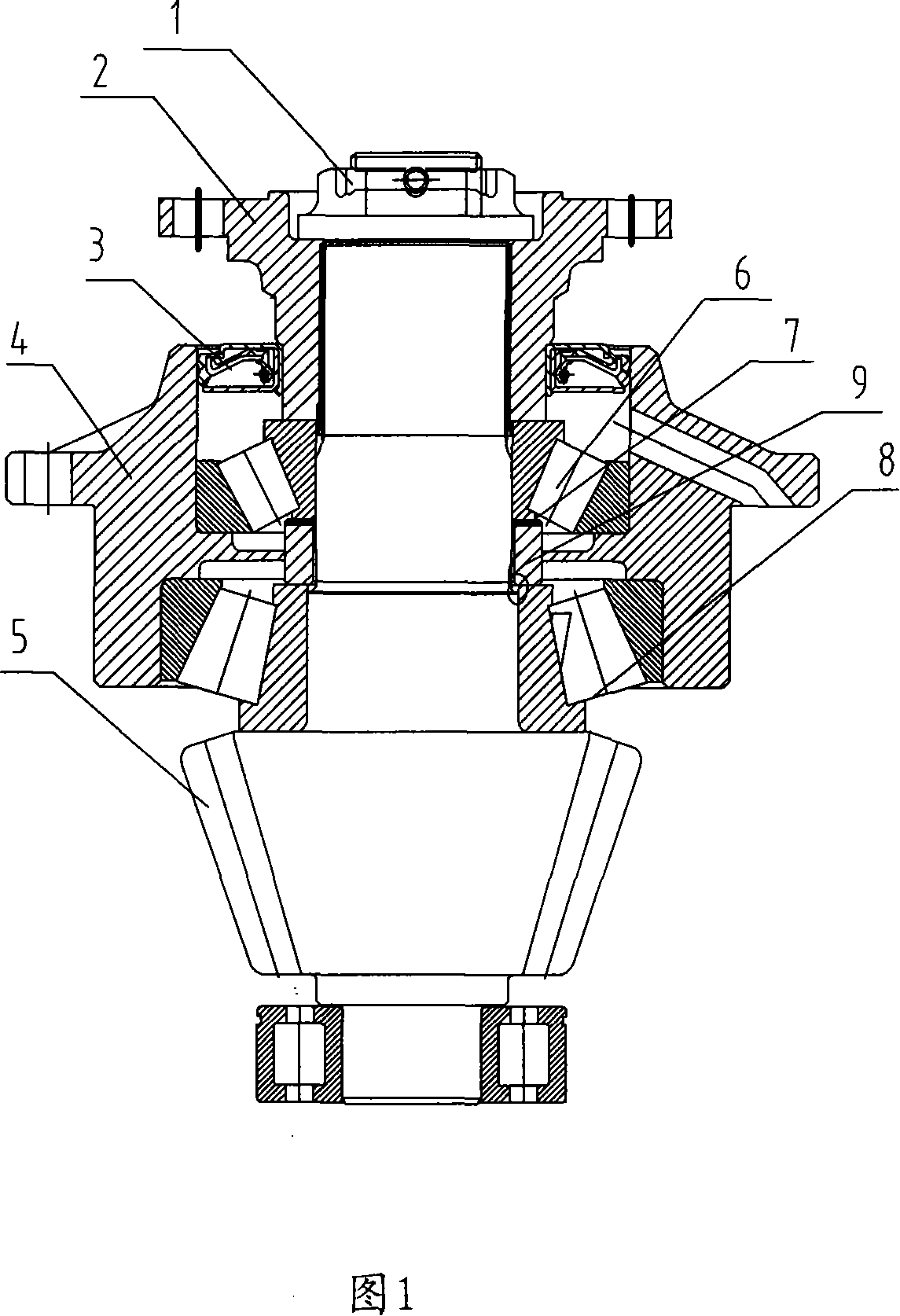

Measuring mechanism for assembling and press-loading vehicle main reducing gear

InactiveCN101109666AImprove quality and efficiencyImprove assembly efficiencyMeasurement of torque/twisting force while tighteningMachine gearing/transmission testingFriction torqueReduction drive

The invention provides a measuring mechanism for the pressure assembling of the main reducers of automobiles, which comprises a friction torque tester for the bearing seat of a main gear assembly and an upper bearing inner ring pressure-assembling mechanism, and is characterized in that the bearing seat friction torque tester takes a servo motor as a drive. The friction torque of a main gear assembly to be measured is transmitted in sequence through the rotation of the bearing seat to a drive fork, a drive disc, a synchronous belt wheel II, a synchronous belt wheel I and a torque sensor, thereby the torque necessary for rotating the bearing seat of the main gear is transmitted to a rotary torque sensor, and a frequency signal is formed; by data acquisition treatment, real-time torque of the bearing seat can be obtained. The invention is for detecting the friction torque of the main gear assembly while pressure assembling the inner ring of the upper bearing of the main gear assembly of the main reducer of an automobile, and realizes automatic measurement of small torque. Measuring the friction torque of the main gear assembly can check whether the selection of the shim in previous station is correct, and effectively improve the quality and efficiency in assembling the main reducers of drive axles of automobiles.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

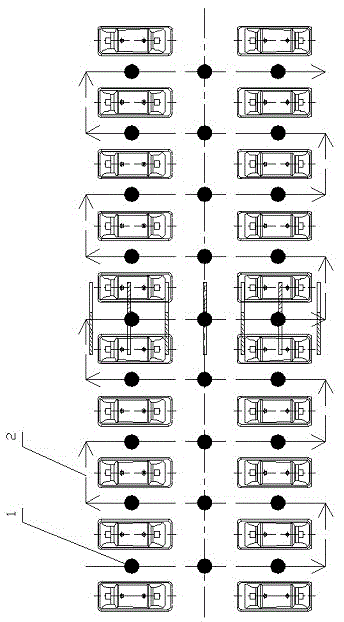

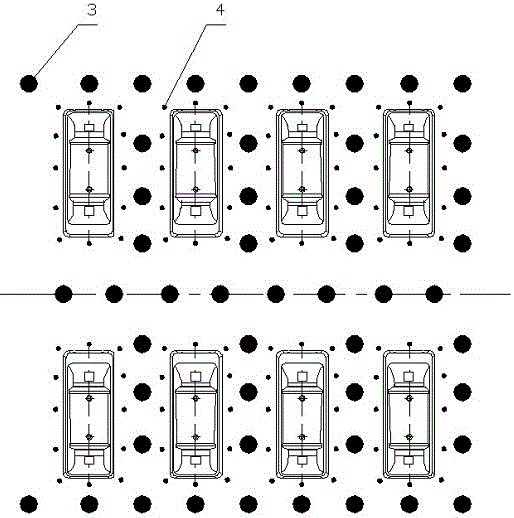

Full-automatic assembly production chain of energy-saving lamp

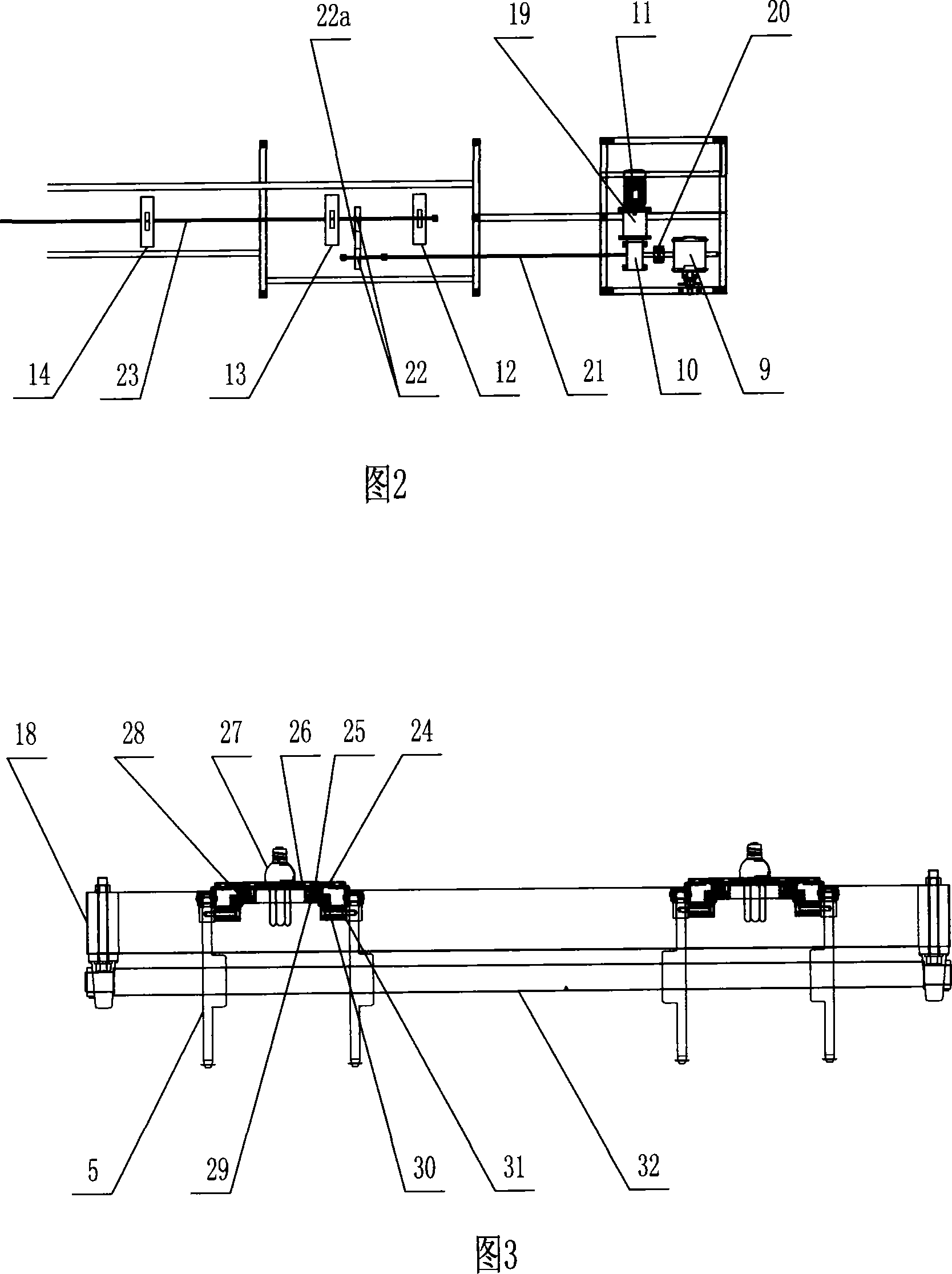

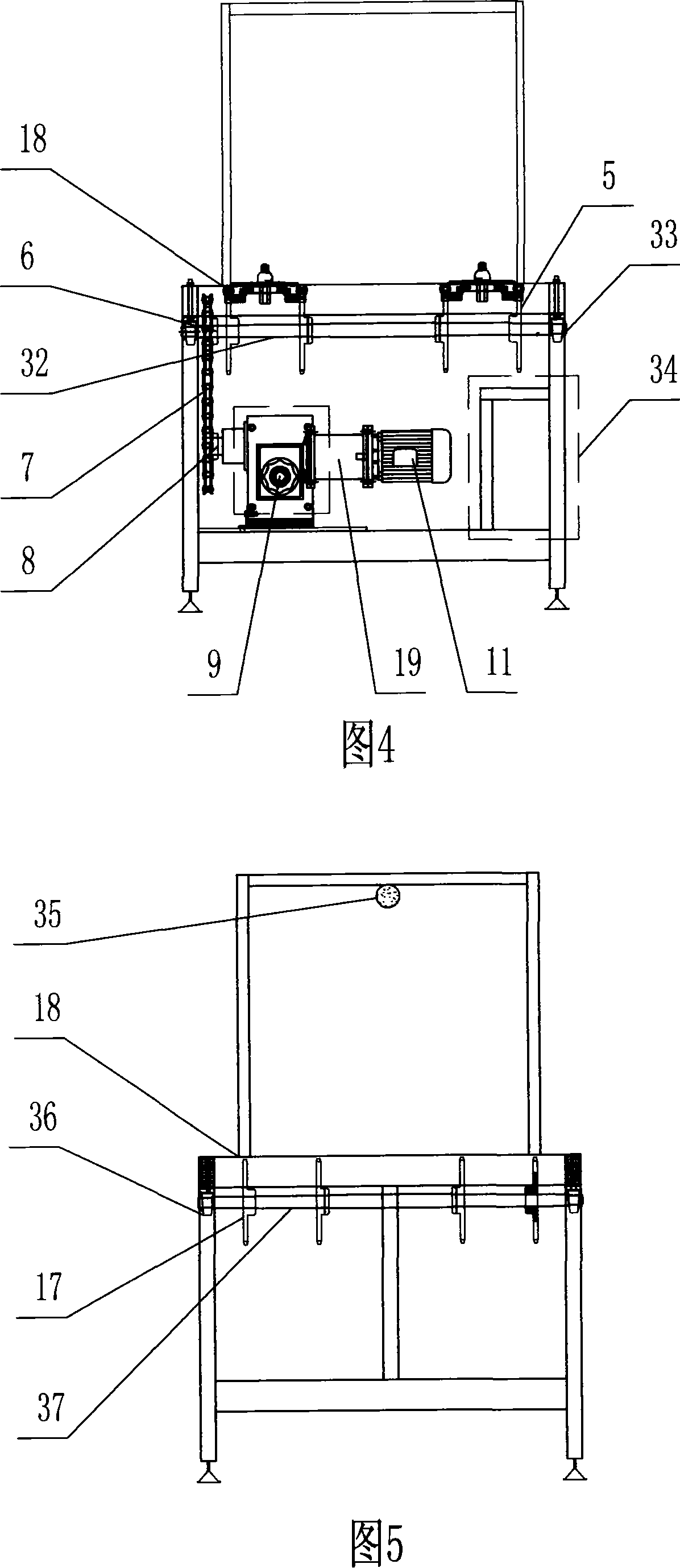

InactiveCN101083190ANovel ideaReasonable process structure designSequential operation station machinesCold cathode manufactureProduction chainEngineering

The invention relates to the energy-saving lamp full automatic-assembly assembly line. It belongs to the energy-saving lamp manufacture equipment technology area. Its characteristic lies in that the rack intermediate deck coordinate installs the work piece conveying appliance by the transmission chain drive, the one output end of the decelerator which installs on the sublayer of the rack and connects the motor driver connects the dynamic major axis which coordinates the cam major axis driver, another output through the cam dismember coordinates to the work piece conveying appliance, above the work piece conveying appliance fit establishes automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment, compression moulding cam, soldering lamp base cam, dial nail cam which installs on the cam major axis separately connects the automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment. The line flow has rational design, the automation pattern substitutes manual work, reduces the suggestion factor of the quality flaw, enormously raises the production efficiency and the product quality, creates the scale effect, take a foundation for promoting the enterprise brand image.

