Patents

Literature

156results about How to "Improve pick-and-place efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

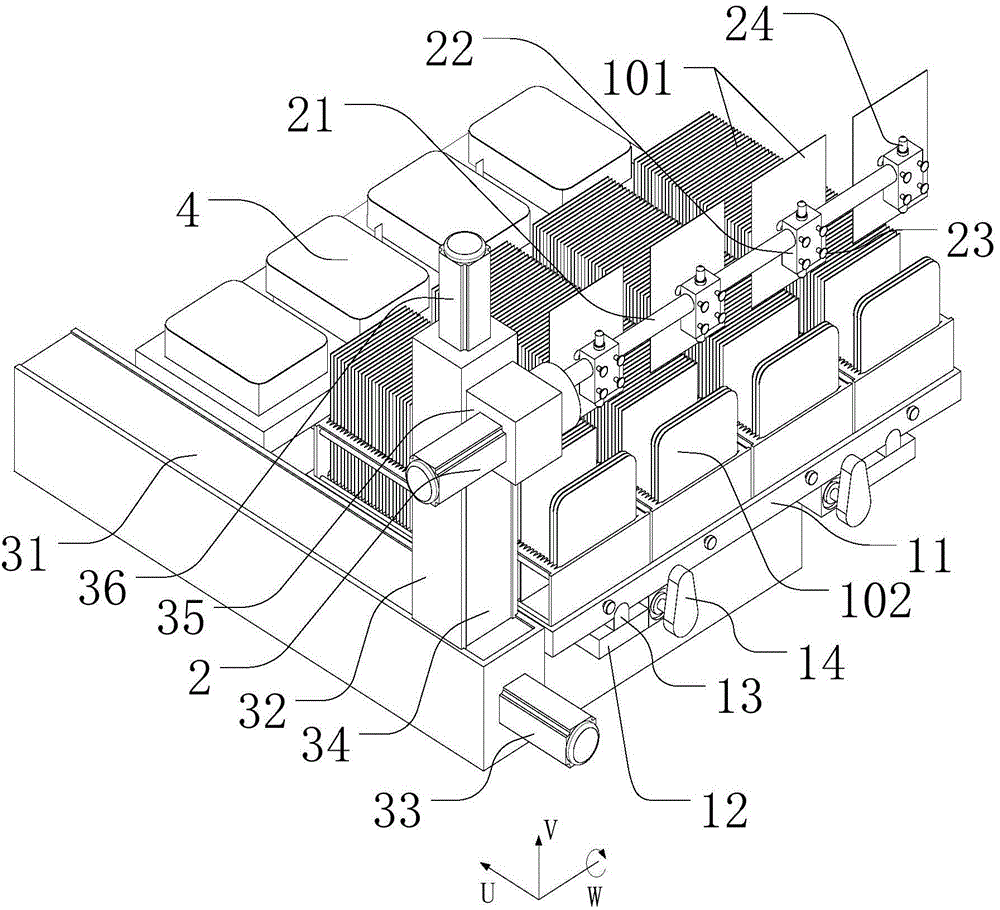

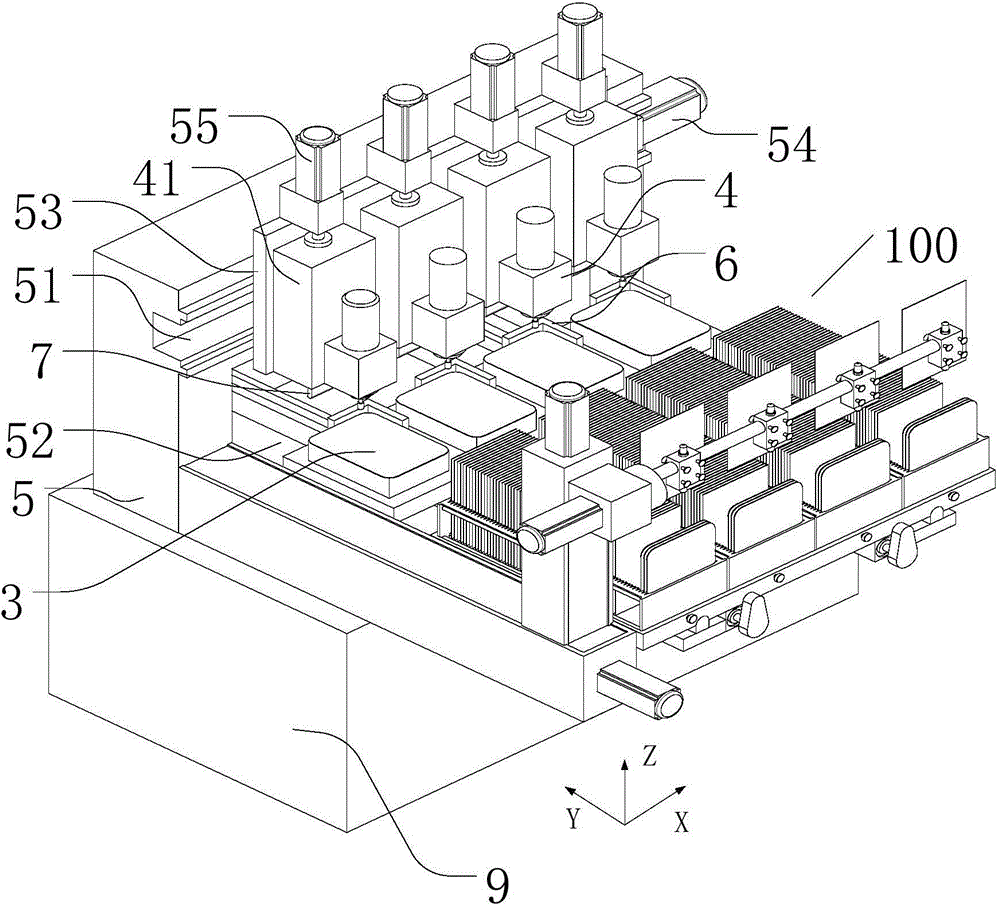

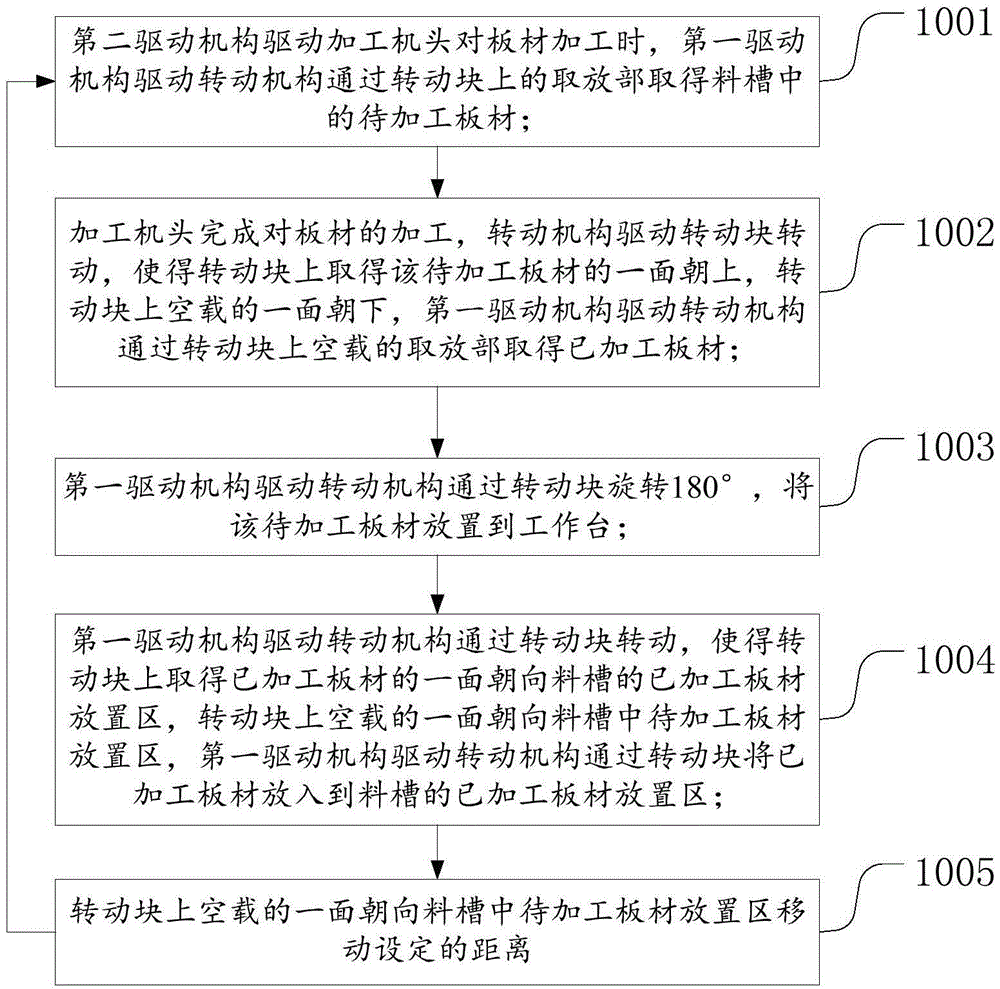

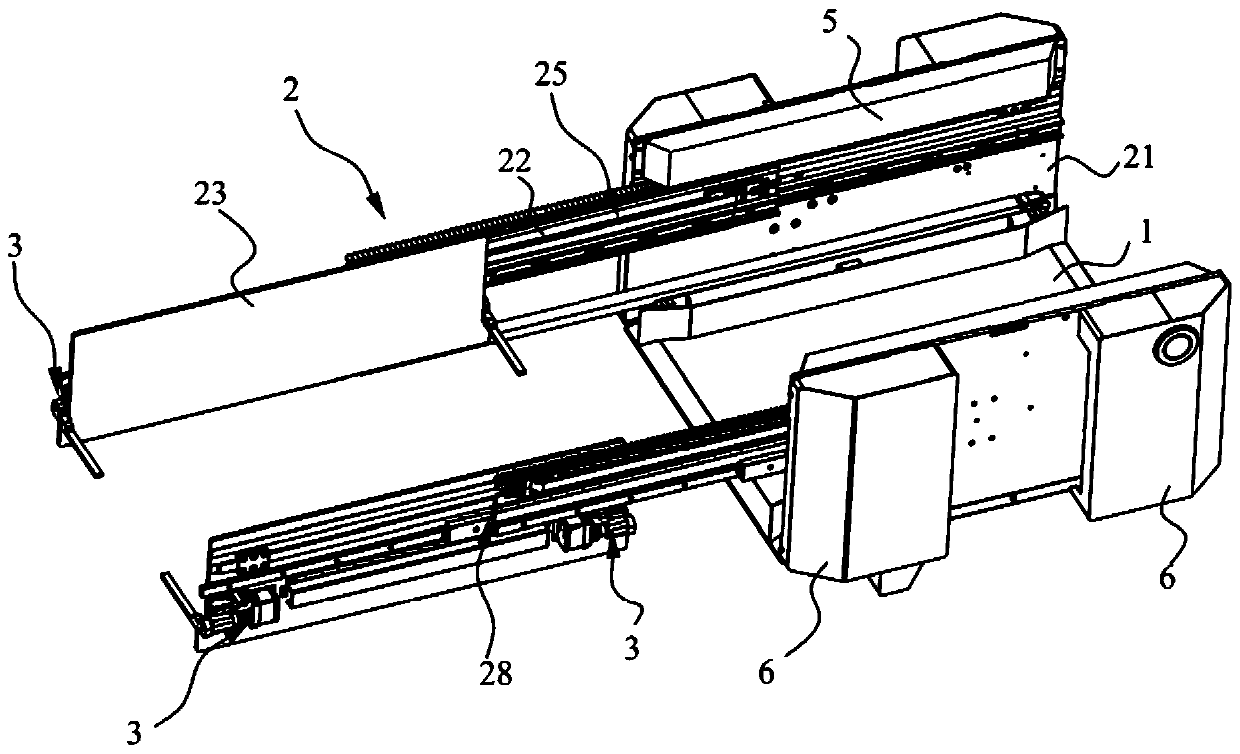

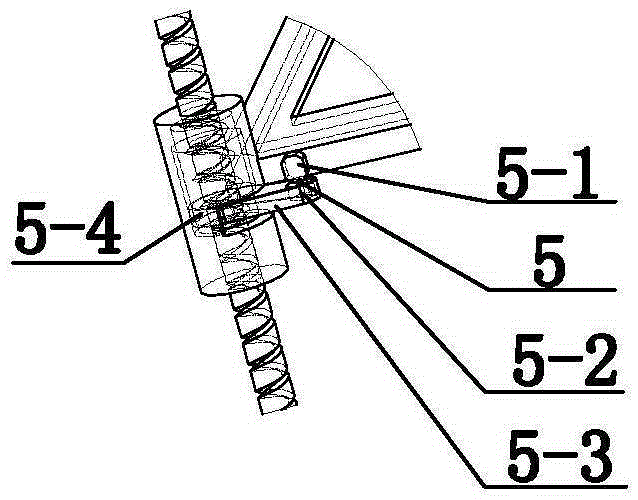

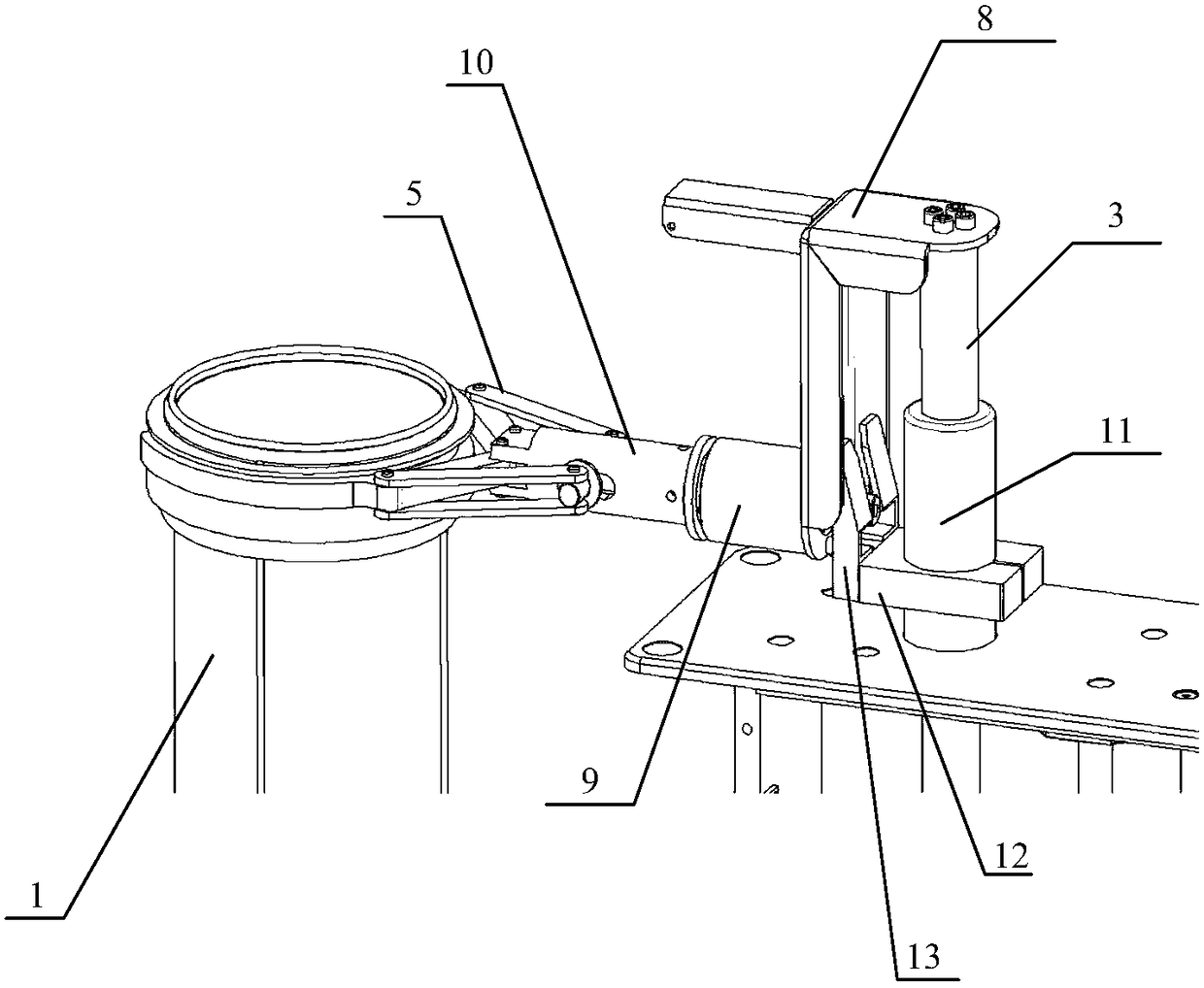

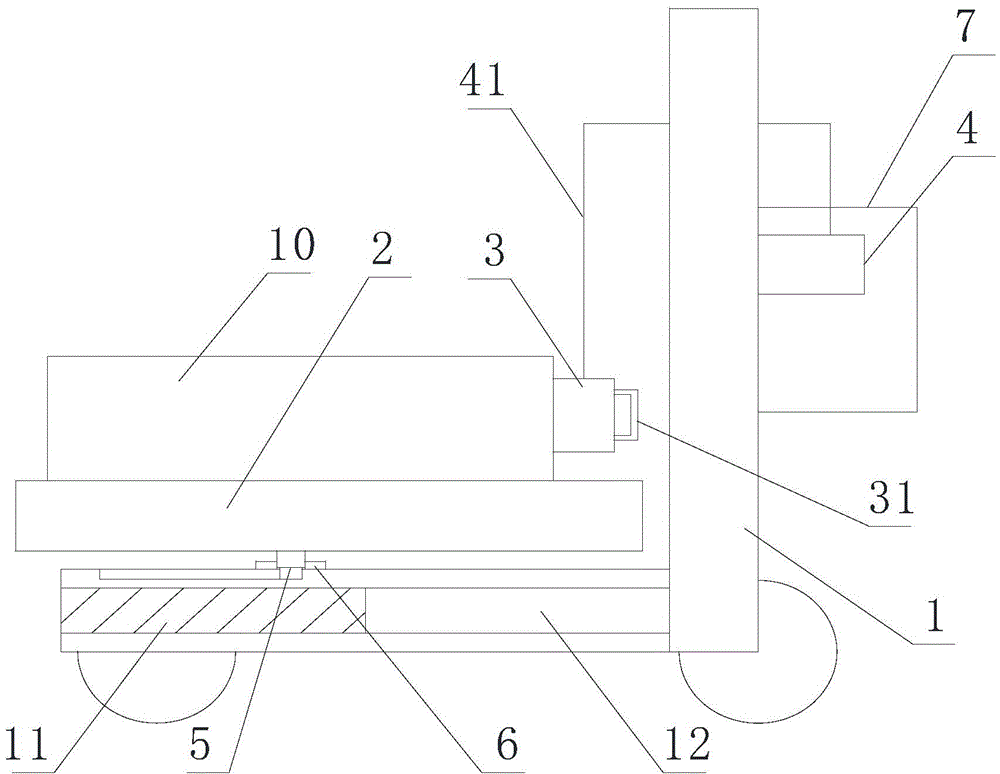

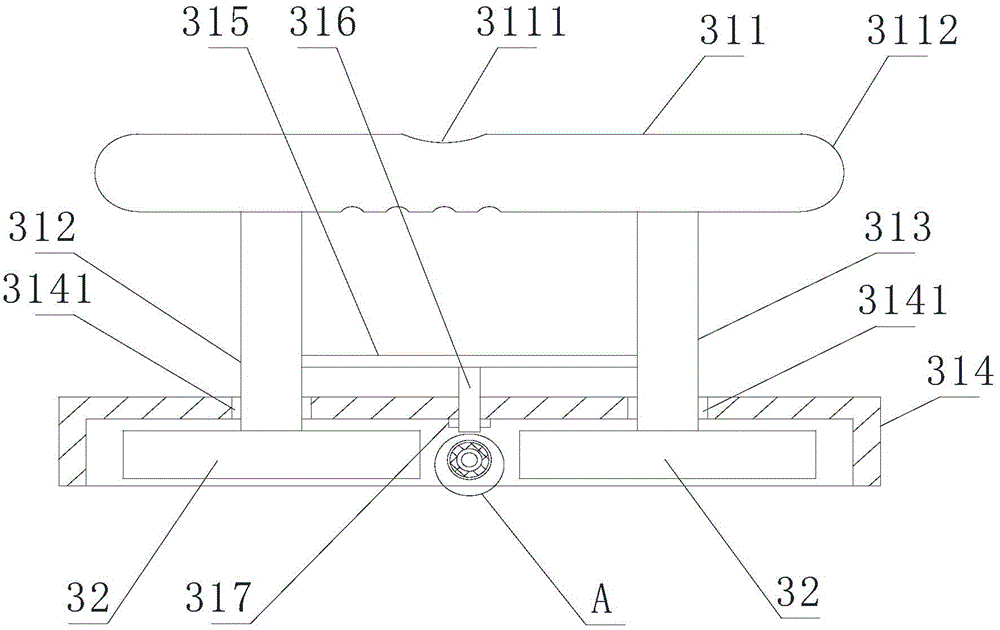

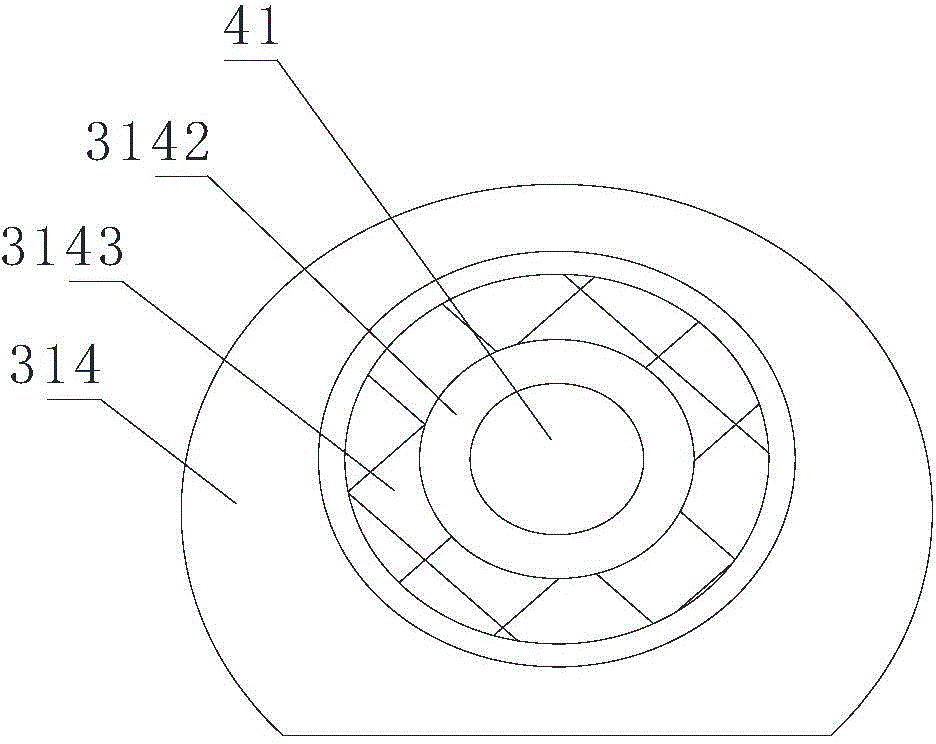

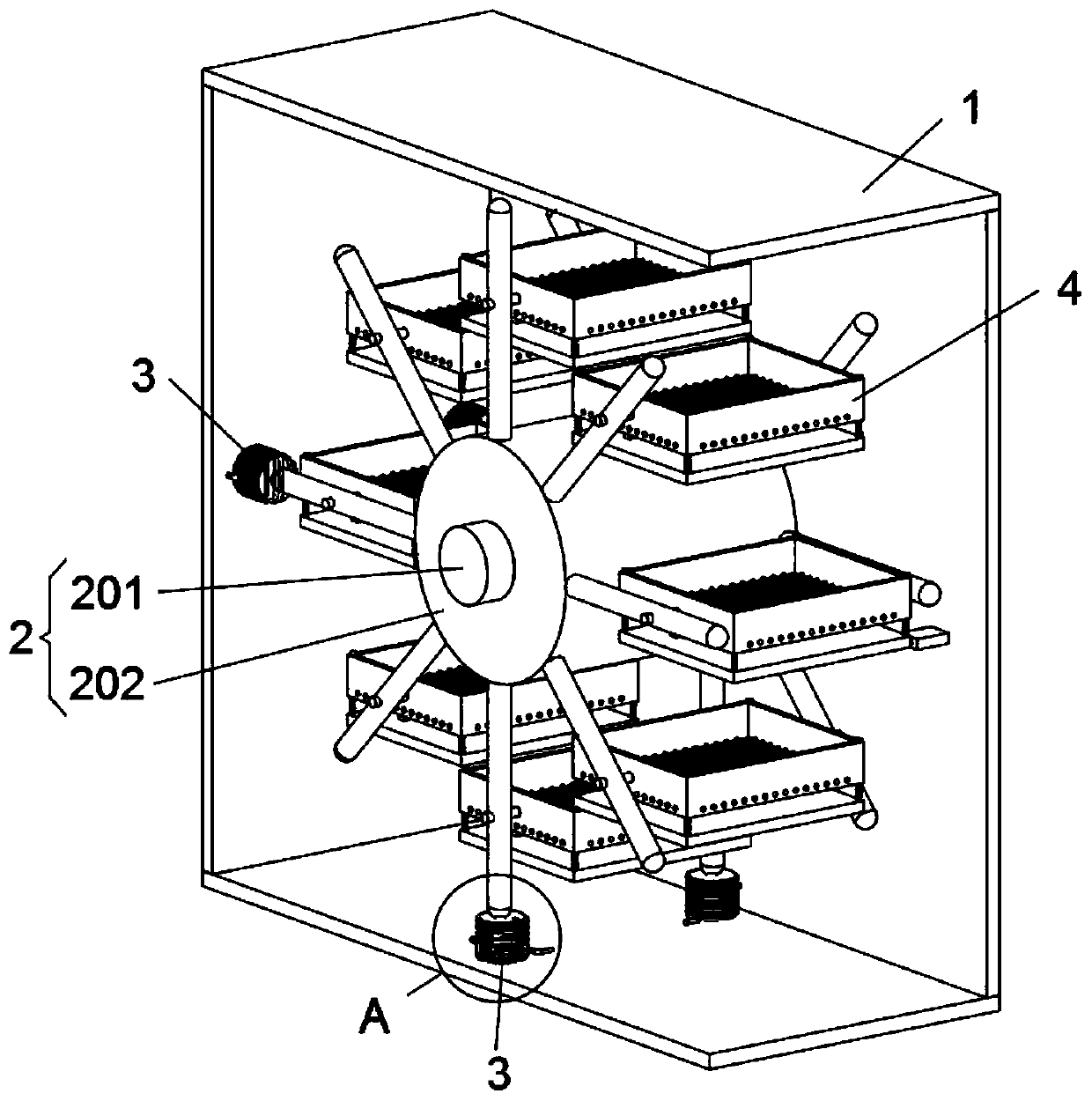

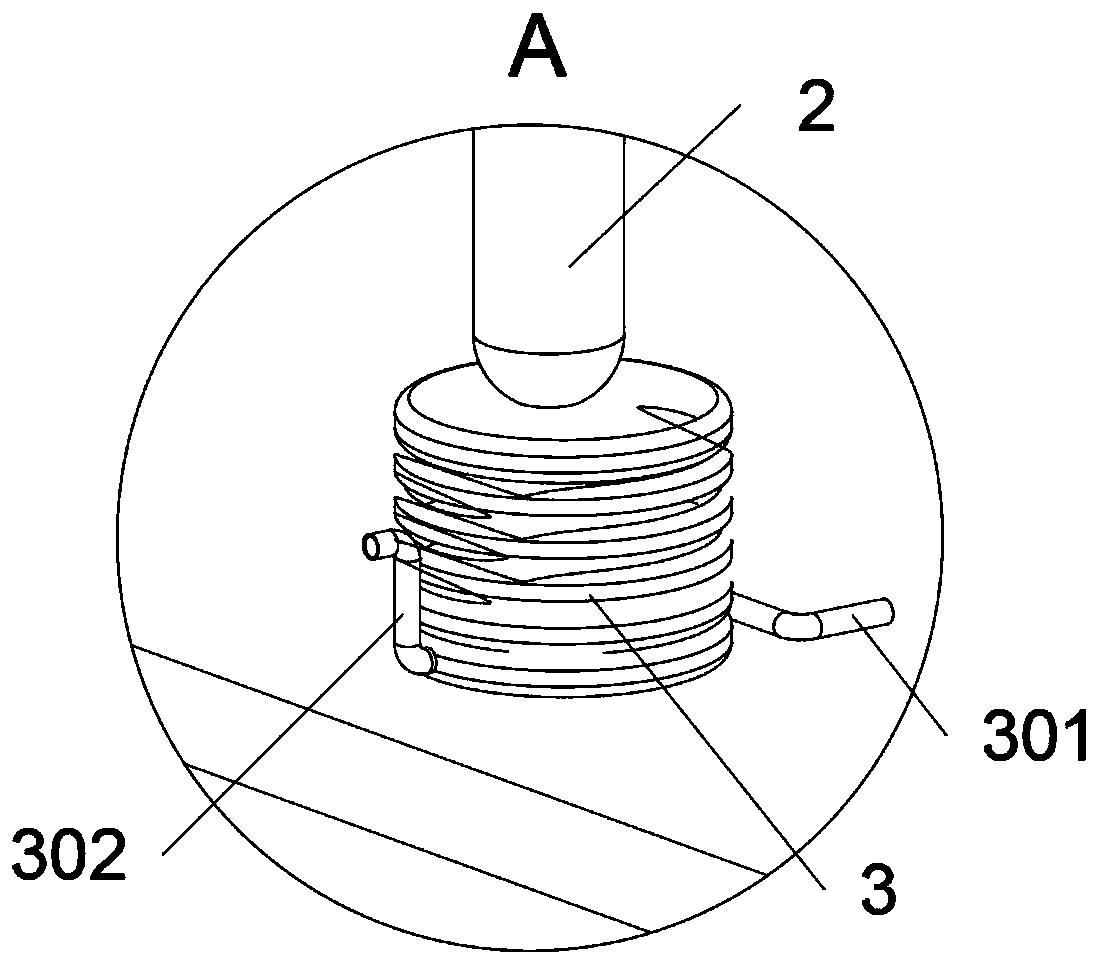

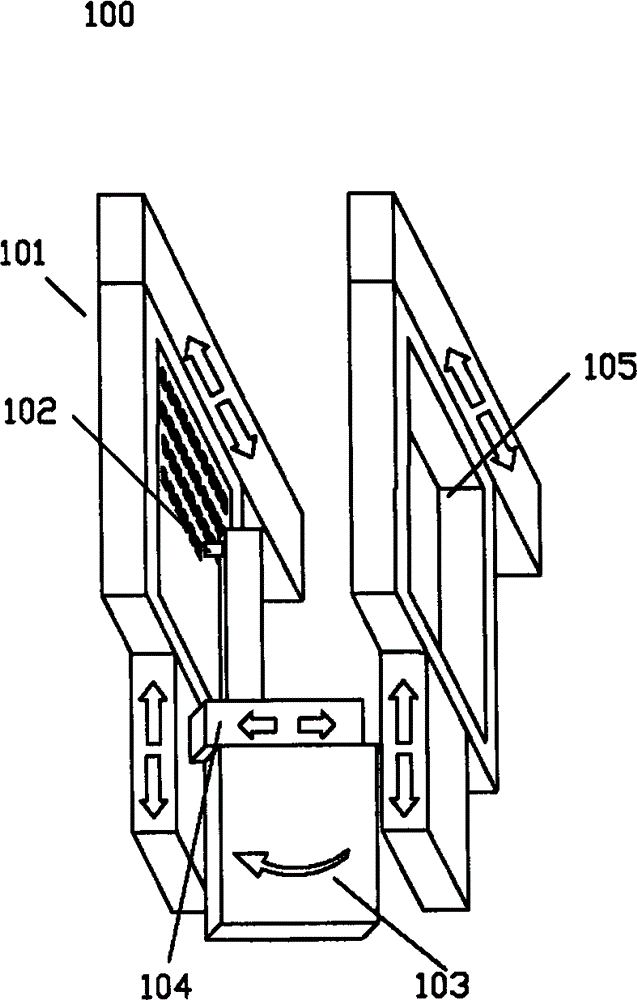

Sheet material feeding and discharging device, mobile phone glass machining center and machining method

ActiveCN104890422AFlexible loading and unloading methodsImprove the efficiency of picking and unloadingGrinding feedersOther artistic work equipmentsEngineeringMachine tool

The invention discloses a sheet material feeding and discharging device, a mobile phone glass machining center and a machining method. The device comprises a material groove, a rotating mechanism provided with a rotating rod, a first drive mechanism and rotating blocks installed on the rotating rod; and taking and placing parts are respectively installed on the front and rear sides of each rotating block, the rotating mechanism is installed on the first drive mechanism, and the rotating blocks are located over the material groove. Two faces of the rotating blocks are provided with the taking and placing parts, the rotating mechanism can drive the rotating blocks to perform 360-degree rotation, a feeding and discharging mode is more flexible, and taking and placing efficiency is greatly improved. After the sheet material feeding and discharging device is applied to the mobile phone glass machining center, a mode that the rotating blocks are fixed to the rotating rod is adopted, and the rotating rod extends to the other side to form a gantry crane type structure, so the rotating blocks can be unlimitedly expanded on the rotating rod, a machining table and the material groove can be correspondingly increased, a plurality of working positions can be increased on one machine tool to the maximum extent, and machining efficiency is greatly improved.

