Turbulence generating device capable of controlling turbulence intensity

A technology of turbulent flow and shunt cavity, which is applied in the field of constant volume incendiary bomb turbulence generating device, can solve the problems of sealing problem, difficult processing, complicated device structure, etc., and achieves the effects of small vibration, easy manufacture and control, and high structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention provides a turbulent flow generating device used in constant volume incendiary bomb equipment. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

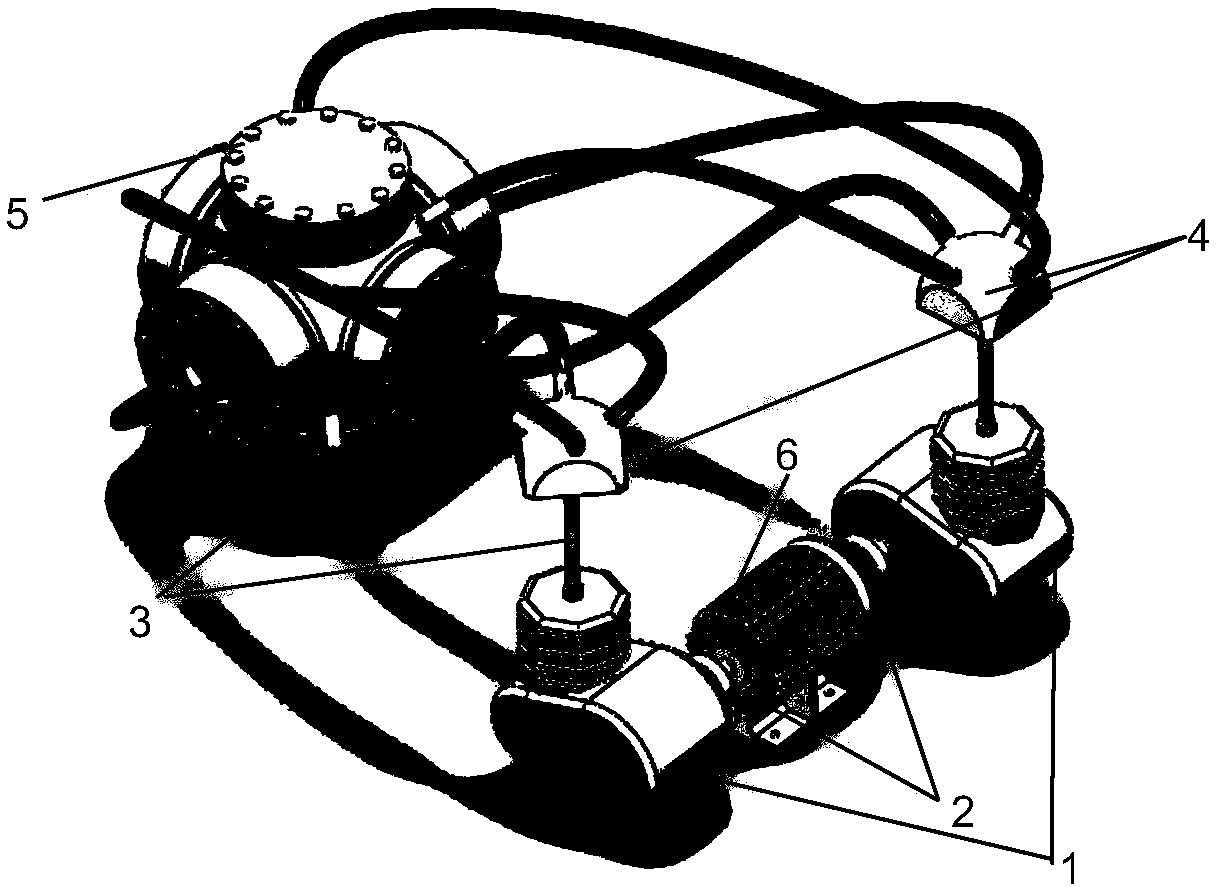

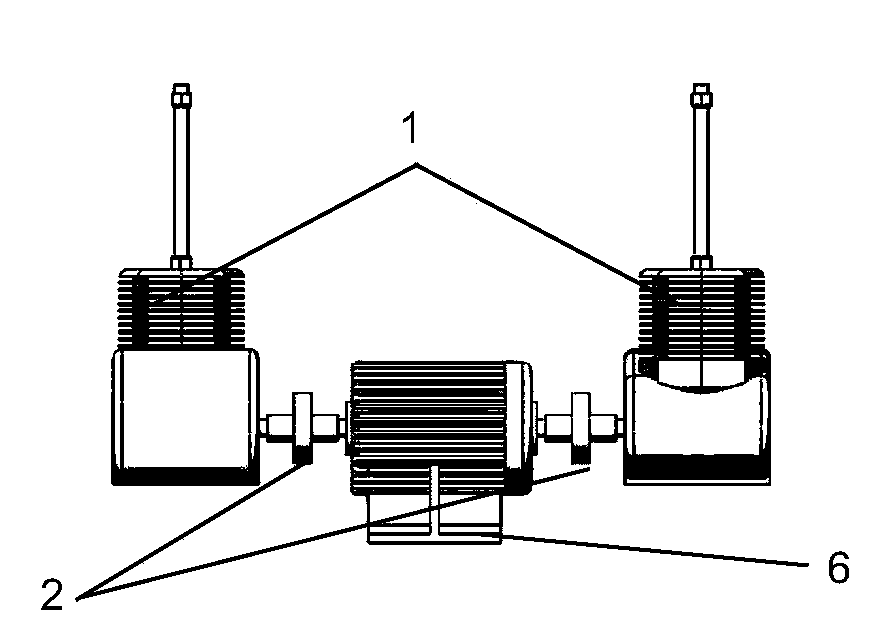

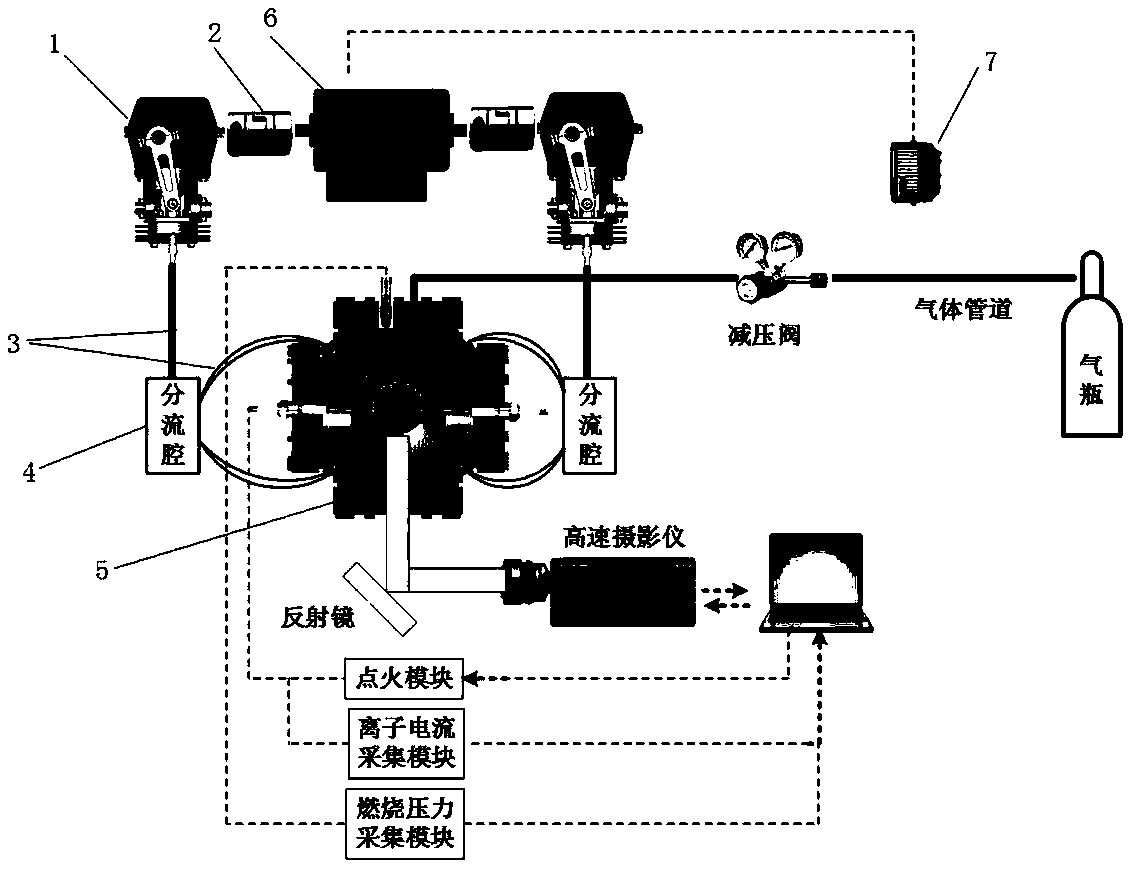

[0017] First, refer to figure 1 , the engine combustion process experimental testing device of the present invention is specifically described. The device consists of a single-cylinder engine (1), a coupling (2), a gas pipeline (3), a split chamber (4), a constant volume incendiary bomb (5), a double output shaft motor (6) and a digital frequency regulator (7). Composition; a single-cylinder engine (1) is respectively arranged on both sides of the double-output shaft motor (6); the split cavity (4) and the gas pipeline (3) are respectively installed on the single-cylinder engine (1) on both sides, and the gas pipeline (3 ) is connected with the constant-volume incendiary bomb (5); between each split chamber (4) and the constant-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com