Patents

Literature

214results about How to "Ensure consistent quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

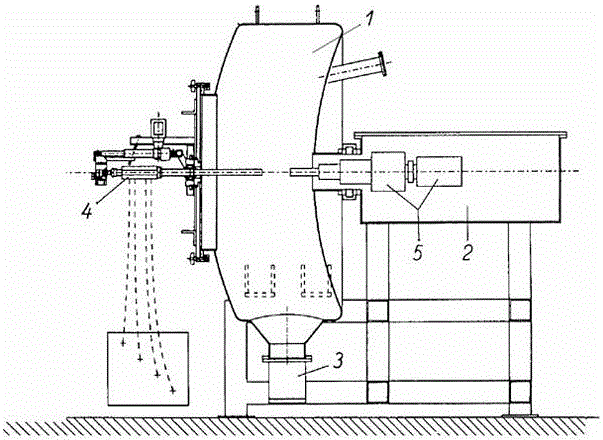

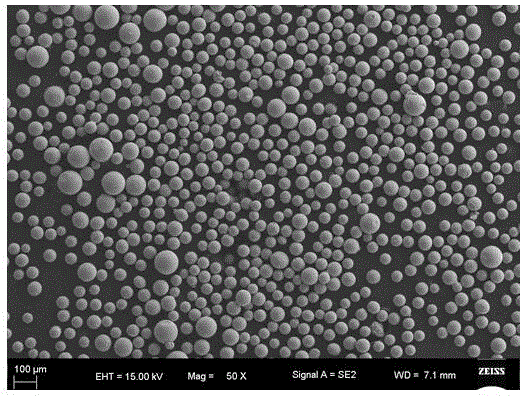

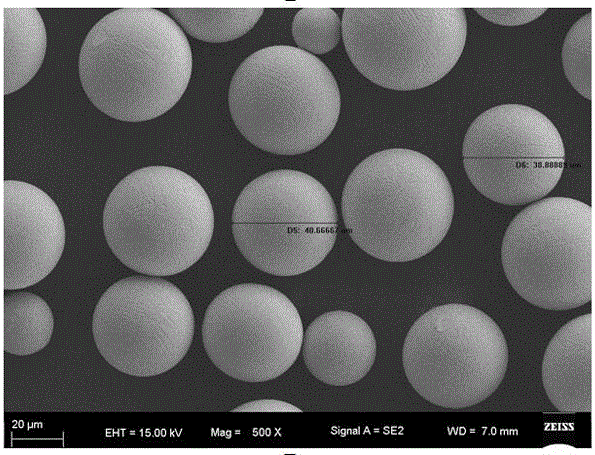

Preparation method of Waspalloy spherical powder for additive manufacturing

InactiveCN106623959AFast pure meltingReduce the introductionAdditive manufacturing apparatusTransportation and packagingVacuum pumpingElectrostatic separation

A preparation method of Waspalloy spherical powder for additive manufacturing includes the steps of conducting alloy component compounding according to AMS 5706 standards and subjecting master ingots to vacuum melting twice; producing the master ingots into alloy electrode bars by means of forging and machining; subjecting an atomizing unit to pre-vacuum-pumping treatment, and feeding the atomizing unit with mixed inert protective gas; feeding the electrode bars into an atomizing chamber by a feeding system, heating electrode bar end faces by a plasma torch, preparing metal liquid droplets under the centrifugal action of a rotating electrode, and making the metal liquid droplets form spherical metal powder by flash setting; using a powder collecting device comprising an electrostatic separation component for removing inclusions of the spherical metal powder and collecting purified powder. The preparation method has the advantages of high production efficiency, high batch stability and high -270-mesh powder yield and can be used for easily preparing the Waspalloy spherical powder high in purity, sphericity and fluidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

