Transport cargo tank

A cargo box and box door technology, which is applied in the direction of transporting objects, transportation and packaging, and vehicles for freight transportation, can solve the problems of low loading and unloading efficiency, and achieve the goal of reducing labor intensity, shortening cargo loading and unloading time, and improving cargo handling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

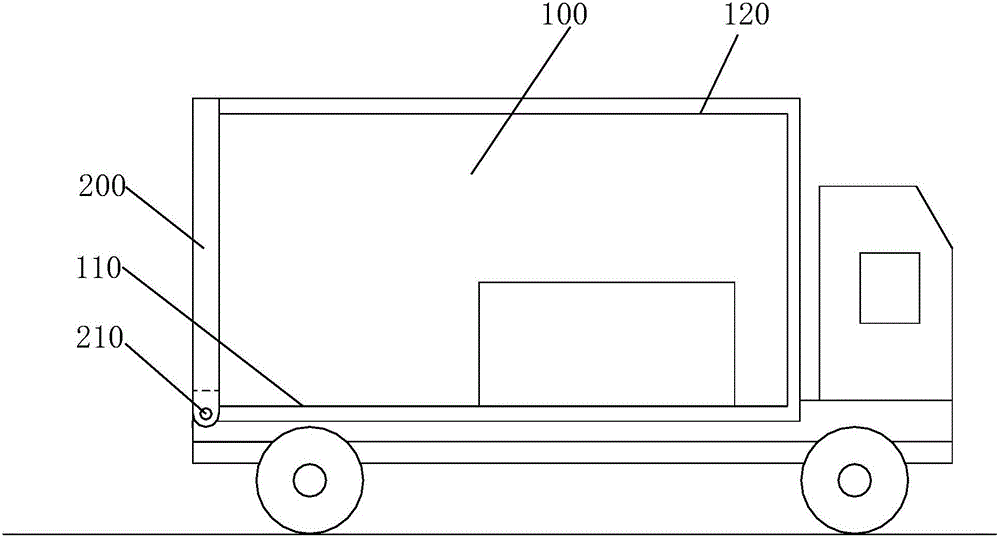

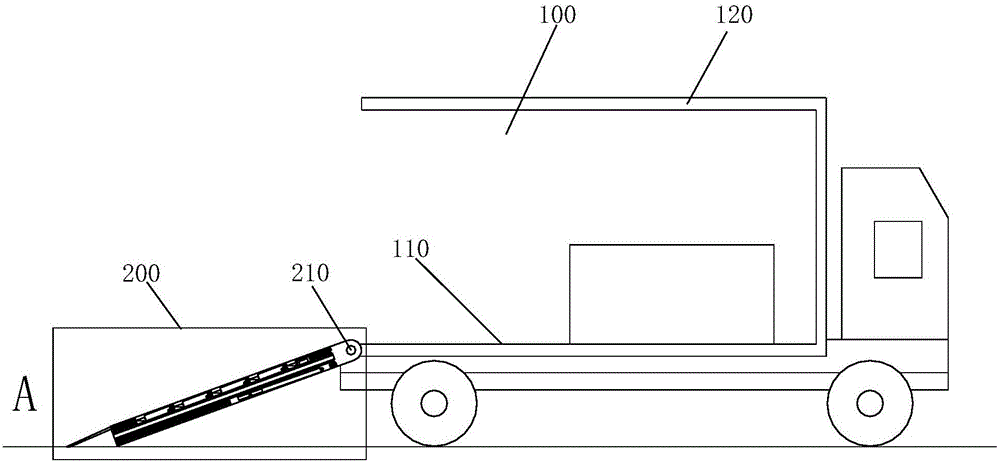

[0027] refer to figure 1 and combine Figure 2-7 with Figure 9 As shown, the present invention proposes a transport cargo box, including a box body 100 and a box door 200 arranged on a vehicle frame, the box body 100 has a bottom plate 110, and the box door 200 is located at the rear side of the box body 100, The bottom of the box door 200 is hinged on the bottom plate 110 through the first shaft 210, and specifically includes:

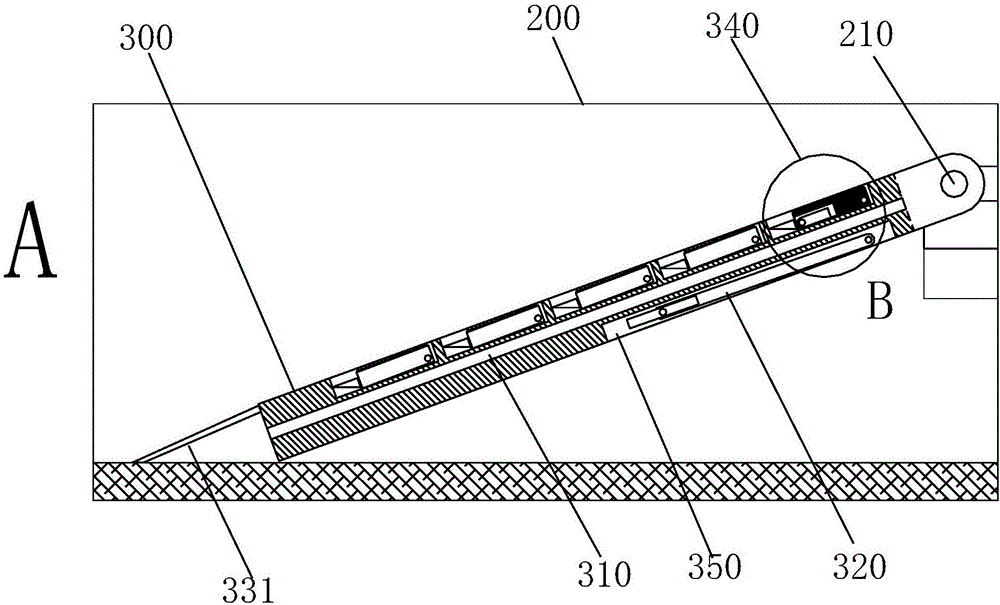

[0028] The box door body 300 is embedded with a reticular rib frame 310 inside, and the box door body 300 is divided into inner and outer two-layer structures by the rib frame 310; wherein,

[0029] The door body 300 is provided with a support mechanism 320 on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com