Owner:苏州恒远精密数控设备有限公司

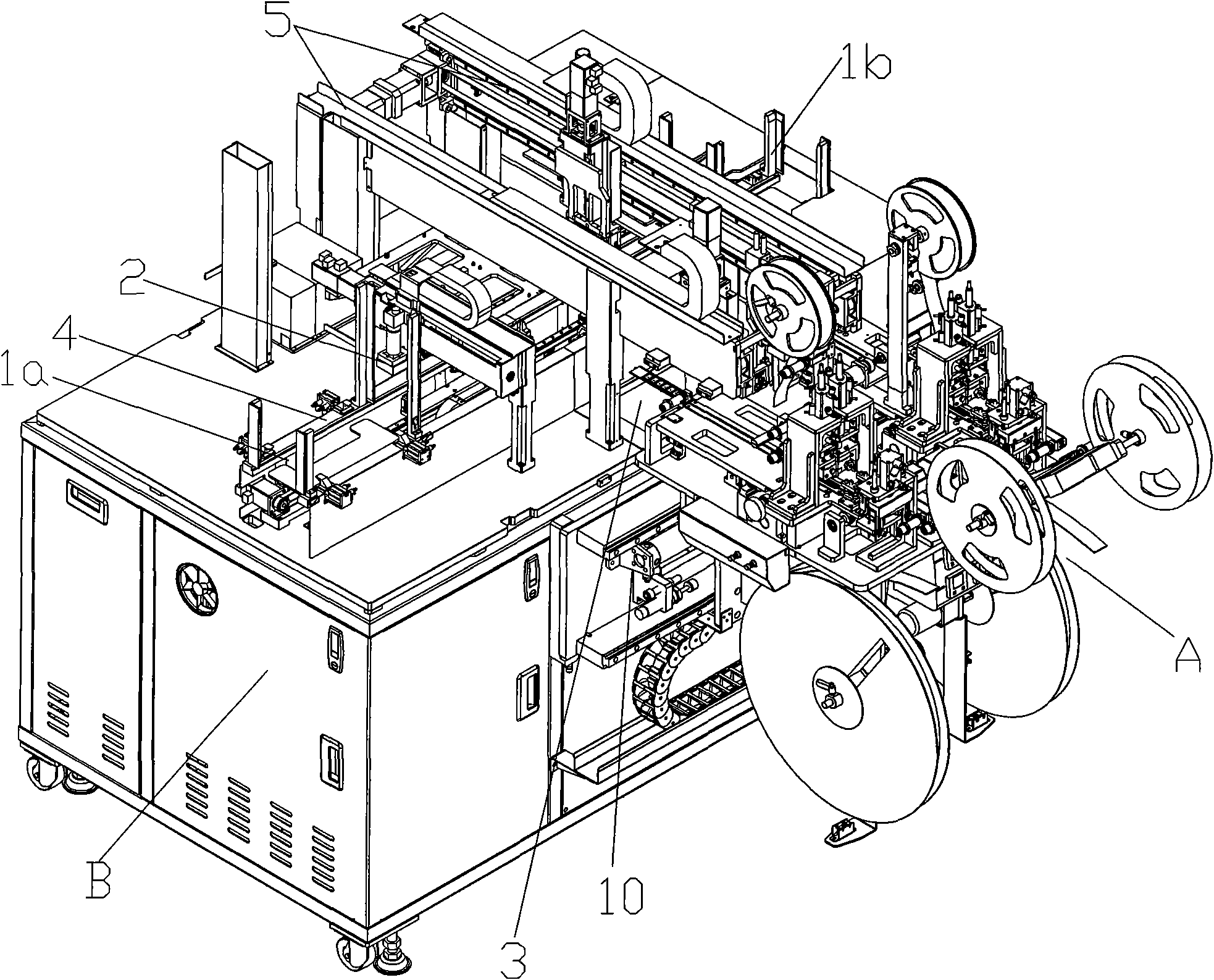

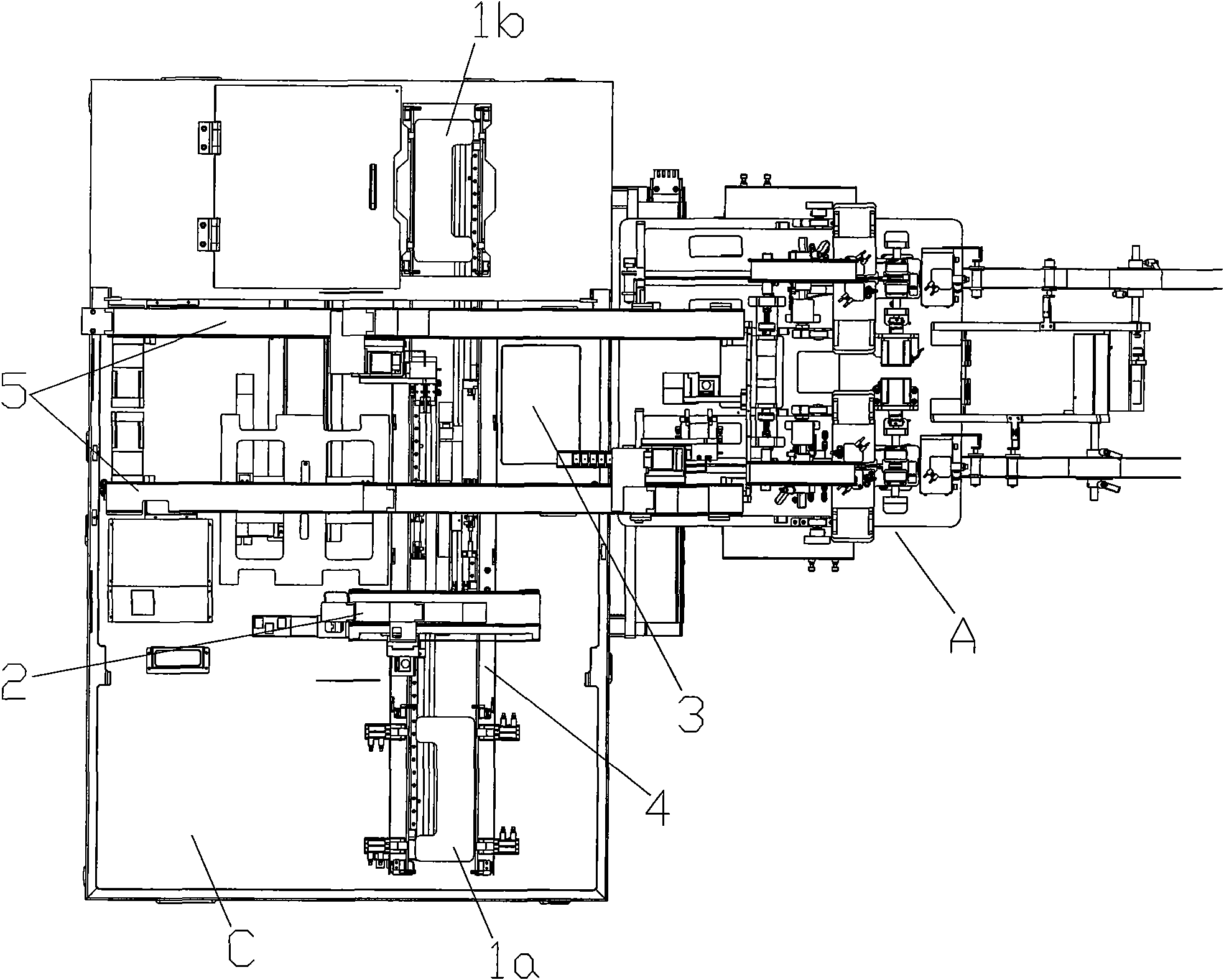

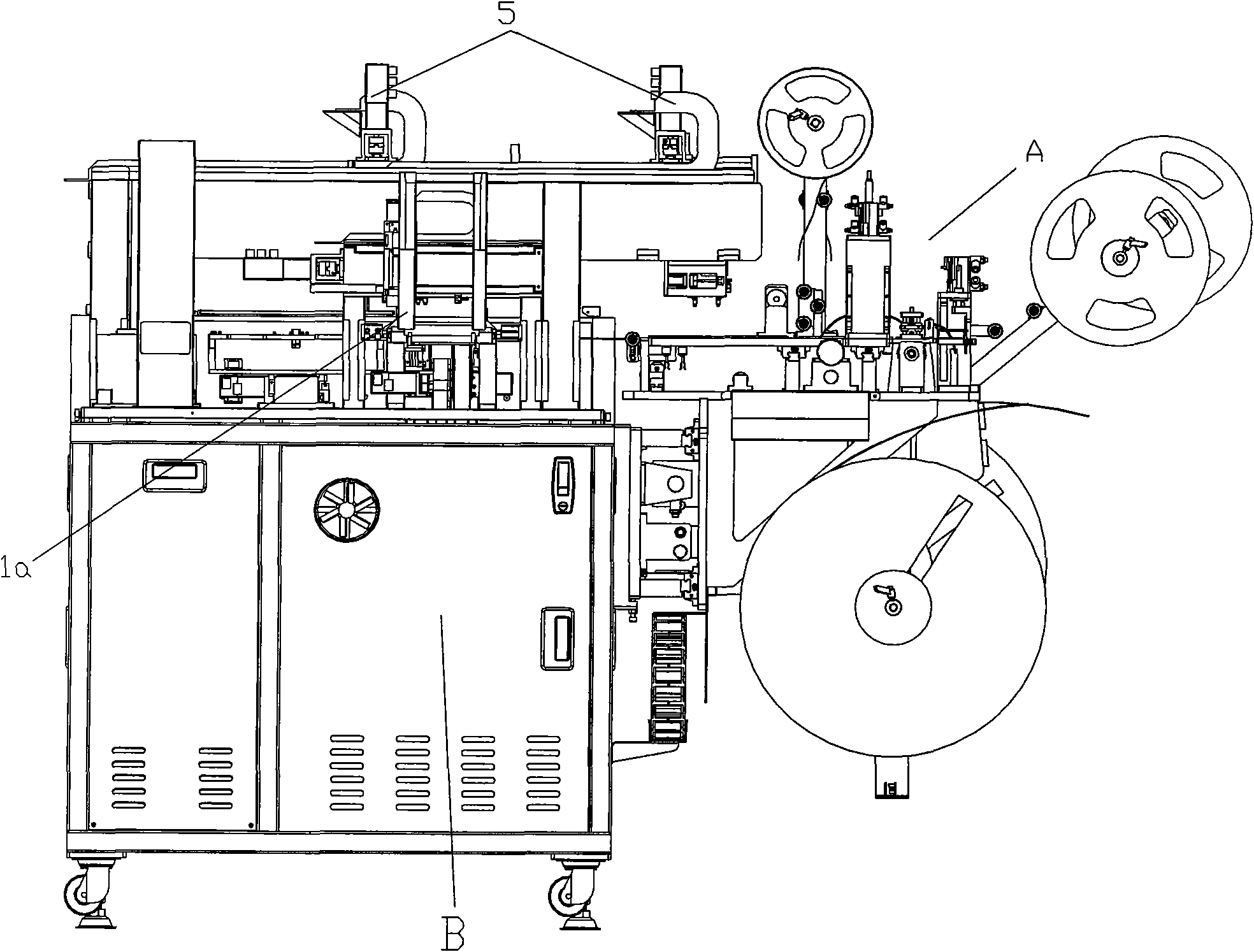

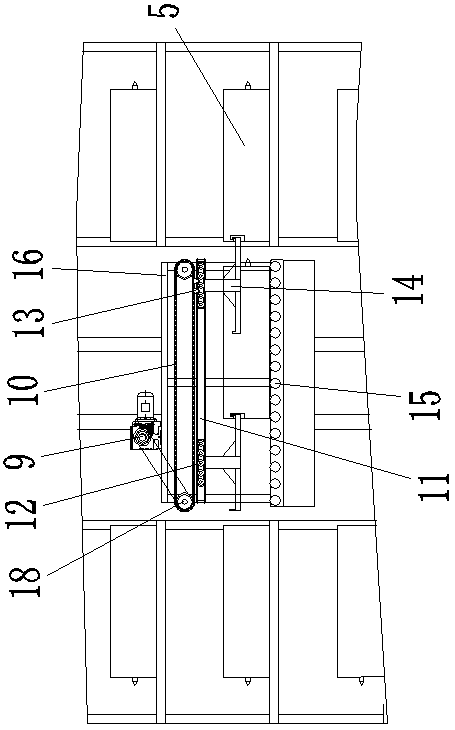

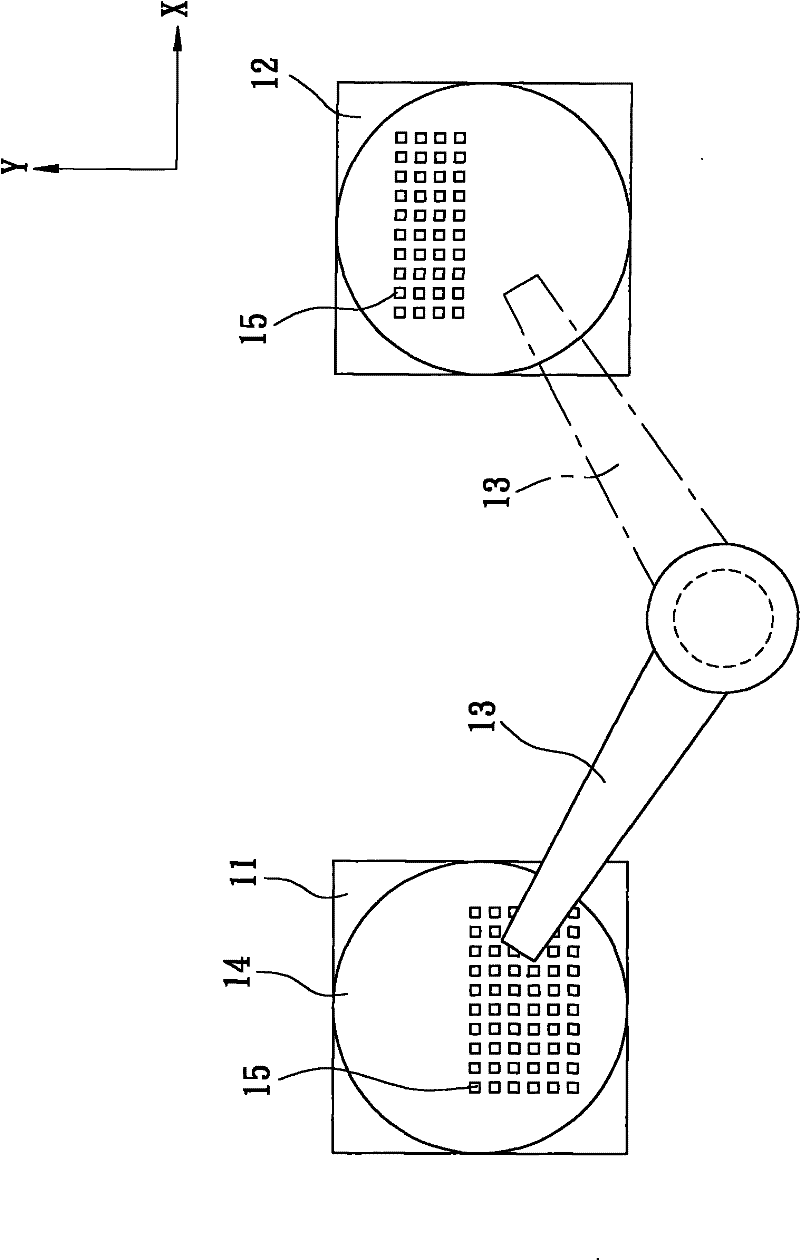

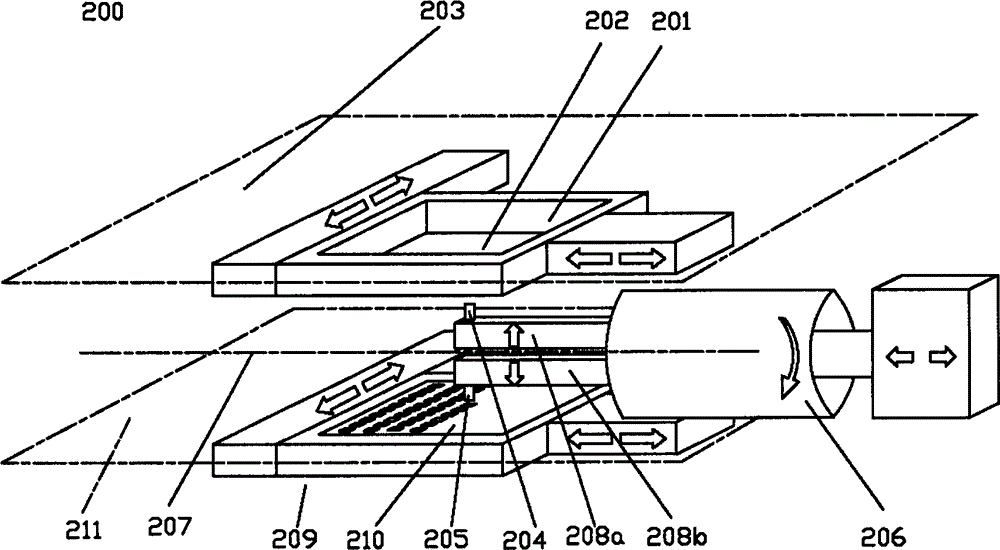

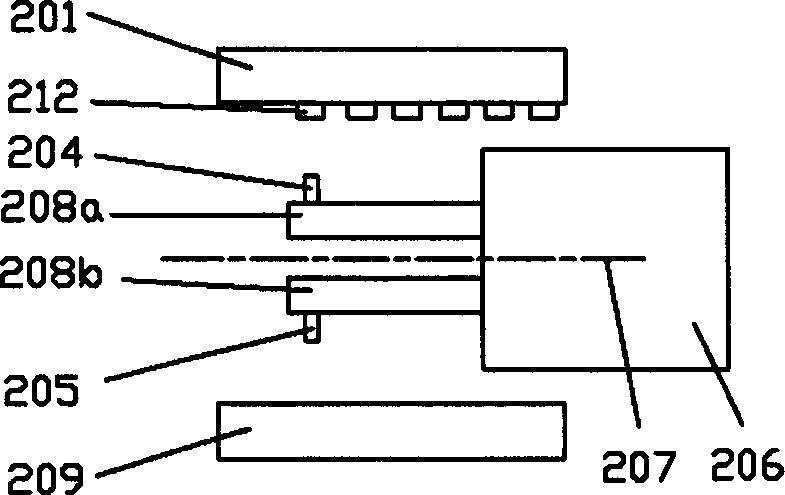

Disk-feeding braider and classified gripping method thereof

InactiveCN101920795AAvoid motion interferenceImprove pick and place efficiencyWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineeringIntegrated circuit

The invention discloses a disk-feeding braider and a classified gripping method thereof. The braider comprises a tray conveying device, a tray separating device, a top surface scanning surface, a three-dimensionally scanning device, a double-gripper classified gripping device, an unaccepted product collecting device, a hollow tray stacking device and a braid packaging device, wherein the tray conveying device is used for conveying a tray; the tray separating device is used for separating the tray onto the tray conveying device; the top surface scanning surface is used for scanning the top surface of an integrated circuit block in the conveyed tray; the three-dimensionally scanning device is used for three-dimensionally scanning the bottom surface and the side face of the integrated circuit board; the double-gripper classified gripping device is used for gripping the top surface-scanned and / or three-dimensionally scanned integrated circuit board in a classified way and comprises a first classified gripping device and a second classified gripping device; the unaccepted product collecting device is used for receiving the integrated circuit board of which the scanning result is unqualified; the hollow tray stacking device is used for stacking a conveyed hollow tray on which classified gripping is finished; and the braid packaging device is used for packaging and winding the integrated circuit board of which the top surface scanning and three-dimensionally scanning results are qualified. The disk-feeding braider and the corresponding classified gripping method have the characteristic of high work efficiency.

Owner:GRAND TECH SHENZHEN

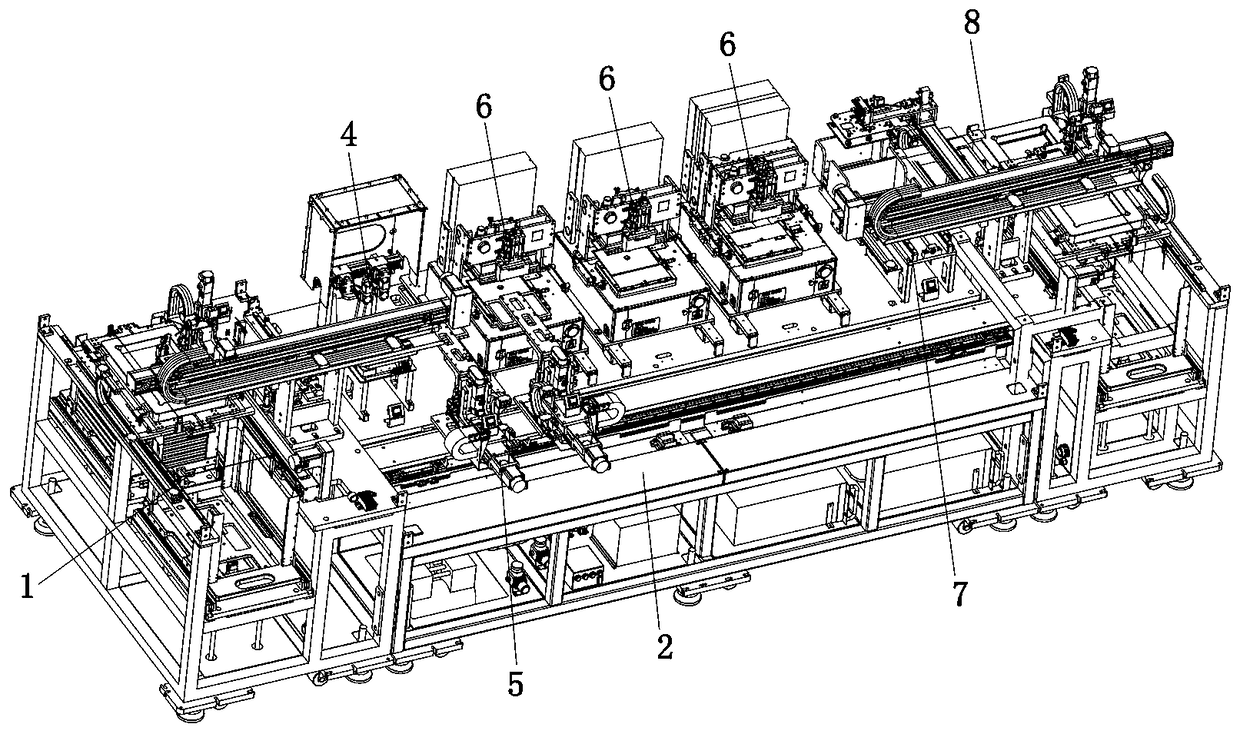

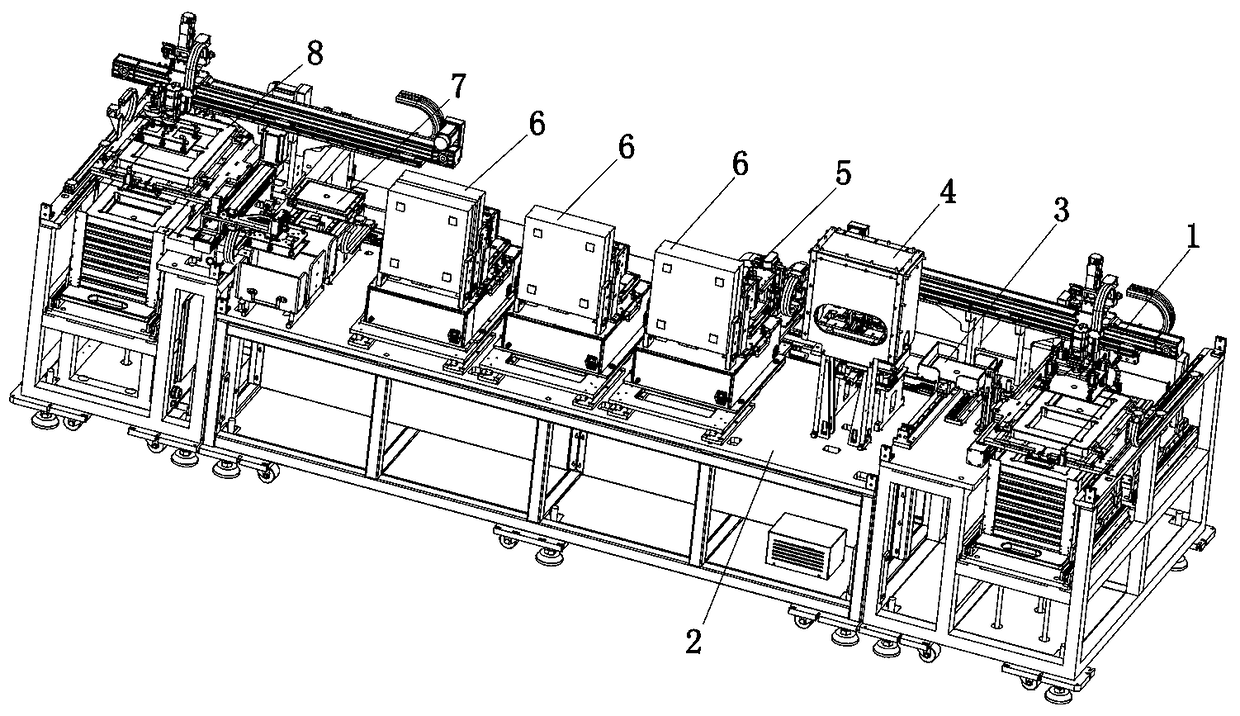

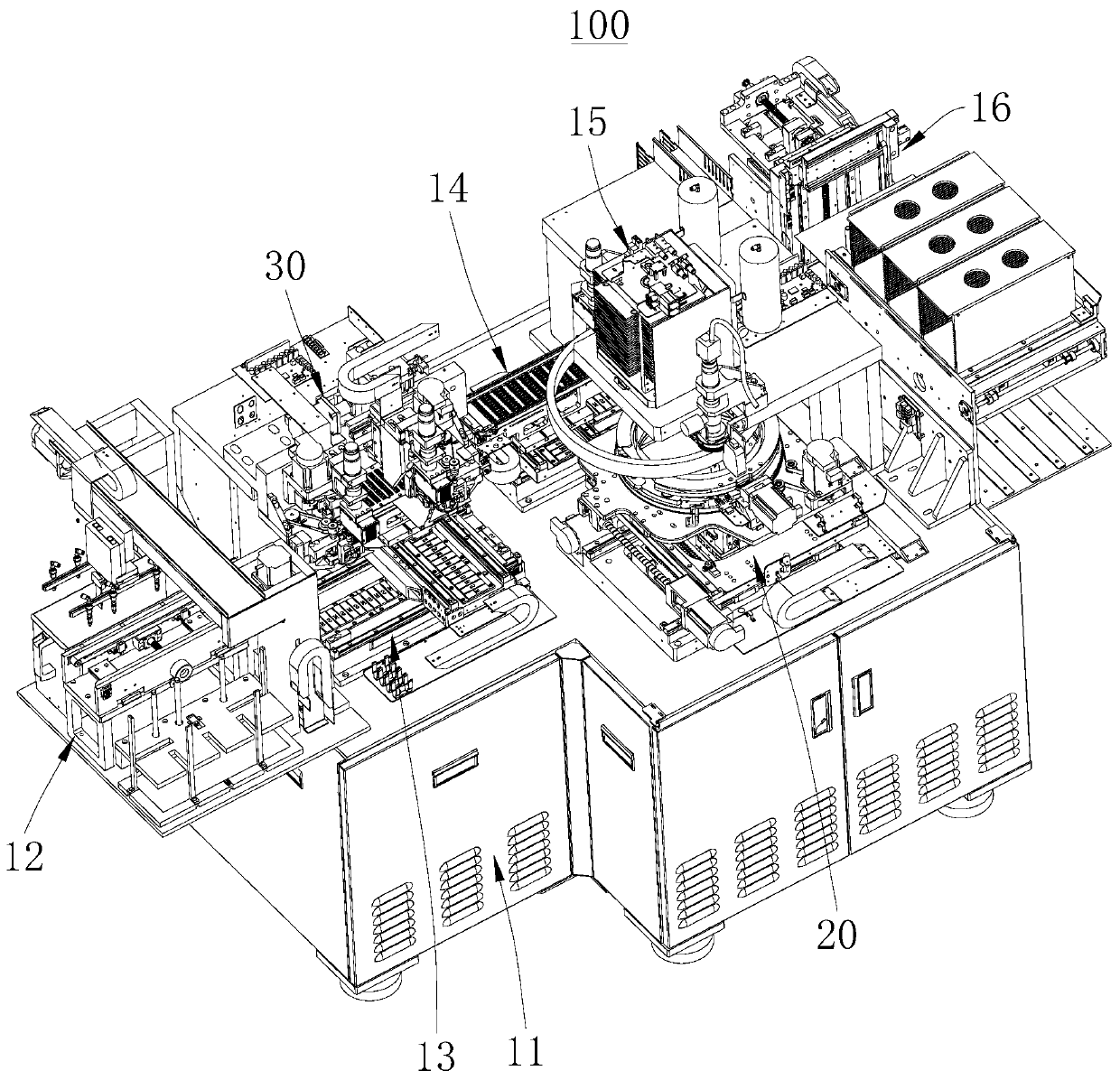

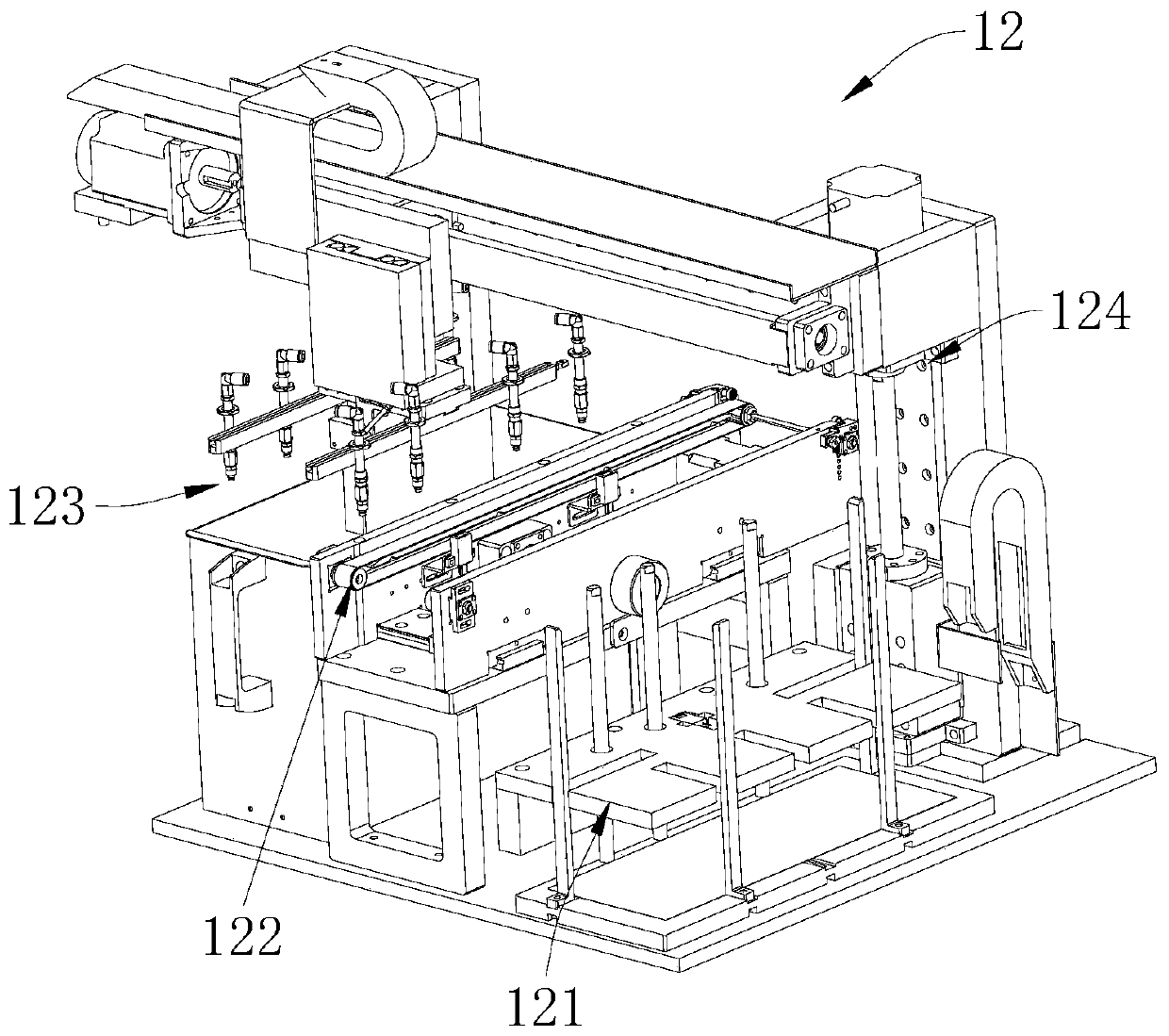

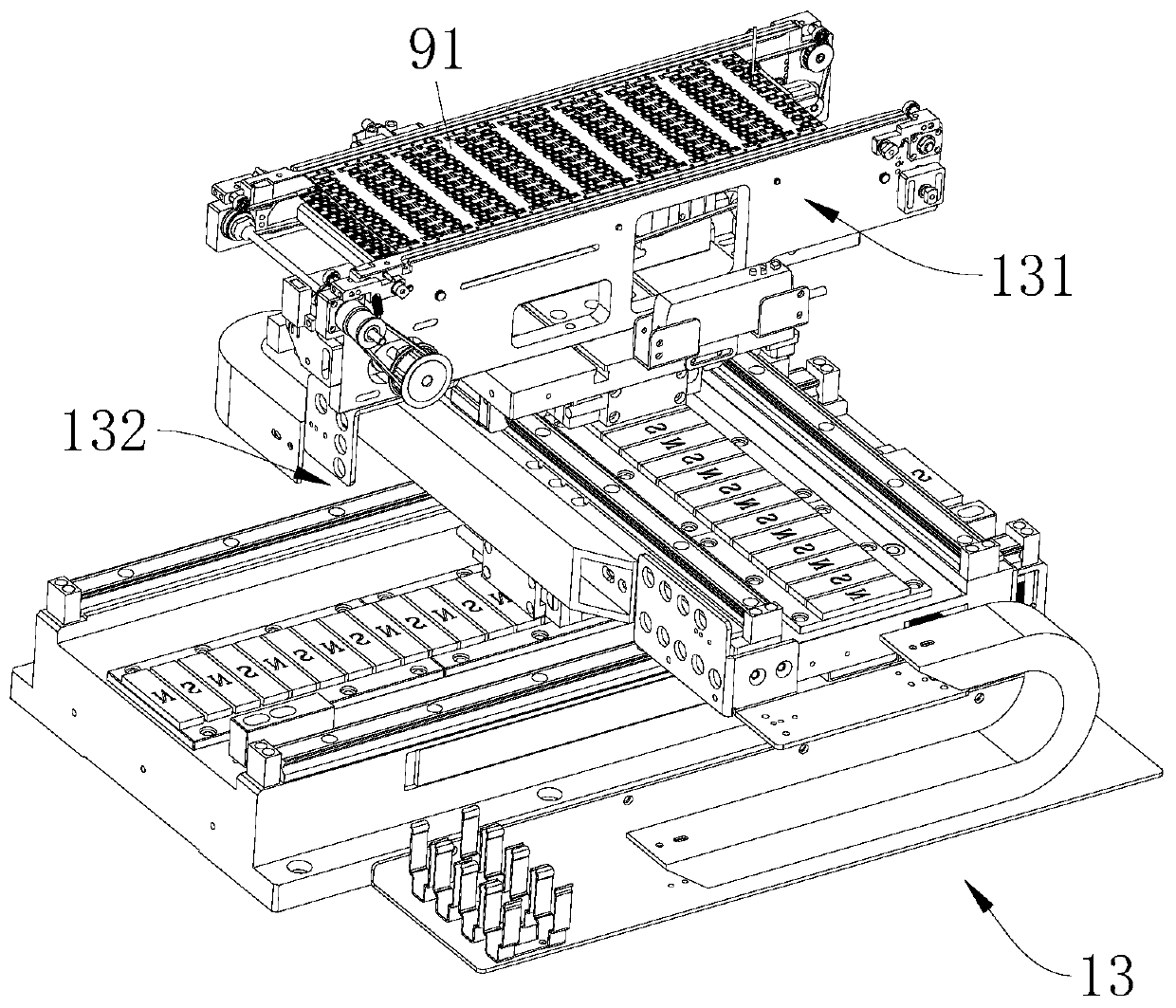

Three-station DITO full-automatic testing machine and testing process thereof

PendingCN109283417AIncrease fluid volumeImprove test efficiencyElectrical testingEngineeringAutomatic testing