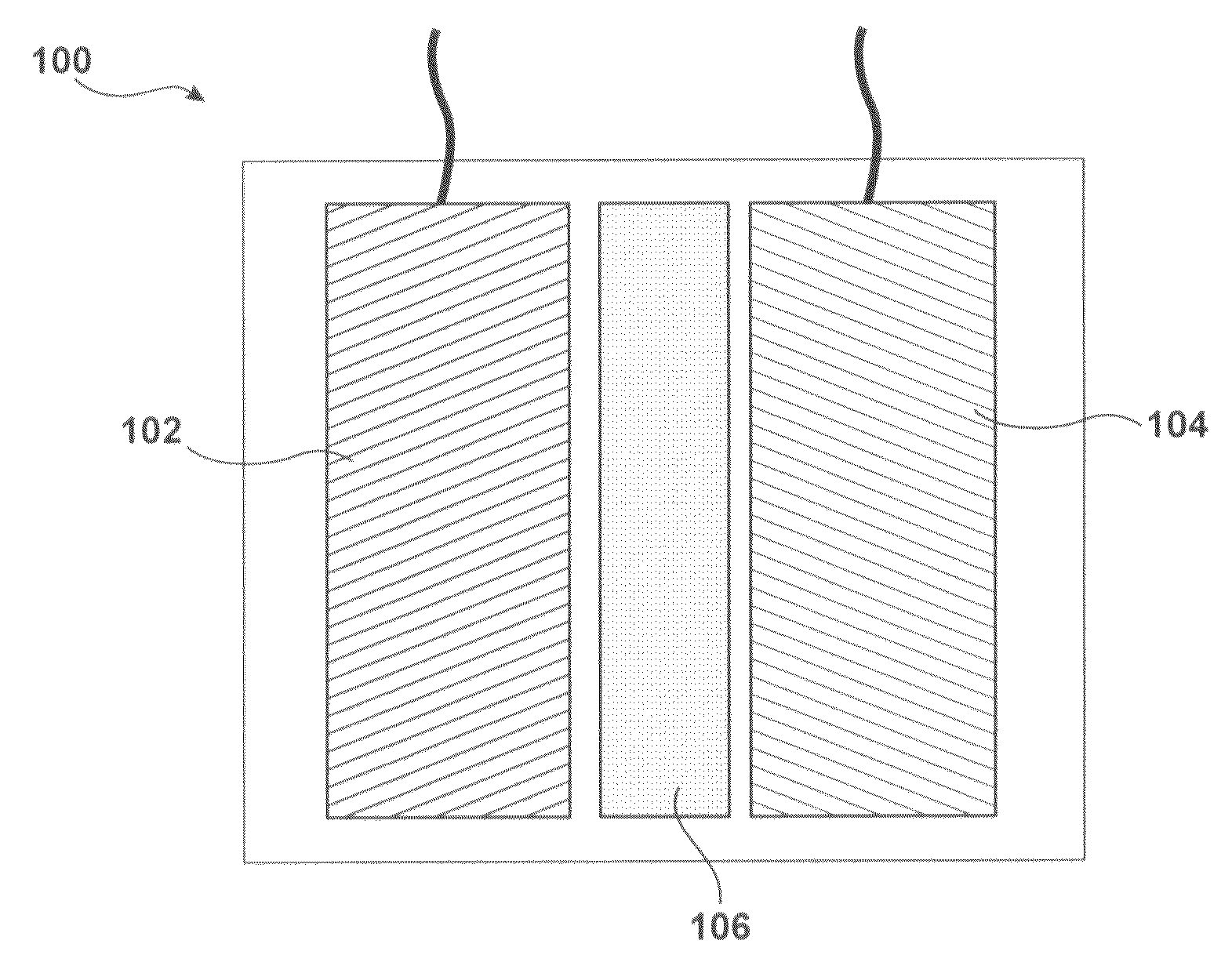

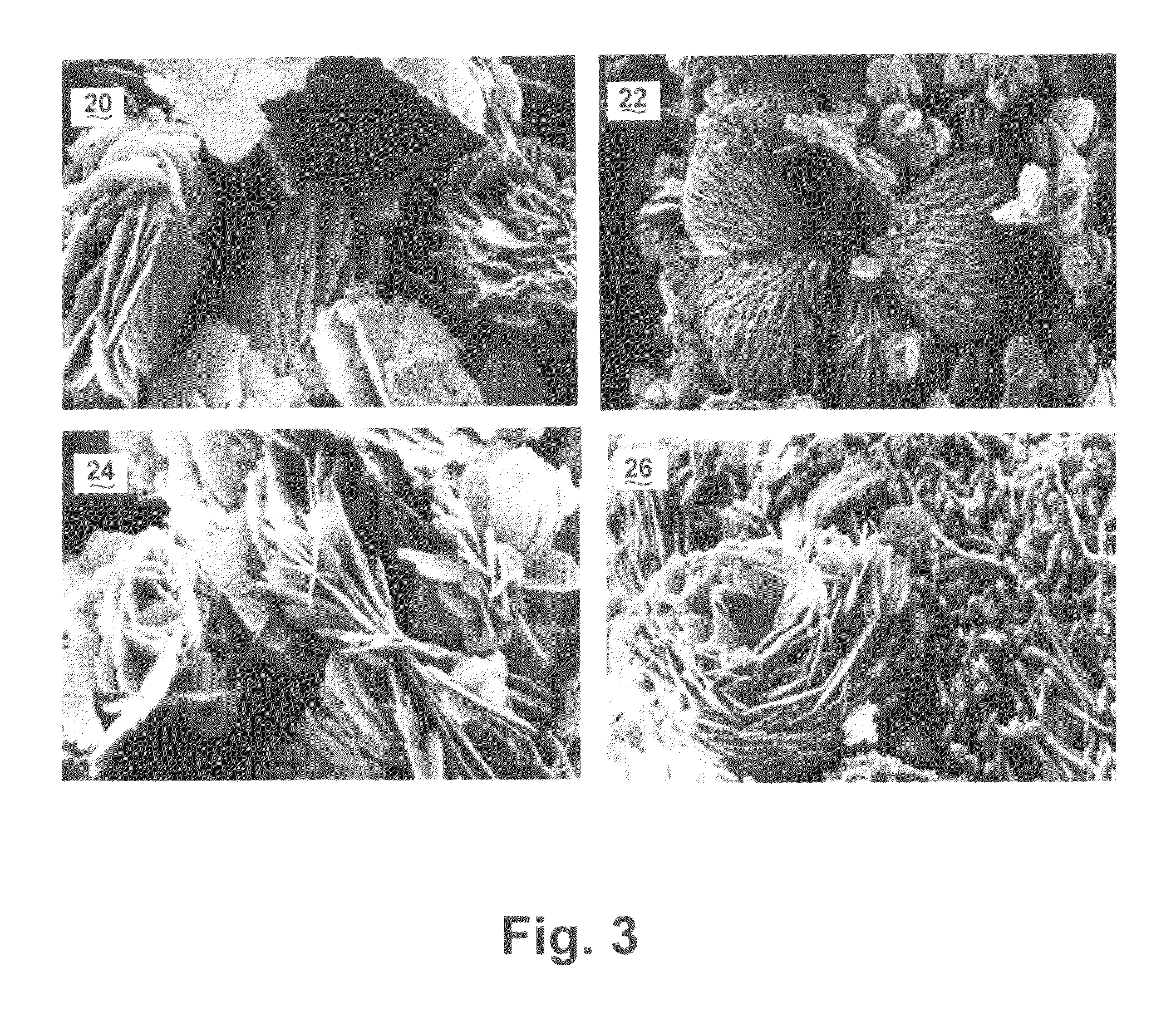

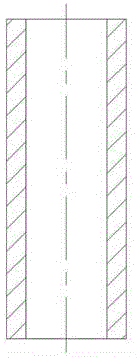

Lithium battery with silicon-based anode and silicate-based cathode

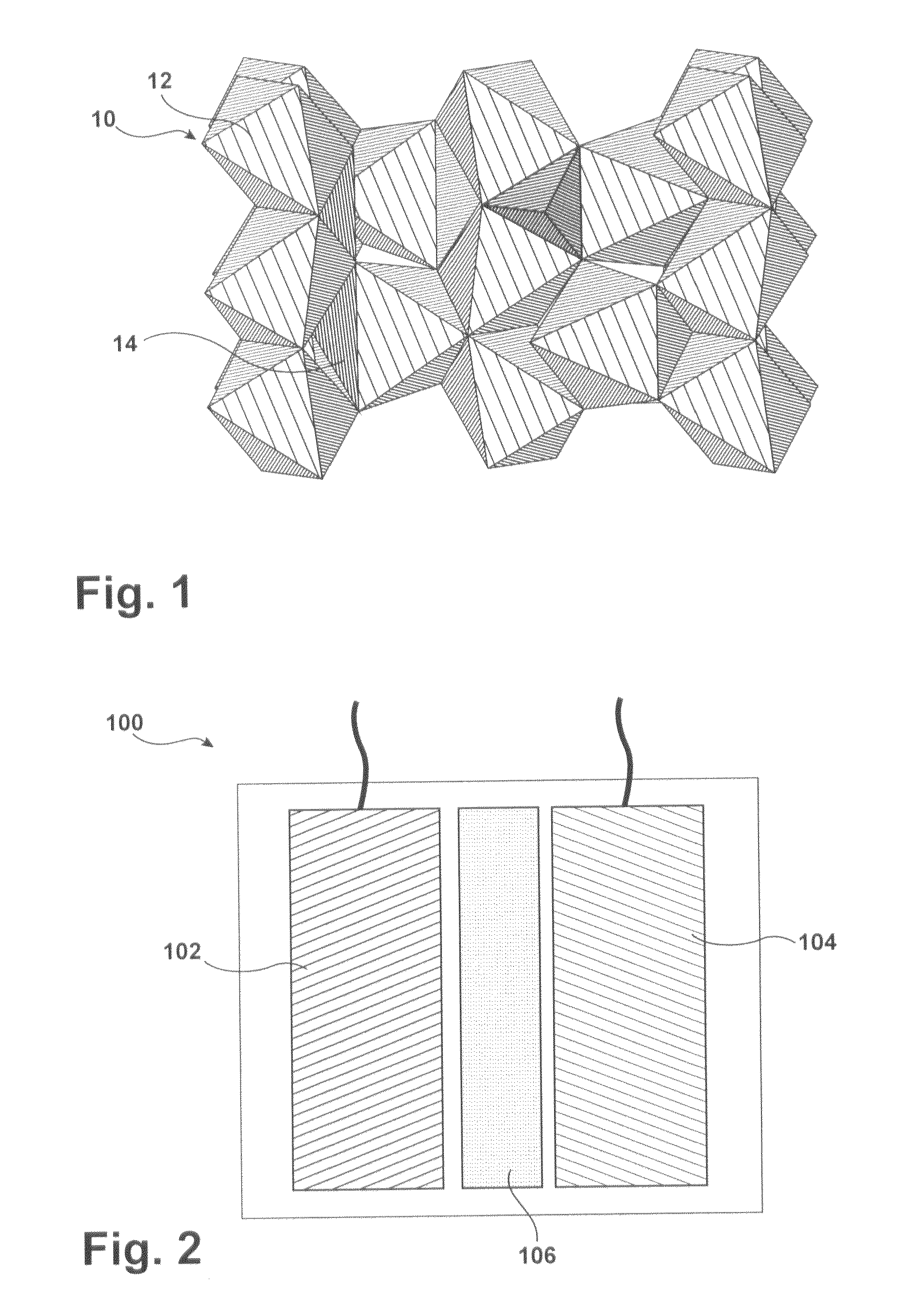

ActiveUS20130234674A1High energy capacityImprove cycle efficiencyMaterial nanotechnologyBatteries circuit arrangementsNickel–lithium batteryCarbon nanofiber

A lithium-ion battery is provided and related methods. The lithium-ion battery includes an electrode comprising an Olivine flake-like structure and an electrode comprising a plurality of coated carbon nanofibers. The Olivine flake-like structures form clusters through which the lithium ions are transported while reducing initial cycle irreversibility. The electrode comprising the coated carbon nanofibers additionally reduce initial cycle irreversibility by controlling expansion of the substrate forming the electrode comprising the coated carbon nanofibers.

Owner:GENERAL MOTORS COMPANY

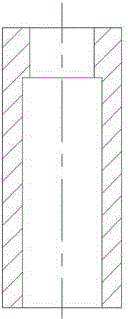

Process for cold extrusion forming of one-way device spline sleeve

InactiveCN104148888AEliminates drilling/boring stepsDrilling/boring steps meetEngineeringUltimate tensile strength

The invention provides a process for cold extrusion forming of a one-way device spline sleeve. The process comprises the steps of utilizing hollow pipes to serve as raw materials, performing blanking according to specified dimensions, sequentially performing annealing, head flattening, shot blasting, phosphatization and saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, shot blasting, cleaning and grinding machine processing, and obtaining finished product one-way device spline sleeves. The one-way device spline sleeves obtained through the process are high in precision, small in individual differences, good in strength performance and long in service lives.

