Patents

Literature

229results about How to "Save loading and unloading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

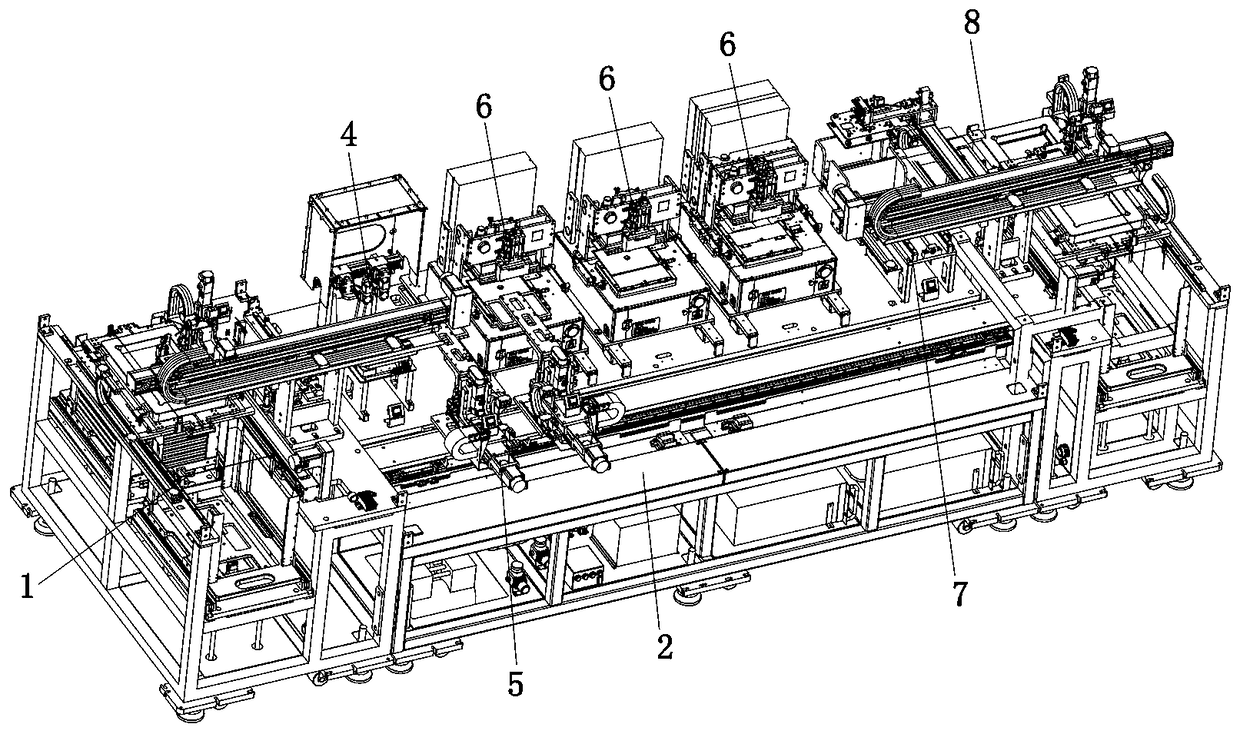

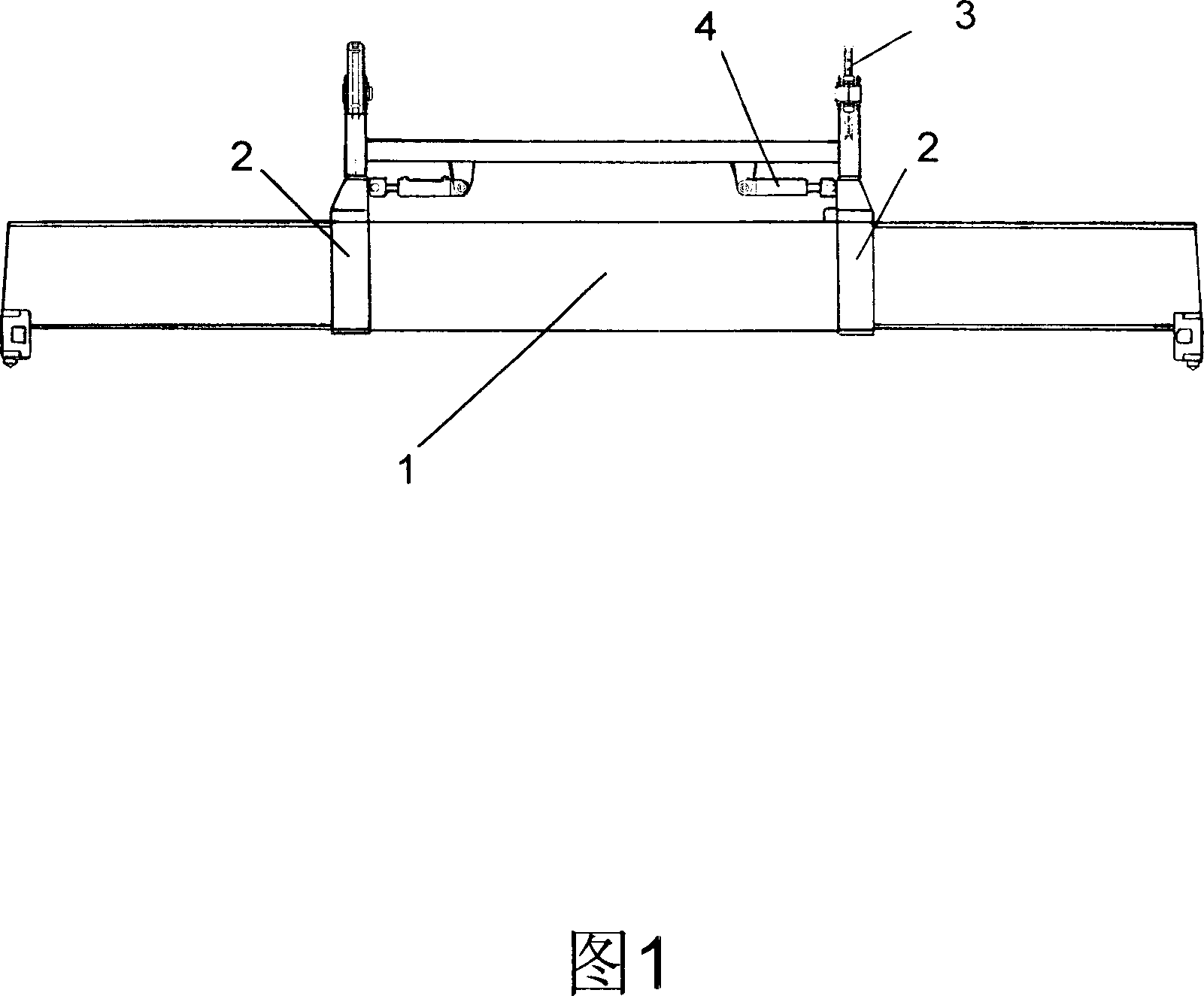

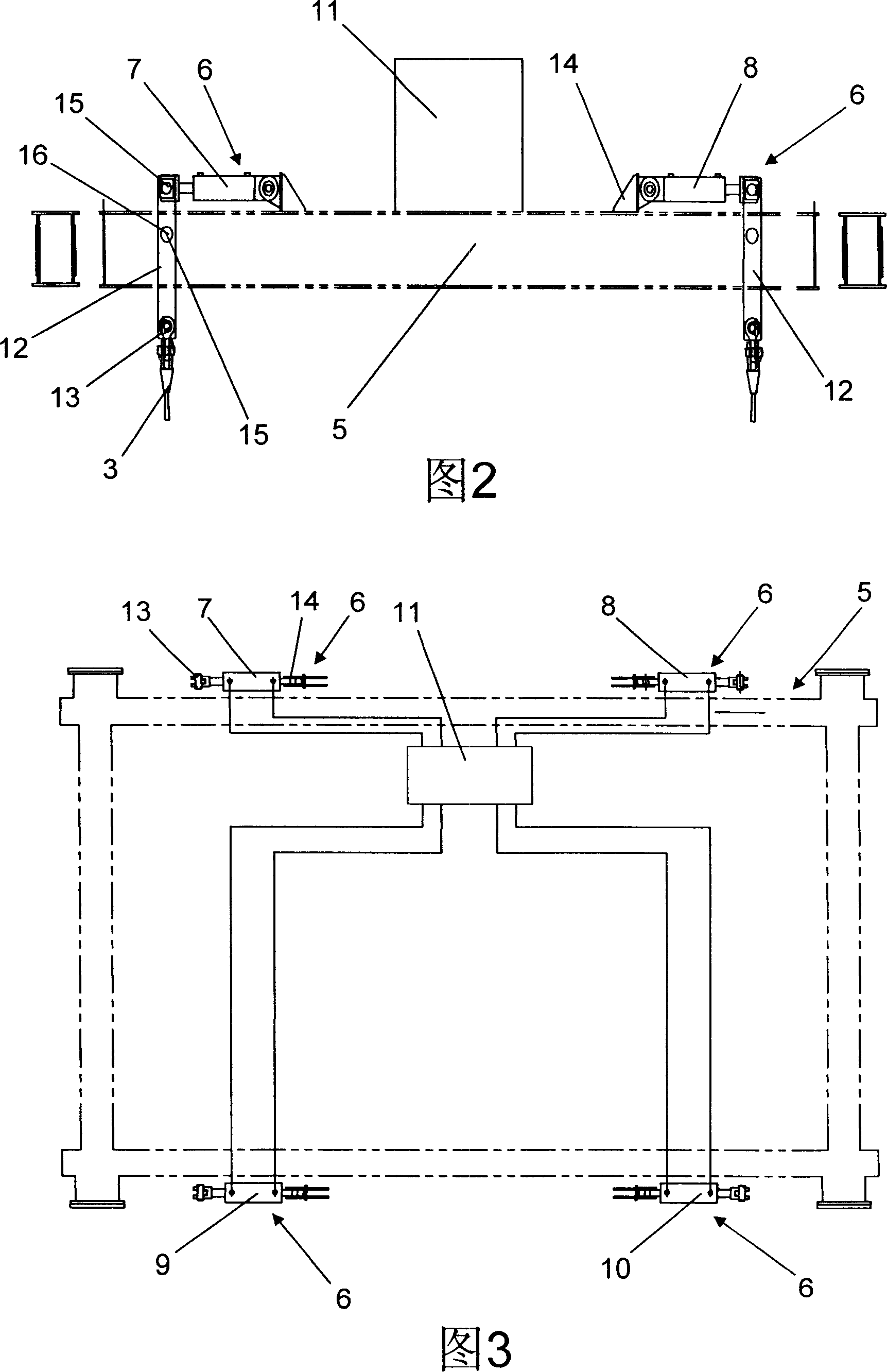

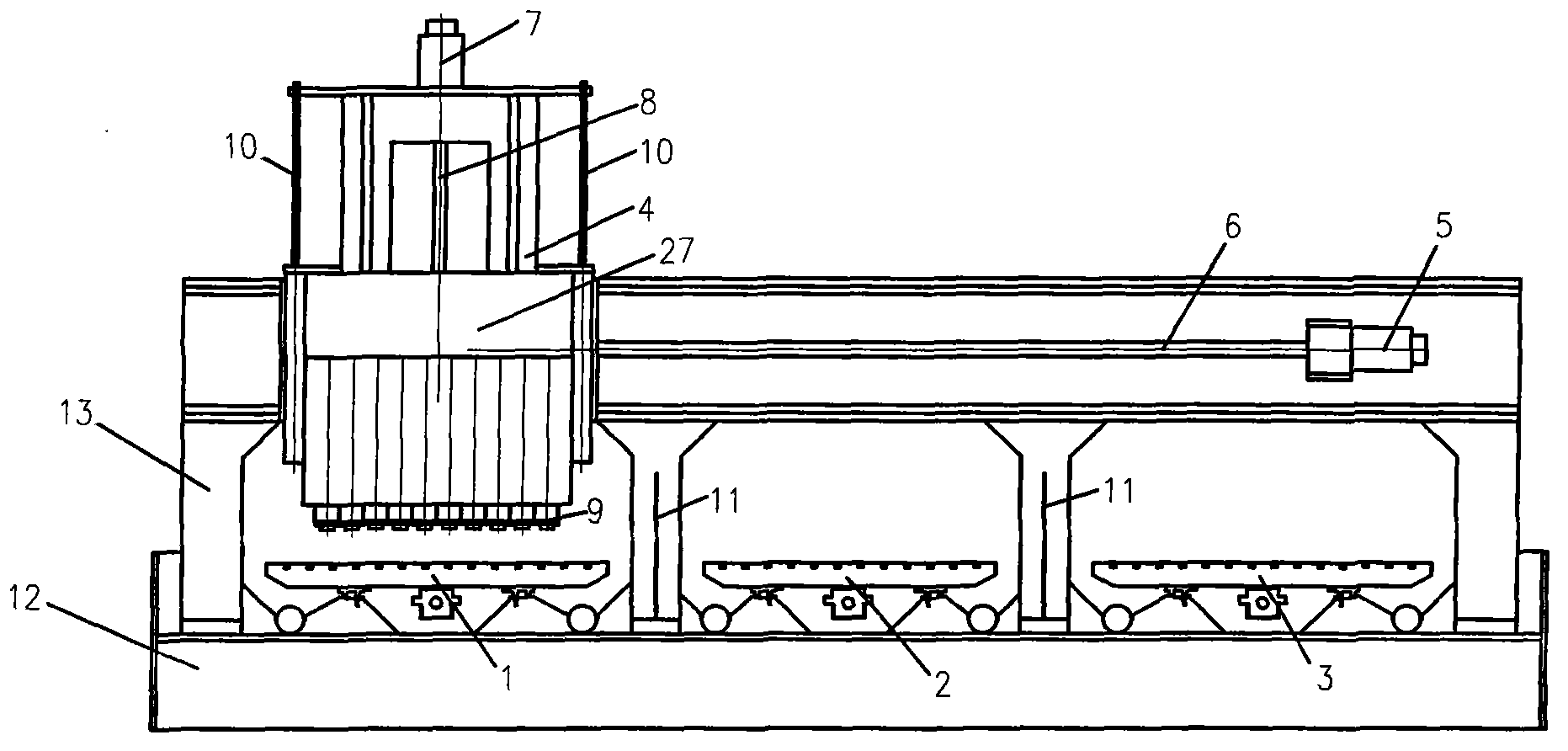

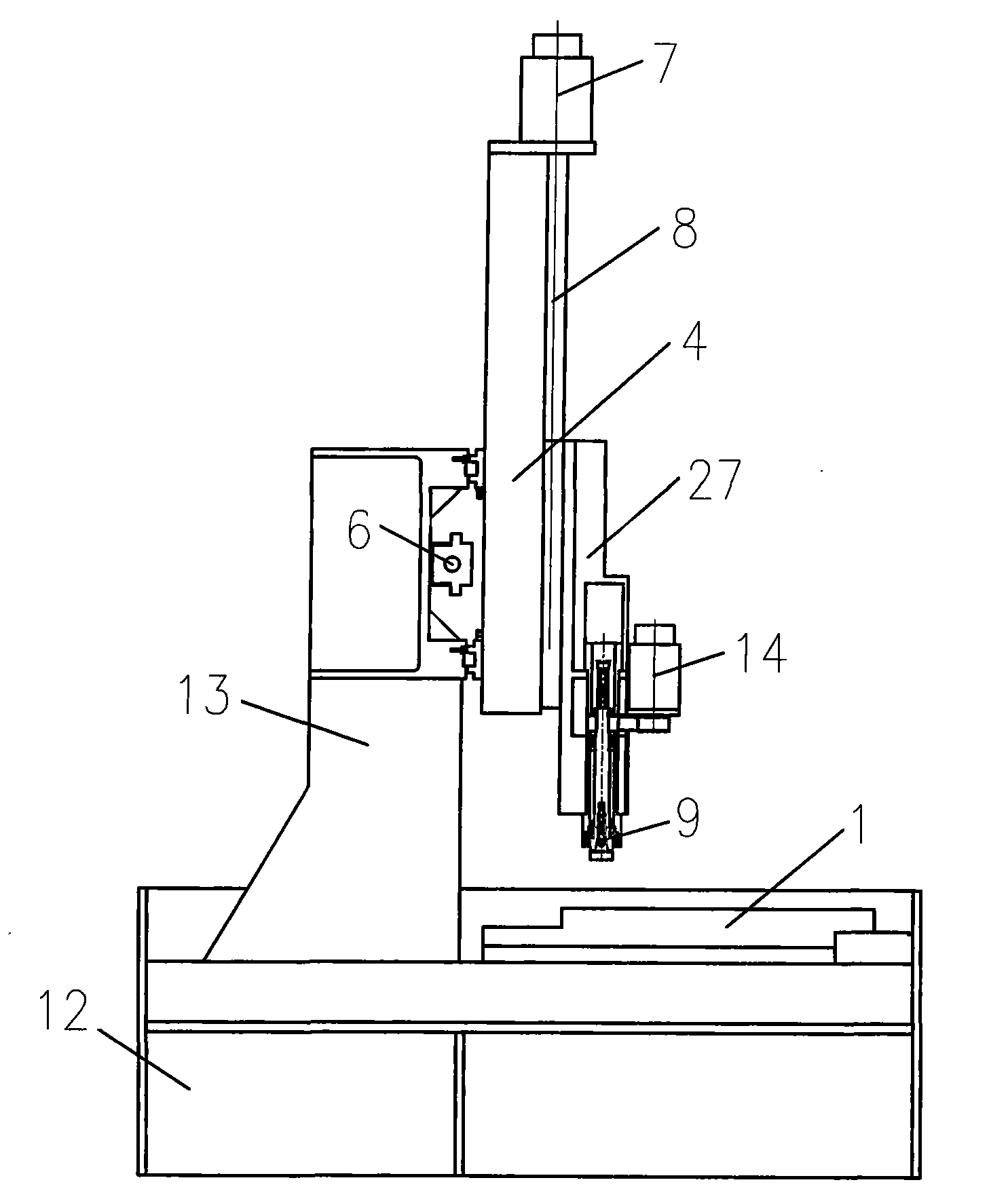

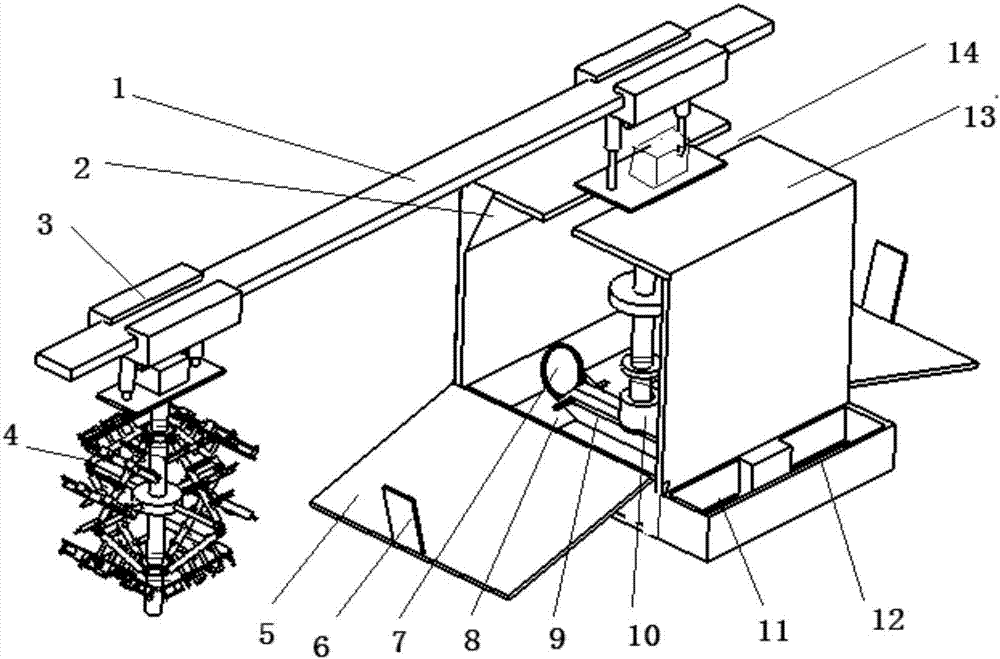

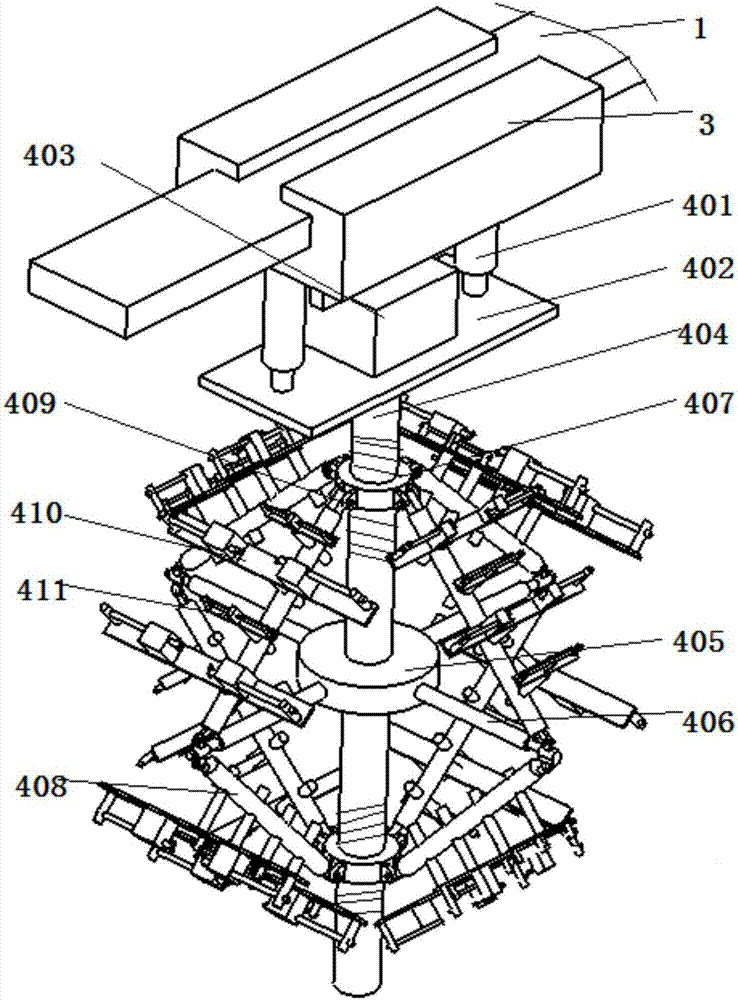

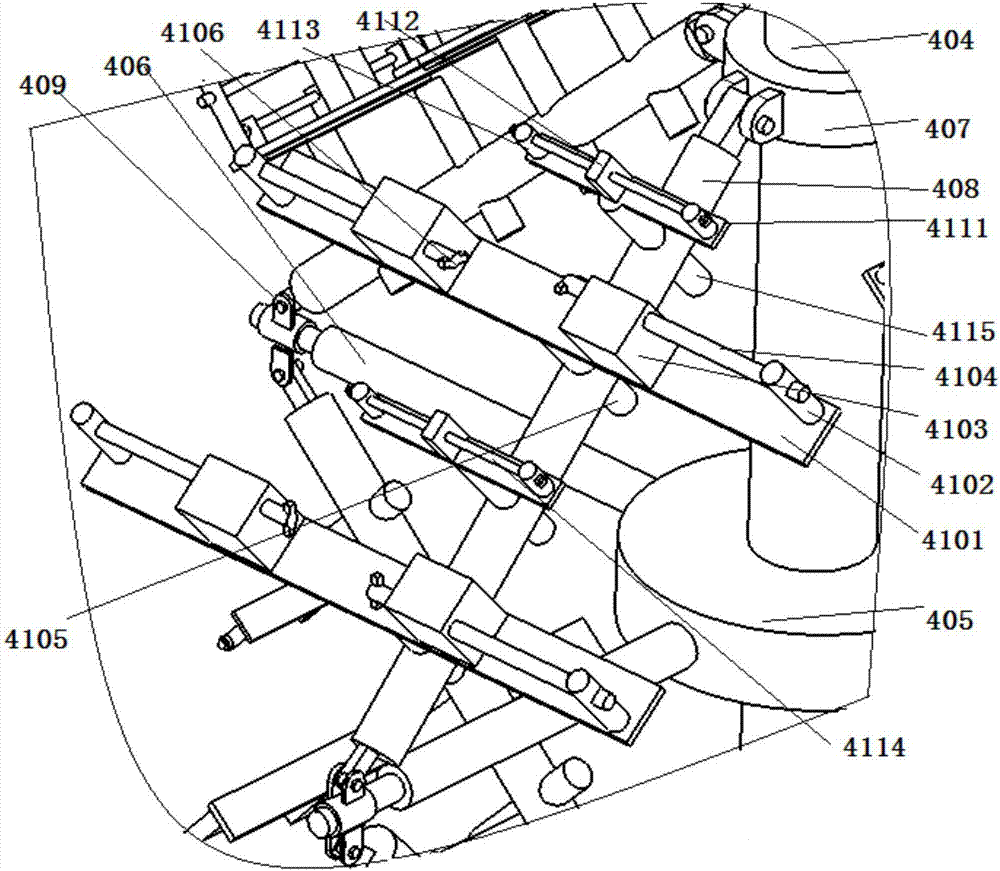

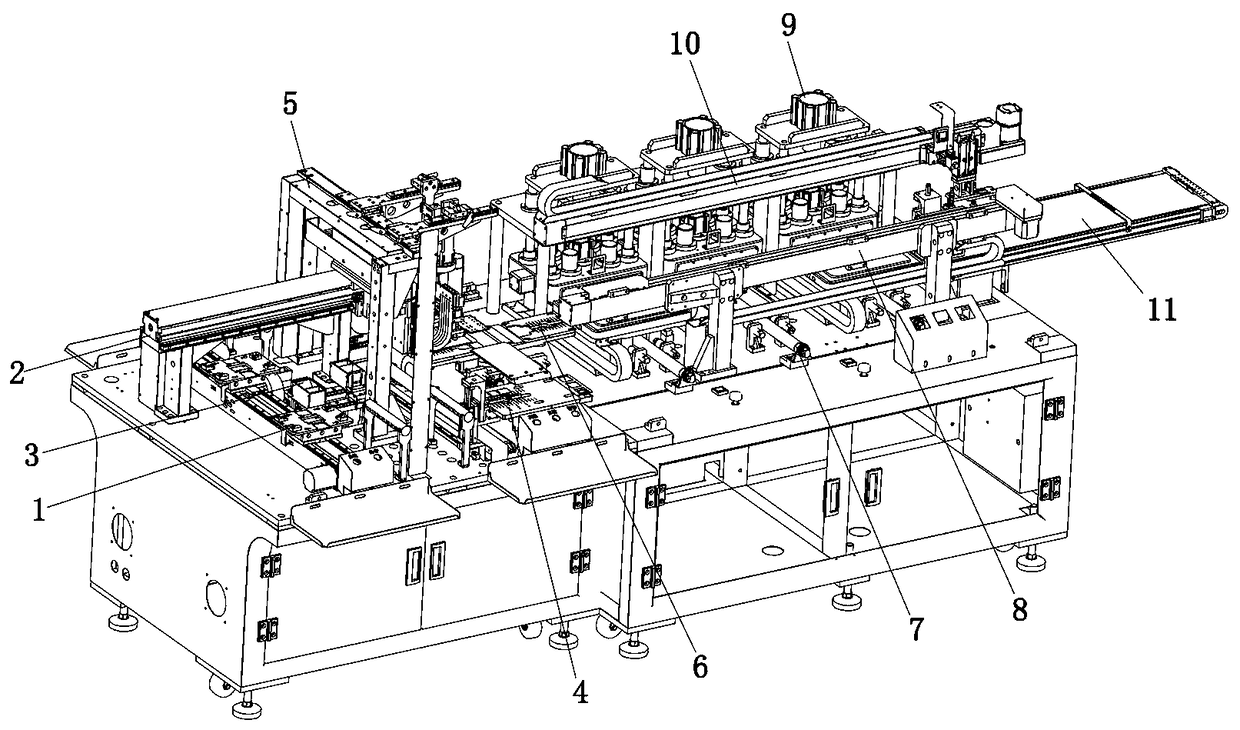

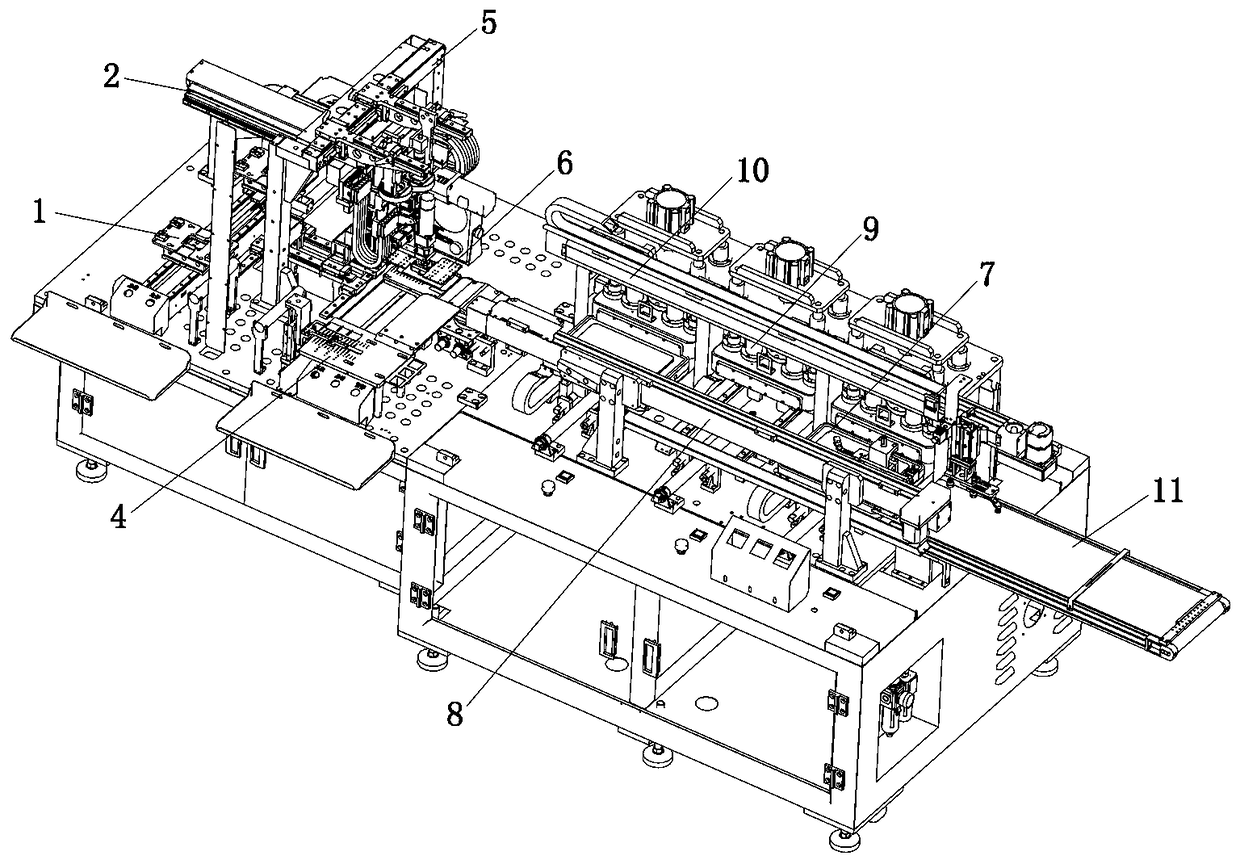

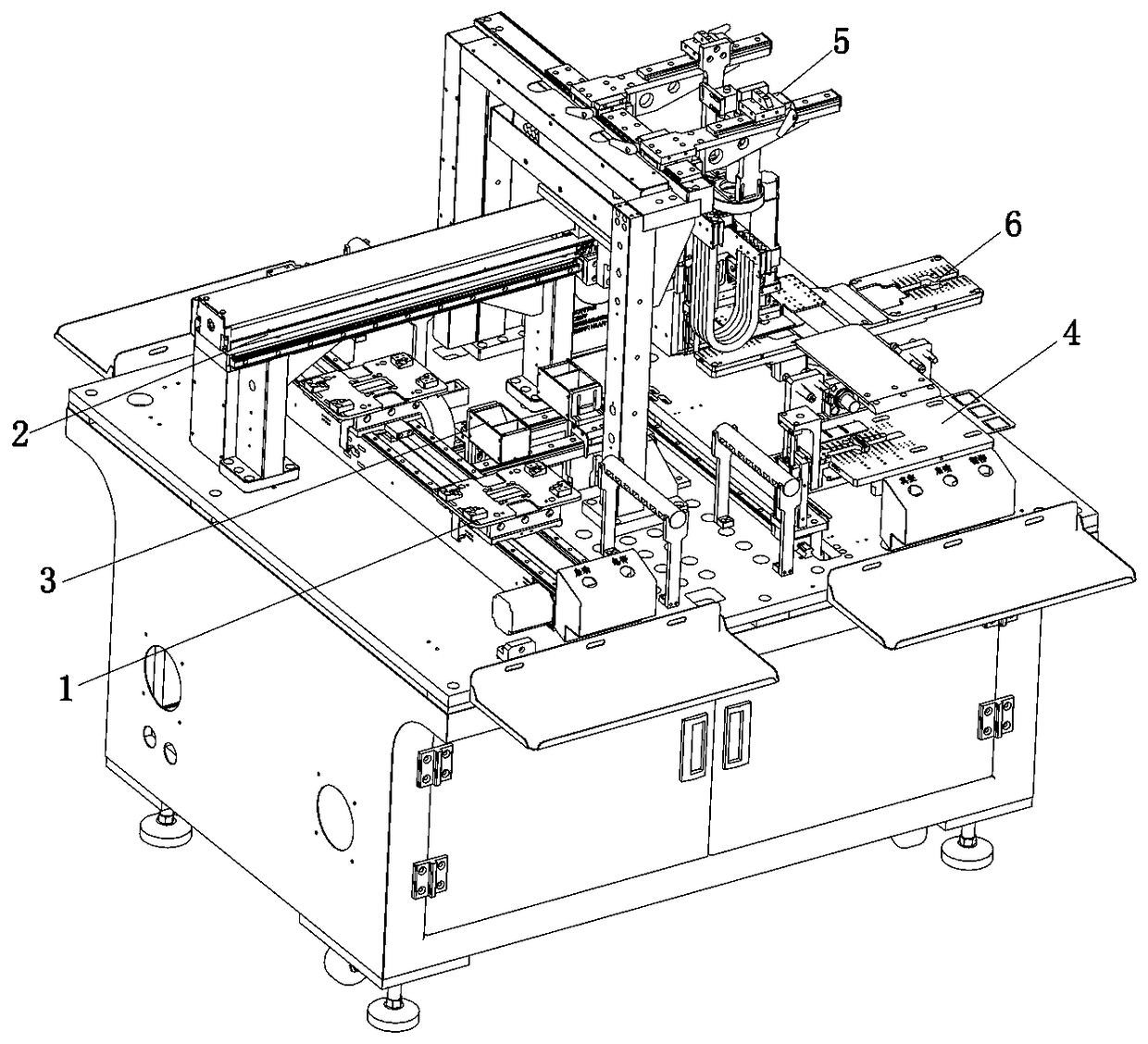

Three-station DITO full-automatic testing machine and testing process thereof

PendingCN109283417AIncrease fluid volumeImprove test efficiencyElectrical testingEngineeringAutomatic testing

The invention discloses a three-station DITO full-automatic testing machine and a testing process thereof. The testing machine comprises a feeding part, a testing part and a discharging part. The testing machine disclosed by the invention comprises the following technical steps: product feeding, product taking and product detection, product photographing correction, product function testing, product transferring and defective product screening, product position correcting and discharging, and material tray discharging. According to the testing machine, a plurality of products are loaded in a centralized manner by adopting the material tray, and the loading part and the discharging part are connected to the front end and the back end of the tested part; the material trays of the feeding part and the discharging part are of a circulating flow type structure, meanwhile, the circulating type taking and placing of the products and the material trays are realized, and the material flowing volume is greatly improved through a laminating and conveying mode; and the test part adopts multi-test-station design, the time periods of testing and product taking and placing are effectively utilized, so that uninterrupted lead-out of the test products is realized, and the screen testing efficiency is greatly improved; and single-piece detection, defective product scanning by two-dimensional codes and the like are integrated to realize real-time screening of defective products.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