Owner:王佩诚

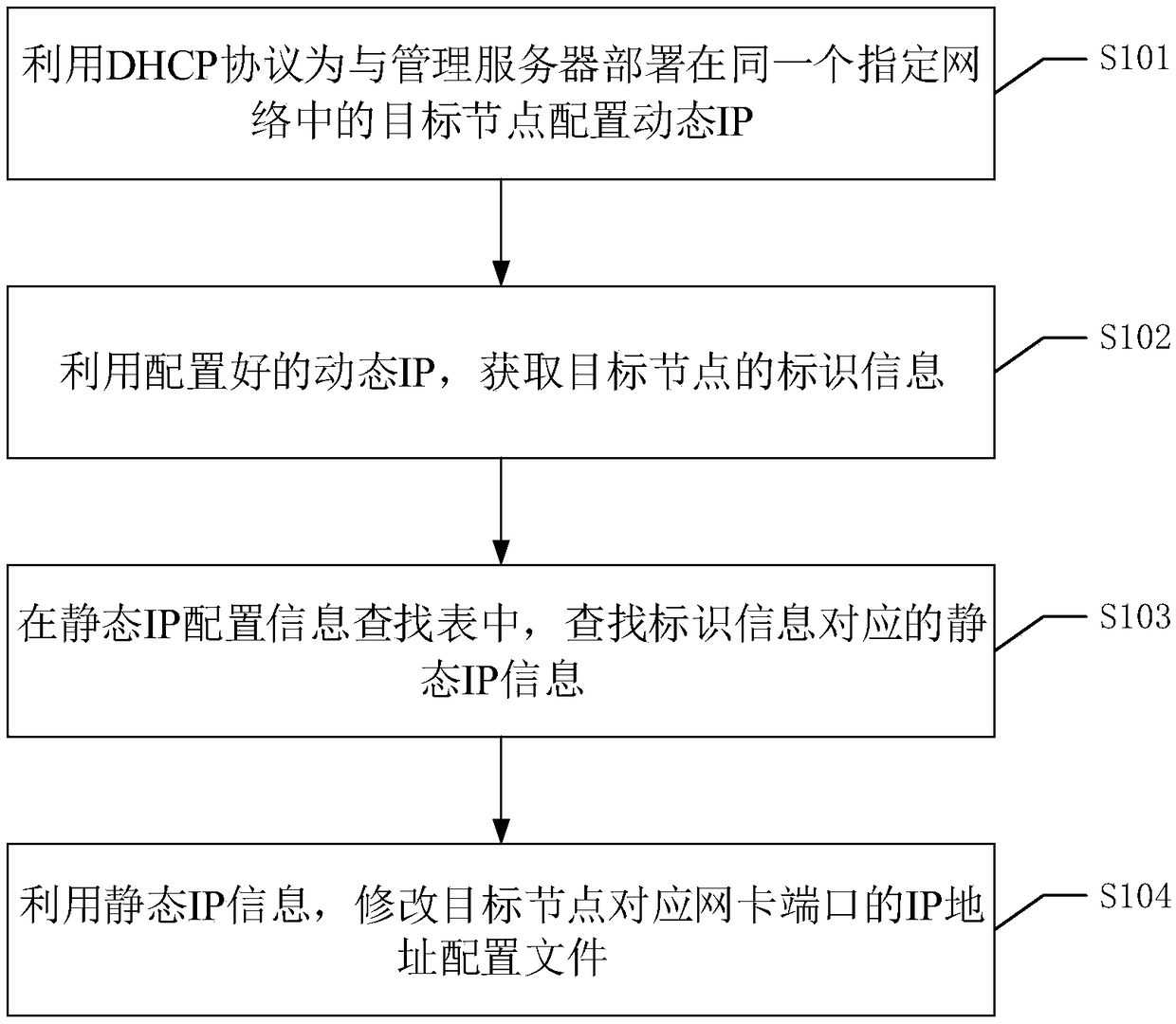

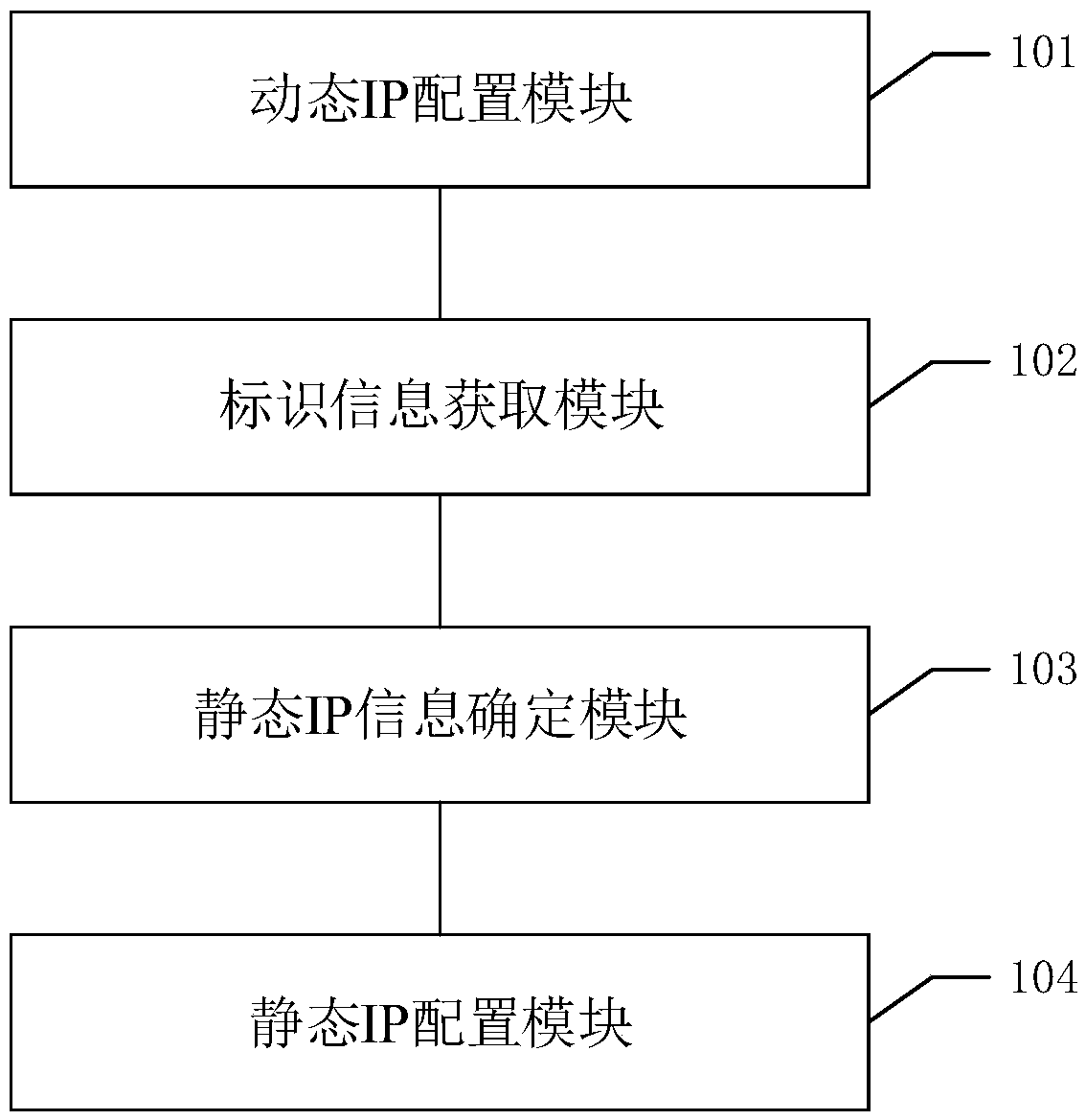

Static IP configuration method, device and equipment and readable storage medium

The invention discloses a static IP configuration method, comprising the following steps: configuring a dynamic IP for a target node deployed in the same designed network with a management server by using DHCP; obtaining the identification information of the target node by using the configured dynamic IP; in a static IP configuration information lookup table, looking up the static IP information corresponding to the identification information; and by using the static IP information, modifying the IP address configuration file of a network card port corresponding to the target node. Configuration of the static IP can be done without manual operation. Especially when the number of nodes to be configured is large, the static IPs can be configured according to the static IP configuration information lookup table, thus saving the time of deploying static IP and reducing the error rate and rework rate. The invention also discloses a static IP configuration device and equipment and a readablestorage medium, which have corresponding technical effects.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Welding tool with cooling structure

ActiveCN104985380AReasonable structural designEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a welding tool with a cooling structure. The welding tool comprises a pedestal; a welding support column and a welding seat are installed on the pedestal. A side clamp plate is installed at the side of the welding seat; a first positioning plate and a second positioning plate are installed on the upper end surface; a horizontal transverse plate is clamped longitudinally between the first positioning plate and the side clamp plate; and the horizontal position of the horizontal transverse plate is limited by the second positioning plate. Besides, a placing groove for placing a lower folding part of a bending arc plate is formed in the pedestal; clamping space for clamping the upper folding part is formed between the welding seat and the side surface of the welding support column; and the welding part of the bending arc plate is placed on the upper end surface of the welding support column horizontally and is in contact with the horizontal transverse plate. An elastic positioning structure is installed between the side clamp plate and the welding seat and includes an abutting pressing plate; one end of the abutting pressing plate is abutted against the bending folding part of the bending arc plate; an end spring is installed between the other end of the abutting pressing plate and the welding seat; and the end portion of the end spring is abutted against a fixed shot column of the welding seat.

Owner:江苏欧力佳电子科技有限公司

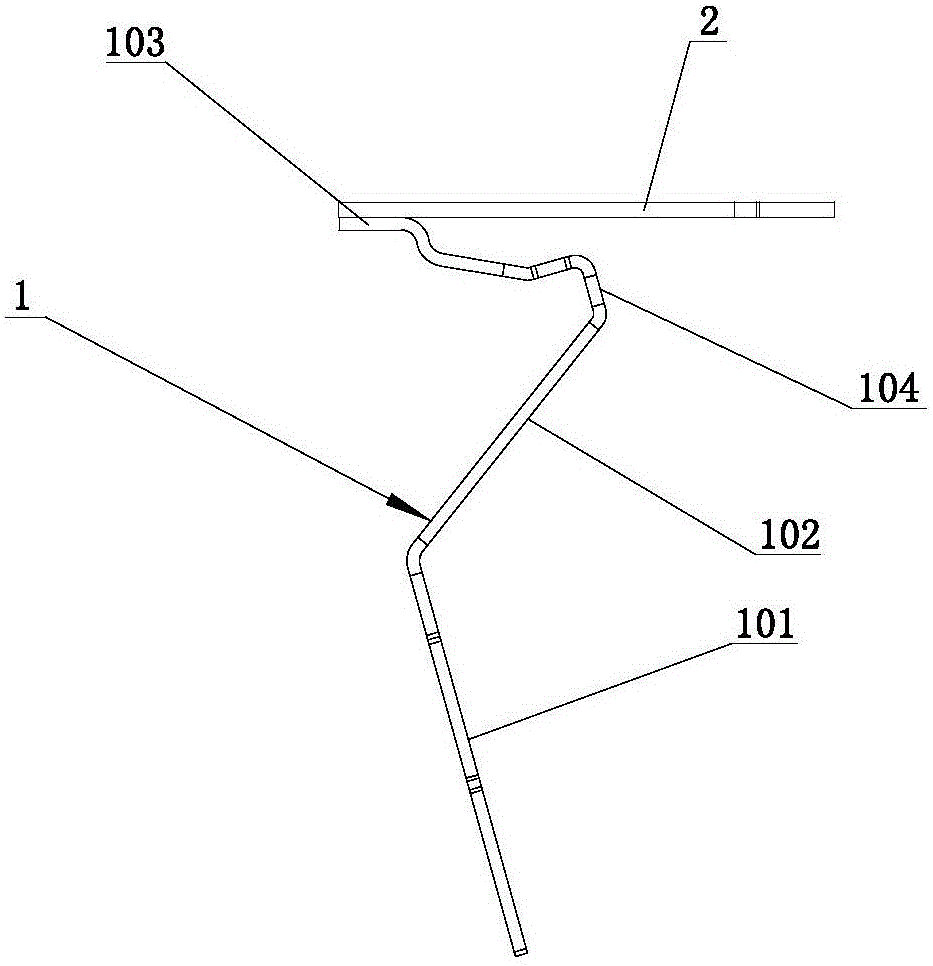

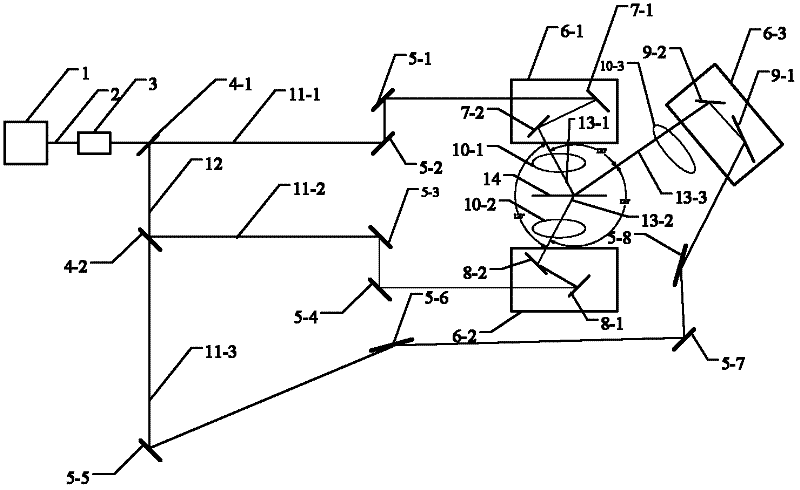

Wire stripper for coaxial wire metallic shielding layer

InactiveCN101409435AStripped thoroughlyPeel fitLine/current collector detailsApparatus for removing/armouring cablesBeam expanderGalvanometer

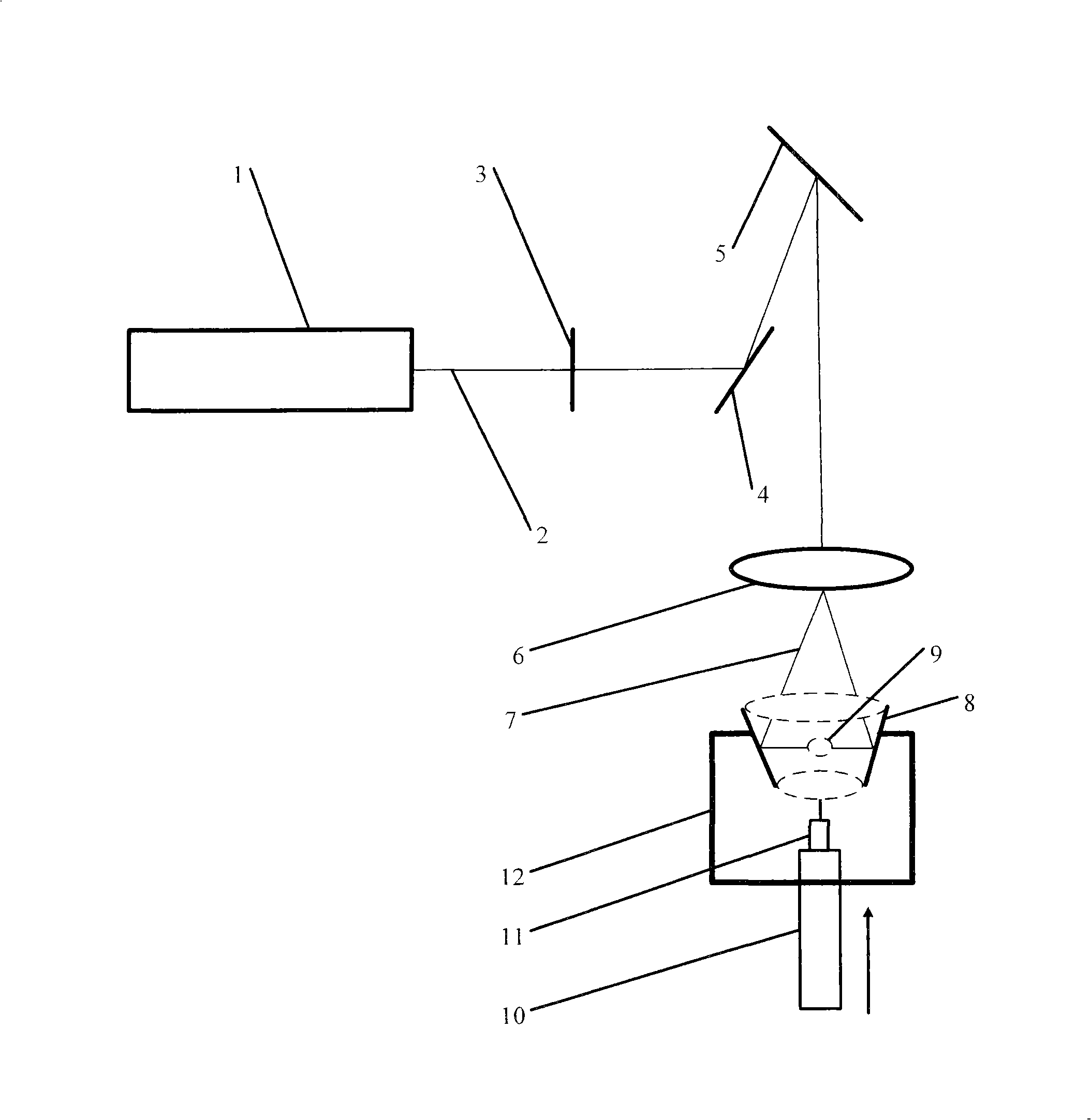

The invention relates to a coaxial metal shielding layer wire stripping machine which comprises a laser source, a galvanometer scanning system, an annular optical reflector and a mechanical device. The machine is characterized in that laser transmitted by the laser source is expanded and collimated by a beam expander, and then passes through a X-direction galvanometer, a Y-direction galvanometer and an F-THETA lens to spatially form a tapered optical path which passes through the annular optical reflector and focuses on a focus to form a focus circle with a certain diameter. The focus circle performs annular stripping on the coaxial metal shielding layer with the same diameter. The machine has novel idea, reasonable design and normative process, can realize effective stripping of the coaxial metal shielding layers of different sizes, and is characterized by fast processing speed, thorough stripping, high yield and high production efficiency. The machine can be widely applied to processing various large-sized coaxial metal shielding layers.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

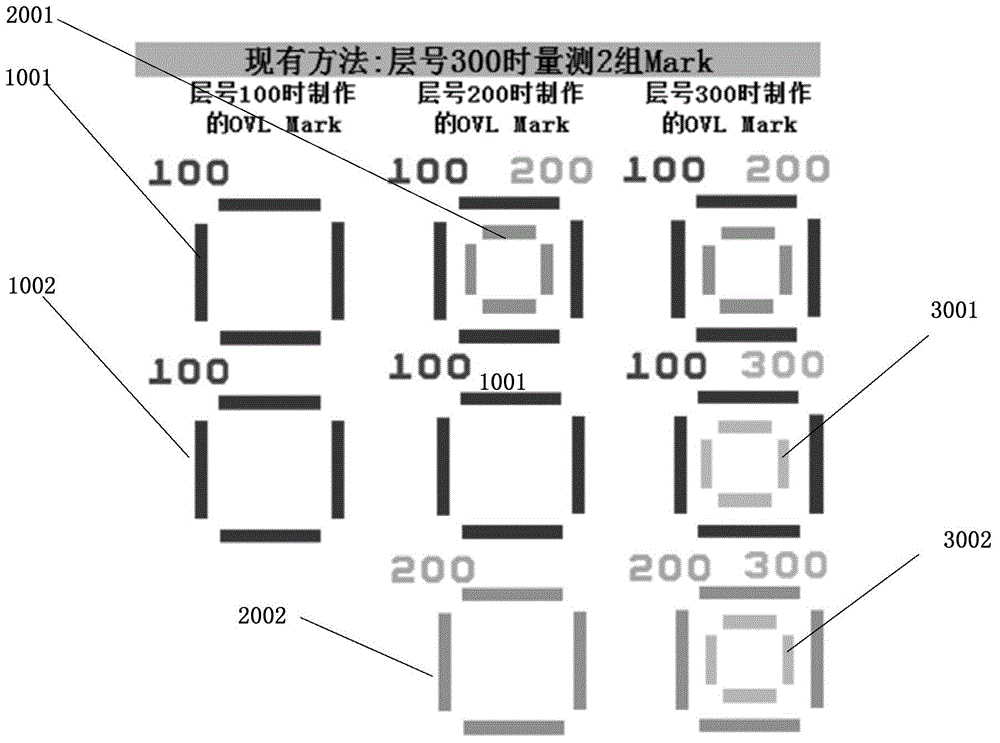

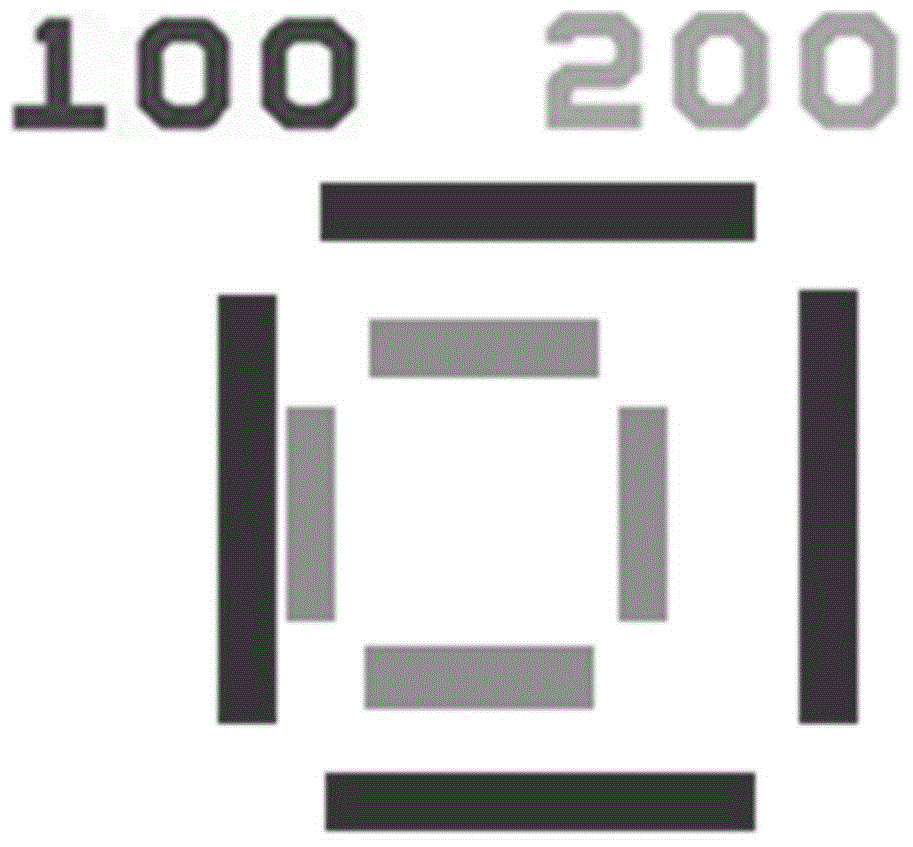

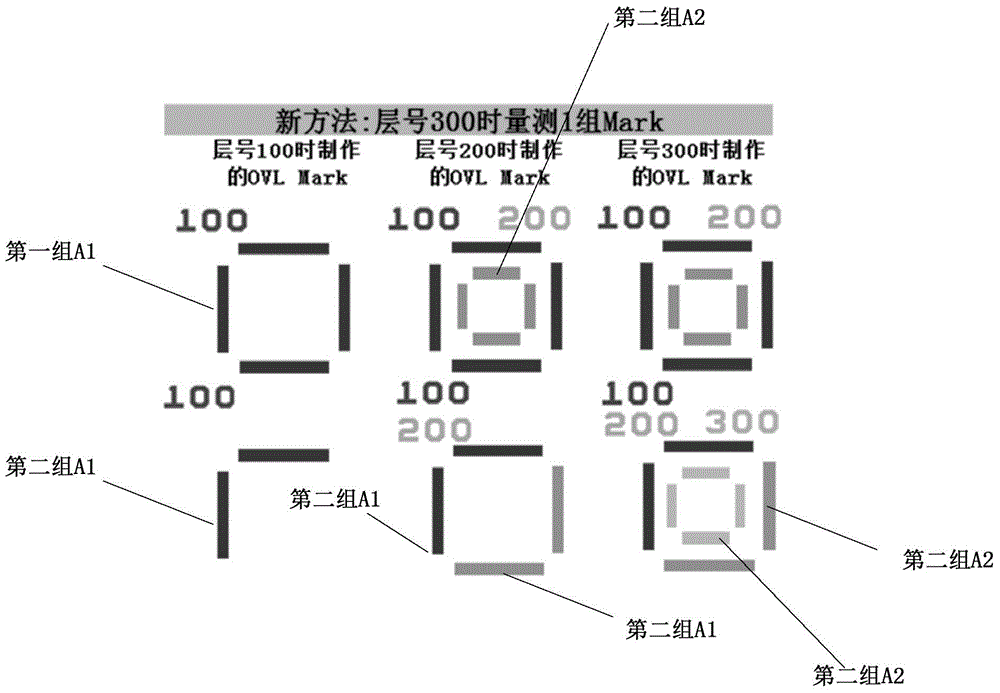

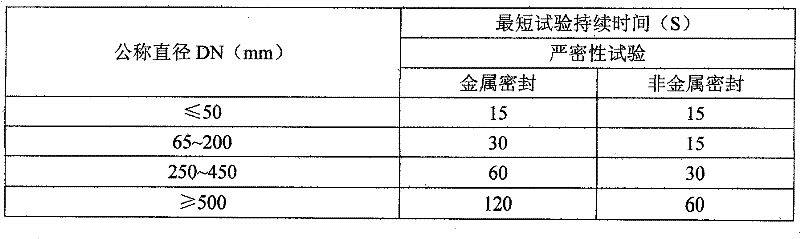

Two-layer overlay accuracy control level management method, calibration mark and measurement system