The invention discloses a three-station DITO full-automatic testing machine and a testing process thereof. The testing machine comprises a feeding part, a testing part and a discharging part. The testing machine disclosed by the invention comprises the following technical steps: product feeding, product taking and product detection, product photographing correction, product function testing, product transferring and defective product screening, product position correcting and discharging, and material tray discharging. According to the testing machine, a plurality of products are loaded in a centralized manner by adopting the material tray, and the loading part and the discharging part are connected to the front end and the back end of the tested part; the material trays of the feeding part and the discharging part are of a circulating flow type structure, meanwhile, the circulating type taking and placing of the products and the material trays are realized, and the material flowing volume is greatly improved through a laminating and conveying mode; and the test part adopts multi-test-station design, the time periods of testing and product taking and placing are effectively utilized, so that uninterrupted lead-out of the test products is realized, and the screen testing efficiency is greatly improved; and single-piece detection, defective product scanning by two-dimensional codes and the like are integrated to realize real-time screening of defective products.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

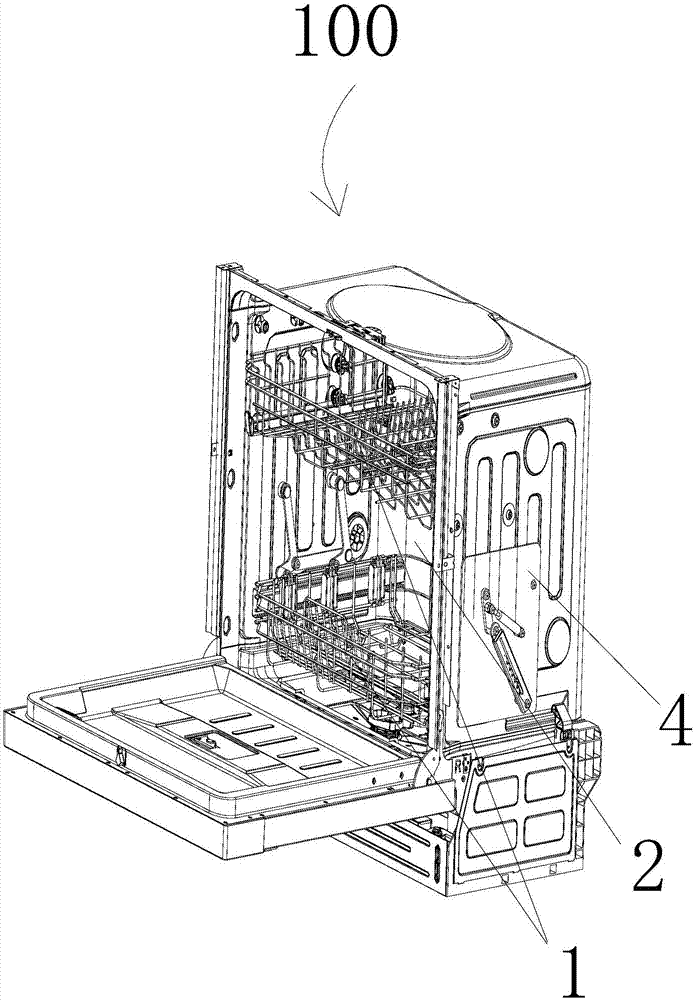

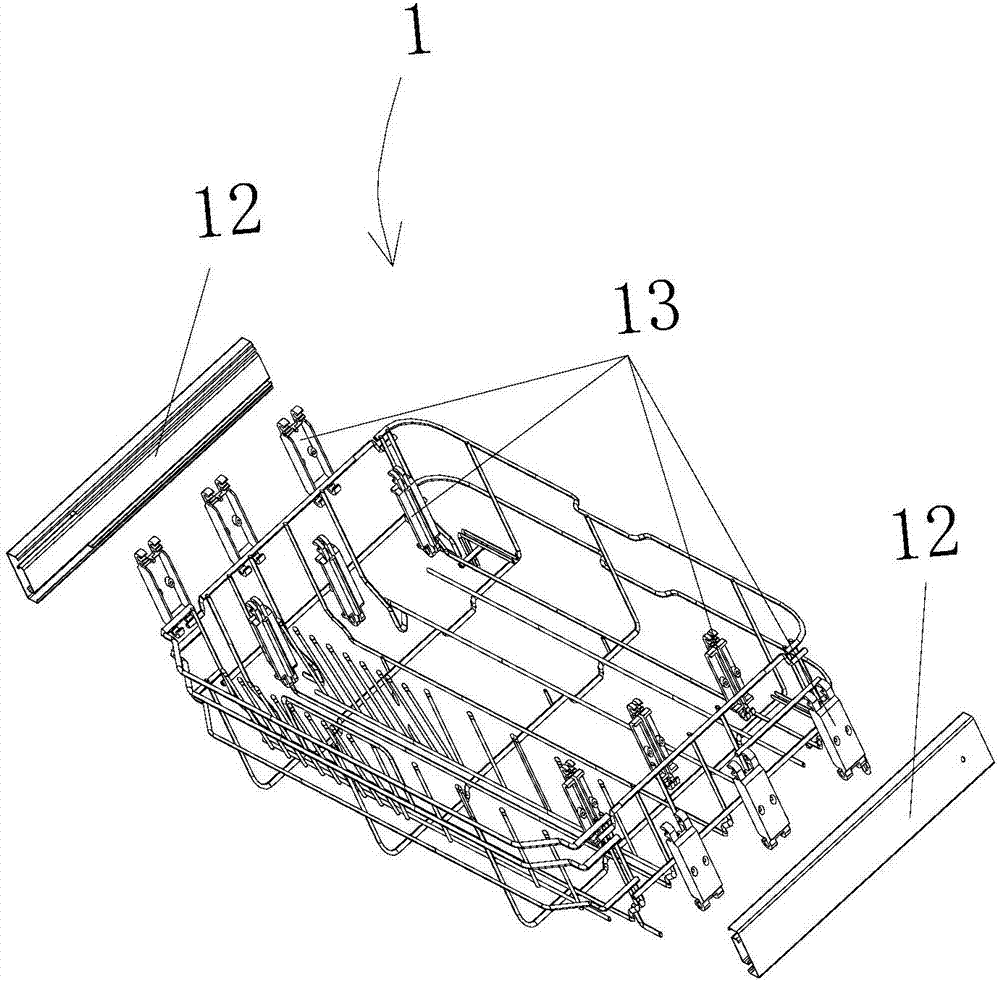

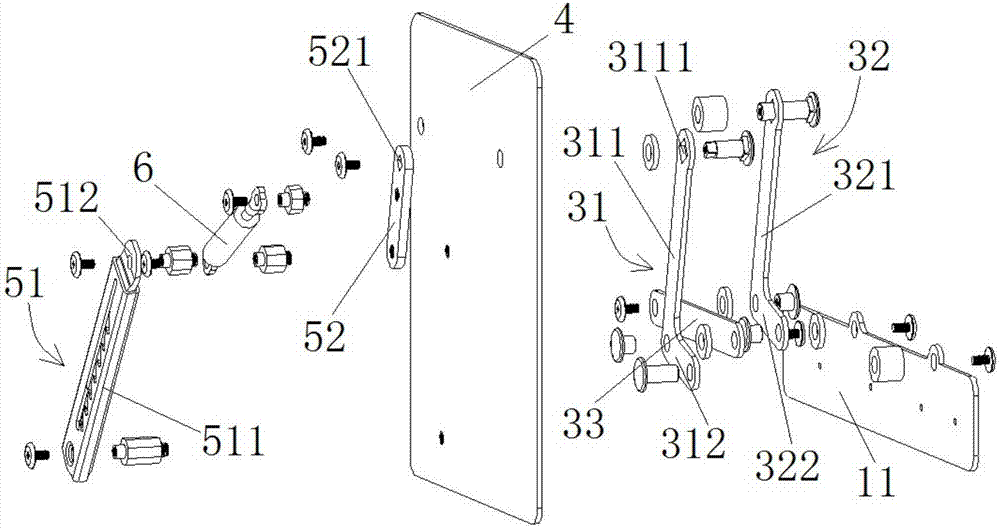

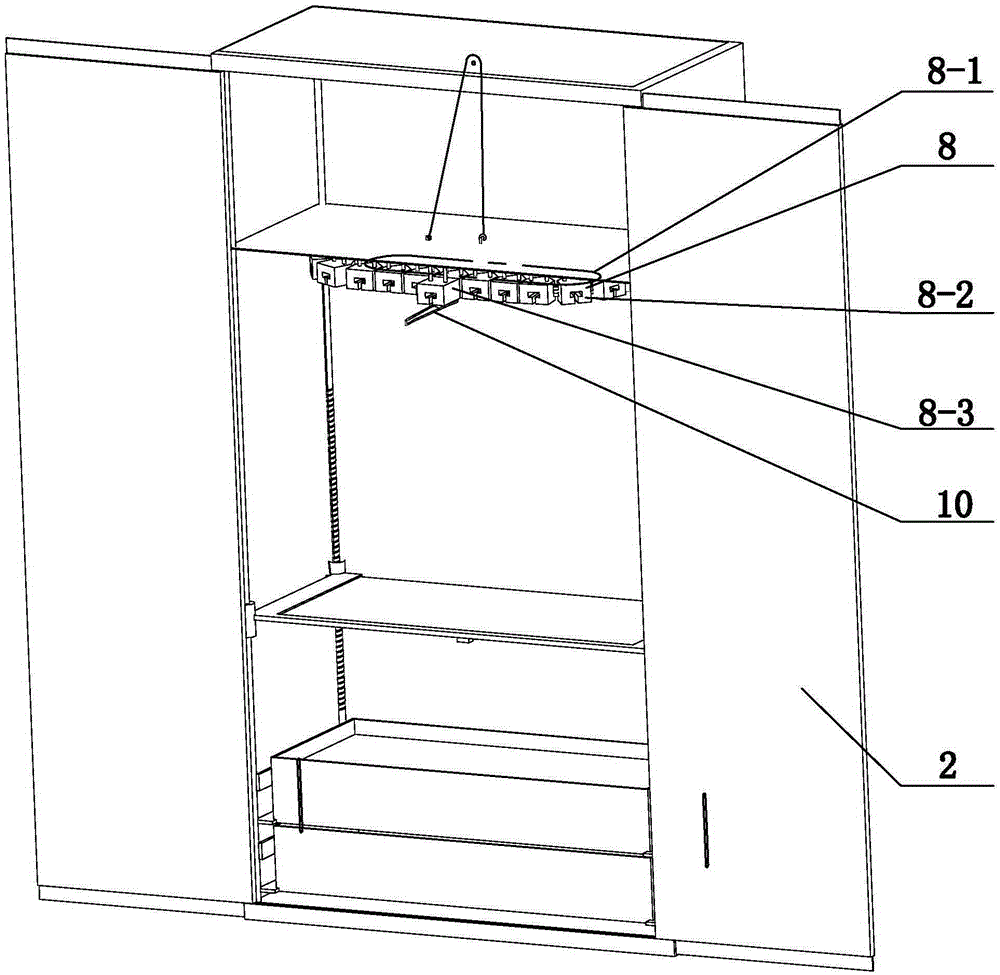

Dish-washing machine bowl basket lifting component and dish-washing machine

ActiveCN107296582AImprove pick-and-place efficiencyEasy to operateTableware washing/rinsing machine detailsMechanical engineeringEngineering

The invention discloses a dish-washing machine bowl basket lifting component which comprises a double-rocker unit and a supporting unit. The double-rocker unit is connected with a dish-washing machine bowl basket (1) to drive the bowl basket (1) to move between the rising position drawing out a dish-washing machine liner (2) and the reducing position pushing in the liner (2), and the supporting unit is connected to the double-rocker unit, so that any position of the bowl basket (1) is positioned and supported when the bowl basket (1) moves from the reducing position to the rising position. The invention further discloses a dish-washing machine comprising the dish-washing machine bowl basket lifting component. According to the dish-washing machine bowl basket lifting component, the height of the dish-washing machine bowl basket changes, a user cannot stoop to take and place tableware, so that taking and placing processes of the tableware are easily operated, and the taking and placing efficiency of the tableware can be improved.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

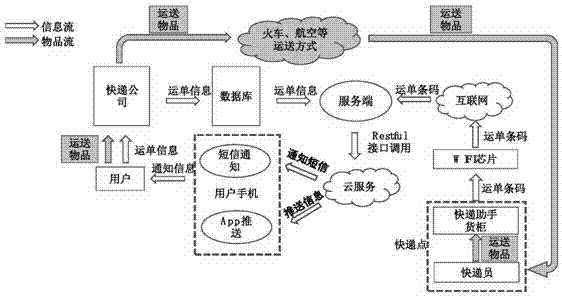

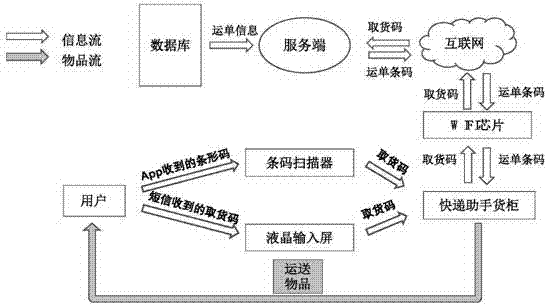

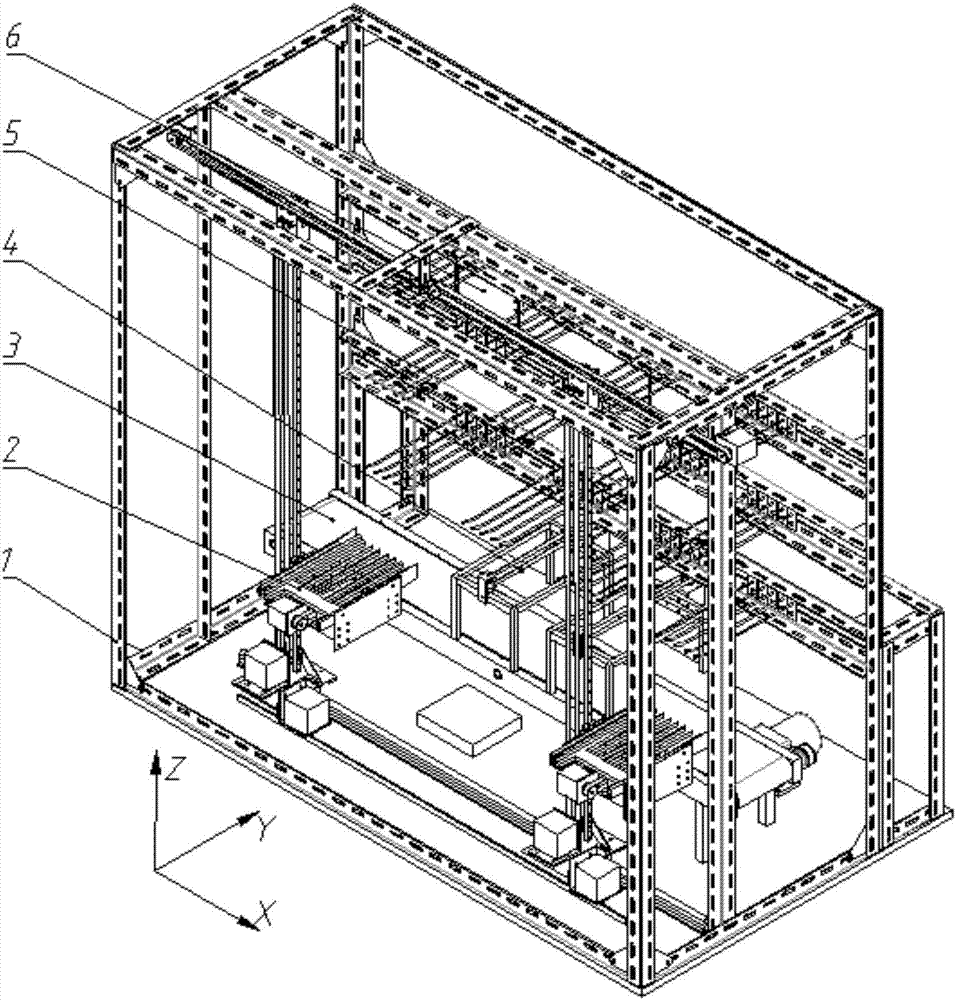

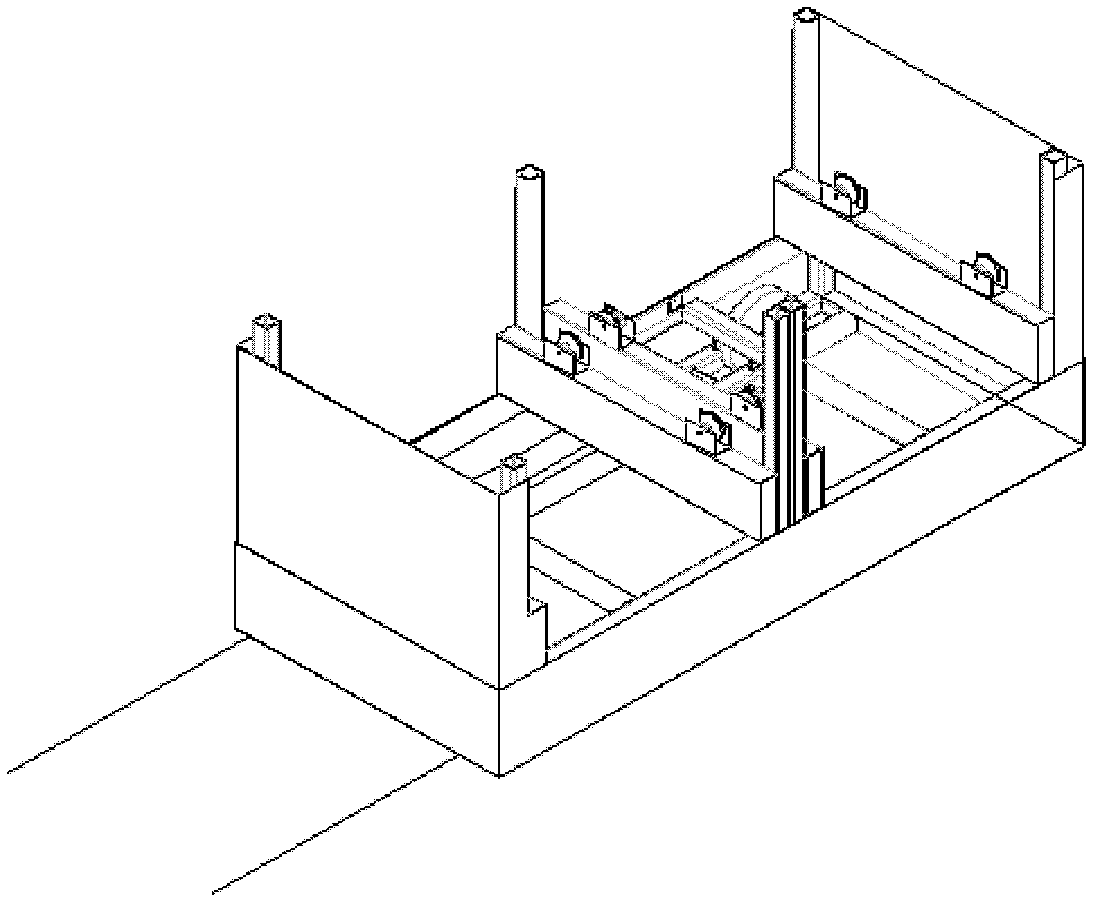

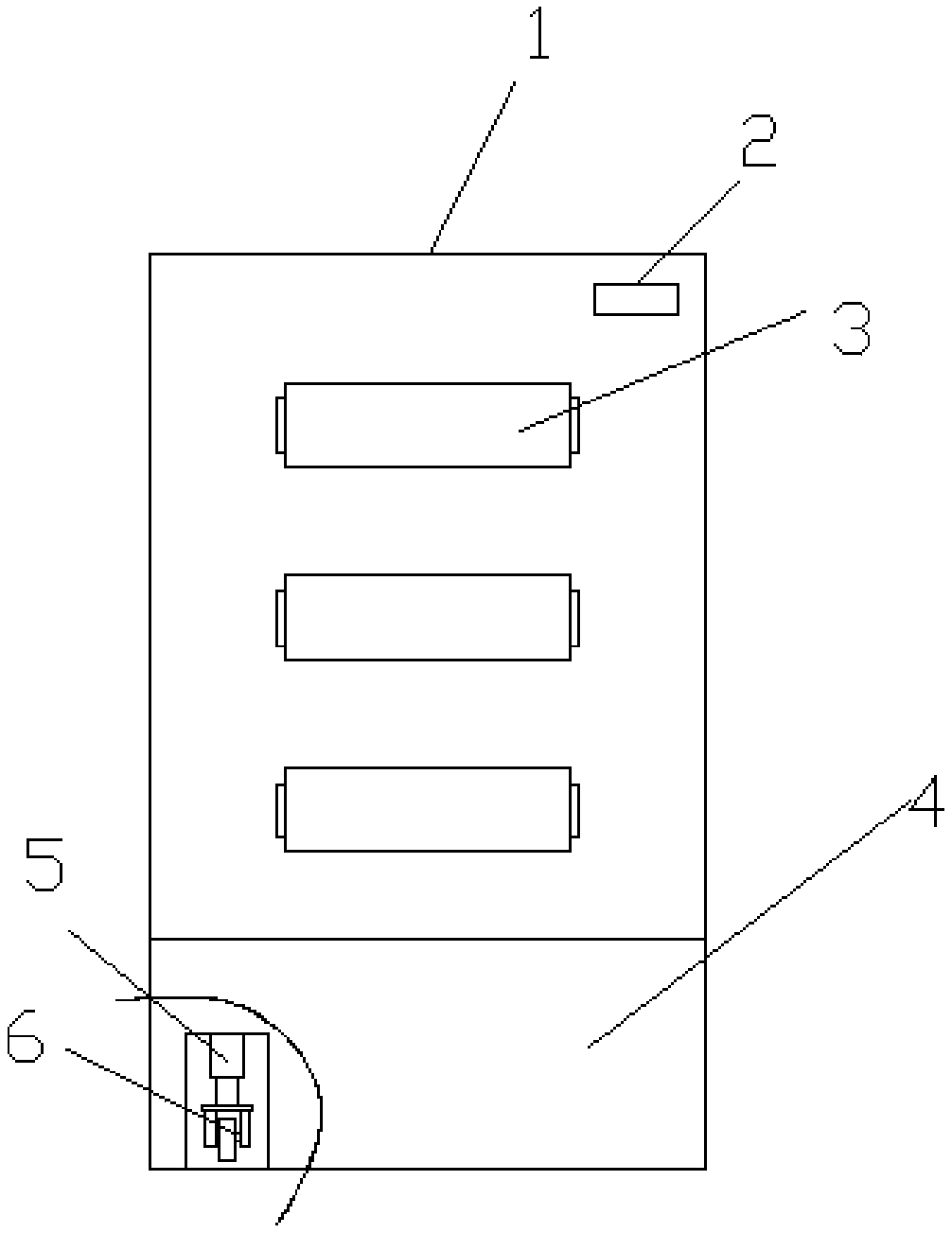

Automatic express storage and fetching system

InactiveCN107452154AReduce labor intensityImprove pick-and-place efficiencyCo-operative working arrangementsApparatus for meter-controlled dispensingTransport engineering

An automatic express storage and fetching system includes a mechanical structure and a control and communication structure; the mechanical structure includes a housing frame for providing a supporting force, a three-coordinate storage and fetching device for storing and fetching goods, a conveying belt device for conveying the goods, a goods pushing device for pushing the goods to the storage and fetching device, a goods shelf for storing the goods, and a goods fetching window for allowing a user to fetch the goods; and the control and communication structure includes a controller and a communication program. The system can improve the automatic level of goods storage and user informing and fetching; when an express reaches, a courier can put the express to the goods cabinet, the goods cabinet can automatically allocate a reasonable storage position for the express and store the express, and can inform fetching information to a user; and when the user fetches the express trough a fetching code, the intelligent cabinet can automatically find the corresponding express, and give the express to the user. The automatic express storage and fetching system can reduce the working load of the courier, can greatly improve the efficiency, and has good use prospect.

Owner:XI AN JIAOTONG UNIV

Replacement system and method for power battery box

InactiveCN102529906ASimple stepsImprove replacement efficiencyElectric propulsion mountingElectric/fluid circuitPower batteryBattery charge

The invention provides a replacement system and a replacement method for a power battery box and solves the problems of replacement adaptability, using of a battery rack, charging environment of a battery and rapid replacement of the battery box of an electric vehicle. The replacement system comprises a manipulator, the battery rack, a shuttle vehicle and a stacking machine, wherein the manipulator is used for loading and unloading the battery from the vehicle; the battery rack is used for storing and charging the battery box; the shuttle vehicle is positioned below the battery rack and is used for temporarily storing the battery required by the manipulator; the stacking machine is used for taking the battery from the shuttle vehicle and placing the battery on the battery rack; the rear part of the stacking machine is provided with a curtain wall; the curtain wall and a closed battery rack front panel have a sealing effect on the system together, so that the optimal battery charging temperature in the battery rack is ensured, the service life of the battery is prolonged and the problem of charging environment of the battery is well solved. In the replacement method, the battery box does not need to be rotated, so that the replacement efficiency of the battery box is improved. The replacement system has reasonable arrangement of parts, small occupied area, high working efficiency, small equipment maintenance amount and stronger universality.

