Clamp for milling half-moon groove

A fixture and milling technology, applied in the field of fixtures for milling half-moon grooves, can solve the problems of difficult to guarantee machining accuracy, low machining efficiency, cumbersome machining, etc., so as to improve machining accuracy and efficiency, facilitate clamping and unloading, and shorten loading and unloading time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

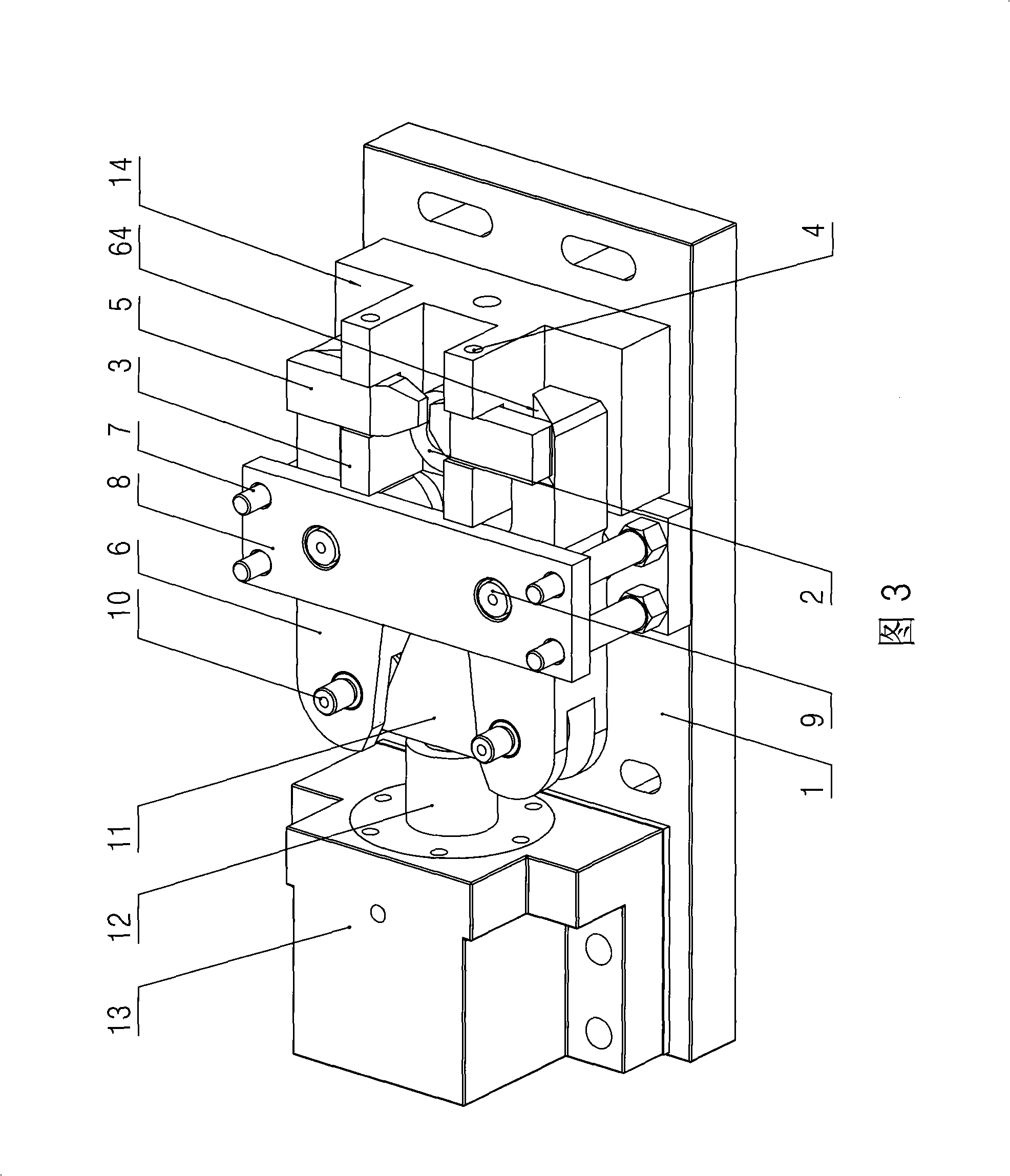

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

