Automatic express storage and fetching system

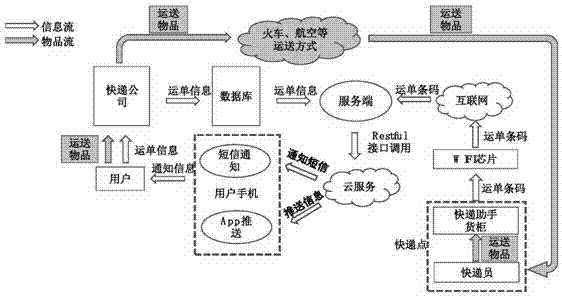

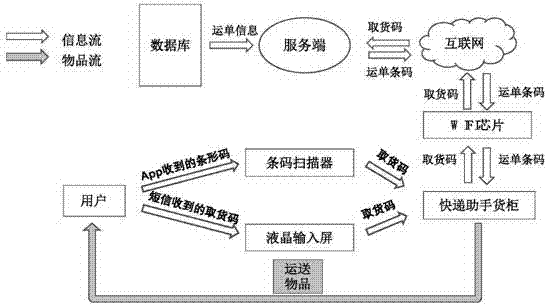

An access system and belt transmission technology, which is applied in the field of terminal equipment in the logistics industry, can solve the problems of notification errors on the user side, reduce the labor load of couriers and users, and limit time, so as to reduce labor intensity and improve the efficiency of picking and placing goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

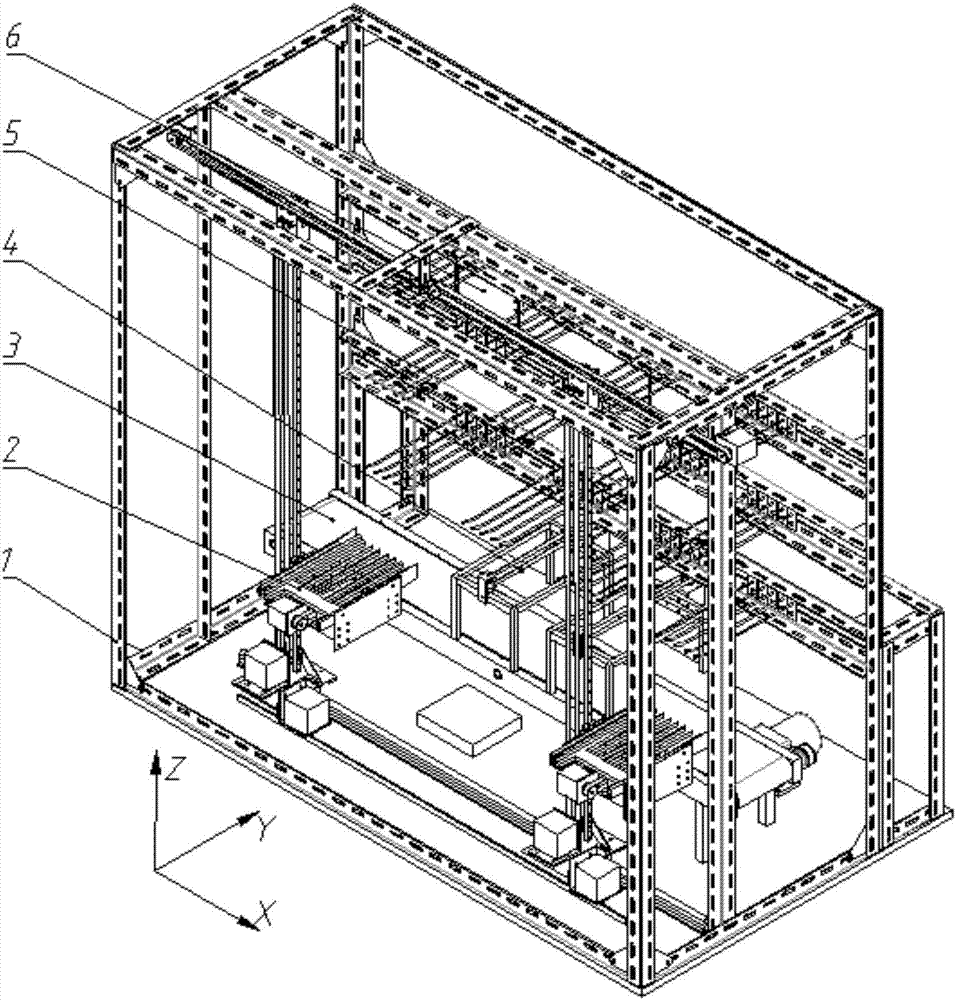

[0040] The present invention is described in detail below in conjunction with accompanying drawing.

[0041] refer to figure 1 , an automated express access system, including a shell frame 1 for providing support, at least one three-coordinate pick-and-place device 2 for storing and picking up goods, a conveyor belt device 3 for transferring goods, at least one The goods pushing device 4 for pushing the goods to the three-coordinate pick-and-place device 2 , the shelf 5 for storing goods, the pick-up window 6 for the user to pick up the goods, and the controller 41 .

[0042] refer to figure 2 , image 3 , the shell support 1 mainly includes the bottom mounting plate 7, the horizontal and vertical directions of the mounting plate 7 are installed with angle steel 8 to form a cuboid frame, the angle steel 8 is fixedly connected by the mounting flange 9, the cuboid frame and the acrylic shell 10 Fastened by means of bolt connection.

[0043] refer to figure 2 , image 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com