Automatic distributing and transporting mechanism

An automatic, blanking trough technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity, low placement efficiency, low placement accuracy, etc., and achieve the effect of ingenious structure and strong linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

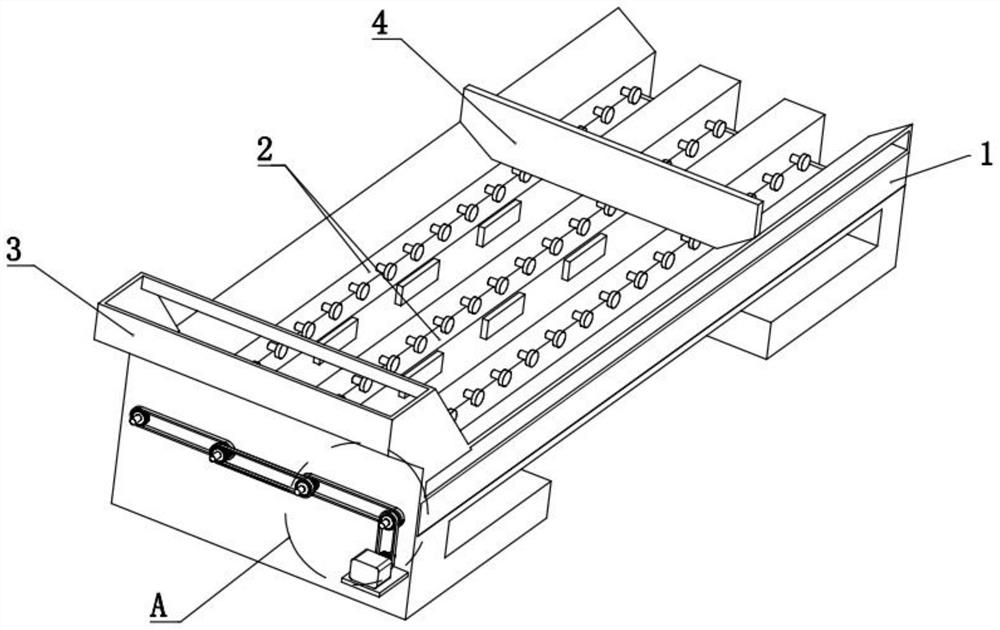

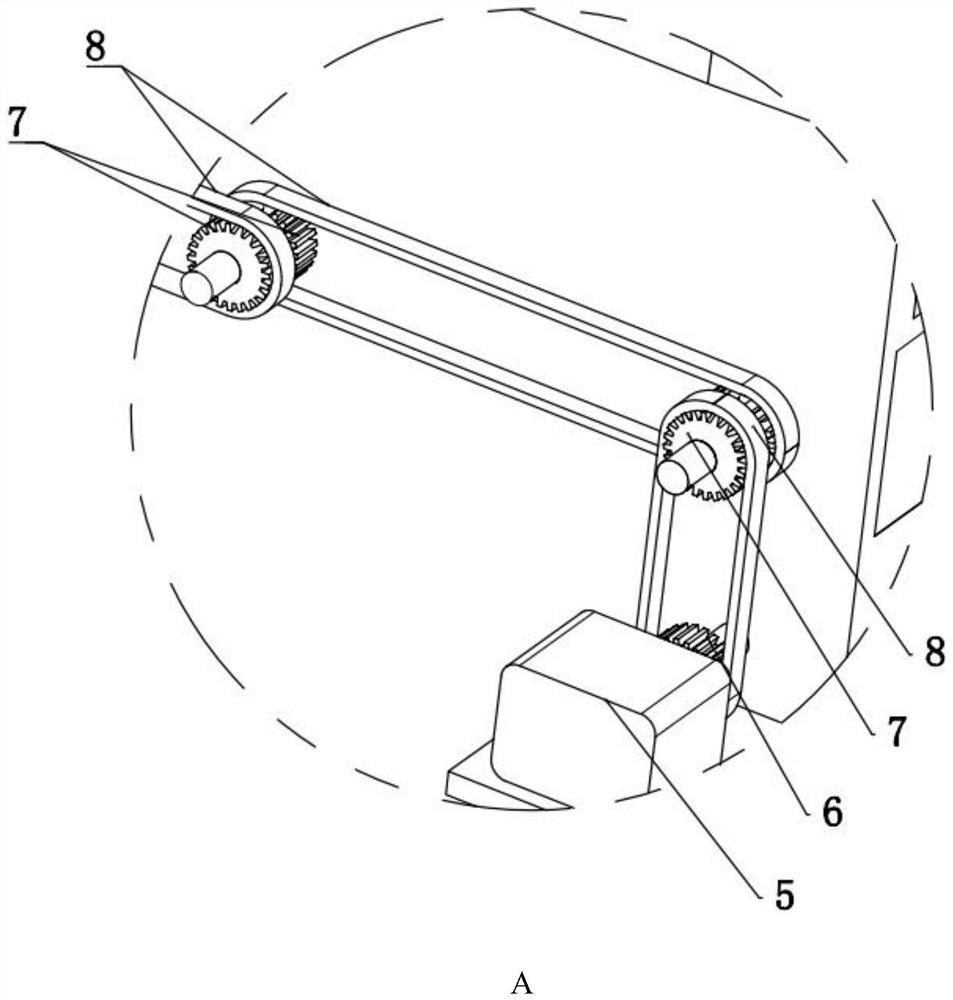

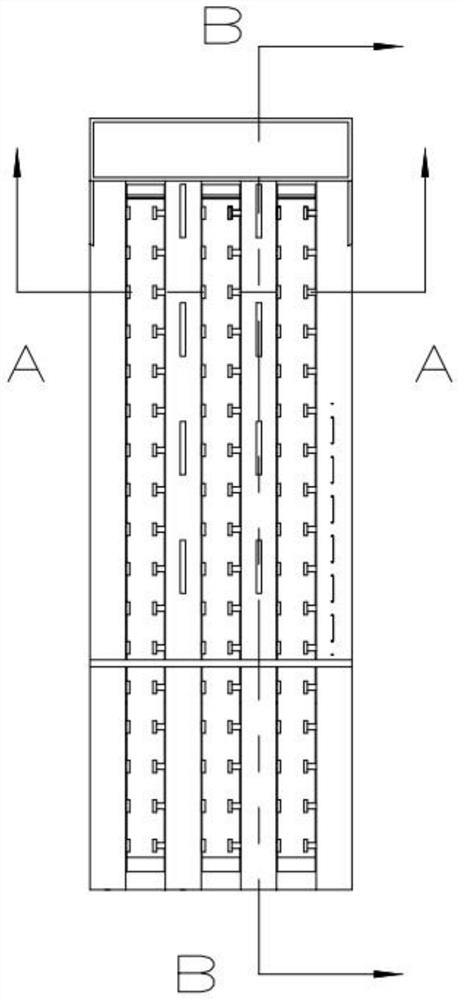

[0032] A kind of automatic material distributing transportation mechanism, refer to Figure 1-Figure 7 As shown, it includes a blanking platform 1, and the upper end surface of the blanking platform 1 is recessed along its transverse interval with at least two blanking grooves 2 running through its axial direction, and in the blanking groove 2, there are provided along the axial direction of the blanking platform 1 Conveyor belt 16 that is conveyed is provided with a mounting plate vertically upwards at one end of the feeding platform 1 that is located at the transmission entrance of the conveyor belt 16, and a blanking funnel 3 is arranged obliquely upward on the top of the mounting plate. The material channel is arranged obliquely downward, and its discharge opening 32 is directly above the conveyor belt 16 on the mounting plate, and a baffle plate 4 is vertically fixed in the middle of the upper end surface of the blanking platform 1 or near the end of the conveyor belt 16 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com