ActiveCN104898383ARealize computingImplement feedbackSemiconductor/solid-state device testing/measurementPhotomechanical exposure apparatusCost ControlsData mining

The invention provides a two-layer overlay accuracy control level management method, a calibration mark structure for implementing the method, and a measurement system comprising the calibration mark structure. According to the method, a combined calibration mark is enabled to include two-layer overlay information by means of modifying layout of an overlay calibration mark, collection of first two layers of overlay accuracy data in current level is completed by one-time measurement, and two-layer overlay accuracy can be controlled differently, so that automatic feedback optimization of overlay accuracy compensation can be completed, simplicity and feasibility are achieved, and production quality and cost control of enterprises can be facilitated more effectively.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Backlight module and flat-panel display

InactiveCN102032512AReduce rework rateReduce the probability of driftNon-linear opticsLight fasteningsLight guideDisplay device

The invention discloses a backlight module and a flat-panel display. The backlight module comprises a rubber frame, a lamp shade, a lamp source, a light guide plate and a plurality of optical films, wherein the lamp shade comprises a baffle plate and a convex component, the rubber frame is provided with a groove, and the inside of the groove is provided with a clamp component, therefore, when the rubber frame and the lamp shade are assembled, the convex component and the clamp component are mutually buckled. The backlight module disclosed by the embodiment of the invention has the advantages that the lamp shade comprises the baffle plate and the convex component, and the rubber frame is provided with the groove and a convex-component buckling part corresponding to the baffle plate, so that when the rubber frame and the lamp shade are assembled, the baffle plate and the groove are mutually buckled, thereby reducing the horizontal and vertical deviation ratios of the rubber frame. Compared with the current general assembling mode of the rubber frame and the lamp shade, the required reworking rate of the backlight module caused by different appearances and sizes of the backlight module after the rubber frame is assembled can be reduced.