Owner:宁波惠山汽配制造有限公司

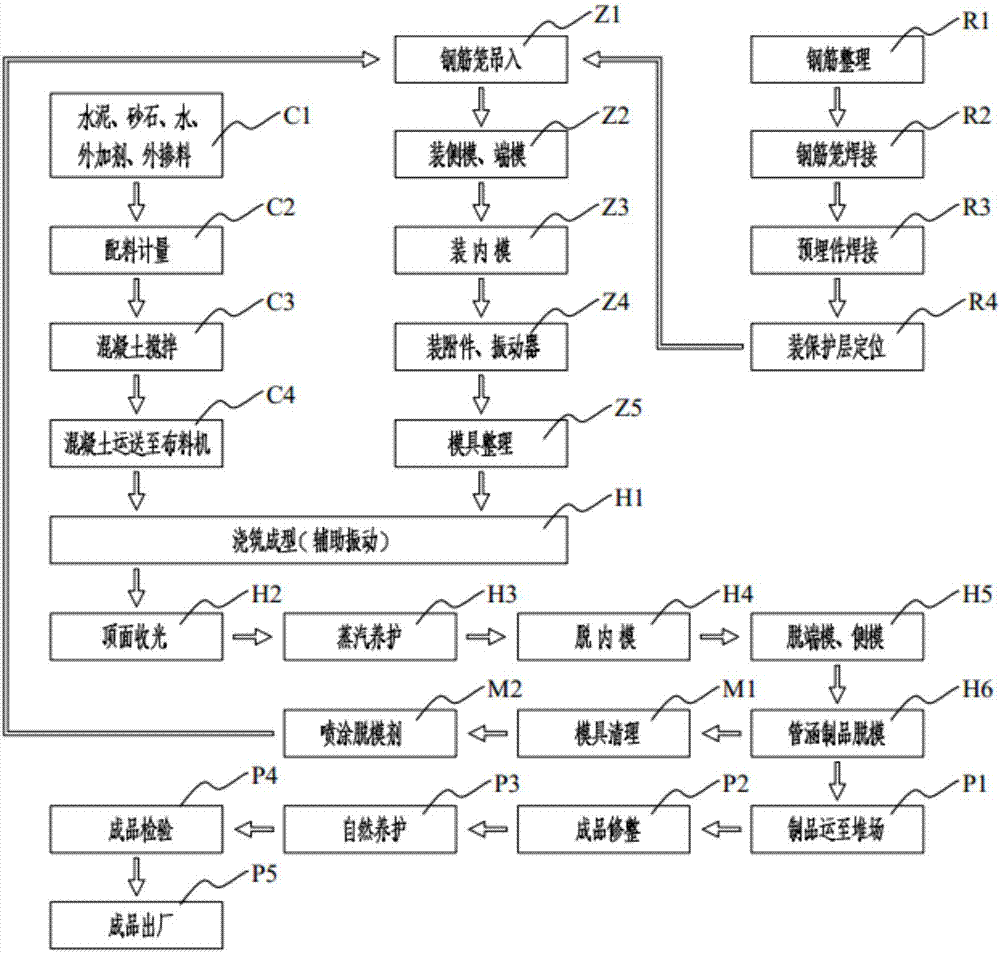

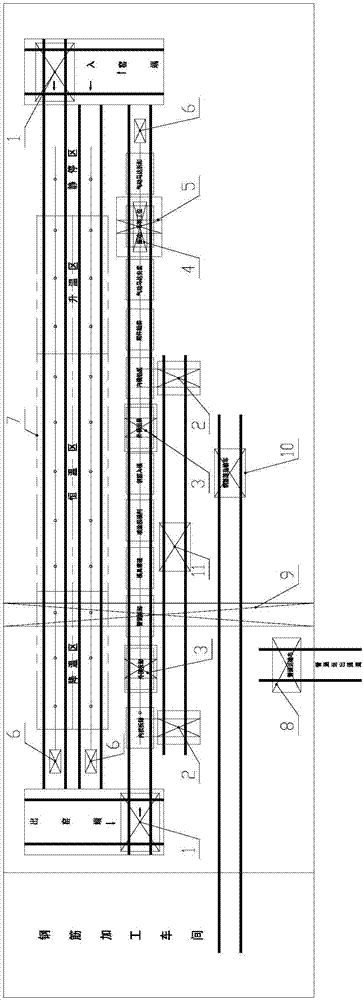

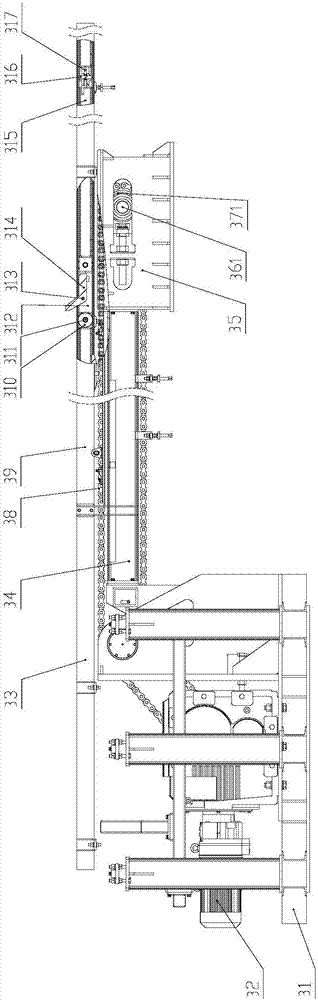

Prefabricated concrete pipe culvert production assembly line and production process

ActiveCN107042580AImprove precast production efficiencySave landVehicle dissasembly recoveryCeramic shaping plantsRebarAssembly line

The invention provides a prefabricated concrete pipe culvert production assembly line and a production process. The production assembly line comprises a reinforcement machining workshop, a reinforcement cage conveying line, a mold dismounting and mounting conveying line, a reinforcement mold assembling line, a material distribution zone, a maintaining line and a finished product conveying-out line. The reinforcement cage conveying line is arranged at an output port of the reinforcement machining workshop, and the mold dismounting and mounting conveying line is parallel to the reinforcement cage conveying line. The reinforcement mold assembling line is parallel to the mold dismounting and mounting conveying line. The material distribution zone is arranged on the reinforcement mold assembling line. The maintaining line is parallel to the reinforcement mold assembling line. Translation shuttle buses are arranged at the two ends of the maintaining line and the two ends of the reinforcement mold assembling line. A crown block is erected on the two outer sides of the reinforcement cage conveying line and the maintaining line. The layout occupies small spaces, workshop land is saved, the prefabrication production efficiency of pipe culverts is effectively improved, the worker labor intensity is lowered, the production cost is lowered, and the quality consistency and reliability of pipe culvert products can be ensured.