Owner:BEIJING STATE GRID PURUI EXTRA HIGH VOLTAGE POWER TRANSMISSION TECH CO LTD +1

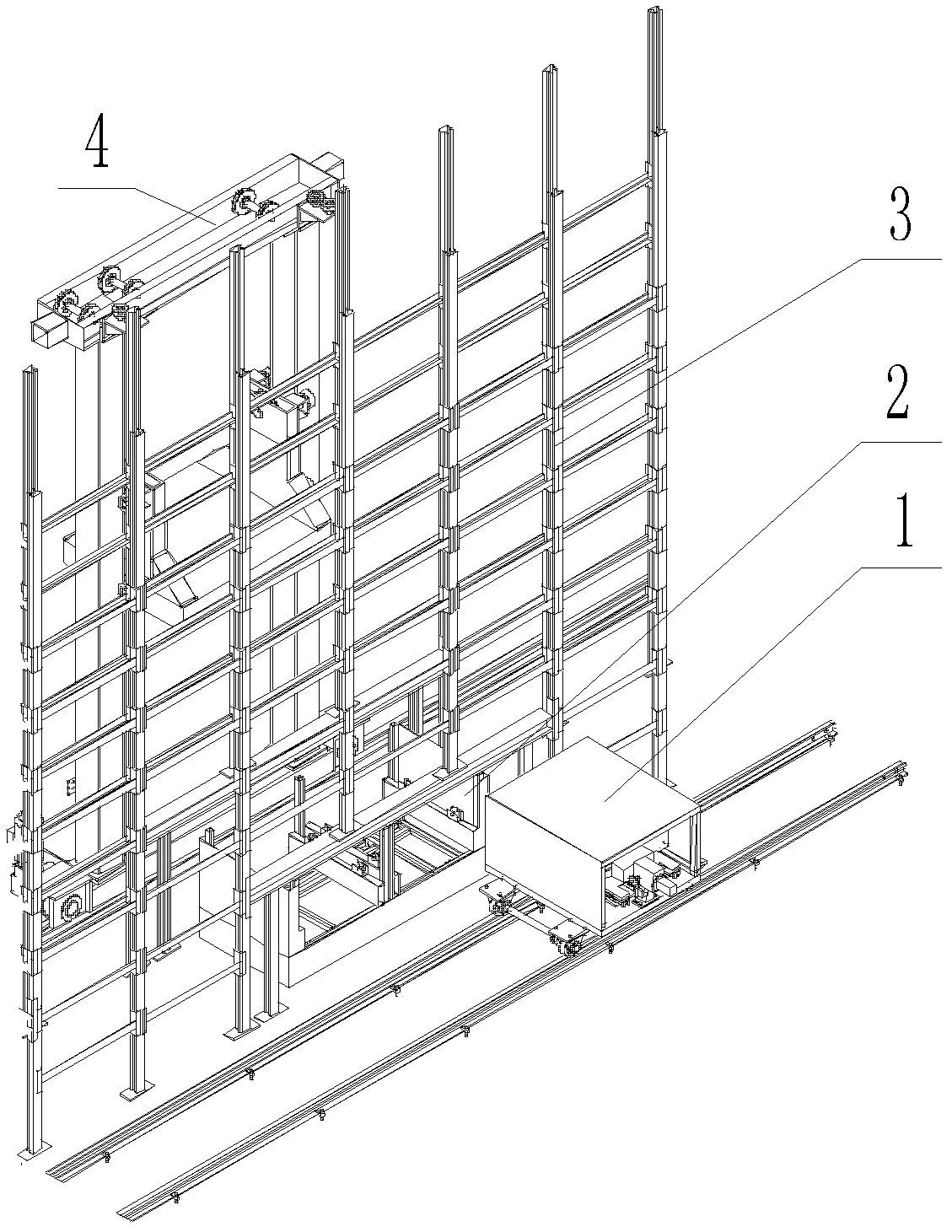

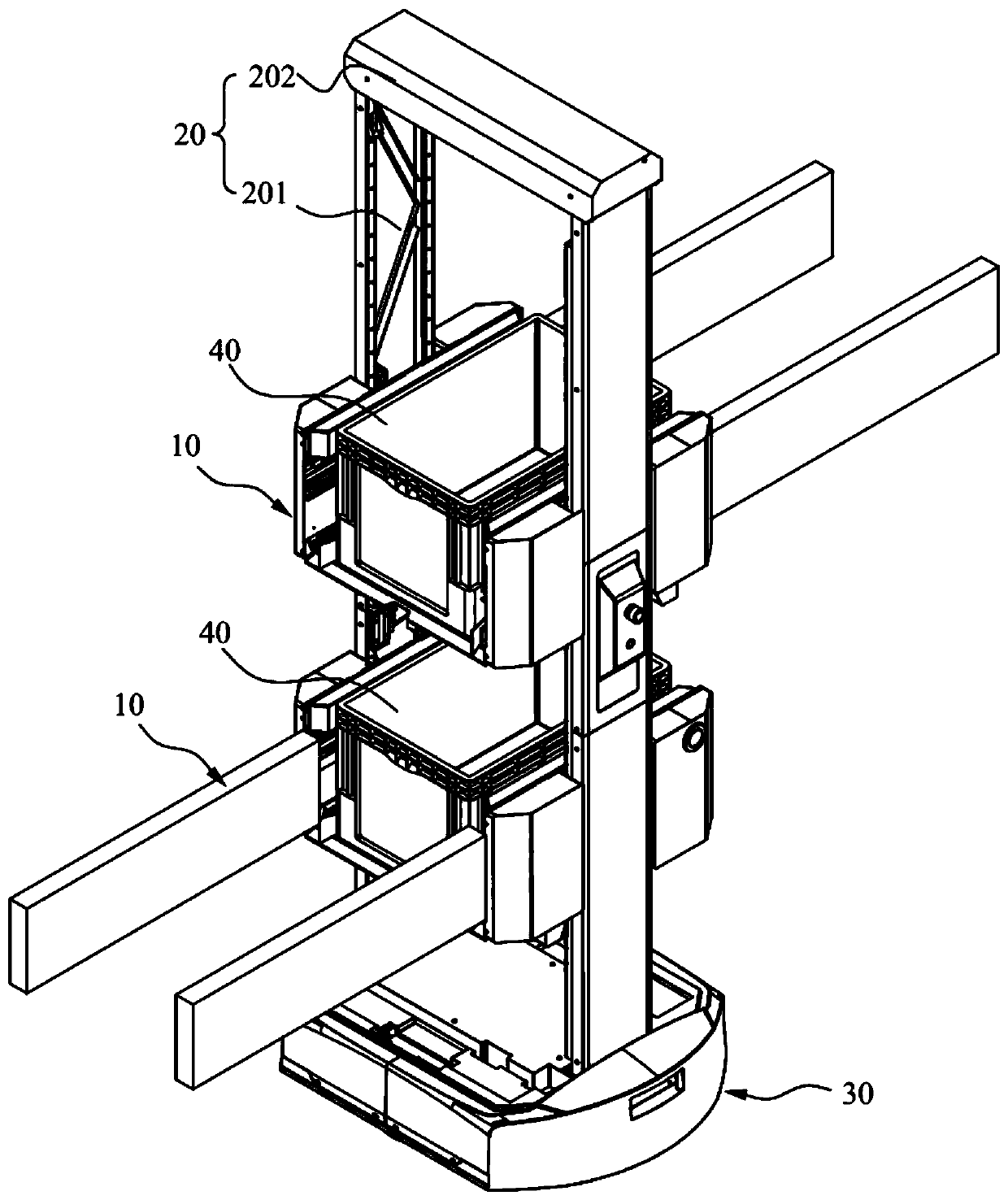

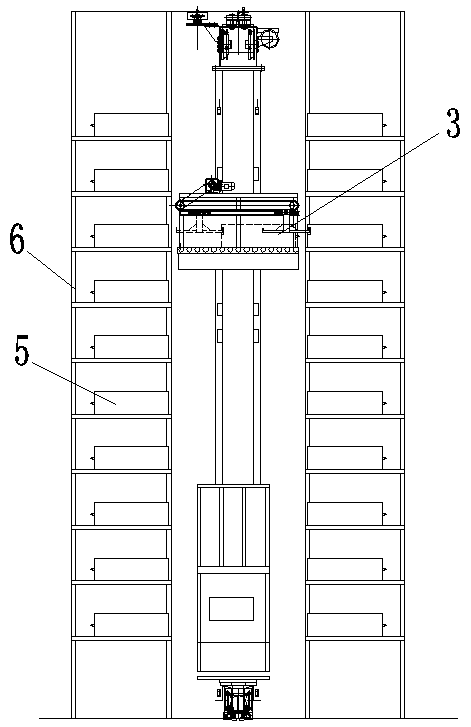

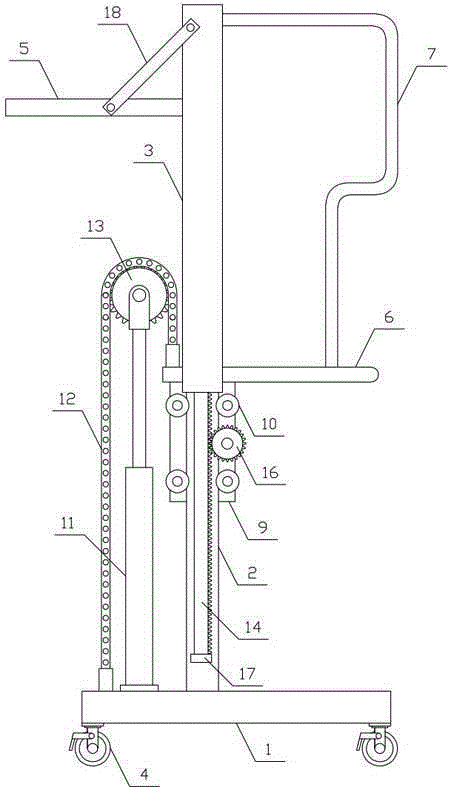

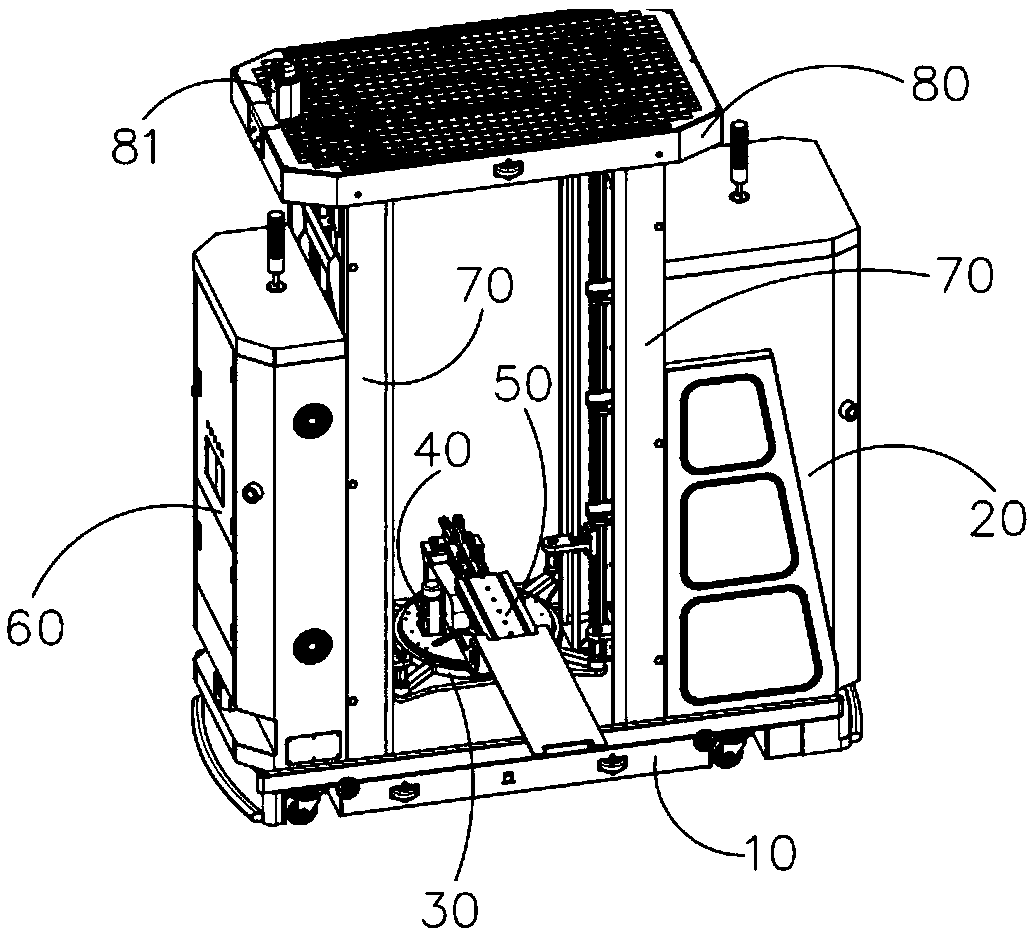

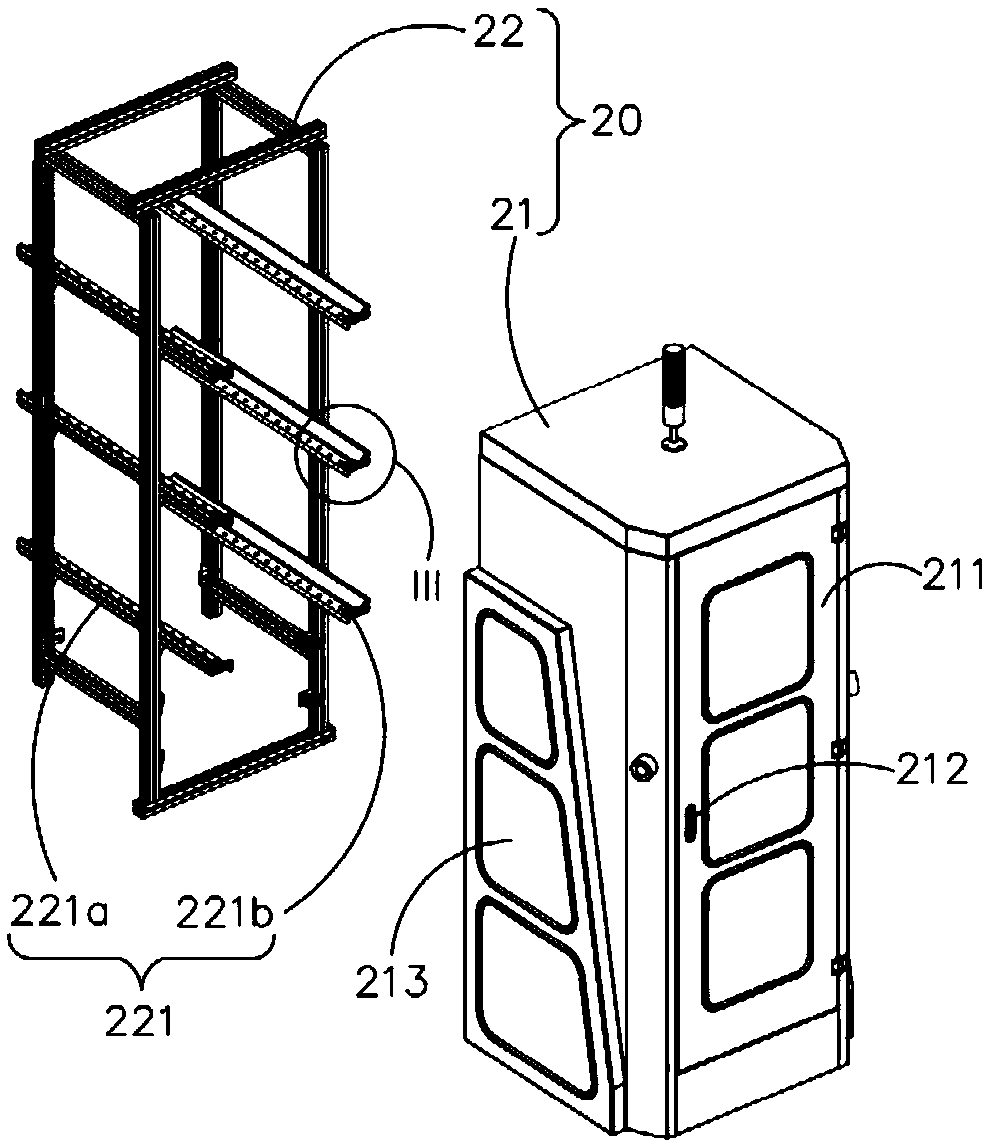

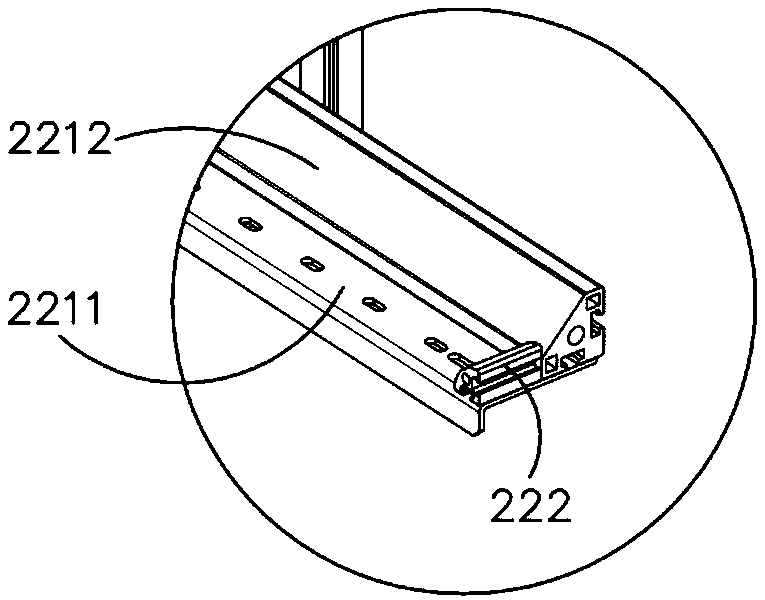

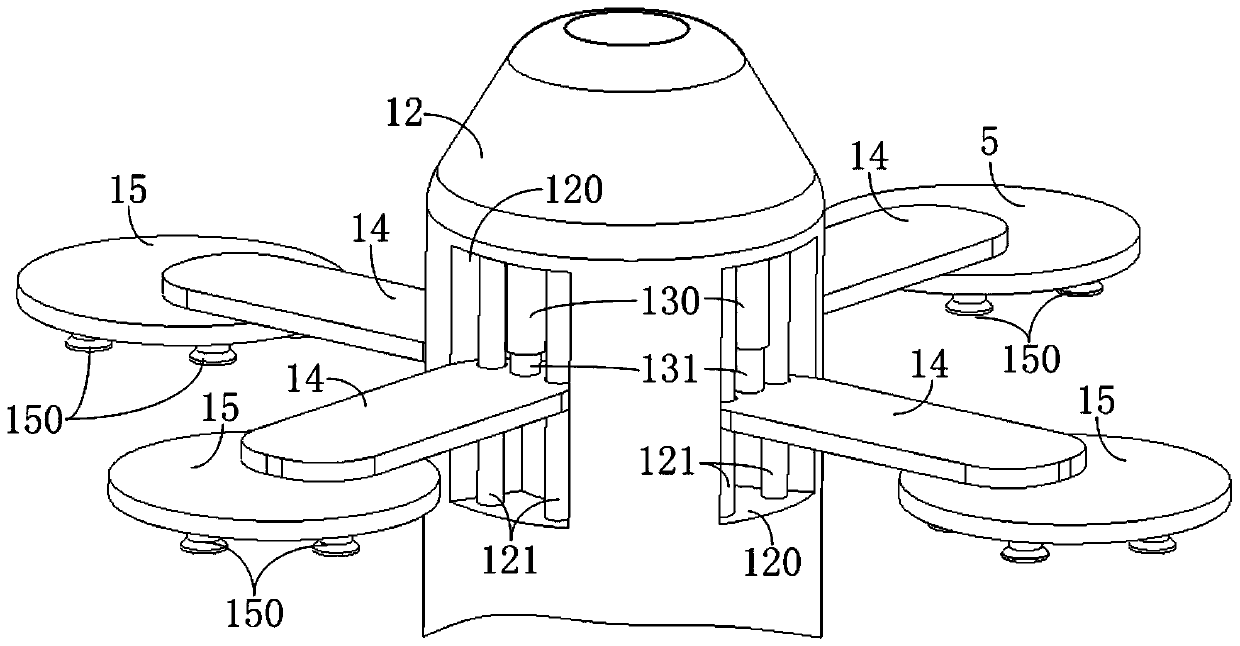

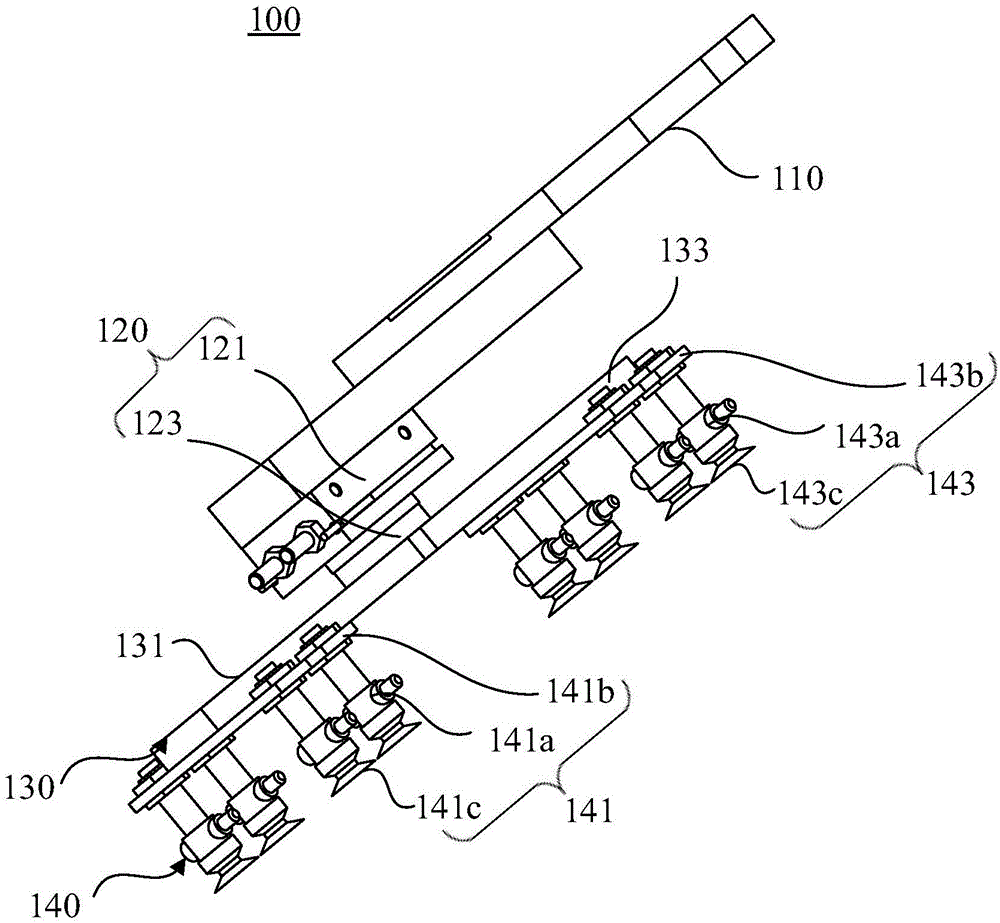

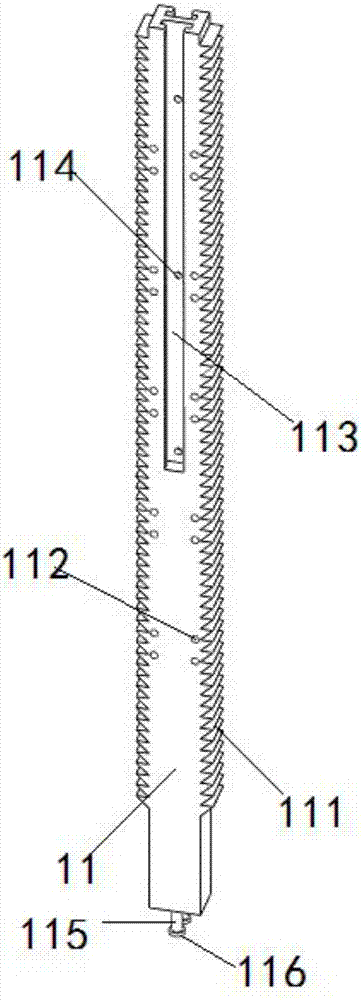

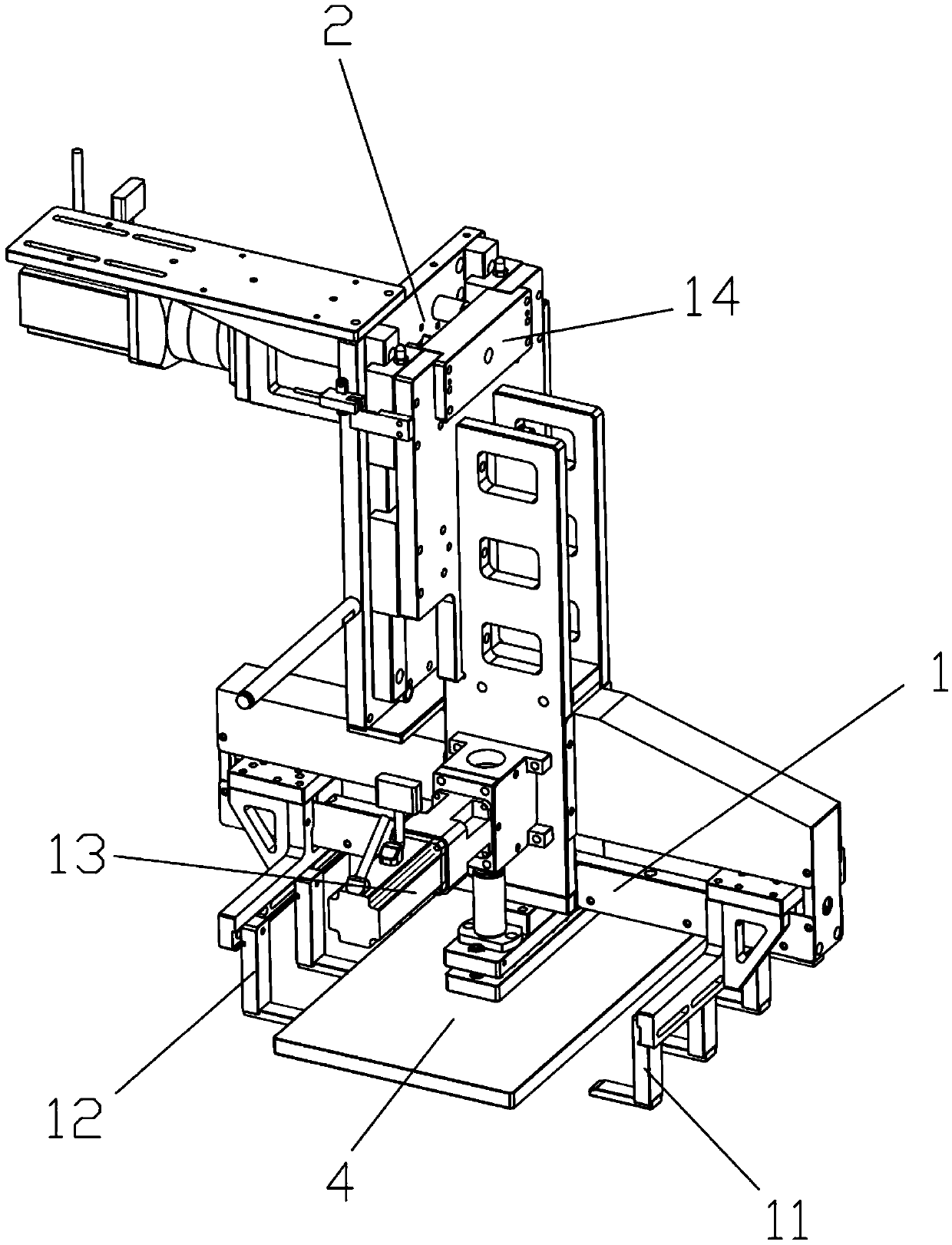

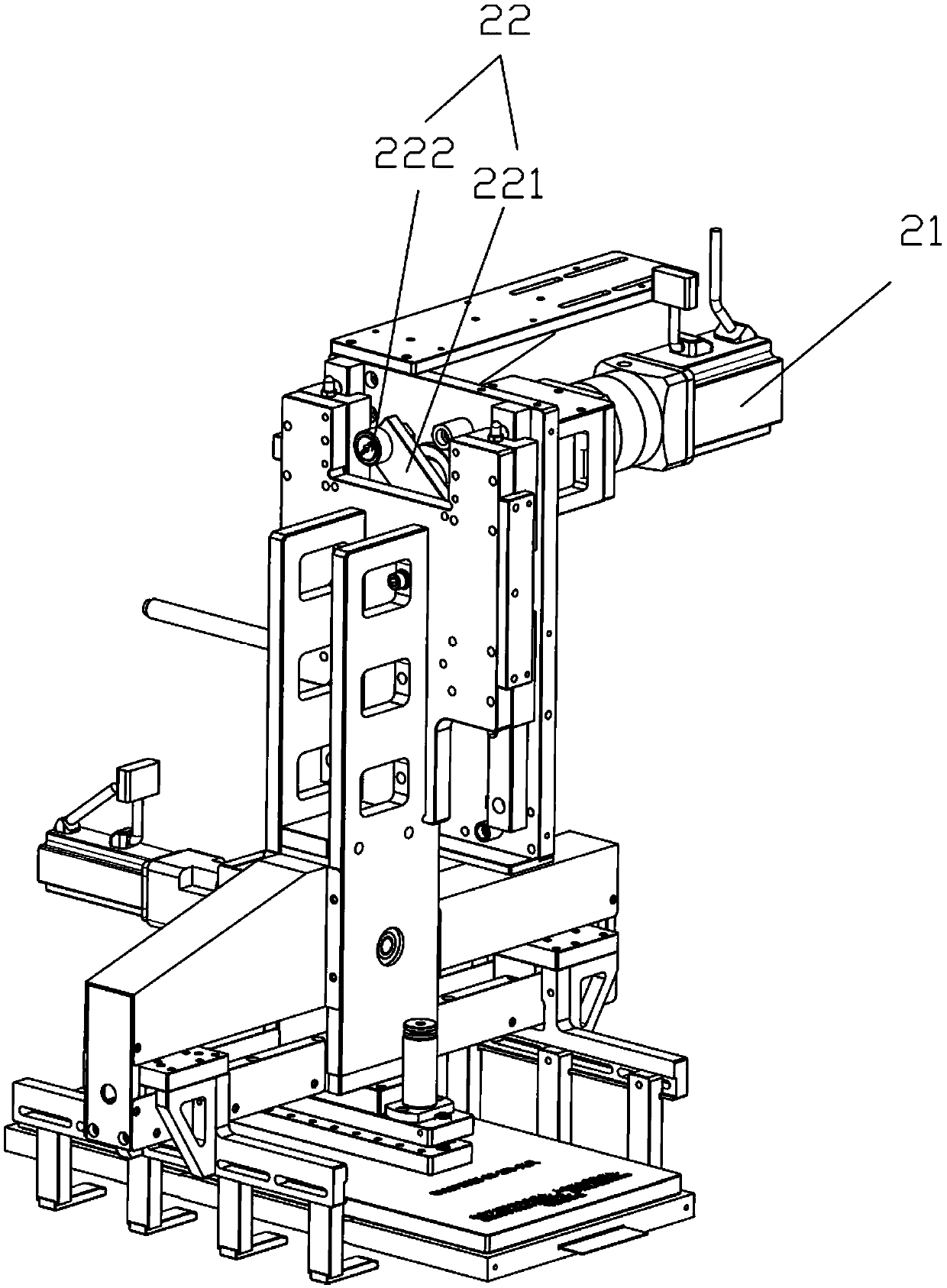

Carrying robot, container taking method, container loading method and warehouse logistics system

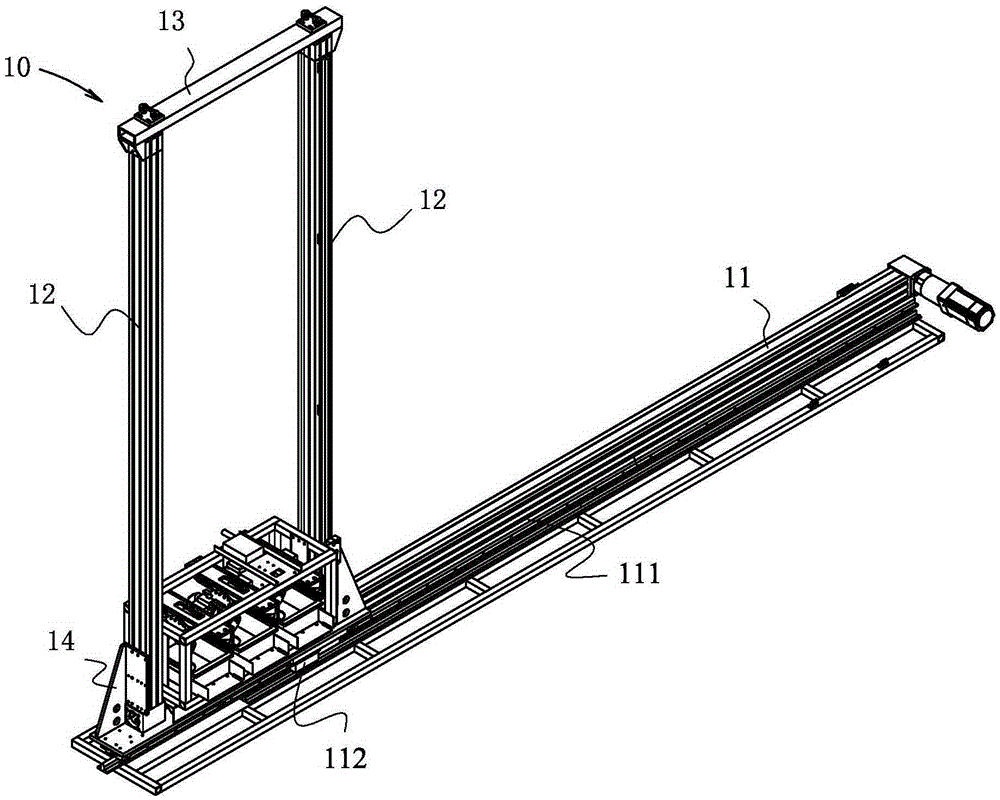

PendingCN111409996AImprove pick-and-place efficiencyImprove picking efficiencyStorage devicesStructural engineeringMechanical engineering

The invention belongs to the technical field of warehouse logistics, and particularly discloses a carrying robot, a container taking method, a container loading method and a warehouse logistics system. The carrying robot comprises a movable bottom plate, a vertical frame and container taking mechanisms, wherein the vertical frame is vertically arranged on the movable bottom plate; and at least twosets of container taking mechanisms are arranged in the height direction of the vertical frame, and each set of container taking mechanisms can horizontally stretch out and draw back and vertically ascend and descend relative to the movable bottom plate so as to pick up a container on an inventory containing device or place the container on the inventory containing device. The container taking method is applied to the carrying robot for container taking operation, the container loading method is used for carrying out container loading operation based on the carrying robot, and the warehouse logistics system comprises the carrying robot. According to the carrying robot, the container taking method, the container loading method and the warehouse logistics system, the sorting and logistics efficiency can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

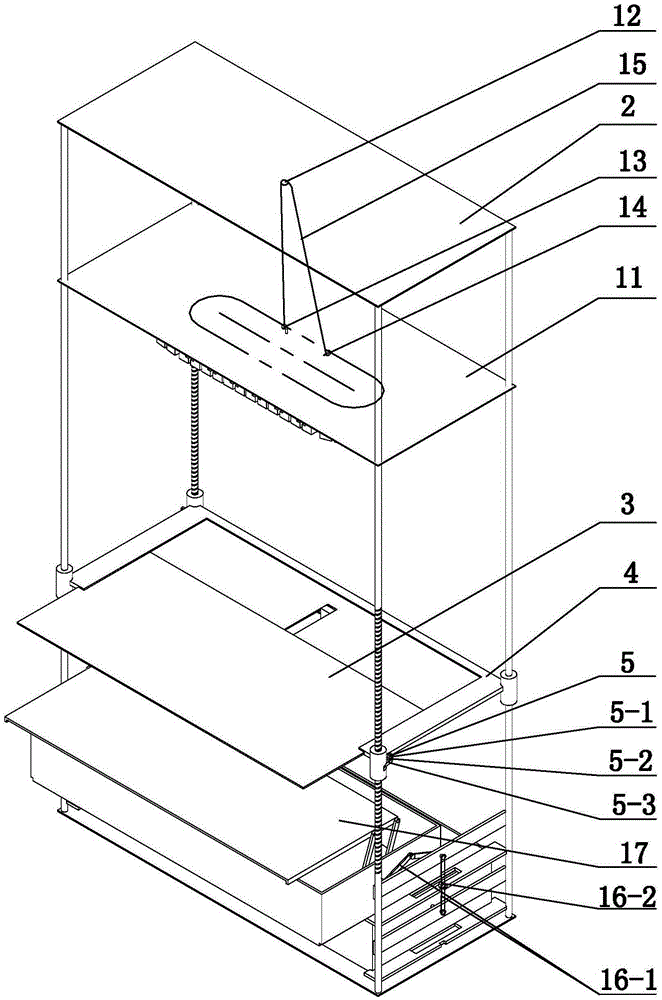

Intelligent wardrobe

The invention discloses an intelligent wardrobe. The intelligent wardrobe comprises a cabinet body and cabinet doors, wherein the cabinet body is divided into two partitions through a middle-layer partition plate, and the middle-layer partition plate moves up and down through a lifting mechanism connected therewith. According to the intelligent wardrobe, clothes can be conveniently taken and placed through the middle-layer partition plate capable of rising and falling and a clothes hanging mechanism; moreover, the clothes can be placed in drawers in a classified mode, thereby being convenient to find.

Owner:苏宁

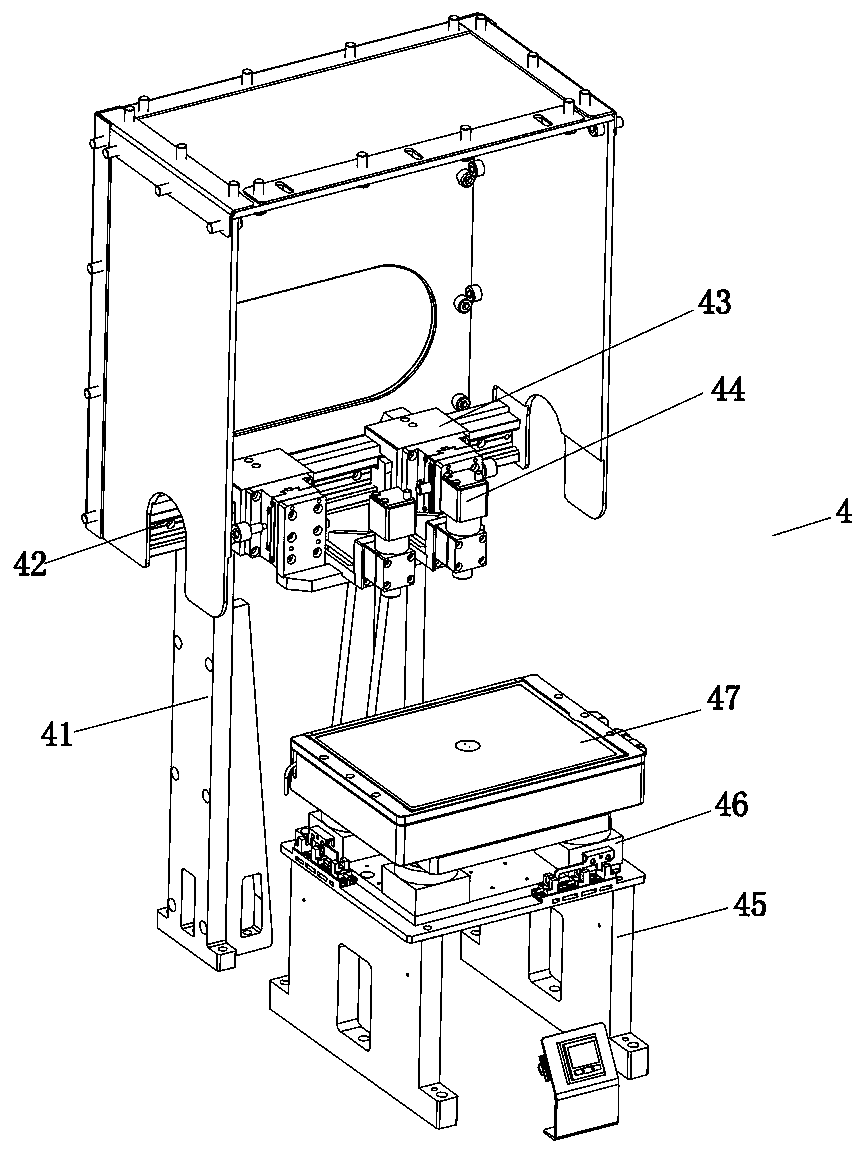

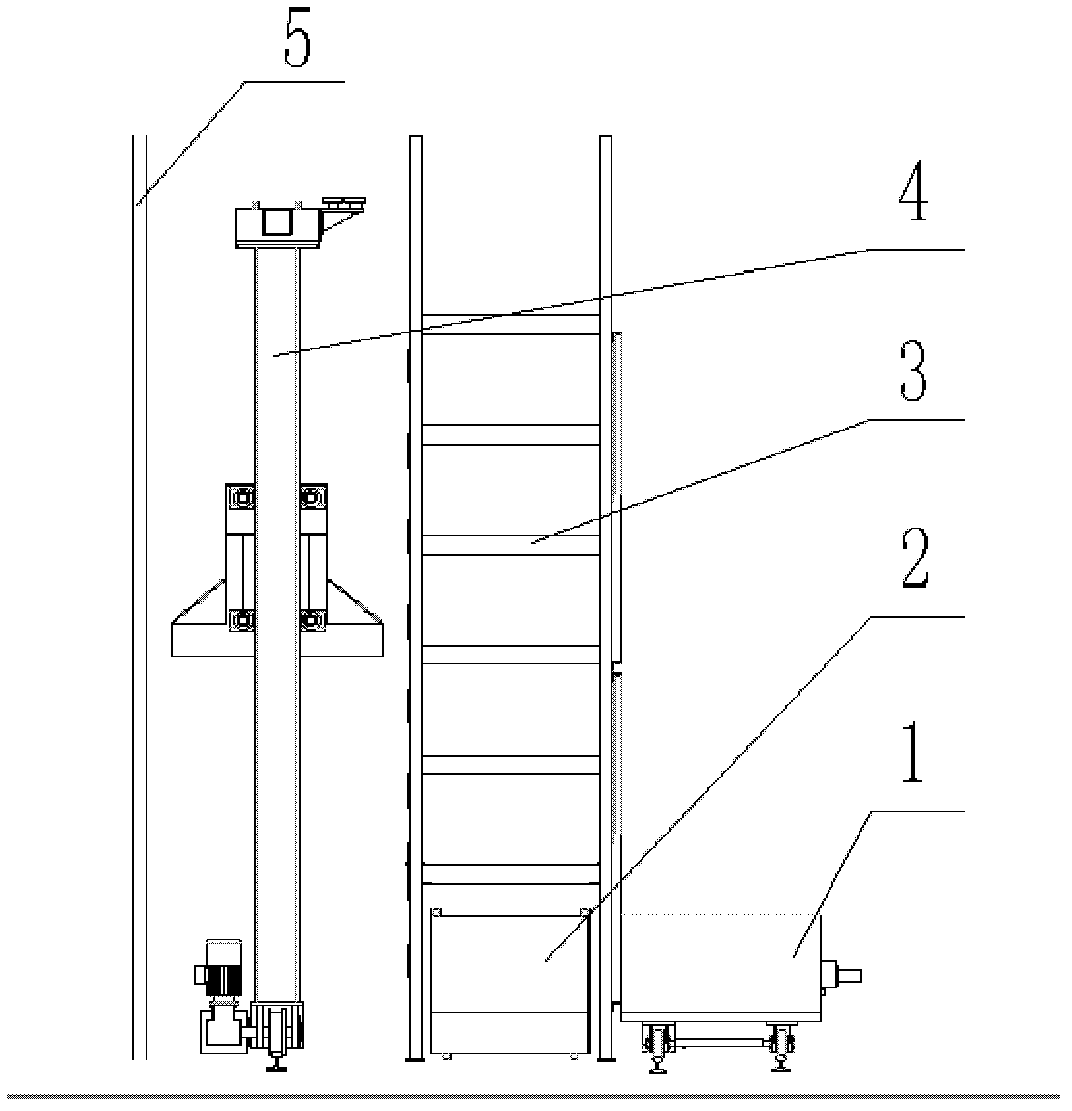

Piano type stacker device

The invention relates to a piano type stacker device. A motor, an electromagnetic clutch drive system and a cantilever type hook are arranged on a cargo carrying table. A transmission shaft is connected with an output shaft of the motor. A driving part of an electromagnetic clutch is connected with the transmission shaft, and a driven part of the electromagnetic clutch is connected with a chain wheel. The chain wheel is connected with a chain and drives the chain to horizontally move back and forth. A connecting part is connected with the chain, and the chain drives the connecting part to horizontally move back and forth. The cantilever type hook is connected with the connecting part, and the connecting part drives the cantilever type hook to horizontally move back and forth. Hooks for hooking battery handles are arranged on the cantilever type hook. According to the piano type stacker device, a stacker quickly and accurately fetches and places batteries in a hooking mode, the multiple batteries in a battery compartment can be simultaneously fetched out at one time and a part of the batteries can be independently fetched out, the stacker device is convenient and flexible to use, and fetching and placing efficiency is greatly improved.