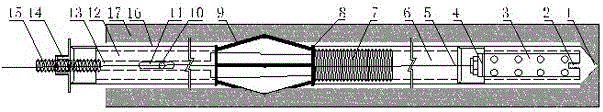

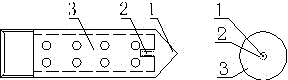

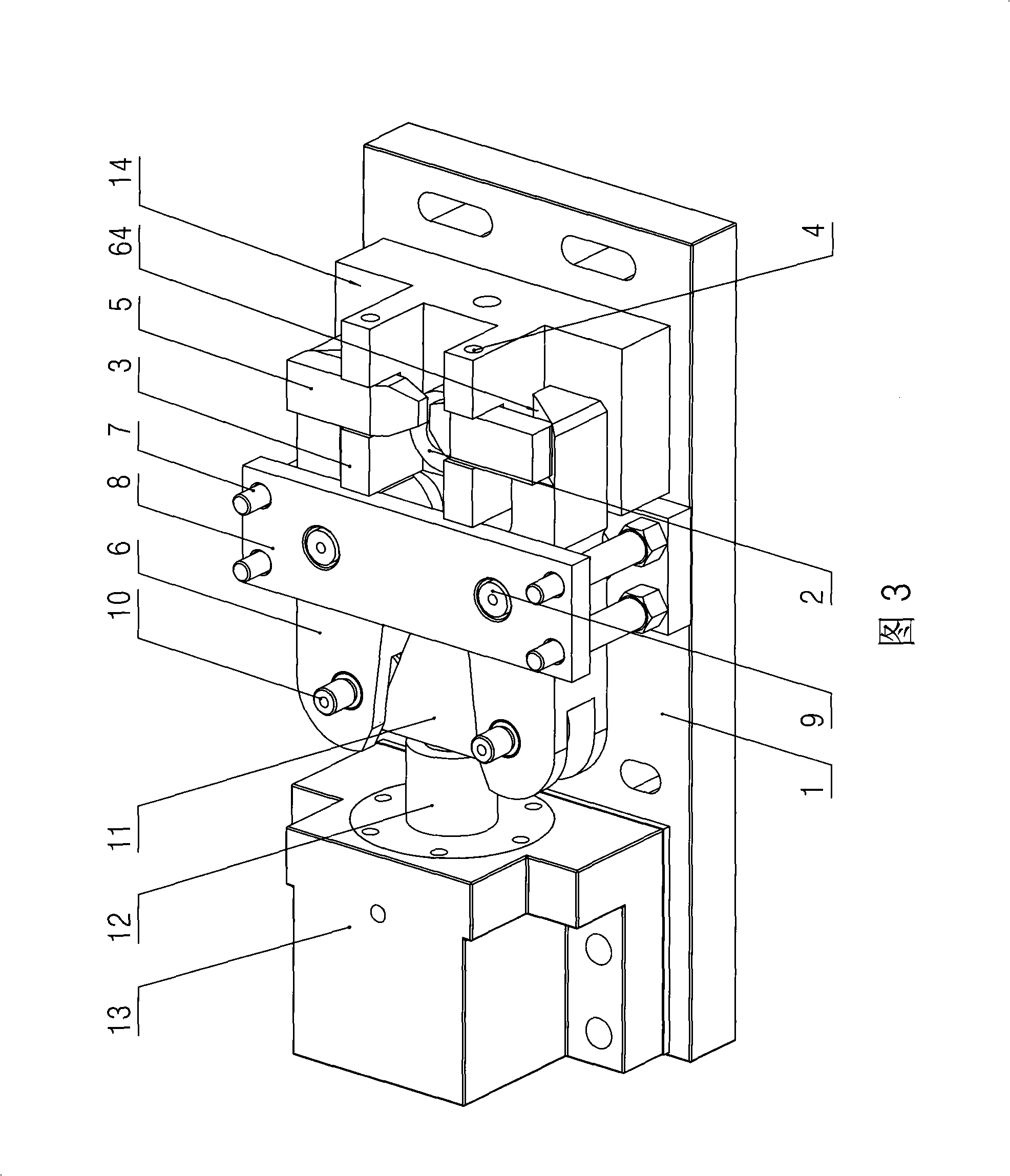

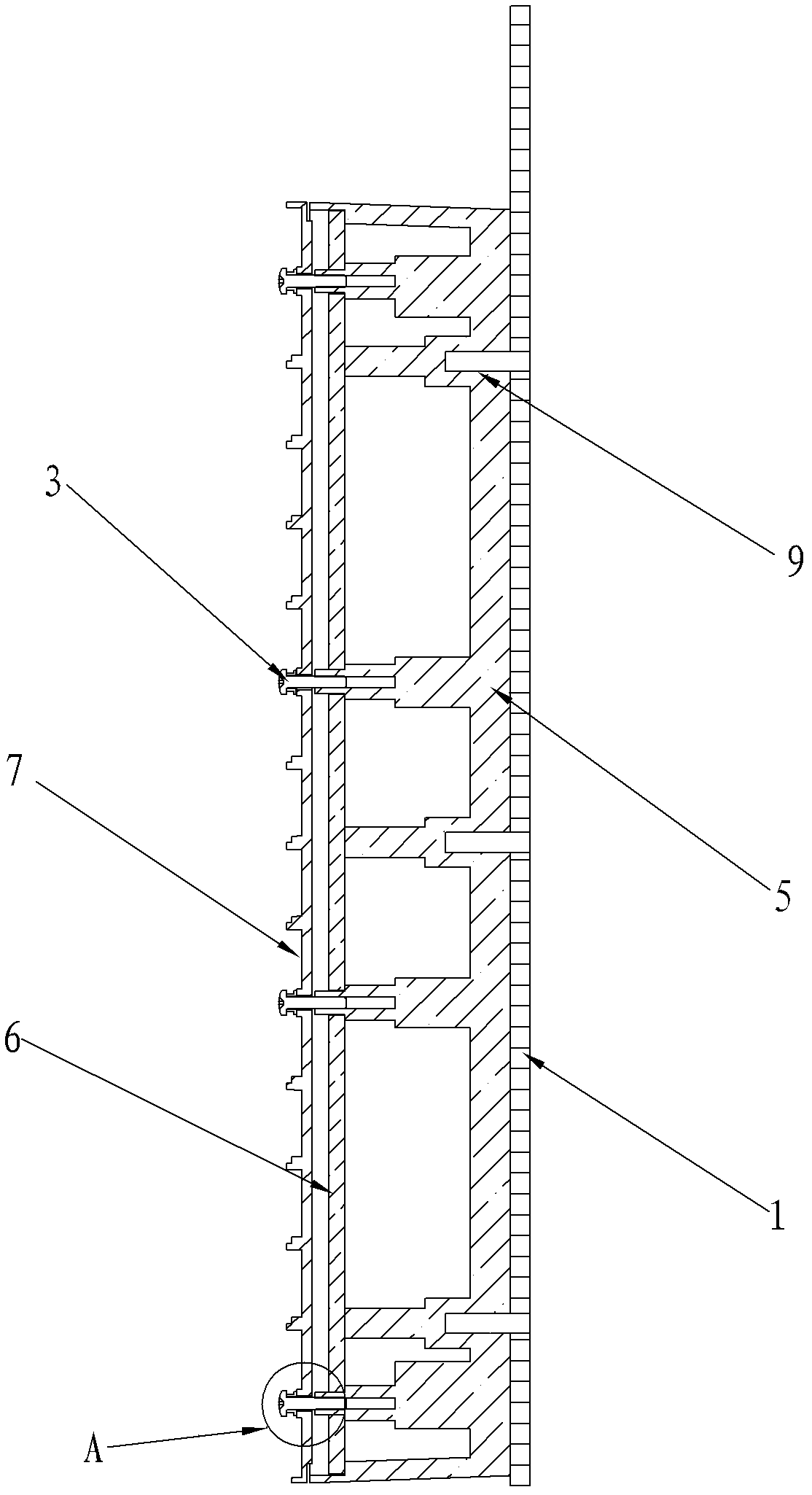

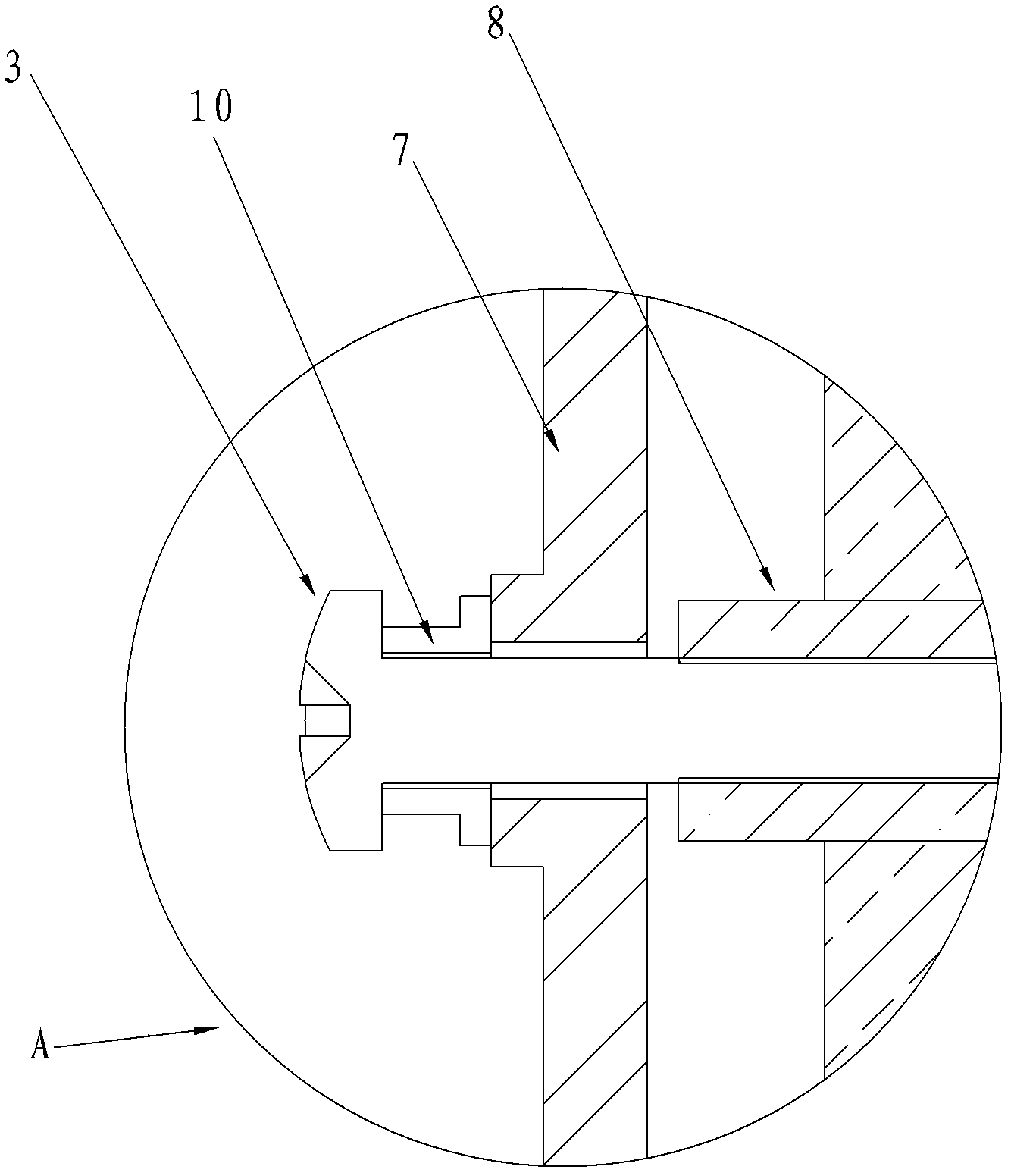

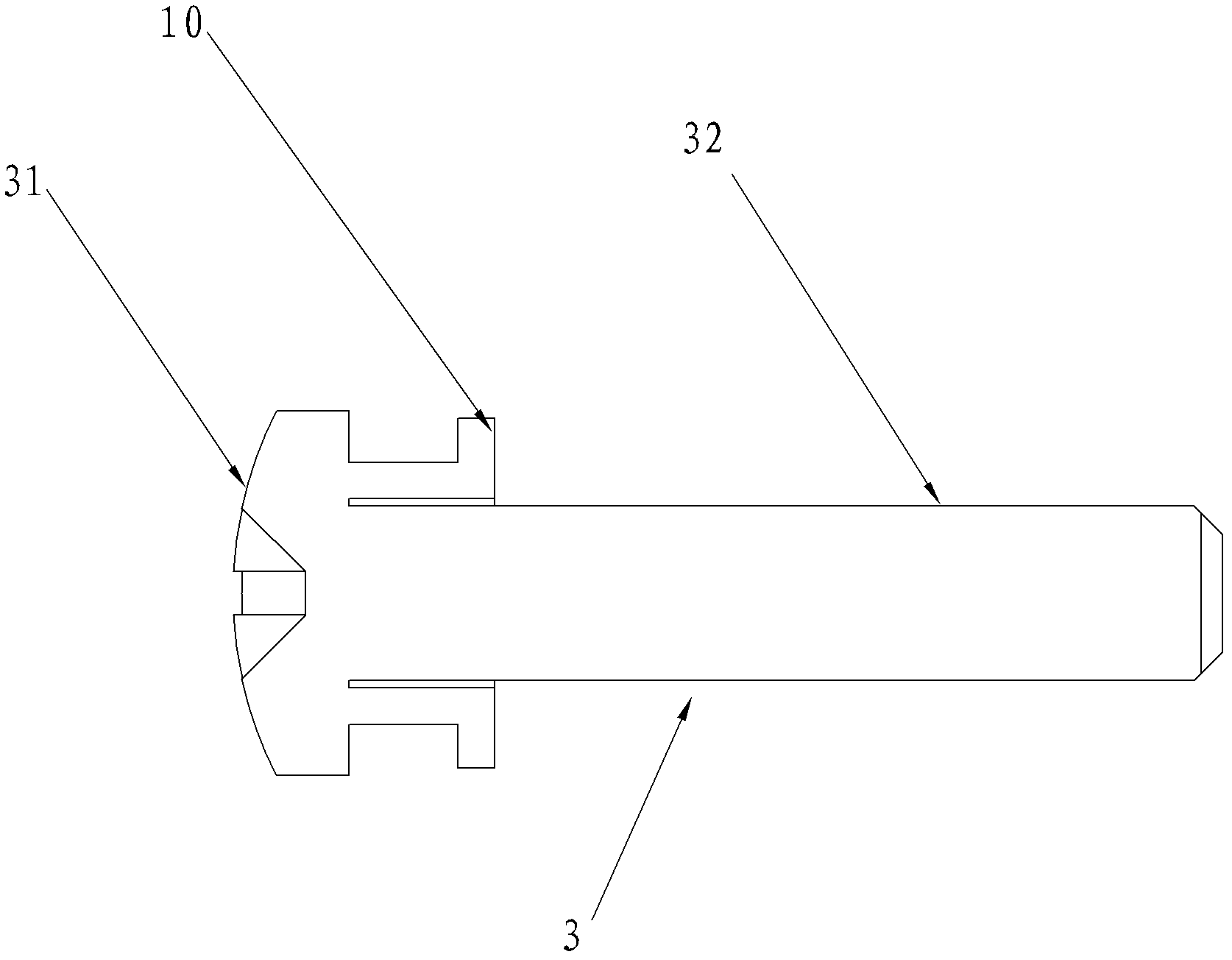

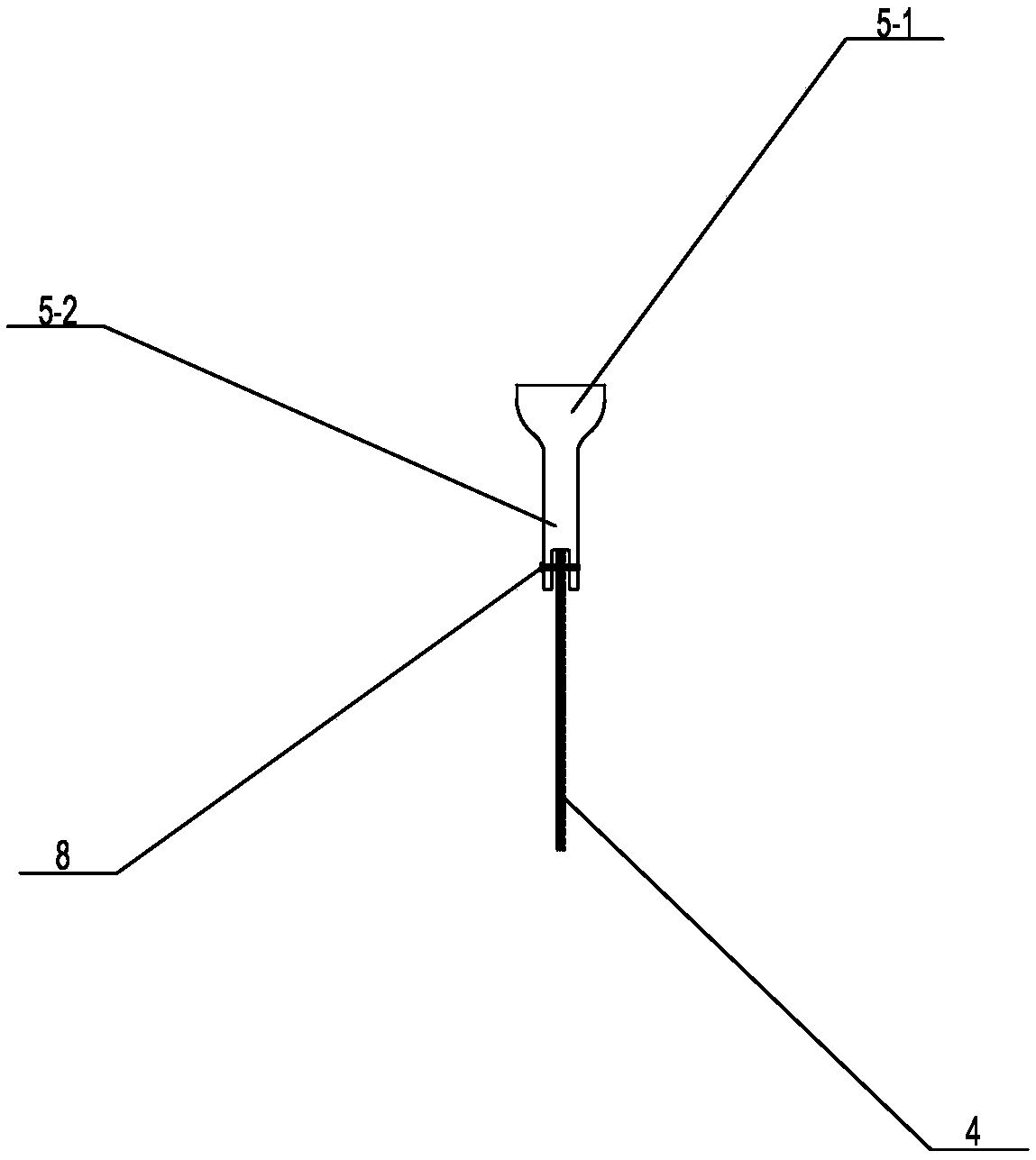

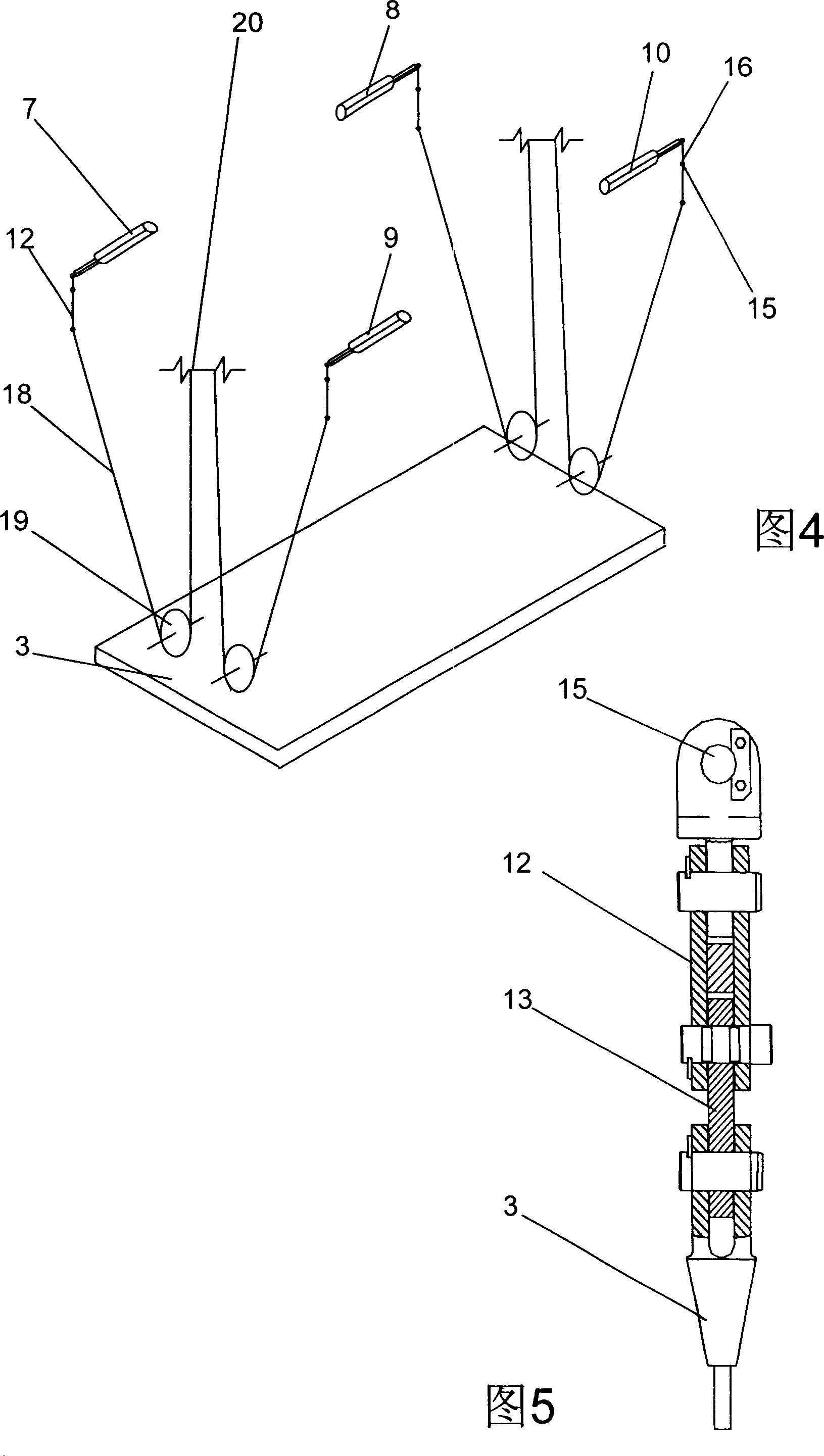

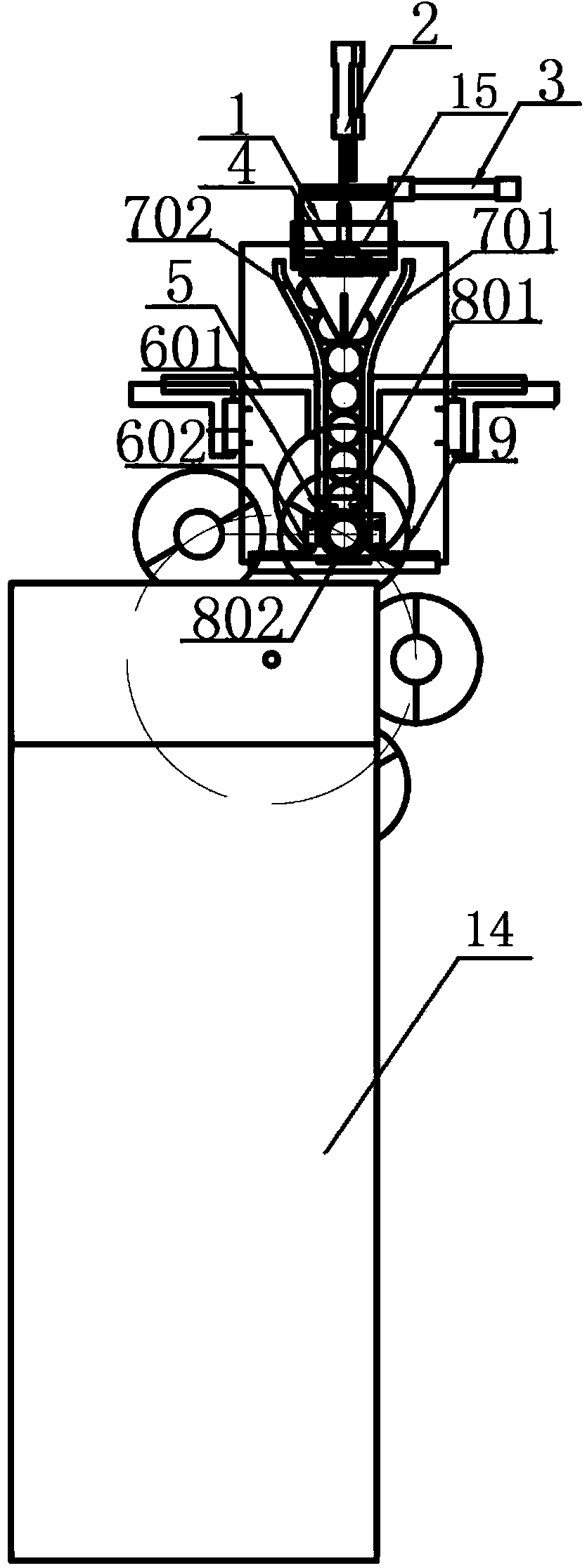

Extendable embedded type device for fixing and recovering microseismic sensor and method of using same

InactiveCN104834002AQuick installationEasy to installSeismic signal receiversEngineeringScrew thread

The invention discloses an extendable embedded type device for fixing and recovering a microseismic sensor and method of using the same. The device comprises three parts of a protective cover, a connecting sleeve, an extendable supporting and fixing structure. The protective cover is composed of a fit cone, a fixing shaft and a cover wall with a mesh. Two ends of the connecting sleeve are respectively provided with internal and external threads. The extendable supporting and fixing structure is composed of a supporting shaft, a connecting ring, a "skeleton", a limit bolt, a limit groove, a supporting pipe, an elastic rod, an elastic cap with a baffle and an elastic shaft. The fit cone at one end of the protective cover is in close contact with coal. A microseismic sensor is located in the protective cover and fixed on the fixing shaft of the protective cover. The other end of the protective cover is connected with one end of the connecting sleeve through the internal thread. The other end of the connecting sleeve is connected with the supporting shaft of the fixing structure through the internal thread. The elastic cap with the baffle is screwed on, the elastic rod is supported tightly, and the supporting pipe is pushed to enable the "skeleton" to open so that the entire device is embedded, supported and fixed into the coal of a drilling hole. In the recovery, the elastic cap is screwed off, the supporting pipe is pulled to enable the "skeleton" structure to close, and the elastic rod, the connecting sleeve, the protective cover and the senor are removed in sequence.

