Internal thread tapper and tapping method thereof

A tapping device and internal thread technology, applied in the field of thread processing, can solve the problems of inability to drive the processing of tap products, low motor power of desktop drilling machines, and inability to meet mass production, so as to shorten loading and unloading time, reduce labor intensity and loss of tools , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

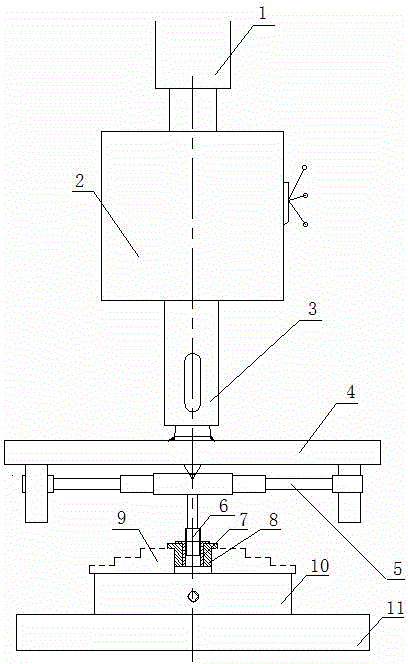

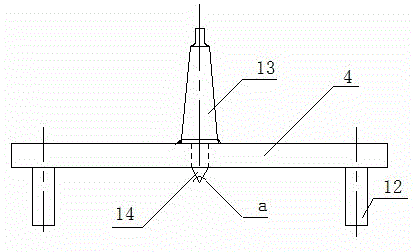

[0025] The internal thread tapping device of the present invention includes a vertical drilling machine, a three-jaw chuck 10 , a guiding push rod 4 , a tap hinge rod 5 and a tap 6 . A Morse taper pin 13 is provided in the middle of the guide push rod 4 , and cylindrical retaining pins 12 are provided at both ends. The lower end of the Morse taper pin 13 is provided with a cylindrical taper pin 14, and the taper angle a of the cylindrical taper pin 14 is 60 degrees. The Morse taper pin 13 and the cylindrical stop pin 12 are connected with the guide push rod 4 by welding. The Morse taper pin 13 on the guiding push rod 4 is connected with the main shaft 3 of the vertical drilling machine.

[0026] Internal thread tapping device of the present invention taps like this:

[0027] A. According to the size specification of the internal thread of the part 7, select the guide push rod 4 that matches the tap hinge rod 5;

[0028] B. Insert the mounting end of the Morse taper pin 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com