Owner:AU OPTRONICS CORP

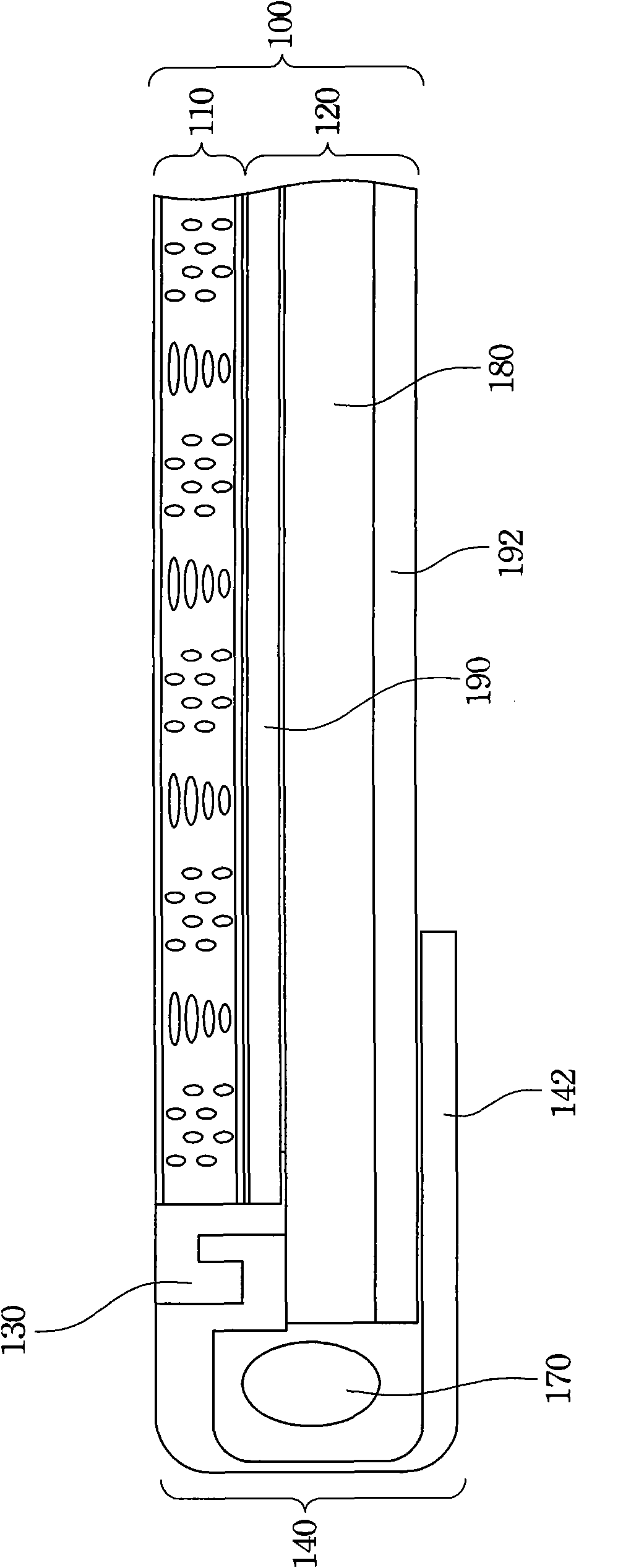

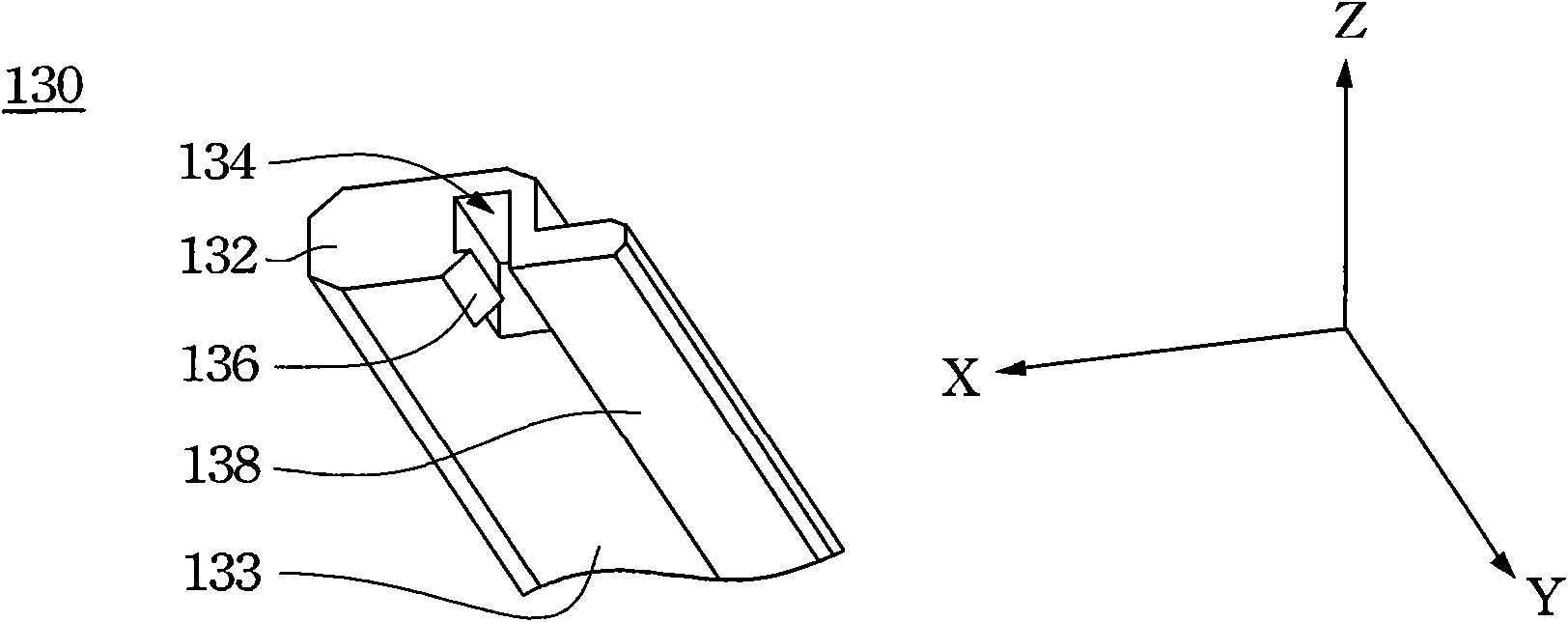

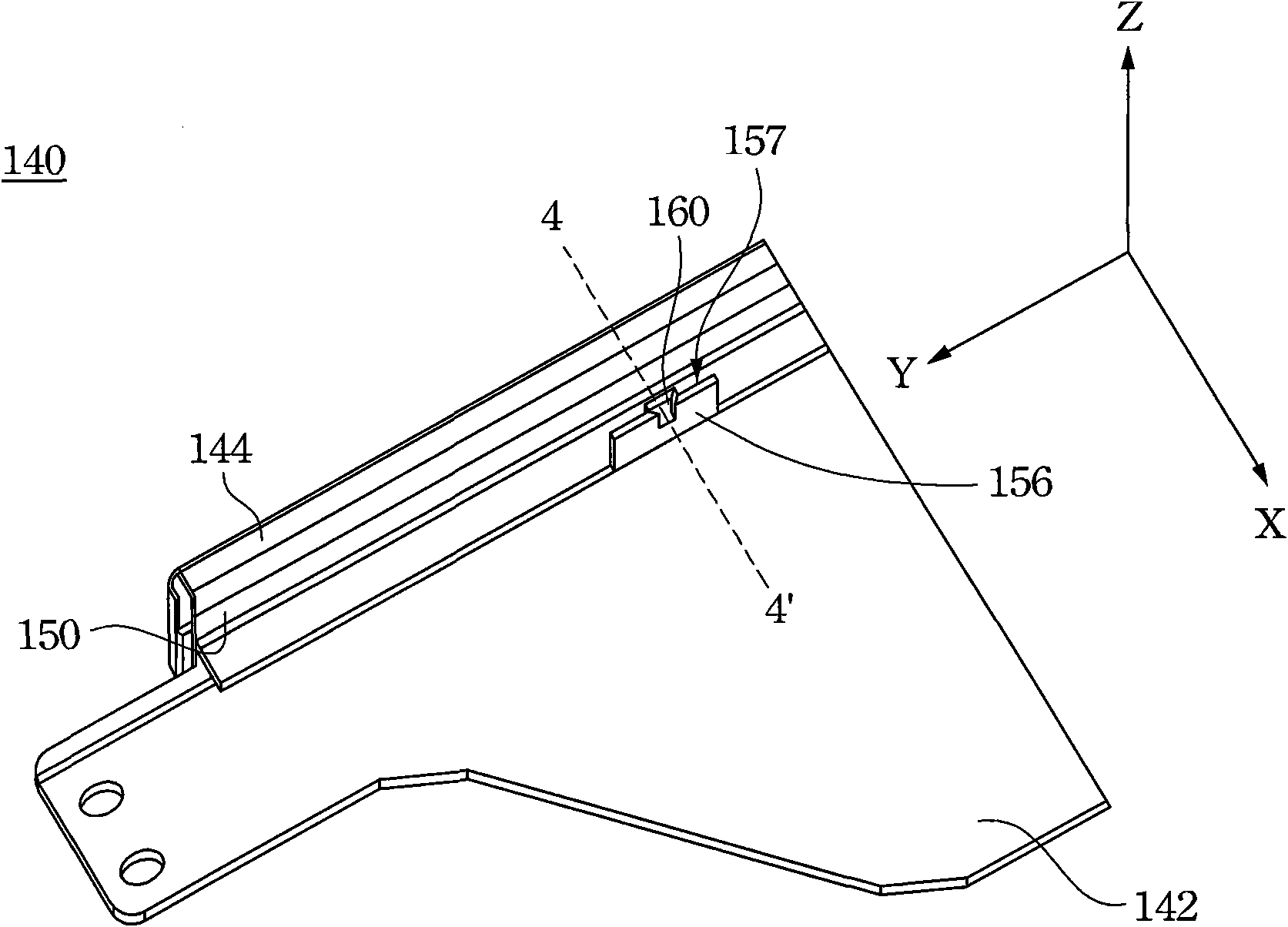

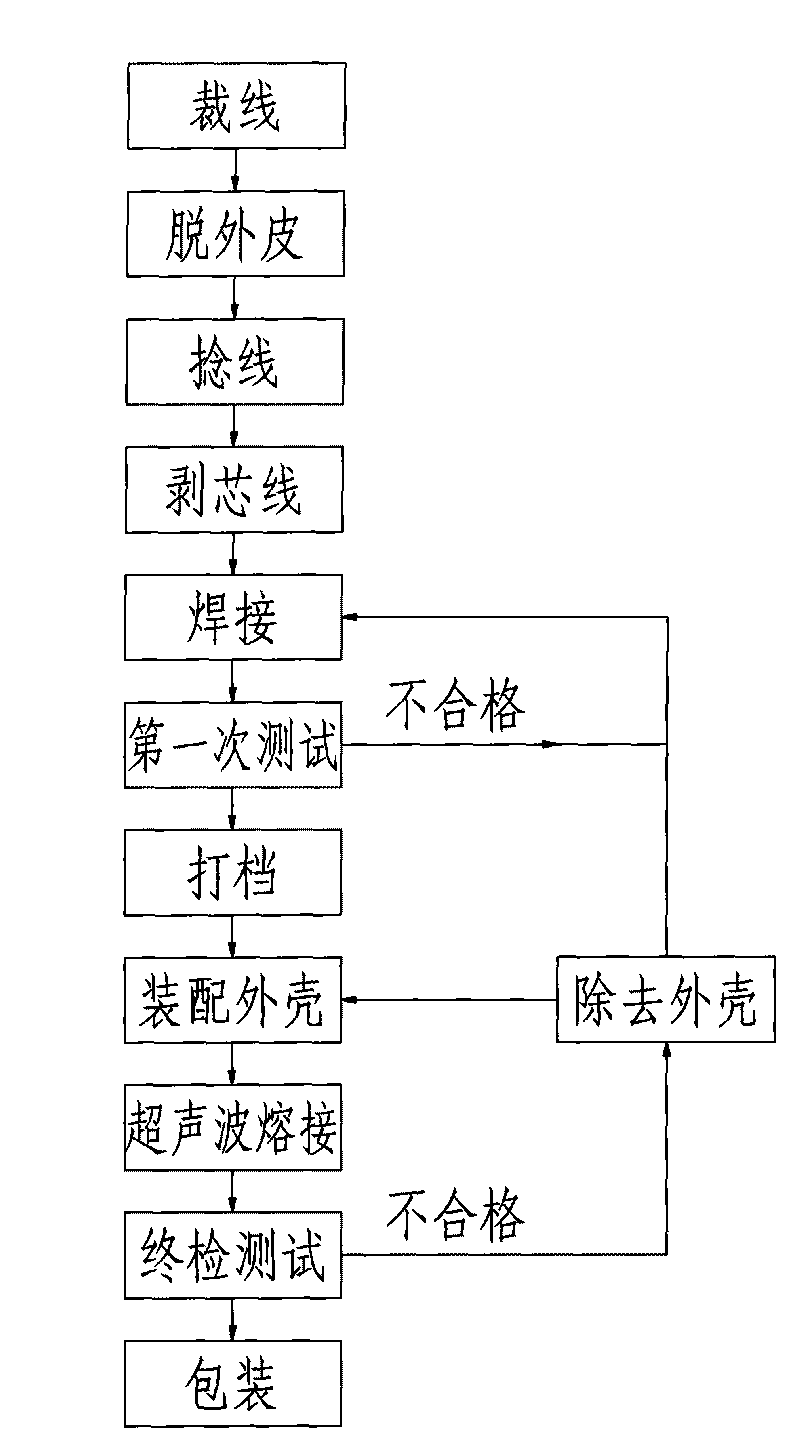

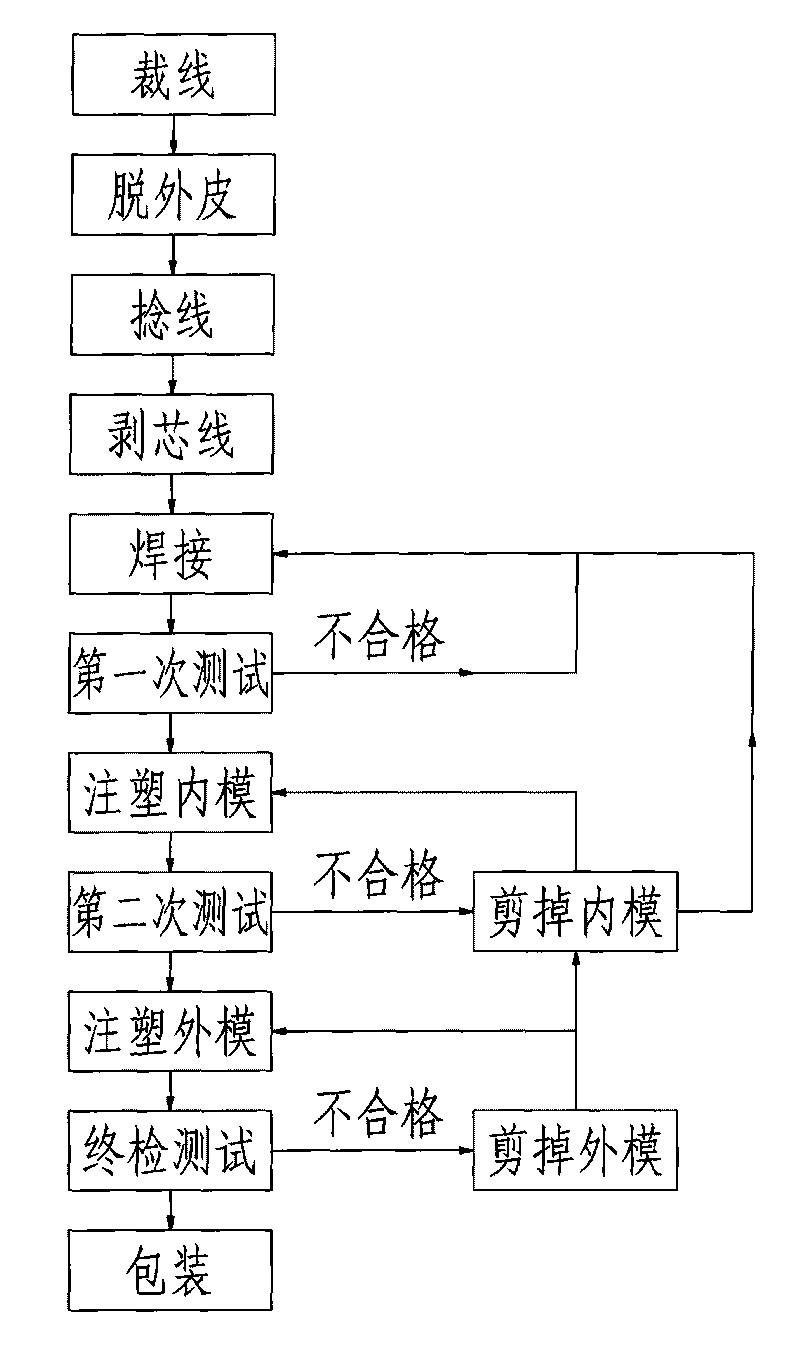

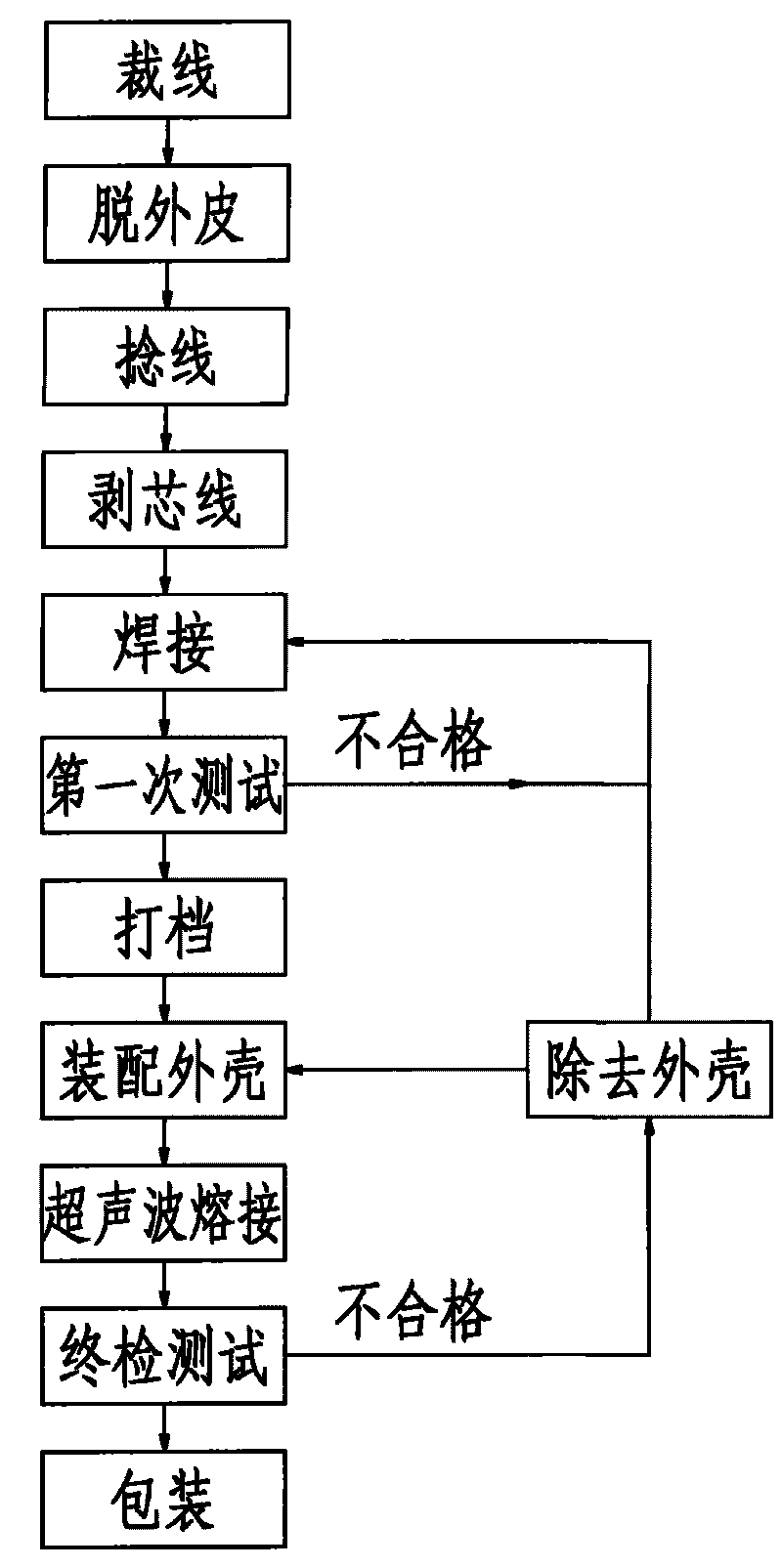

Manufacturing method of connecting wire with high-definition multimedia interface

InactiveCN101752769AAccept easyLove easyContact member assembly/disassemblyUltrasonic weldingEngineering

The invention discloses a manufacturing method of a connecting wire with a high-definition multimedia interface, comprising the following steps of: firstly cutting a wire, peeling the sheath of the wire, twisting the wire, peeling a core wire, welding and then testing for the first time, wherein products unqualified in the first test are returned to be welded again; after the products are qualified in the first test, assembling an upper plastic shell and a lower plastic shell with injection molding on a head part of a metal head of the high-definition multimedia interface and a cable wire thereof; then welding the upper plastic shell and the lower plastic shell by adopting an ultrasonic welding machine; performing a final test after the upper plastic shell and the lower plastic shell are welded, wherein the products qualified by the finial test are packaged and stored, and the products unqualified by the final test are reassembled with a shell or returned to the welding procedure to be welded again after the shell is removed. The manufacturing method is suitable for manufacturing the connecting wire with the high-definition multimedia interface.

Owner:KAIXINTONG ELECTRONICS NANJING

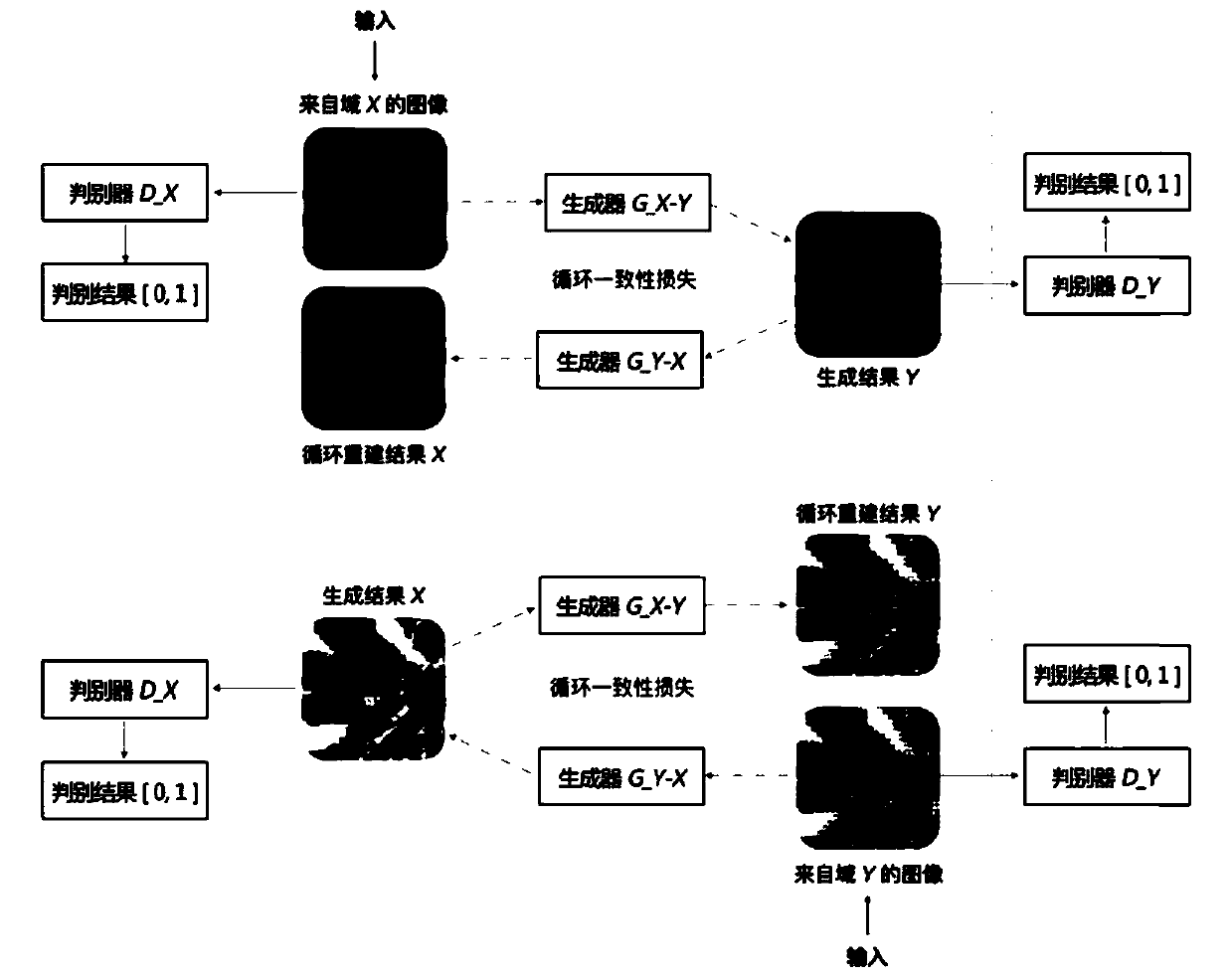

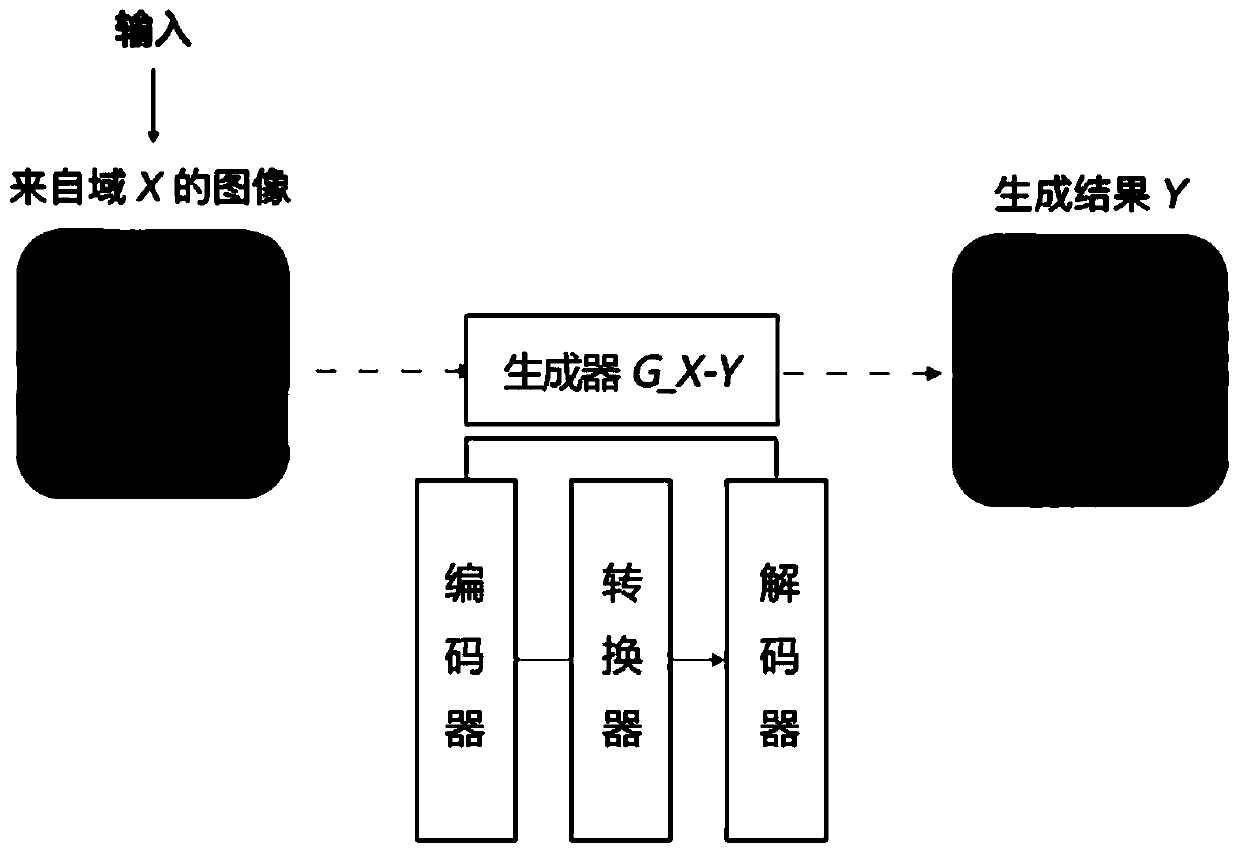

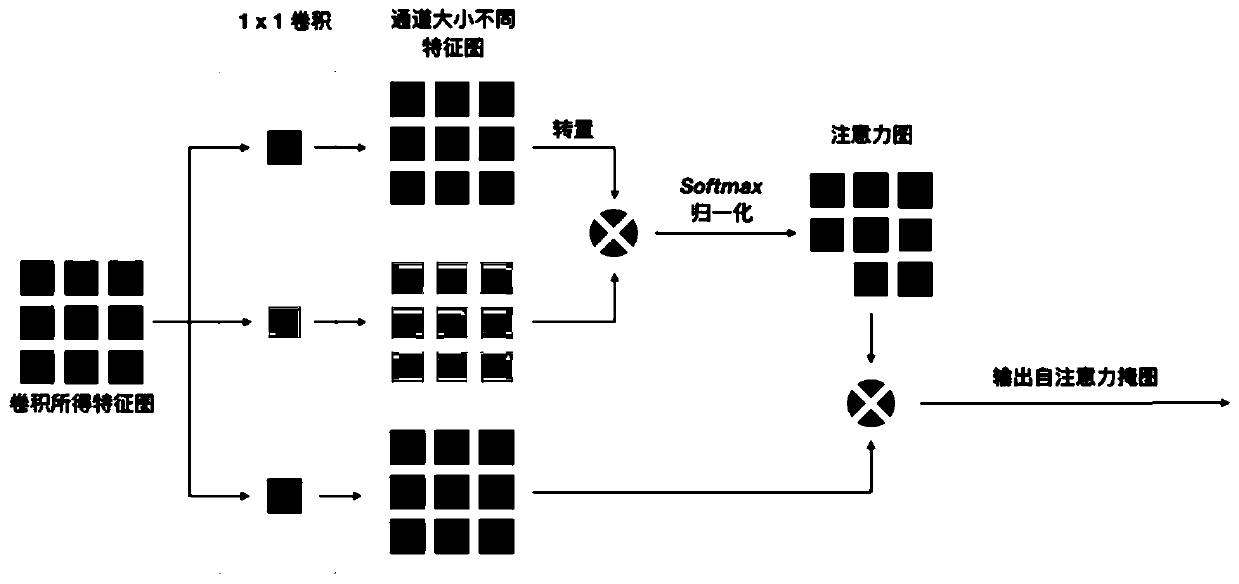

Refined embroidery texture migration method based on sample domain

ActiveCN110097609AGenerate good effectOptimize the generation processImage enhancementImage analysisPattern recognitionSelf attention

The invention discloses a refined embroidery texture migration method based on a sample domain, which comprises the following steps: in a model training stage, based on a cyclic generative adversarialnetwork, adding a Waserstein loss item, a feature matching loss item and an MS-in loss item into a loss function, and performing feature matching on the loss item and the MS-in loss item; according to the SSIM loss item, a self-attention mechanism is added to a generator G network, and a resolution enhancement method from coarse to fine is introduced. A training model is used for synthesizing embroidery textures; performing color quantization processing based on self-organizing network mapping on the input embroidery vector design drawing, performing color correction on the generated embroidery textures through the quantization method, and finally combining the embroidery textures with the generated normal map to obtain an embroidery texture map which meets the three-dimensional display requirement and has both embroidery colors and concave-convex textures. According to the method, rapid generation from image design to refined embroidery texture is realized, and the rework rate of production personnel is reduced while the communication efficiency of the design personnel is improved.

Owner:SHANGHAI LINCTEX DIGITAL TECH CO LTD

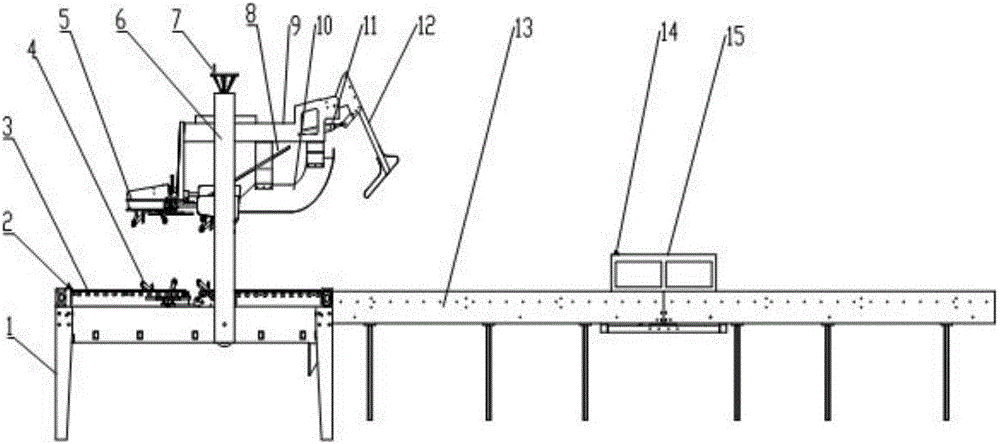

Method for realizing automatic screw driving and automatic screw driving machine

ActiveCN105499977AHigh precisionShorten the timeMetal working apparatusElectric machineryEngineering

An embodiment of the invention discloses a method for realizing automatic screw driving and an automatic screw driving machine. The method comprises steps as follows: a knockout plate is positioned visually, and the position of the knockout plate in the automatic screw driving machine is acquired; whether a screw of the corresponding specification exists on a loading tray or not is detected; a descending motor runs to the screw taking height; a screw conveying motor conveys the screw sucked by a screwdriver bit from the position above the loading tray to the position above the knockout plate; position coordinates of a hole where the screw is to be driven in the automatic screw driving machine on the knockout plate are acquired, and the hole where the screw is to be driven on the knockout plate is conveyed to the position under the screwdriver bit; a follow motor moves to the position under the screwdriver bit driven by the screw conveying motor, and an ejection motor rises to the corresponding height according to the length of the screw; a rotating motor starts to rotate, the descending motor descends slowly, and the screw is driven into the corresponding position of the knockout plate. With the adoption of the method for realizing automatic screw driving and the automatic screw driving machine, the downward driving height of different screws can be controlled, the precision is high, the time is short, the labor cost can be reduced, the reworking rate can be decreased, and the overall efficiency can be improved.