Owner:GUIZHOU INST OF COAL SCI

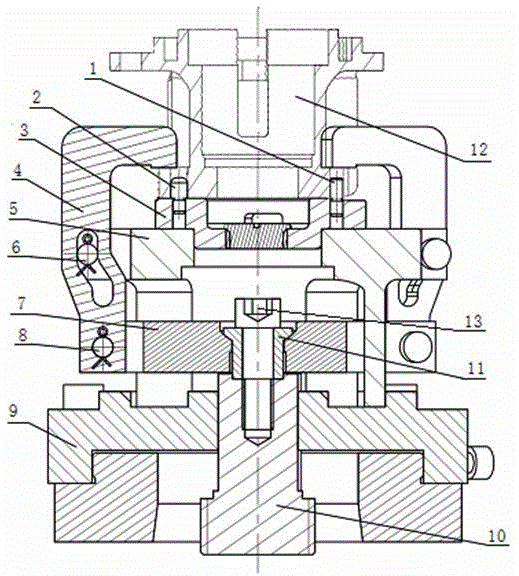

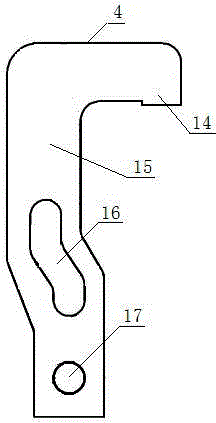

Clamp for milling half-moon groove

InactiveCN101332566AEasy clampingEasy to unloadMilling equipment detailsPositioning apparatusHydraulic cylinderEngineering

The invention discloses a clamp which is used for milling a semilunar groove and can finish the milling and molding by once clamping. The clamp comprises a base; the base is provided with a locating shaft, a pair of lugs and a pair of storage platforms; the top of each lug is provided with a pressure plate groove, and each pressure plate groove is movably provided with a pressure plate; the base is also provided with a support and a hydraulic cylinder; the support is provided with a locating plate; a pair of clamping arms symmetrically arranged at the two sides of the lugs are movably arranged on the locating plate respectively by a spindle; the front part of each clamping arm is laid on the corresponding storage platform and provided with a clamping bevel; the end face of the rear part of each clamping arm is provide with a clamping groove; each clamping groove is penetratively provided with a clamping pin; a back-moving spring is arranged between the two clamping pins; a piston rod of the hydraulic cylinder is provided with a shim block; two bevel edges at the inside of the shim block are respectively embedded into the corresponding clamping grooves and are pressed against the clamping pins. The clamp of the invention greatly improves the milling precision and efficiency.

Owner:ZHANGJIAGANG YUCHENG MASCH C0 LTD

LED (Light-Emitting Diode) box body, LED display screen and maintenance tool

ActiveCN102314814AEasy to debugQuick releaseCasings/cabinets/drawers detailsIdentification meansLED displayEngineering

The invention discloses an LED (Light-Emitting Diode) box body, which approximately comprises a module and an installing frame, wherein the module comprises a veil, a PCB (Printed Circuit Board) lamp board and a bottom shell, and the bottom shell of the module and the installing frame are magnetically adsorbed and fixed; the veil, a PCB lamp board and the bottom shell are fixedly connected; and a bolt is arranged on the veil of the module, and a clamping space is left between a screw cap of the bolt and the outer surface of the veil. In an LED display screen disclosed by the invention, by adopting a magnetically adsorbing and fixing structure of the bottom shell of the module and the installing frame, the module is more convenient and rapider to install, the work efficiency is improved, and meanwhile, the problem that the bolt is easy to fall when the bolt is assembled and disassembled is solved; and a structure that the clamping space is left between the screw cap of the bolt and the outer surface of the veil is adopted by the invention, so that a maintenance tool can be conveniently utilized for clamping the bolt on the veil of the module, the module can be more conveniently assembled and disassembled, and the work efficiency is further improved.

Owner:UNILUMIN GRP

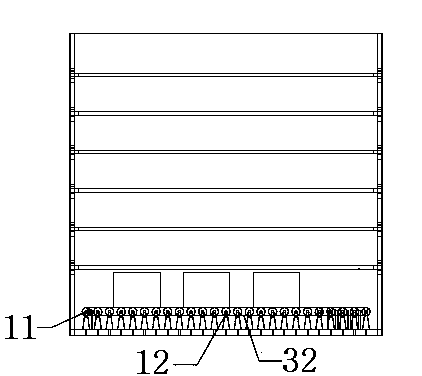

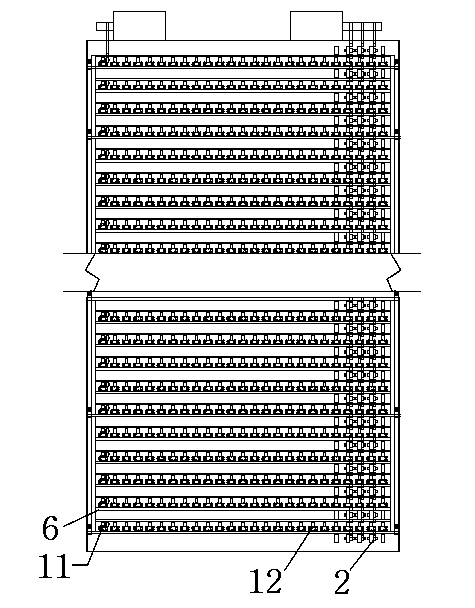

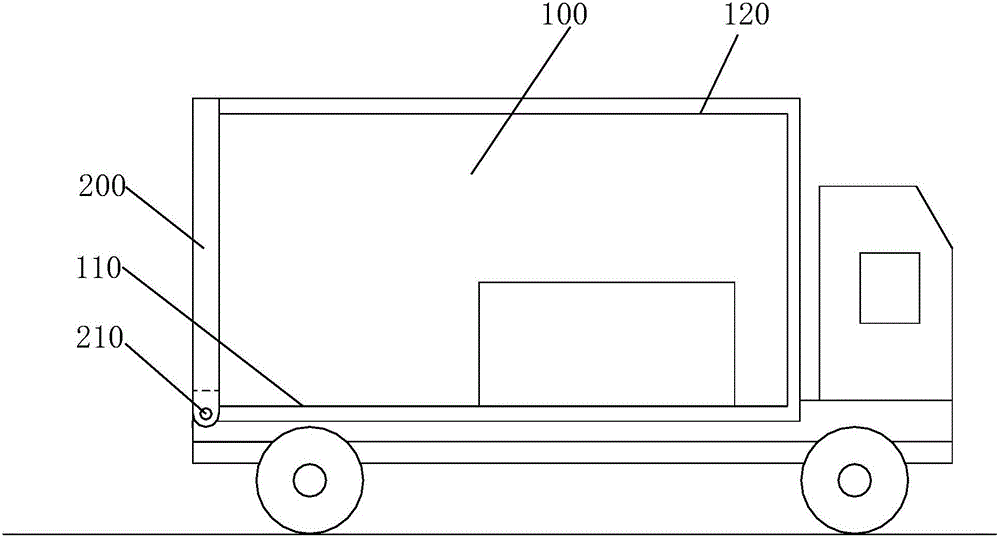

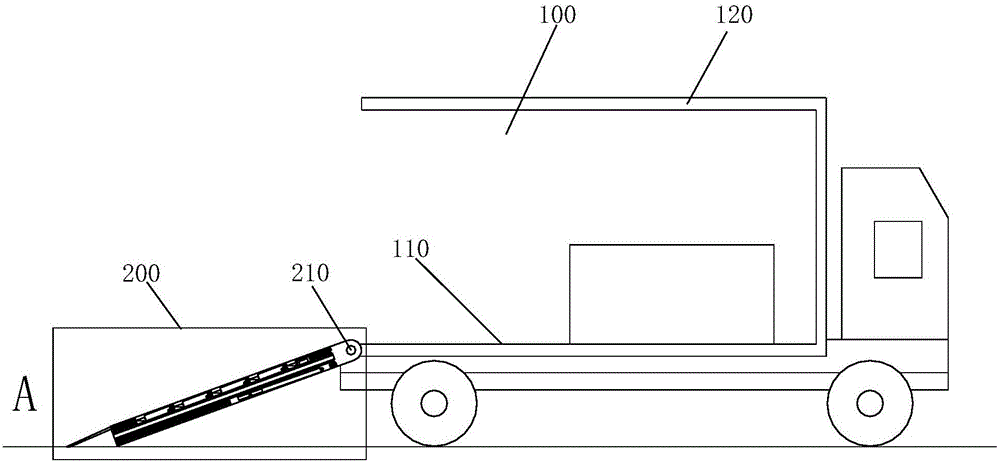

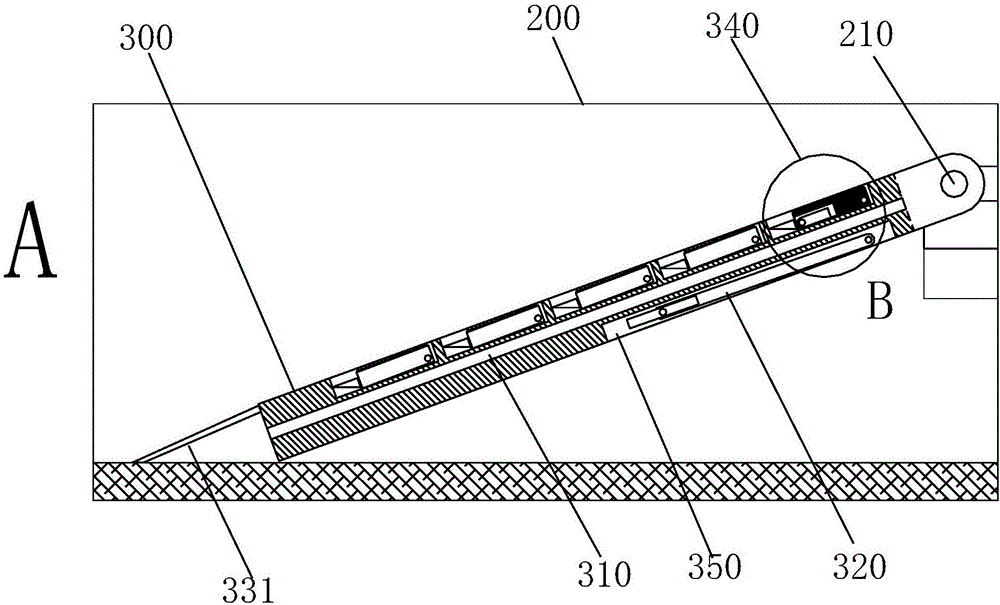

Automatically loaded carriage

InactiveCN103568918ARealize automatic loading and unloadingSave loading and unloading timeVehicle with raised loading platformVehicle with endless chains/beltsDrive wheelEngineering

The invention provides an automatically loaded carriage, which is characterized by comprising a horizontal driving wheel, a horizontal driven wheel, a longitudinal idler wheel, a longitudinal driving belt, a horizontal driving belt, a driving chain, a conical gear, a lifting goods shelf, a rope, a fastening lock, a horizontal motor, a longitudinal motor, a rope motor, a chain guide wheel, a belt guide wheel and a guide groove, wherein the horizontal motor, the longitudinal motor and the rope motor are arranged at the end of the carriage, the horizontal motor drives the conical gear to rotate through the chain, the chain is guided by the chain guide wheel arranged at a box bottom, the conical gear is meshed with the horizontal driving wheel provided with conical gears, and the horizontal driving wheel is connected with a horizontal driven idler wheel through the horizontal driving belt. The device can be matched with a warehouse conveying goods crawler belt for realizing automatically loading goods into a warehouse and unloading the goods from the warehouse; the carriage is more applicable to fragile articles fear of heavy loading, and the carriage structure enables the goods to be placed in a layered manner and to be prevented from being pressed, so that the carriage is particularly suitable for the express industry.

Owner:王延斌

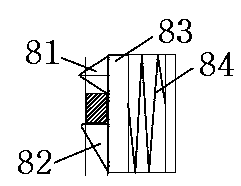

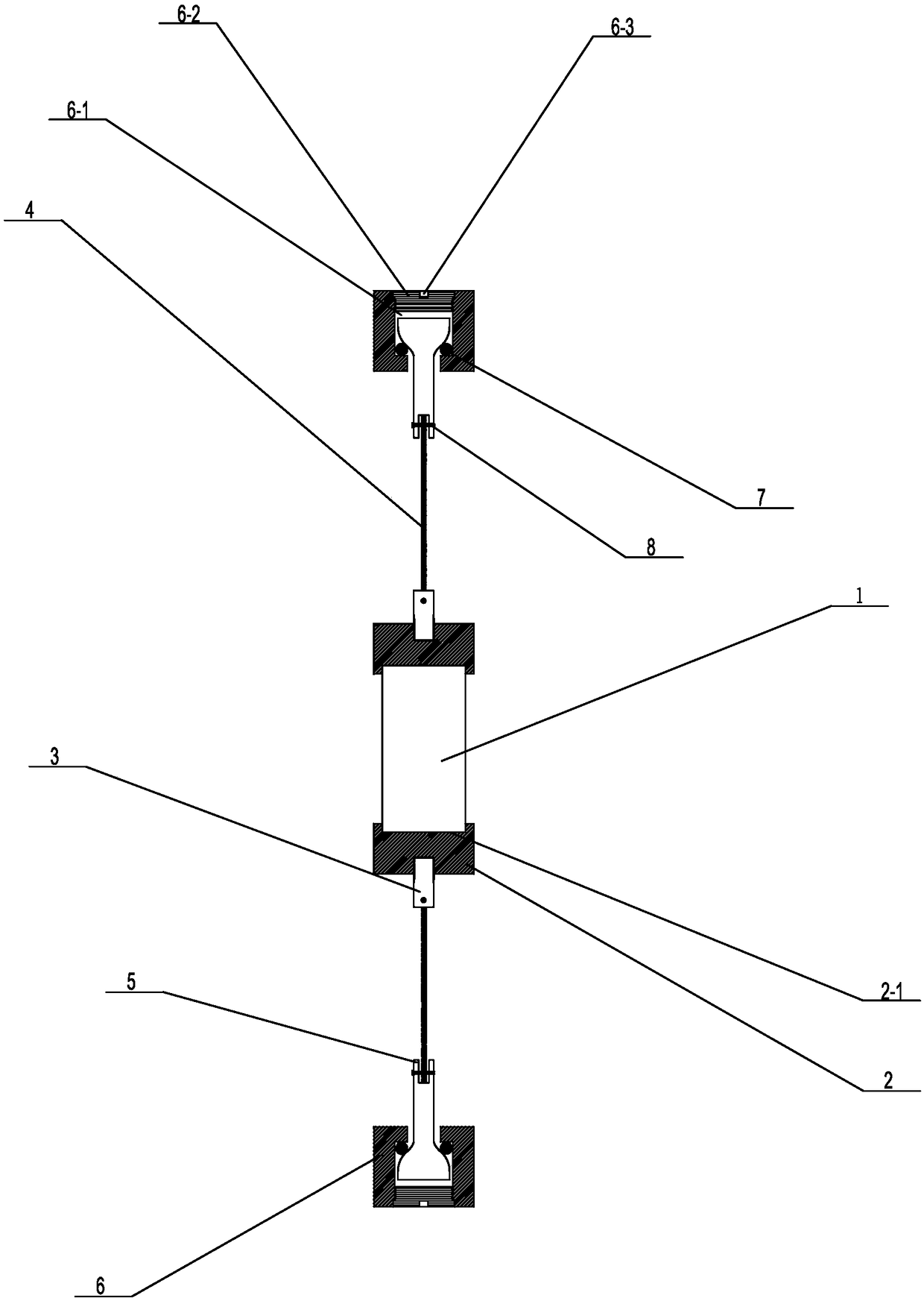

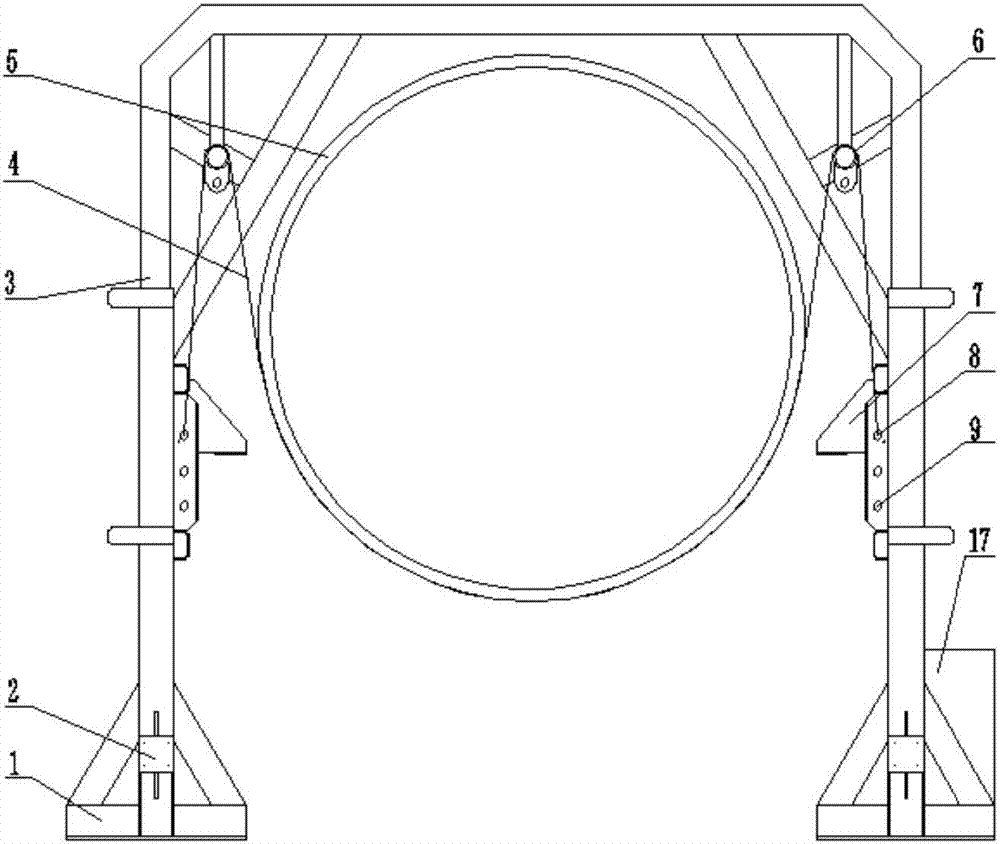

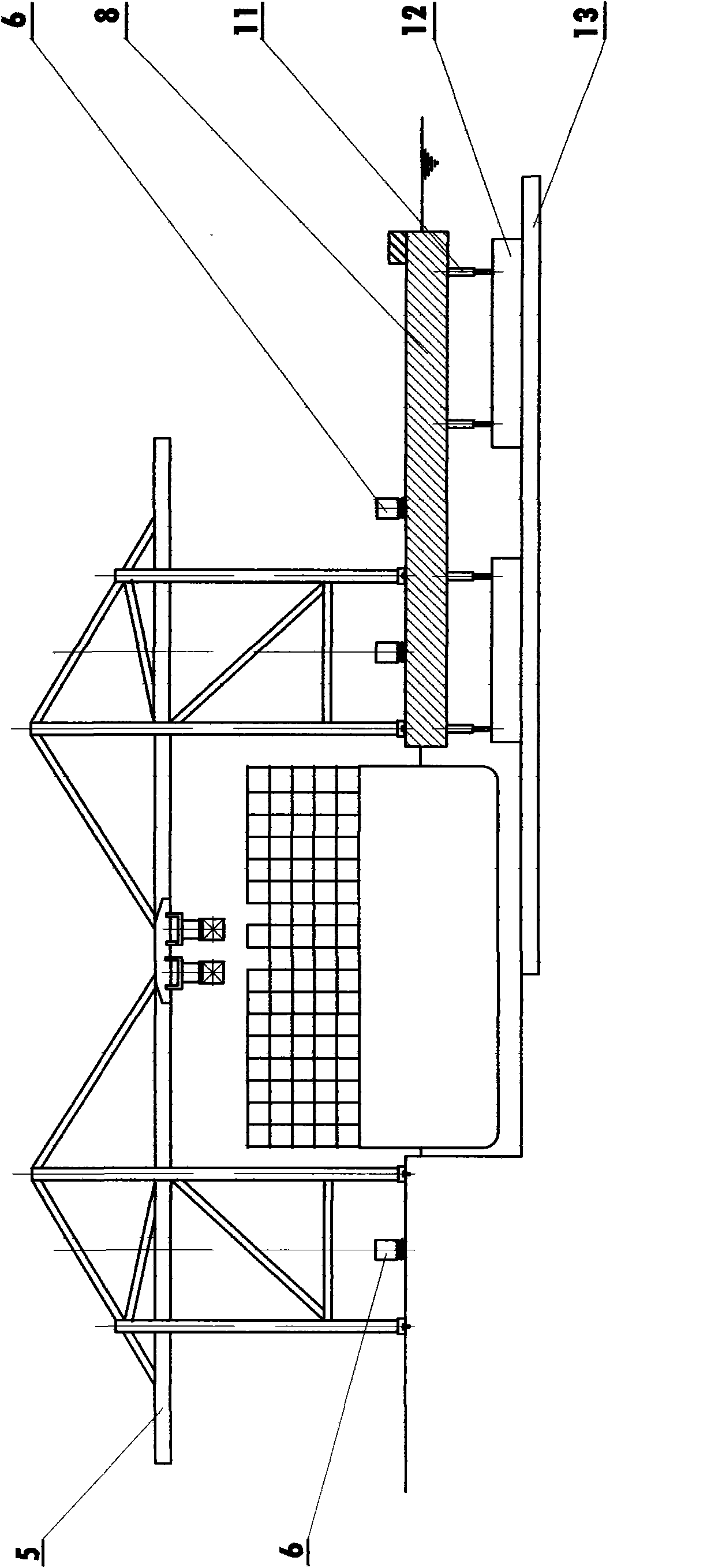

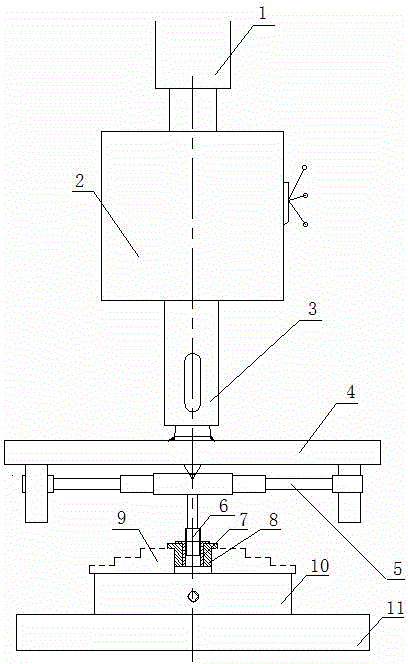

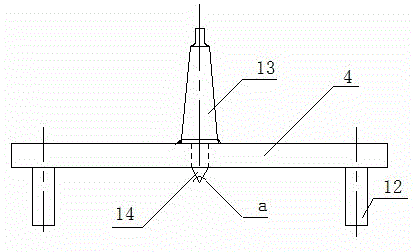

Automatic centering type direct rock tensile test device

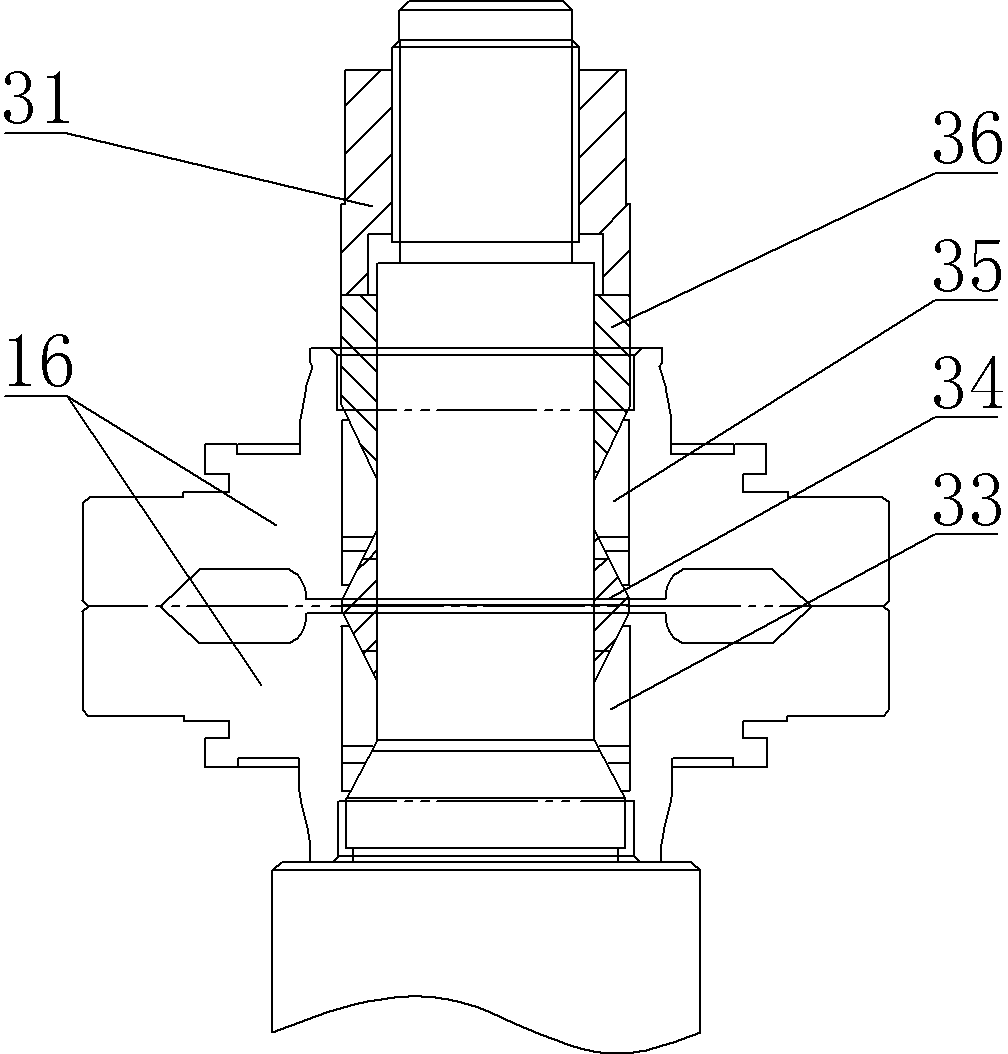

PendingCN108562491AAccurately Test Tensile StrengthFlexible rotationMaterial strength using tensile/compressive forcesEngineeringRock sample

The invention discloses an automatic centering type direct rock tensile test device. The device comprises sample sleeve caps, ball-head tension rods, roll balls and sleeves; the sample sleeve caps areconnected with connecting members; ends of the connecting members are hinged with flexible anti-tensile ropes; the ends of the flexible anti-tensile ropes are hinged to the ends of tension rods of the ball-head tension rods; a plurality of the roll balls are disposed in embedding grooves along the end surfaces of the ball-head tension rods; and embedded groove covers are detachably disposed on the sleeves and located above the embedding grooves. According to the tensile test device, flexible anti-tensile ropes are adopted to connect ball-head turning members and the sample sleeve caps, and the roll balls and the sleeves as well as the roll balls and the ball-head turning members are in point contact, so that angles of the test device can be adjusted in all directions with flexible rotation and automatic deviation adjustment; after a rock sample is stressed, the tensile stress of the rock sample is always ensured along the axis, so that the problem of eccentric tensile stress is avoided; and the device is simple in structure, easy to operate, and easy to load and unload, and can accurately test the anti-tensile strength of the rock sample.