Owner:CHINA UNITED ENG +1

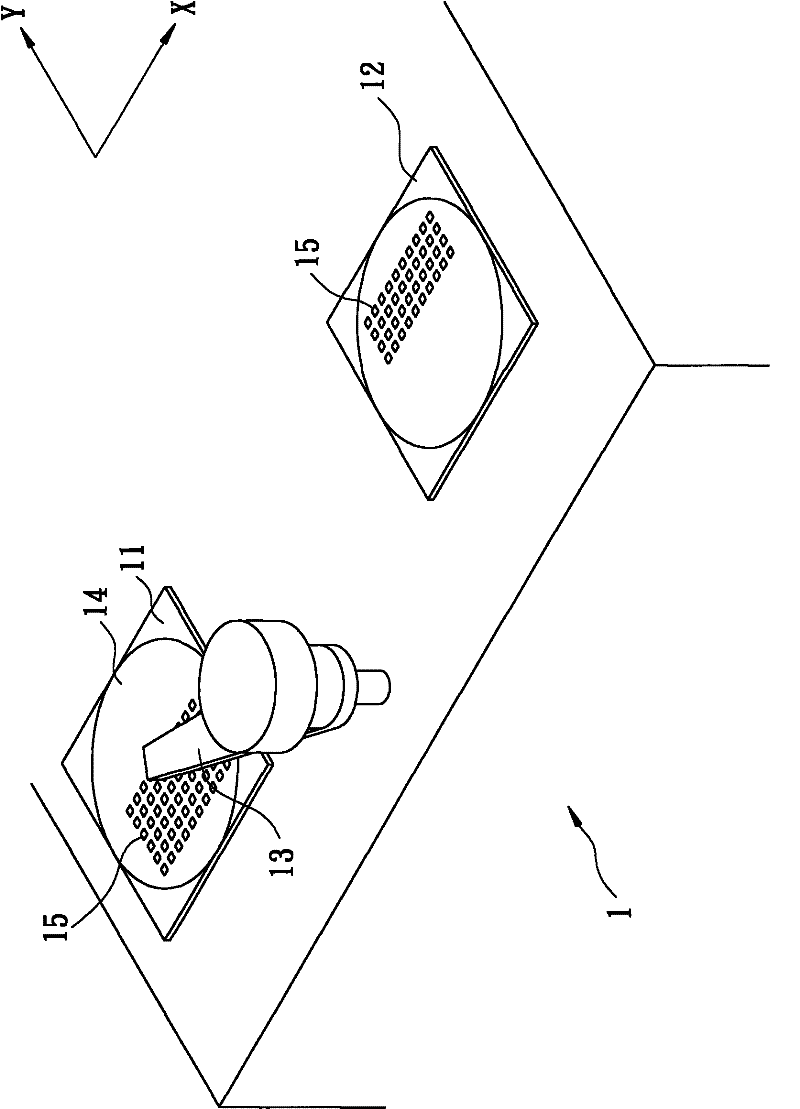

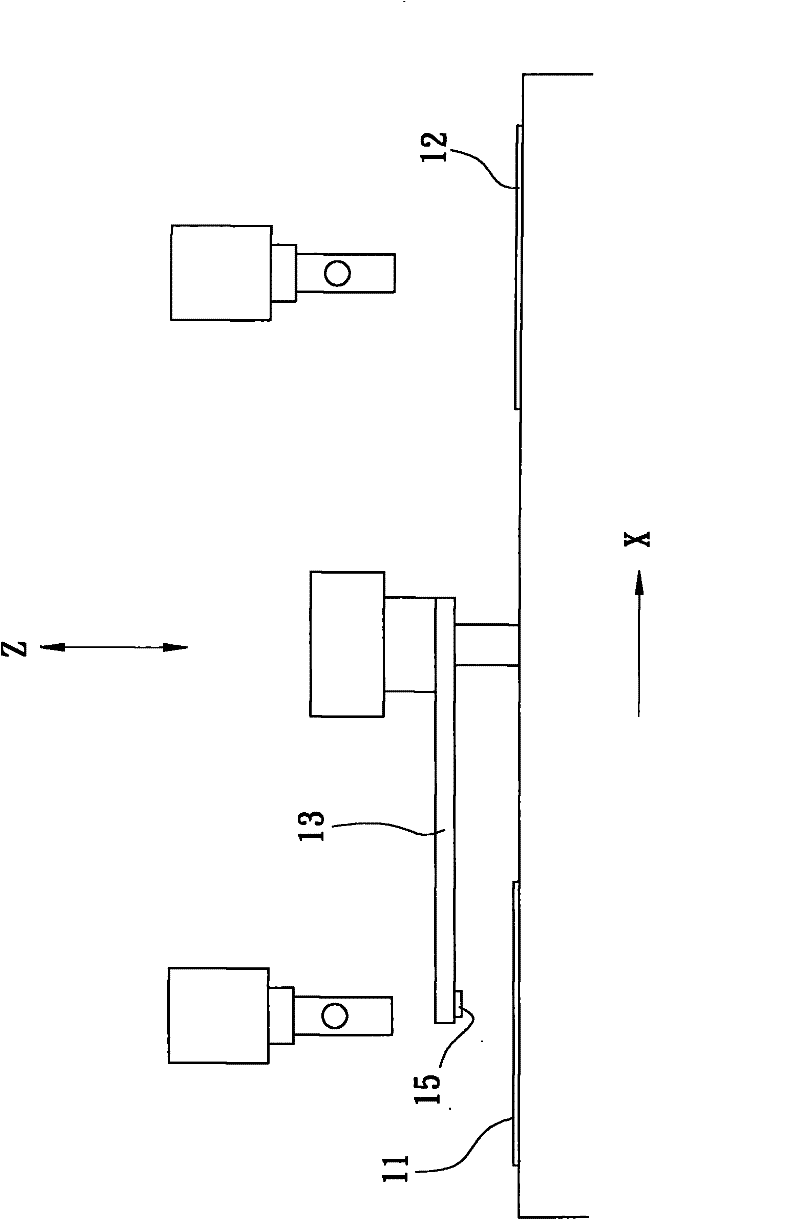

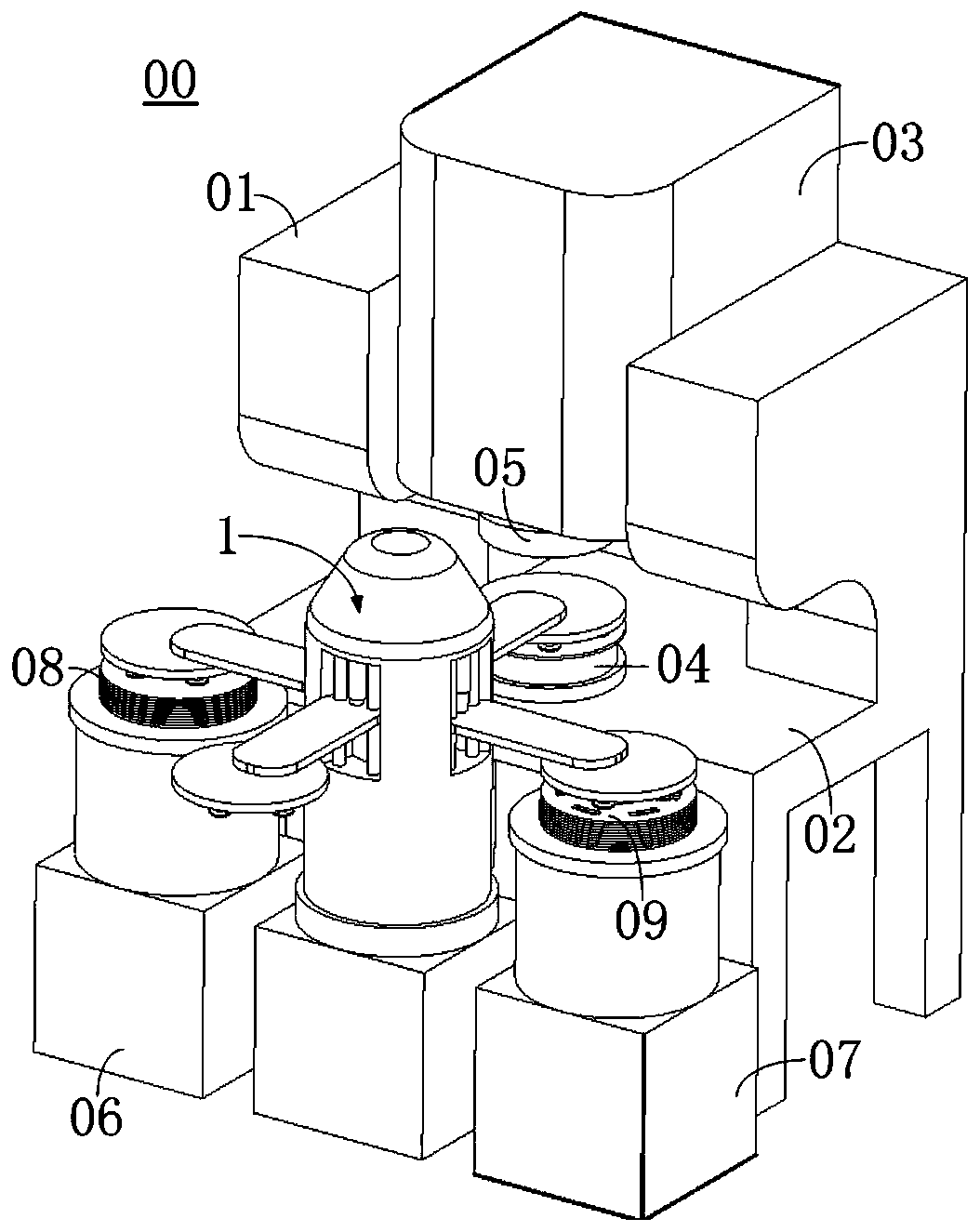

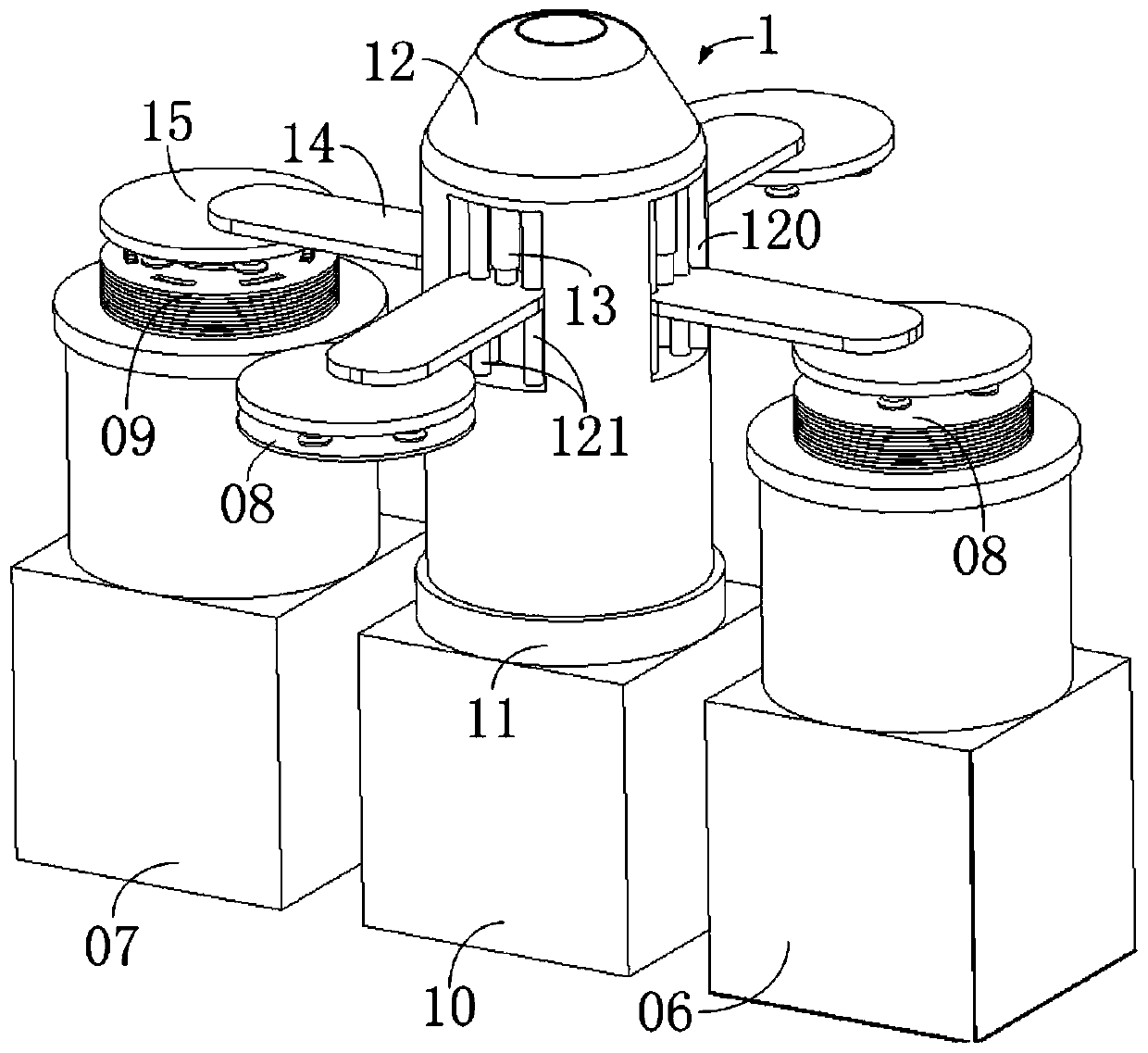

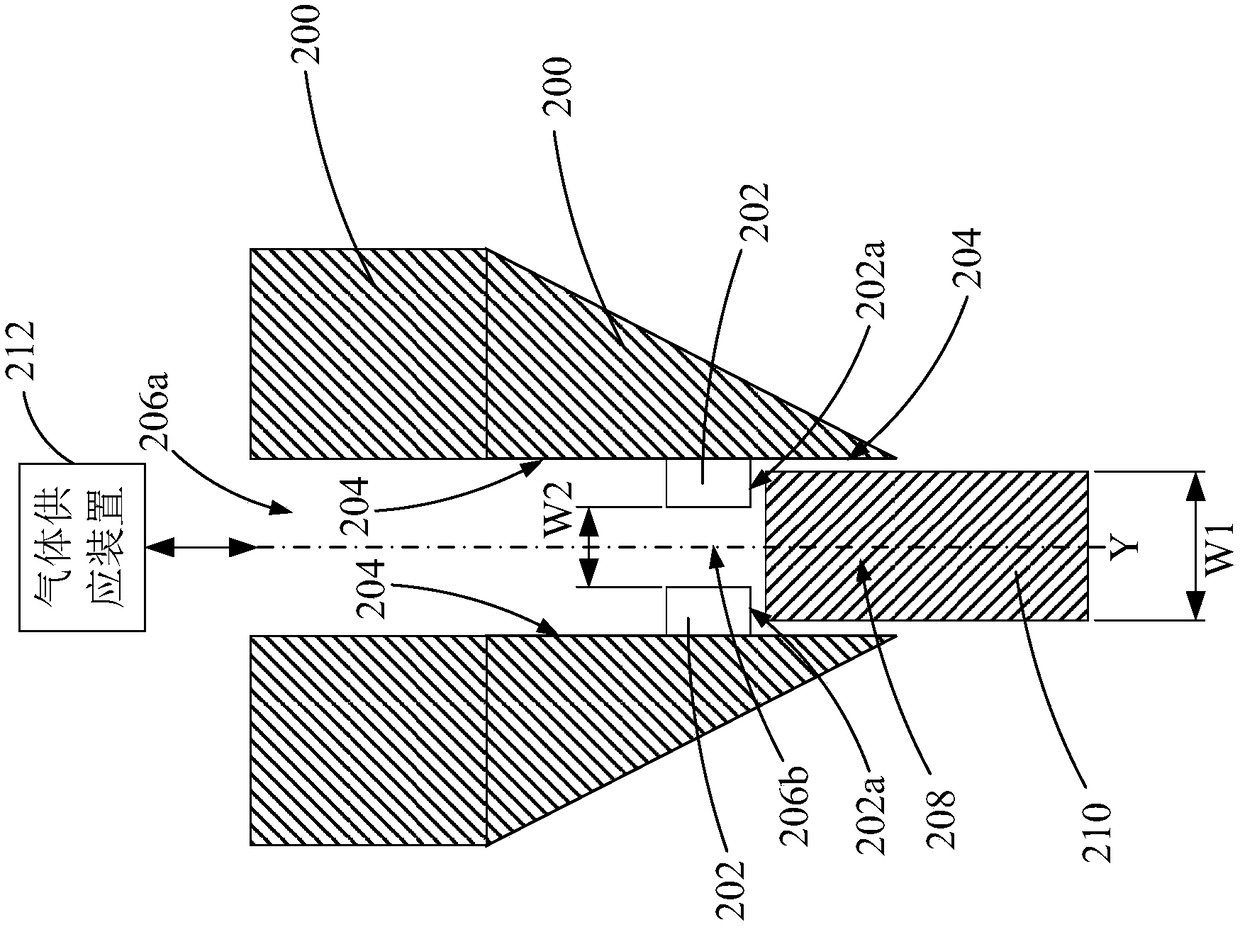

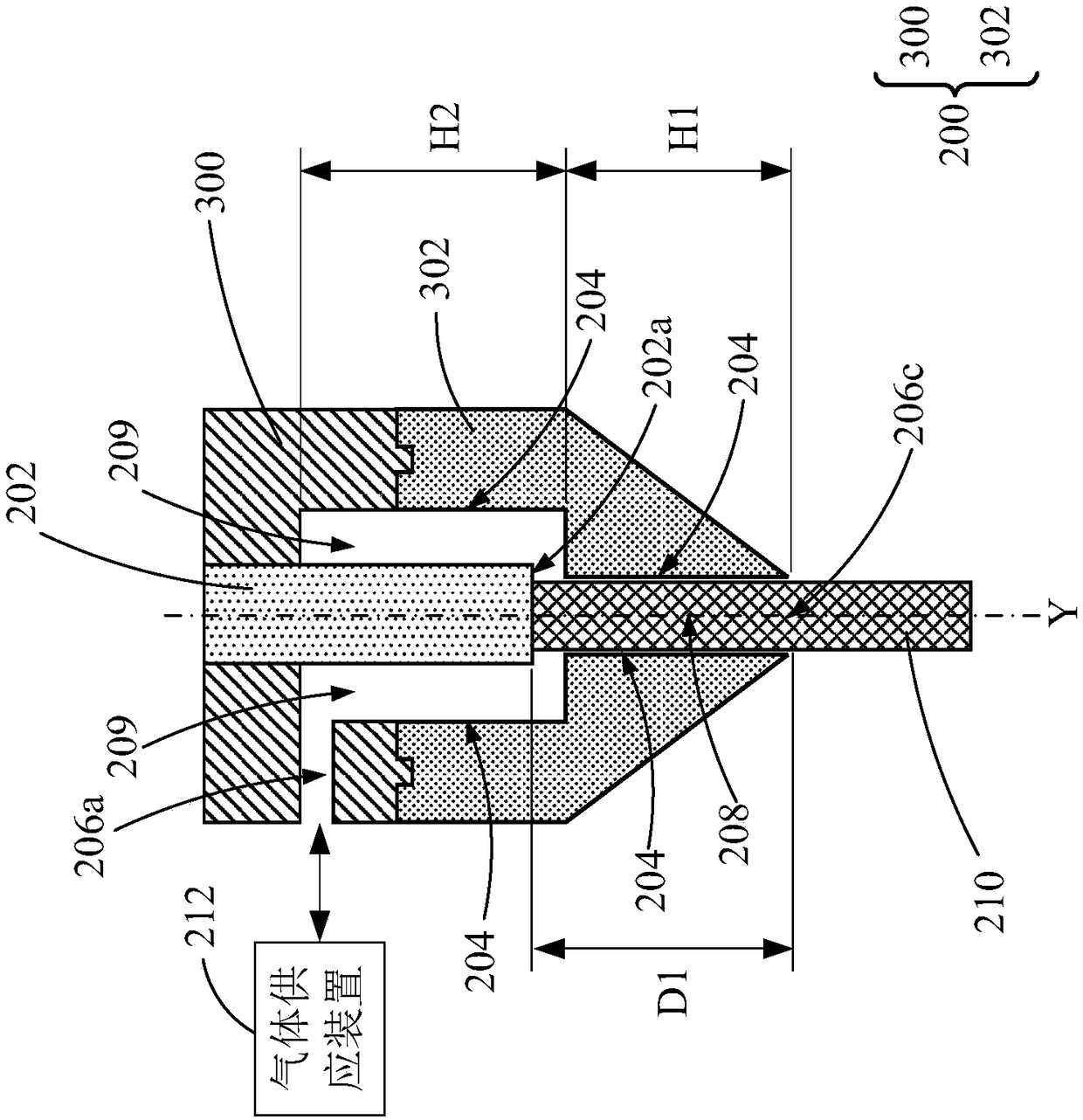

Sorter pick-and-place device

InactiveCN102266855AReduce volumeImprove pick-and-place efficiencyGripping headsSortingEngineeringMechanical engineering

A pick-and-place device for a sorter includes a tray to be sorted and a tray to be sorted that move along a first direction and a second direction respectively, the sorted tray is arranged at intervals from the tray to be sorted along the first direction, and a pick-and-place arm set It is arranged in the middle of the tray to be sorted and the sorted tray along the first direction. The pick-and-place arm group includes two pick-and-place arms arranged at 180 degrees apart from each other. The placing arm is positioned above the sorted tray to place semiconductor components synchronously, effectively improving the efficiency of picking and placing semiconductor components.

Owner:PRECISION MACHINERY RES & DEV CENT +1

Lifting type cargo taking device

InactiveCN105217524AEasy accessImprove pick-and-place efficiencyLifting devicesMechanical equipmentIndustrial engineering

The invention discloses a lifting type cargo taking device, and belongs to the field of storage mechanical equipment. The lifting type cargo taking device comprises a transverse movement base, a lifting guide rail, a lifting support and a driving mechanism; the driving mechanism is vertically arranged between the transverse movement base and the lifting support, and a plurality of universal wheels with brakes are evenly arranged on the lower side of the transverse movement base; the lifting support is vertically and symmetrically arranged on the upper side of the lifting guide rail and can move along the lifting guide rail, a cargo carrying platform is horizontally arranged on one side of the upper end of the lifting support, and a person carrying platform is horizontally arranged on the other side of the lower end of the lifting support; supporting plates are vertically and symmetrically arranged on the two sides of the lower portion of the person carrying platform, and two sets of lifting rollers are sequentially arranged on the outer side of each supporting plate from top to bottom; and guide grooves matched with the lifting guide rail are arranged on the lifting rollers. The lifting type cargo taking device is simple in structure, the person carrying platform can be lifted according to requirements, cargoes on the high positions can be rapidly and efficiently taken and placed, and the storage and using requirements are met.

Owner:曹林仙

Die bonder

ActiveCN111370350AGuaranteed dispensing accuracyEnsure dispensing qualitySemiconductor/solid-state device manufacturingWaferingElectric machinery

The invention provides a die bonder. The die bonder comprises a rack; a dispensing device; a dispensing shifting mechanism; a feeding mechanism; a die bonding swing arm device; a crystal supply platform; a die bonding displacement mechanism; and a material receiving mechanism. The die bonding swing arm device comprises a rotating frame, a plurality of die bonding swing arms, a lifter and a die bonding motor, and each die bonding swing arm is provided with a suction nozzle; the dispensing device comprises a plurality of dispensing modules. The invention provides a die bonder. According to the invention, the plurality of dispensing modules are combined with the plurality of die bonding swing arms, so that the operation speeds of the plurality of dispensing modules can be adjusted to be matched with the operation speeds of the plurality of die bonding swing arms on the premise of ensuring the dispensing precision and quality and ensuring the wafer taking and placing precision, the idle time of each dispensing module and each die bonding swing arm is reduced, and the die bonding efficiency is greatly improved.

Owner:SHENZHEN XINYICHANG TECH CO LTD

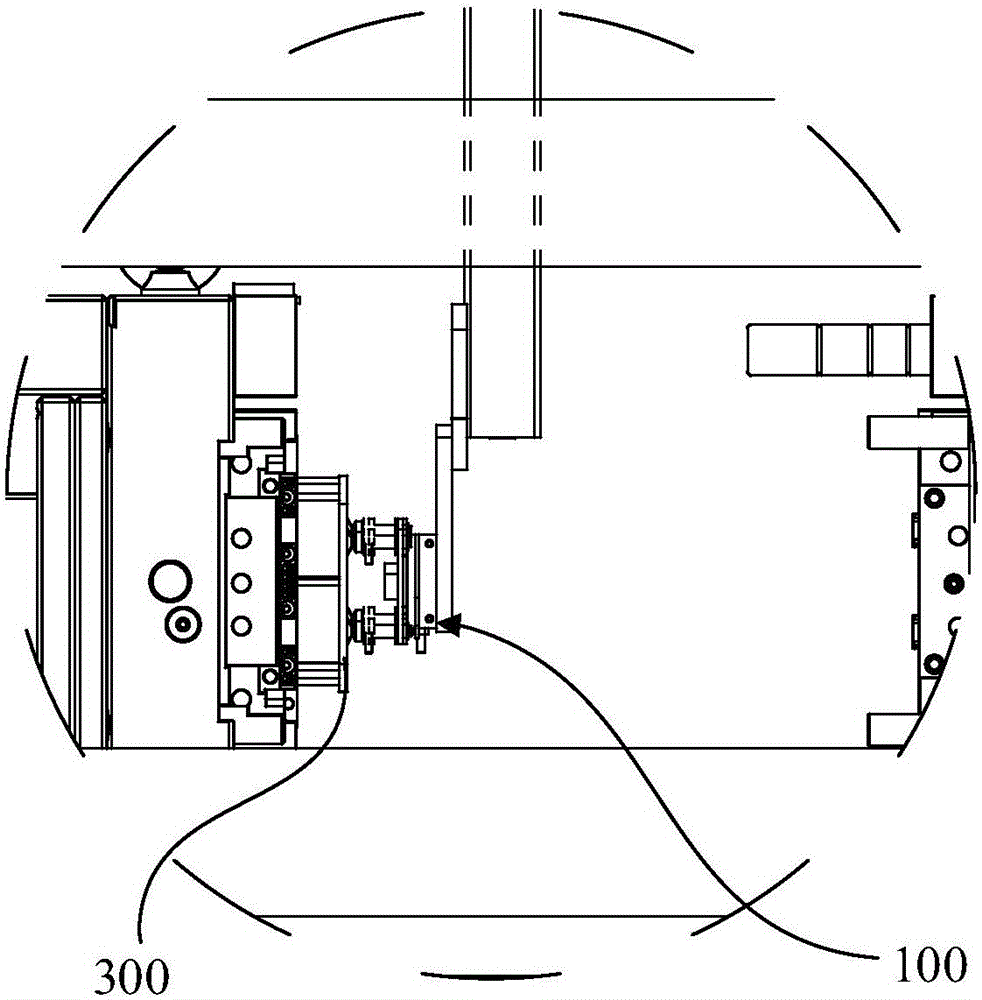

Full-automatic AGV

PendingCN108658005AImplement the fork actionSolve the problem of human assistanceLifting devicesTime costTransport engineering

The invention discloses a full-automatic AGV which comprises a chassis assembly, a lifting device and a fork assembly. A goods temporary storage bin used for storing goods is arranged on the chassis assembly. The lifting device is arranged on the chassis assembly. The fork assembly comprises a supporting seat, a first drive mechanism arranged on the supporting seat and a fork body fixedly connected with the first drive mechanism. The supporting seat is arranged on the lifting device and used for driving the first drive mechanism and the fork body to ascend and descend to the position of any layer of goods shelf under drive of the lifting device. The first drive mechanism is used for driving the fork body to fork the goods and rotationally putting the goods on any layer of goods shelf or forking the goods from any layer of goods shelf and rotationally moving the goods out of the goods shelf. According to the full-automatic AGV, full automation of goods taking and putting is achieved, the manual cost and time cost are saved, and the goods taking and putting efficiency and accuracy are improved.

Owner:YONEGY LOGISTICS AUTOMATION TECH

Stamping device with automatic pick-up and put-down apparatus and of steel discs for motor iron core

InactiveCN109877206AReduce labor intensity and labor costsImprove pick-and-place efficiencyShaping toolsMetal-working feeding devicesEngineeringMachining process

The invention relates to the technical field of motor manufacturing, in particular to a stamping device with an automatic pick-up and put-down apparatus and of steel discs for a motor iron core. The stamping device comprises a machine frame and a high-speed stamping cylinder which is arranged on the machine frame; a counting device and a photo heating device are disposed below a supporting platform; and a rotary motor is disposed below the supporting platform. By means of the automatic pick-up and put-down apparatus which is composed of a supporting box body, a rotating portion, a supporting barrel body, a mechanical arm and a suction cup, original steel discs and formed steel discs are automatically picked up and put down in the stamping machining process of the steel discs, the labor cost and labor intensity can be reduced, the pick-up and put-down efficiency of the steel discs is improved, and thus the production efficiency of whole steel disc stamping machining is improved. Meanwhile, by means of the automatic pick-up and put-down apparatus, automatic operation is conveniently achieved, and flow line production is facilitated.