Owner:GUANGDONG INST OF INTELLIGENT MFG +1

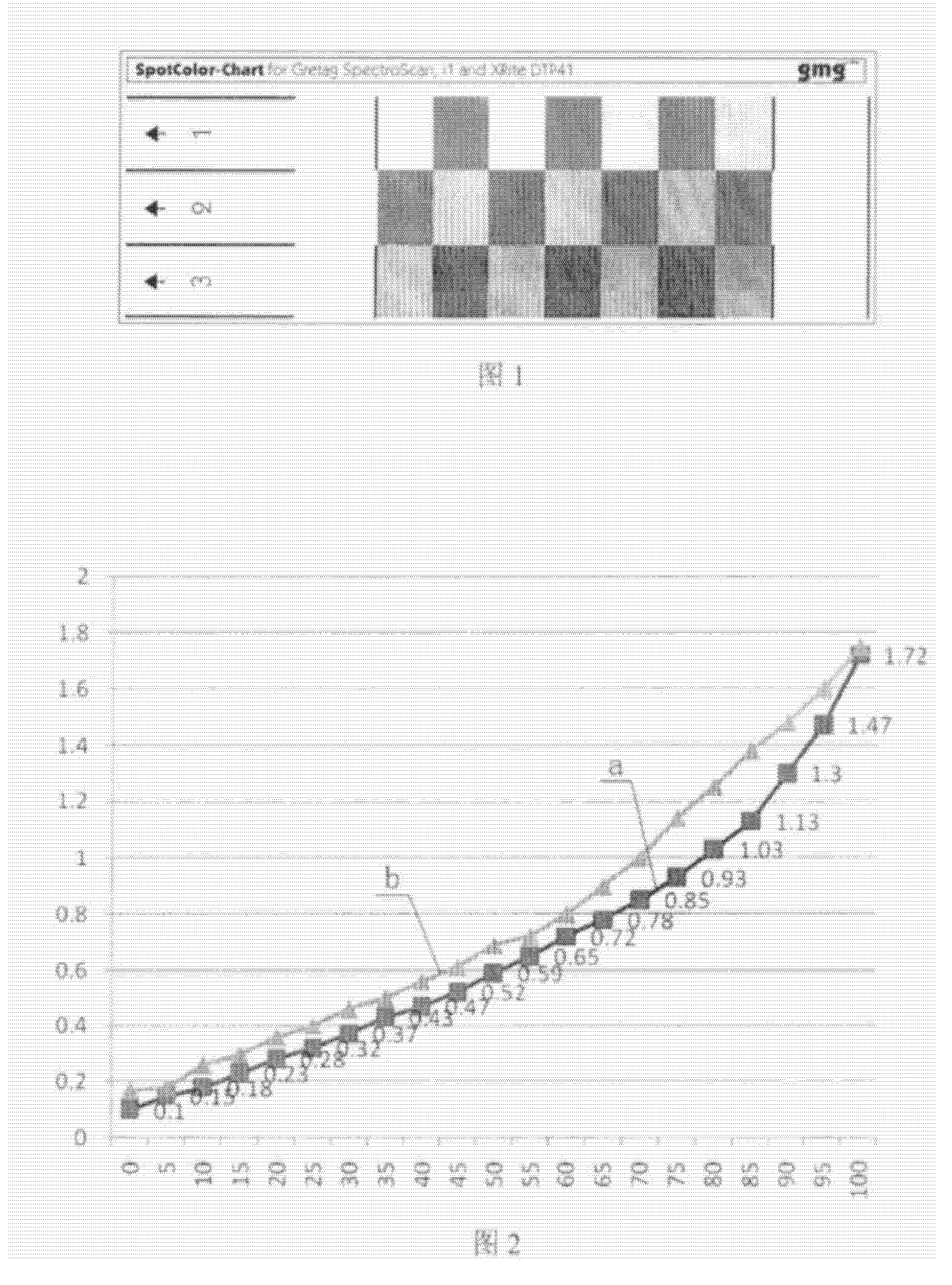

Digital sample printing method of spot color participation image

ActiveCN101987529AMeet the sample requirementsReduce rework rateRotary intaglio printing pressPattern recognitionArea coverage

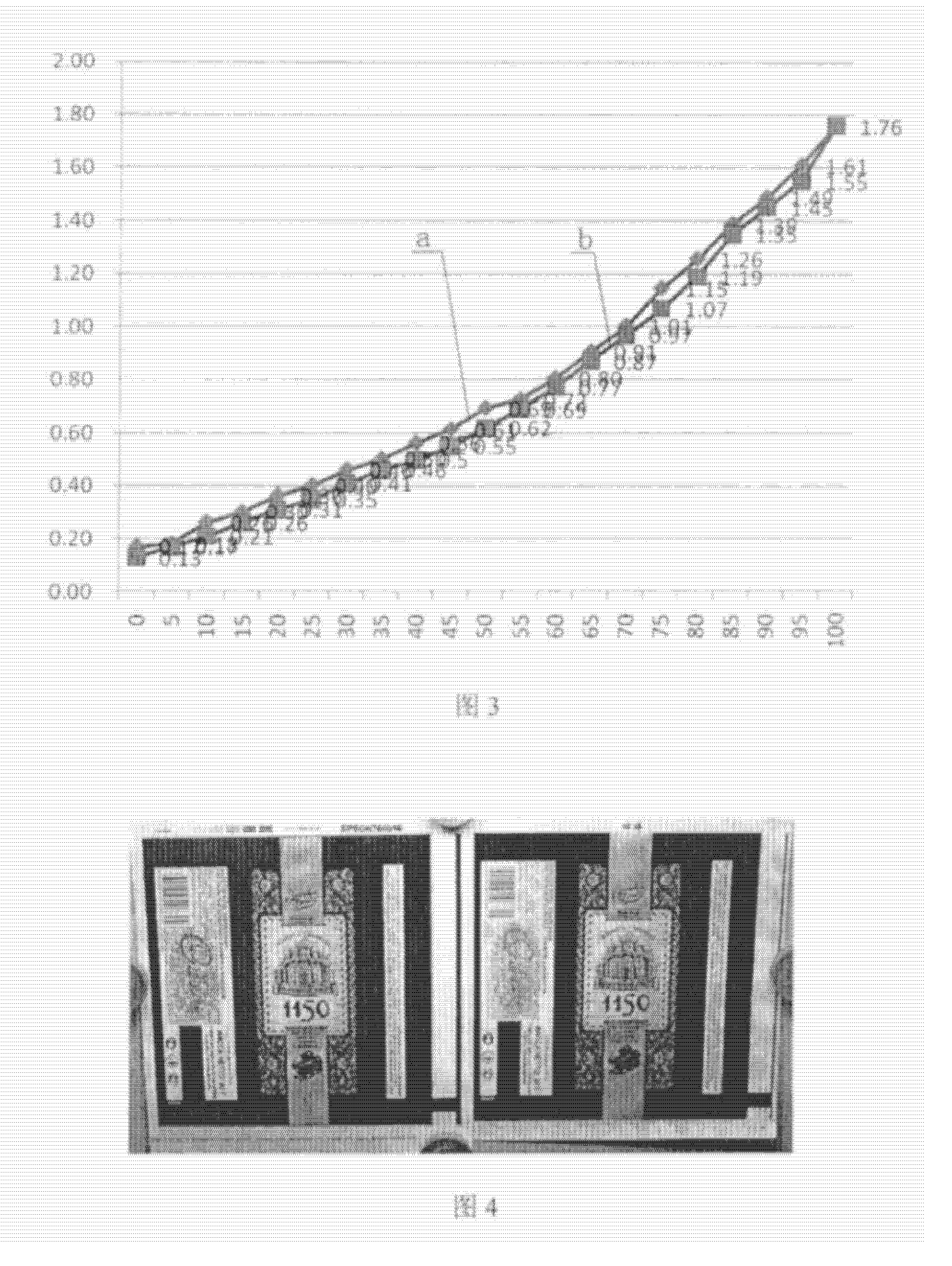

The invention relates to a digital sample printing method of a spot color participation image, comprising the following steps of: preparing a GMG (Gif Movie Gear) spot color scale plate; correcting the difference between a GMG built-in Pantone spot color library and a gravure sample, including printing a spot color scale digital sample by using the built-in Pantone spot color library before printing; printing a spot color gravure sample by using the GMG spot color scale plate to make a field color value consistent with the digital sample; respectively measuring the dot area coverage rate or the density value of the spot color scale digital sample and the spot color gravure sample, and respectively generating a curve; and improving the effect of the spot color scale digital sample to make the two curves approximate as much as possible. The invention provides an adjustment basis for prepress staffs on the manuscript type of spot color participation electroanalysis, and the EPSON effect of using GMG sample printing is very approximate to the gravure sample printing effect; the prepress staffs can use EPSON sample printing to carry out accurate spot color simulate sample printing to realize color sample printing; the spot color simulated by digital sample printing is very approximate to the printing effect, and thereby, the sampling demand of clients on such type of manuscripts is satisfied, the rework rate is reduced and the cost is reduced.

