Polishing machine for chemically-mechanically polishing ultrathin flexible display substrate

A flexible display and chemical mechanical technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., to achieve the effects of easy industrialization and popularization, high polishing efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

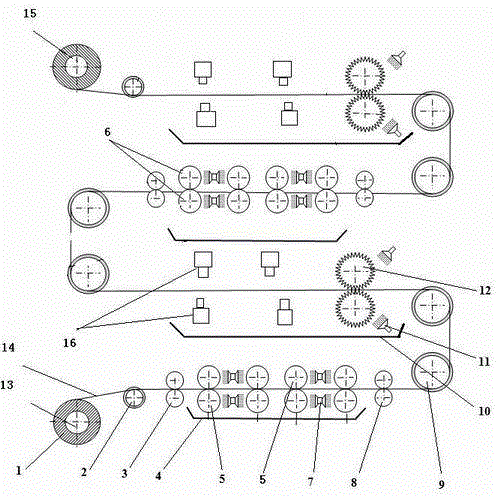

[0012] Describe embodiment in detail in conjunction with accompanying drawing,

[0013] A polishing machine for chemical mechanical polishing of ultra-thin flexible display substrates, which includes an unwinding roller 1, a winding roller 15, a horizontal roller 2, polishing roller mechanisms 5, 6, a cleaning mechanism 11, and a polishing liquid spraying device 7 1. Cleaning liquid collecting device 4, the rear of the unwinding roller is provided with a horizontal roller, the rear of the horizontal roller is provided with a rear driving wheel device 3, the rear of the rear driving wheel device is provided with a polishing roller mechanism 5, and the bottom of the polishing roller mechanism is provided with a cleaning roller mechanism. A liquid collecting device, a polishing liquid spraying device is arranged in front of the polishing roller and between the rollers of the polishing roller mechanism, a front driving wheel device 8 is arranged at the rear of the polishing roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com