Owner:博奥重工装备制造(天津)有限责任公司

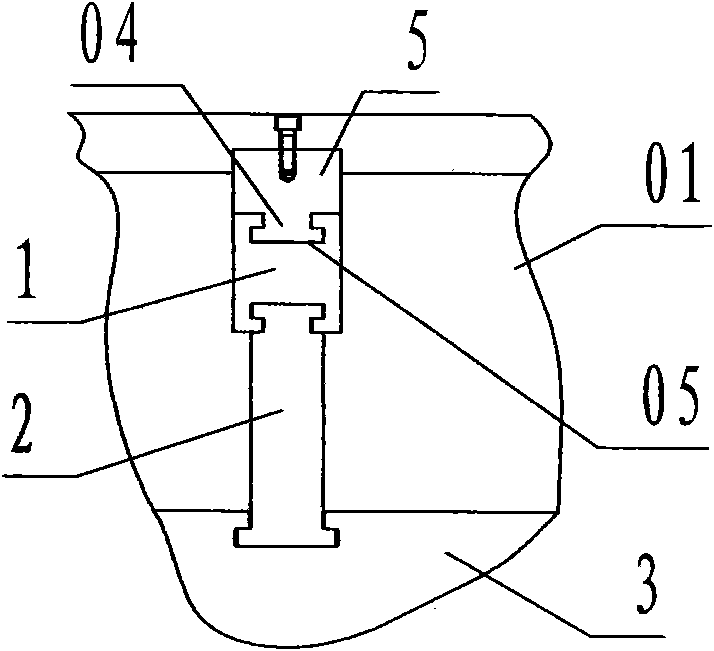

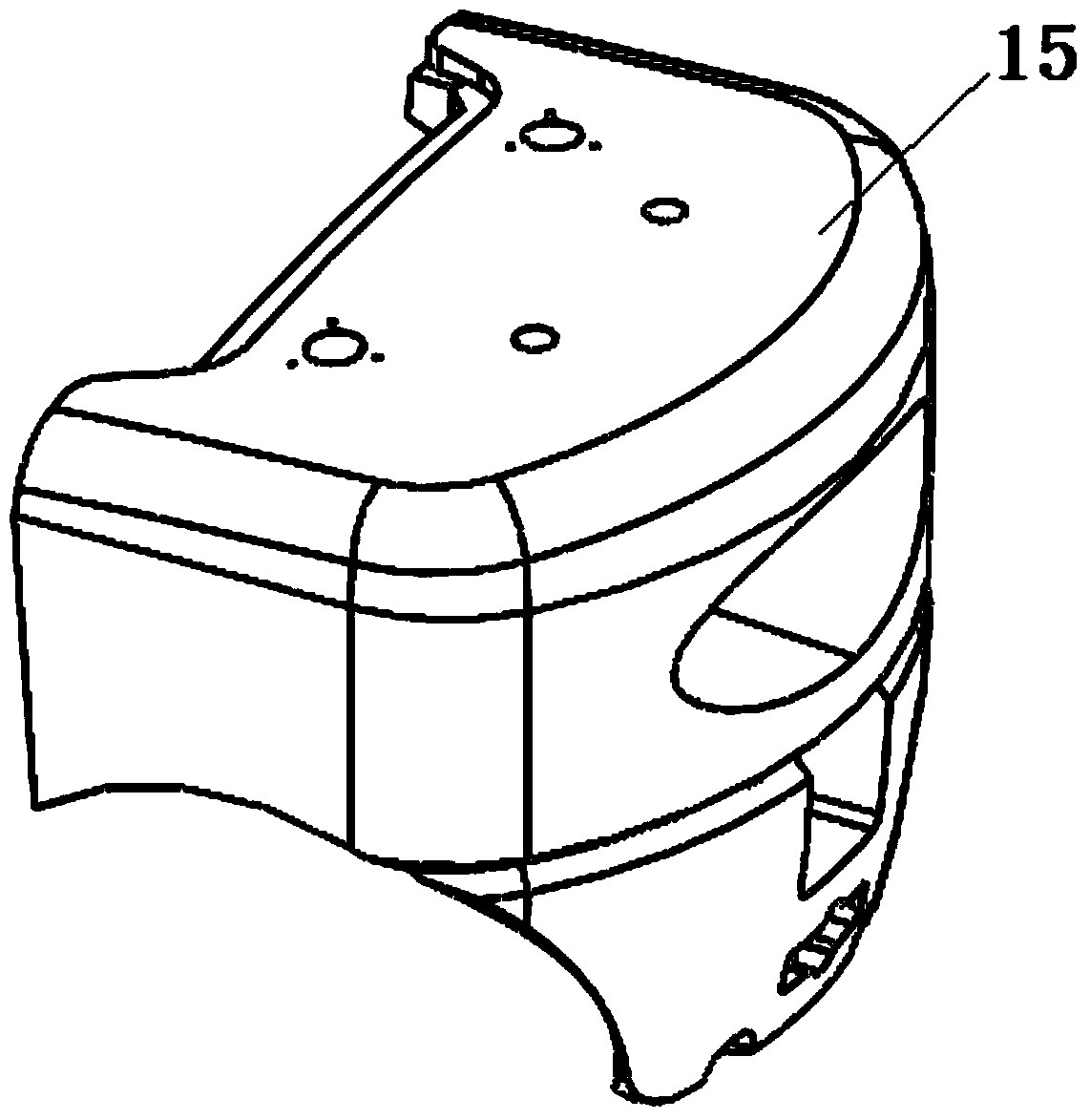

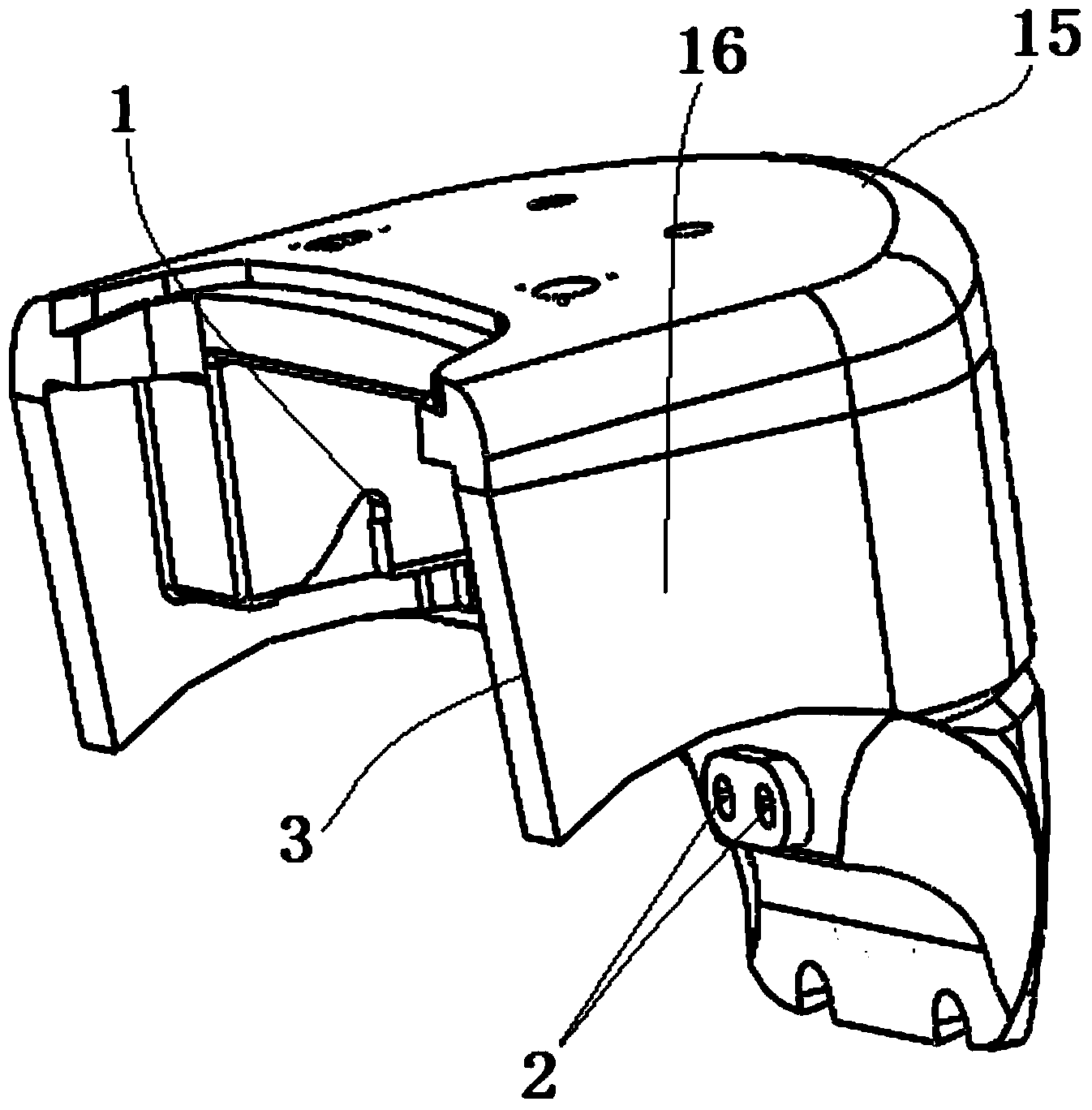

Injection mold core with air suction, discharge and rapid cooling functional structure

The invention provides an injection mold core with an air suction, discharge and rapid cooling functional structure. The injection mold core consists of a core body (1), a ventilated surface (2), an air suction and discharge channel (3) and a heat-conductive pin (4). In the injection mold core, the technical scheme that: the core body is made from a beryllium copper material with high heat conductivity; the ventilated surface which is made of porous ventilated steel is fixedly inlaid at the top of the core body; the air suction and discharge channel which is connected with a mold is reserved in the core body; and the heat-conductive pin which is directly inserted into a mold cooling water pipe is arranged at the bottom of the core body is adopted, so that the problems of low qualification rate, high cost and poor quality consistency of products in the molding of small-diameter deep-cavity injection products in the prior art are solved. The injection mold core with the air suction, discharge and rapid cooling functional structure provided by the invention fulfills the aims of improving the qualification rate, reducing the cost and ensuring the quality consistency of the products of the molding of the small-diameter deep-cavity injection products by increasing cooling rate and improving air suction and discharging conditions of the core body structurally.

Owner:NINGBO RUIYUAN MOLD & PLASTICS

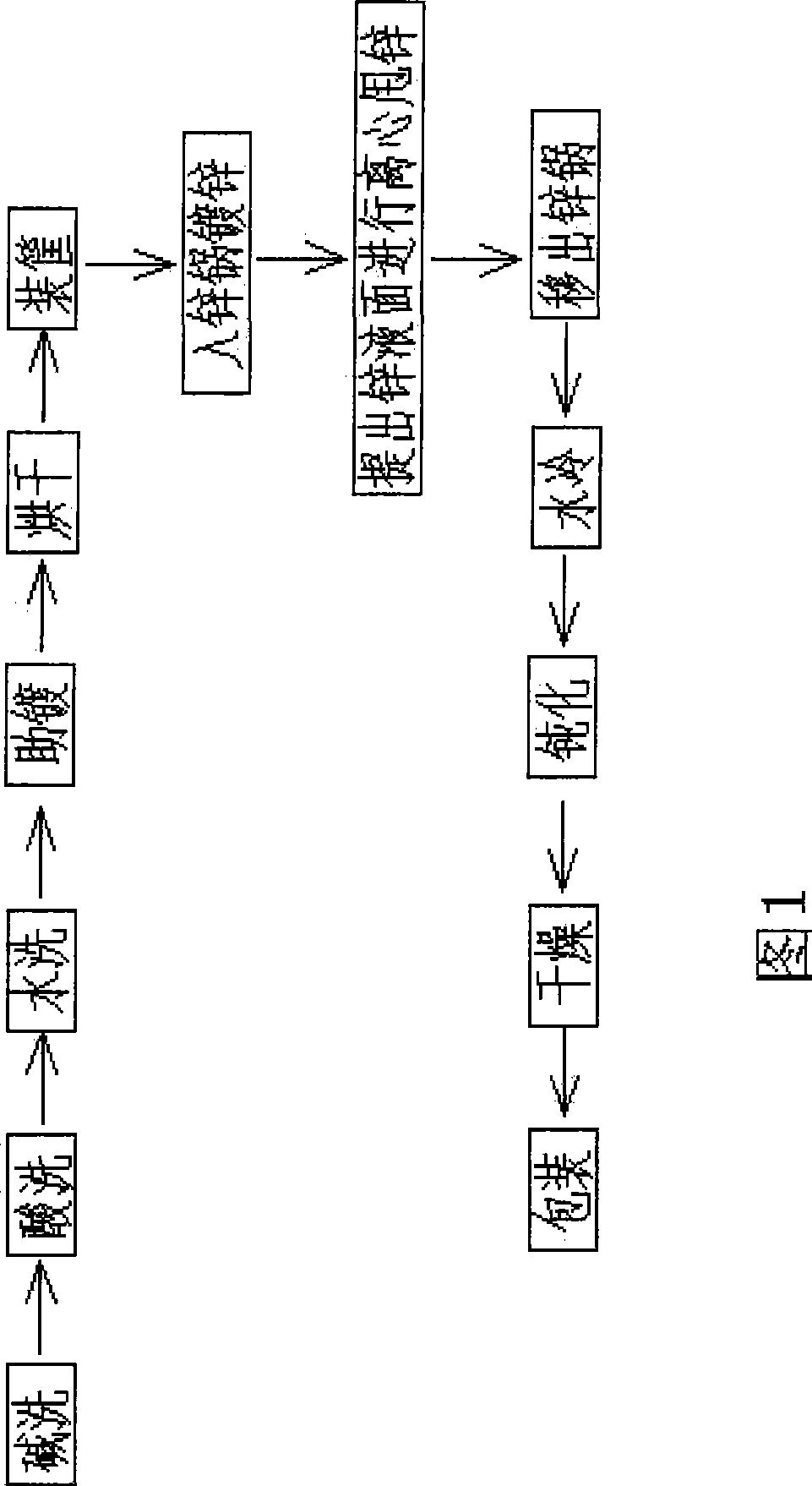

Automatic hot galvanizing technique for steel fastener

InactiveCN101368253AGuaranteed accuracyGuaranteed StrengthHot-dipping/immersion processesAutomatic controlAcid washing