Owner:苏州匠恒智造科技有限公司

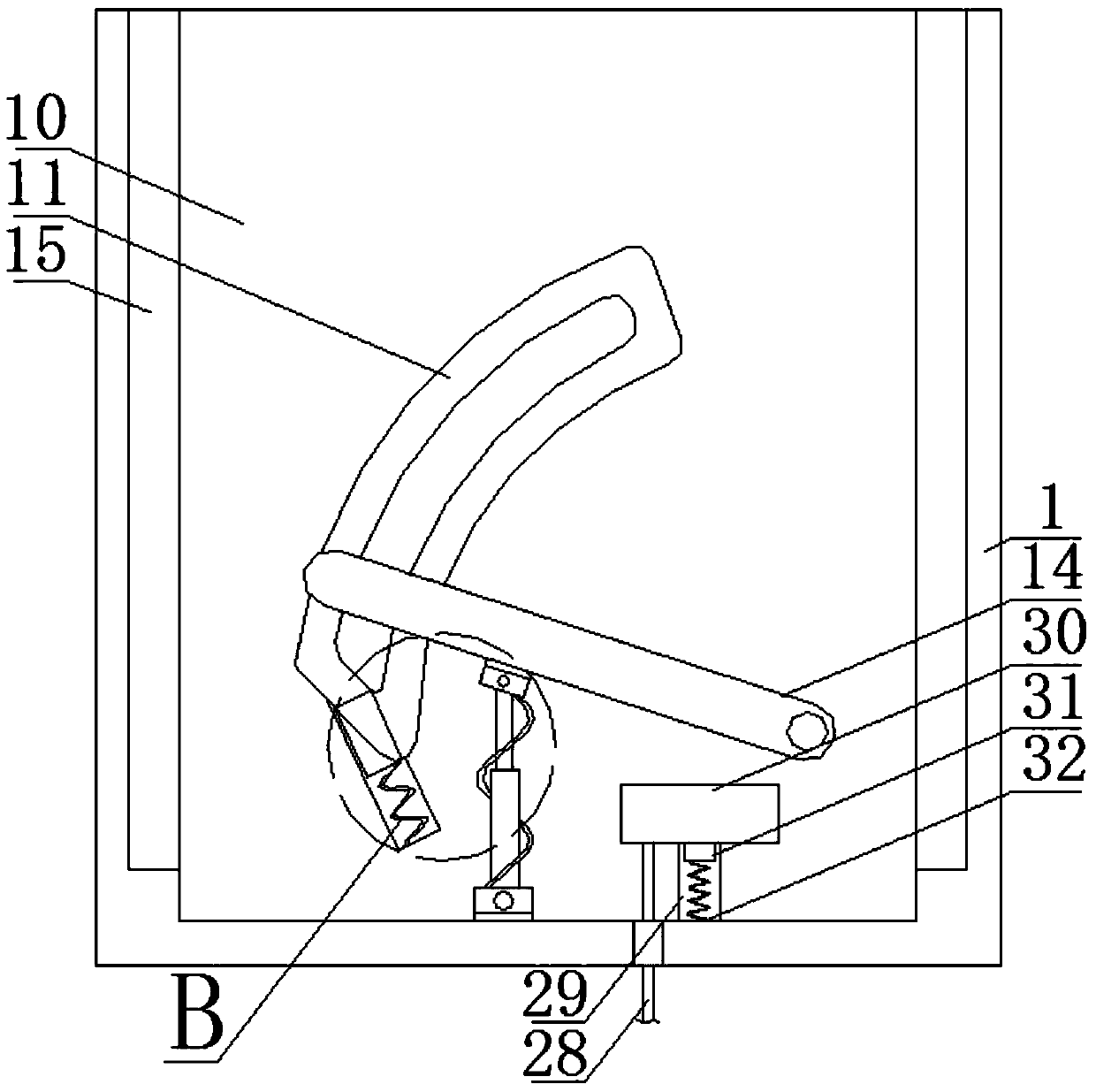

Sterilizing cabinet convenient for installing and disassembling sterilizing device

PendingCN109602938AEasy to install and disassembleEasy to removeLavatory sanitoryRadiationEngineeringOpen surface

The invention discloses a sterilizing cabinet convenient for installing and disassembling a sterilizing device. The cabinet body has an accommodating cavity for placing sterilized articles; the innerwall of the accommodating cavity is provided with a slot for installing the sterilizing device; one side of the slot facing the sterilized articles is an open surface; the top of the slot is rotatablyconnected with a rotating rod; the back of the slot is rotatably connected with one end of a telescopic rod; the other end of the telescopic rod is rotatably connected to the side wall of the rotating rod; a first spring sleeves on the telescopic rod; the two ends of the first spring respectively abut the back of the slot and the side wall of the rotating rod; the rotating rod is provided with apositioning device; the inner top of the slot is provided with a moving slot matched with the positioning device; the moving slot is further internally provided with a closing device for closing the moving slot; the sterilizing device comprises a lamp socket; the two side walls of the slot are respectively provided with mounting devices; the lamp socket is in insertion connection with the slot through the mounting devices; and the lamp socket is provided with a controllable disinfecting device. The sterilizing device can be disassembled and assembled quickly without removing the sterilized articles in the cabinet.

Owner:厦门市信达光电科技有限公司

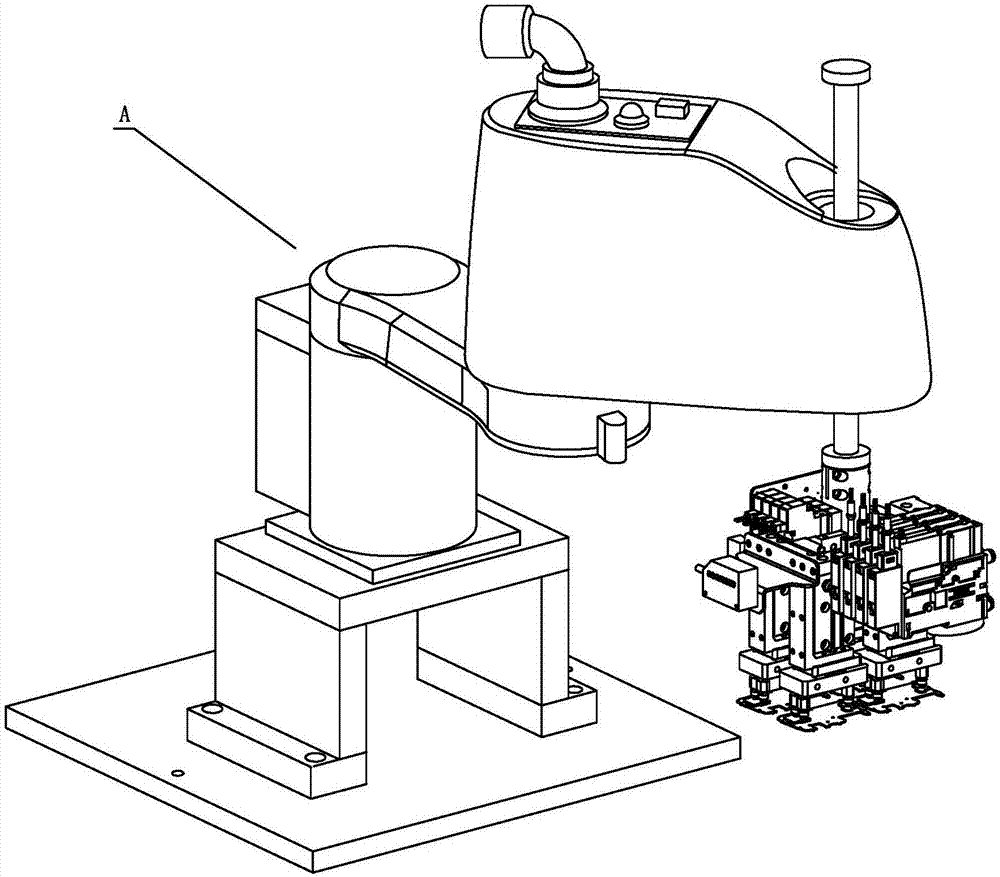

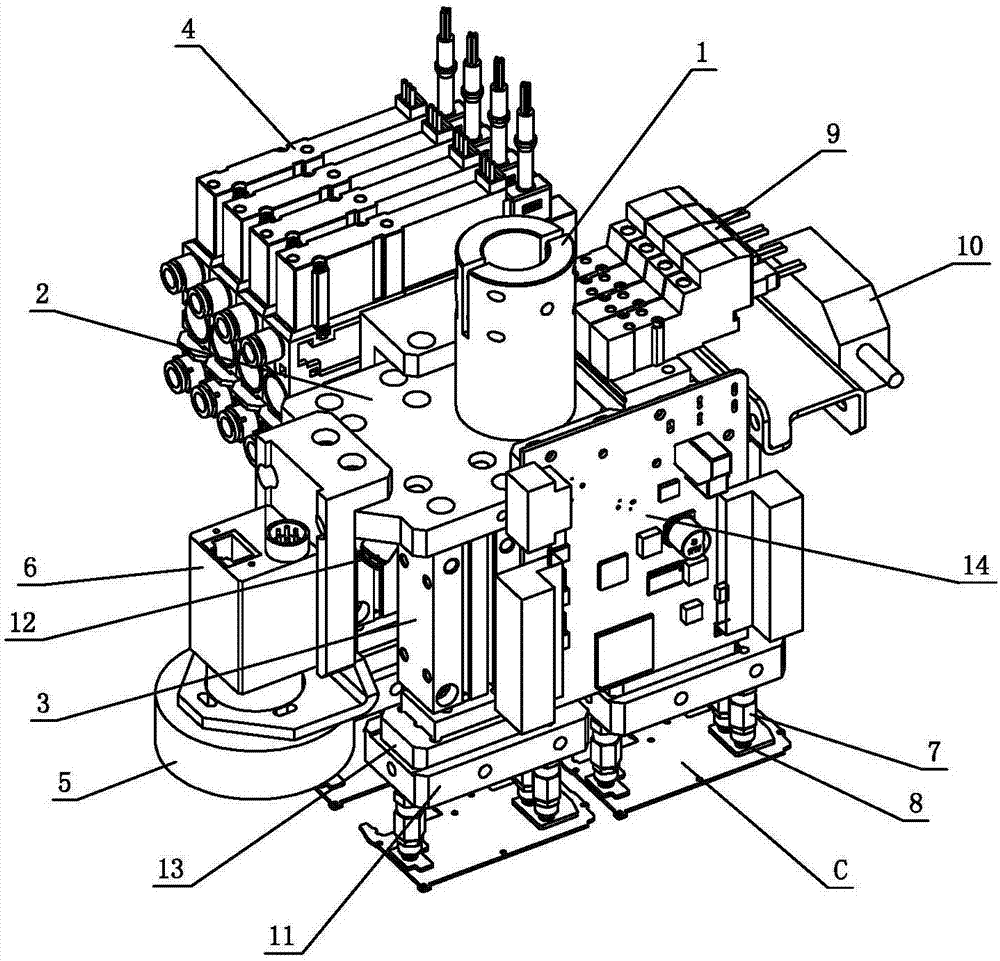

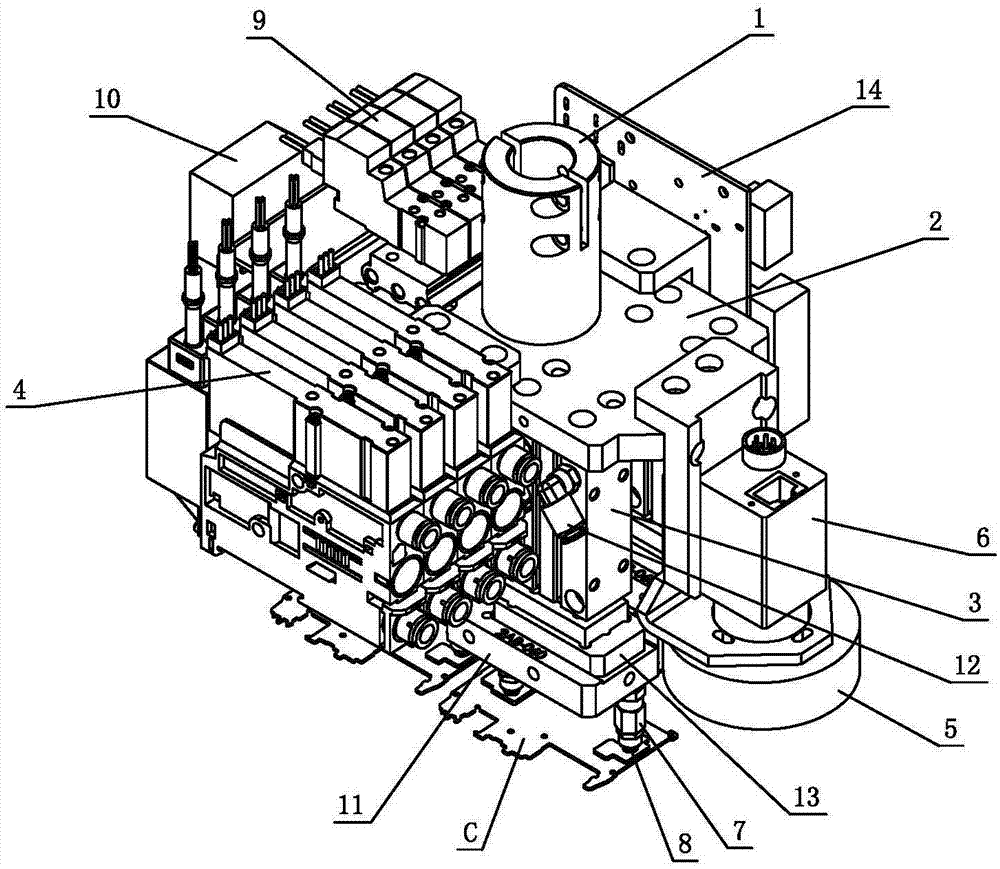

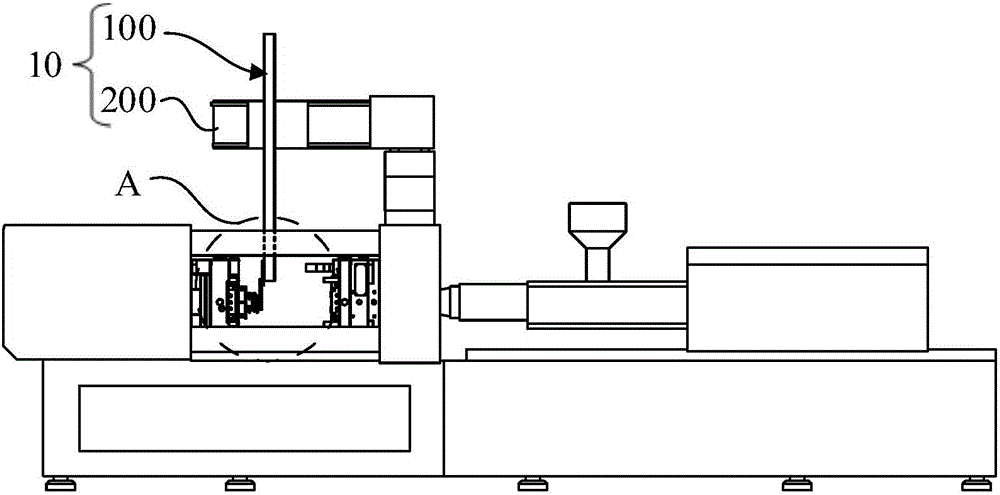

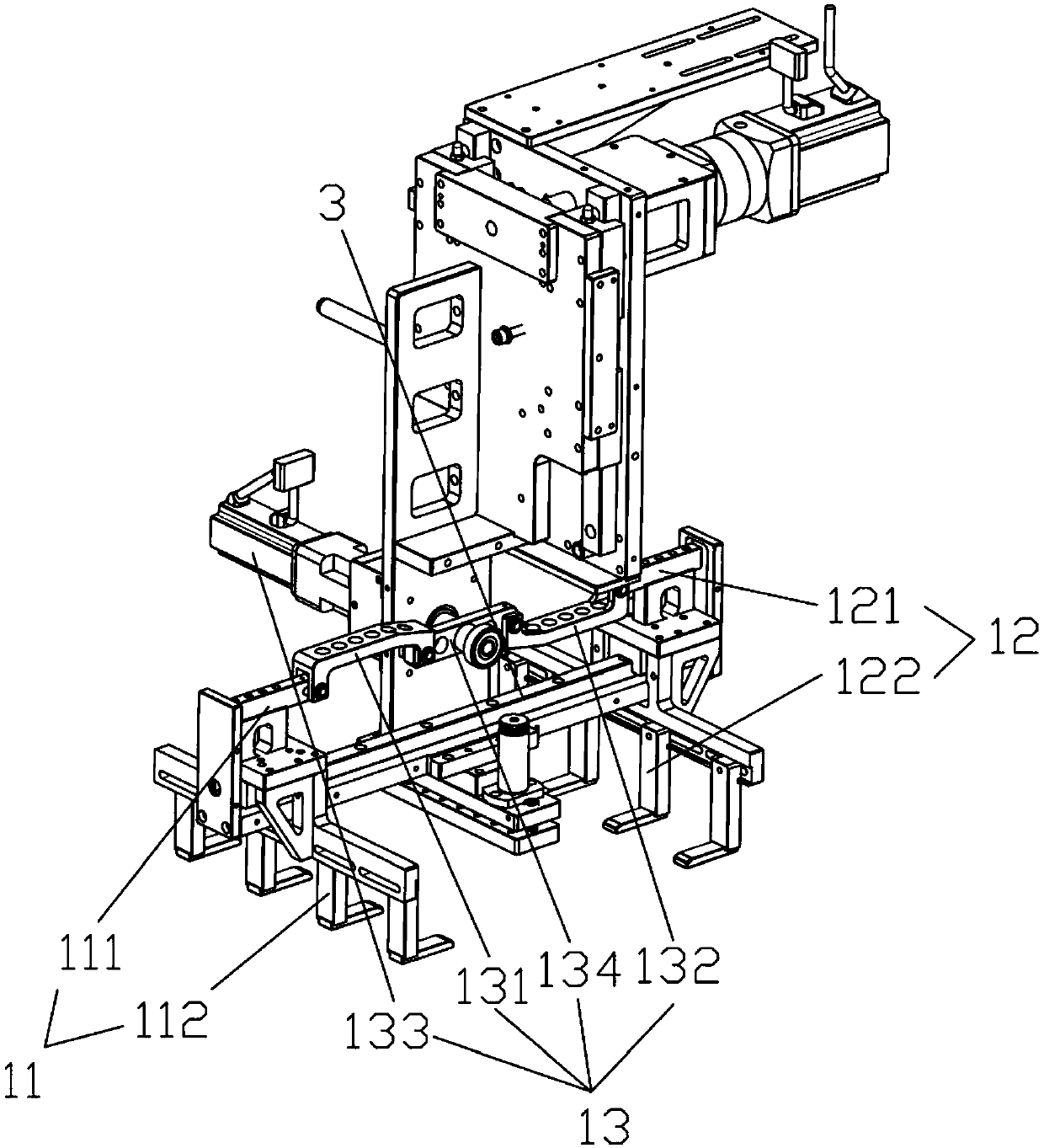

Robot fixture for carrying mobile phone main boards

PendingCN107572252AReduce labor intensityAvoid electrostatic damageGripping headsConveyor partsMobile phoneFlange

A robot fixture for carrying mobile phone main boards comprises a connecting flange and a mounting plate. More than one set of relatively independent picking and placing mechanisms are arranged on themounting plate, the picking and placing mechanisms comprise vacuum generators and picking and placing assemblies, and the vacuum generators and the picking and placing assemblies are oppositely fixedto the mounting plate; each picking and placing assembly comprises a precise sliding table air cylinder, a vacuum air distributing block and more than one vacuum suction cup, cylinder bodies of the precise sliding table air cylinders are fixedly connected with the mounting plate and a rod body to drive the vacuum air distributing blocks to conduct lifting motion, and the vacuum suction cups are fixedly connected with the vacuum air distributing blocks; and air-distributing air channels are formed in the vacuum air distributing blocks, the air extraction ends of the vacuum generators communicate with the air outlet ends of the air-distributing air channels, and the vacuum suction cups communicate with the air inlet ends of the air-distributing air channels. According to the robot fixture for carrying the mobile phone main boards, circuit boards are picked and placed by adopting a robot, static damage can be avoided, the yield is increased and the stability is improved, the labor intensity is relieved, and the labor cost is reduced; and in addition, the picking and placing transfer frequency is reduced by arranging the multiple sets of picking and placing mechanisms, and the pickingand placing efficiency is improved.

Owner:GUANGDONG LXD ROBOTICS CO LTD

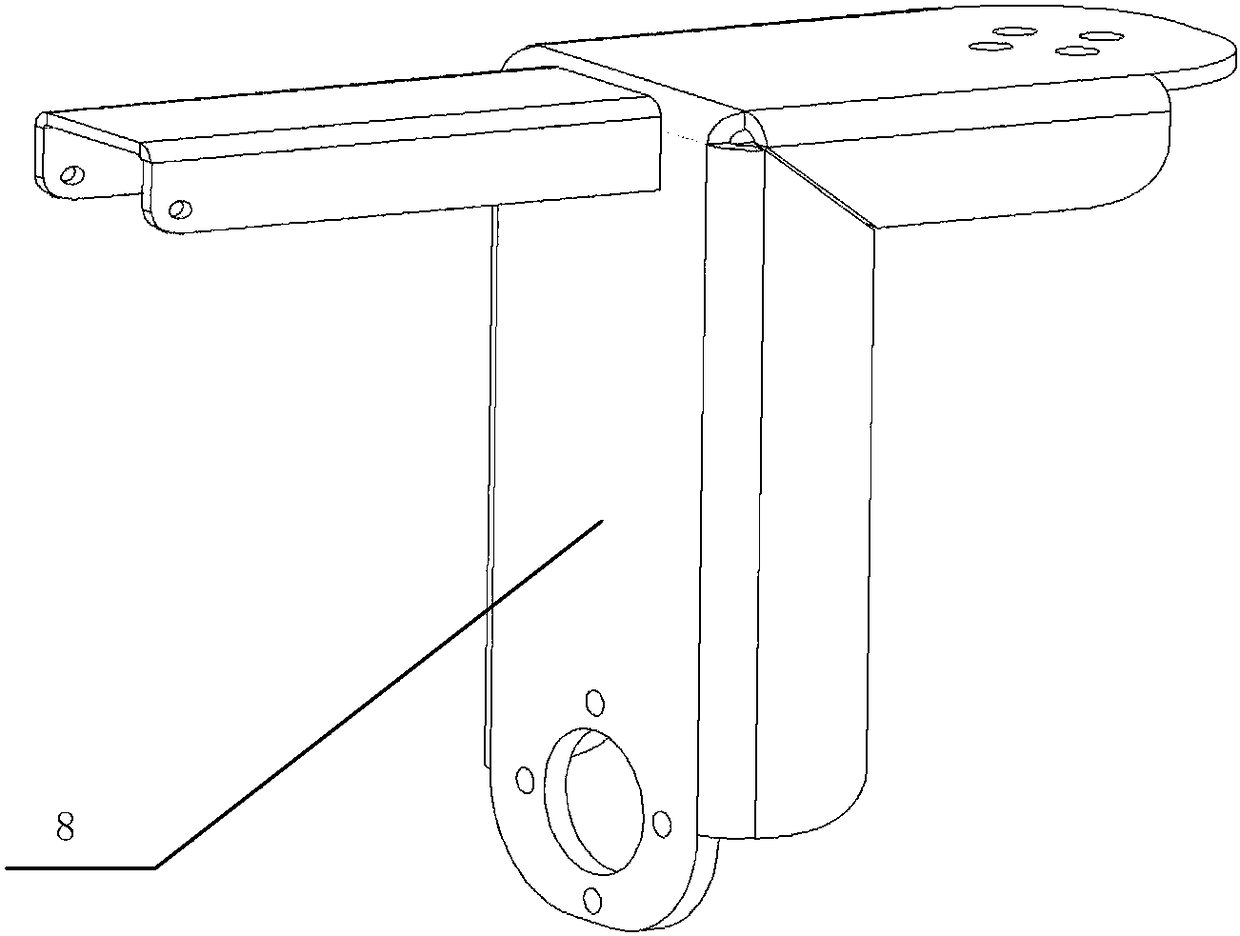

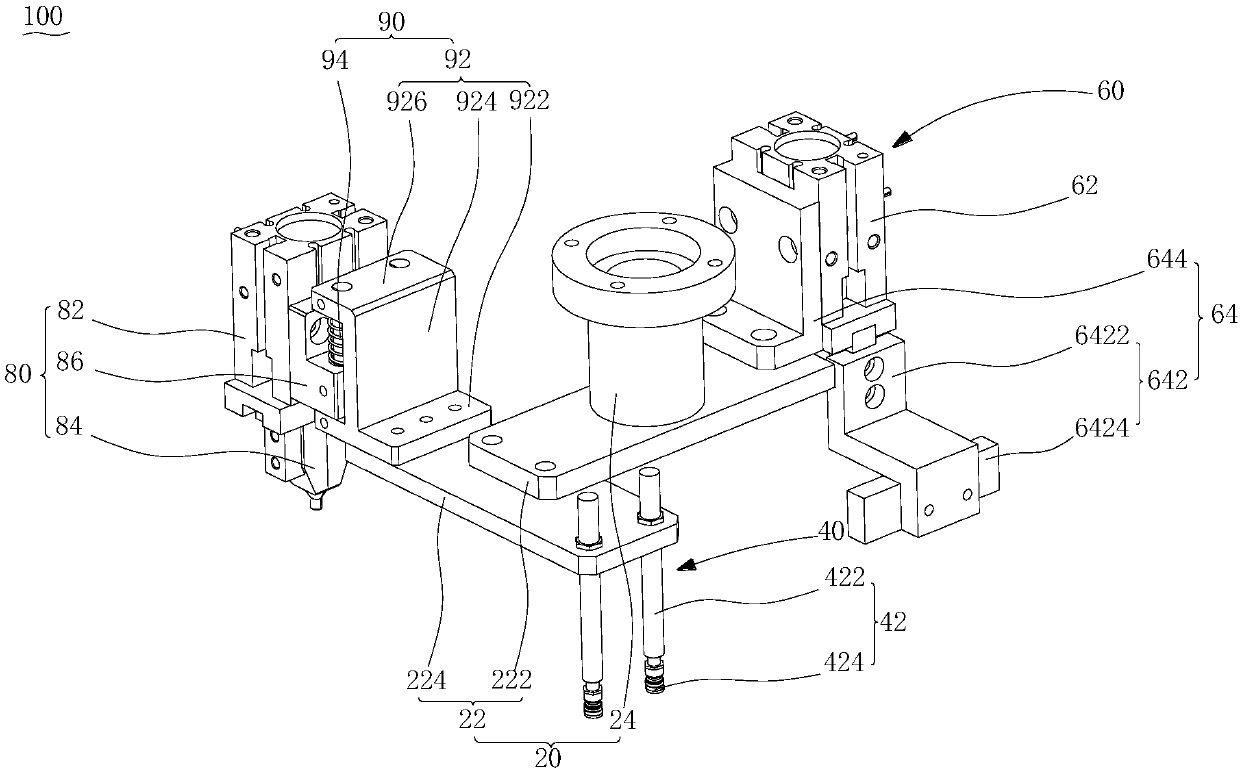

Material taking device and material taking assembly thereof

InactiveCN106737620ASimple structureImprove pick-and-place efficiencyProgramme-controlled manipulatorGripping headsEngineeringCantilever

The invention relates to a material taking device and a material taking assembly thereof. The material taking assembly can be used for taking and placing a plurality of blank materials at the same time and comprises a supporting piece, a rotating piece, a connecting piece and a material taking piece. The rotating piece comprises a body and a rotating part. The body is fixedly connected on the supporting piece and rotatably connected with the rotating part and can drive the rotating part to rotate. The connecting piece comprises a first cantilever part and a second cantilever part. The material taking piece comprises a first material taking part and a second material taking part. One end of the first cantilever part is fixedly connected with the rotating part. The other end of the first cantilever part is fixedly connected with the first material taking part. One end of the second cantilever part is fixedly connected with the rotating part. The other end of the second cantilever part is fixedly connected with the second material taking part. The first material taking part and the second material taking part are both used for taking and placing the blank materials and can work at the same time. The material taking assembly is simple in structure and suitable for taking and placing the multiple blank materials in a mould cavity simultaneously, high in taking and placing efficiency and good in universality.

Owner:GUANGDONG EVERWIN PRECISION TECH

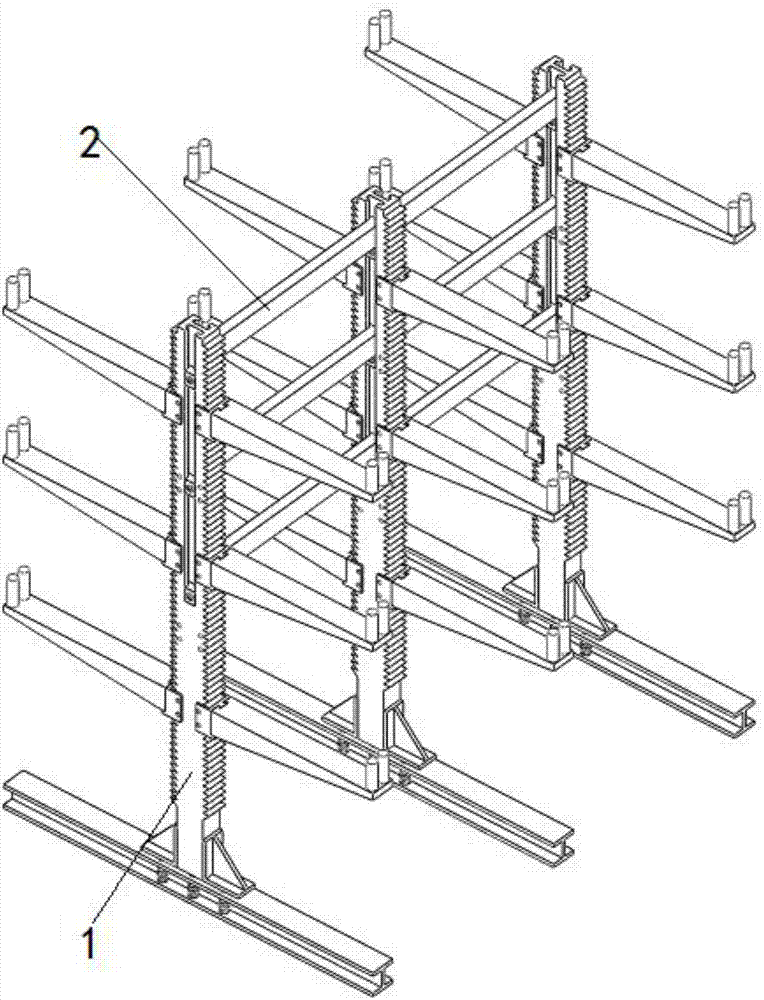

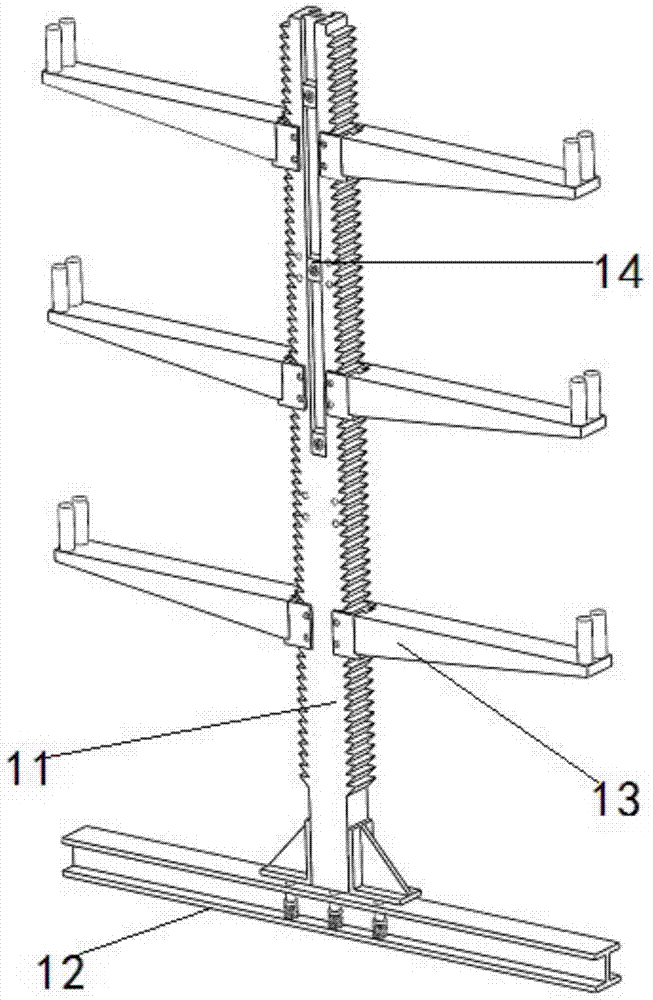

Adjustable cantilever rack capable of expanding

InactiveCN107157213AImprove pick-and-place efficiencyAvoid damageShow shelvesShow hangersEconomic benefitsEngineering

The invention discloses an adjustable cantilever rack capable of expanding. The cantilever rack comprises multiple supporting units which are distributed at equal intervals in the line direction, and the adjacent supporting units are in connection through three connecting beams which are distributed at equal intervals in the vertical direction; each supporting unit comprises a supporting column and a buffering positioning base, wherein the buffering positioning base is perpendicularly installed on the bottom of the supporting column, adjusting arms are evenly distributed on the front side and the rear side of each supporting column in the vertical direction, and three limiting mechanisms are installed at the top ends of the left side and the right side of each supporting column at equal intervals in the vertical direction. According to the adjustable cantilever rack capable of expanding, through scientific and reasonable structure design, the intervals between upper cantilevers and lower cantilevers can be adjusted in real time based on the size requirement of a real placement article, so that the use requirements of different placement articles are satisfied, the utilization of a limited space is greatly improved, and the pick-and-place efficiency of the placement article is improved; meanwhile, through the damping structure design of the buffering positioning bases on the bottom, a damage to the placement article caused by collision in the picking and placing process is avoided to some degree, the use effect is obvious, and the cantilever rack has good economic benefits and popularization value.