Owner:QINZHOU UNIV

Translational device for crane slings

InactiveCN1962393ASimple structureEasy to operateLoad-engaging elementsHydraulic cylinderHydraulic pump

The invention relates to a translator of crane, wherein it comprises a carrier cart and a driver; the driver is on the cart; the driver comprises hydraulic cylinder, hydraulic pump, lever, and steel wire coiling system; there are four groups of hydraulic cylinders while each two are mounted at one side of cart; one end of each hydraulic cylinder via base is fixed on the cart, while another end is connected to the upper end of lever; the support point of lever is fixed on the of cart; the lower end of lever has steel wire coiling system to connect the lifter upper frame; the hydraulic pump is between four hydraulic cylinder groups and connected to each cylinder; the steel wire coiling system comprises steel wire, block, and steel wire roller. The invention has simple structure, while it can translate the lifter on the large cart of crane and rotate lifter, etc.

Owner:SHANGHAI PORT MACHINERY HEAVY IND

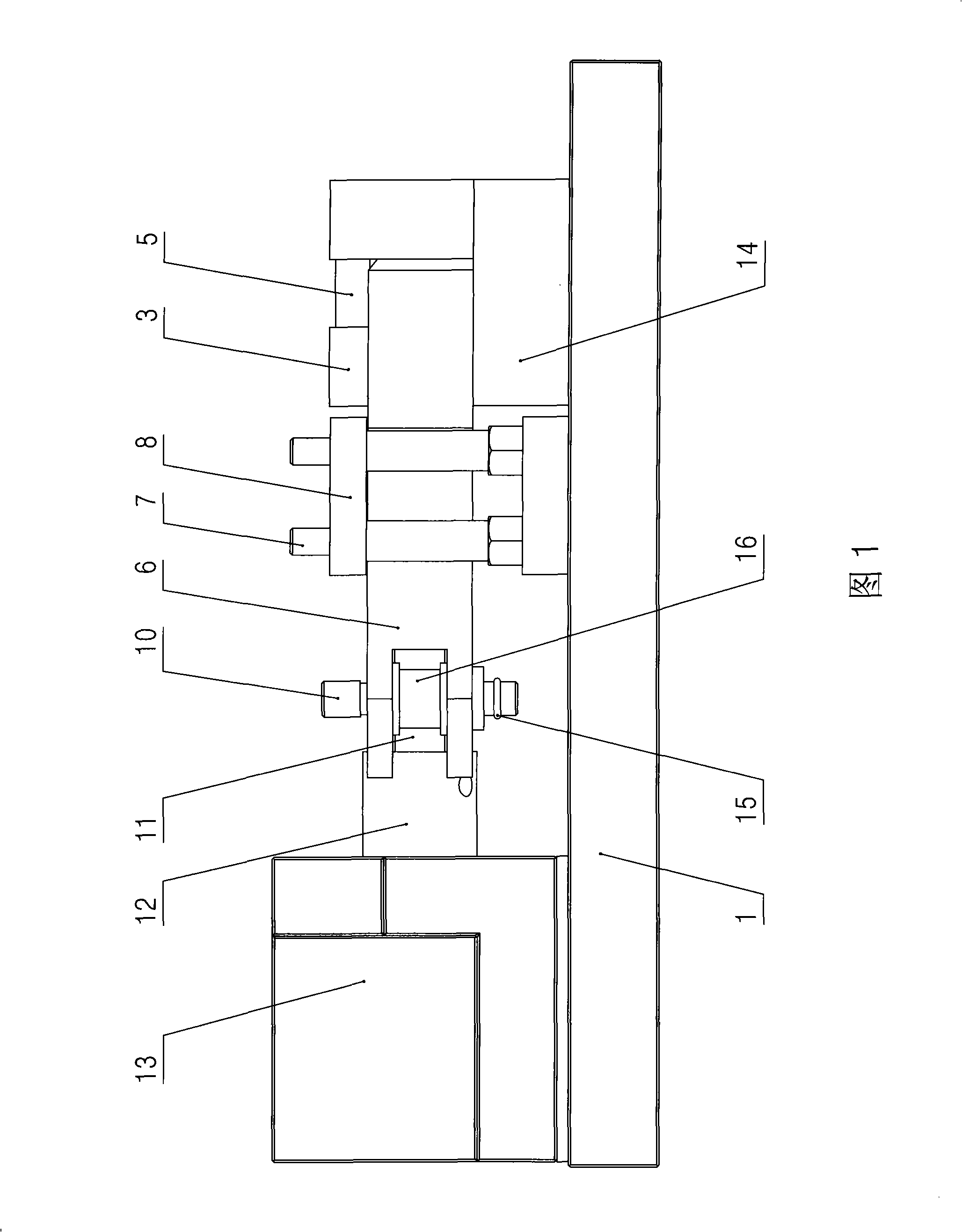

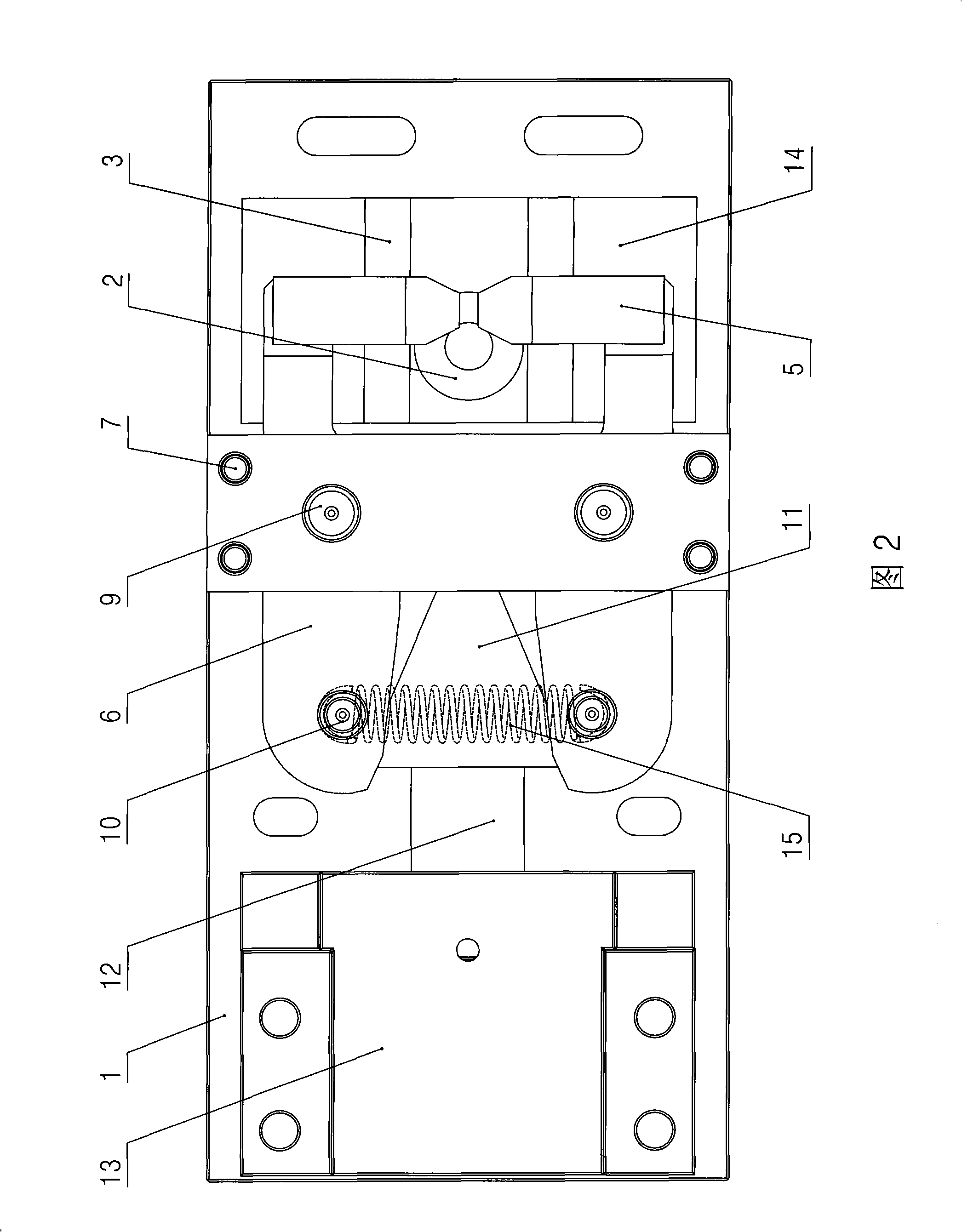

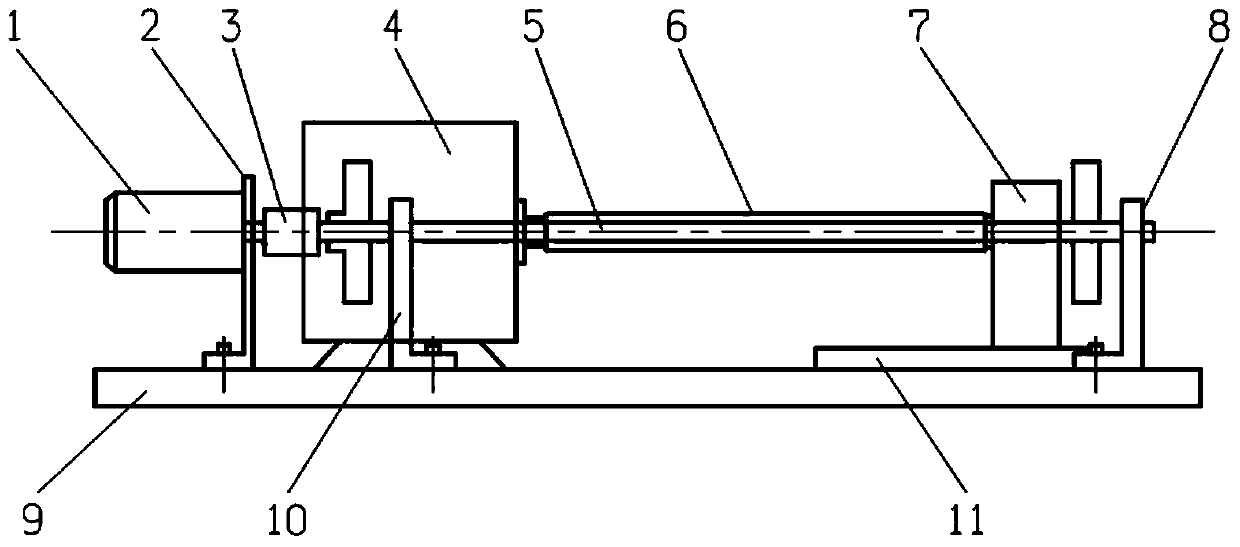

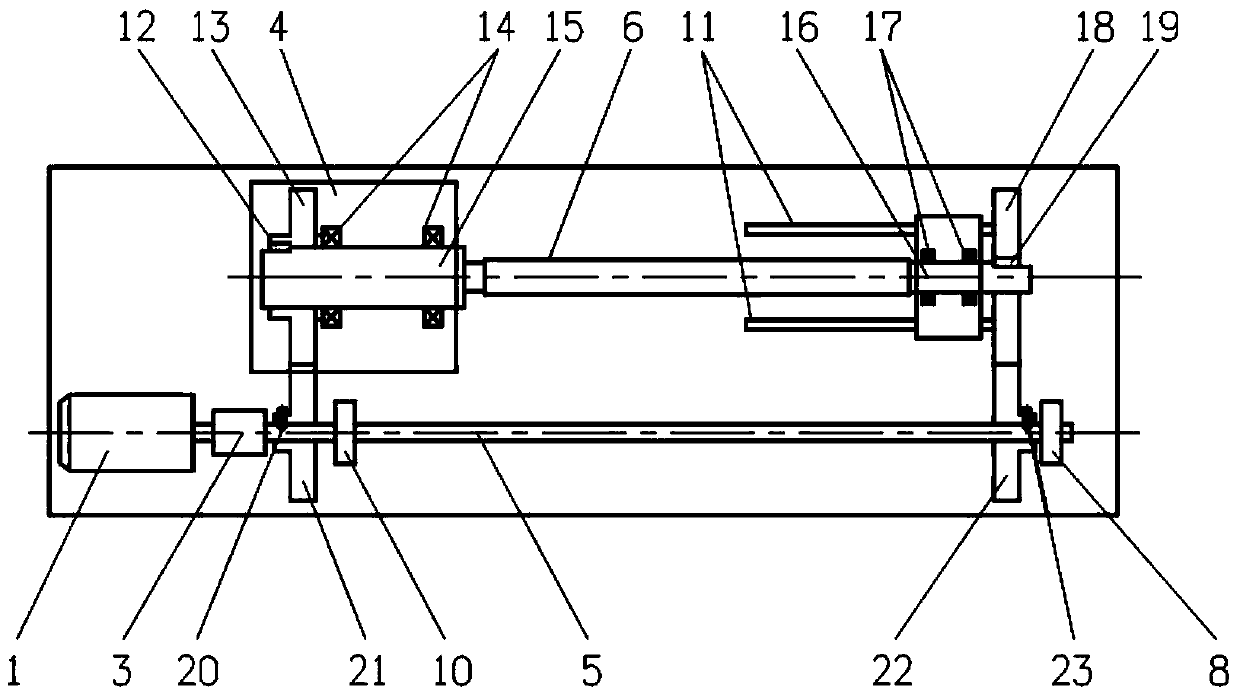

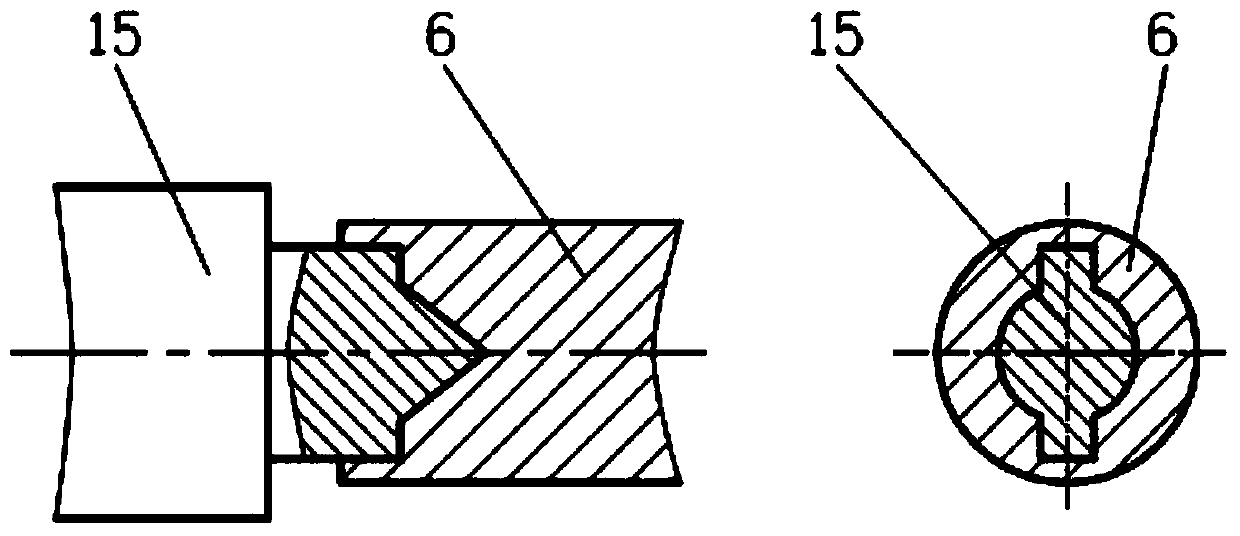

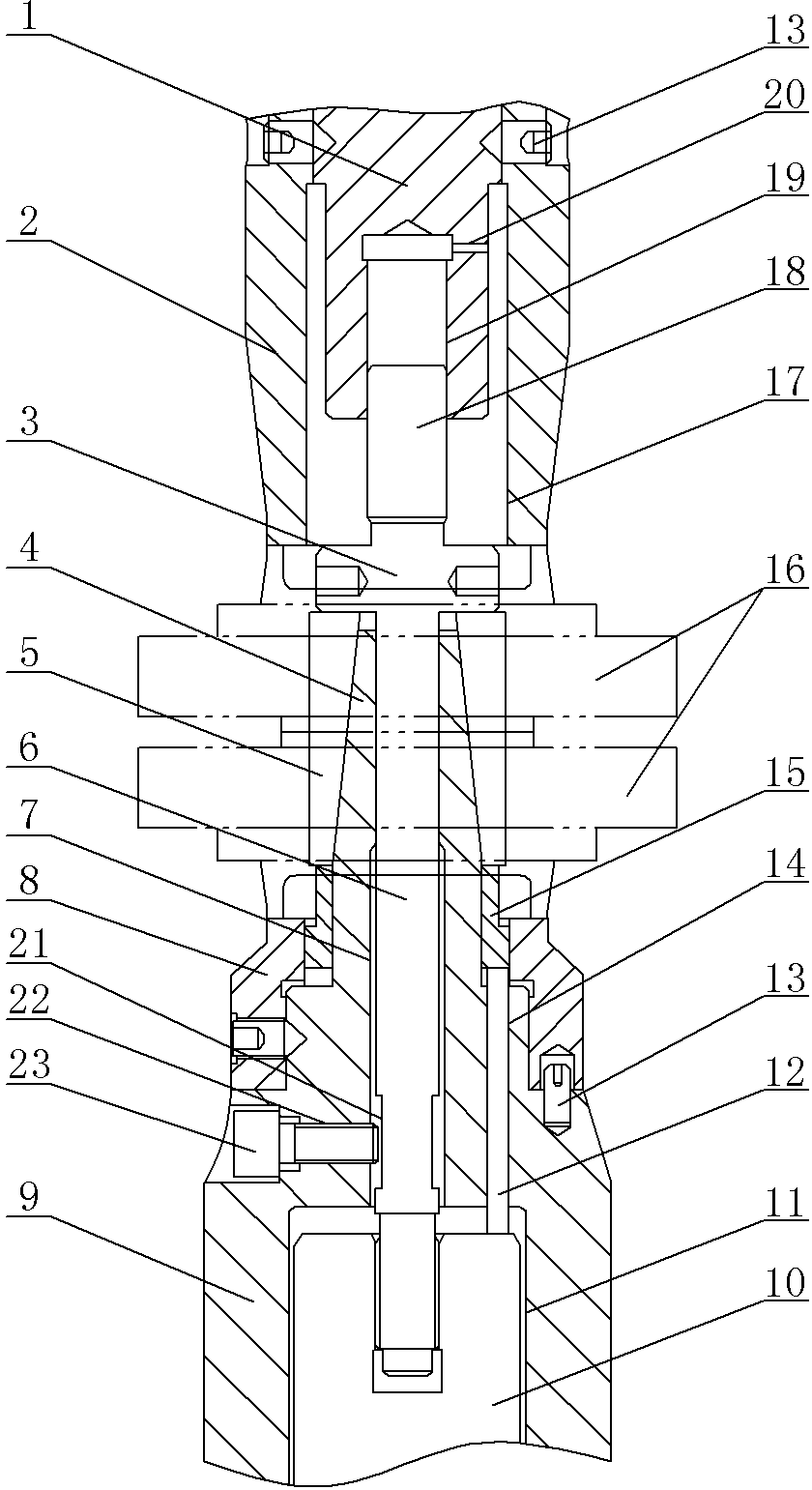

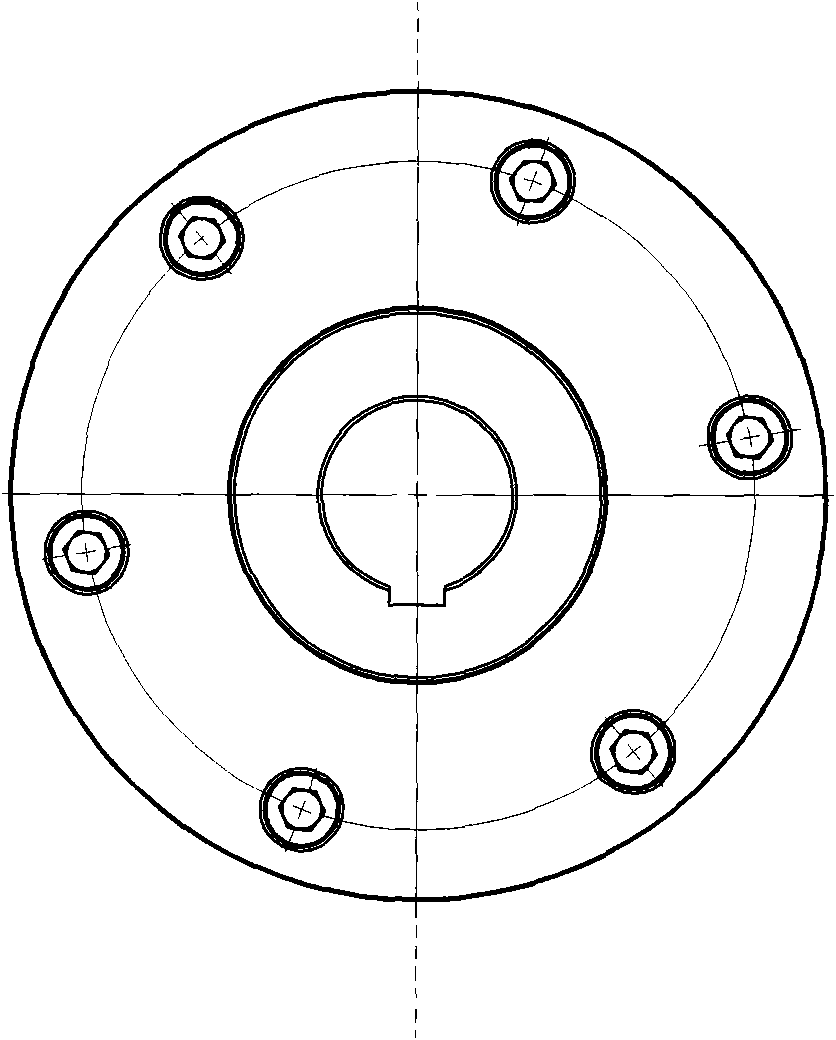

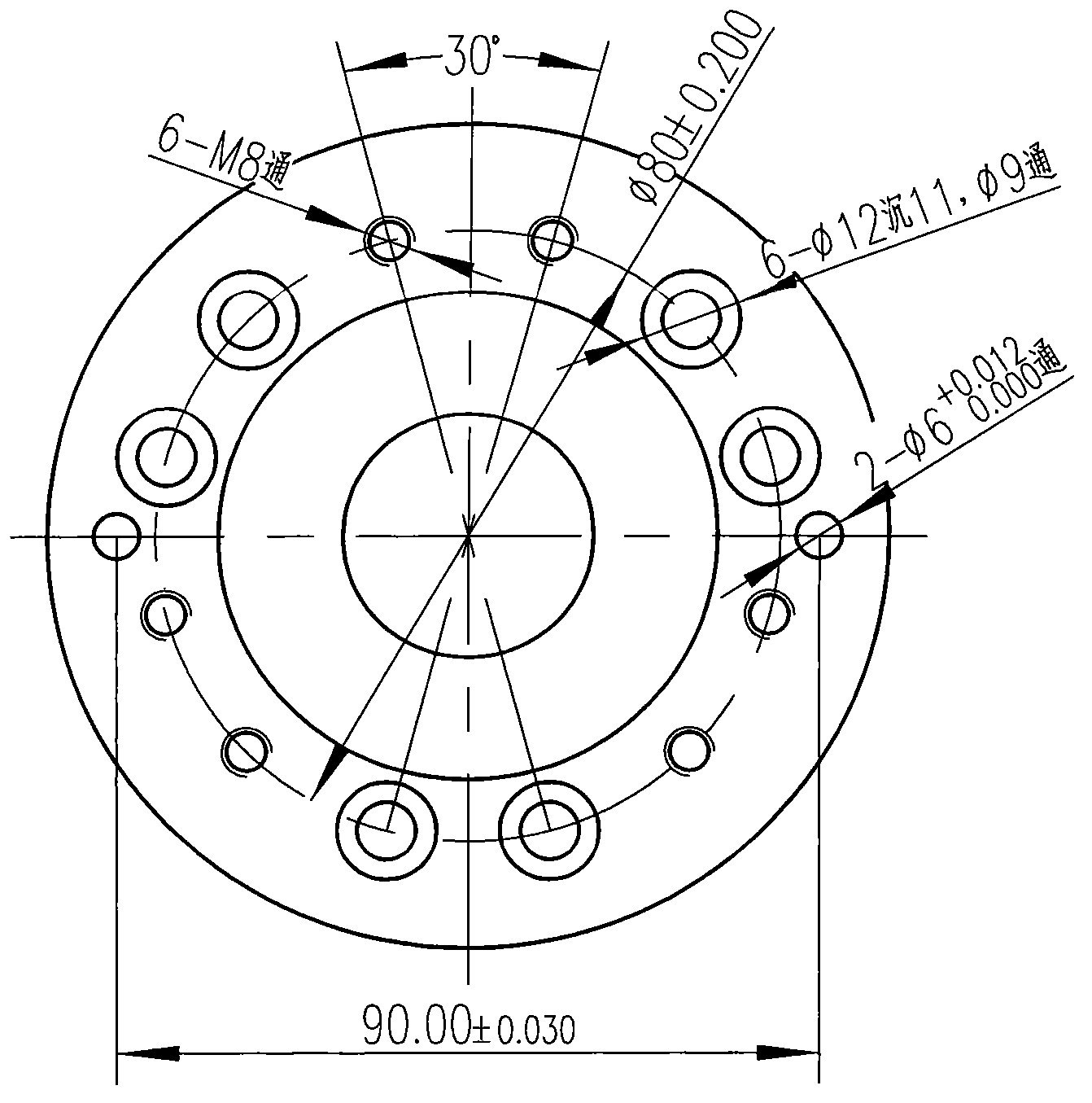

Workpiece clamping and driving device of numerical-control camshaft grinding machine

ActiveCN103737489ARotate synchronouslyNo torsional deformationGrinding drivesGrinding work supportsNumerical controlControl system

The invention relates to a workpiece clamping and driving device of a numerical-control camshaft grinding machine. The workpiece clamping and driving device comprises a workpiece clamping system, a workpiece driving system and an electric control system. The workpiece clamping and driving device has the advantages that the device can be mounted on the numerical-control camshaft grinding machine for clamping a workpiece and driving the workpiece to rotate; the workpiece clamping and driving device of the numerical-control camshaft grinding machine can guarantee that two ends of the workpiece synchronously rotate, torsional deformation can be prevented when the workpiece is machined, and accordingly the machining precision can be improved; a heart carrier for the workpiece clamping and driving device of the numerical-control camshaft grinding machine is omitted, accordingly, the workpiece loading and unloading time can be shortened, and the workpiece machining efficiency can be improved; an existing numerical-control camshaft grinding machine can be modified by the aid of the device, or the device can be used for clamping and driving workpieces of novel numerical-control camshaft grinding machines, and accordingly has an excellent application prospect.

