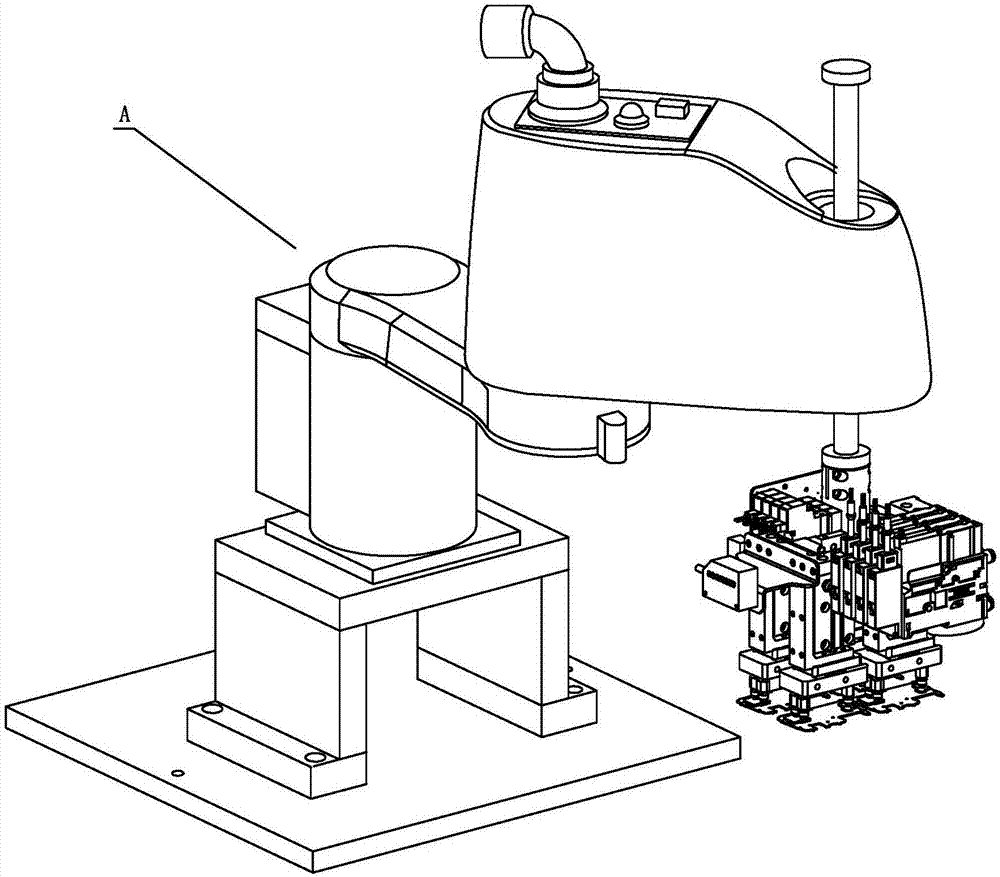

Robot fixture for carrying mobile phone main boards

A robot fixture and robot technology, which is applied in chucks, manipulators, manufacturing tools, etc., can solve problems that affect the pass rate of mobile phone motherboards, easily damaged mobile phone motherboards, and low work efficiency, so as to reduce labor intensity and avoid electrostatic damage. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