Owner:HEFEI CALSIION ELECTRIC POWER SYST

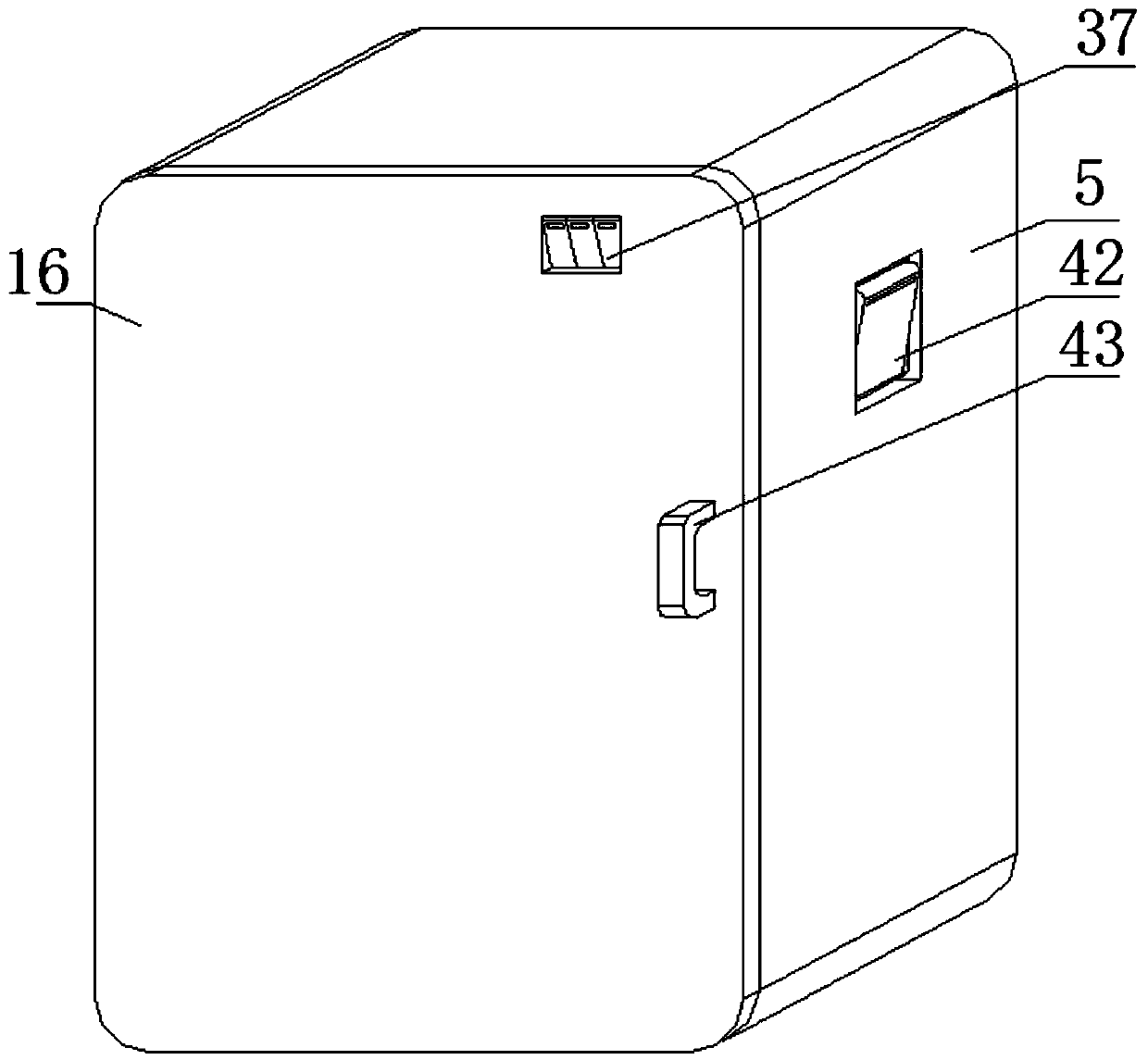

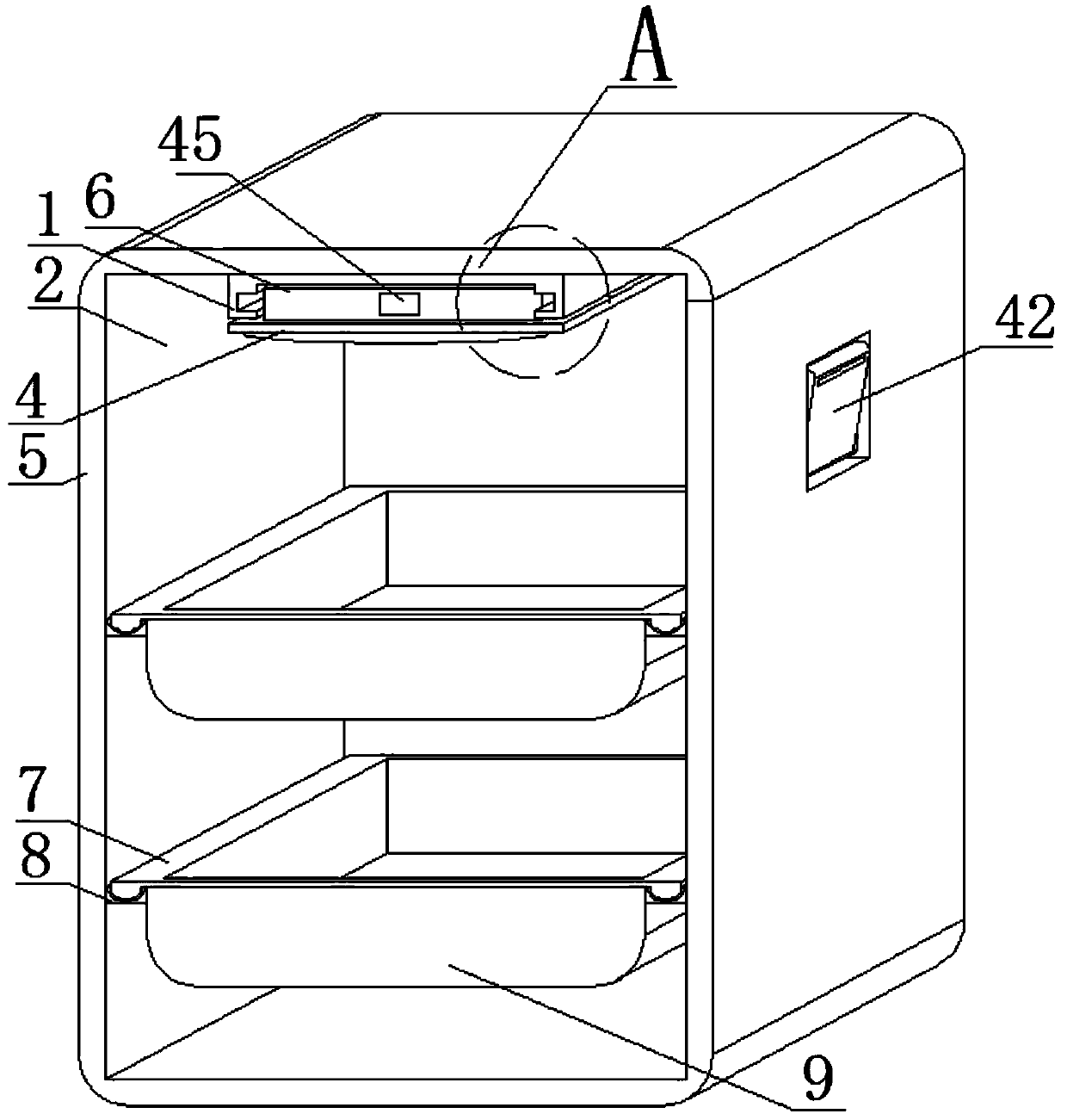

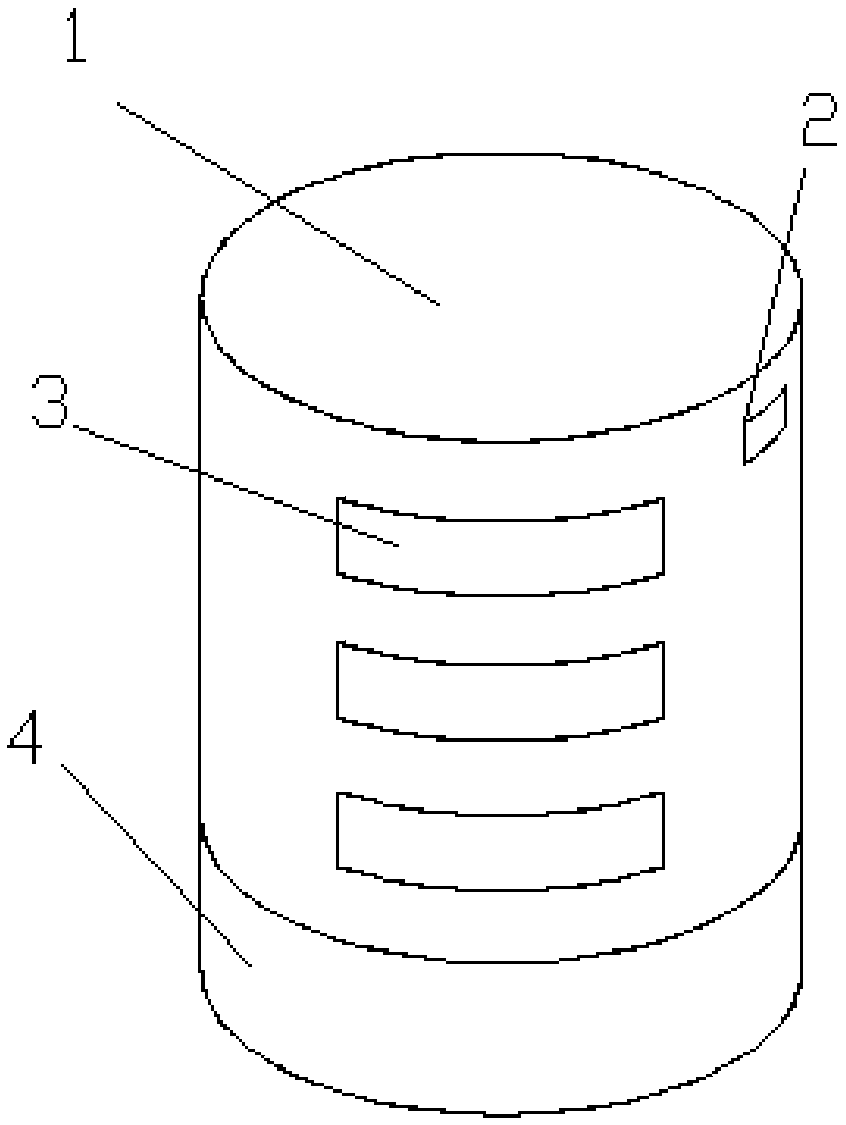

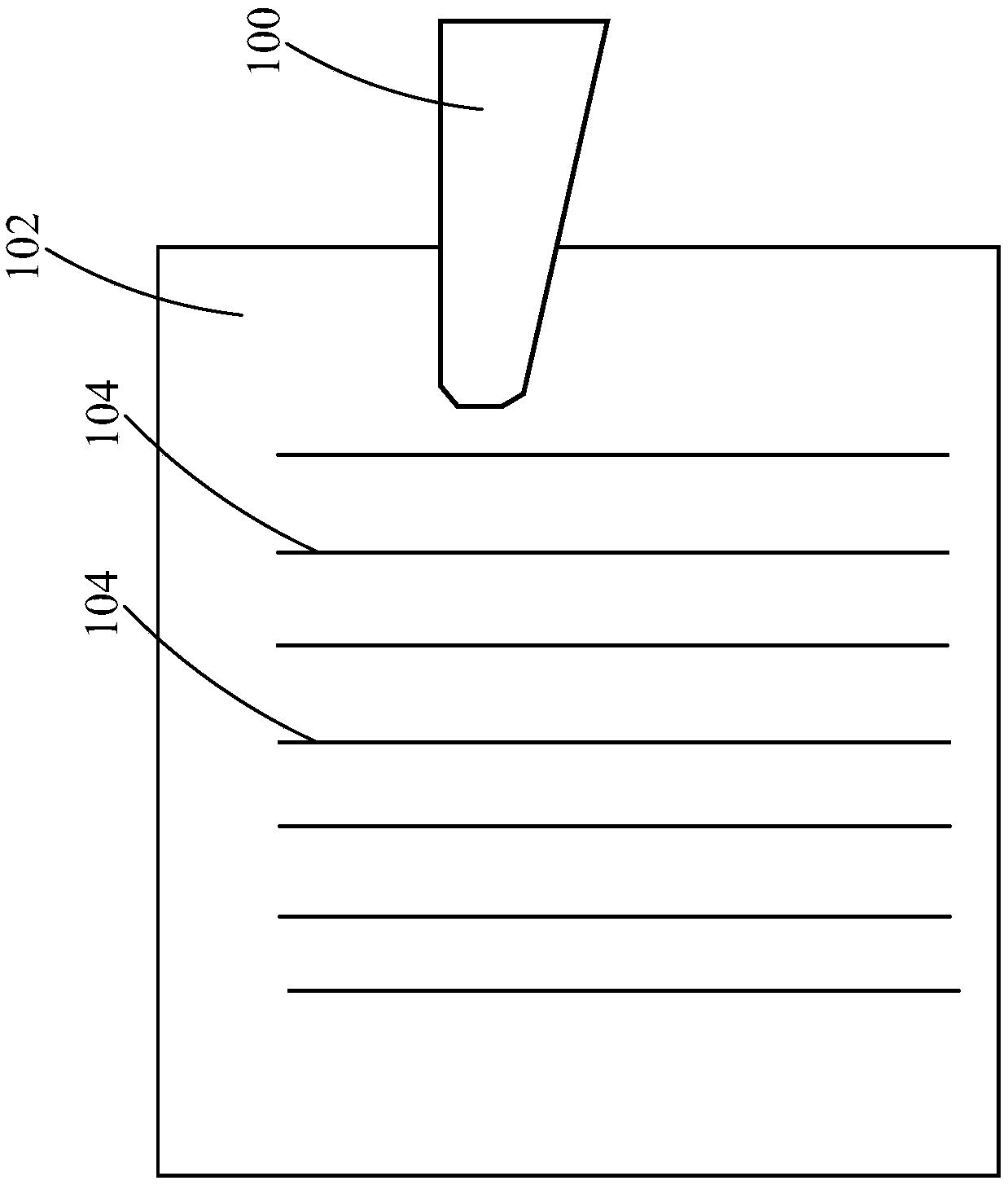

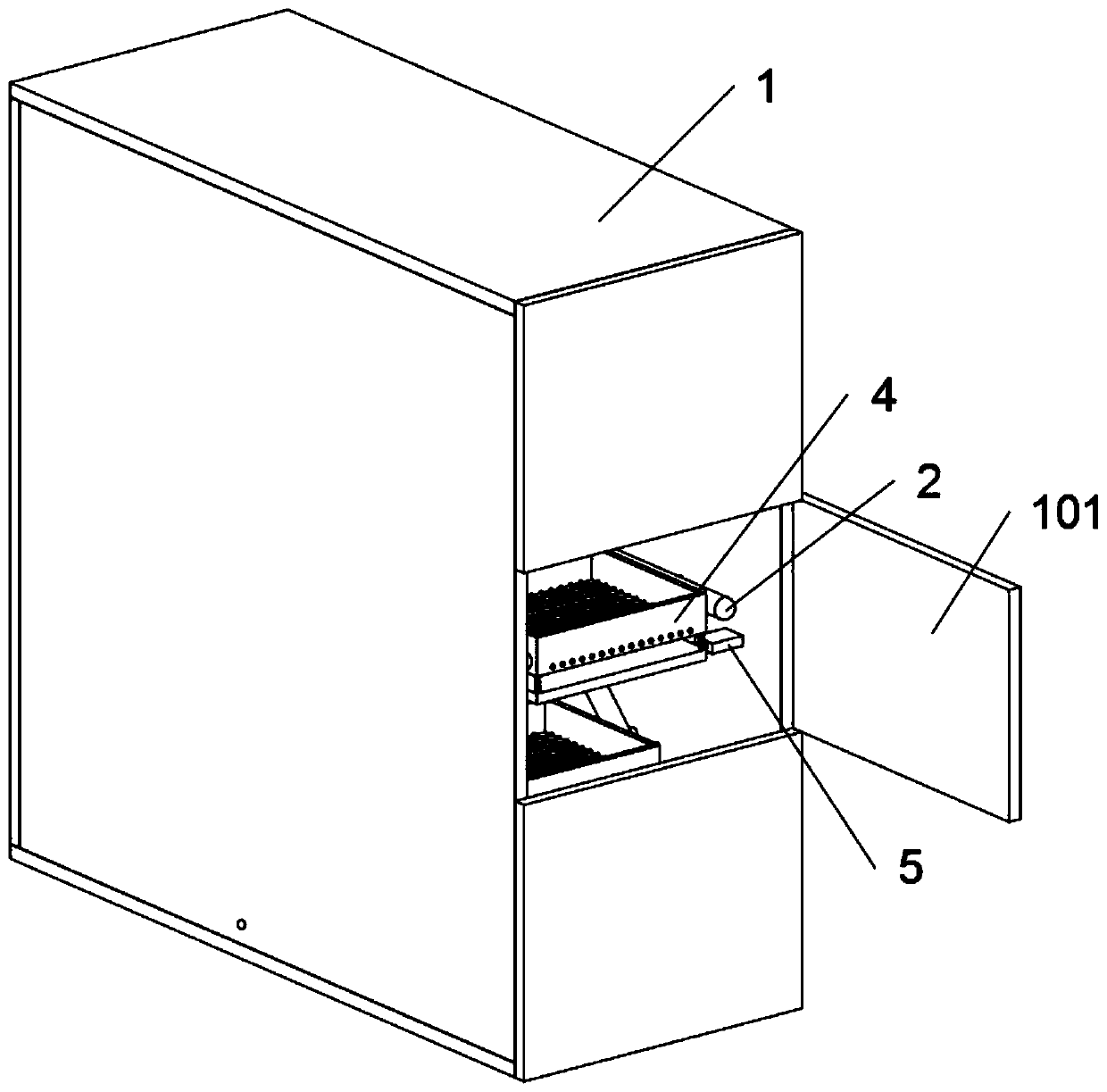

Medical refrigerator with intelligent sample storing and fetching function

PendingCN107763921AGuaranteed stabilityImprove storage efficiencyLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention relates to the technical field of a refrigerator, in particular to a medical refrigerator with an intelligent sample storing and fetching function. Not less than four layer plates (12) are arranged equidistantly along the height direction in a storage bin (1). A refrigerator door (3) is mounted between each two adjacent layer plates (12) at the side surface of the storage bin (1). Arotary storage frame (7) is rotationally mounted between each two adjacent layer plates (12) and two ends of the rotary storage frame (7) are mounted on the layer plates (12) by bearings. Not less than four storage brackets (18) are uniformly distributed on each rotary storage frame (7) along the circumferential direction. The medical refrigerator is provided with a plurality of refrigerator doors(3) and a single storing mechanism is arranged corresponding to each refrigerator door (3). Each mechanism is capable of completing the task of sample picking and placing, so that the storing and placing efficiency can be improved. A positioning structure is arranged at the bottom of each storage pallet (19), so that the storage pallet (19) can remain stable whether in transportation state or instorage state. The storage pallets (19) are fixed in physical manner, so that the problem of being incapable of preventing slippage in power-off state can be solved.

Owner:成都智宸科技有限公司

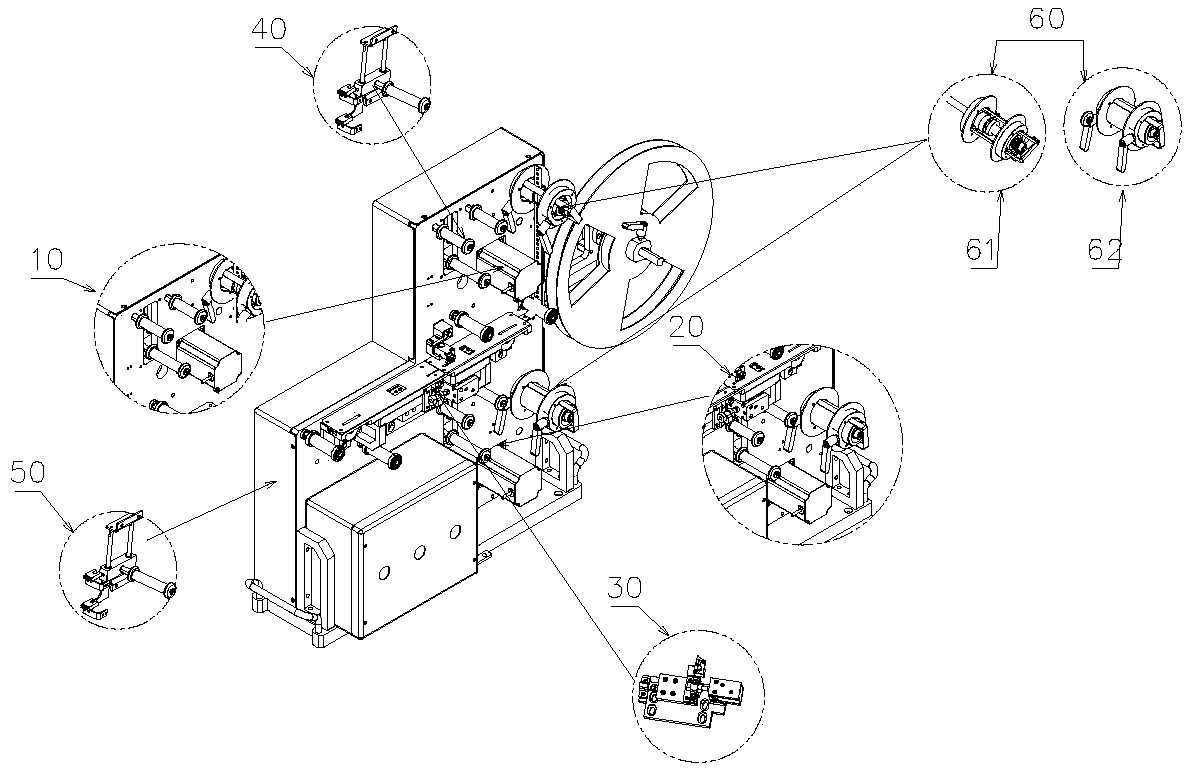

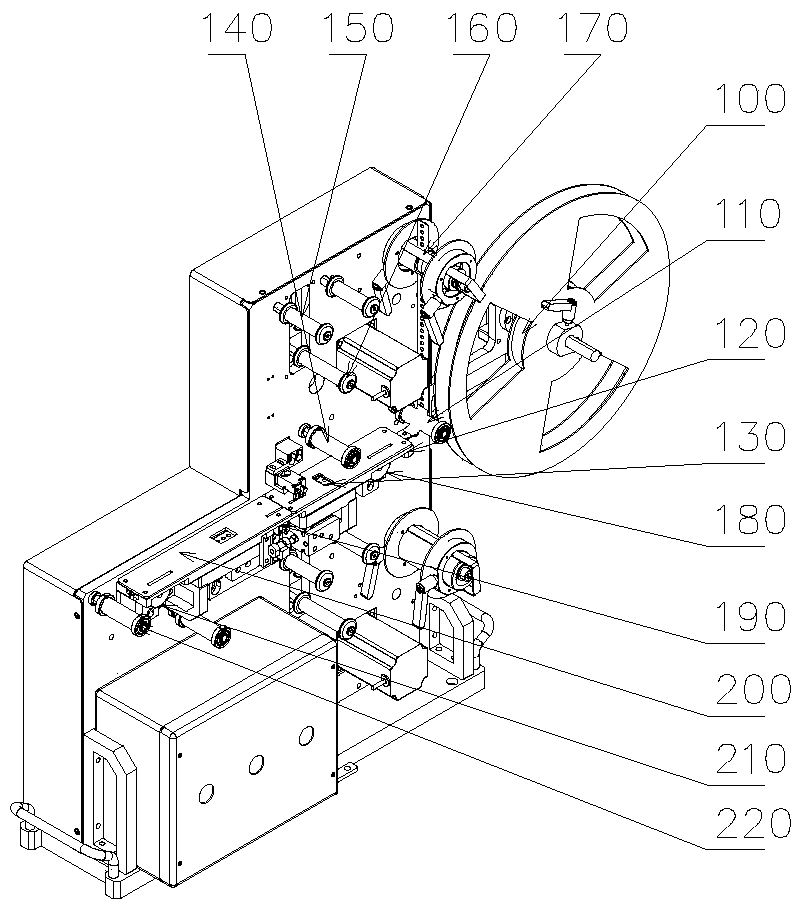

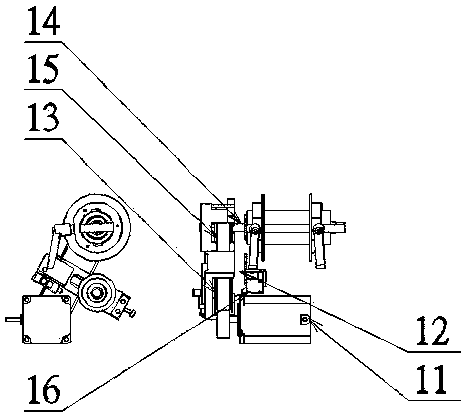

SMT carrier band dismantling packaging feeding device

InactiveCN108622449AImprove pick-and-place efficiencyEnsure consistent qualityPackagingStart stopMass Consistency

Owner:SHANGHAI SHARETEK TECH CO LTD

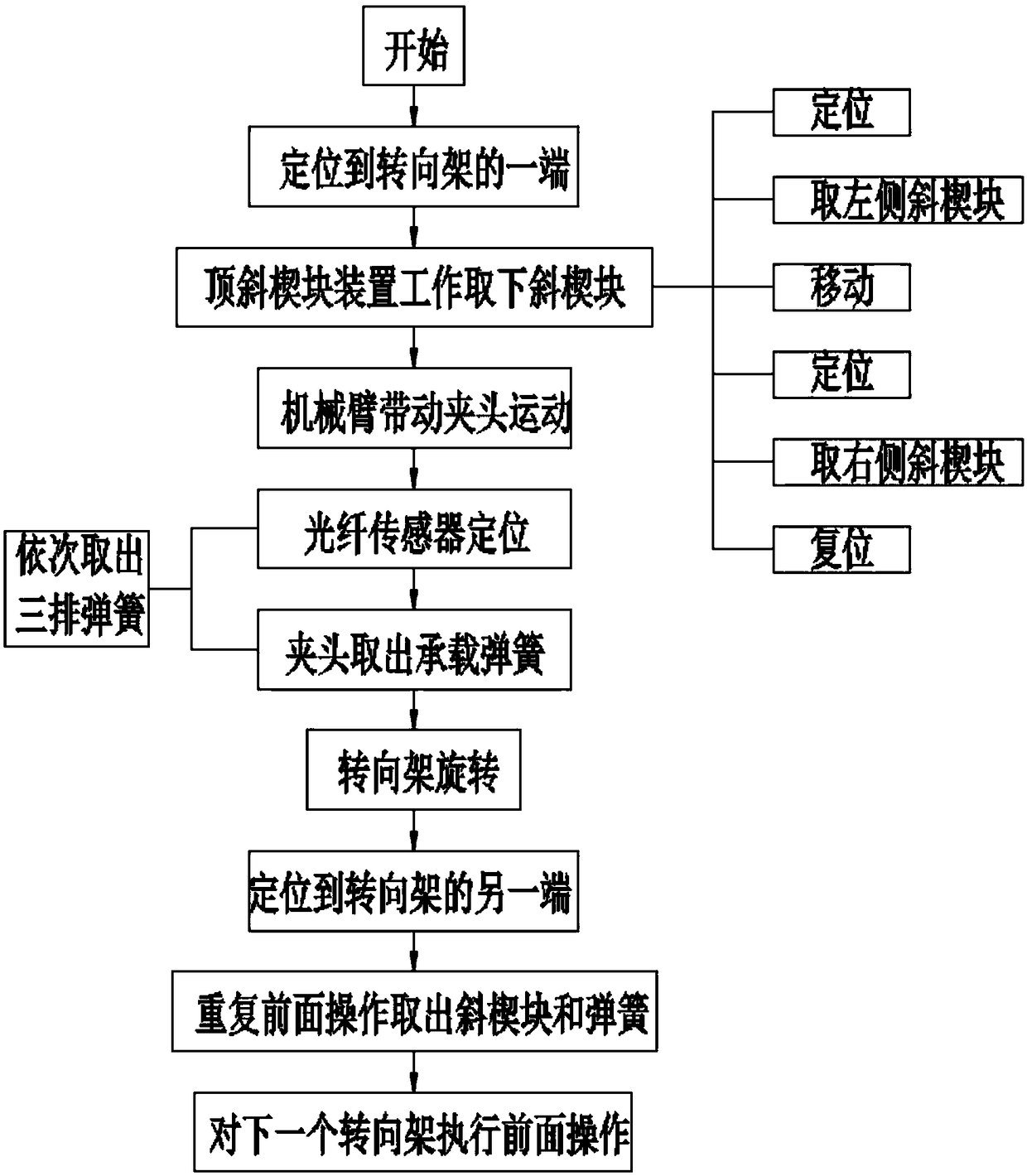

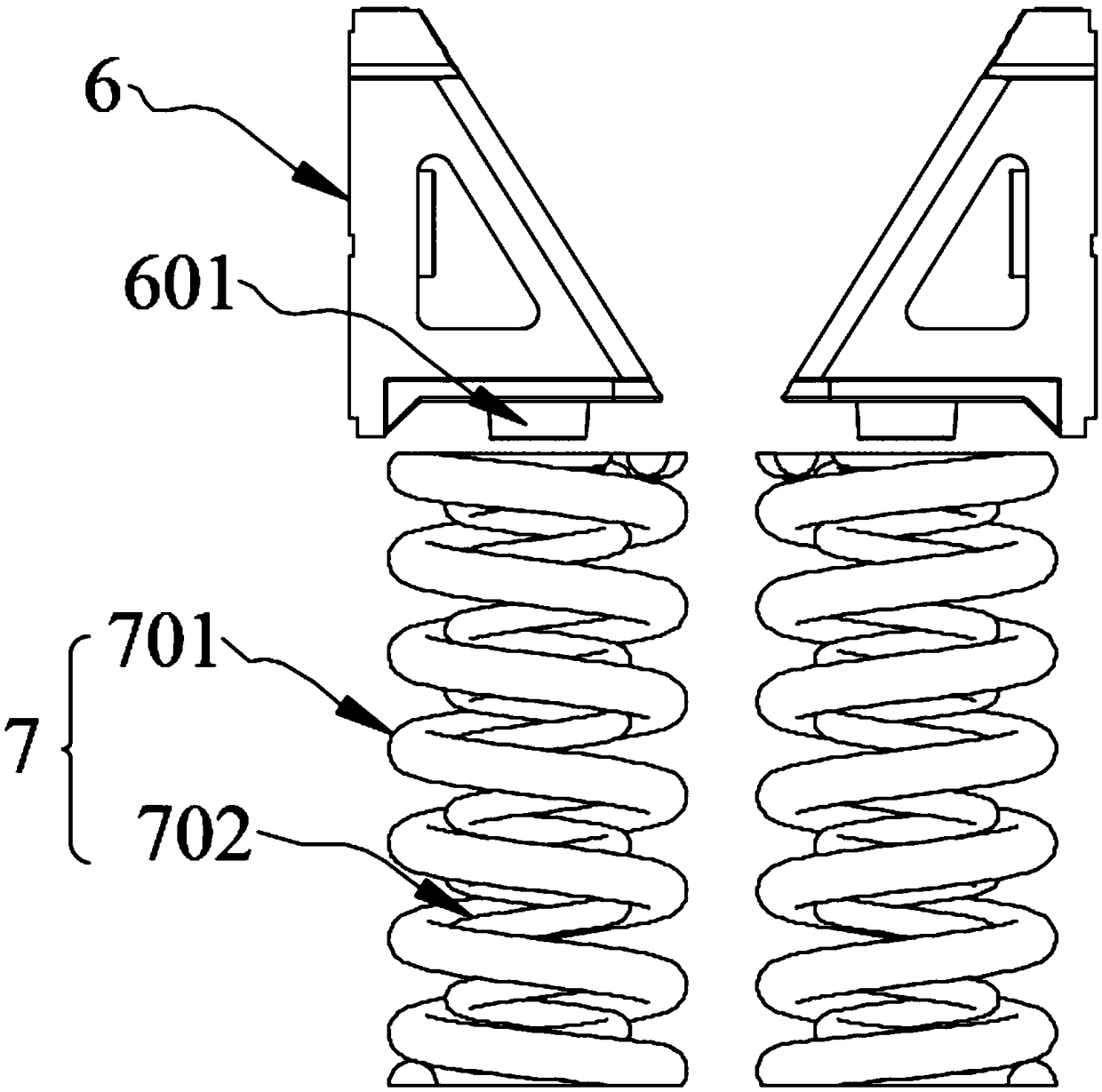

Bogie bearing spring disassembling process

ActiveCN108857312AImprove pick-and-place efficiencyReduce labor intensityMetal working apparatusBogieEngineering

The invention discloses a bogie bearing spring disassembling process, and belongs to the technical field of disassembly of bogie bearing springs. The process is used for solving the problems that in the existing bogie disassembling process, by adopting the mode of manually carrying bearing springs, the labor intensity is large, hidden safety hazards exist in the carrying process, and the work efficiency is low. The process comprises the following steps that S1, one end of a bogie is located; S2, a jacking device works to remove tapered wedges; S3, a mechanical arm drives a chuck to move; S4, alocating device locates bearing springs, and a bijective optical fiber sensor locates outer spring bodies of the bearing springs; S5, the chuck takes out the bearing springs, and three rows of bearing springs are sequentially taken out, the out-taken bearing springs are placed on a transfer frame, and the outer spring bodies and inner spring bodies of the bearing springs are separated; S6, the bogie rotates, and the other end of the bogie is located; S7, the operation of S1 to S5 is repeated, and the tapered wedges and the bearing springs are taken out; S8, the operation of S1 to S7 is repeated for a next bogie.

Owner:成都岁生科技有限责任公司

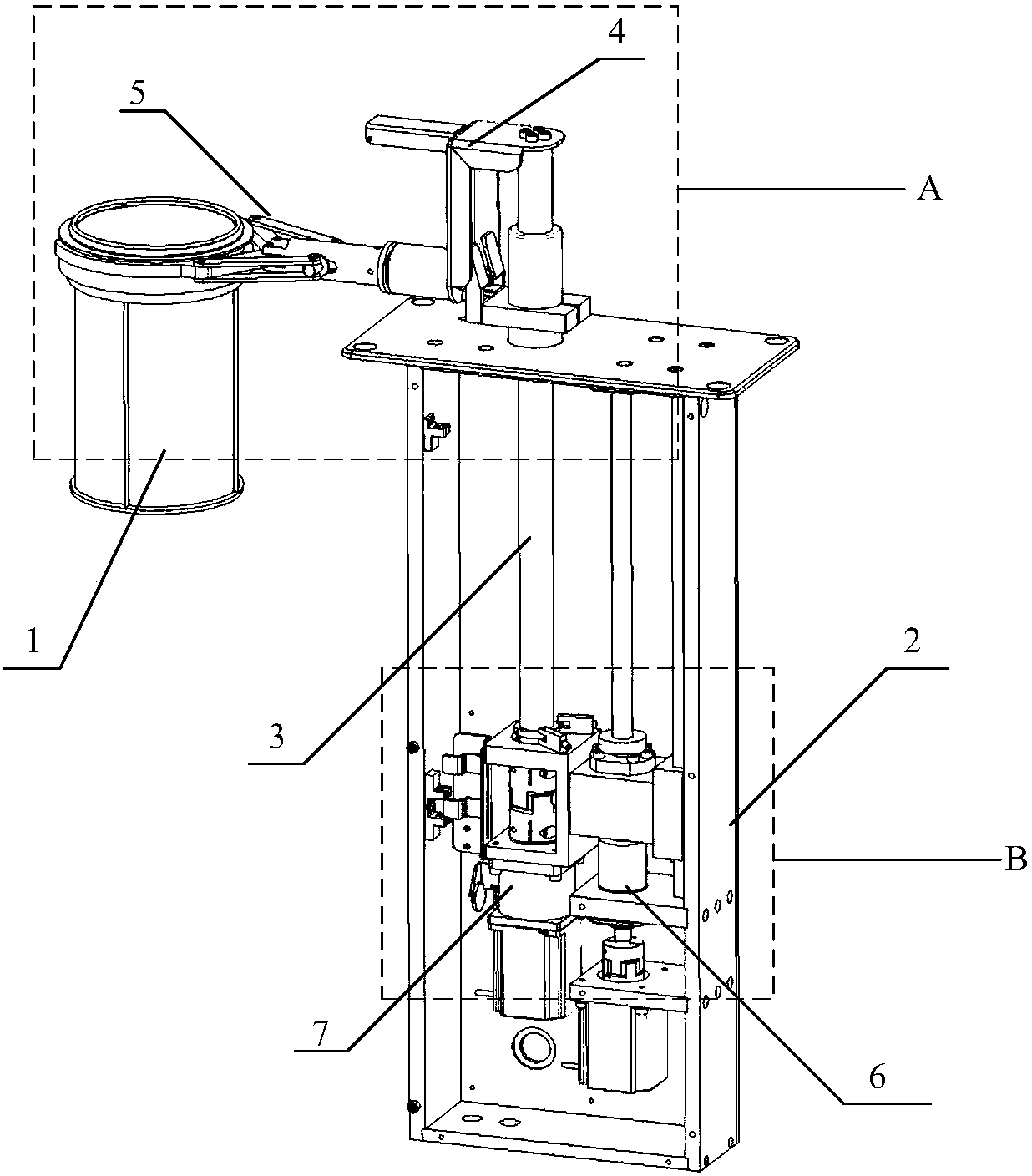

Taking and putting device

InactiveCN108652455AFully automatedImprove pick-and-place efficiencyCooking vesselsDrive shaftEngineering

The invention discloses a taking and putting device, and relates to the technical field of catering automation. The taking and putting device is used for improving the taking and putting efficiency ofa noodle boiling basket. The taking and putting device comprises a controller, a machine case, a driving shaft, a mechanical arm and a mechanical claw, wherein the mechanical claw is used for takingand putting the noodle boiling basket; an ascending and descending mechanism and a rotating mechanism are arranged in the machine case, and are connected with the controller; one end of the driving shaft is connected with the rotating mechanism; the other end of the driving shaft extends out of the machine case; the rotating mechanism is connected with the ascending and descending mechanism; the mechanism arm is fixed on a part, positioned outside the machine case, of the driving shaft; the mechanical claw is fixed on the mechanical arm; when the driving shaft downwards moves, the mechanical claw can be opened; and when the driving shaft upwards moves, the mechanical claw can be closed. The taking and putting device is used for performing taking and putting operation on the noodle boilingbasket.