Owner:内江金鸿曲轴有限公司

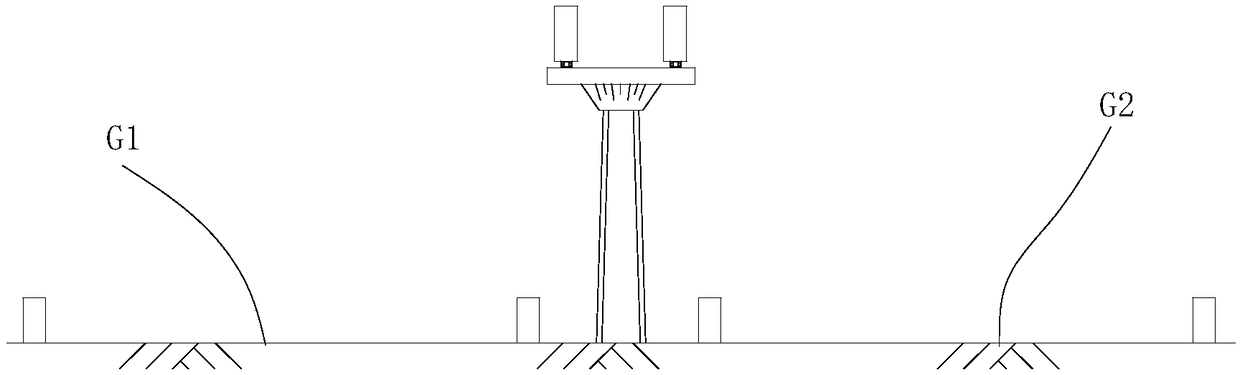

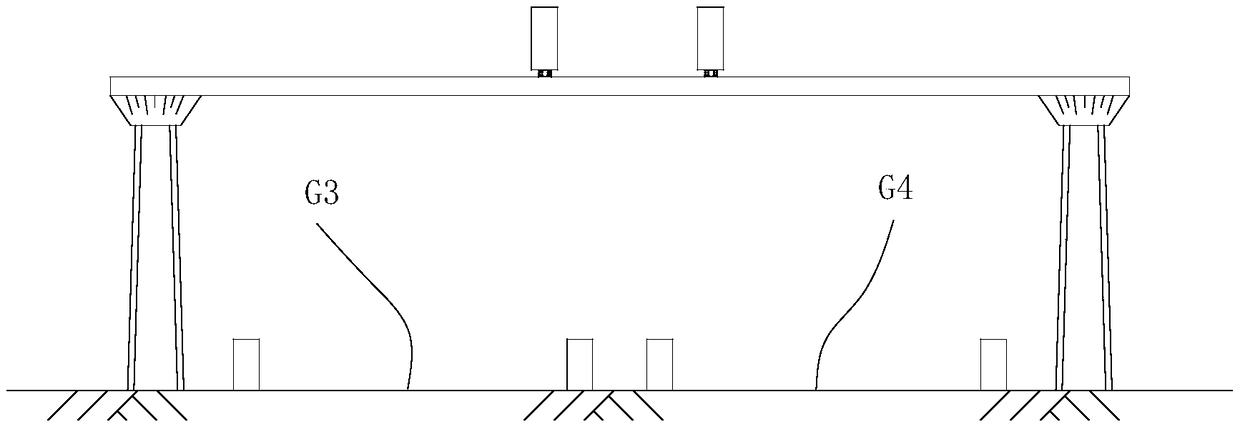

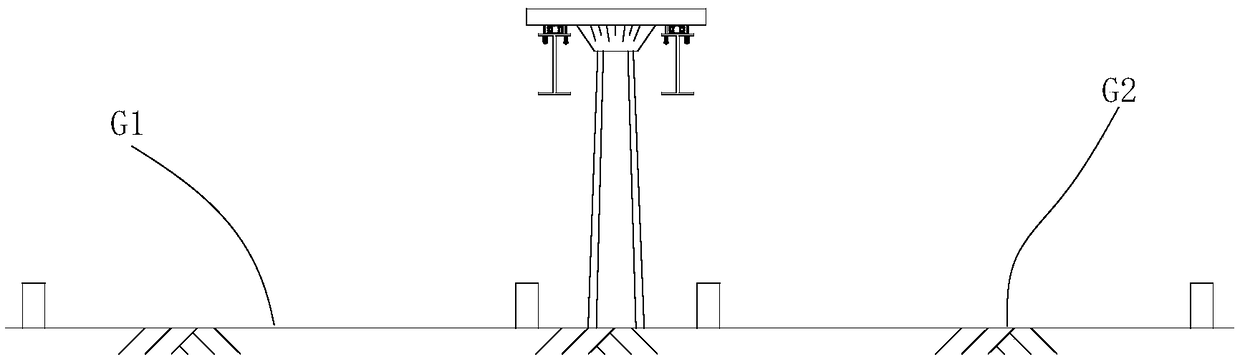

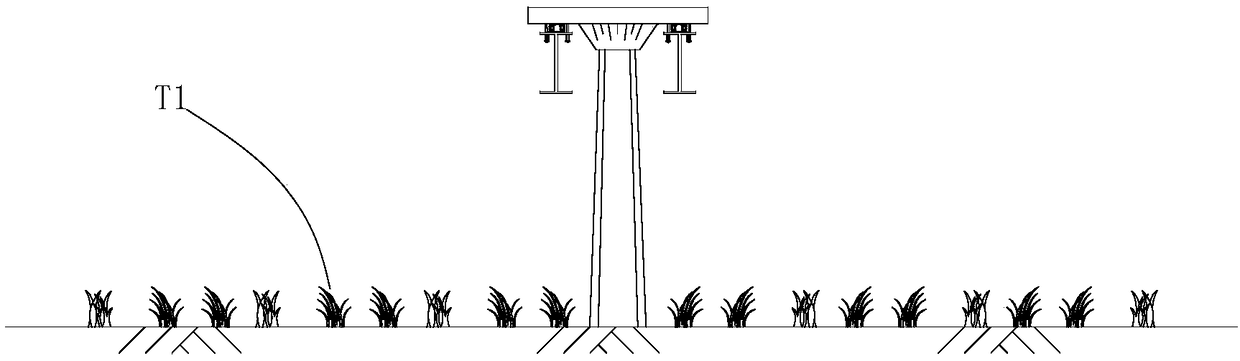

A straddle-type logistics monorail transportation system

The patent discloses a straddle-type logistics monorail transportation system, which belongs to the field of monorail transportation. By proposing a straddle-type logistics monorail transportation system, using straddle-type logistics monorail girder bridge system, straddle-type logistics monorail vehicle system, straddle-type logistics monorail switch system, straddle-type logistics monorail loading and unloading system and straddle-type logistics monorail signal system, solve the problems of short distance, large size, high cost and low speed of the existing maglev transportation, and achieve the goal of long distance, lightweight, low cost and high speed straddle-type logistics monorail transportation system.

Owner:BEIJING JIAOTONG UNIV

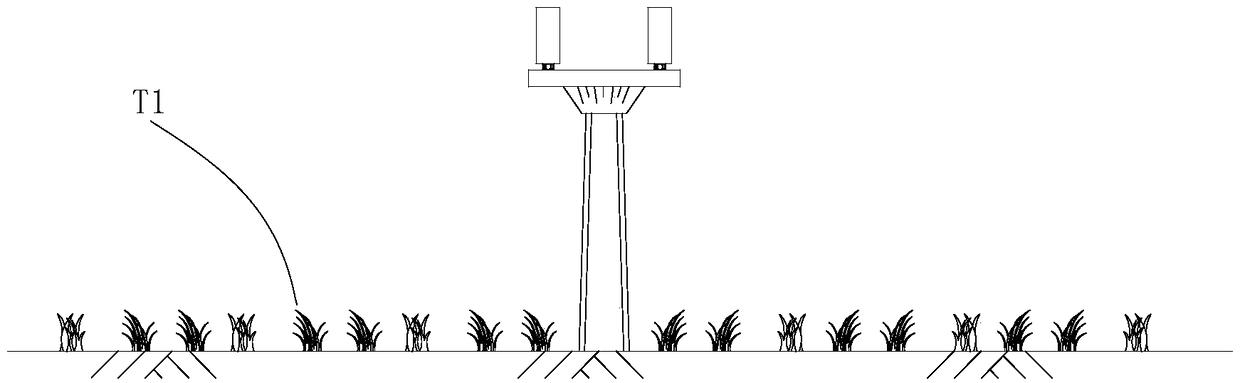

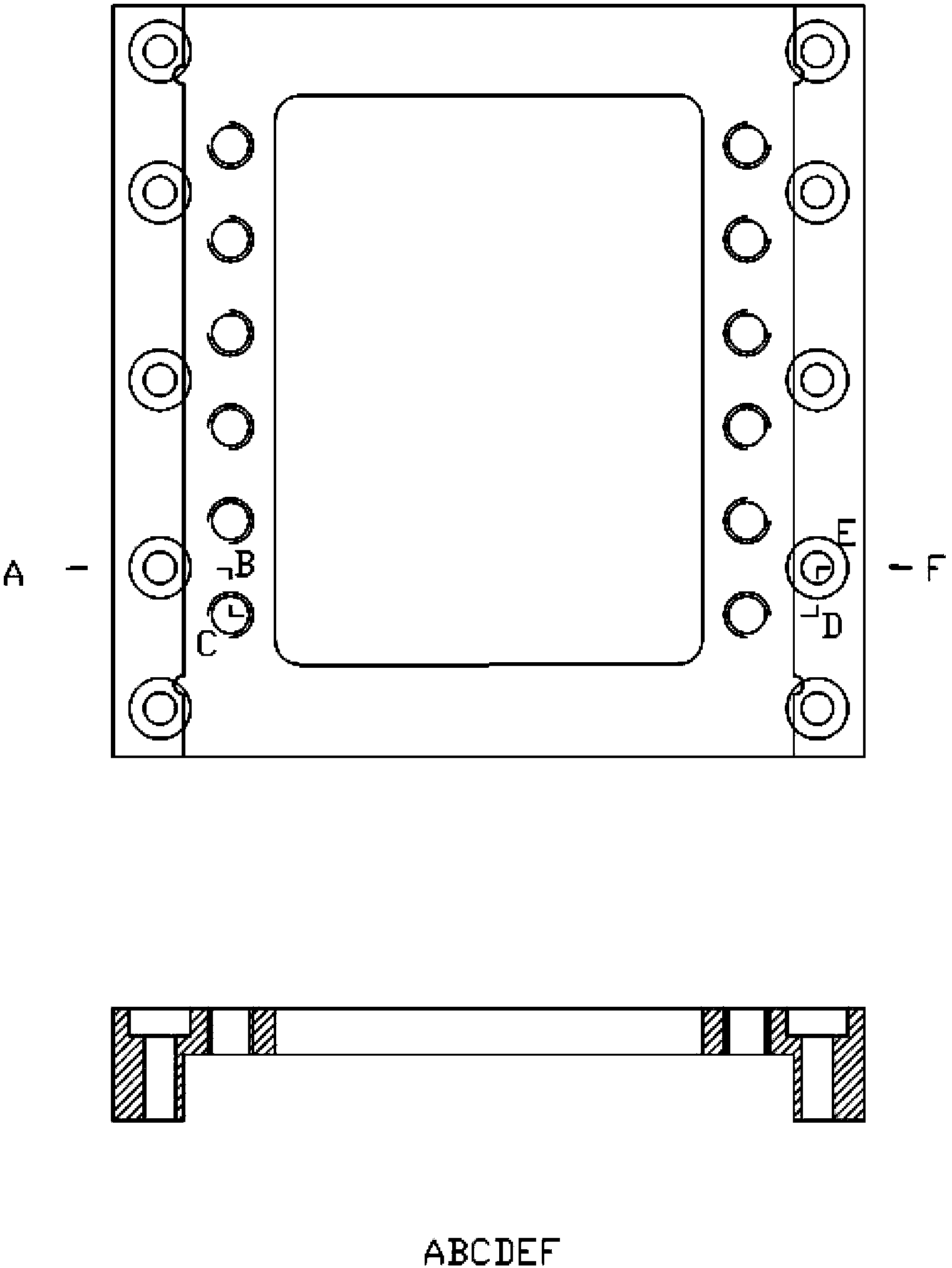

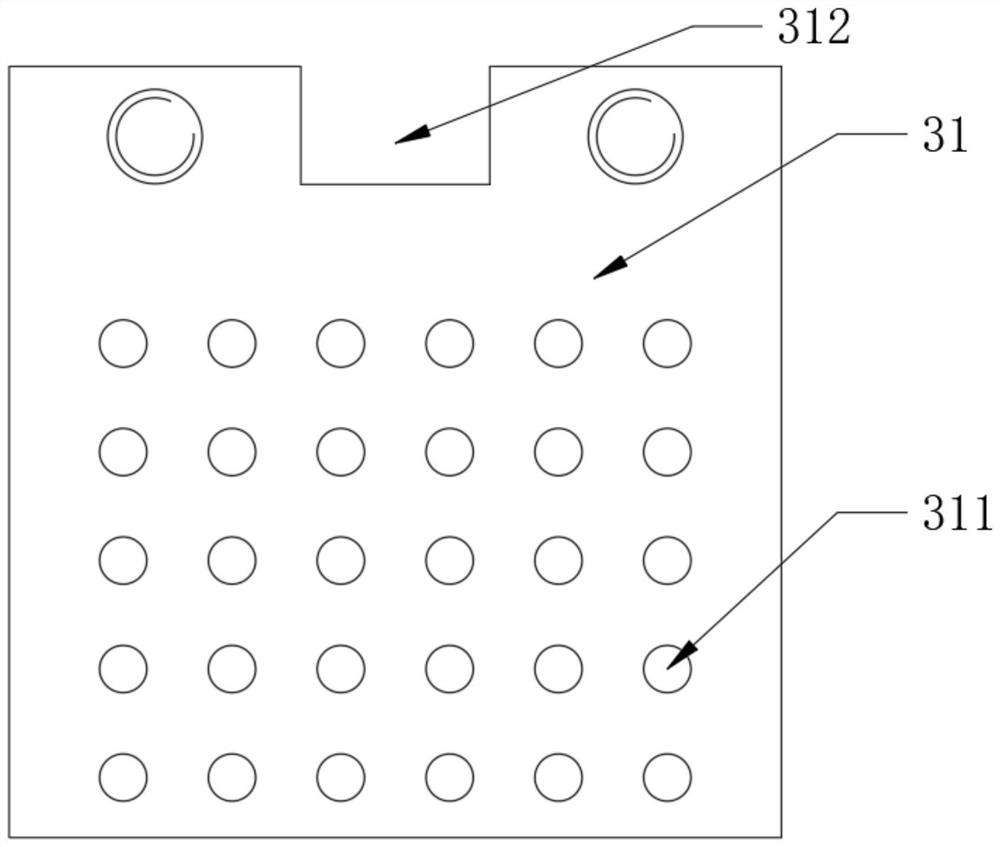

Universal microfluidic chip fixture

ActiveCN103878038AImprove sealingImprove pressure resistanceLaboratory glasswaresEngineeringScrew press

The invention relates to a universal microfluidic chip fixture. The universal microfluidic chip fixture is composed of a fixture B plate, a chip, a polyvinyl fluoride blade ring, a screw, a fixture A plate, a connecting screw, a sleeve and a glass capillary. The universal microfluidic chip fixture has the advantages that a V-shaped hole is adopted by the chip; the connecting screw presses the glass capillary tightly through the polyvinyl fluoride blade ring; sealing property is good; and operations are convenient. By adopting 3 / 16''N=32 standard screw, the fixture is convenient and economic. Two sides of the fixture A plate are cut apart, so that the chip can be assembled and disassembled conveniently; and the fixture B plate is provided with twelve [phi]4 observation wells, thereby facilitating observation of assembly conditions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

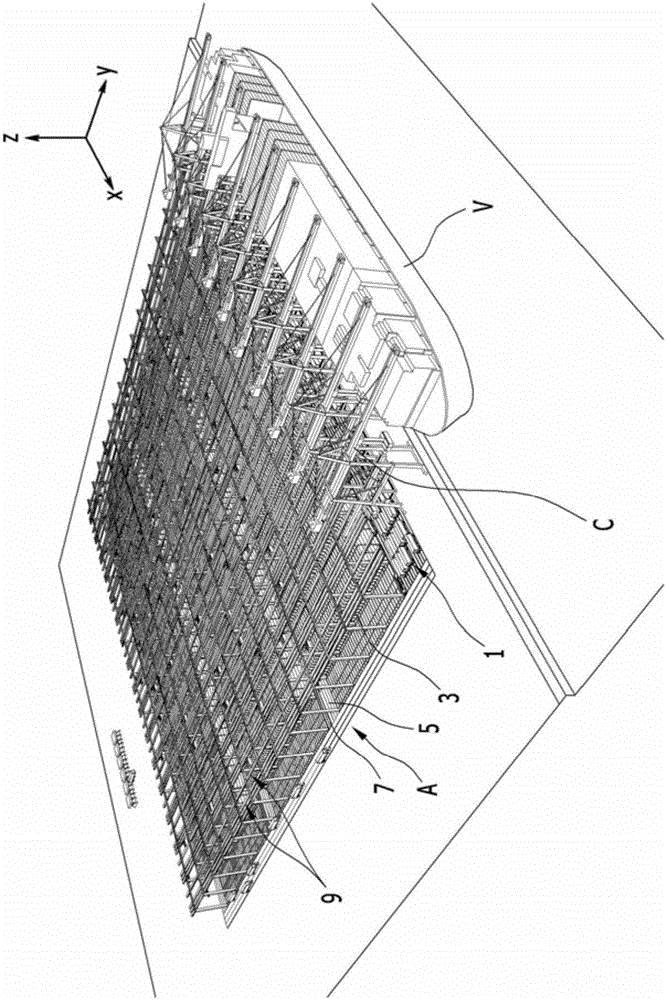

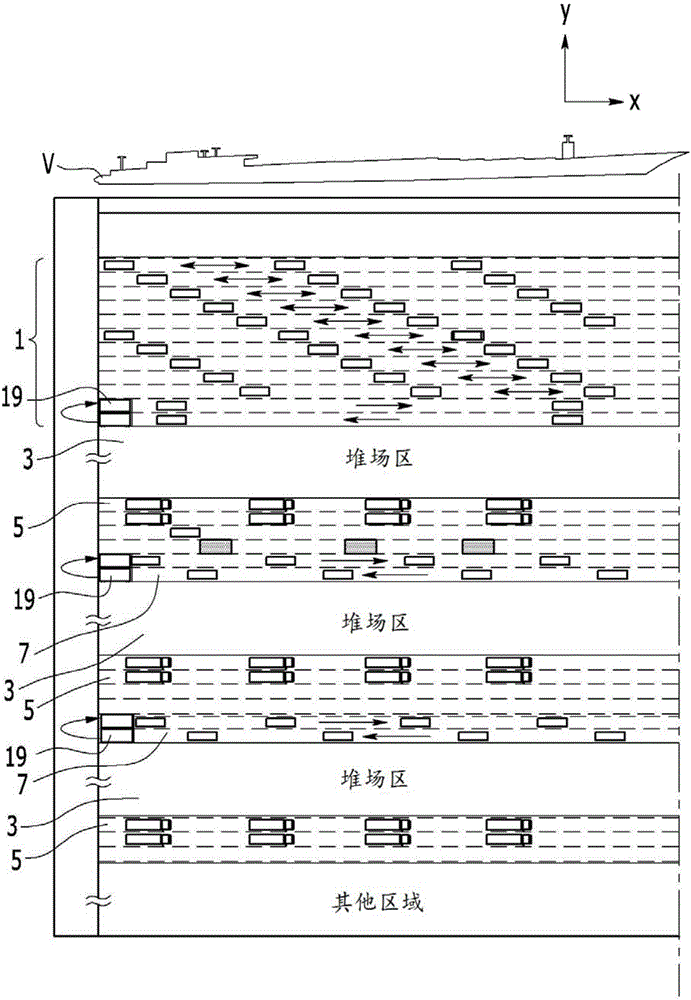

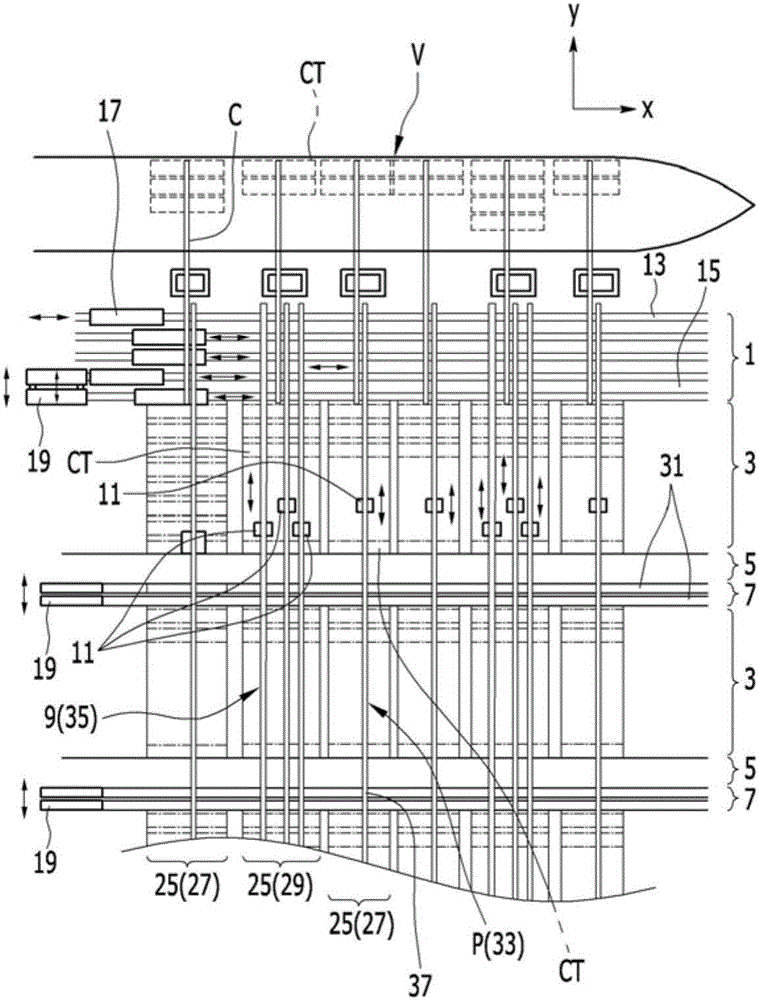

Container terminal system

InactiveCN106232510ASave loading and unloading timeReduce movementStorage devicesLoading/unloadingEngineeringMechanical engineering

The present invention provides a container terminal system capable of efficiently loading, unloading, and storing containers in a container terminal or capable of moving containers into / out of a container terminal. The container terminal system according to the present invention comprises: a main automatic transfer area arranged near a quay wall such that containers are transferred in a direction parallel with the quay wall; a yard area adjacent to the main automatic transfer area, containers being stored in the yard area; a vehicle transfer area arranged adjacent to the yard area; an overhead rail unit installed over the main automatic transfer area, the yard area, and the vehicle transfer area in a direction perpendicular to the quay wall; and a shuttle for moving along the overhead rail unit and transferring containers.

Owner:KOREA MARITIME INST

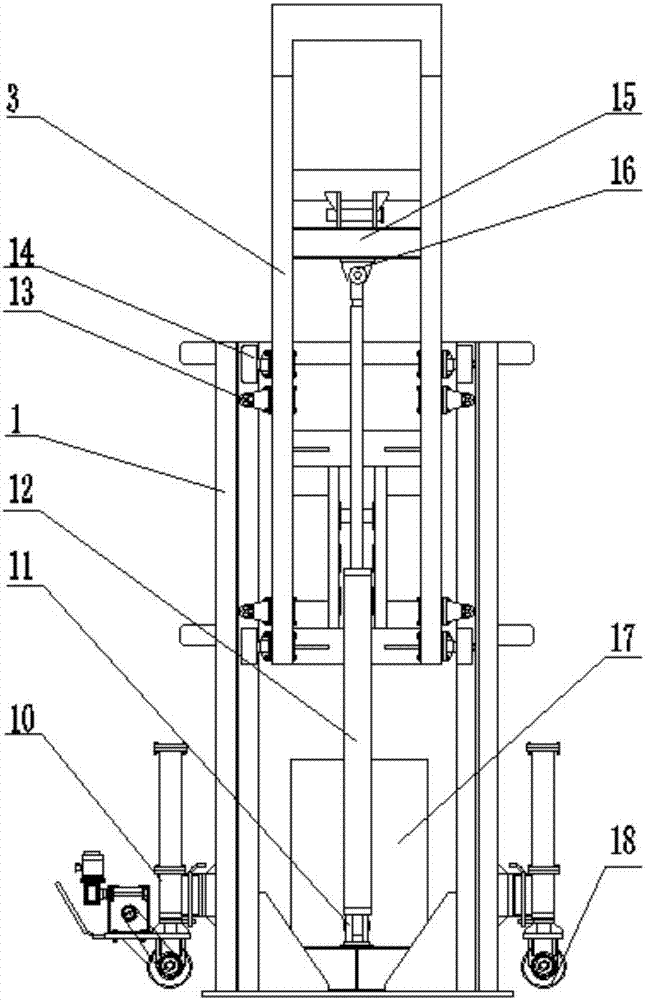

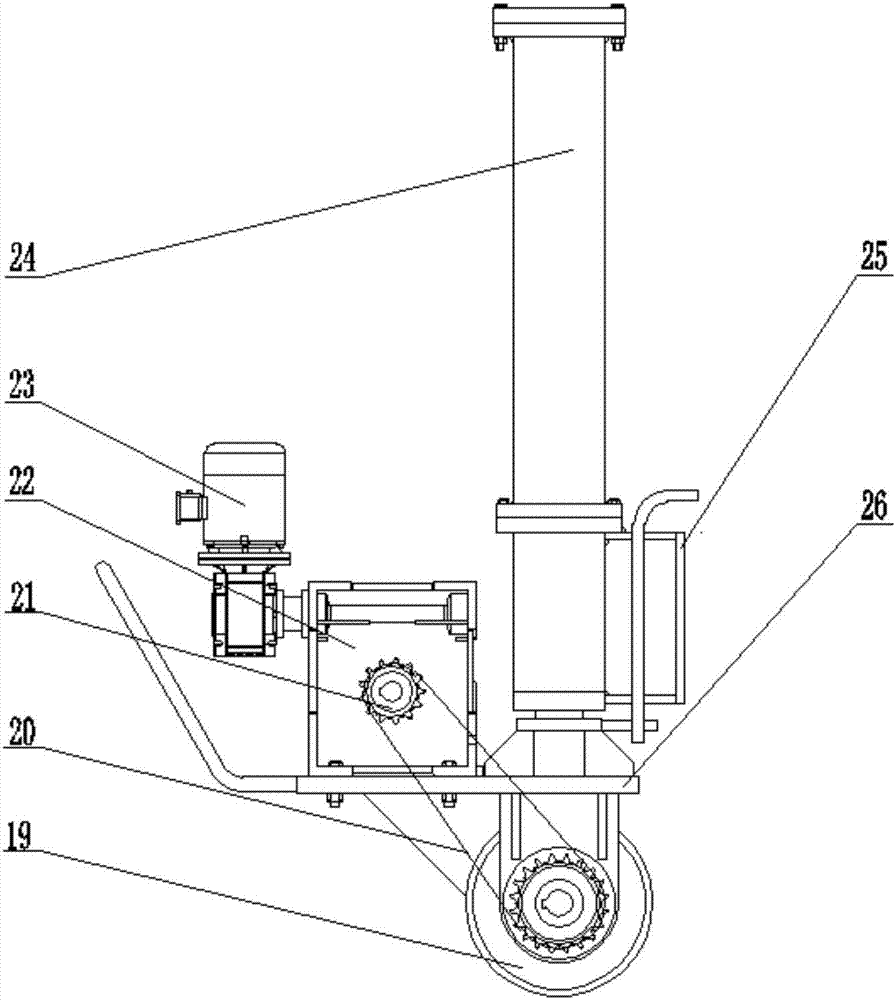

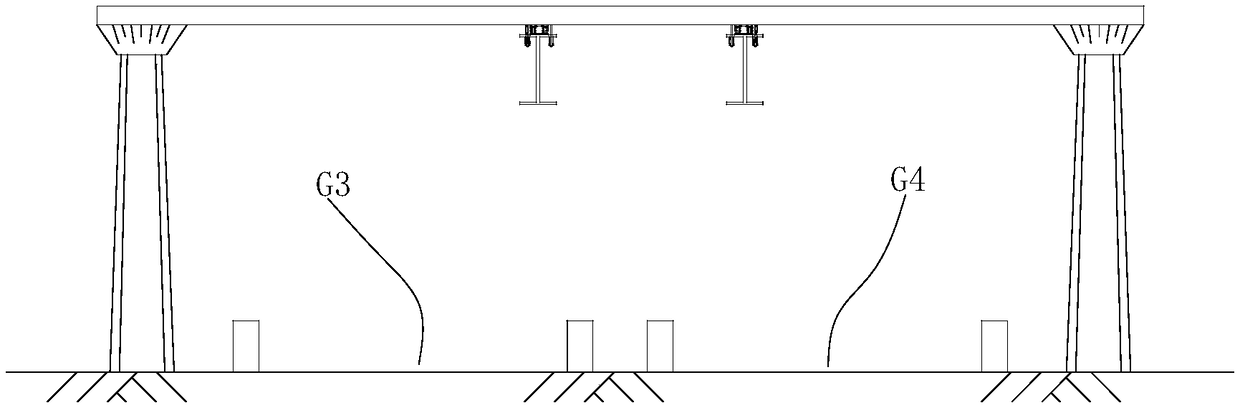

Self-walking gantry lifting device

InactiveCN107381343AHeight adjustableSave loading and unloading timeBase supporting structuresBraking devices for hoisting equipmentsDrive wheelMarine engineering

