Three-station DITO full-automatic testing machine and testing process thereof

A fully automatic testing, three-station technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems that the screen cannot be transported directly through the conveyor belt, the screen cannot be transported by the conveyor belt, and the surface requirements are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

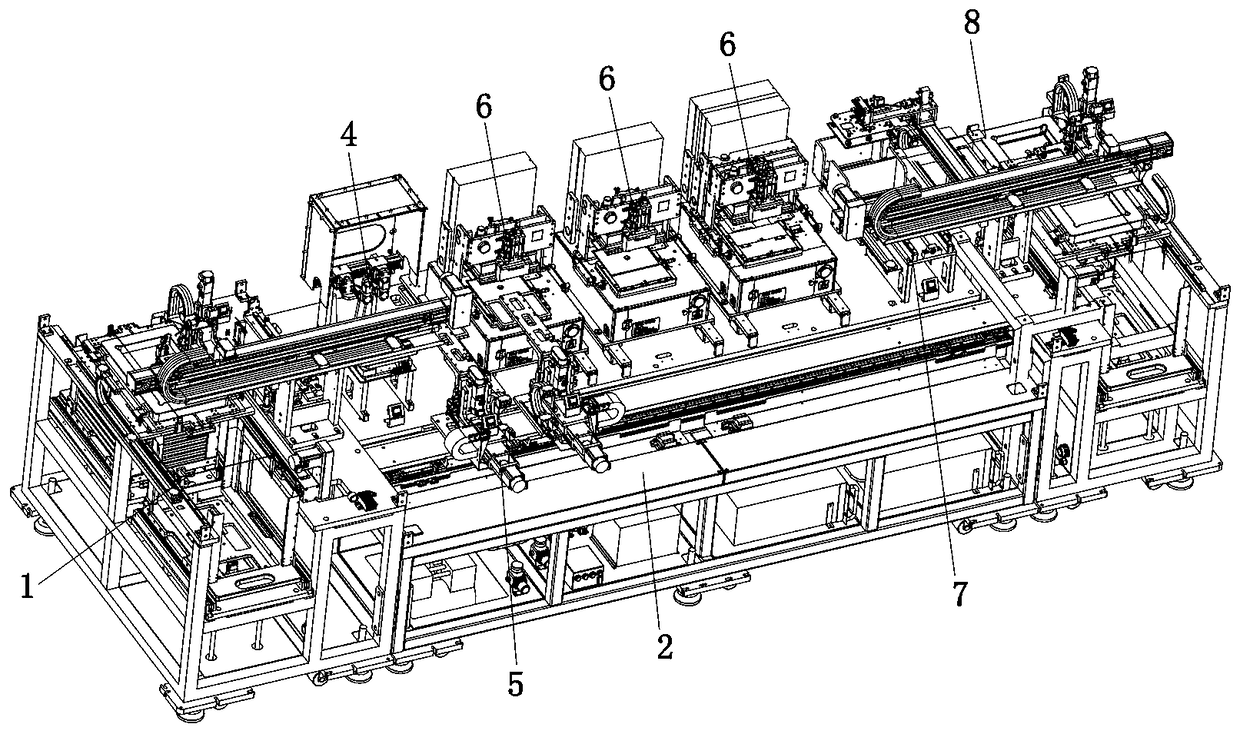

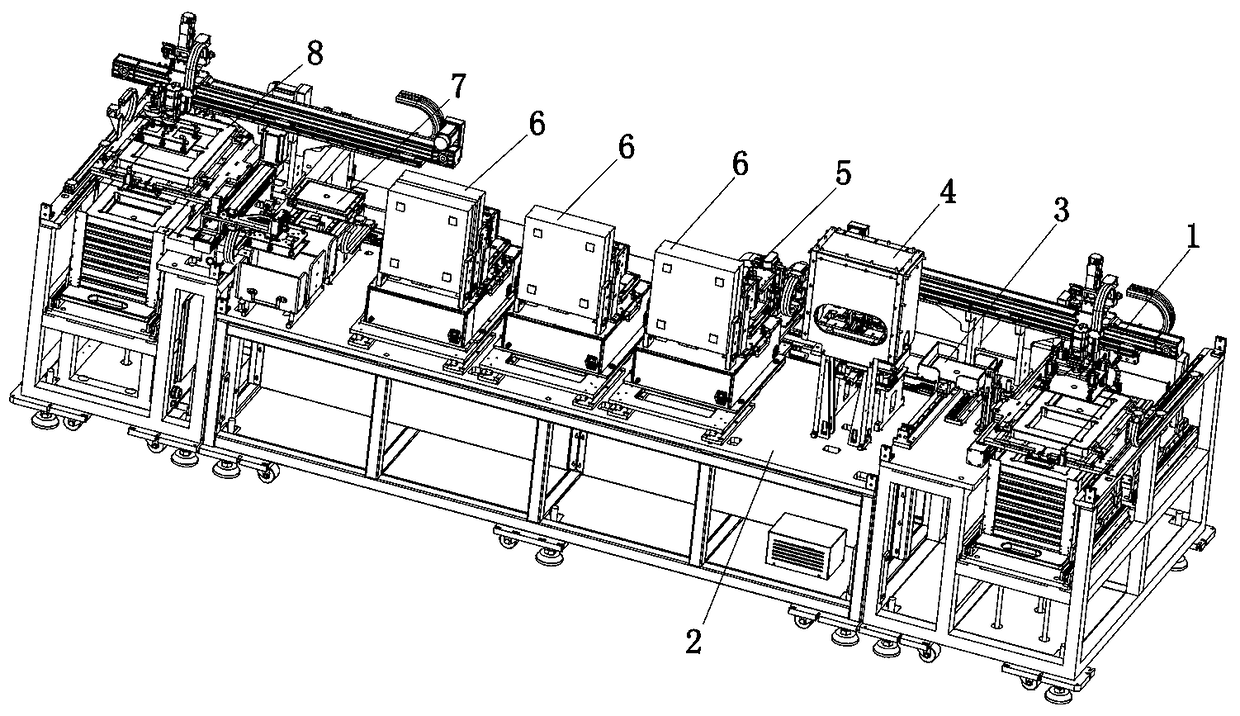

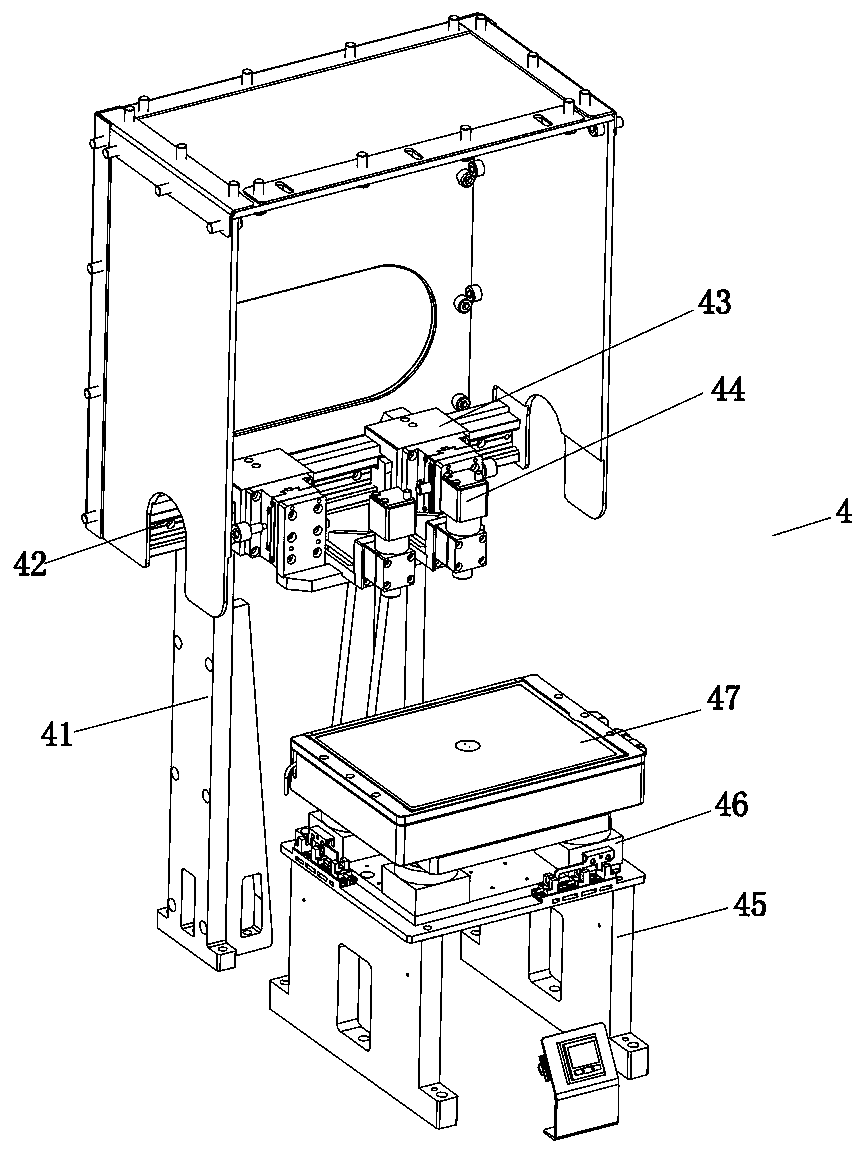

[0045] Such as Figure 1 to Figure 13 As shown, the technical scheme adopted by the present invention is as follows: a three-station DITO full-automatic testing machine includes a loading part 1, a testing part and a blanking part 8, wherein,

[0046] The above-mentioned loading part 1 includes a product taking station and a tray stacking station. The product taking station and the tray stacking station are respectively provided with jacking support components. There is a transfer platform 15 that can move back and forth between the two horizontally; at least two trays 14 full of products are stacked up and down at the product taking station, and the jacking support assembly lifts the tray 14 upwards, moving The loading platform 15 clamps and fixes the uppermost material tray 14, and the loading manipulator 17 takes out the products in the material tray 14 and transports the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com