Owner:TONGCHENG YUNCHENG PLATEMAKING

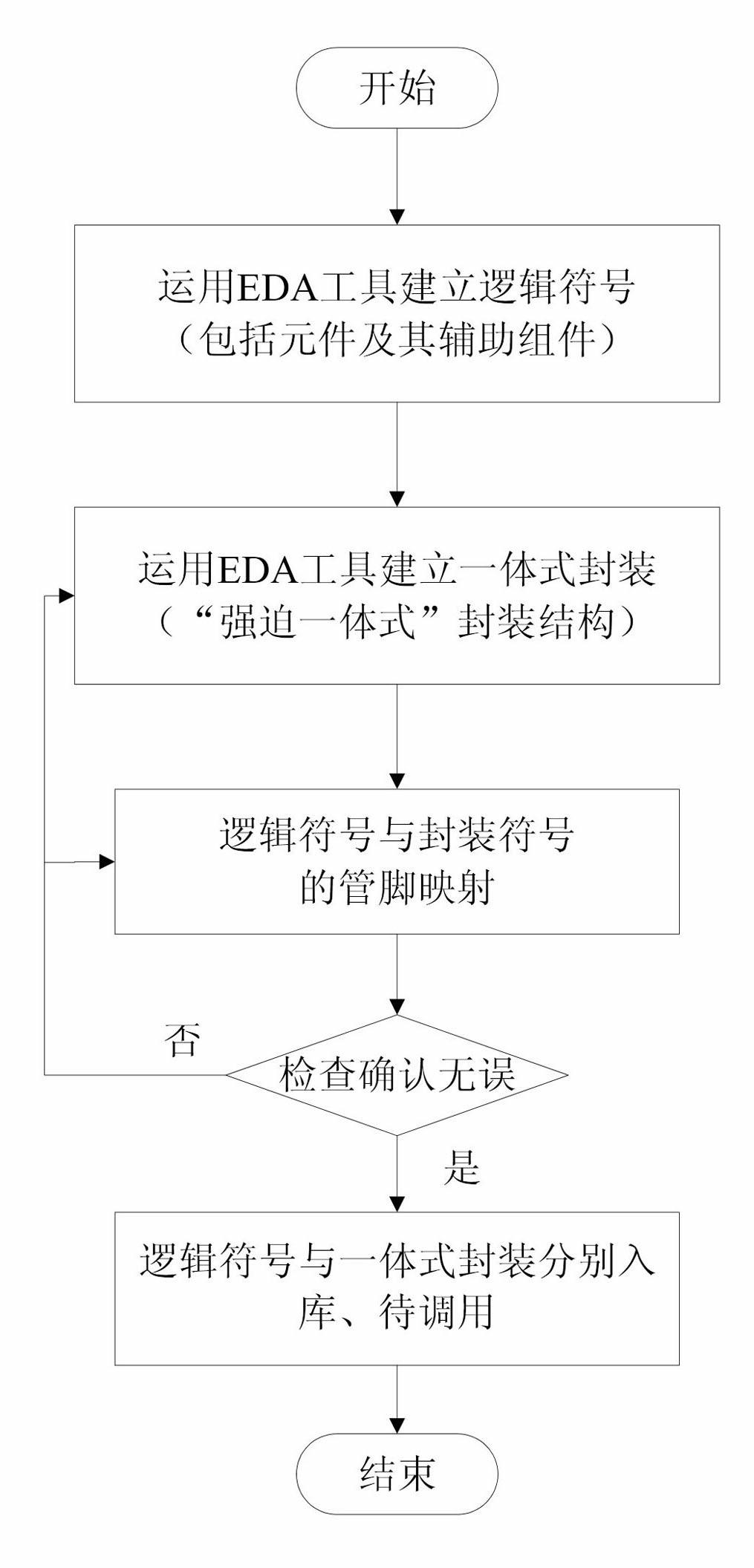

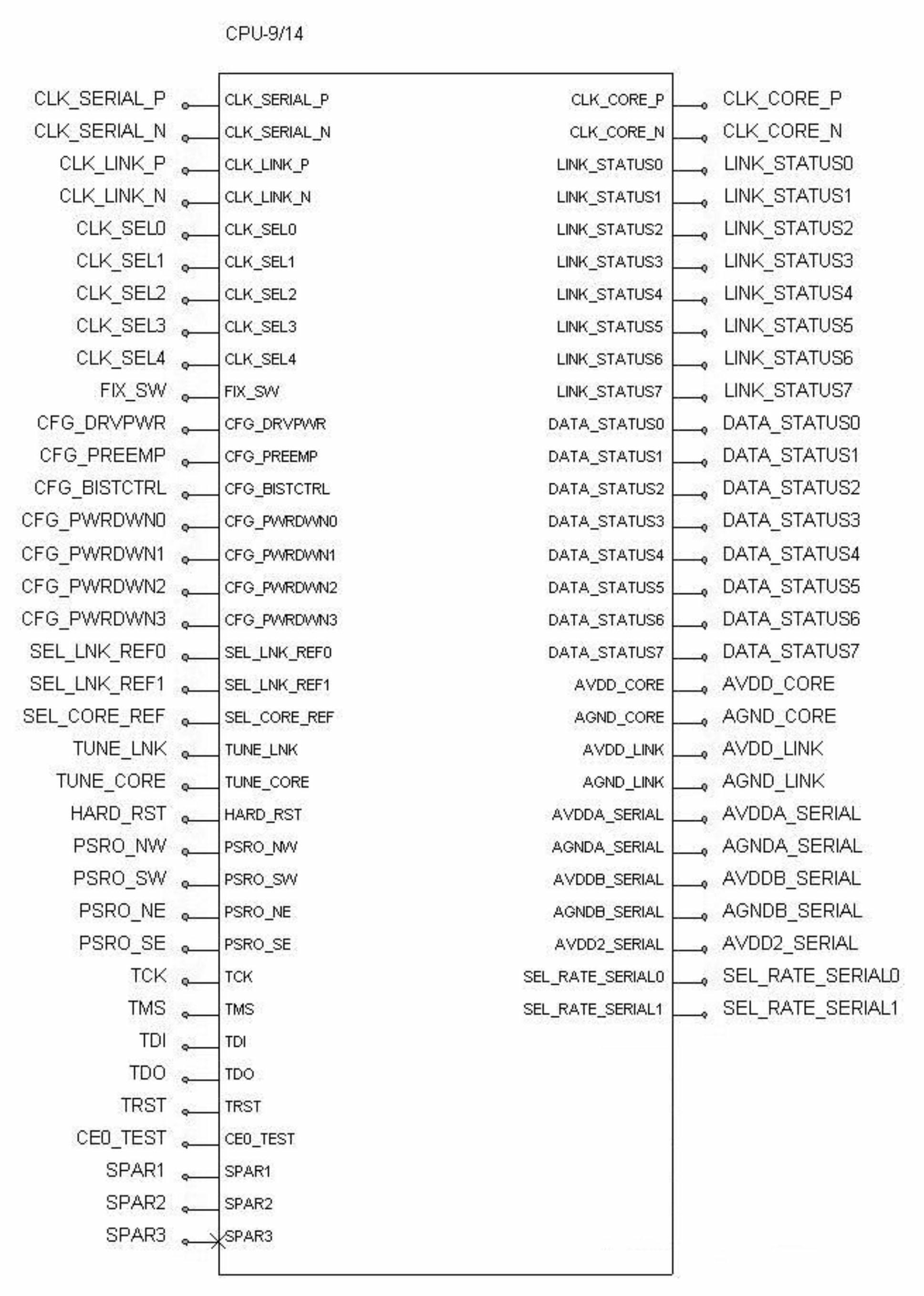

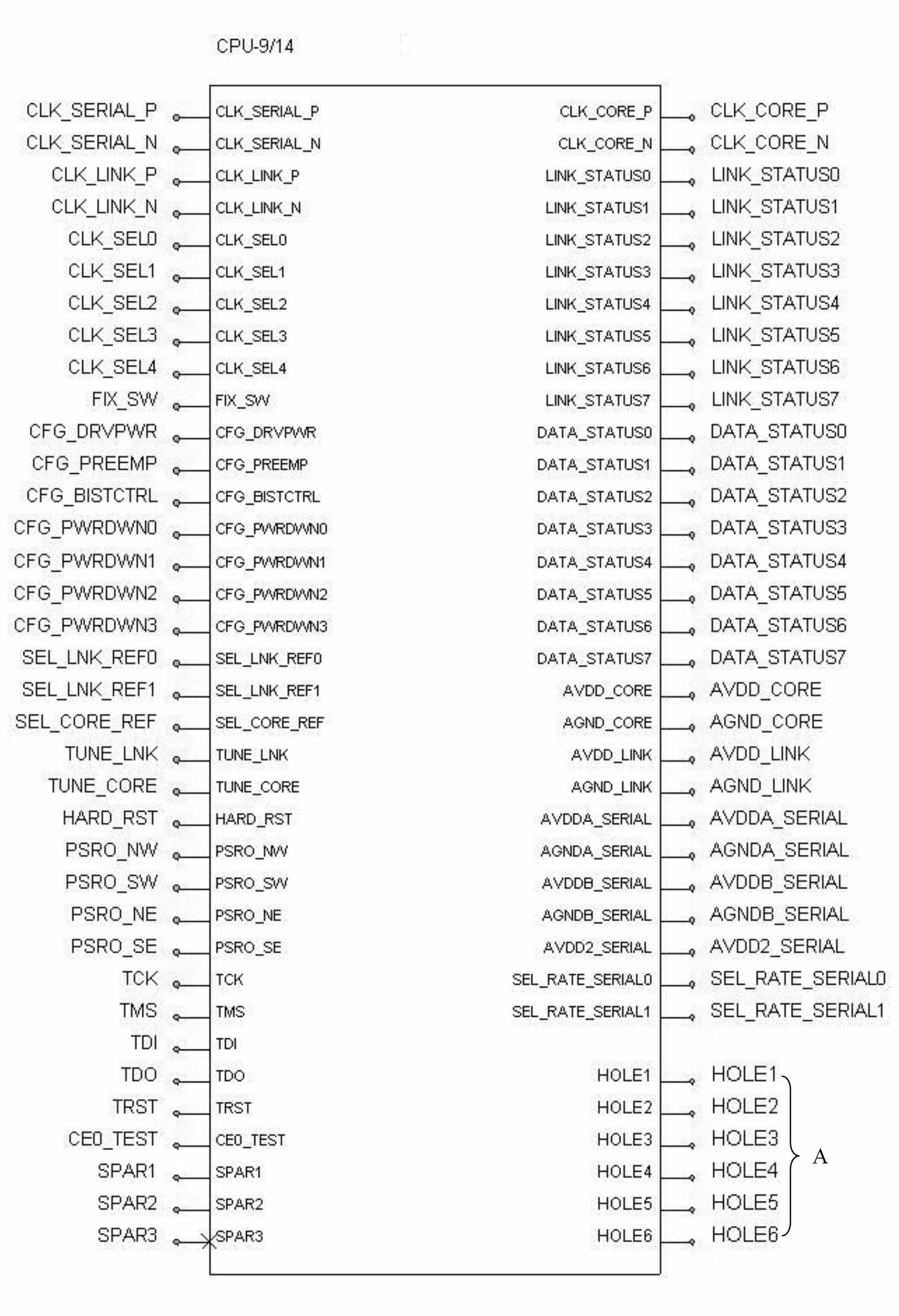

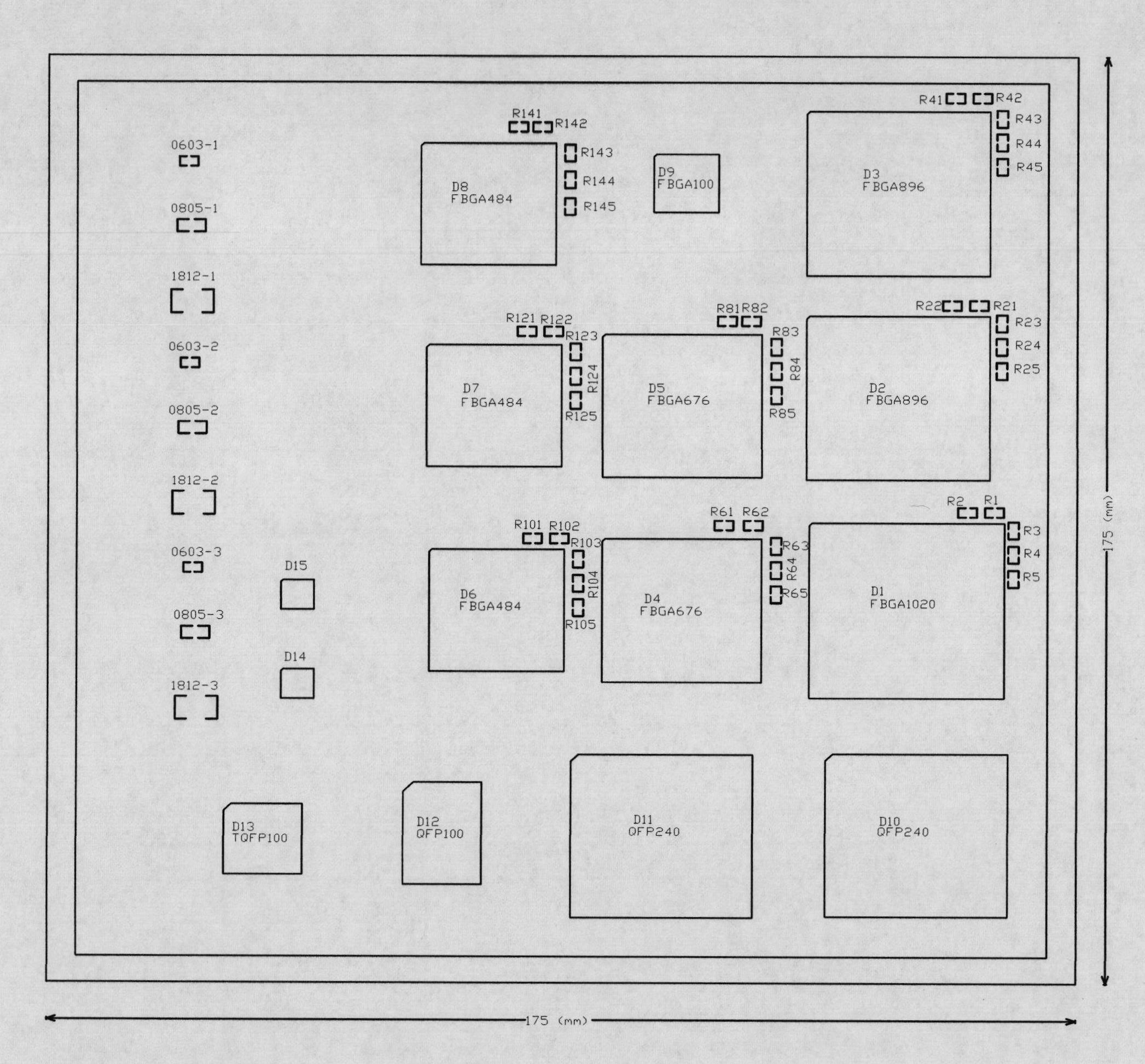

PCB (printed circuit board) packaging architecture method

InactiveCN102637226AGuaranteed correctnessEasy Placement and Routing DesignSpecial data processing applicationsPrinted circuit boardSoftware engineering

The invention discloses a PCB (printed circuit board) packaging architecture method, which includes the steps: setting up a logic symbol in a logic symbol library, wherein the logic symbol comprises pins and mounting holes of an element and an auxiliary component thereof; setting up a traditional packaging symbol of the element, setting up an auxiliary packaging symbol according to the structural characteristics of the auxiliary component of the element, and combining the traditional packaging symbol and the auxiliary packaging symbol into integrated package or associating the traditional packaging symbol with the auxiliary packaging symbol into a combined packaging symbol; and mapping the logic symbol and the corresponding integrated package or combined package, and storing the integrated package or combined package into a PCB packaging bank for integral calling or combination calling. Using the PCB packaging architecture method can improve operating efficiency, reduce repetitive operations in PCB design and improve PCB design accuracy.

Owner:NAT UNIV OF DEFENSE TECH

Method for controlling cracks of double-block type ballastless track bed slabs

The invention discloses a method for controlling cracks of double-block type ballastless track bed slabs. The method includes steps of pouring concrete back and forth among double-block type sleepers according to 'Z'-shaped paths; vibrating the concrete, in other words, performing a secondary vibrating process in procedures for pouring the concrete of double-block type track bed slabs according to slump and the initial setting time of the concrete, performing press polish on plastered surfaces, performing rough screeding by the aid of wood float after the concrete is filled into forms, secondarily plastering the surfaces 2 hours after the concrete is filled into the forms, and performing tertiary press polish on the plastered surfaces 4 hours after the concrete is filled into the forms; loosening vertical screw adjusters, fish plates and fasteners, in other words, loosening vertical adjusting screws 4.5 hours after the concrete is plastered on the surfaces, loosening the corresponding fish plates from two sides of a pouring starting end, timely loosening the fasteners by the aid of a bolt fastening machine after bolts of the fish plates are loosened, and removing connection; spraying maintenance liquid. The cracks of the ballastless track bed slabs can be reduced in construction procedures, so that trains can assuredly run safely, economically and quickly. The method has the advantages of simplicity in process, convenience in operation and easiness in construction. Besides, the construction quality of the ballastless track bed slabs can be improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

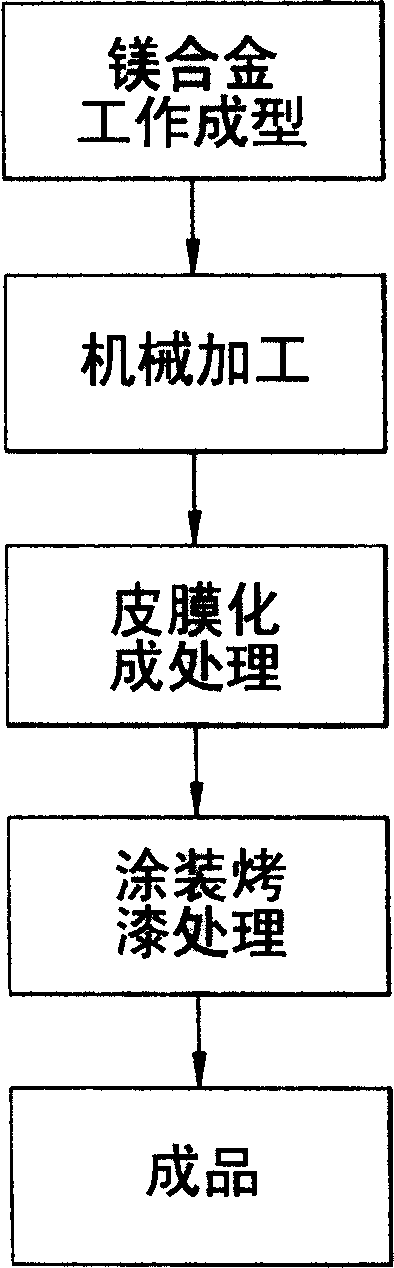

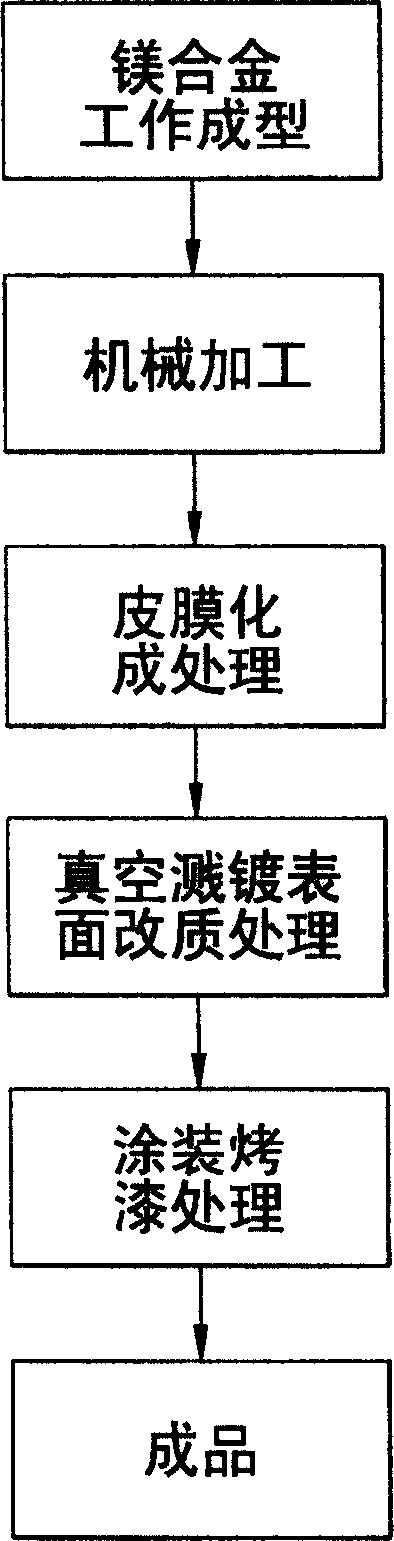

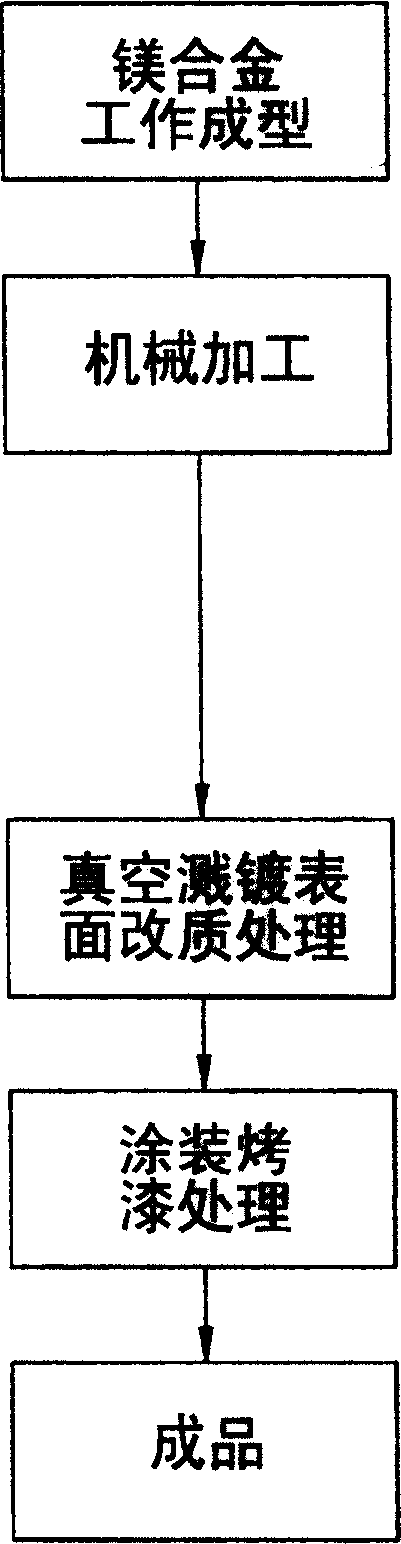

Method for manufacturing metallic products and production

InactiveCN1660510AReduced burst defectsImprove the excellent rateVacuum evaporation coatingPretreated surfacesSputteringMaterials science

A method for preparing the product of the soft metal difficult to machine, such as Mg-alloy or MgAl-alloy, features a vacuum sputtering method is used for modifying the surface of said product. Said Mg-alloy product has high surface quality.

Owner:SILITECH TECH CORP

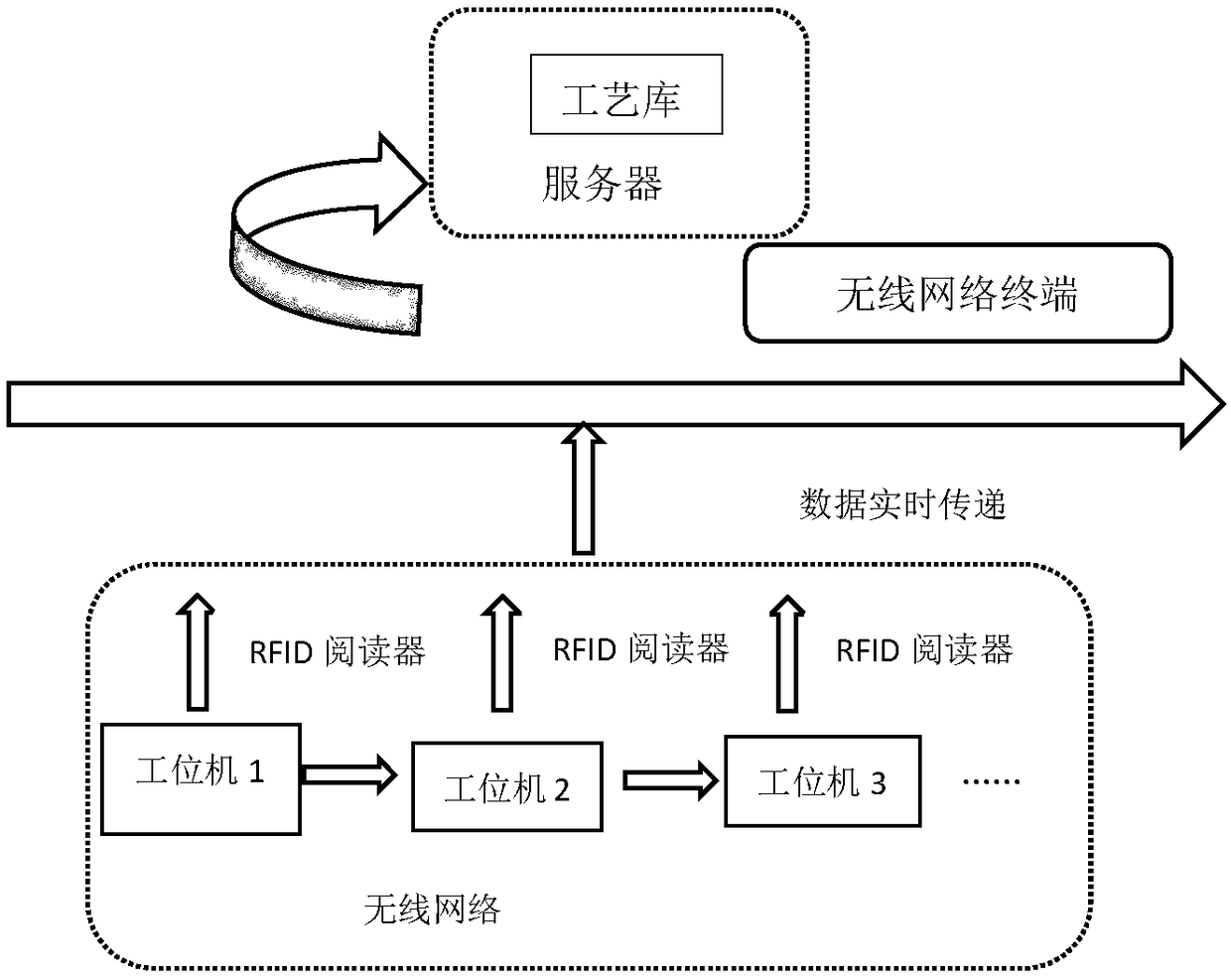

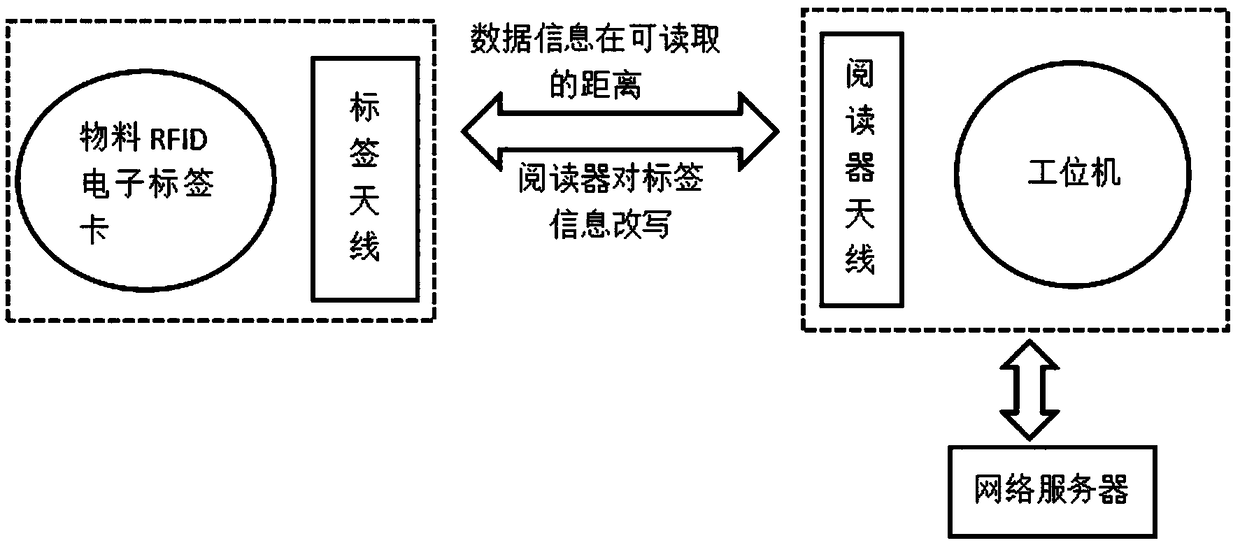

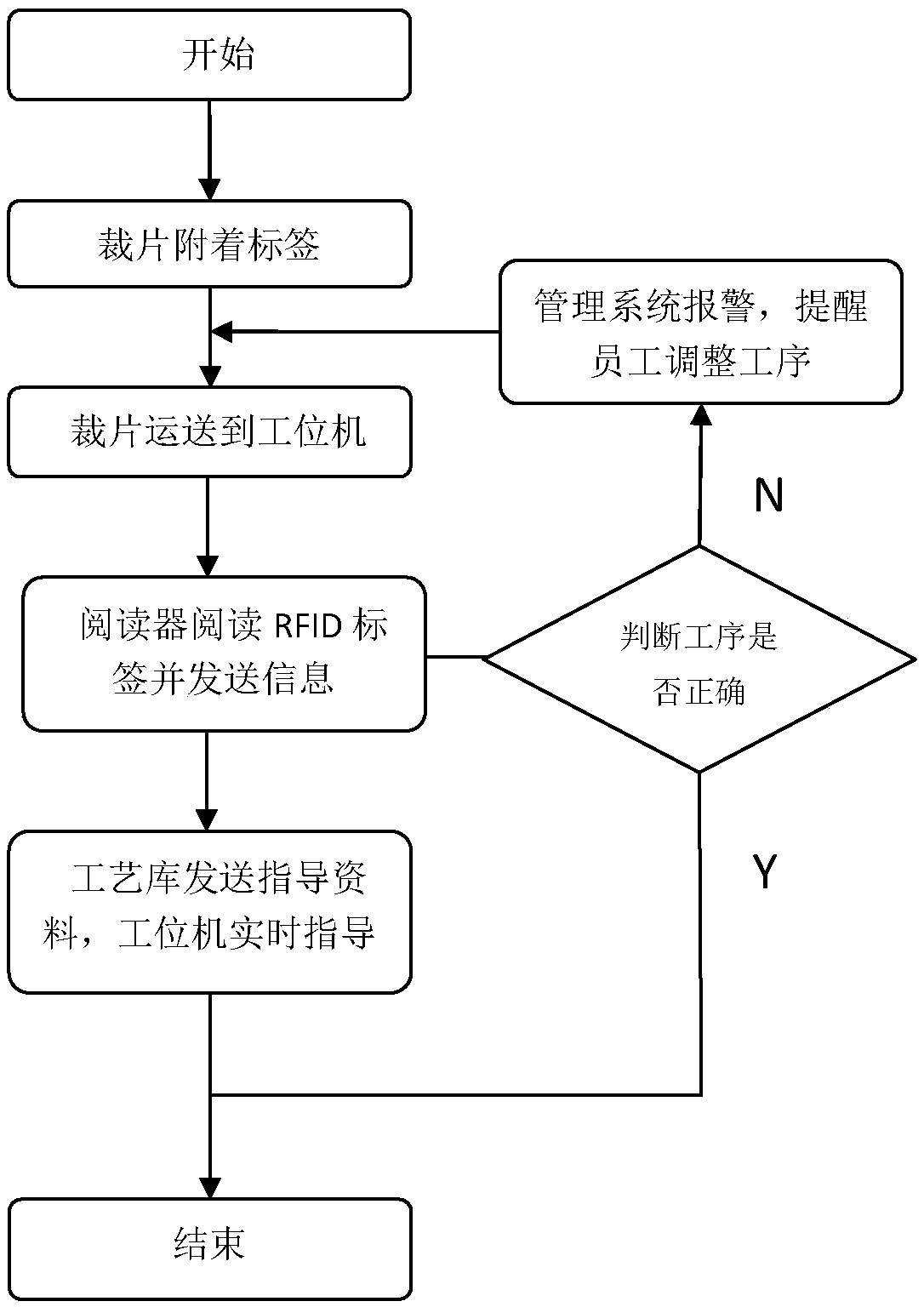

RFID garment process guidance system and guidance method thereof, and production management system and method