Owner:北京快端科技有限公司

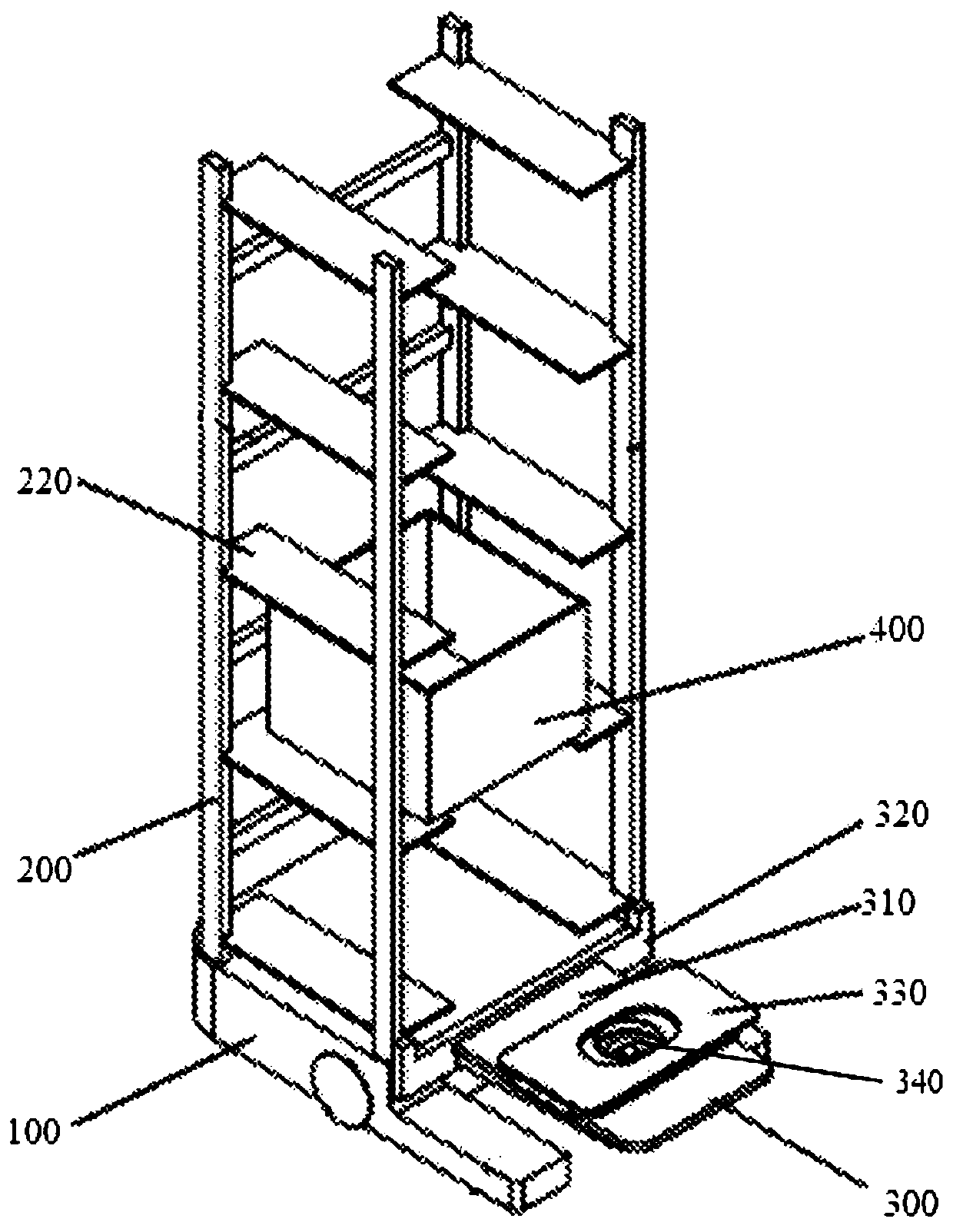

Flat battery transferring cart

InactiveCN104149833AImprove pinching and pinching phenomenonImprove pick-and-place efficiencyHand carts with multiple axesCartElectrical battery

The invention relates to a flat battery transferring cart which comprises a cart body, a tray and a suction disc assembly. The suction disc assembly comprises a handle and at least one electromagnetic chuck, a control assembly is arranged on the cart body, a steering assembly is arranged on the tray, and a limiting assembly is arranged on the cart body. The flat battery transferring cart has the advantages that a flat battery is controlled by the control assembly to be sucked to the electromagnetic chuck on the suction disc assembly, and is taken through the handle, so that when an existing flat battery is taken and placed, the phenomena of pinching fingers and foots of operators are avoided, the flat battery taking and placing efficiency is improved, and flat battery taking and placing are facilitated; through the arrangement of the steering assembly, the tray can be rotated leftwards or rightwards by 90 degrees on the cart body, it is guaranteed that the tray can conduct flat battery taking and placing under different environments, the practical performance is improved, and the cart can be used by different operators to conduct flat battery taking and placing; through the arrangement of the limiting assembly, it is guaranteed that in the conveying and moving process of the cart body, rotating of the tray is avoided, and conveying safety is improved.

Owner:金华八达集团有限公司 +2

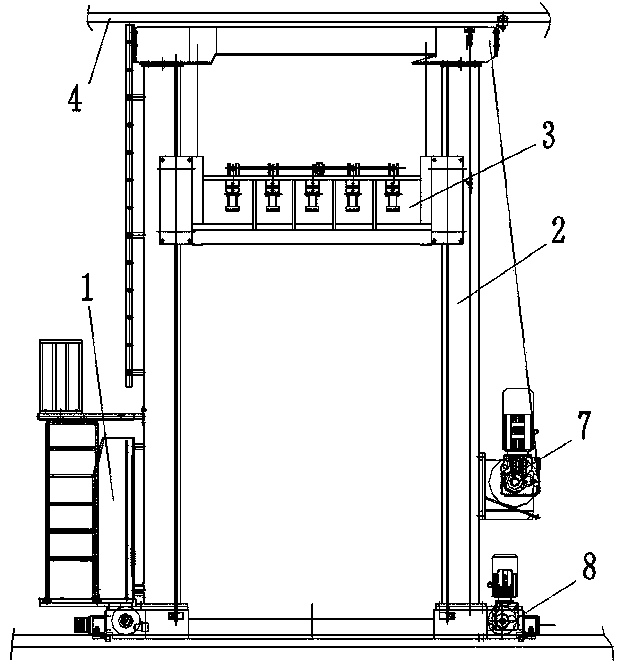

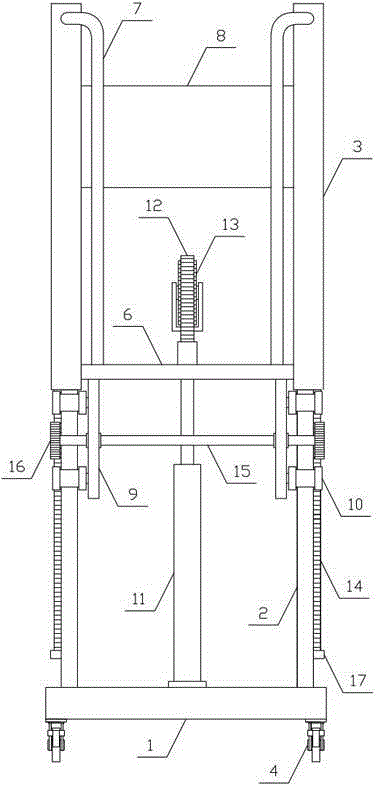

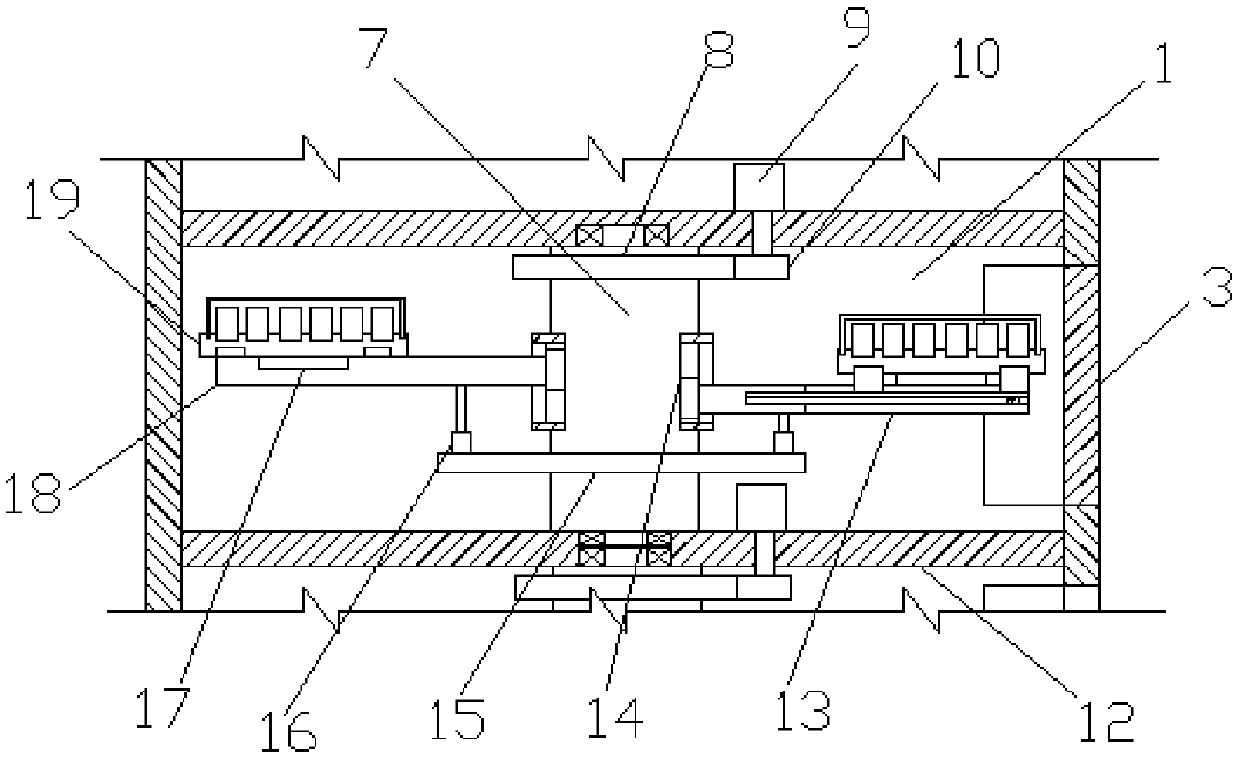

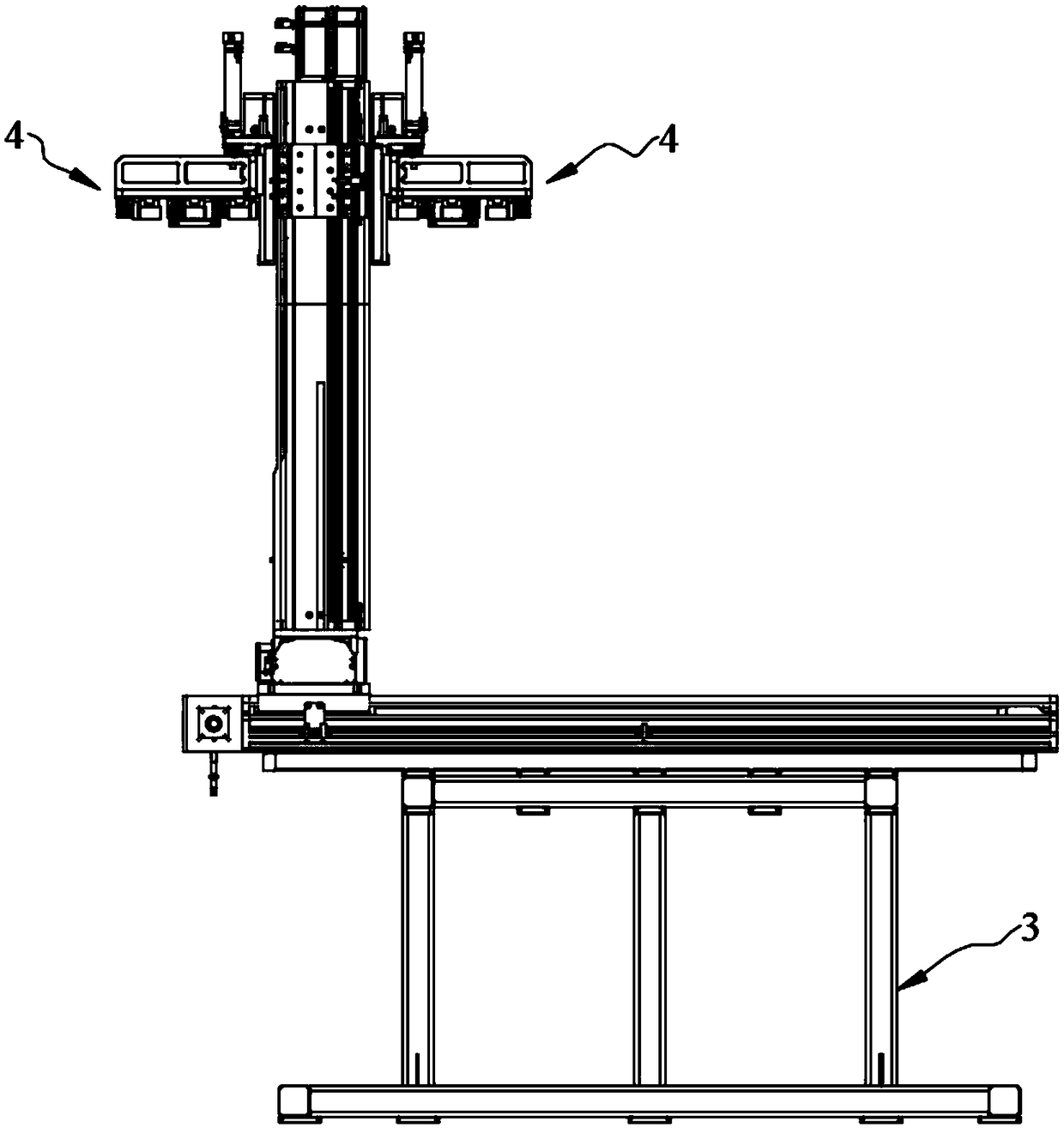

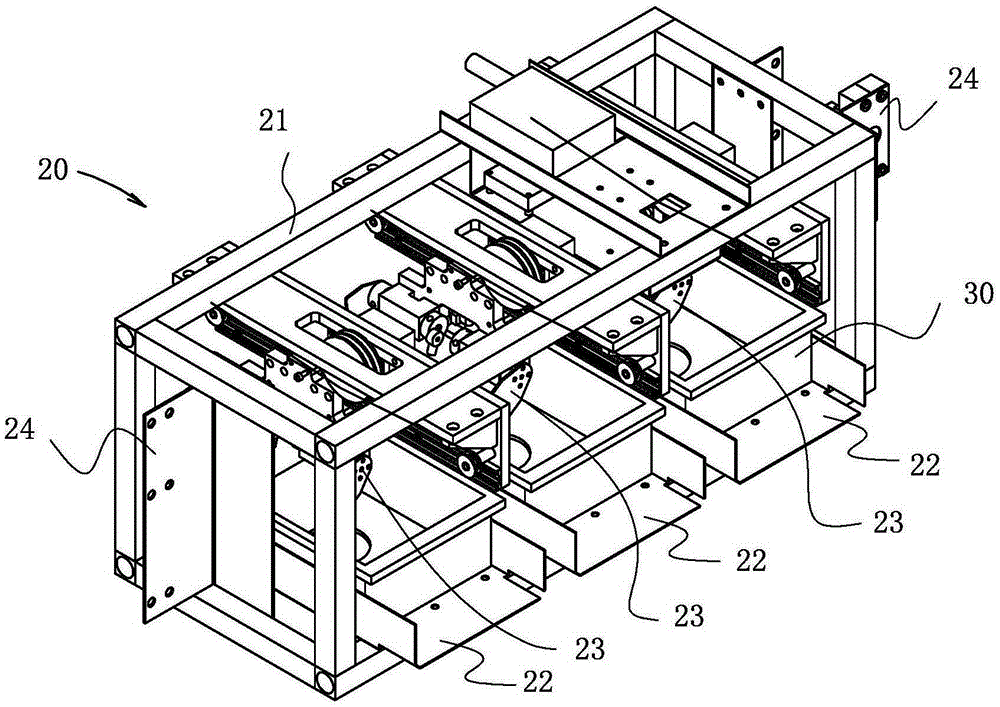

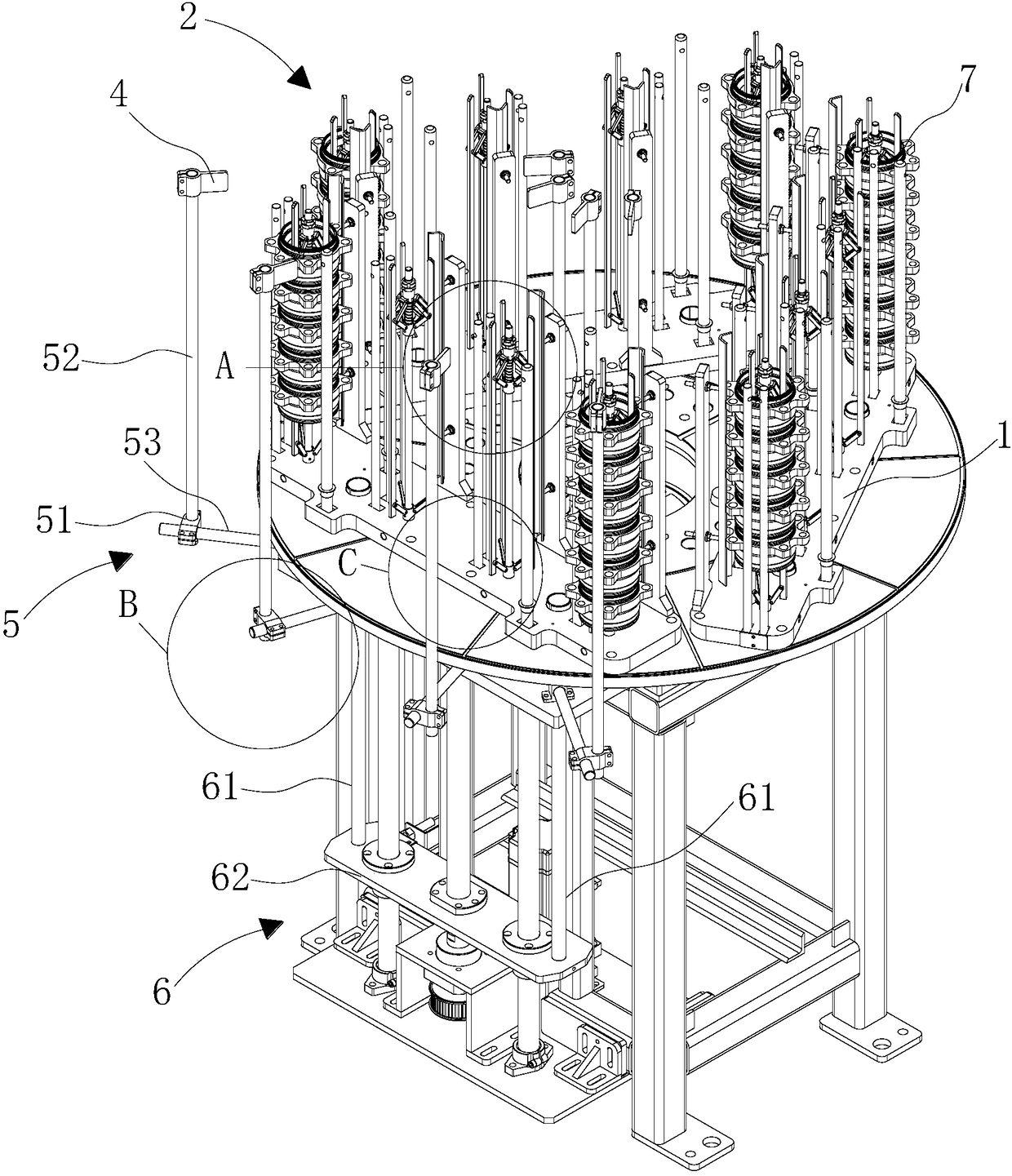

Stacking equipment capable of simultaneously taking and placing logistics boxes on multiple stations

InactiveCN105236062AImprove pick-and-place efficiencyAdapt to management requirementsStacking articlesDe-stacking articlesLogistics managementStack machine

The invention provides stacking equipment capable of simultaneously taking and placing logistic boxes on multiple stations. The stacking equipment comprise a supporting frame and a stacking machine, wherein the supporting frame comprises a horizontal movement rail and two perpendicular movement rails; the tops of the two perpendicular movement rails are connected through a beam; the stacking machine is arranged on the bottoms of the perpendicular movement rails and slides along the horizontal movement rail by following the perpendicular movement rails; the stacking machine comprises a framework, a logistics box working chassis, at least two mechanical hands and slide parts which are arranged at left and right sides of the framework for connecting the perpendicular movement rails in a sliding mode. The stacking equipment capable of simultaneously taking and placing logistic boxes on multiple stations provided by the invention realizes simultaneously taking and placing logistic boxes on multiple stations in dual directions, improves taking and placing efficiency of the logistic boxes, is suitable for modern large stereoscopic warehouse management requirements, and effectively overcomes the defect that stacking equipment in the prior art only can load one logistic box at the same moment.

Owner:KINCO ELECTRIC SHENZHEN

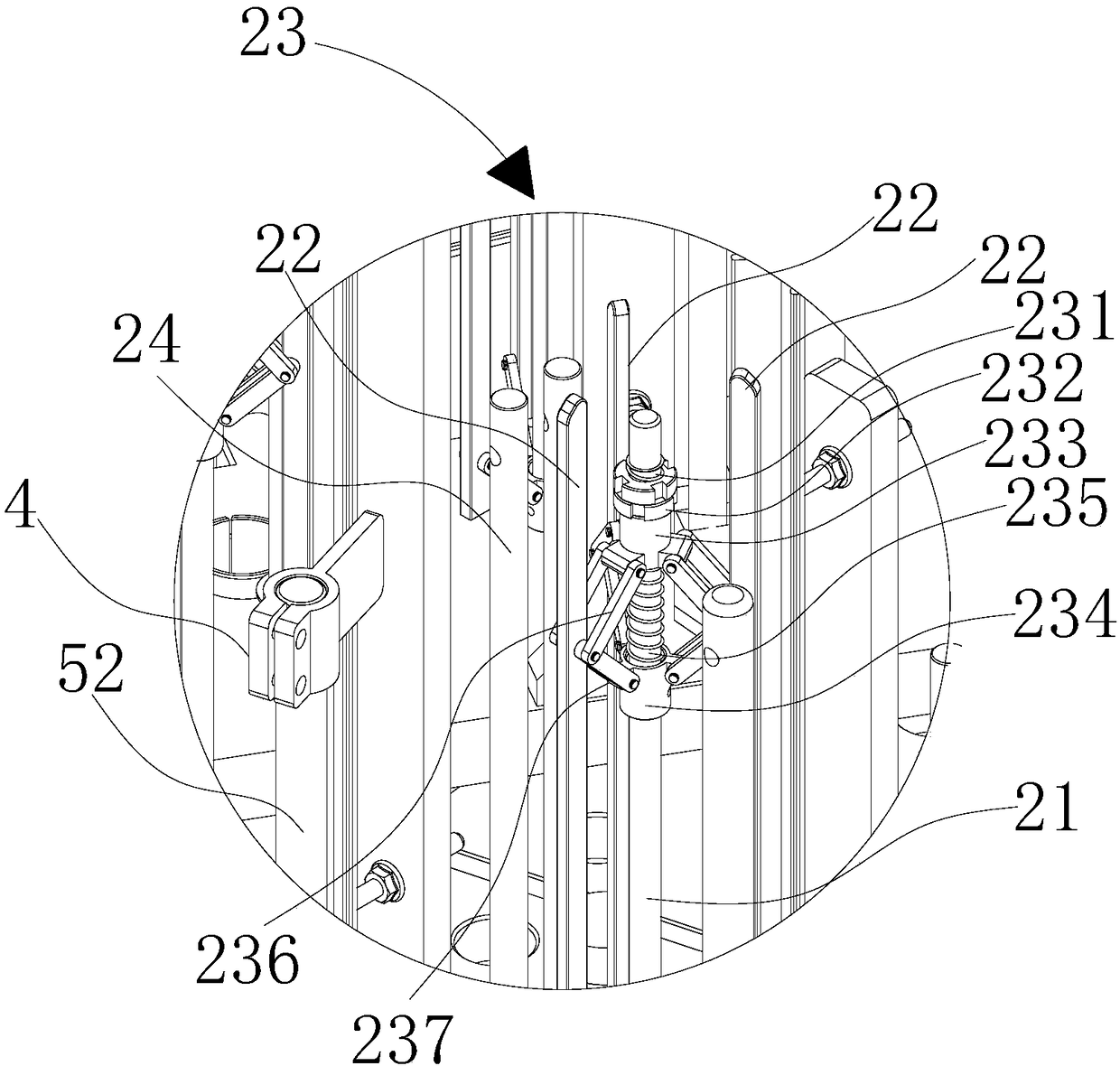

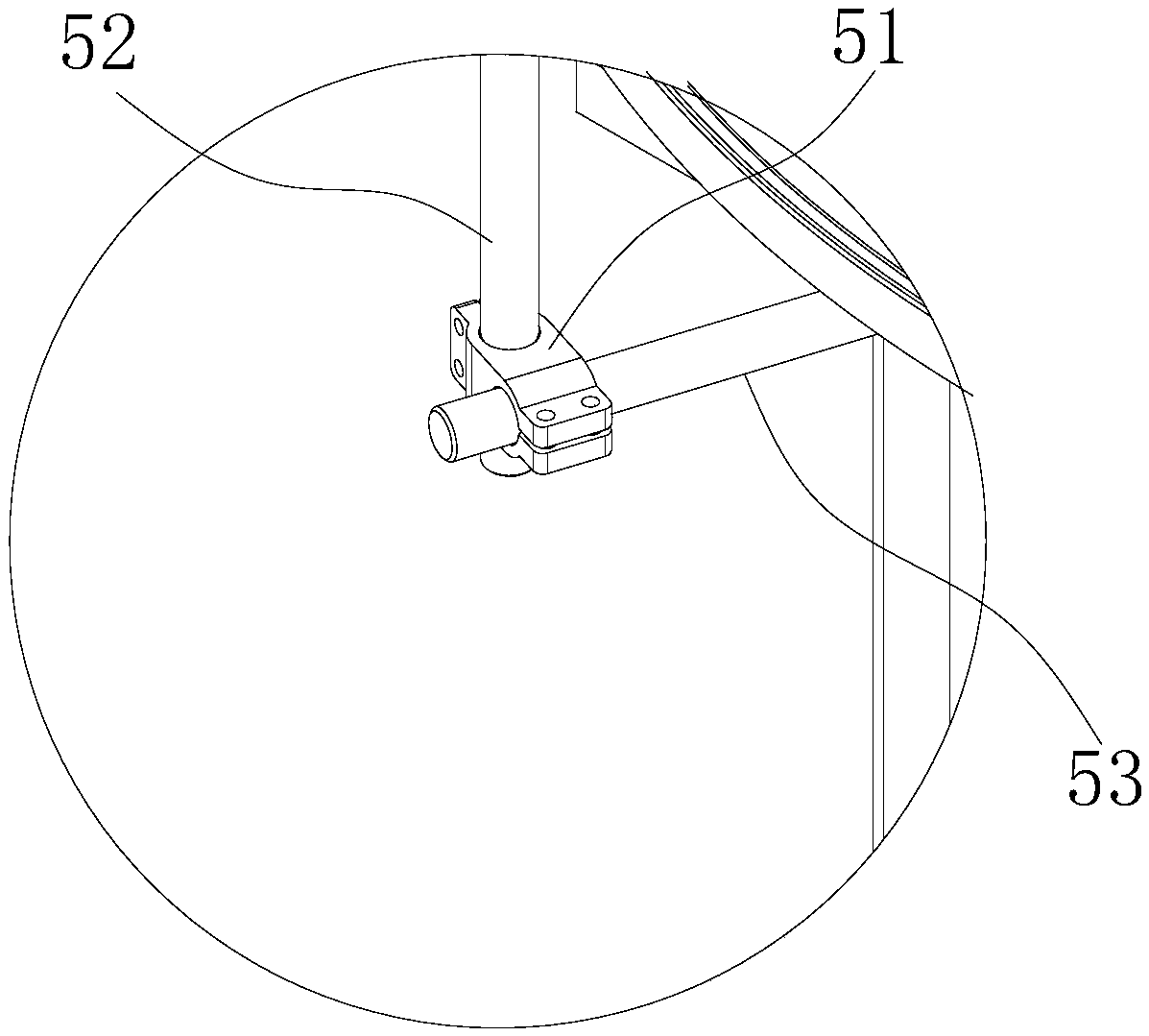

Knitting machine edge block replacement device

PendingCN107825099AImprove pick-and-place efficiencyImprove accuracyMetal working apparatusStructural engineeringMechanical engineering

The invention relates to a knitting machine edge block replacement device which comprises a mounting base, a suction structure, a first taking and releasing structure and a second taking and releasingstructure; the suction structure is connected with the mounting base, the suction structure comprises suction pieces for sucking a first edge block; the first taking and releasing structure is connected with the mounting base and comprises a first driving piece and a first taking and releasing piece; and the second taking and releasing structure is connected with the mounting base and comprises asecond driving piece and a second taking and releasing piece connected with the second driving piece. According to the knitting machine edge block replacement device, the first taking and releasing structure is used for placing or taking out an edge seat; the suction structure is used for taking down the first edge block, which is originally placed on the edge seat and is to be replaced, from theedge seat, and the second taking and releasing structure is used for acquiring a second edge block from an external structure and putting the acquired second edge block on the edge seat, so that thereplacement between the first edge block on the edge seat and the second edge block is completed. Thus, the knitting machine edge block replacement device can automatically complete the adjustment onthe edge blocks on the edge seat, the taking and releasing efficiency of the edge blocks is improved and the taking and releasing accuracy rate of the edge blocks is raised.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Probe suction device

InactiveCN108627679AImprove pick-and-place efficiencyImprove yieldElectrical measurement instrument detailsElectrical testingBiomedical engineeringEngineering

Owner:CHUNGHWA PRECISION TEST TECH

Clamping robot structure

PendingCN109605332AQuick responseImprove pick-and-place efficiencyProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

The invention relates to the technical field of battery production equipment, in particular to a clamping robot structure. The clamping robot structure comprises a clamping mechanism and a lifting driving mechanism for driving the clamping mechanism to move in the vertical direction. The clamping mechanism comprises a first clamping assembly, a second clamping assembly and a connecting rod drive assembly, wherein the connecting rod drive assembly is used for driving the first clamping assembly and the second clamping assembly to get close to each other or get away from each other. The clampingrobot structure has the characteristic of being high in response speed, the ascending, descending and clamping actions can be conducted at the same time, and the robot taking and placing efficiency is improved.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

Vertical accounting bill storage mechanism convenient for checking

InactiveCN111480992AEasy accessEasy to moveBook cabinetsFurniture partsStructural engineeringMechanical engineering

The invention provides a vertical accounting bill storage mechanism convenient for checking, belonging to the field of accounting. The invention aims to solve the problem that bills are inconvenient to check; ventilation effect on bills at the bottommost layer is poor, and the phenomenon of mildewing is likely to happen; bill lifting cannot be automatically achieved, and bill taking and placing are not convenient enough; and ventilation cannot be automatically achieved when bills are taken and placed. The vertical accounting bill storage mechanism convenient for checking comprises a cabinet body, wherein a rotating structure is arranged in the cabinet body. According to the invention, the elastic force of elastic telescopic rods is greater than the elastic force of four elastic members; when a mounting frame is rotated, an adjusting seat is shifted by the elastic members to be in an upward moving state; when the elastic members reach a maximum compression state and a mounting frame isfurther rotated, the elastic telescopic rods are in an extrusion and contraction state; and therefore, when the mounting frame is rotated, the adjusting seat can move, so air contact and lifting actions of bills in a placement box are further achieved, and the elastic telescopic rod with a conical head end can adapt to forward and reverse rotation of the mounting frame.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

Chip taking and placing device

InactiveCN102751169AImprove pick-and-place efficiencyIncrease productivitySemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeNozzle

The invention provides a chip taking and placing device which can be used for technologies including a preparation technology of light-emitting diodes and the like which require chip movement. The chip taking and placing device comprises a chip storage area, a chip placing area, a rotating shaft, a first sucking nozzle and a second sucking nozzle, wherein the first sucking nozzle and the second sucking nozzle are arranged on the rotating shaft, and the rotating shaft rotates to drive the first sucking nozzle and the second sucking nozzle to place chips from the chip storage area to the chip placing area. The chip taking and placing device is characterized in that the first sucking nozzle and the second sucking nozzle are in even symmetry around the axis of the rotating shaft and on the same plane perpendicular to the axis of the rotating shaft and are distributed corresponding to the chip storage area and the chip placing area. The chip taking and placing device can perform sucking-taking and placing simultaneously, thereby effectively improving the overall production efficiency.

Owner:EVERLIGHT ELECTRONICS (CHINA) CO LTD +1

Arrangement device

PendingCN108406719AEasy to storeImprove pick-and-place efficiencyWork tools storageEngineeringMechanical engineering

Owner:HANGZHOU RUIGUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com