Pressure resisting type air pipe air leakage preventing structure of ventilation air conditioner system and air pipe joint machining method

An air-leakage-proof structure, air-conditioning system technology, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc., can solve unclear cognition, lack of thorough theoretical analysis of air leakage mechanism, unclear cognition of main areas, etc problem, to achieve the effect of simple processing, low input cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

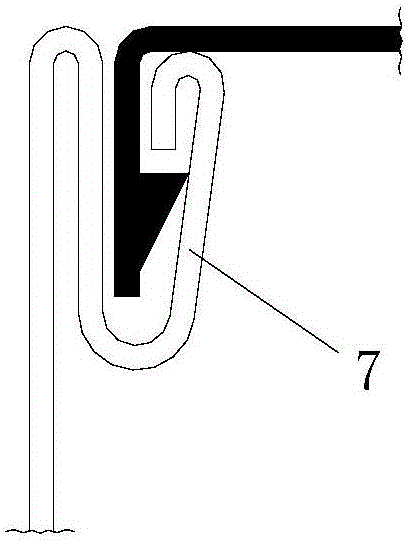

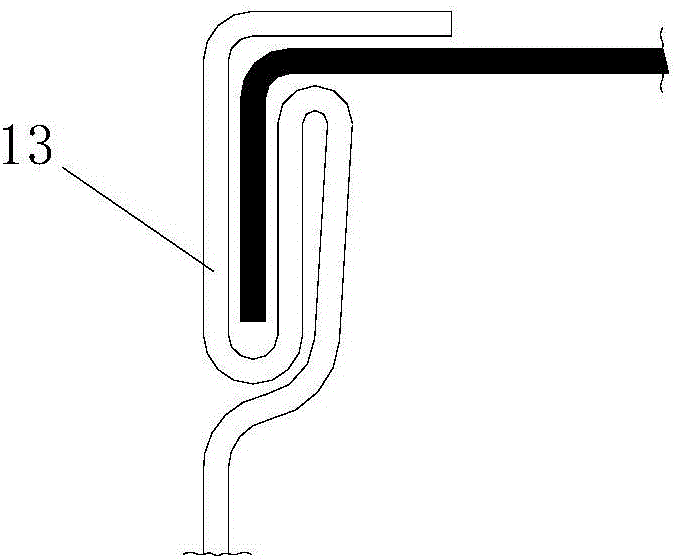

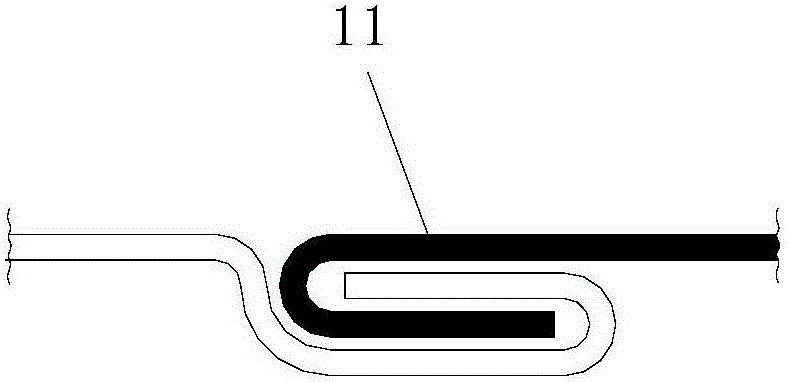

[0195] Such as Figure 5-2 with Figure 6-2 As shown, in this embodiment, the pressure-resistant metal air duct anti-leakage structure used for the ventilation and air-conditioning system is different from Embodiment 1. The two flange edges 2 of the angle steel flange are fixed on The air pipe section 1 or the right angle steel outside the connecting end of the connecting pipe fitting, and the connecting end of the air pipe pipe section 1 or the connecting pipe fitting is provided with a flange 4 fixed inside the right angle steel. The folding edge 4 is arranged parallel to the clamping strip 3-1 of the T-shaped sealing strip, and the clamping strip 3-1 is fastened and clamped between the folding edges 4 on the inner sides of the two flanges 2.

[0196] During actual installation, one right-angle side of the right-angle steel is fixed on the duct section 1 or the connecting pipe fitting, and the other right-angle side is arranged parallel to the clamping strip 3-1 of the T-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com