InactiveCN109359895AShort memorySolve the production difficulties of wrong sequence and missing sequenceResourcesManufacturing computing systemsProcess guidanceWorkstation

A RFID garment process guidance system and a guidance method thereof, a production management system and method are provided. The RFID garment process guidance system includes RFID electronic tags, workstations, network servers; information can be transmitted between the components; RFID electronic tags are attached to the pieces, the information of the pieces is written therein; the station machine includes an RFID reader and a display screen. The RFID reader reads the information on the RFID electronic tag and transmits the read piece information to the network server. Features: The networkserver includes a database and a process library, and the process library determines the process flow chart according to the style type, and performs the process division on the clothing style, and stores produce process guidance materials in the data base. When receiving the piece piece information, the process library transmits the corresponding process guidance materials to the employee's station machine for guiding the employees to operate to instruct employees to produce in real time, avoid sewing errors, better guide employees to sew, and improve production efficiency.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

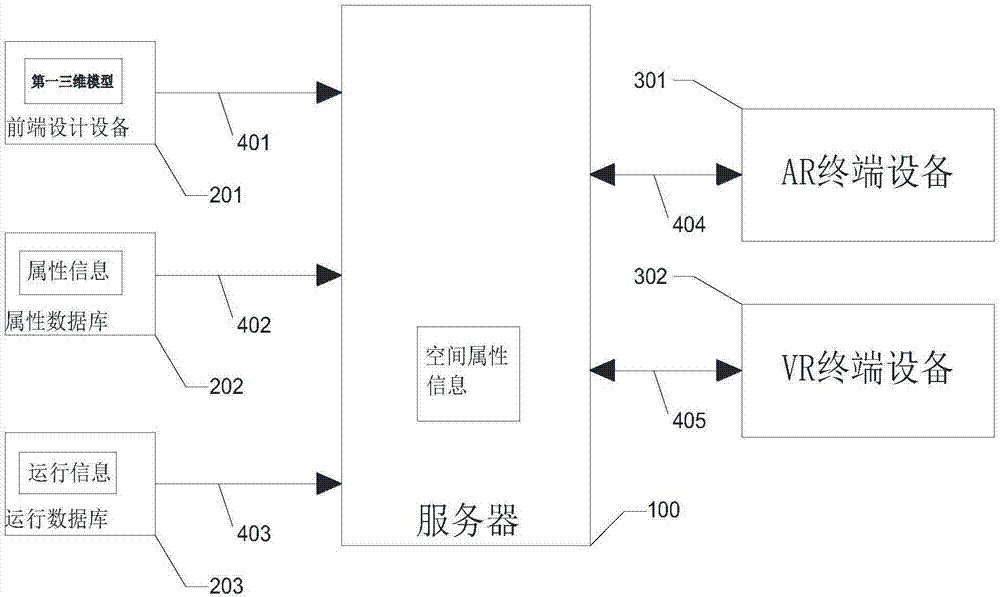

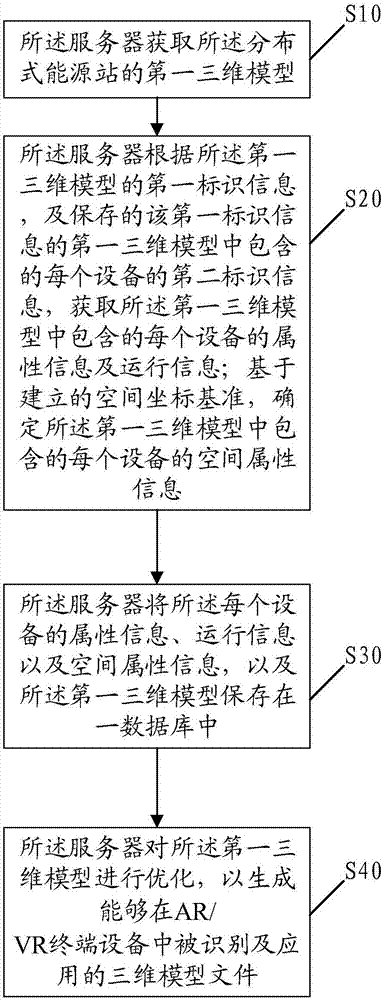

Three-dimensional model processing method, server and computer readable storage medium

InactiveCN107330970ASolve the technical problems of development inefficiencyImprove development efficiency3D modellingTerminal equipmentComputer terminal

The present invention provides a three-dimensional model processing method, a server and a computer readable storage medium. The objective of the invention is to improve the efficiency in the processes of design, installation and maintenance of a device. The method comprises: obtaining the first three-dimensional model of a distributed energy station through a server; obtaining attribute information, operation information and space attribute information of each device included in the first three-dimensional model through the server; storing the attribute information, operation information and space attribute information of each device and the first three-dimensional model in a database through the server; and performing optimization of the first three-dimensional model through the server to generate a three-dimensional model file capable of being identified and applied in an AR / VR terminal device.

Owner:ENN ENERGY SERVICE

Construction method of integrated clean operating room

InactiveCN102691417AReduce rework rateImprove the success rate of an installationBuilding material handlingAutomatic controlNitrogen gas

The invention discloses a construction method of an integrated clean operating room. The construction method comprises the following steps of: 1) surveying and mapping in situ, carrying out three-dimensional simulation, and paying off; 2) mounting a containment steel rack of the operating room; 3) mounting a base of a hanging tower of a shadowless lamp; 4) mounting a wall roof; 5) mounting an operating room door and fixed facilities; 6) laying a floor material of the operating room; 7) integrally spraying the operating room; 8) carrying out mounting gap treatment; 9) mounting a system for purifying an air duct of an air conditioner; 10) mounting a valve; 11) mounting a high-static pressure coil for an air blower; 12) mounting and cleaning a blowing-in roof and an air vent; 13) mounting a system for purifying water of the air conditioner; 14) mounting a unit for purifying the air conditioner; 15) mounting illumination devices and electric sockets in the operating room; 16) mounting automatic-control weak current systems in the operating room and an equipment room; and 17) mounting a medical gas pipeline made of a copper tube, and introducing nitrogen in a pipeline welding process. The construction method provided by the invention has the advantages of low rework ratio, standardization of a construction flow, stable quality and time conservation.

Owner:JIANGSU PANASIA MEDICAL TECH GRP CO LTD

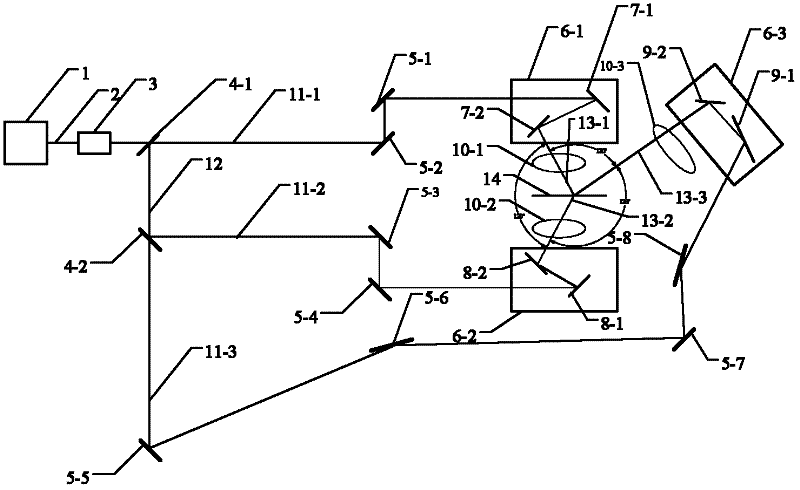

Laser paint stripping machine

InactiveCN102386547ARealize online stripping paintStripped thoroughlyLine/current collector detailsLacquerGalvanometer

The invention relates to a laser paint stripping machine. The machine comprises: a solid laser light source (1); a beam expanding lens (3); two spectroscopes; eight holophotes; three galvanometer scanning systems. The each galvanometer scanning system comprises: one X-direction galvanometer, one Y-direction galvanometer and one field lens. Focal lengths of the three field lenses are the same. Laser passes through the beam expanding lens so as to be aligned and amplified, and passes through the two spectroscopes and then the eight holophotes. The laser is reflected and formed scanning beams which have mutual 120 DEG angles between each other. Three scanning beams scan simultaneously so as to form circle paint stripping around an enameled wire in space. In the invention, a speed is fast andan efficiency is high. A paint layer can be peeled thoroughly. The machine can be widely applied in a magnetic-head enameled wire, an inductance coil and surface paint stripping of a surface-varnished object whose cross section is heterotypical, such as a circle, a square, a triangle and the like.

Owner:ZHENGZHOU CHUSHANG LASER SCI & TECH

Digital printing method of woodgrained paper

ActiveCN105383199AEasy to controlPromote reductionDuplicating/marking methodsOther printing apparatusPulp and paper industryDigital printing

The invention relates to the technical field of gravure plate making, in particular to a digital printing method of woodgrained paper. The digital printing method comprises the steps of: (1) manuscript scanning; (2) manufacturing and color separation; (3) digital sample printing: files, after the color separation, are directly output and subjected to sample printing through a printer; printed objects adopt 80 g woodgrained paper; the sample products and manuscripts are compared to check if the color separation structure is reasonable and if the sample printing effect can satisfy the demands; if the sample printing effect cannot satisfy the demands, the color separation processing is performed again by returning to the last step; and if the sampling effect satisfies the demands, the next step is performed; (4) plate making through carving; and (5) printing. The digital printing method enables sample paper printed by a digital sampling system to be very approximate to actual printing sample paper through controlling a color management system and adjusting a process, preferably achieves actual gravure effects, improves the plate making quality, and reduces the rework rate.

Owner:DONGGUAN YUNCHENG PLATE MAKING

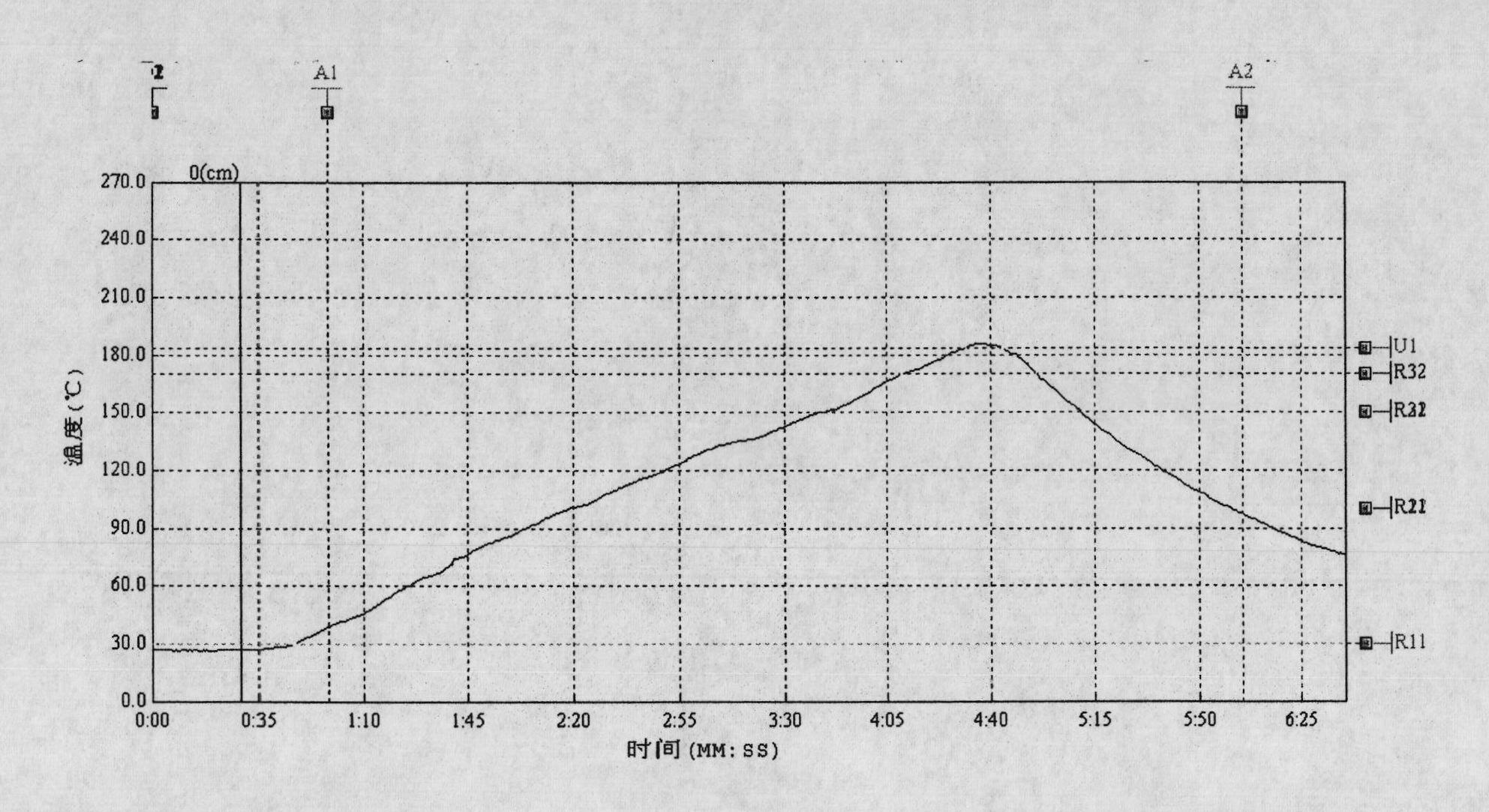

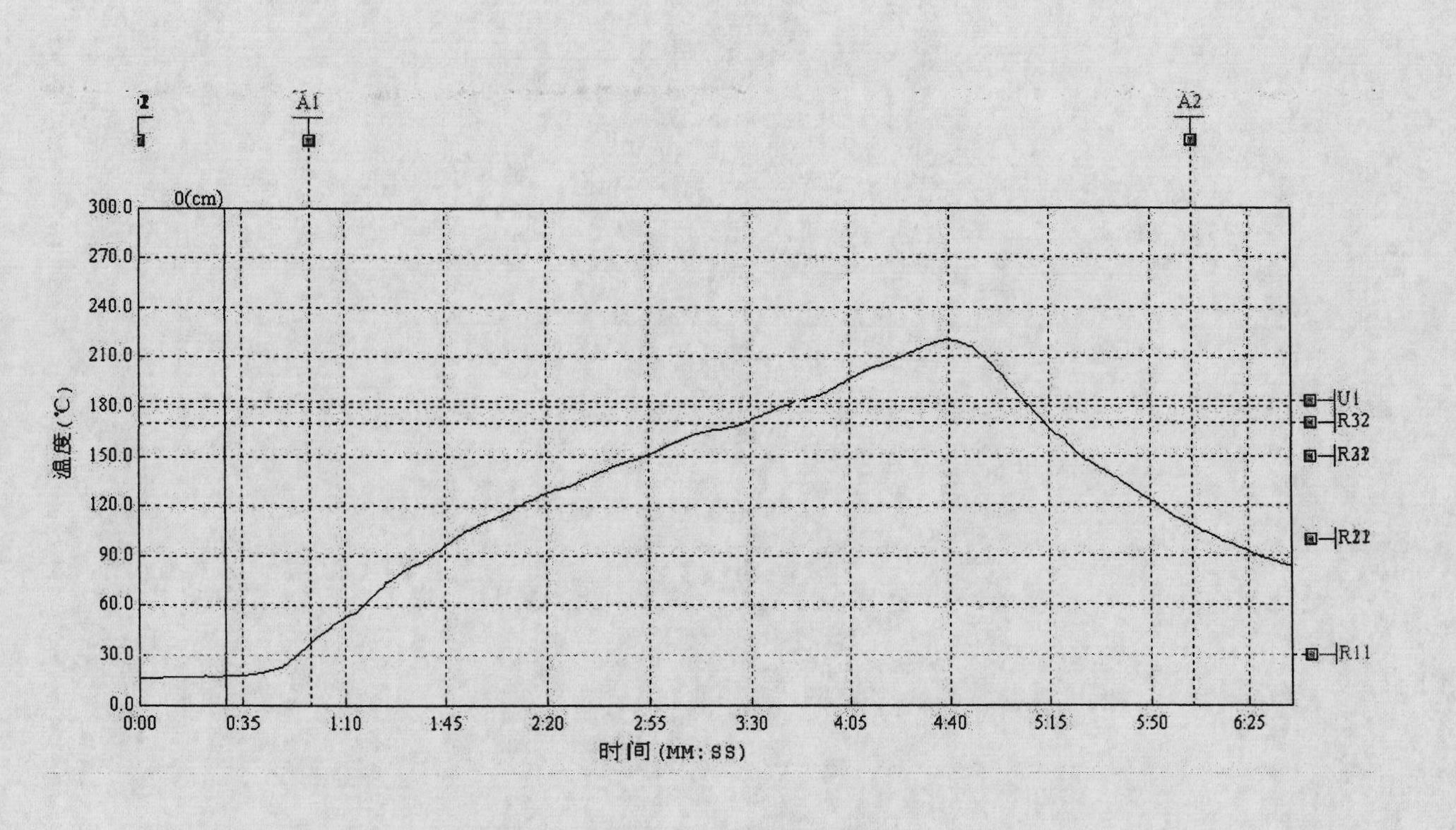

One-board welding process for printed circuit board components

InactiveCN102625597AFast simulation optimizationAddressing the increasing miniaturizationPrinted circuit assemblingProcess engineeringMonoboard

The invention relates to a one-board welding process for printed circuit board components. A large number of experiments conducted confirm that the welding spot temperature is mainly affected by thickness of bare boards of printed circuit boards and quality of elements of the printed circuit boards. Based on the law that when the set temperature of every temperature zone of a reflow oven is increased by a value, the obtained actual temperature curve and the original temperature curve are basically unchanged, a simulation optimization method of oven temperature setting-up parameters is summed up. When the one-board welding process for the printed circuit board components is applied to passage printed circuit board components, measured temperature curves of cold spots and hot spots of board surfaces of the passage printed circuit board components meet requirements of the lead-containing reflow welding, shapes of the welding spots are good, and electrical performance of the assembling unit before and after experiment is normal when temperature impact experiment is used for testing the quality of the welding spots. By the one-board welding process for the printed circuit board components, the rapid simulation optimization of process parameters is realized, the production efficiency of aerospace electronic products and the product percent of pass are greatly improved and the hidden quality dangers are eliminated, so that the one-board welding process for the printed circuit board components plays a very active role in guaranteeing the quality and the reliability of products.

