Workpiece clamping and driving device of numerical-control camshaft grinding machine

A driving device and camshaft technology, which is applied in the direction of grinding driving device, grinding workpiece support, grinding machine tool parts, etc., can solve the problems of affecting the accuracy of the camshaft, increasing the error of the camshaft, affecting the work efficiency, etc., and achieving improvement The effects of processing efficiency, improving precision and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

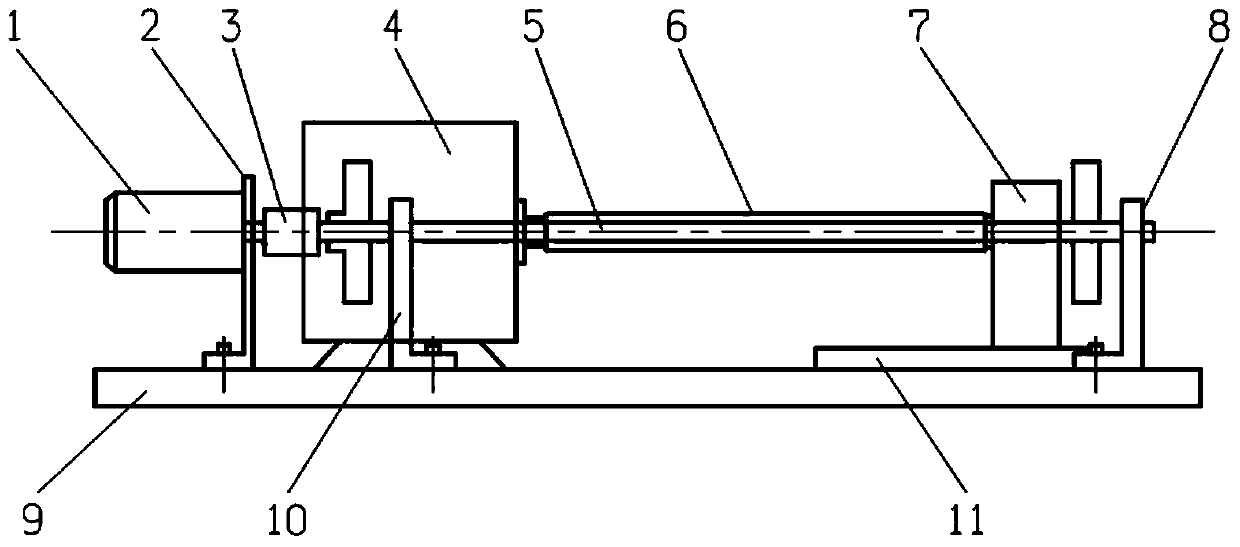

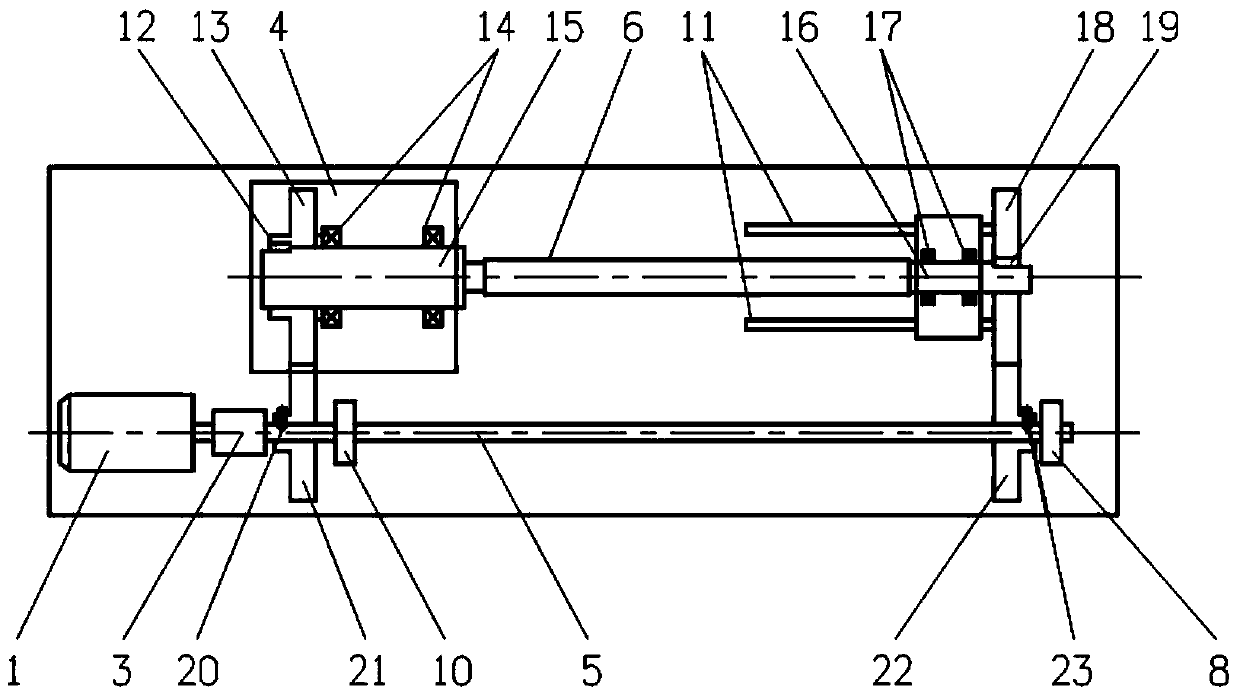

[0022] Such as figure 1 , figure 2 As shown, the technical solution adopted by the present invention is a workpiece clamping and driving device for a CNC camshaft grinder, which includes a workpiece clamping system, a workpiece driving system and an electrical control system.