The invention discloses an automatic pot galvanizing technique of a steel fastener which orderly includes the working procedures like caustic washing, acid washing, water washing, assistant plating, drying, crating, galvanizing, centrifugal zinc throwing, water cooling, passivating, drying, packaging, and the like. The galvanizing temperature is between 450 and 480 DEG C; the working procedures of galvanizing and centrifugal zinc throwing are automatically controlled; the centrifugal zinc throwing is to hoist a galvanized workpiece out of a galvanized surface with a galvanizing material basket and lead the galvanized workpiece to horizontally rotate with the galvanizing material basket to make centrifugal movement. The technique leads the galvanized workpiece to instantly carry out zinc throwing without pouring the basket; the temperature drop of the workpiece is small; the galvanizing temperature can be reduced below 480 DEG C; energy is saved; the coherence for the intensity, the precision and the quality of the fastener is ensured; the service life of a zinc boiler is prolonged; the production cost is reduced; the processes for galvanizing and zinc throwing are automatic, safe and effective; besides, the working intensity is low. The technique provided by the invention can be used for carrying out pot galvanizing on the steel fasteners like bolts, nuts, nails, and the like.

Owner:陈冬

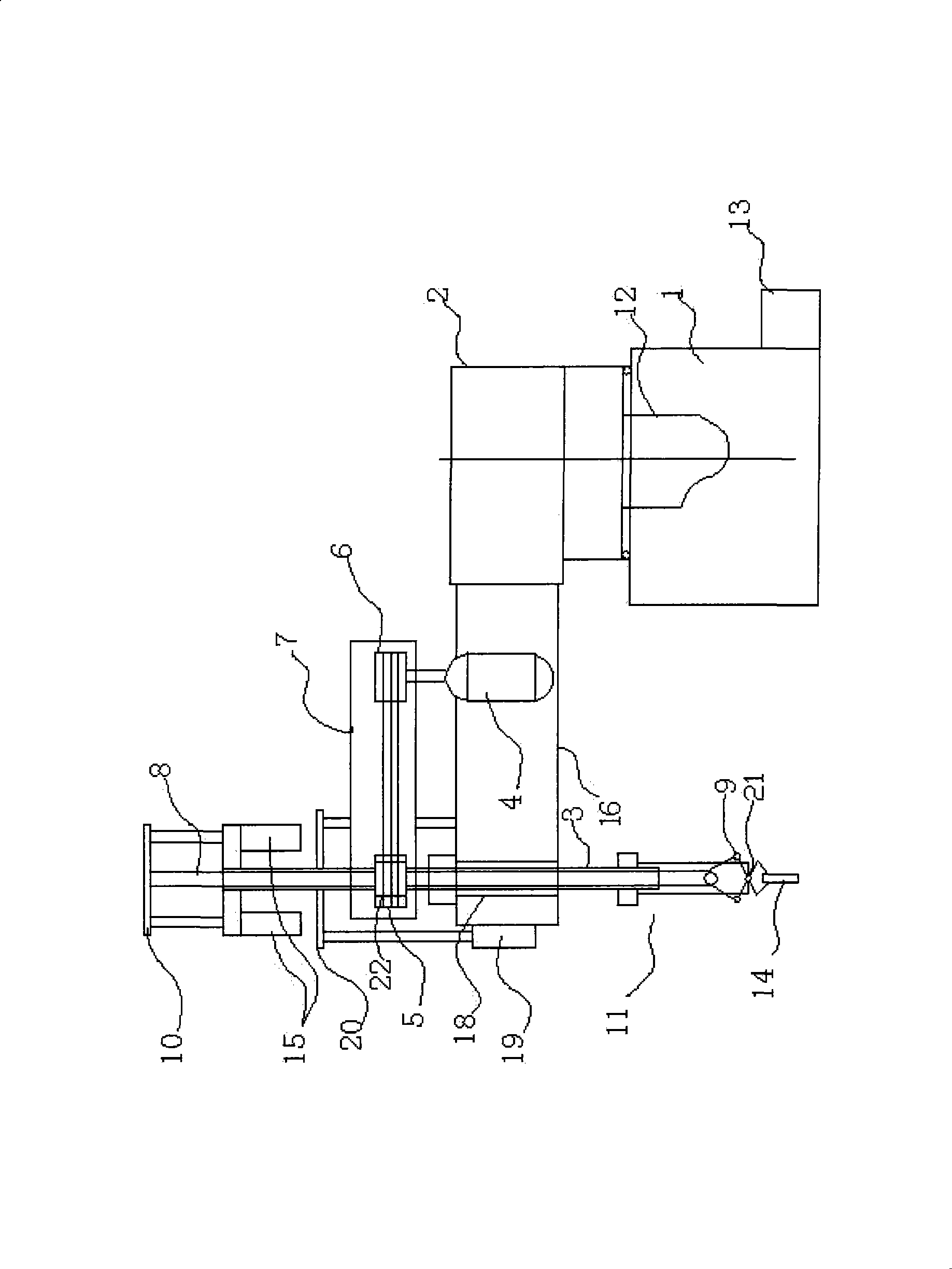

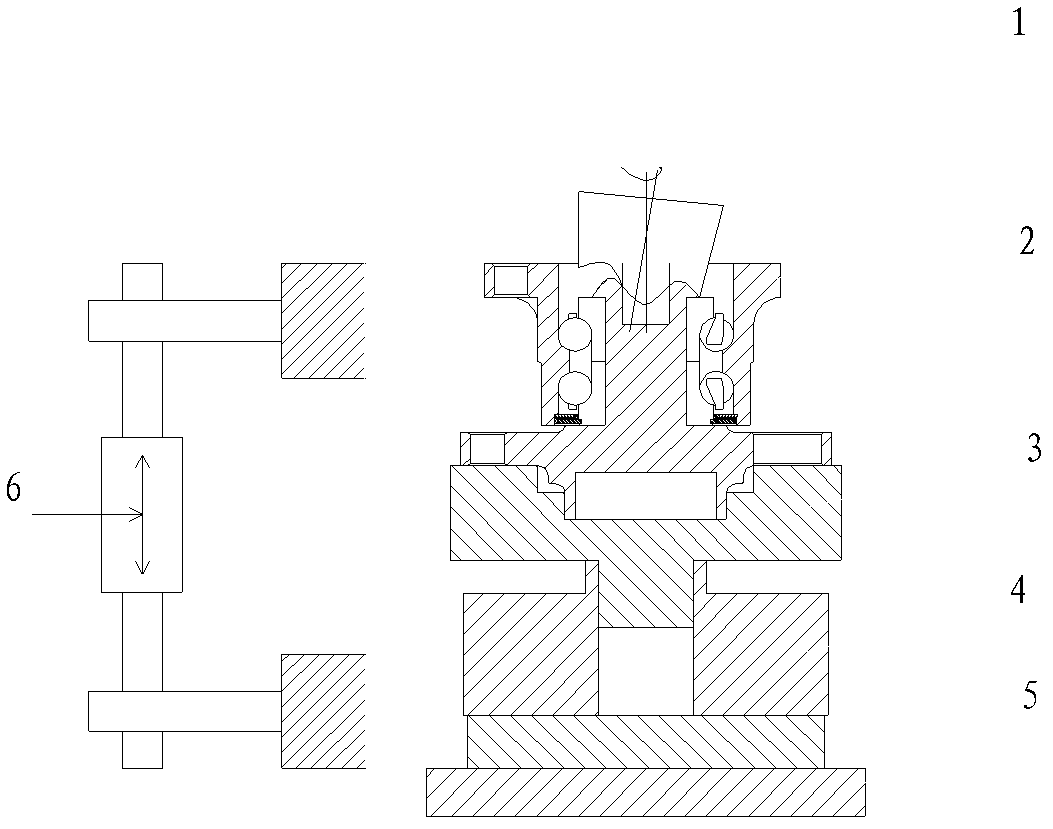

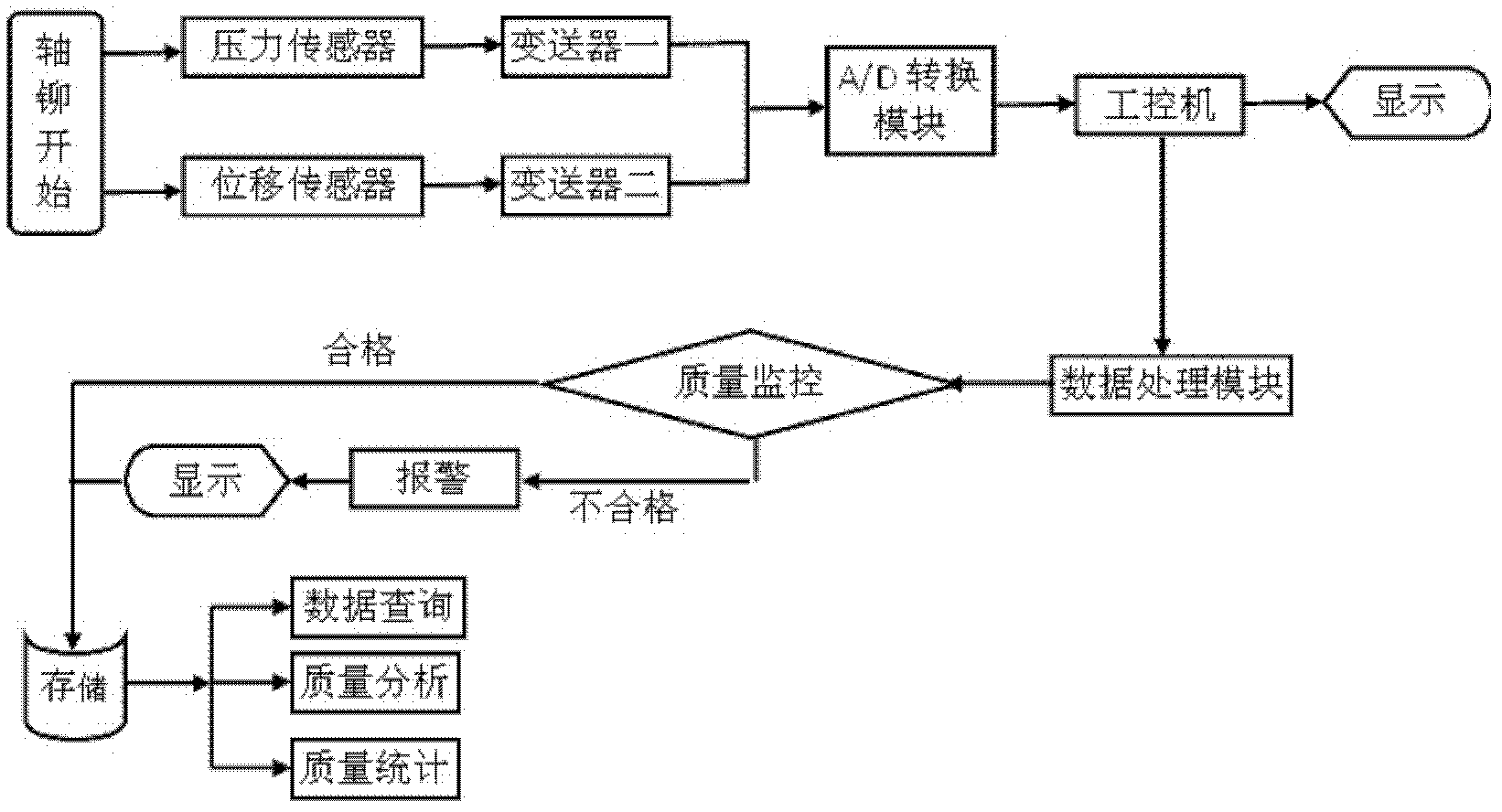

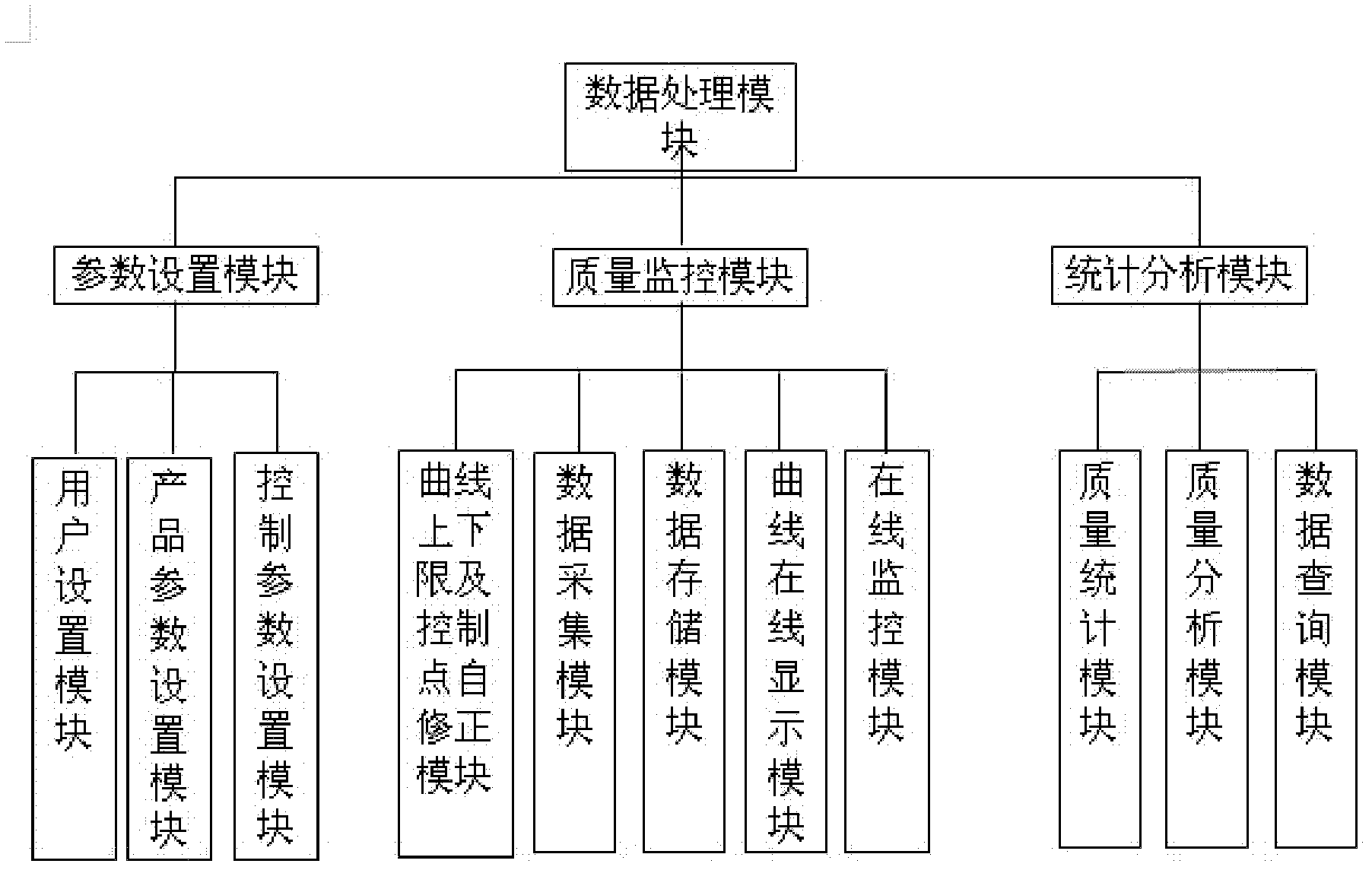

Shaft pivoted hub bearing unit monitoring system for axial pivoting force and displacement and method

InactiveCN102323059ASimple technical meansEnsure product quality consistencyMachine bearings testingForce measurementEngineeringData processing

The invention discloses a shaft pivoted hub bearing unit monitoring system for axial pivoting force and displacement and a method. The system comprises a pressure sensor, a transducer I, a displacement sensor, a transducer II, an A / D (Analog to Digital) conversion module, an industrial computer and a data processing module, wherein the pressure sensor and the transducer I are connected in sequence; the displacement sensor and the transducer II are connected in sequence; the transducer I and the transducer II are connected with the A / D conversion module respectively; and the A / D conversion module, the industrial computer and the data processing module are connected in sequence. By adopting the system, pivoting force-displacement data measured in each pivoting process can be recorded, the qualification of a shaft pivoting process can be judged automatically according to a measured pivoting force-displacement curve, possible causes leading to defective goods can be given automatically, and data can be counted and analyzed or called automatically. The system has an easy, convenient and practical technical means and positive and beneficial technical effects.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for continuously coating high-viscosity sizing agent used for preparing positive pole piece of lithium-manganese primary cell

InactiveCN103357557AGuaranteed thickness consistencyEnsure uniformityLiquid surface applicatorsElectrode manufacturing processesElectrolysisPrimary cell

The invention provides a method for continuously coating a high-viscosity sizing agent used for preparing a positive pole piece of a lithium-manganese primary cell, wherein thermally treated electrolyzed manganese dioxide is mixed with a conductive black, then deionized water or distilled water containing a polar alcohol solvent is added for continuous mixing to obtain a wet mixture, then an aqueous solution of a binder commonly used by a lithium battery is added for continuous mixing to obtain the high-viscosity sizing agent, the high-viscosity mixed sizing agent is prepared into particles, is rolled by a coating roller into a continuous piece, and is bonded on the two sides of a current collector after being rolled, so that a positive pole material piece with uniform thickness is continuously prepared, and the required positive pole piece can be obtained after the processes of drying, rolling, cutting and clearing the powder. According to the method for continuously coating the high-viscosity sizing agent used for preparing the positive pole piece of the lithium-manganese primary cell, the production efficiency and the production consistency are improved, the uniformity of the thickness of the material piece is guaranteed, and the performance of the pole piece is improved.