Owner:JIANGHAN UNIVERSITY

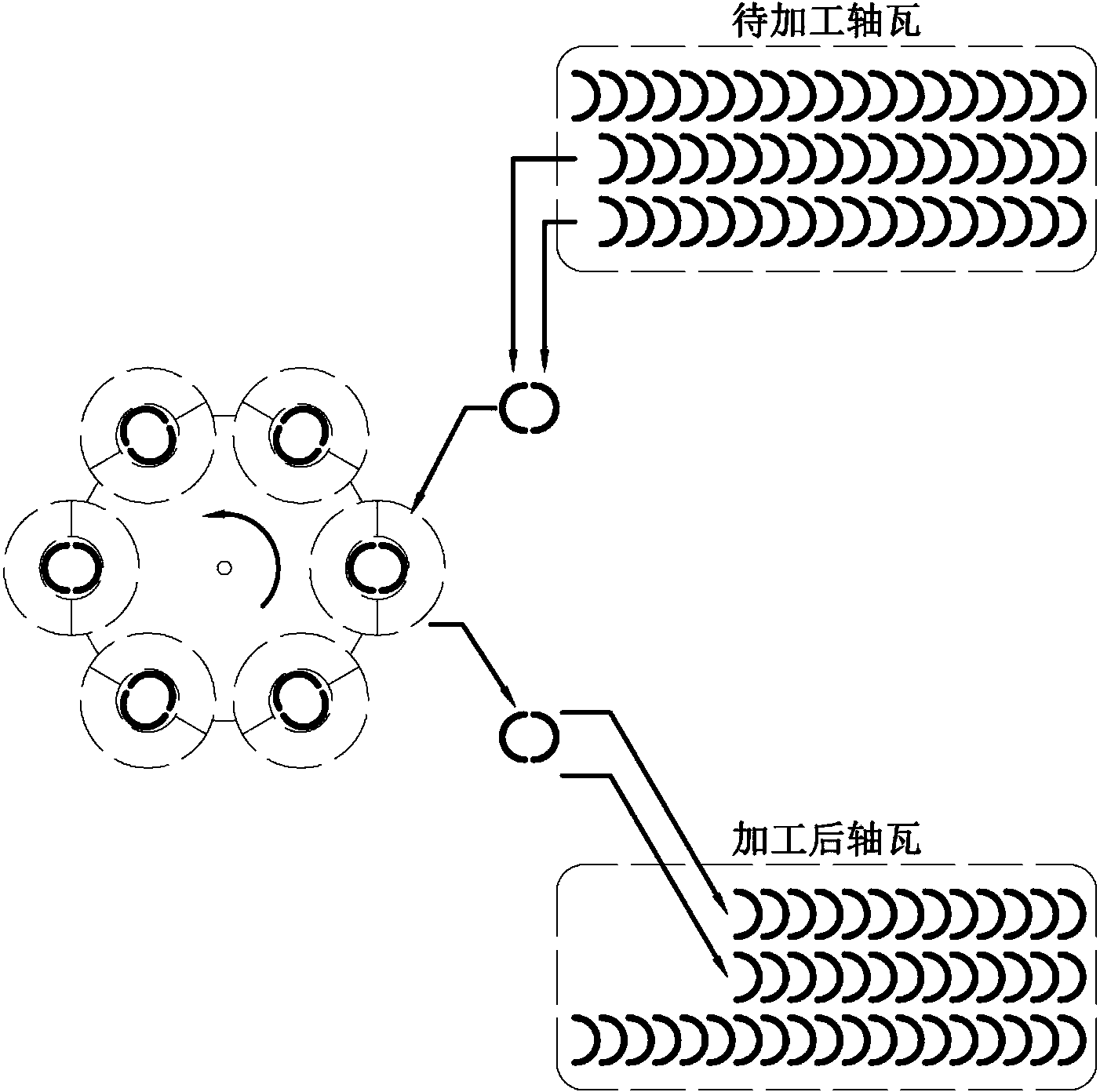

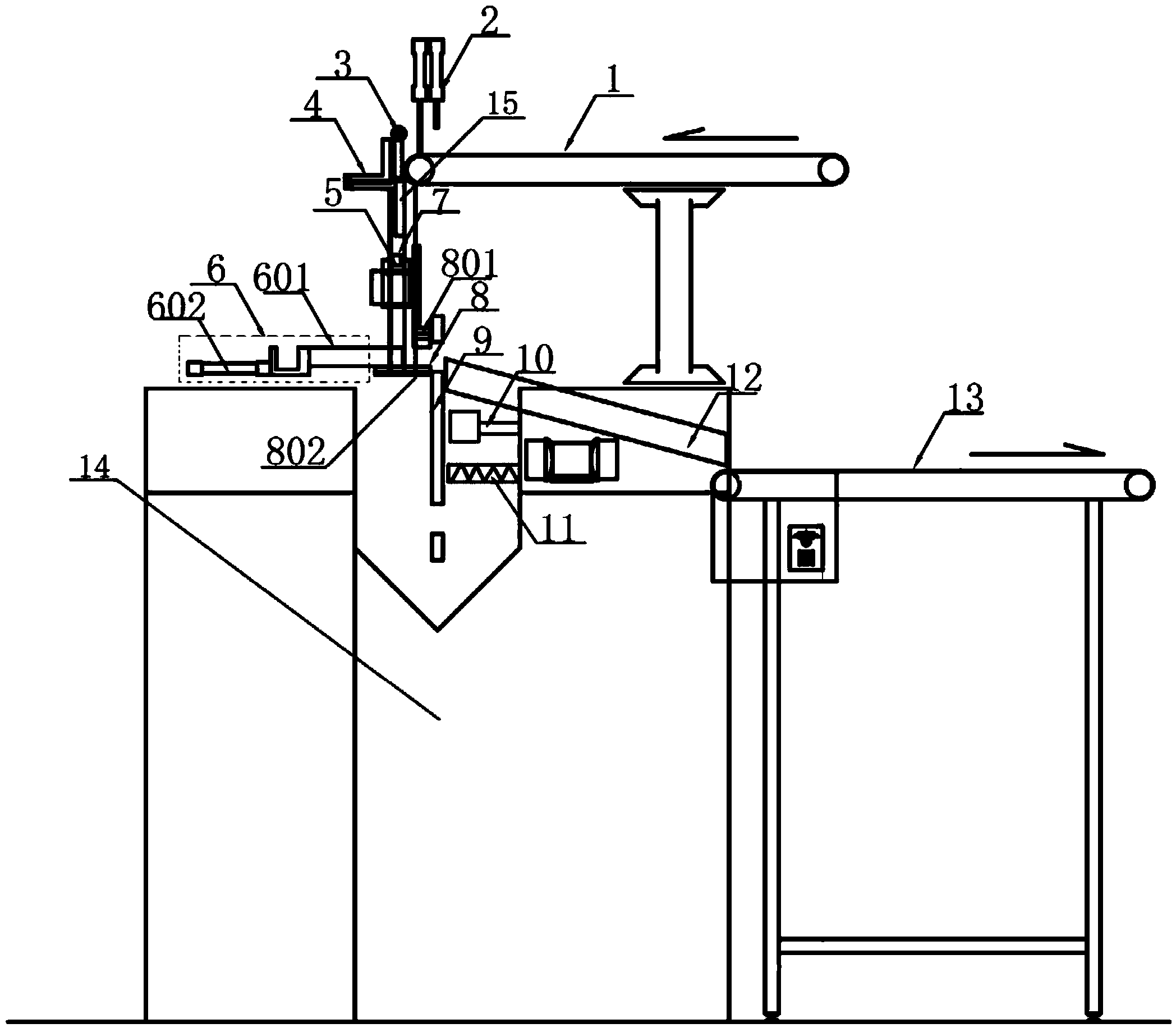

Bearing bush two-sided chamfering machine with automatic feeding and discharging function and use method thereof

InactiveCN103949730AReduce labor intensityAvoid security issuesMetal working apparatusMachineCylinder block

The invention relates to a bearing bush two-sided chamfering machine with an automatic feeding and discharging function, and a use method thereof. According to the invention, a pushing device, a blanking groove, a material feeding conveying device, a stirring platform, a retaining cylinder block and an allocation cylinder are arranged on an original machine tool, so that bearing bush blank can be fallen onto the bottom of the blanking groove in pairs and can be pushed into a station moulding bed by the pushing device; the bearing bush blank rotates along with the station moulding bed and is pushed out by the pushing device after being processed by a compressing device and a two-end-face processing device, so that an automatic circulating continuous processing production line is formed. The bearing bush two-sided chamfering machine with the automatic feeding and discharging function is simple in structure, high in automation degree, high in processing efficiency, high in machining precision and low in labor strength; meanwhile, the chamfering machine is simple in use method and operation, and the whole machining process is highly harmonious and unified and is high in security.

Owner:大丰市明月轴瓦有限公司

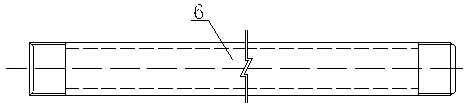

Dual-piece hobbing fixture

InactiveCN103418856AHigh positioning accuracyGuaranteed machining accuracyGear-cutting machinesGear teethHydraulic cylinderHobbing

The invention discloses a machine tool part and particularly relates to a dual-piece hobbing fixture which comprises a conical core shaft, an upper vertical column and a first draw rod, wherein the conical core shaft comprises a stepped shaft and a conical body; the upper end of the stepped shaft and one end, which has larger diameter, of the conical body are connected and are equal to each other; the lower end face of the conical core shaft is provided with a first through hole along the axial direction; the stepped shaft is provided with a locating sleeve; the conical body is provided with a spring tensioning sleeve; one end of the first draw rod is coaxially provided with a truncated cone with the diameter not greater than the outer diameter of the spring tensioning sleeve, and the other end of the first draw rod passes through the first through hole; the upper vertical column coaxial with the first draw rod is arranged above the first draw rod, and is fixedly connected with a pressing sleeve. After such a structure is adopted, the machine tool hydraulic cylinder and the upper vertical column are fully utilized, so that workpiece loading and unloading time is shortened, and the labor efficiency is improved; meanwhile the rigidity of the fixture is enhanced; since a sliding bush capable of performing relative movement is not adopted, the workpiece locating precision is high, and the gear processing accuracy is stably ensured.

Owner:CHONGQING YUQING MACHINERY MFR

Suspension-type logistic monorail transportation system

The patent discloses a suspension-type logistics monorail transportation system, belonging to the monorail transportation field. By proposing a hanging logistics monorail transportation system, and byadopting the a suspension-type logistic monorail girder bridge system, a suspension-type logistic monorail girder bridge system suspended logistics monorail vehicle system, a suspension-type logistics monorail switch system, a suspension-type logistics monorail loading and unloading system and suspended logistics monorail signal system, the problems of short distance, large size, high cost and low speed of the existing maglev transportation are solved, and the goals of long distance, lightweight, low cost and high speed suspension logistics monorail transportation system are achieved.

Owner:BEIJING JIAOTONG UNIV

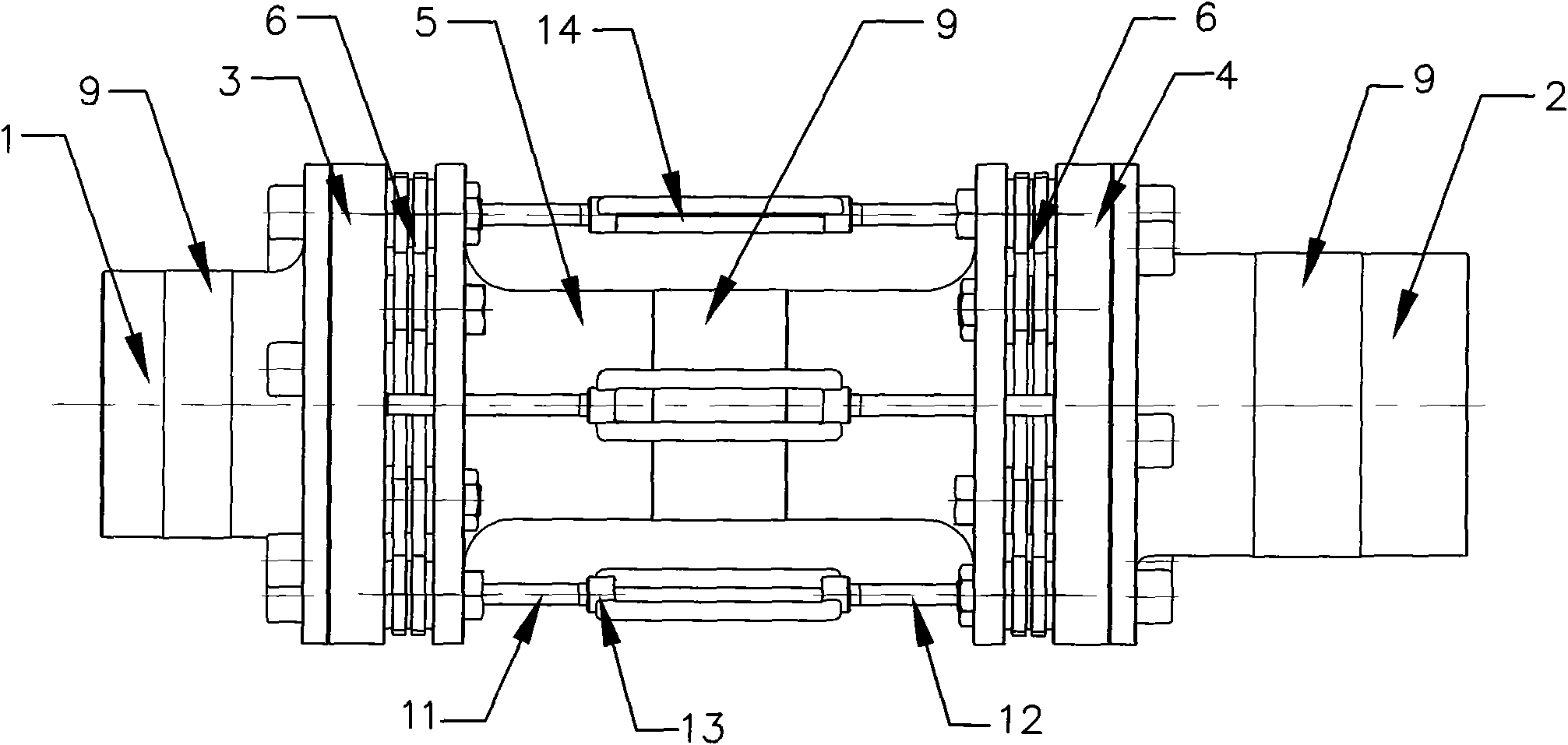

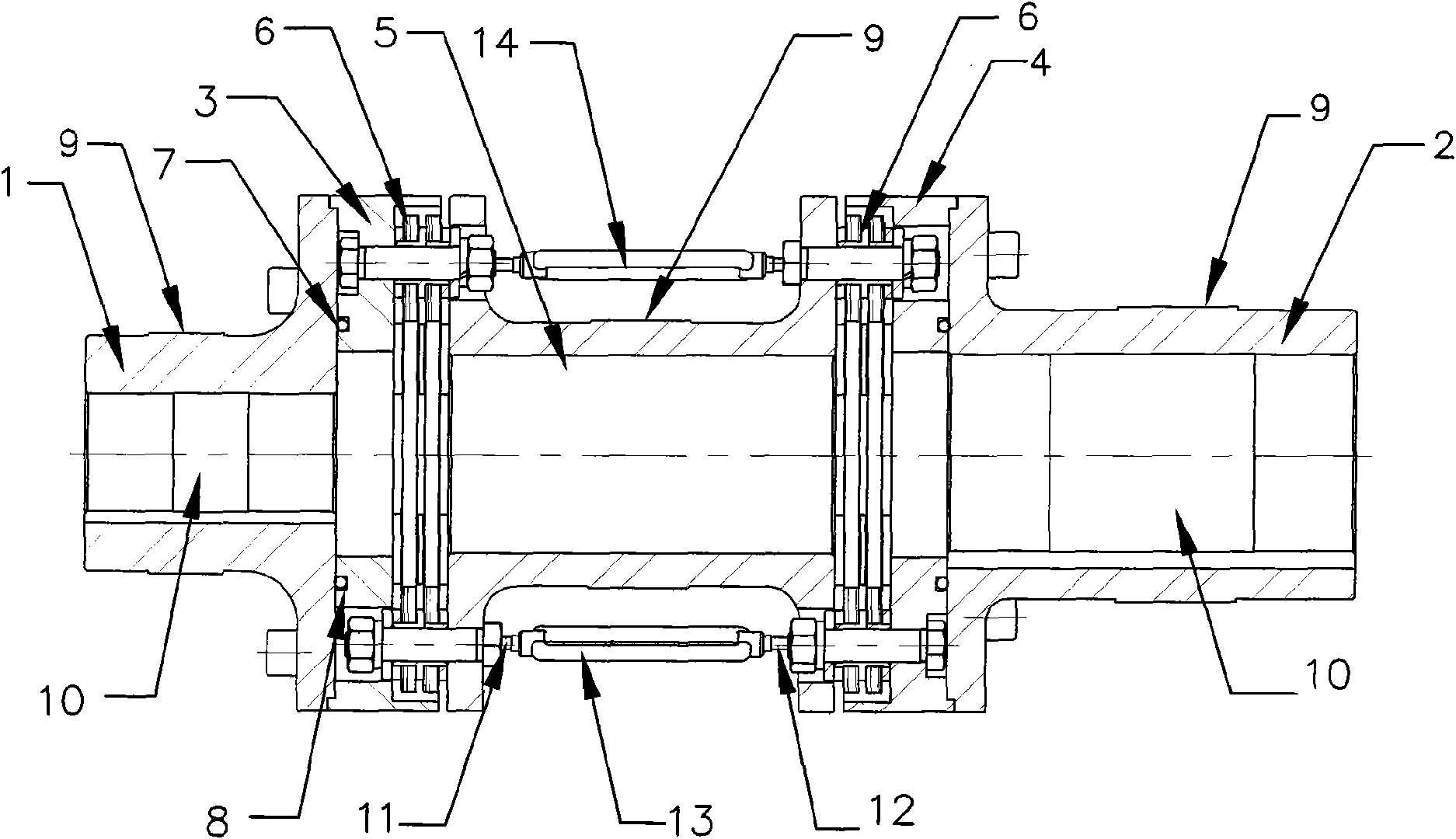

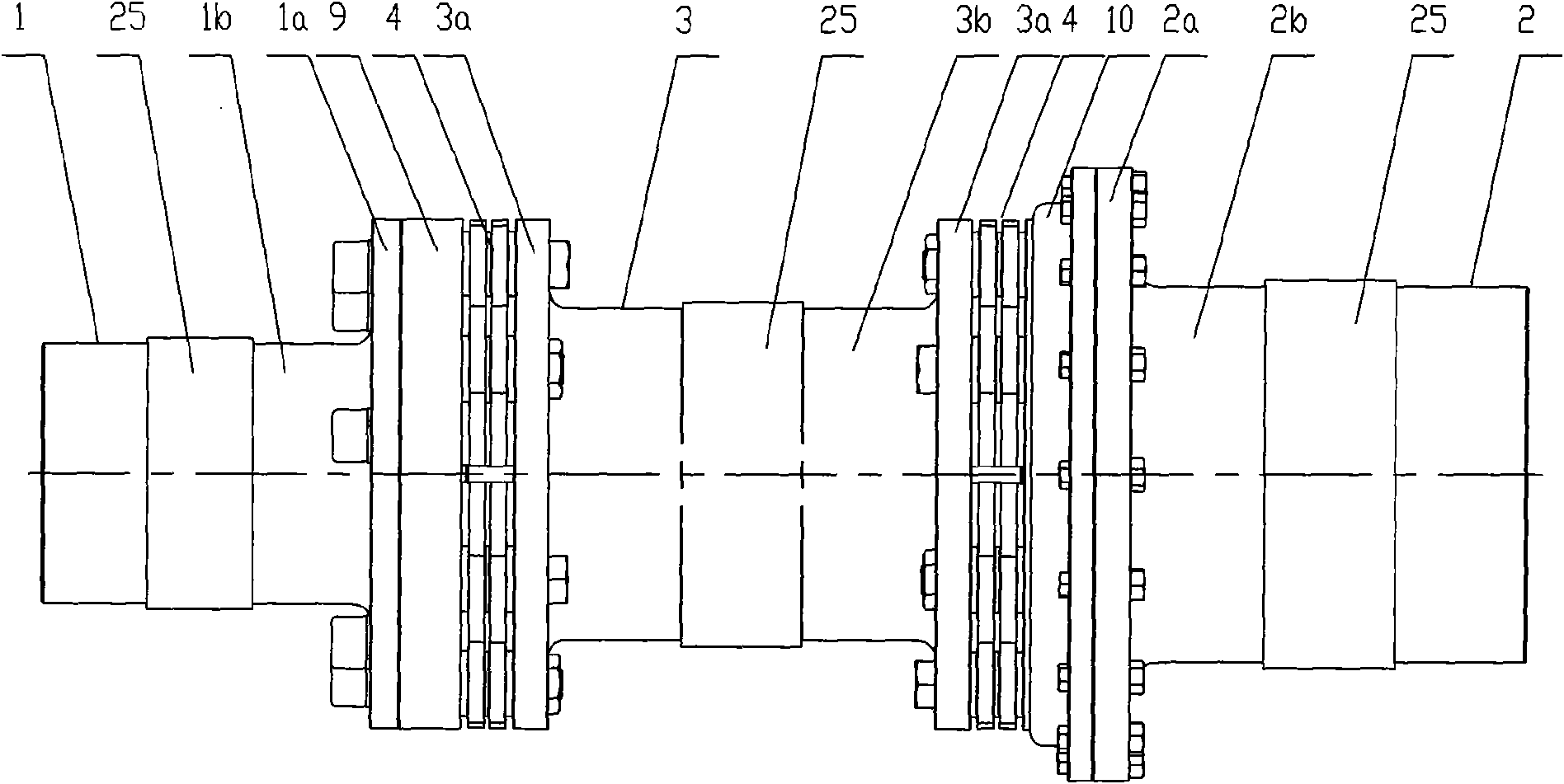

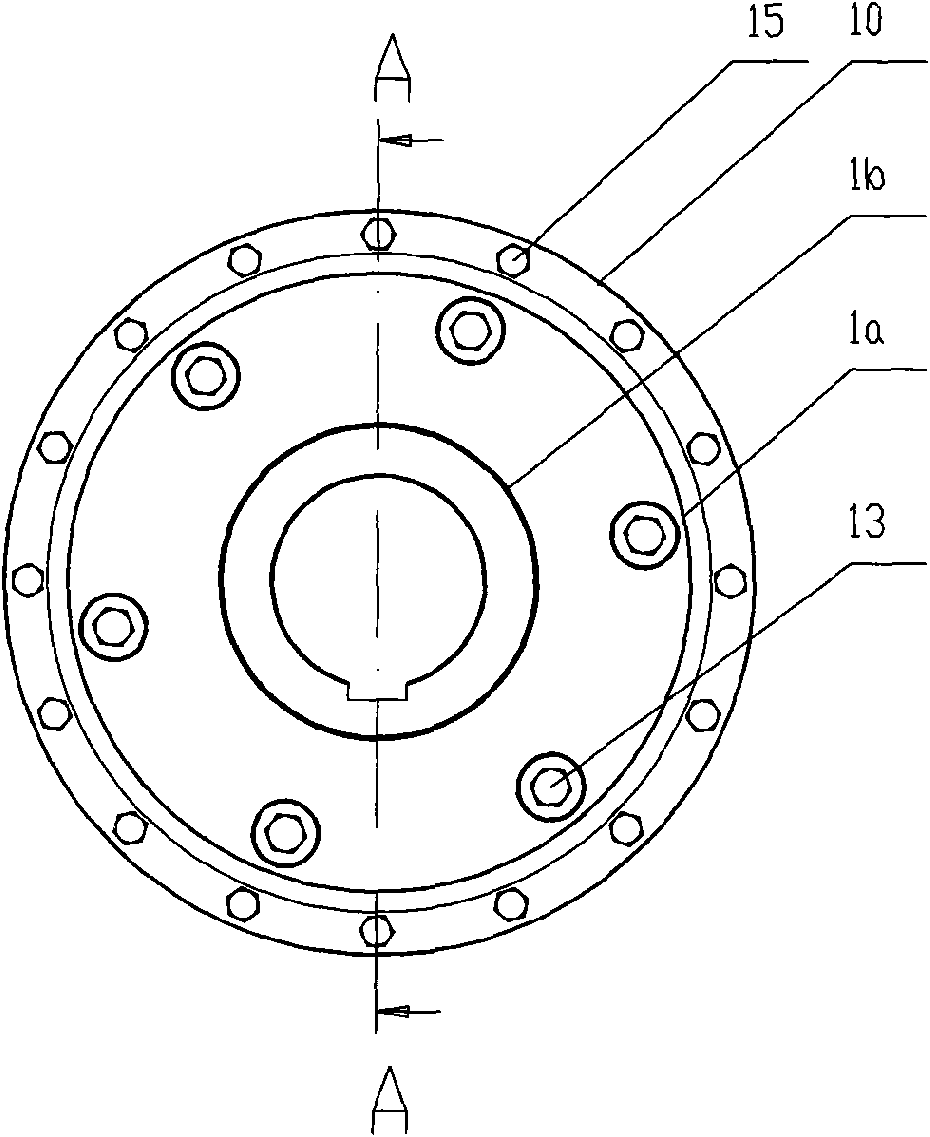

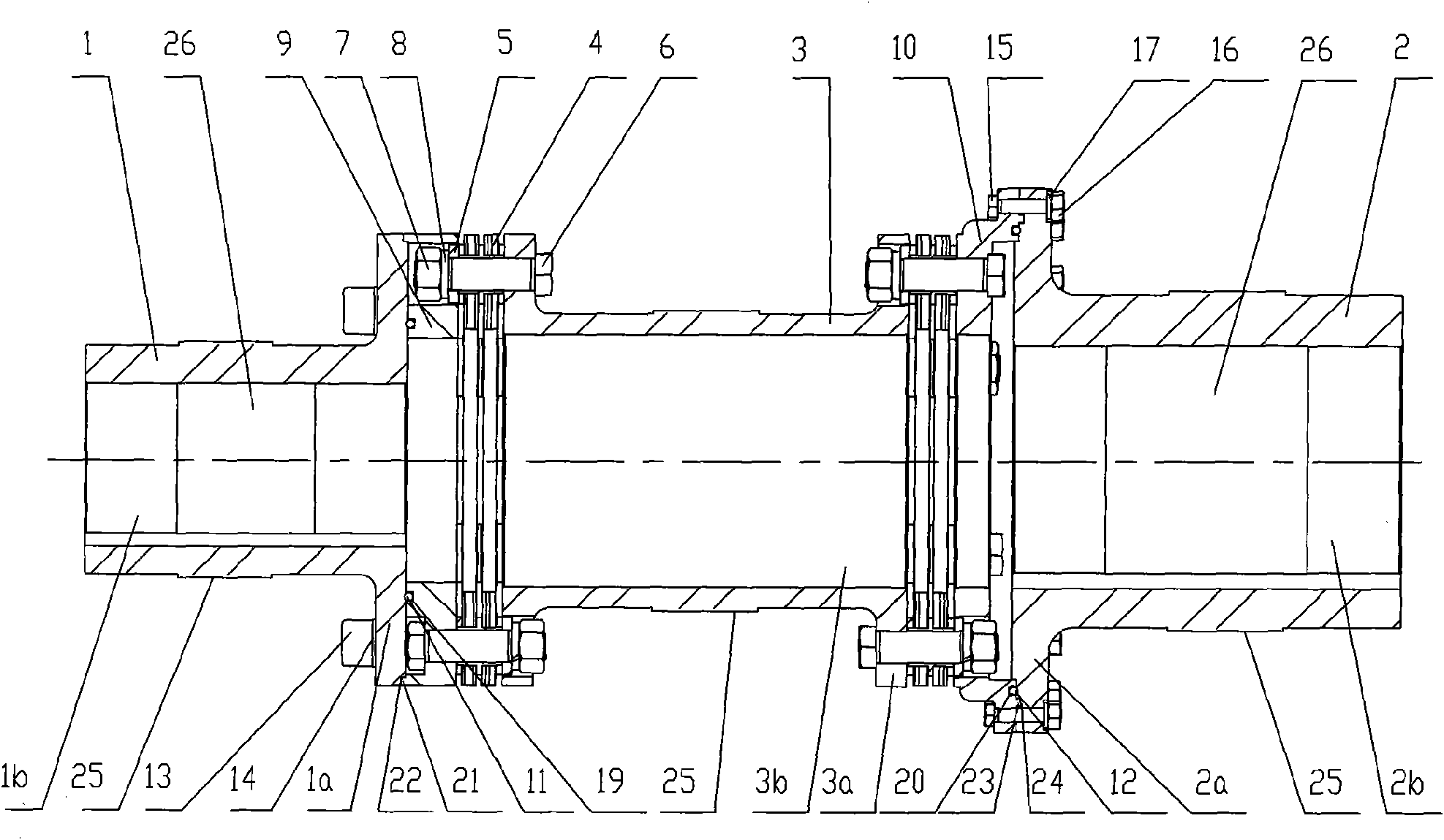

Actuation balance-free type large-torque flexible coupling

InactiveCN101629604AGuaranteed uptimeIncrease torqueYielding couplingCouplingArchitectural engineering

The invention relates to an actuation balance-free type super large torque flexible coupling with an intermediate section, which comprises two half-couplings, two butting discs and a diaphragm group and has improvements in also comprising the intermediate section, high-strength elastic rings and a tightening device, wherein the two butting discs and the two half-couplings are installed on both ends of the intermediate section through bolts and positioned by bayonets; the diaphragm group is laminated and installed among the butting discs and the intermediate section; the external side surfaces of the butting discs are provided with grooves in which the high-strength elastic rings are installed; the two half-couplings and the intermediate section are respectively provided with a circle of outward bulgy lug bosses; and the tightening device comprises two tightening bolts and a long nut, wherein one end of each tightening bolt is connected with each butting disc and the other end is screwed into the long nut. The actuation balance-free type super large torque flexible coupling with the intermediate section has the advantages of large power transfer torque, longer service life, wider configuration range and simple loading and unloading, thereby being suitable for fields of petroleum, chemical engineering, metallurgy, machinery, environmental protection, mining, shipping, aerospace, diversion engineering, nuclear power, military affairs, and the like.

Owner:李文聪

Method for improving ship handling efficiency of containers (or bulk cargo) and equipment thereof

InactiveCN101941510AEasy to movePrecise positioningCargo handling apparatusPassenger handling apparatusBulk cargoMechanical equipment

The invention discloses a method for improving handling efficiency of containers (or bulk cargo) and equipment thereof. The equipment is a floating pier with self-propulsion and continuous propulsion functions, wherein, the floating pier is arranged on a submarine locating platform, handling mechanical equipment carries out handling operation at one side by the sea, and the unloaded (loaded) containers (or the bulk cargo) are output or input by floating pier horizontal transportation equipment. The invention has the following advantages: 1. compared with the traditional handling mode, the handling efficiency is doubled; 2. dead-weight of the structure of the mechanical equipment is lowered on the existing basis, thus saving a great amount of investment cost; 3. infrastructure investment cost of ports and docks is greatly reduced; and 4. the floating pier is firmly bonded with the submarine locating platform without displacement, thus greatly improving safety performance, guaranteeing safety of the floating pier during the handling process, achieving the purpose of handling the containers (or the bulk cargo) from two sides of a ship at the same time, enhancing the handling efficiency, accelerating the ship turnover, and saving a great quantity of shore land of the ports and the docks and a great quantity of infrastructure cost of the docks.