Owner:BEIJING RES INST OF TELEMETRY

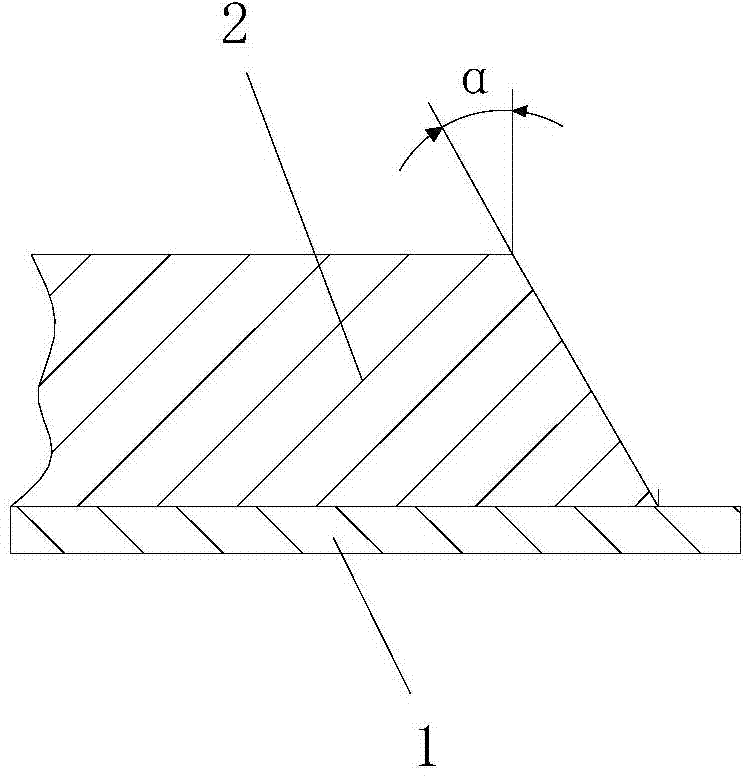

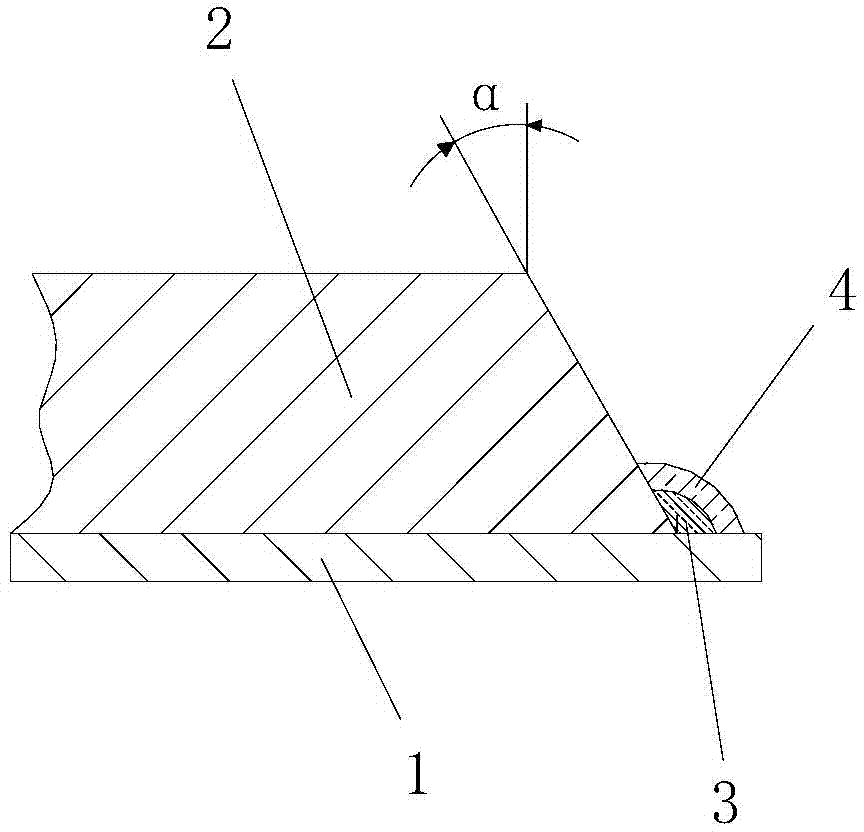

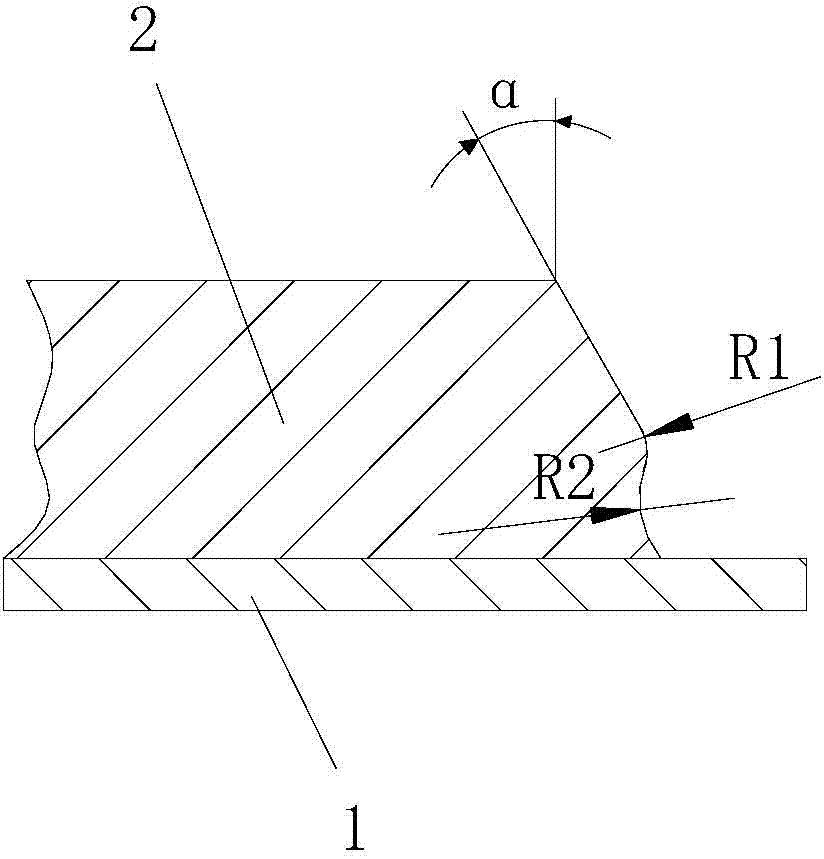

Bimetal composite pipe end sealing weld technology based on R-shaped groove

ActiveCN103612001AIncreasing the thicknessEffective protectionArc welding apparatusMetal working apparatusCarbon steelInert gas

The invention discloses a bimetal composite pipe end sealing weld technology based on an R-shaped groove. A sealing weld bimetal composite pipe is composed of a stainless steel lining pipe and a carbon steel base pipe. The technology comprises the first step of machining the R-shaped groove, namely, the R-shaped groove is formed in the carbon steel base pipe end of a bimetal composite pipe to be sealed and welded; the second step of carrying out backing weld, namely, the backing weld is carried out on the joint between a circular arc plane and the stainless steel lining pipe through an argon arc welding machine to form a backing weld layer which is located inside a circular arc section; the third step of carrying out cosmetic welding, namely, under the protection of inert gases, the cosmetic welding is carried out on the outer side of the backing weld layer through the argon arc welding machine to form a cosmetic welding layer, and the upper portion of the cosmetic welding layer is higher than the upper portion of a circular arc transmission section. The sealing weld technology steps are simple, the sealing weld technology process is controlled easily, the welding quality is good, and the problems that an existing bimetal composite pipe end sealing weld method is poor in welding quality, the welded bimetal composite pipe has the quality defect easily can be effectively solved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

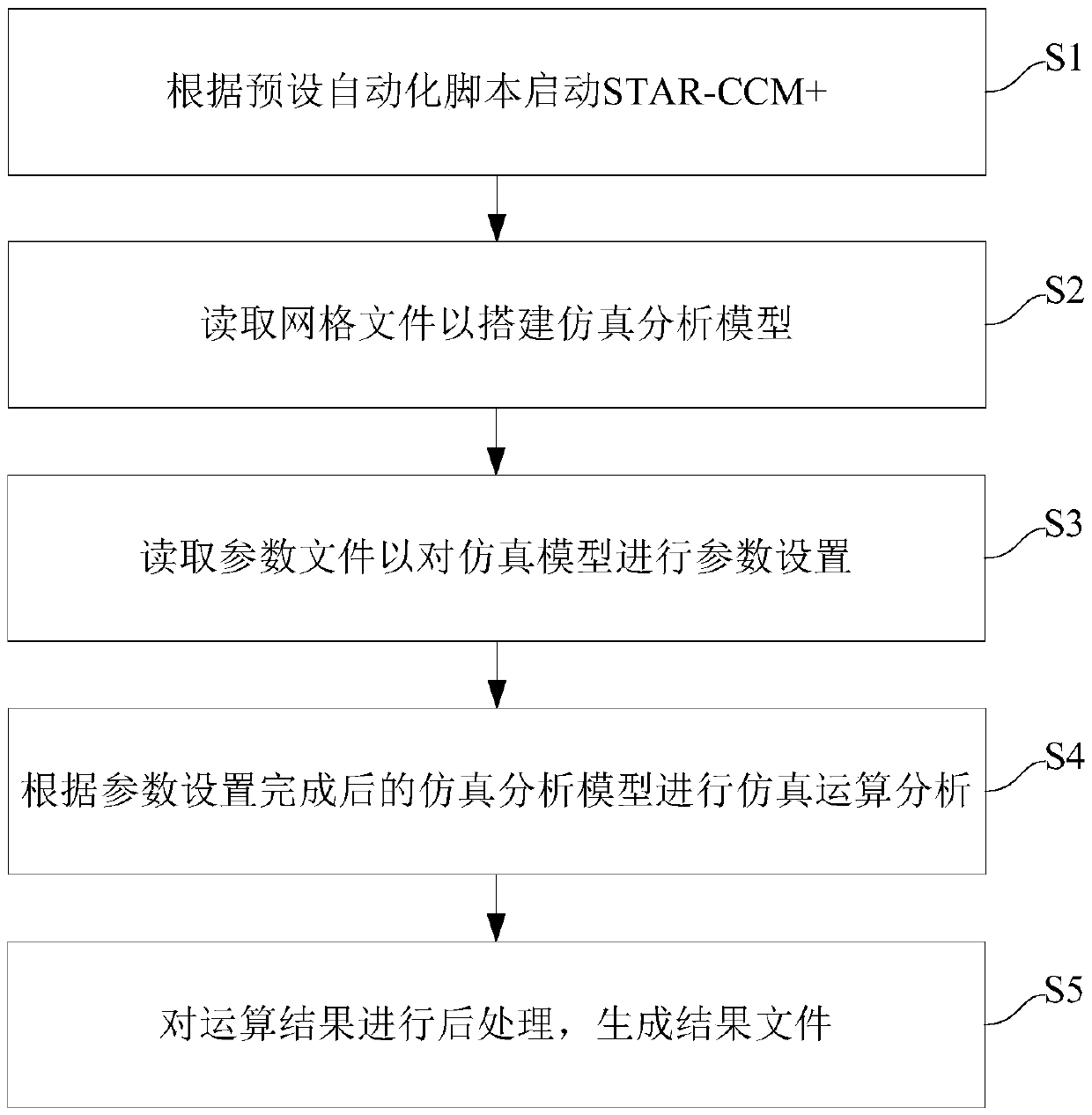

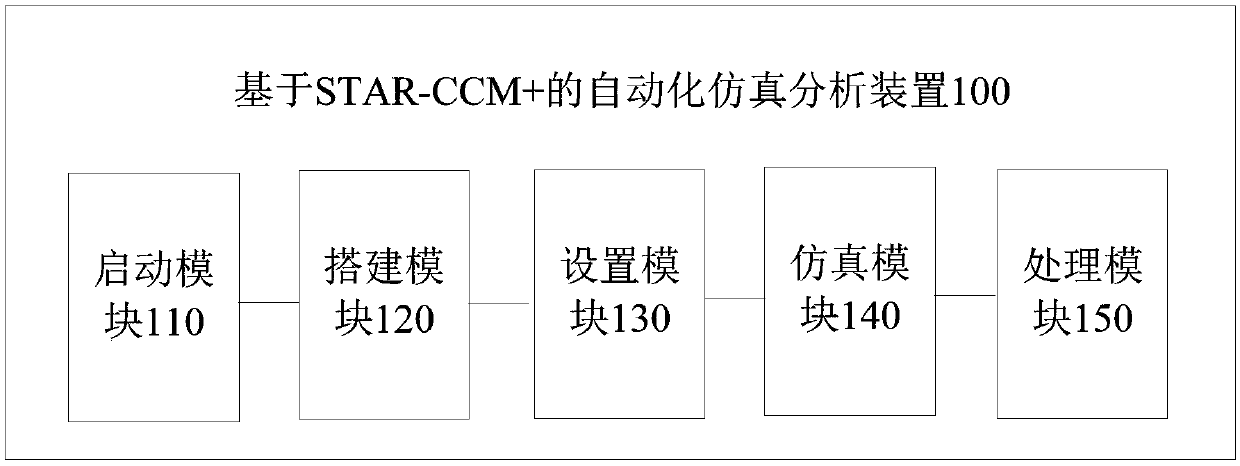

Automatic simulation analysis method and device based on STAR-CCM +

PendingCN111027164AHigh degree of standardizationImprove accuracyDesign optimisation/simulationAlgorithmSimulation

The invention provides an automatic simulation analysis method and device based on STAR-CCM +. The method comprises the following steps: starting the STAR-CCM + according to a preset automatic script;reading the grid file to build a simulation analysis model; reading the parameter file to perform parameter setting on the simulation model; performing simulation operation analysis according to thesimulation analysis model after parameter setting is completed; and carrying out post-processing on the operation result to generate a result file. According to the invention, the automation of simulation analysis can be realized, the working efficiency is improved, the cost is reduced, and the accuracy of a simulation result is improved.

Owner:GREAT WALL MOTOR CO LTD

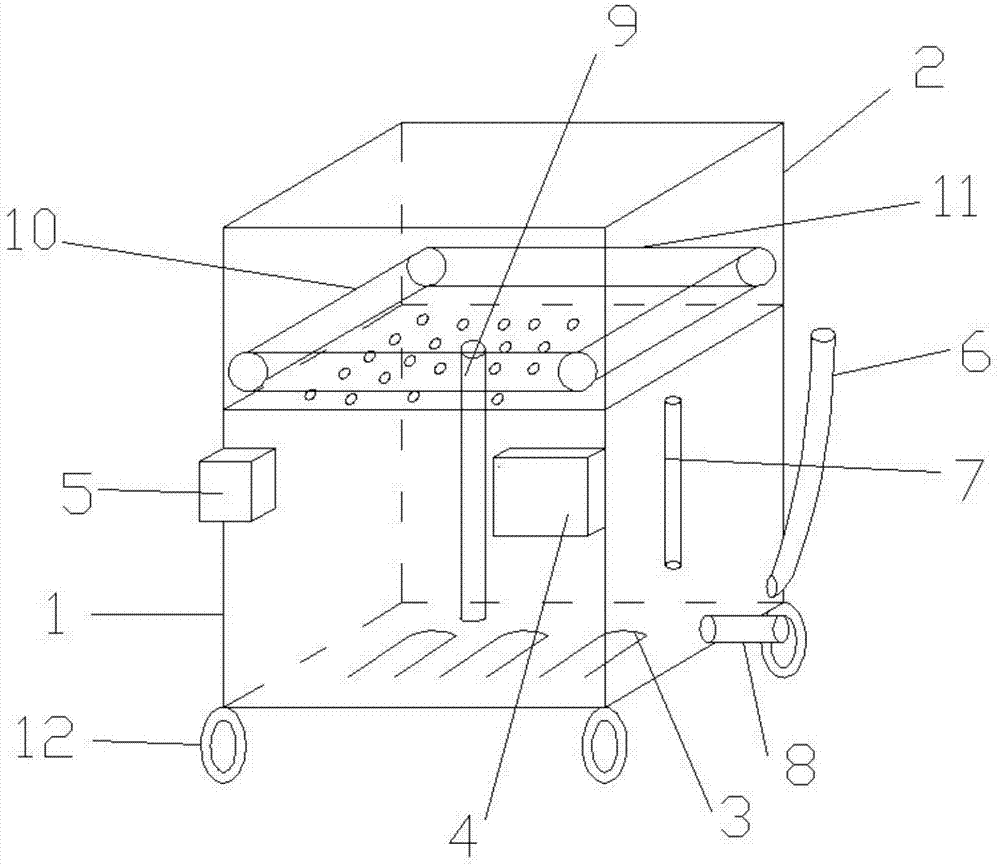

Steam heat shrink film packing machine

The invention relates to a steam heat shrink film packing machine. The steam heat shrink film packing machine comprises a water storage heating chamber with the upper end open, wherein the upper end of the water storage heating chamber is connected with a cargo passing bin with two sides open, a heating device is arranged on a bottom plate of the water storage heating chamber, an electric control box and a motor are arranged on the outer surface of the side face of the water storage heating chamber, the electric control box is connected with the motor and the heating device, a water inlet pipe, a water level pipe and a water outlet are arranged on the side face of the water storage heating chamber, a bottom plate of the cargo passing bin is in a concave shape, a plurality of holes are formed in the bottom plate of the cargo passing bin, a water leakage pipe is arranged between the middle of the bottom plate of the cargo passing bin and the upper end of the bottom plate of the water storage heating chamber, two rotation shafts are respectively arranged on openings in two sides of the cargo passing bin, the rotation shafts are connected with two side walls of the cargo passing bin, a netted conveying belt is arranged between the two rotation shafts, and the rotation shafts are connected with the motor. The steam heat shrink film packing machine solves the problems that a plastic film on the surface of a product is unevenly heated and irregularly shrunk.

Owner:JIANGSU ESSENCE AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com