Owner:中国兵器工业第二一三研究所

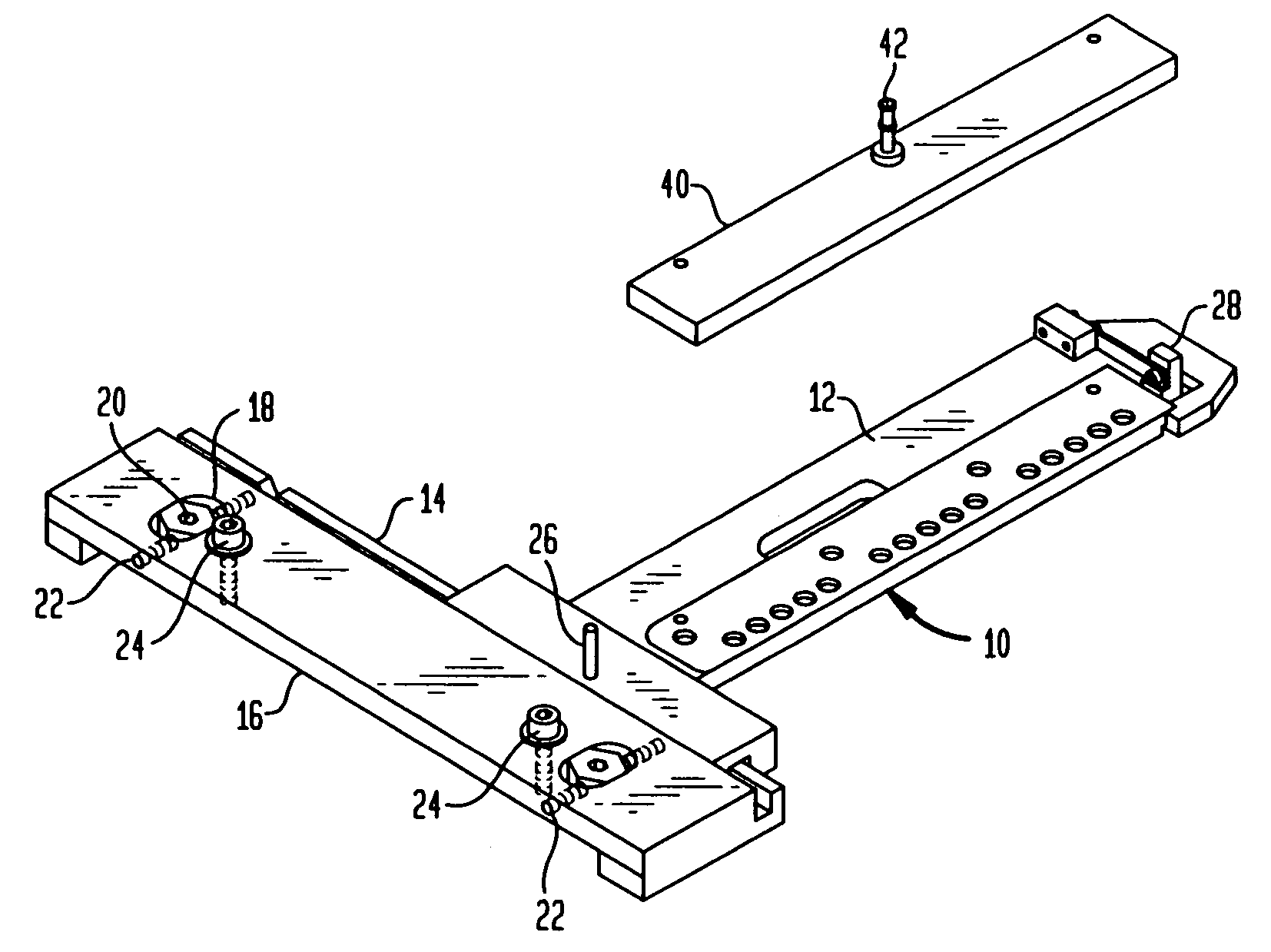

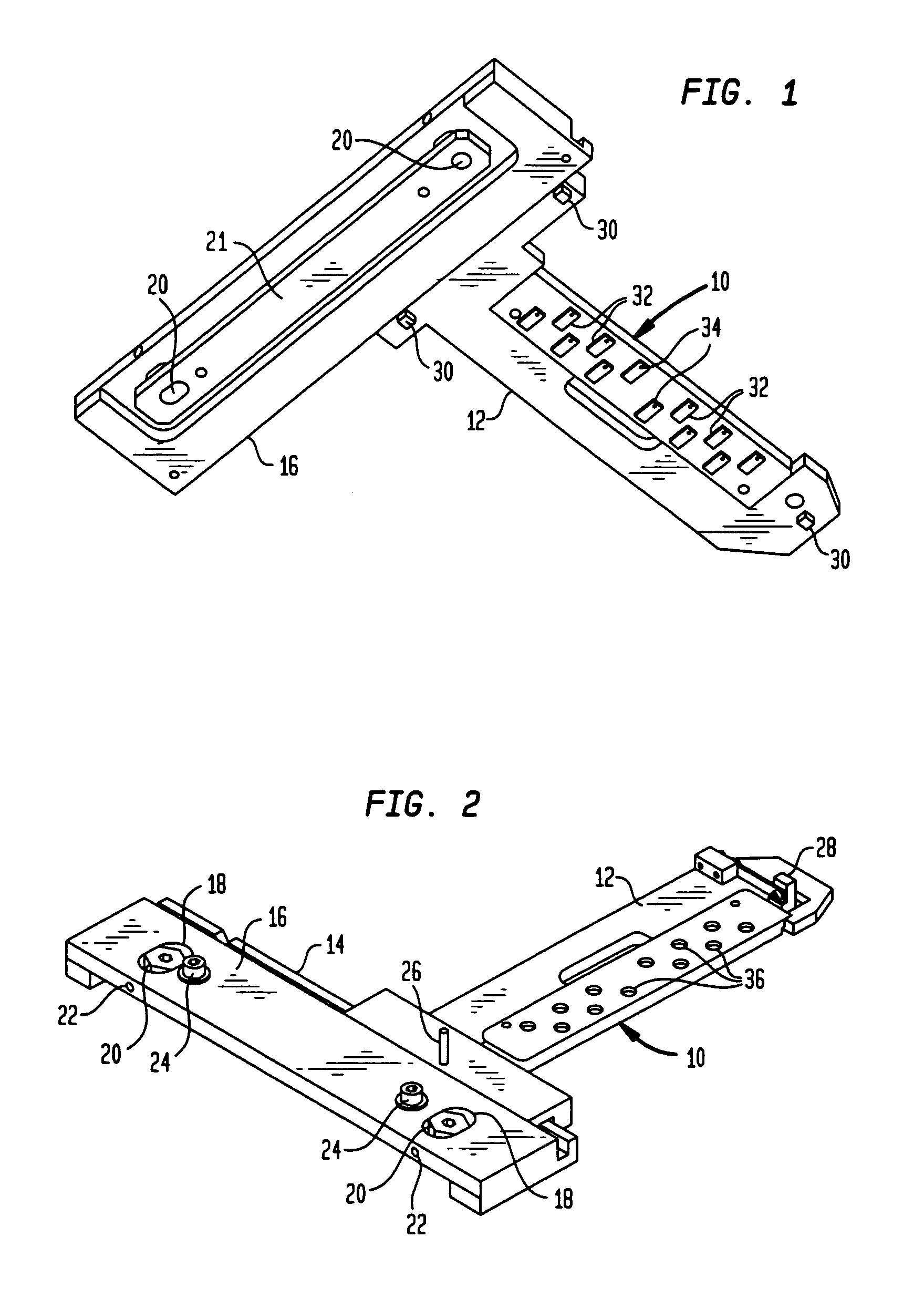

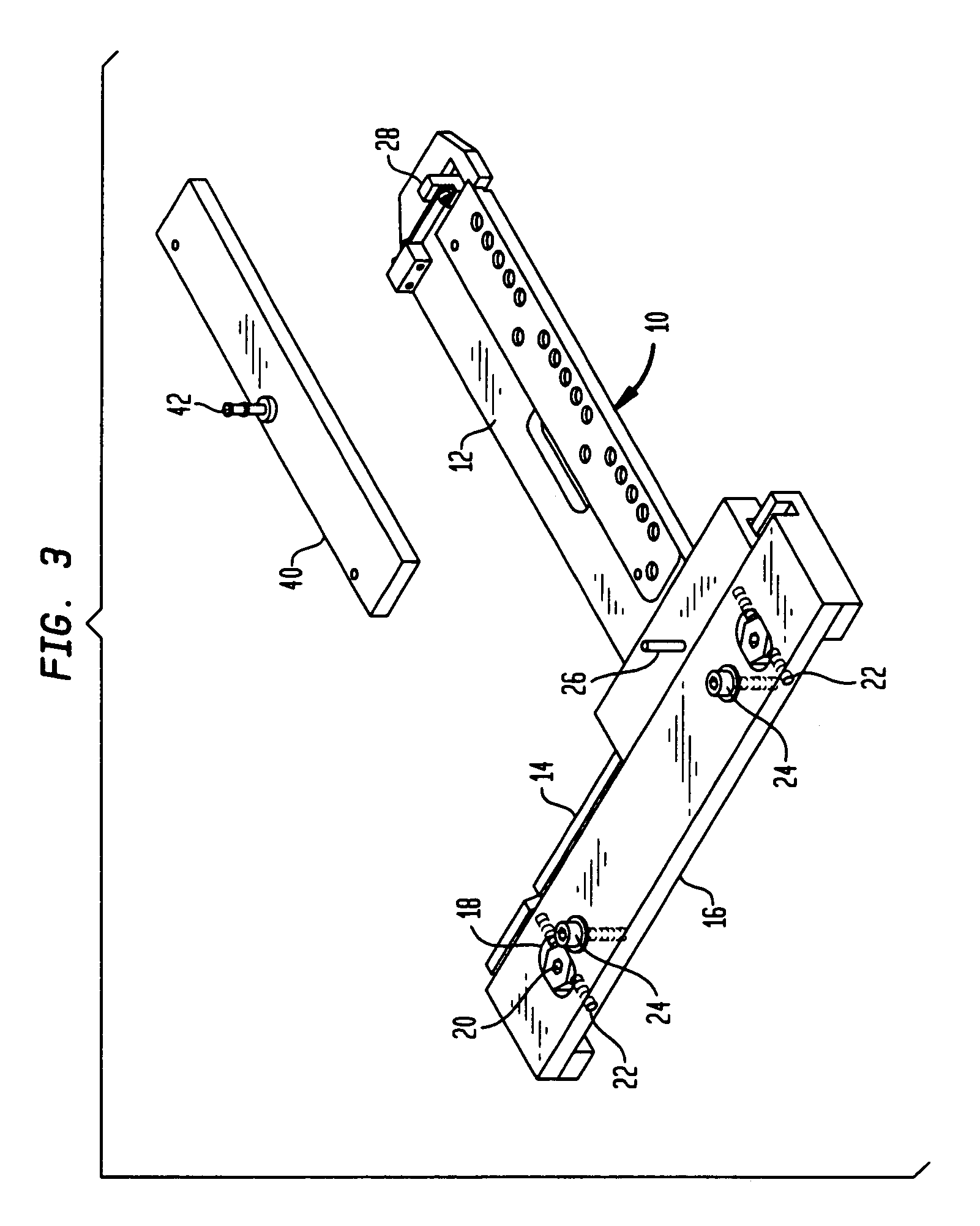

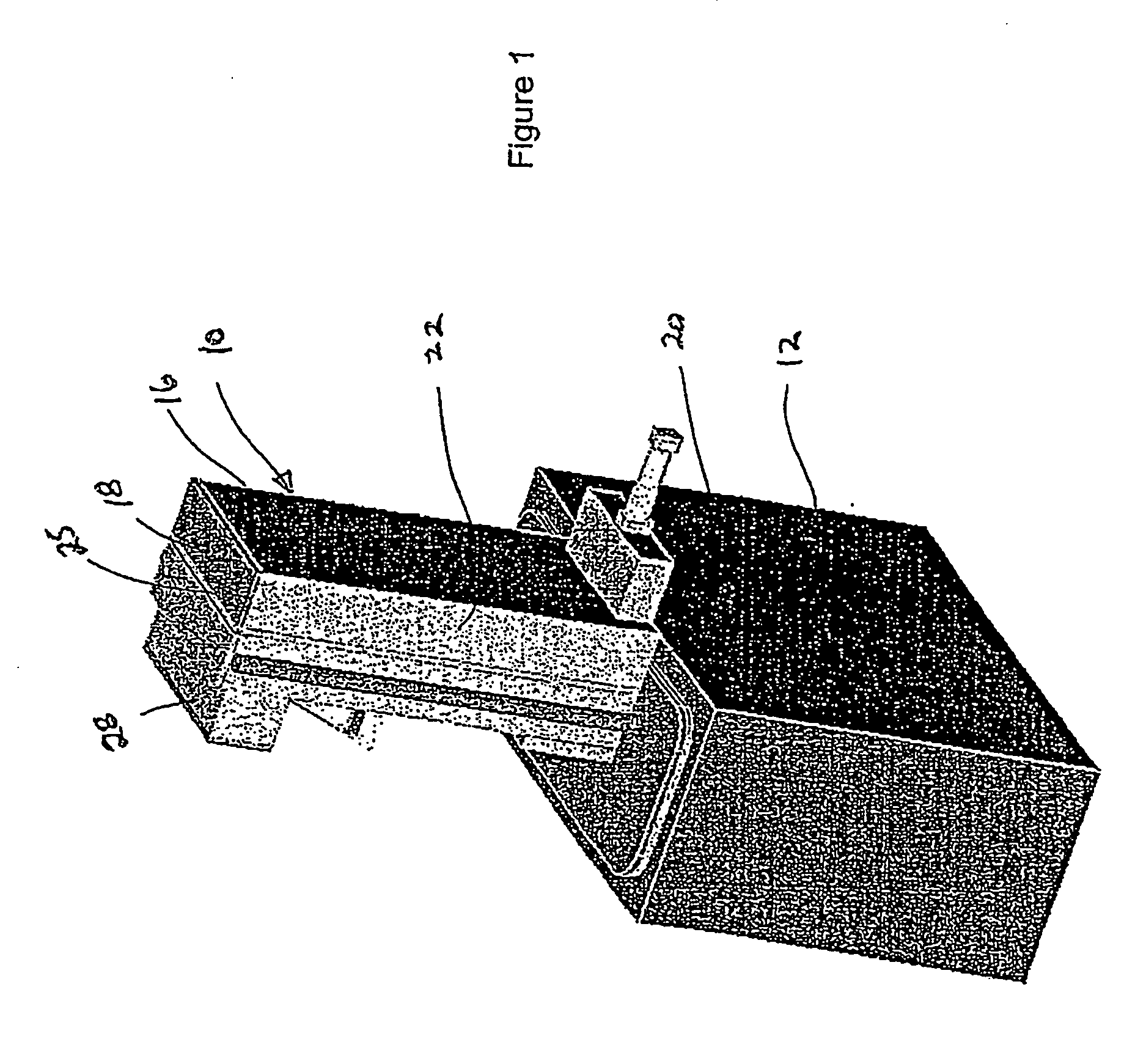

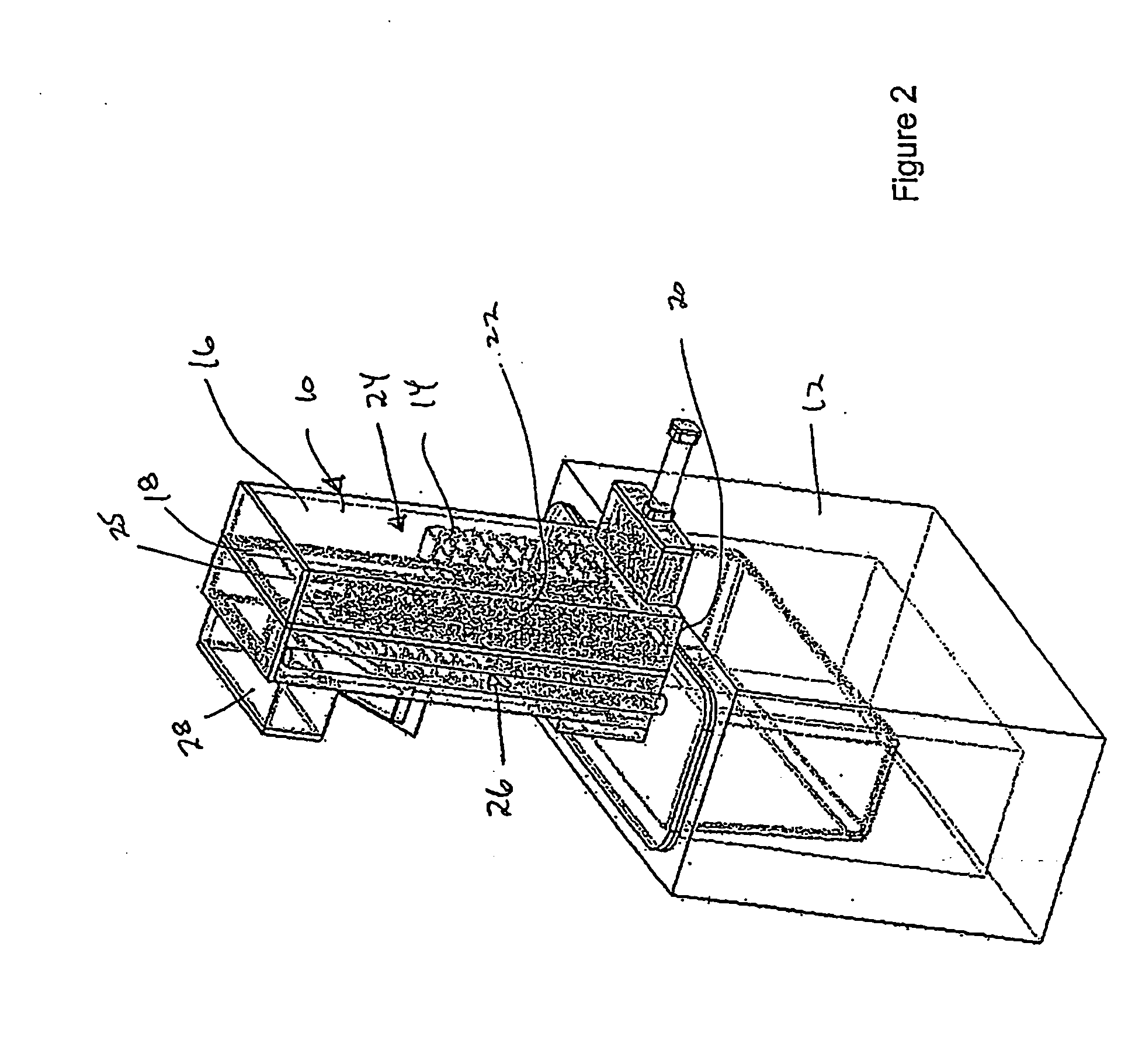

Mask for depositing and distributing reagents on an analytical support

InactiveUS7048893B2Low costEasy loadingBioreactor/fermenter combinationsSludge treatmentElectrophoresisEngineering