Owner:刘德义

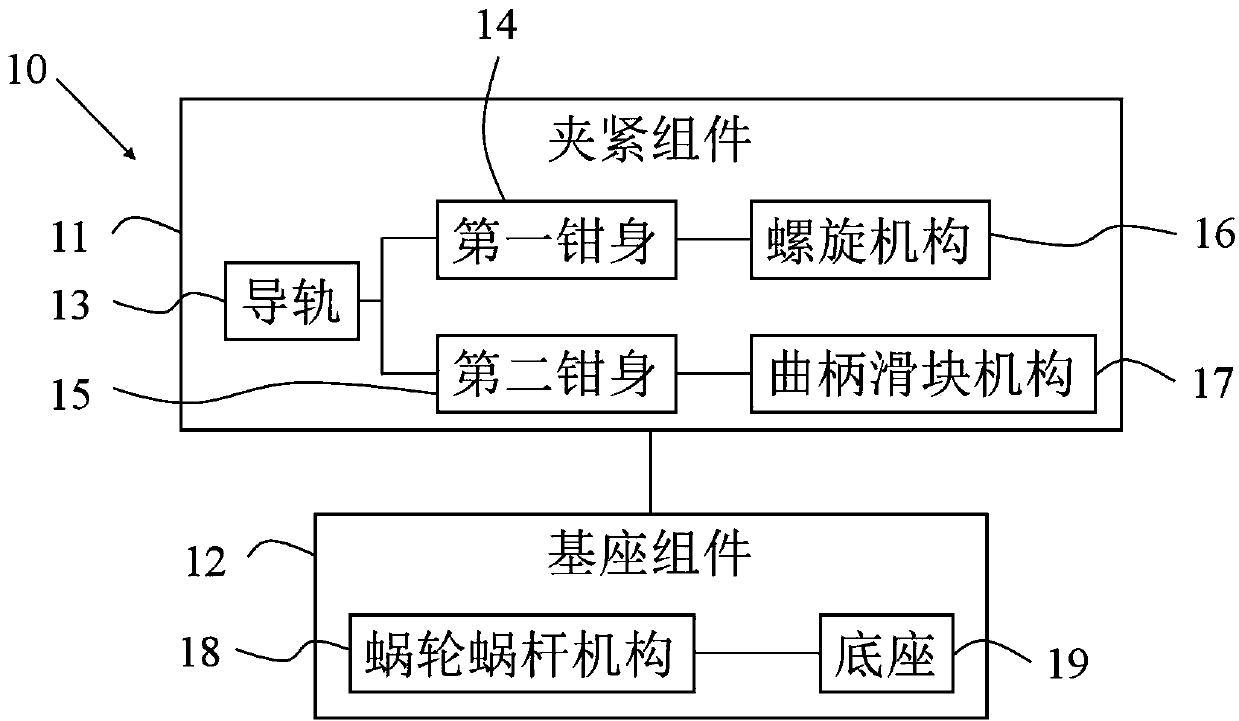

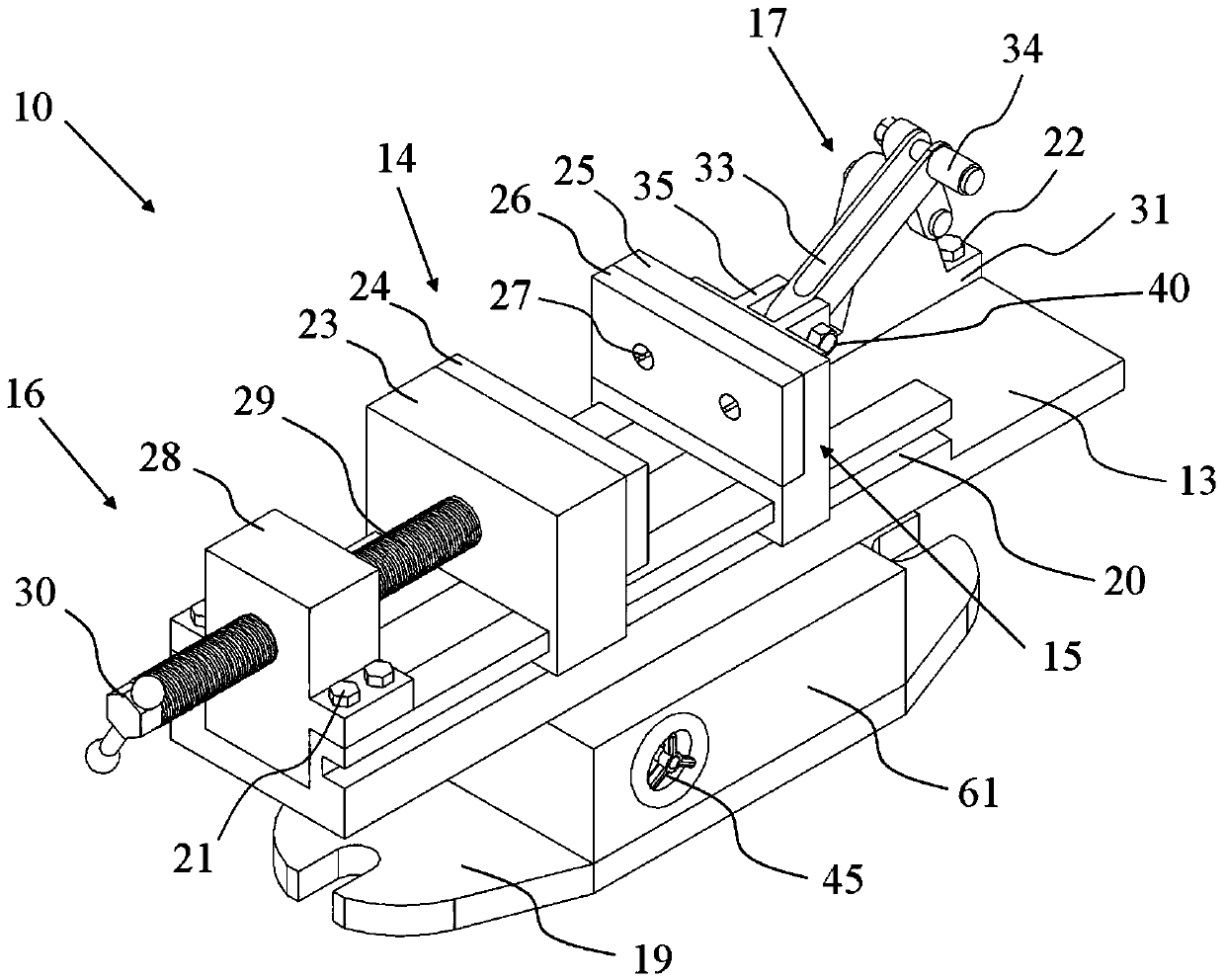

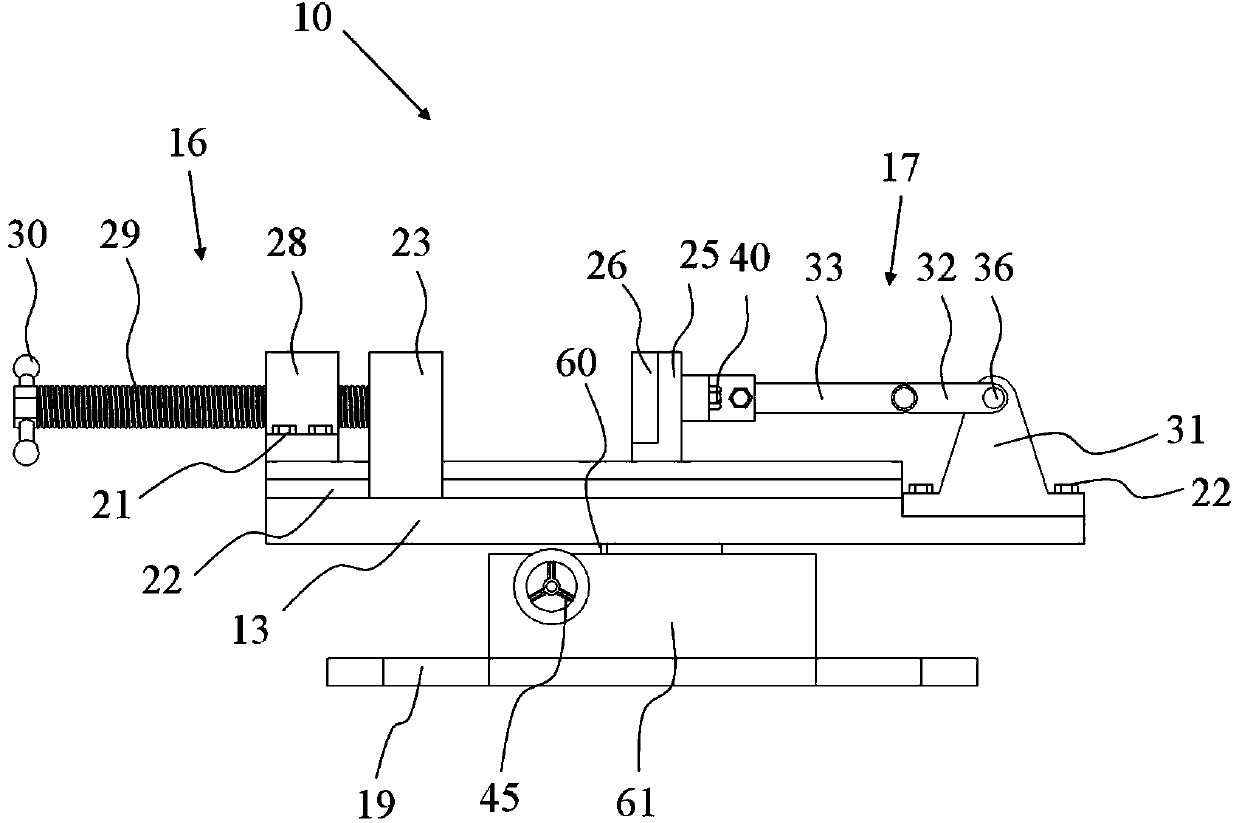

Vice

InactiveCN103991042ASave loading and unloading timeIncrease productivityVicesSlider crankMechanical engineering

The invention provides a vice which is used for clamping a workpiece. The vice is characterized by comprising a clamping assembly used for clamping the workpiece, and a base assembly used for installing the clamping assembly and driving the clamping assembly to rotate, wherein the clamping assembly comprises guide rails capable of being rotationally fixed to the base assembly, a first vice body, a second vice body, a spiral mechanism and a crank slider mechanism, the first vice body and the second vice body are installed on the guide rails and move back and forth along the guide rails, the spiral mechanism is installed at one end of the guide rails and abuts against the first vice body through rotation so as to make the first vice body move along the guide rails, the slider crank mechanism is installed at the other end of the guide rails and connected with the second vice body, and the second vice body is driven to move by the crank slider mechanism through a crank slider; the base assembly comprises a worm and gear mechanism used for installing the guide rails and driving the guide rails to rotate, and a base used for installing the worm and gear mechanism.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

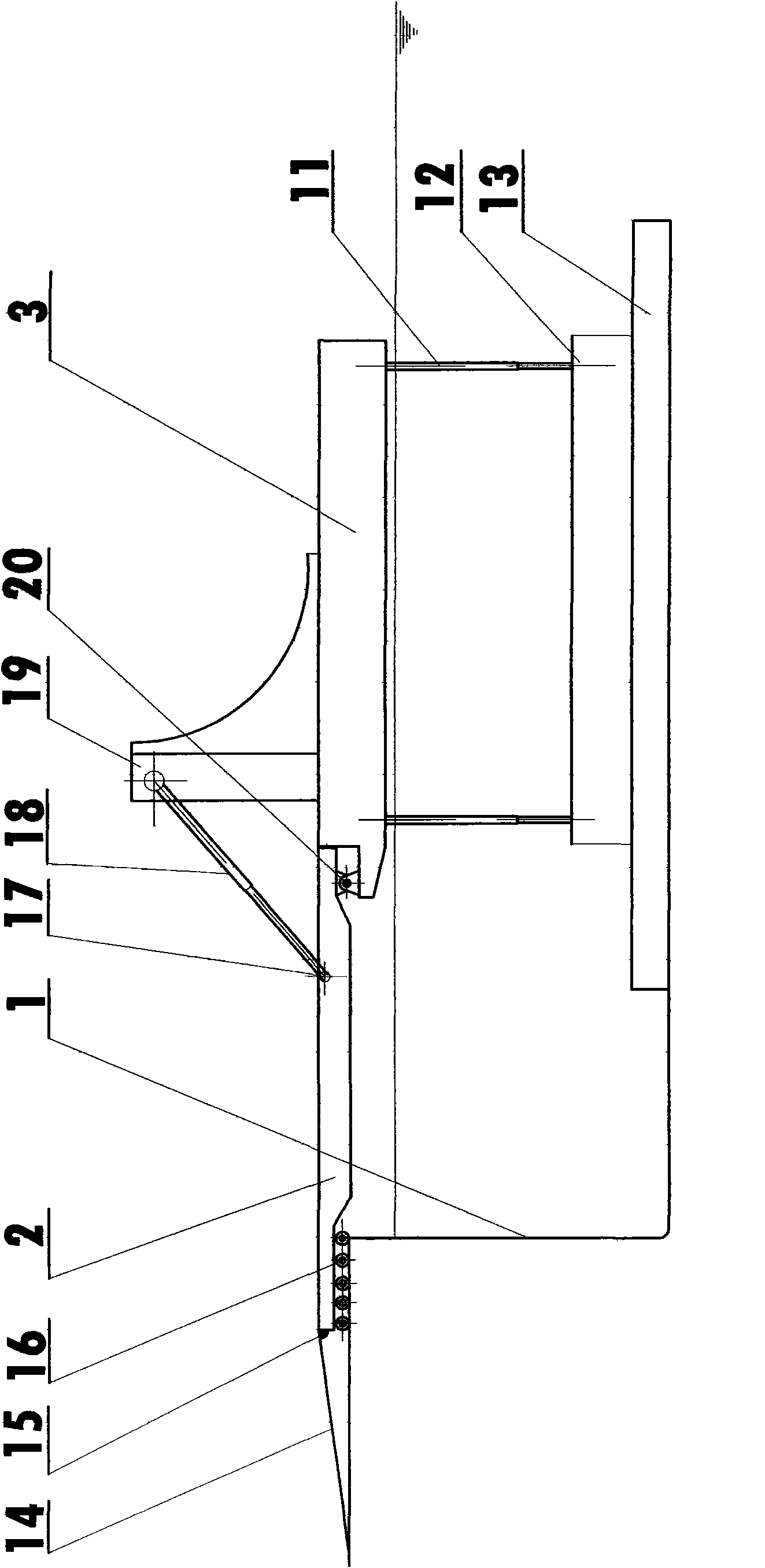

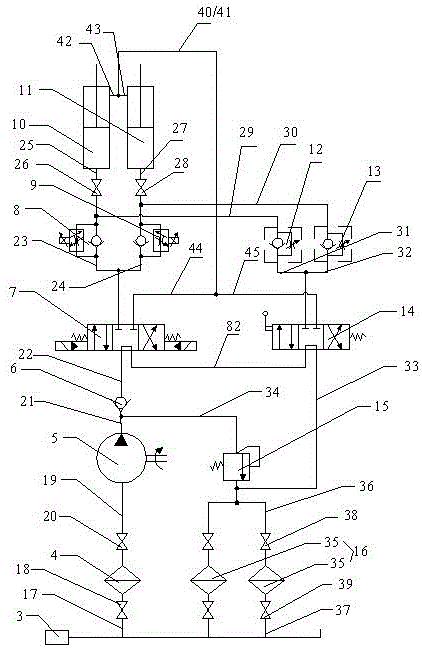

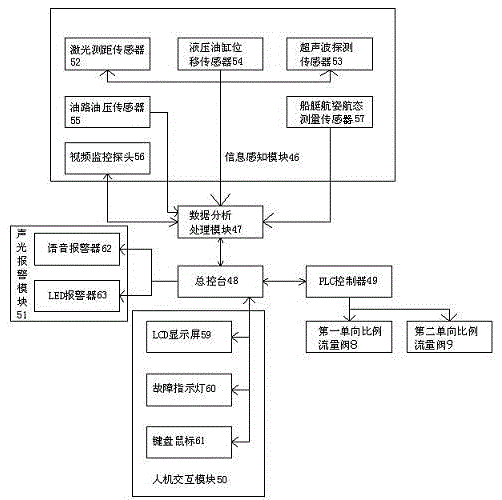

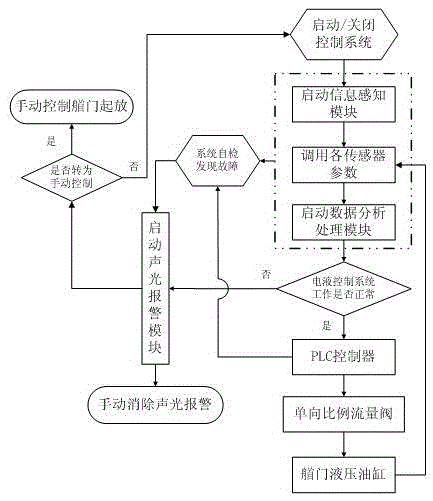

Raising and laying down sensing system of ship bow door

ActiveCN105649461AAvoid misalignmentImprove securityServomotorsPower-operated mechanismData acquisitionMultiple sensor

The invention relates to a raising and laying down sensing system of a ship bow door. The system comprises a hydraulic control system and a data acquisition and processing system; the hydraulic control system comprises an oil tank, an oil absorption filter, an oil pump, a one-way valve, an electro-hydraulic directional valve, a first one-way proportional flow valve, a second one-way proportional flow valve, a first double-action single-piston-rod oil cylinder, a second double-action single-piston-rod oil cylinder, a first one-way throttling valve, a second one-way throttling valve, a manual reversing valve, an overflow valve and an oil returning filter set; and the data acquisition and processing system comprises an information perceiving module, a data analysis and processing module, a master control table, a PLC, a man-machine interaction module and a sound-light alarm module. On the basis that the hydraulic control system is redesigned, control precision of bow door raising and laying down is improved through data measured by multiple sensors, and the aim that materials in a ship can be safely and rapidly unloaded and loaded is achieved.

Owner:中国人民解放军军事交通学院镇江校区

Actuation balance-free type single-reducing coupling

The invention relates to an actuation balance-free type single-reducing coupling which comprises two half-couplings, an intermediate section and a diaphragm group, wherein each of the two half-couplings is an axis connecting sleeve provided with a flange at one end; the intermediate section is an axis connecting sleeve provided with flanges at both ends; the external side of the flange at one end of the intermediate section is sequentially connected with the diaphragm group and a butting disc; the external side of the flange at the other end of the intermediate section is sequentially connected with the diaphragm group and a reducing disc; the two half-couplings are respectively connected with the butting disc and the reducing disc in a bayonet positioning mode; the axis connecting sleeves of the two half-couplings and the intermediate section are respectively provided with an outer lug boss; and the diaphragm group is laminated and produced in such a way that all elastic flakes are threaded and connected by double-faced rivets and hydraulically punched. The actuation balance-free type single-reducing coupling can meet precision requirements of 2.5 level dynamic balance without actuation balance at the rotating speed of 10000r / min or below, thereby omitting the working procedure of actuation balance and overcoming the defect of unprepossessing appearance caused by the drilling of the coupling.

Owner:李文聪

Gantry type multiple-spindle machining center

InactiveCN103722378ASave loading and unloading timeIncrease productivityOther manufacturing equipments/toolsLarge fixed membersNumerical controlSlide plate

The invention relates to a gantry type multiple-spindle machining center. A gantry type machining center frame is adopted for the machining center body. The gantry type multiple-spindle machining center is characterized in that X-direction sliding tables of a base of the machining center are formed by installing a plurality of numerical control servo sliding tables in parallel, and at least two sliding tables are used for installing parts to be machined; Y-direction sliding tables on a gantry can be moved between the several X-direction sliding tables in a numerical control servo mode according to the travel; Z-direction sliding tables are installed on the Y-direction sliding tables, and a plurality of spindles with automatic tool changing mechanisms are installed on sliding plates of the Z-direction sliding tables; a horizontally arranged tool magazine is adopted as the tool magazine for automatic tool changing. Machining can be carried out by the machining center through the multiple spindles at the same time, tools can be changed automatically and synchronously, workpieces can be loaded and unloaded in the machining process, and the production efficiency is high. The gantry type multiple-spindle machining center is widely applicable to mechanical cutting of medium and small parts.

Owner:林志贺

Hydraulic clamp of numerical control lathe

InactiveCN104308579ASimple structureLow costChucksPositioning apparatusCircular discNumerical control

The invention relates to a hydraulic clamp of a numerical control lathe. The hydraulic clamp comprises a body, a positioning lock, a lever, a connecting disc and a pull rod. The hydraulic clamp is characterized in that the body consists of a positioning platform and a support cylinder, wherein three slide support seats are uniformly distributed on the positioning platform, and are respectively provided with a slide pin, three through grooves are uniformly distributed in the support cylinder, the lever consists of a circular disc and three connecting rods, the three connecting rods are uniformly distributed on the circumference and are connected with hook-shaped press plates, the lever is connected with the pull rod by a connecting bolt, the circular disc and the connecting rods of the lever are respectively and glidingly connected with the support cylinder and the through grooves, and the body is tightened on the connecting disc by screws. The hydraulic clamp has the advantages that the structure is simple, the manufacturing is easy, and the cost is low; a spherical bushing is arranged in a connecting hole of the lever, and the lever can rotate around the spherical bushing in the vertical and circumferential directions; when the clamp is used for parts of shaped casings, the uniformity and reliability of the pressing force for pressing the parts are good, the installation and detachment of the parts are convenient, the installation and detachment time of the parts is shortened, the processing efficiency and processing quality of the parts are improved, and the economy is good.

Owner:中国航发湖南南方宇航工业有限公司

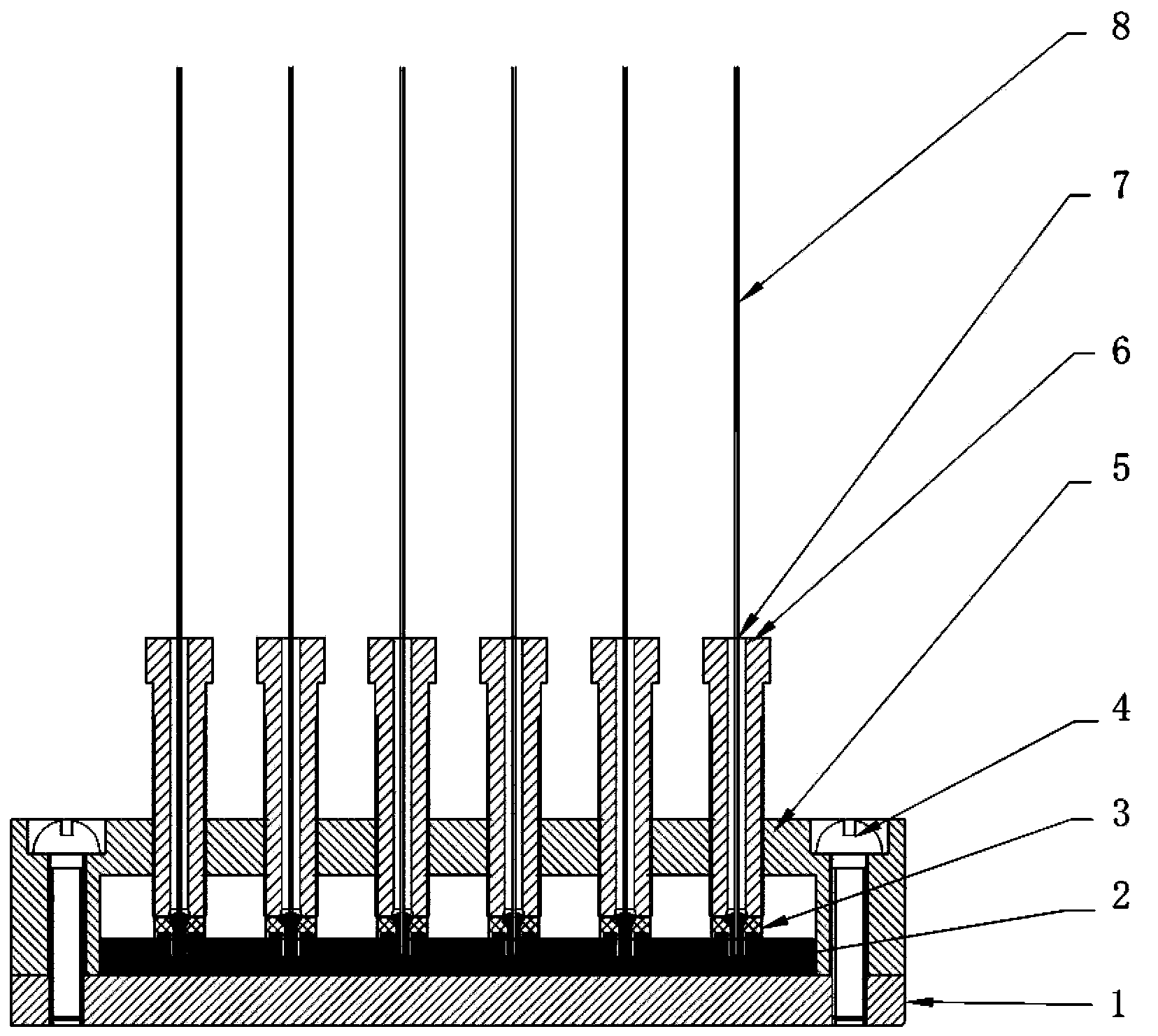

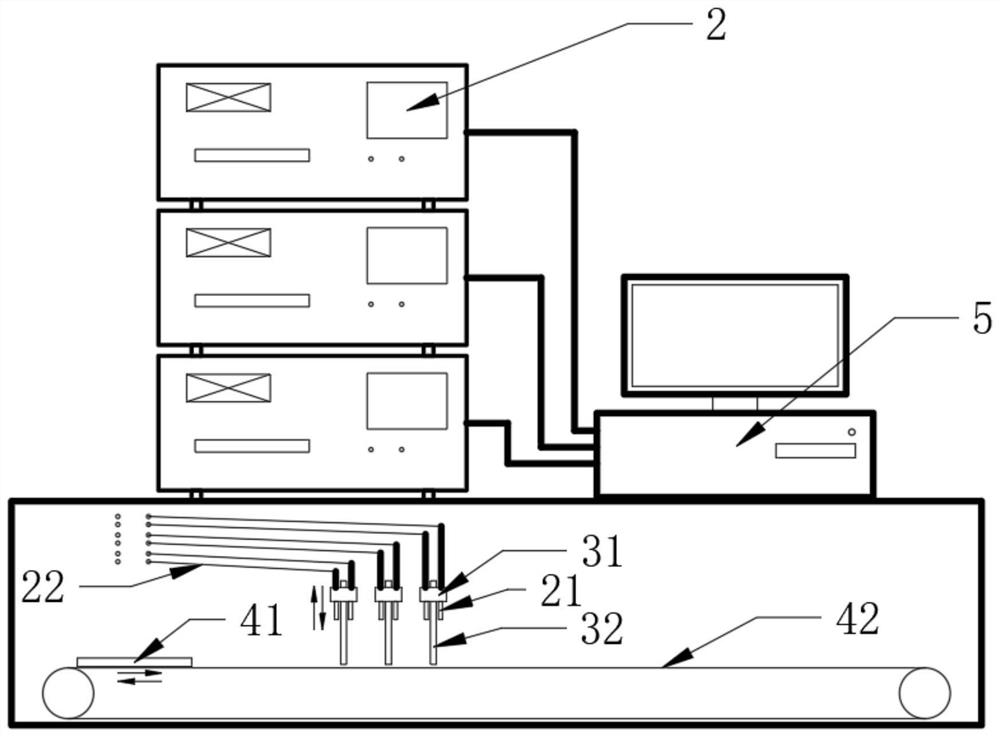

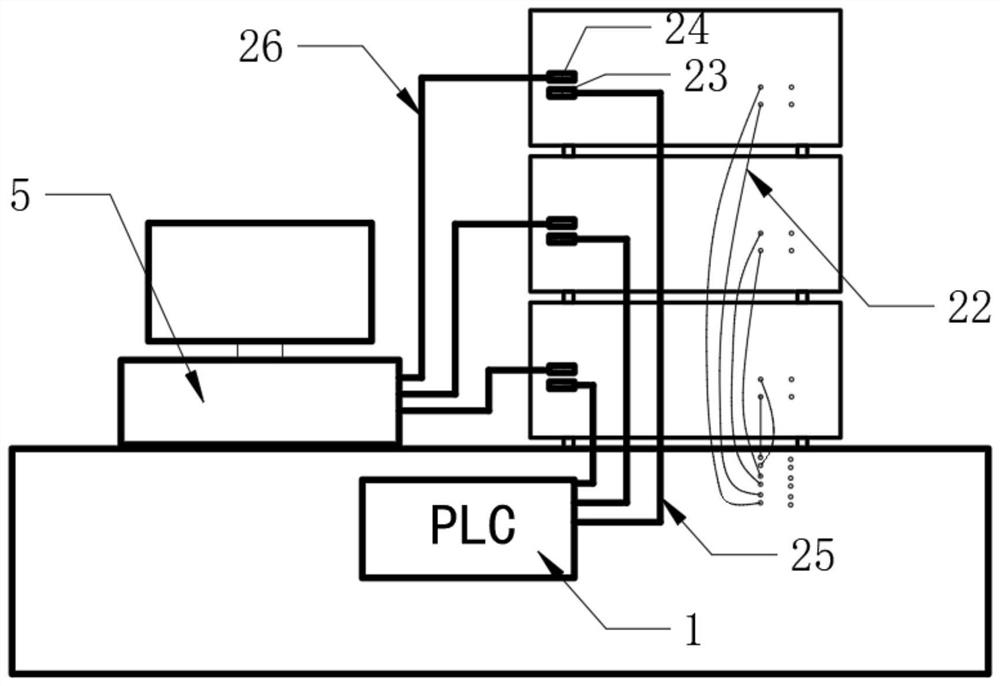

Semiconductor device testing device

PendingCN111638438AImprove test efficiencyImplement automated testingElectrical measurement instrument detailsIndividual semiconductor device testingDevice materialElectrical connection

The invention discloses a semiconductor device testing device in the technical field of semiconductor devices. The testing device comprises a testing machine which is used for testing the performanceof a semiconductor device; a probe fixing unit which is used for fixing a probe of the testing machine and driving the probe to move in the vertical direction; a bearing unit which is located under the probe fixing unit, and used for bearing the semiconductor device and driving the semiconductor device to move in the horizontal direction; and a PLC which is electrically connected with the testingmachine, the probe fixing unit and the bearing unit and controls the testing machine, the probe fixing unit and the bearing unit to work. According to the semiconductor device testing device, the testing machine is controlled by the PLC to test the semiconductor devices passing through the lower parts of the probes one by one; automatic testing of multiple packaged semiconductor devices on a largescale is achieved, the assembling and disassembling time during testing of the semiconductor devices is saved, the testing efficiency of the semiconductor devices on a large scale is improved, the labor cost is reduced, and the company operation cost is reduced.