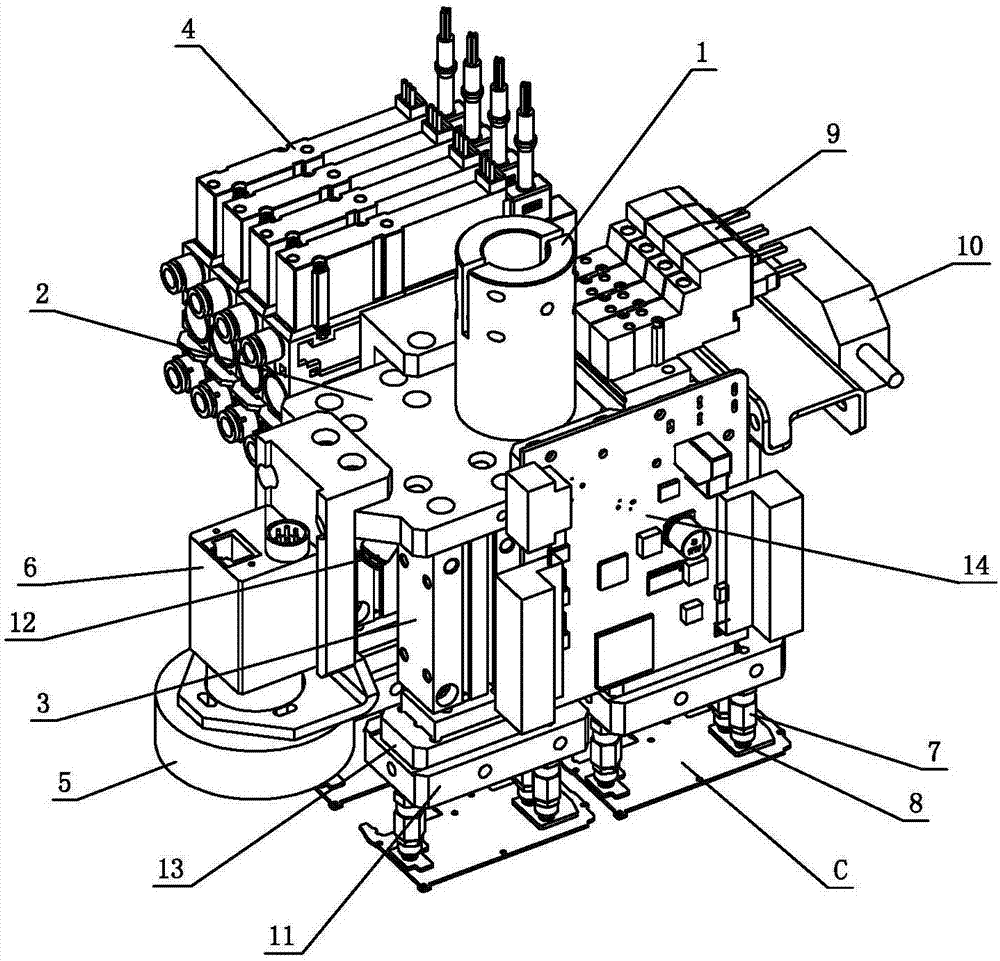

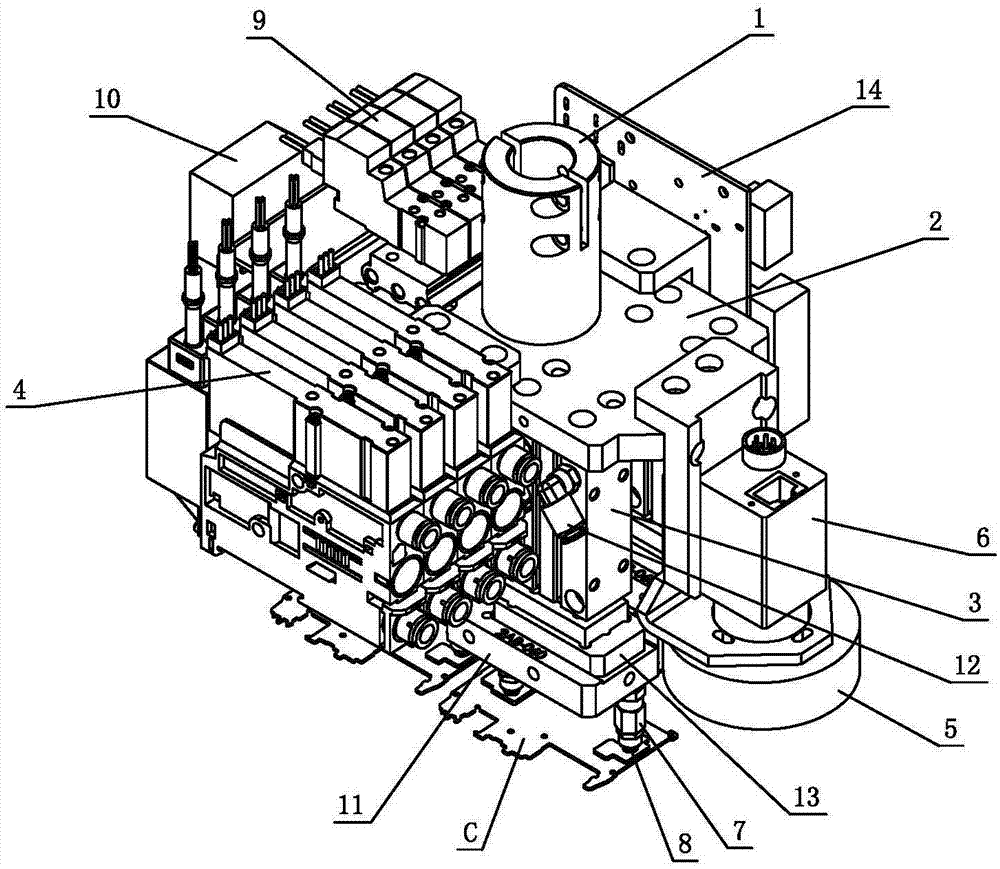

[0025] see Figure 1-Figure 8 , this robot fixture is used to carry mobile phone PCBA motherboard C for dispensing (or testing, etc.); the robot fixture includes a connecting flange 1 for connecting robot A and a mounting plate 2 for loading various mechanisms, connecting flange 1 and The mounting plates 2 are fixedly connected to each other, and the robot involved may be a four-axis robot or a six-axis robot; wherein, the mounting plate 2 is provided with four sets of relatively independent pick-and-place mechanisms; the pick-and-place mechanisms include mutually supporting vacuum generators 4 and Pick and place components, four vacuum generators 4 are integrated side by side and fixed on one side of the mounting plate 2 as a whole, four sets of pick and place components are arranged in a square shape under the mounting plate 2; each pick and place com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com