The invention concerns a mask for distributing reagents on an analytical support, such as an electrophoresis gel, the mask having a body with parallel upper and lower surfaces, a plurality of lanes located on the lower surface of the mask have wedge-shaped projecting elements with a sloped surface between first and second ends thereof, an opening extends from the upper surface of the body of the mask to the lowest point of the sloped surface. The mask is positioned over an analytical support and loaded with the desired reagents which are held by capillary action between the mask and the analytical support. The mask can then be moved in a sweeping motion across the analytical support to deposit the reagents thereon. In another embodiment, the projecting elements are rectangular in shape and the mask is positioned at an incline with respect the analytical support.

Owner:SEBIA

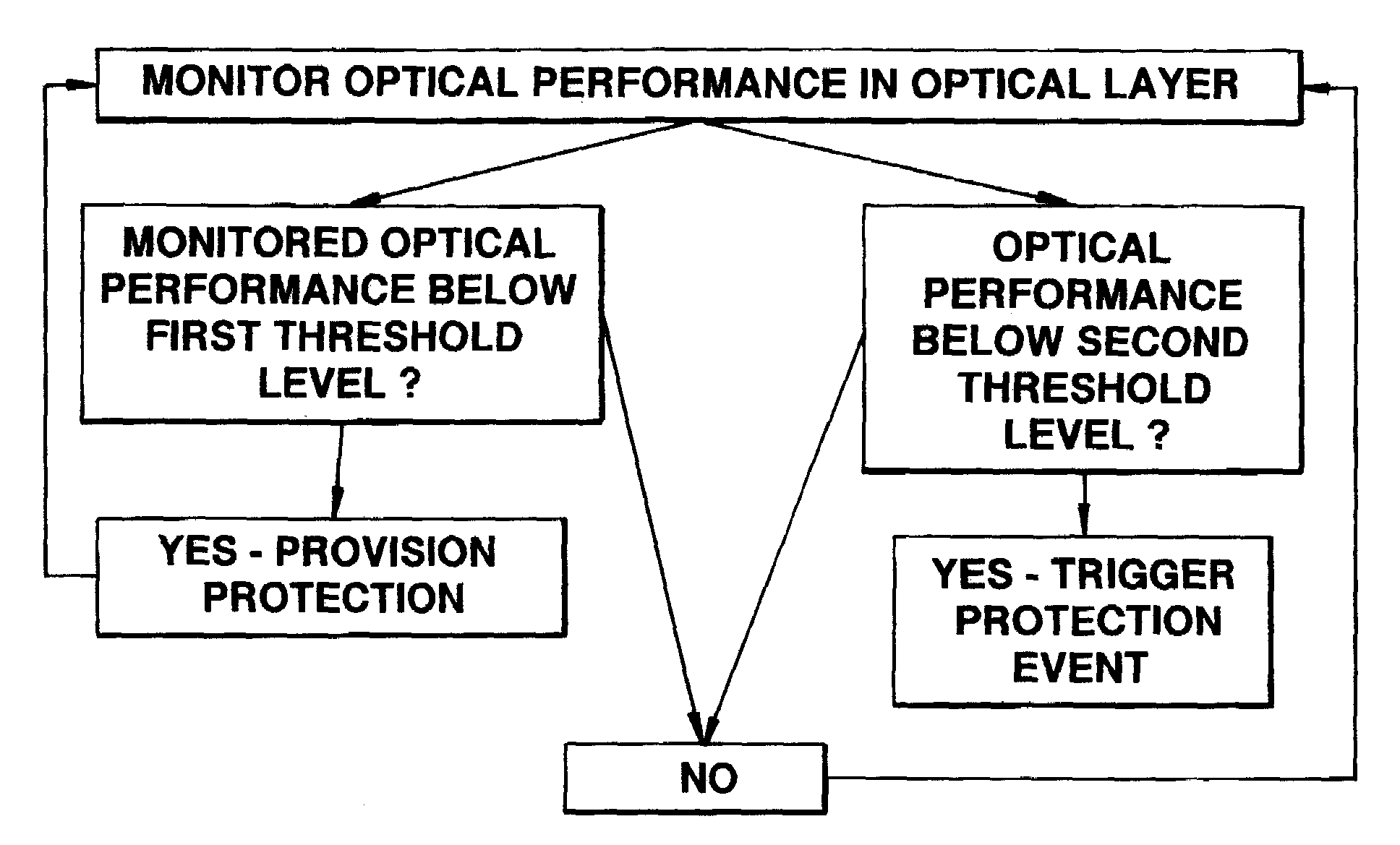

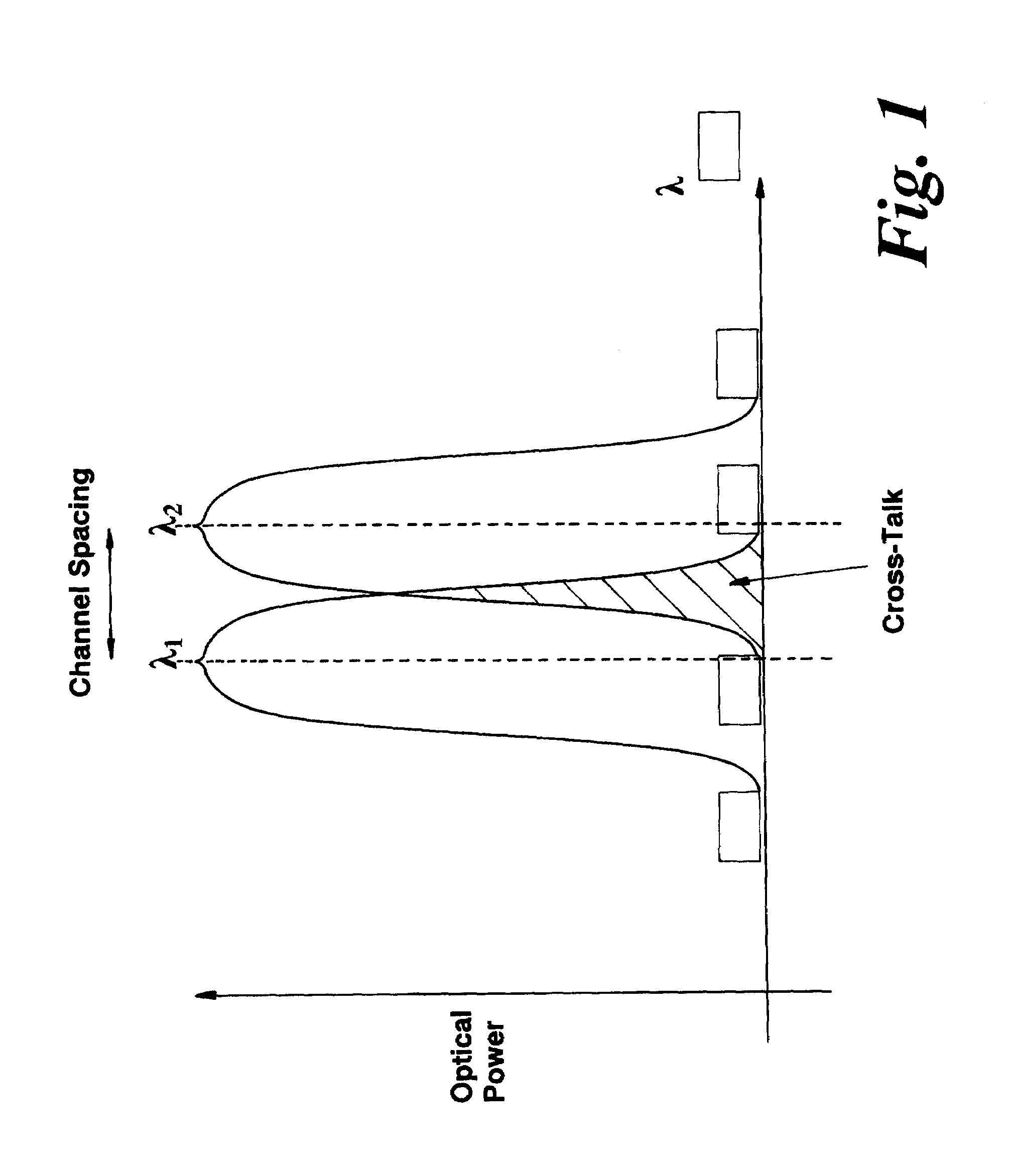

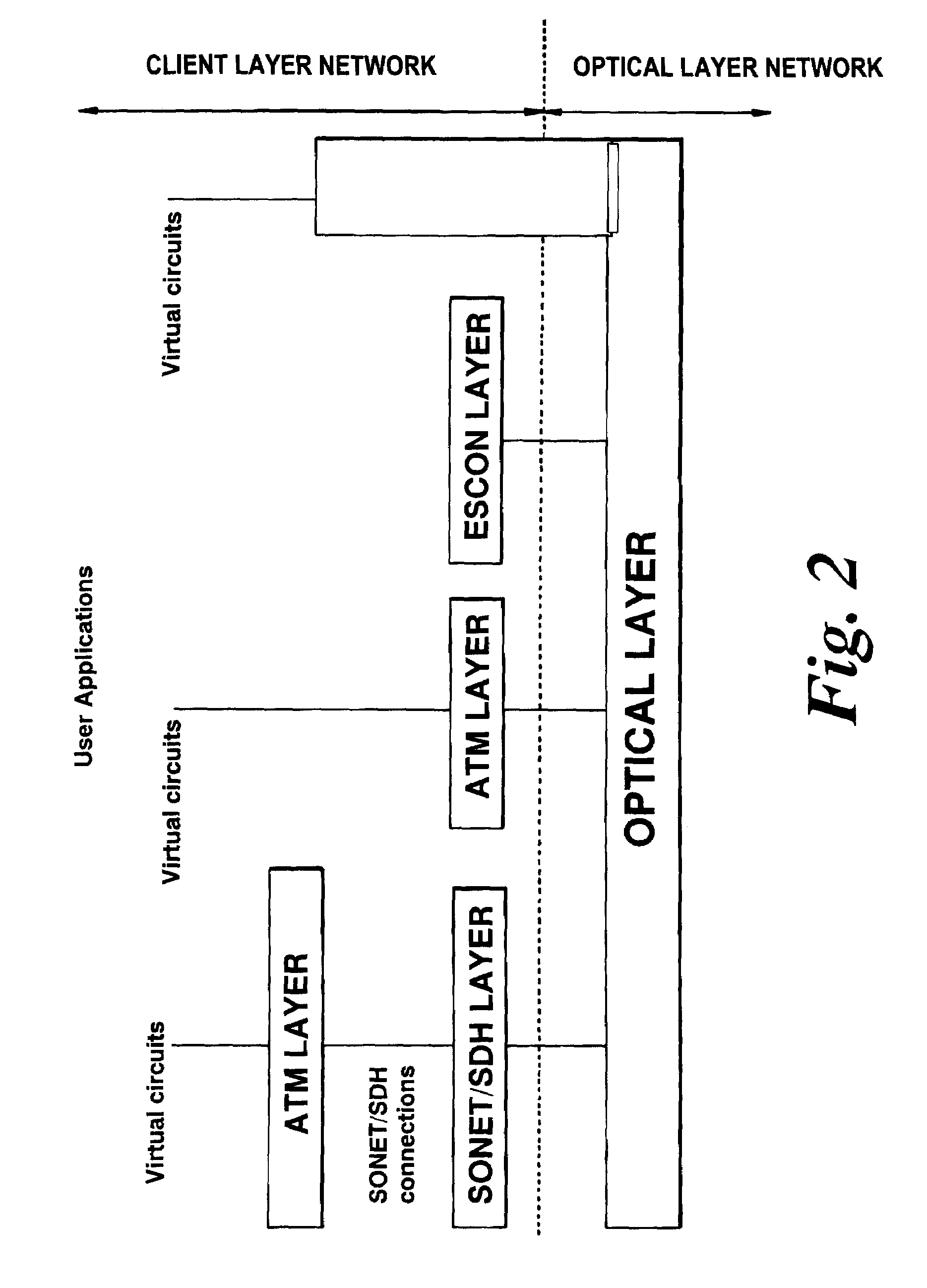

Optical protection scheme

ActiveUS7146098B1Level of redundancy can be reducedAvoid performanceLaser detailsTransmission monitoringEngineeringTransmission quality