Owner:YANGZHOU HY TECH DEV

Multidirectional shot blasting device stable in structure

PendingCN107186628AShot blastingShot blasting is fast and efficientAbrasive machine appurtenancesAbrasive blasting machinesHydraulic cylinderFixed frame

The invention provides a multidirectional shot blasting device stable in structure. The multidirectional shot blasting device comprises a sliding block and a hydraulic cylinder arranged below the sliding block. A fixed plate is arranged at the top of the hydraulic cylinder. An electromotor is arranged on the fixed plate. A center shaft penetrates the fixed plate to be connected with the output end of the electromotor. A center disc is arranged on the center shaft. The side face of the center disc stretches outwards to form multiple circumferentially-distributed telescopic rods. Symmetric sliding rings are rotationally connected to the positions, arranged on the two sides of the center disc, on the center shaft. Struts are hinged to the telescopic rods through pin shafts. Multiple fixed frames are arranged on the struts. The multidirectional shot blasting device stable in structure is simple in structure and is designed for complex and irregular automobile castings; more workpieces can be clamped on the basis that the workpieces do not influence on another during shot blasting; it can be guaranteed that faces of more angles can be subjected to shot blasting; product quality can be improved; shot blasting efficiency is higher; and production cost is reduced.

Owner:中联精工(天津)有限公司

Internal thread tapper and tapping method thereof

ActiveCN104057161ASimple structureEasy to manufactureThread cutting auxillary apparatusEngineeringUltimate tensile strength

The invention relates to an internal thread tapper and a tapping method thereof. The internal thread tapper comprises a vertical driller, a three-jaw chuck, a guide push rod, a screw tap toggle and a screw tap. The internal thread tapper has the key points that the middle of the guide push rod is provided with a Morse cone pin, and both ends of the guide push rod are respectively provided with a cylindrical stop pin; the lower end of the Morse cone pin is provided with a cylindrical taper pin; the Morse cone pin and the cylindrical stop pin are fixedly connected with the guide push rod; a part is arranged on the three-jaw chuck; the guide push rod and the screw tap are driven to rotate in sequence by the main shaft of the vertical driller to perform tapping on the part. The tapper disclosed by the invention is simple in structure, easy to manufacture and low in cost; the screw tap is guided by adopting the guide push rod to perform internal thread tapping on the part on the vertical driller; the part is convenient to assemble and disassemble, the process is simple, the operation is easy, and the positioning accuracy is high, so that the assembly and disassembly time of the part is shortened, the labor strength of a worker and the tool loss are reduced, the production efficiency is improved, the production cost is reduced, and the processed part is stable in quality and high in reliability.

Owner:HUNAN NANFANG AVIATION HIGH ACCURATE DRIVE

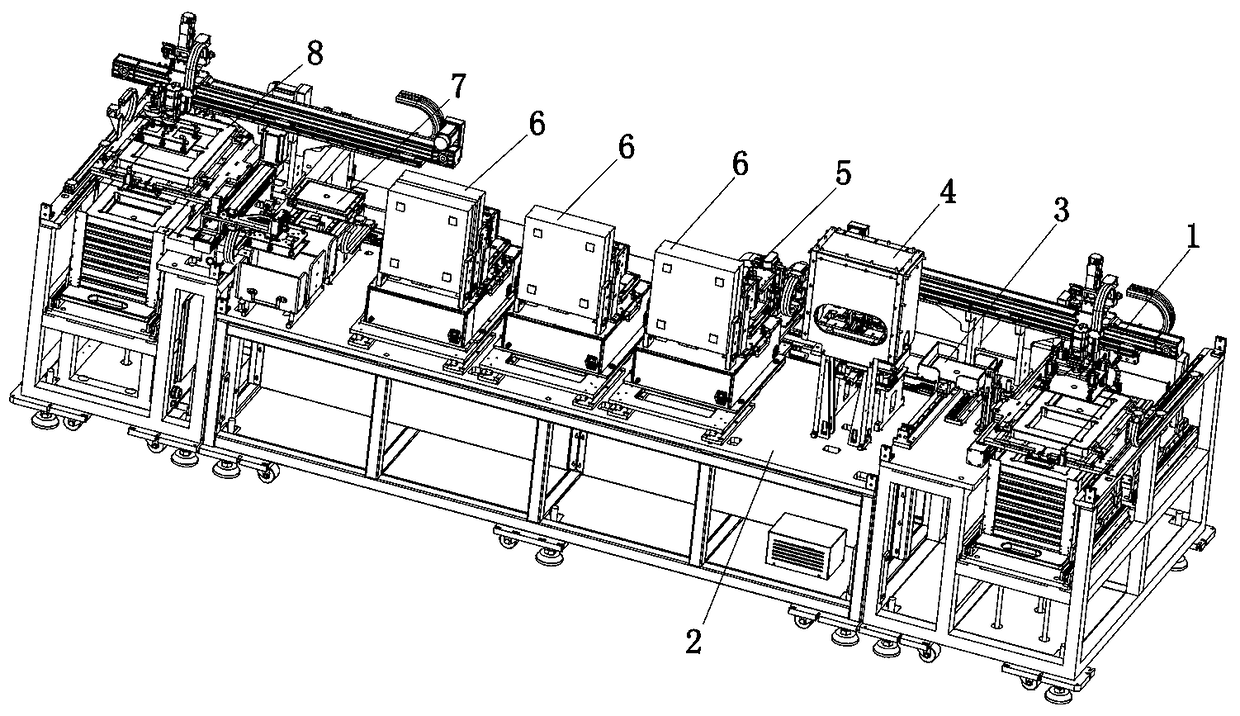

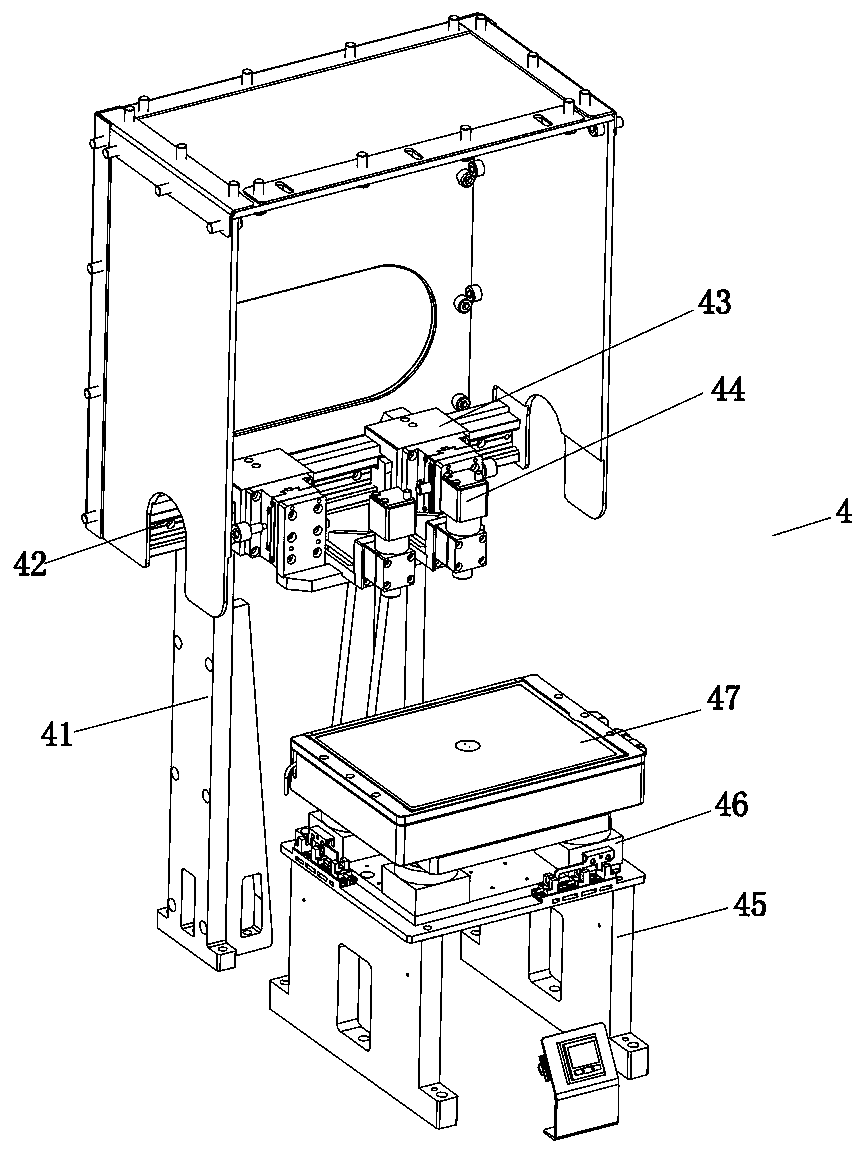

Double-feeding vacuum fitting production line and fitting process thereof

PendingCN109353106AImprove bonding efficiencyImprove time utilizationLamination ancillary operationsLaminationManipulatorEngineering

The invention discloses a double-feeding vacuum fitting production line and a fitting process thereof. The double-feeding vacuum fitting production line comprises a pre-fitting portion and a vacuum fitting portion which are in parallel arrangement, a glass sheet and a TP film are mutually fitted to an integral filmed glass sheet on the pre-fitting portion, and the filmed glass sheet is vacuum fitted on the vacuum fitting portion; the pre-fitting portion comprises a glass sheet feeding mechanism, a fitting manipulator, a TP film feeding platform and a pre-fitting platform; the vacuum fitting portion is provided with at least two vacuum fitting workstations parallelly and comprises a sliding feeding platform, a feeding manipulator, a vacuum fitting mechanism and a discharging manipulator. Multiple vacuum fitting workstations are adopted, so that fitting efficiency is improved effectively, and individual clamping and fixing of a film and the glass sheet are not needed; positioning correction is not needed during vacuum fitting, so that requirements on accuracy during vacuum fitting are lowered and production cost are lowered; vacuum fitting time period is utilized to complete pre-fitting and material conveying, so that time utilization rate is increased, and improving of whole line production capacity is facilitated.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

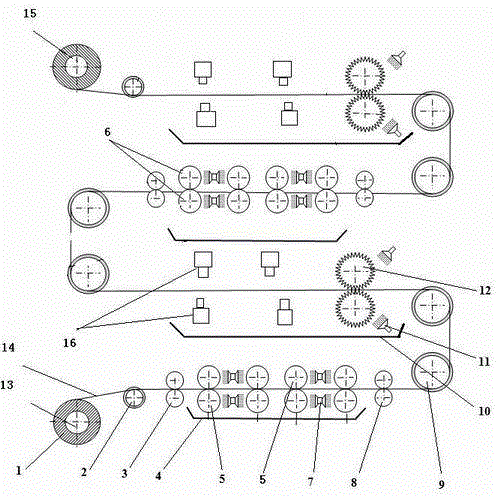

Polishing machine for chemically-mechanically polishing ultrathin flexible display substrate

InactiveCN104924189AUnlimited lengthSave loading and unloading timePolishing machinesEngineeringFlexible display

The invention discloses a polishing machine for chemically-mechanically polishing an ultrathin flexible display substrate. The technical scheme mainly includes that a horizontal roller is arranged behind an unwinding roller, a rear driving wheel device is arranged behind the horizontal roller, a polishing roller mechanism is arranged behind the rear driving wheel device, a cleaning liquid collecting device is arranged below the polishing roller mechanism, polishing liquid spraying devices are arranged in the front of a polishing roller and between rollers of the polishing roller mechanism, a front driving wheel device is arranged behind the polishing roller mechanism, s guide wheel is arranged behind the front driving wheel device, a cleaning mechanism is arranged behind the guide wheel, an air spraying device is arranged behind the cleaning mechanism, the cleaning liquid collecting device is arranged below the air spraying device, and a winding roller is arranged behind the air spraying device. The polishing machine has the advantages of simple structure and low cost.

Owner:HENAN INST OF SCI & TECH

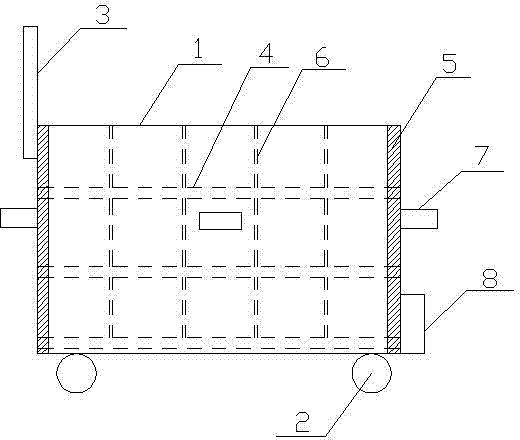

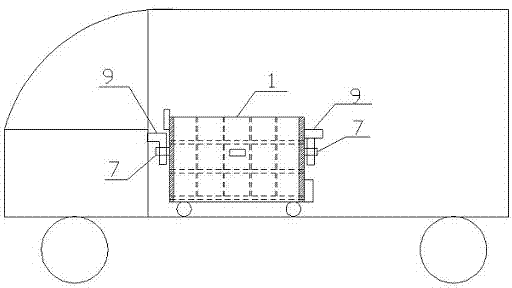

Automobile casting transportation device

InactiveCN104494657ASave loading and unloading timeImprove transportation efficiencyHand carts with multiple axesProper timeTruck

The invention discloses an automobile casting transportation device. The vehicle casting transportation device comprises a vehicle body, rollers which are arranged on the lower part of the vehicle body, a handle which is arranged on the vehicle body, storage plates which are arranged in the vehicle body and provided with chutes with baffle plates, wherein automobile castings are placed in the baffle plates, the periphery of the baffle plate is provided with a buffer cotton, locking blocks are arranged on the outer sides of the vehicle body, a counting plate is arranged on the vehicle and used for counting the number of the castings in the vehicle body. A transporter is directly arranged in a truck and transported, the workers' loading and unloading time is saved, the transport efficiency of the castings is greatly increased, the fixation of the locking blocks and locking rings is arranged to reduce the collision of the castings, and the baffle plates can be combined and adjusted at the proper time on the chutes according to the different castings, and the collision of the castings is reduced to the maximum limit. The structure of the transportation device is simple, the loading and unloading time is saved, and the transportation efficiency is greatly increased.

Owner:WUHU FUMA AUTO SPARE PARTS

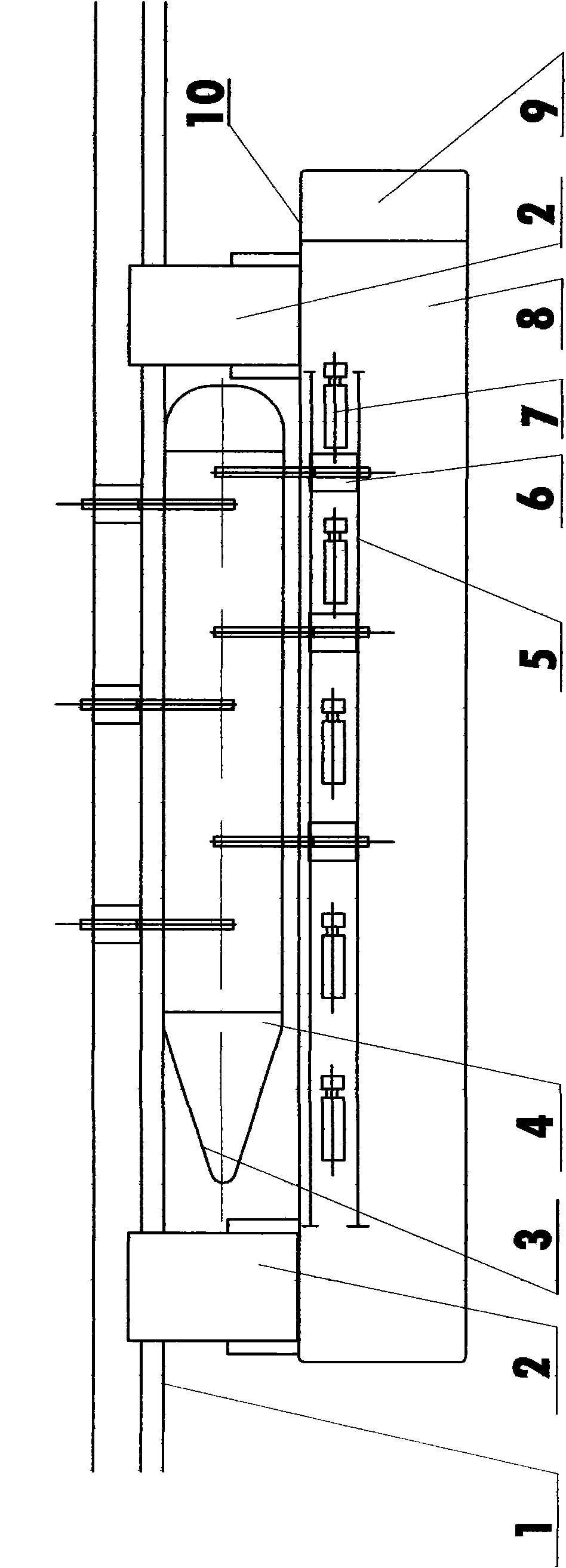

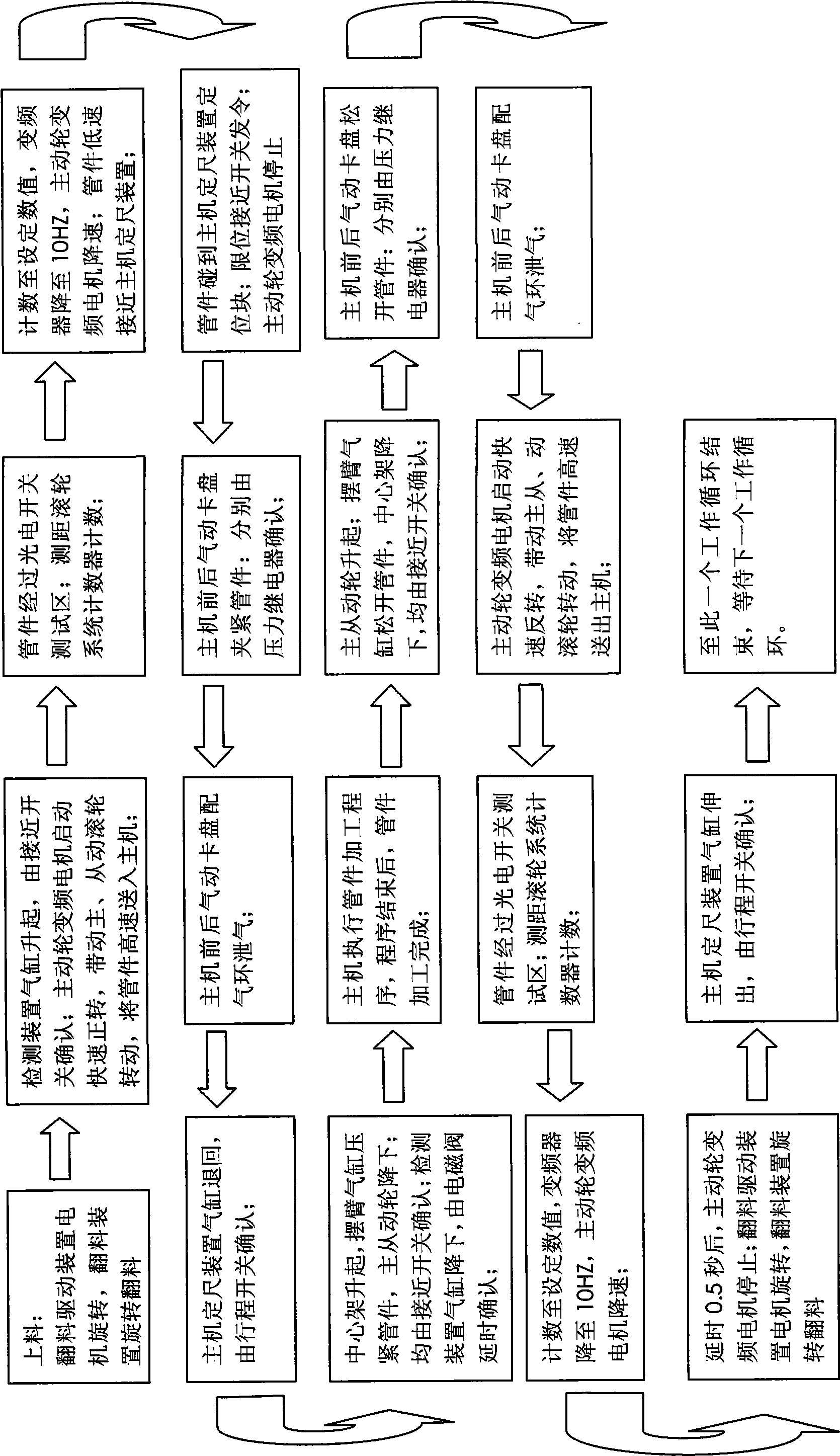

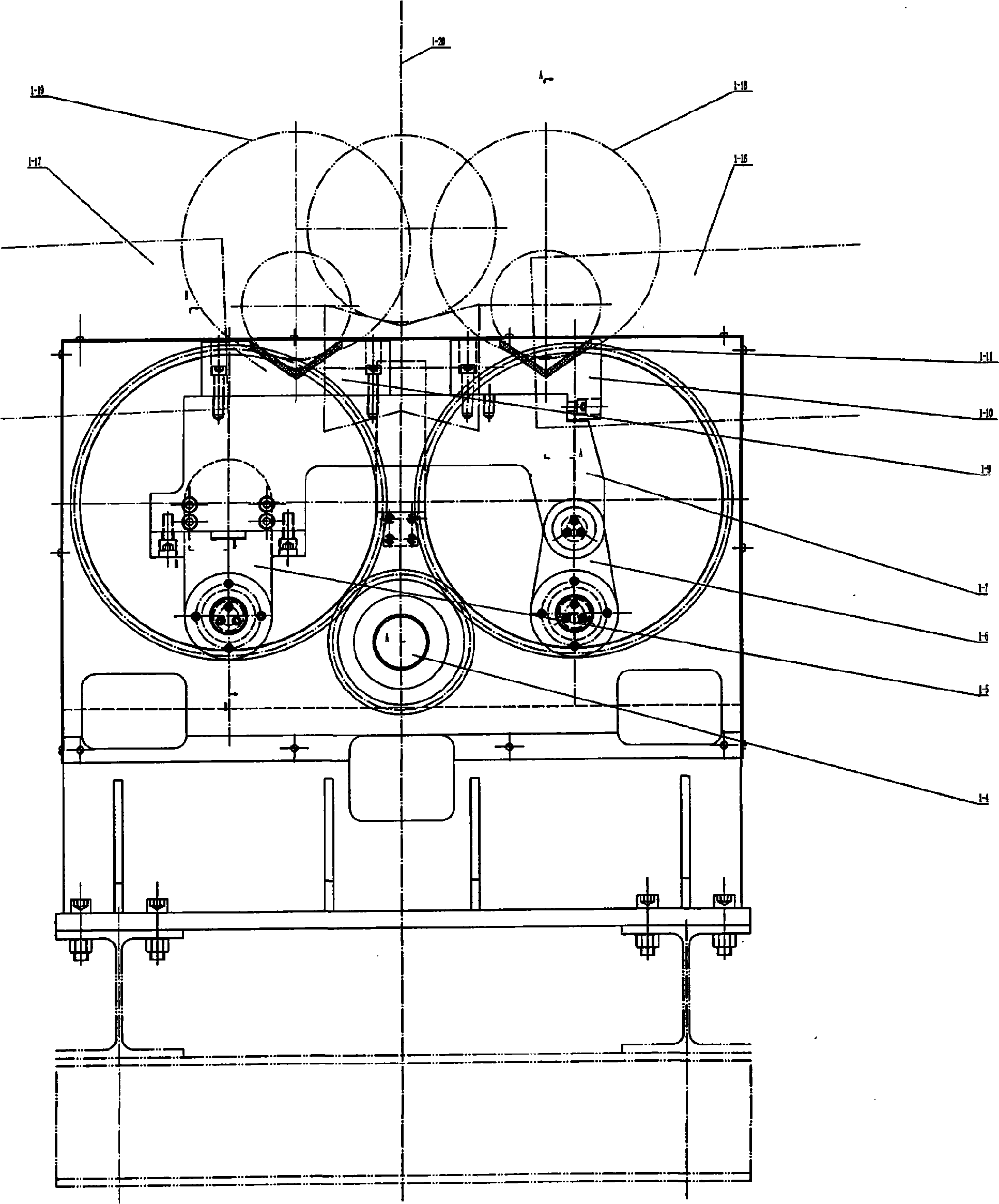

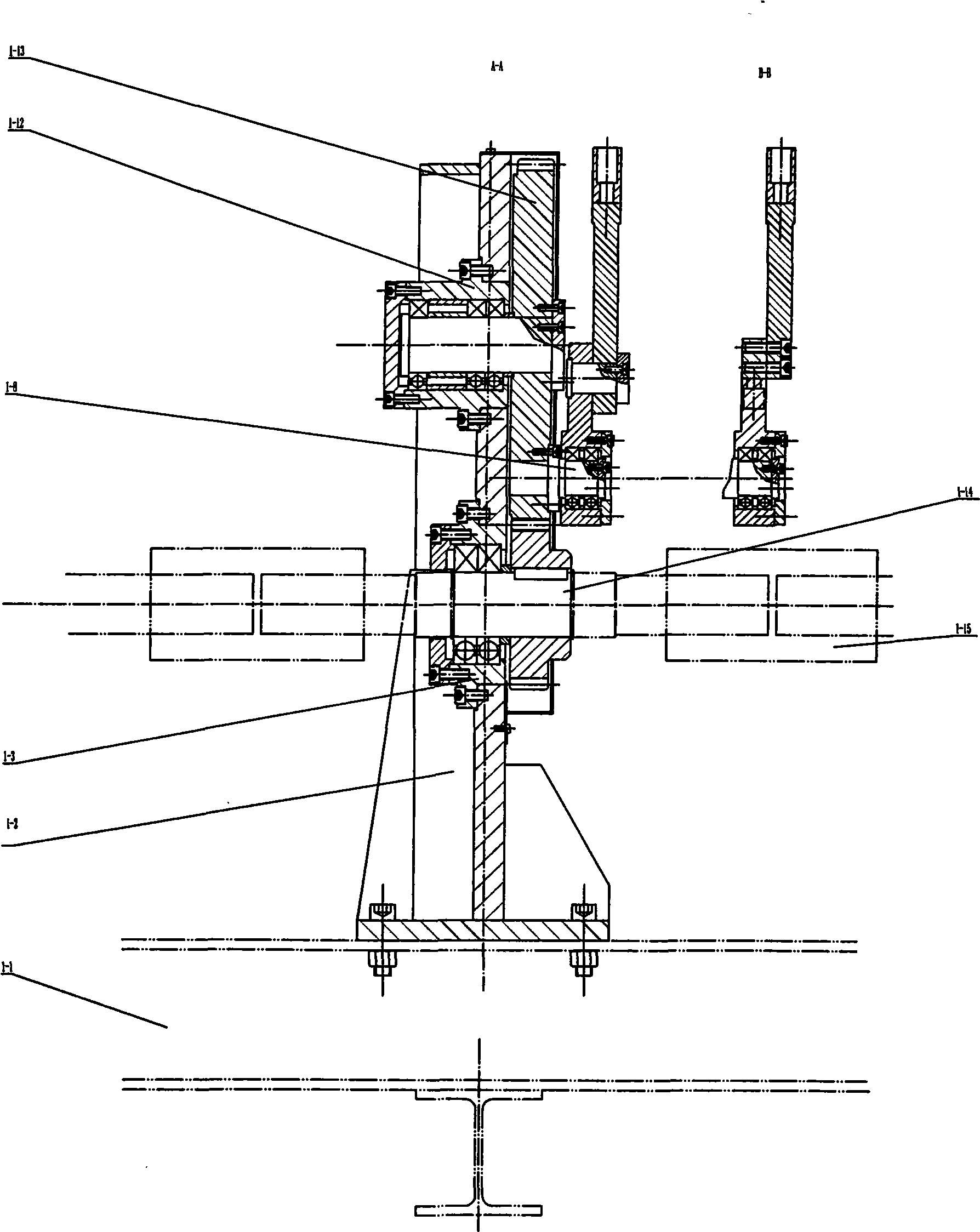

Automatic oil pipe conveying appliance

ActiveCN101518828ASave loading and unloading timeImprove processing efficiencyAutomatic conveying/guiding stockMechanical ProcessesEngineering

The invention belongs to the technical field of mechanical process and relates to machine tool auxiliary equipment, in particular to an automatic oil pipe conveying appliance. The appliance comprises a walking beam device part, a center beam device part, a driving wheel device part, a driven wheel device part and a detecting device part; the five parts are combined to realize that parts with long pipes automatically churn, feed and discharge, enter at a high speed from the rear end of a main shaft of a machine tool when feeding, rapidly reduce the speed when approaching to a locating position and stop when a switch is triggered; the parts with long pipes withdraw from the main shaft of the machine tool at a high speed when discharging, and rapidly reduce the speed and stop when approaching to the churning position; and when rotating, a workpiece performs functions of rotation support, clamping roller floating compaction, blockage, and the like to the parts suspending out of the main shaft of the machine tool.

Owner:宁夏新瑞长城机床有限公司

Transport cargo tank

InactiveCN106515540ASave loading and unloading timeImprove handling efficiencyTransportation itemsVehicle with loading rampWaste management

Owner:重庆首顺货厢制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com