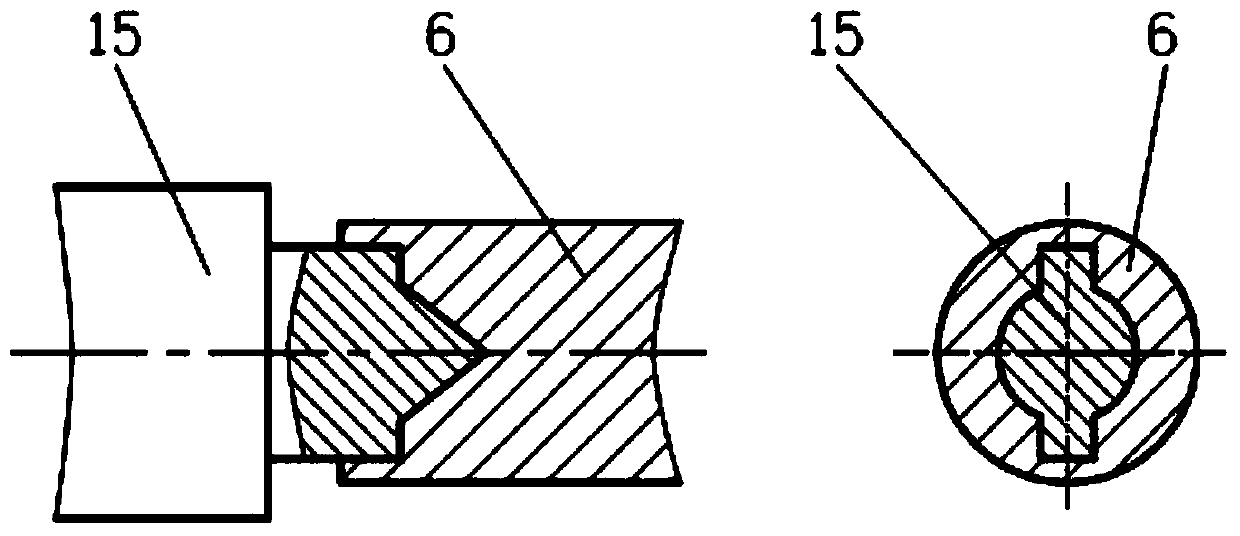

[0023] The workpiece clamping system of this device comprises base plate 9, headstock box 4, bearing a14, top 15, guide rail 11, tailstock box 7, bearing b17, tail tip 16, workpiece 6; Headstock box 4 is fixed on the base plate 9, The top 15 is installed in the headstock box 4, the top 4 is supported by a pair of bearings a14, and can rotate in the bearings a14; the guide rail 11 is fixed on the bottom plate 9, and the tailstock box 7 is installed on the guide rail 11, and can slide along the guide rail 11, Realize the fixed adjustment of the workpiece 6; the tailstock box 7 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com