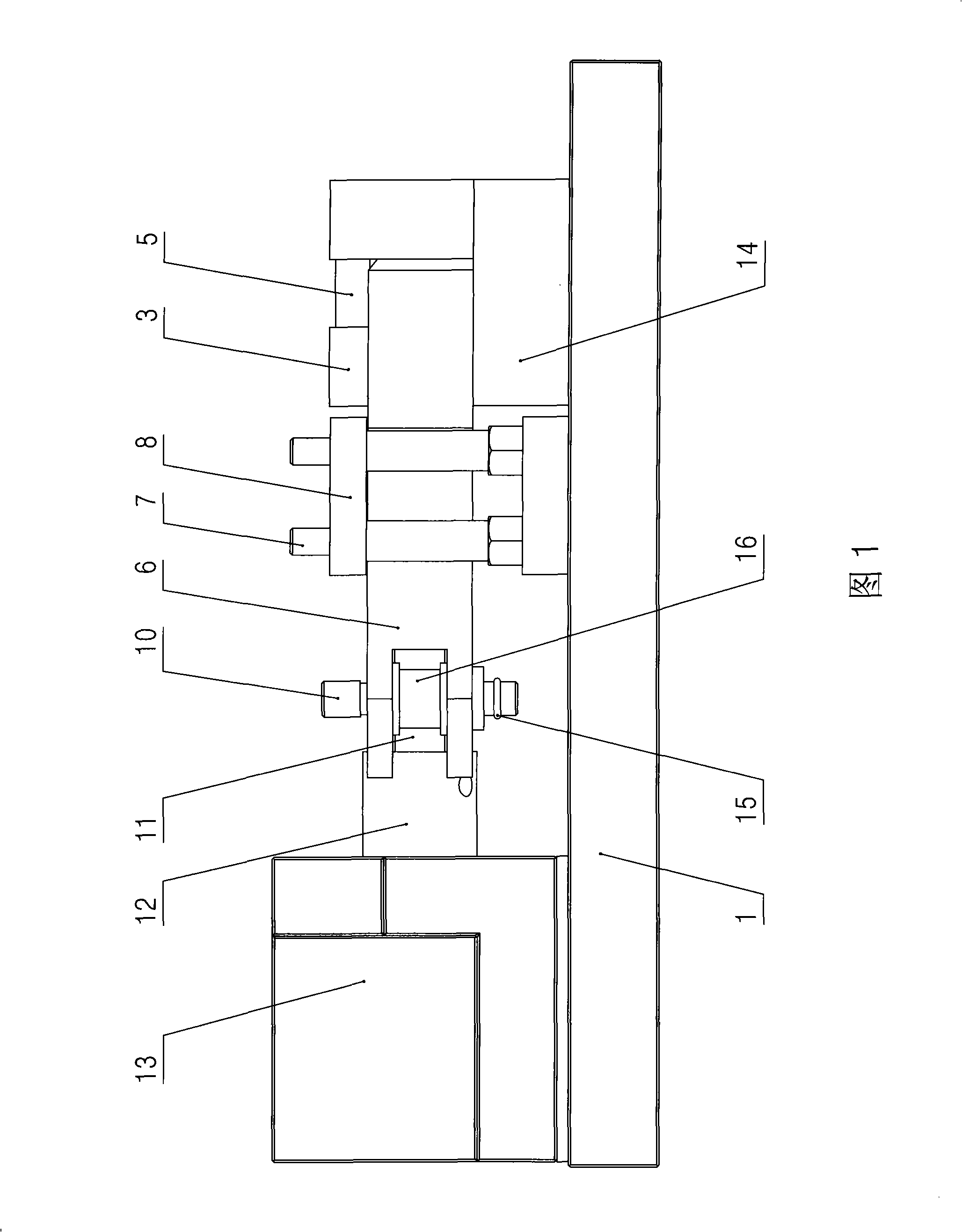

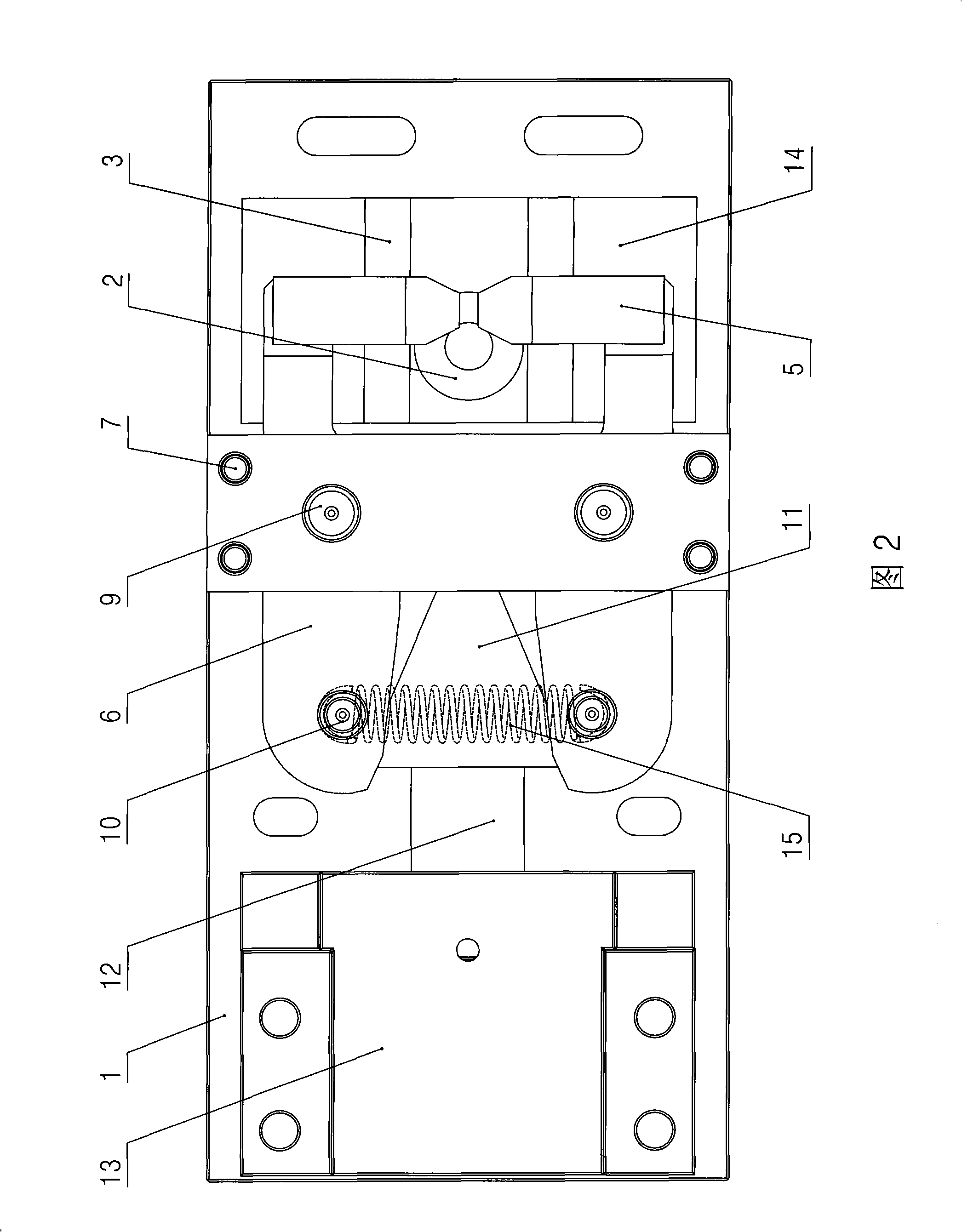

[0015] As shown in Fig. 1, Fig. 2 and Fig. 3, the jig for milling the half-moon groove according to the present invention includes: a base 1, a positioning shaft 2 and a pair of positioning shafts located on both sides of the positioning shaft 2 are arranged on the base 1 For the lugs 3 and a pair of resting platforms 14, the top of each lug 3 is provided with a pressure plate groove, and each pressure plate groove is provided with a pressure plate 5 through a pin shaft 4. The specific structure is: the pressure plate 5 and the pressure plate groove. The side walls are respectively provided with pin holes matched with the pin shaft 4, and the pin shaft 4 passes through the side wall on the right side of the pressure plate groove and the pin shaft hole of the pressure plate 5 successively, and extends into the left side of the pressure plate gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com