A method for triggering an optical protection event in an optical layer of a network comprising the following steps: i) monitoring the optical performance of an optical signal transmitted within the optical layer of the network; ii) provisioning optical protection in the event the monitored optical performance falls below a first threshold level; and iii) triggering an optical protection event, in the event the monitored optical performance falls further to below a second threshold level. The monitoring step is performed within the optical layer of the network by using a proxy to determine an optical performance characteristic which corresponds to the transmission quality of electronic signals extracted from said optical layer signal.

Owner:CIENA

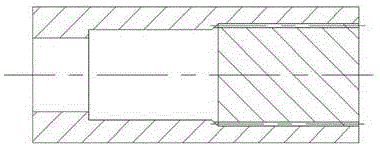

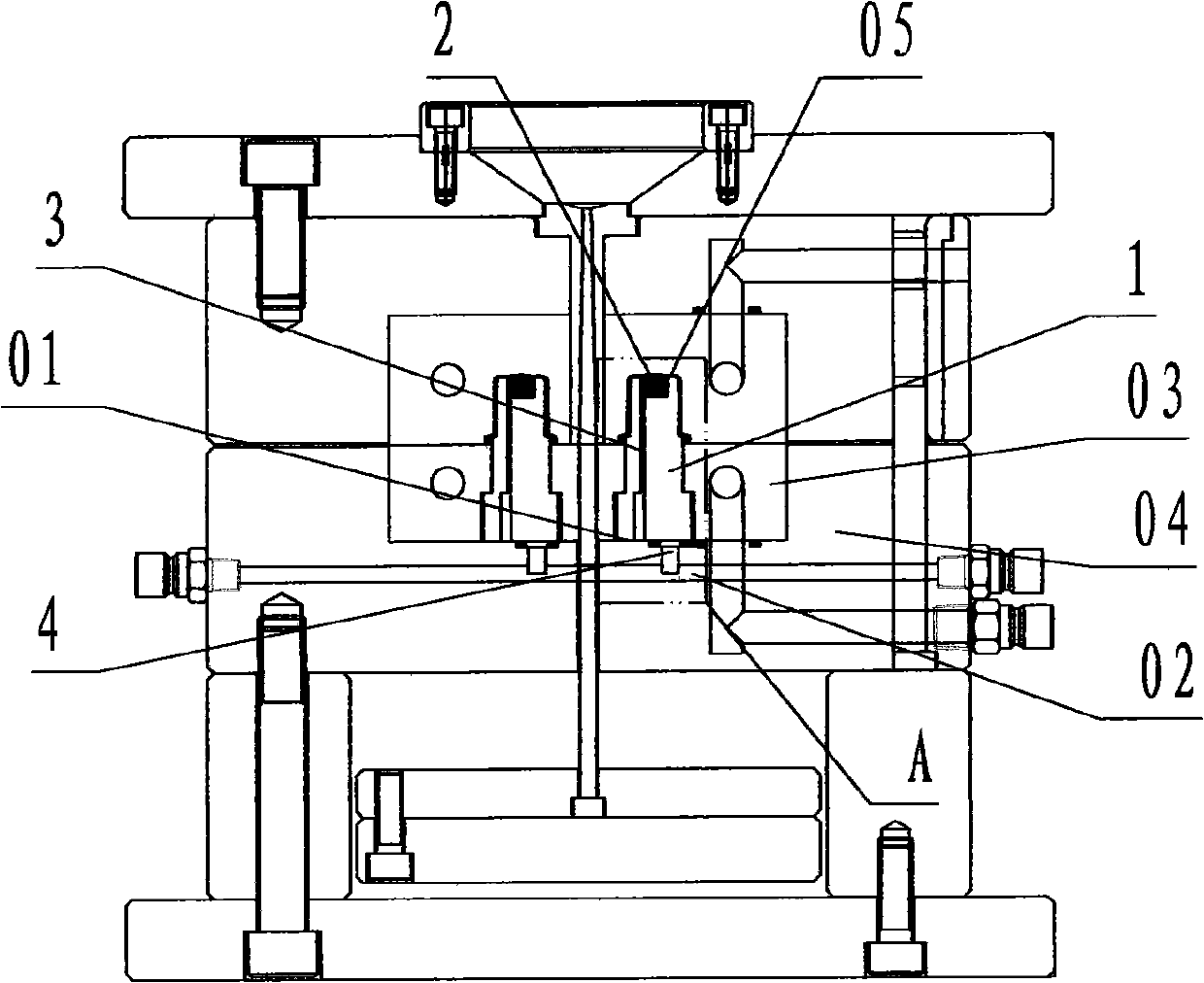

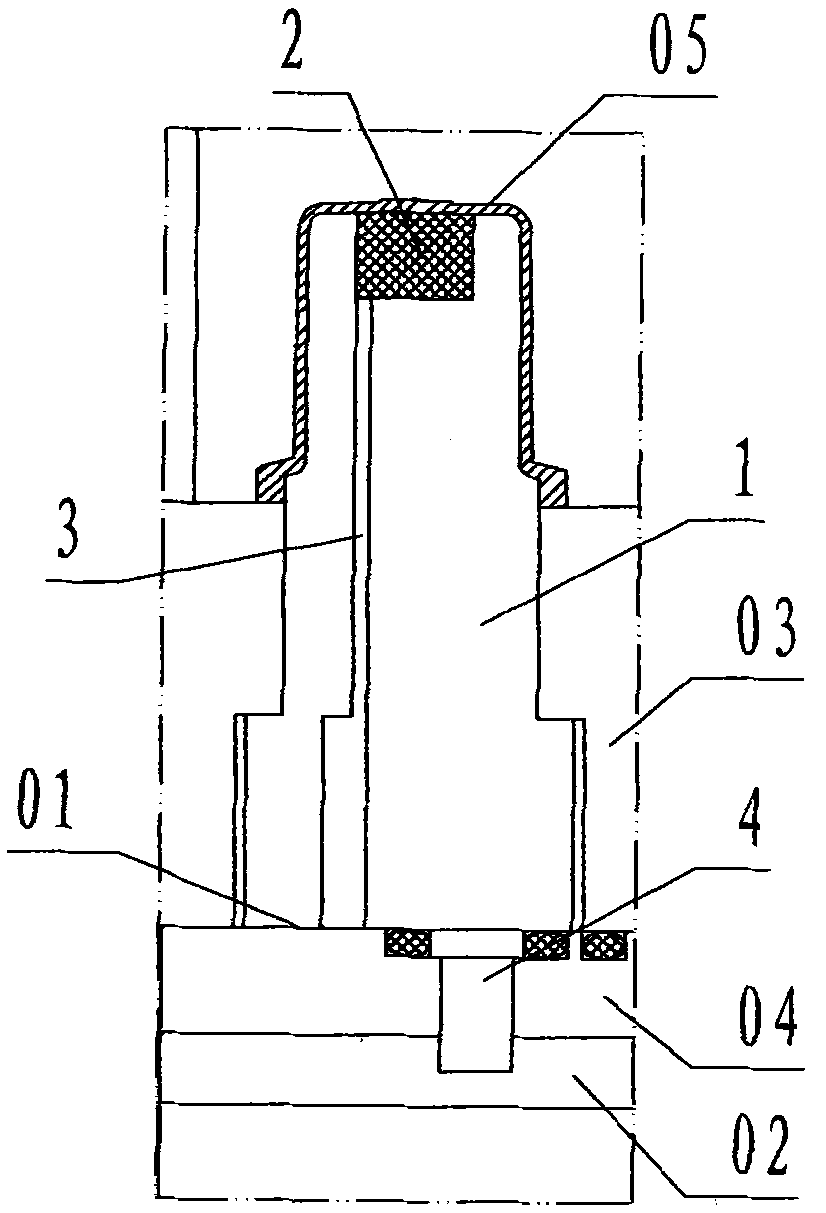

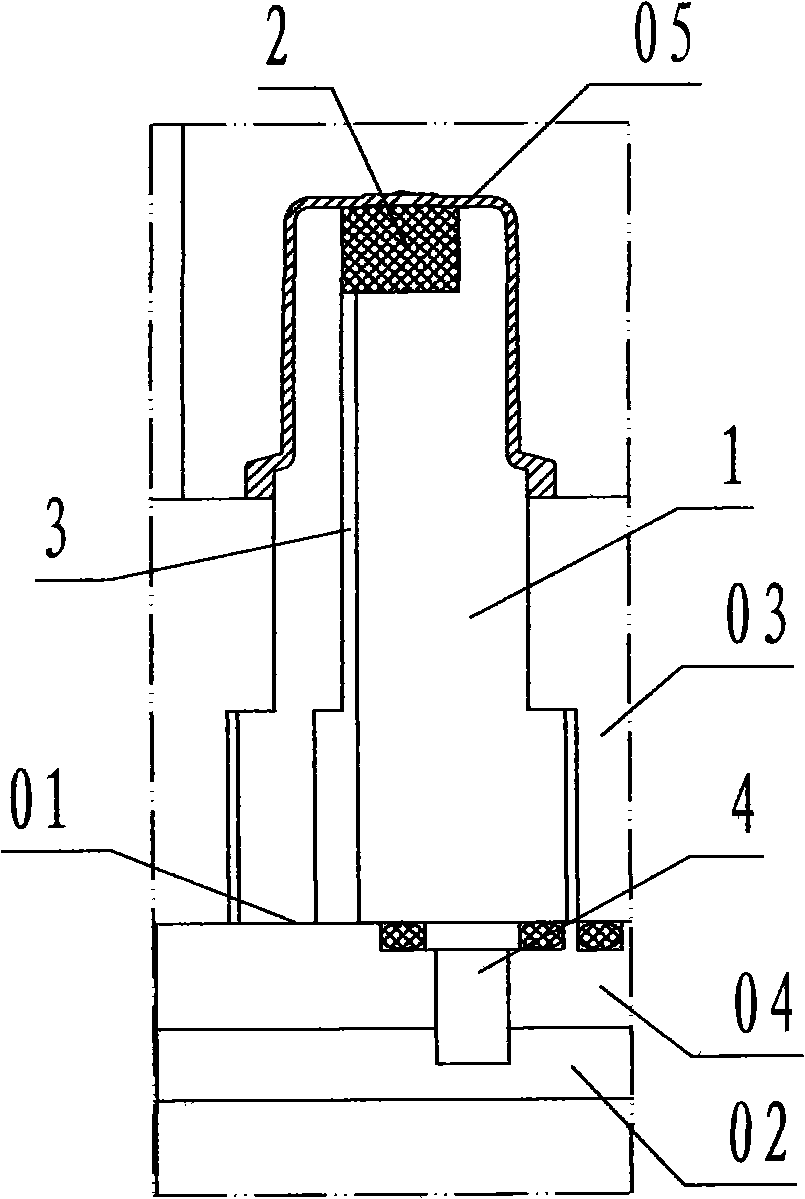

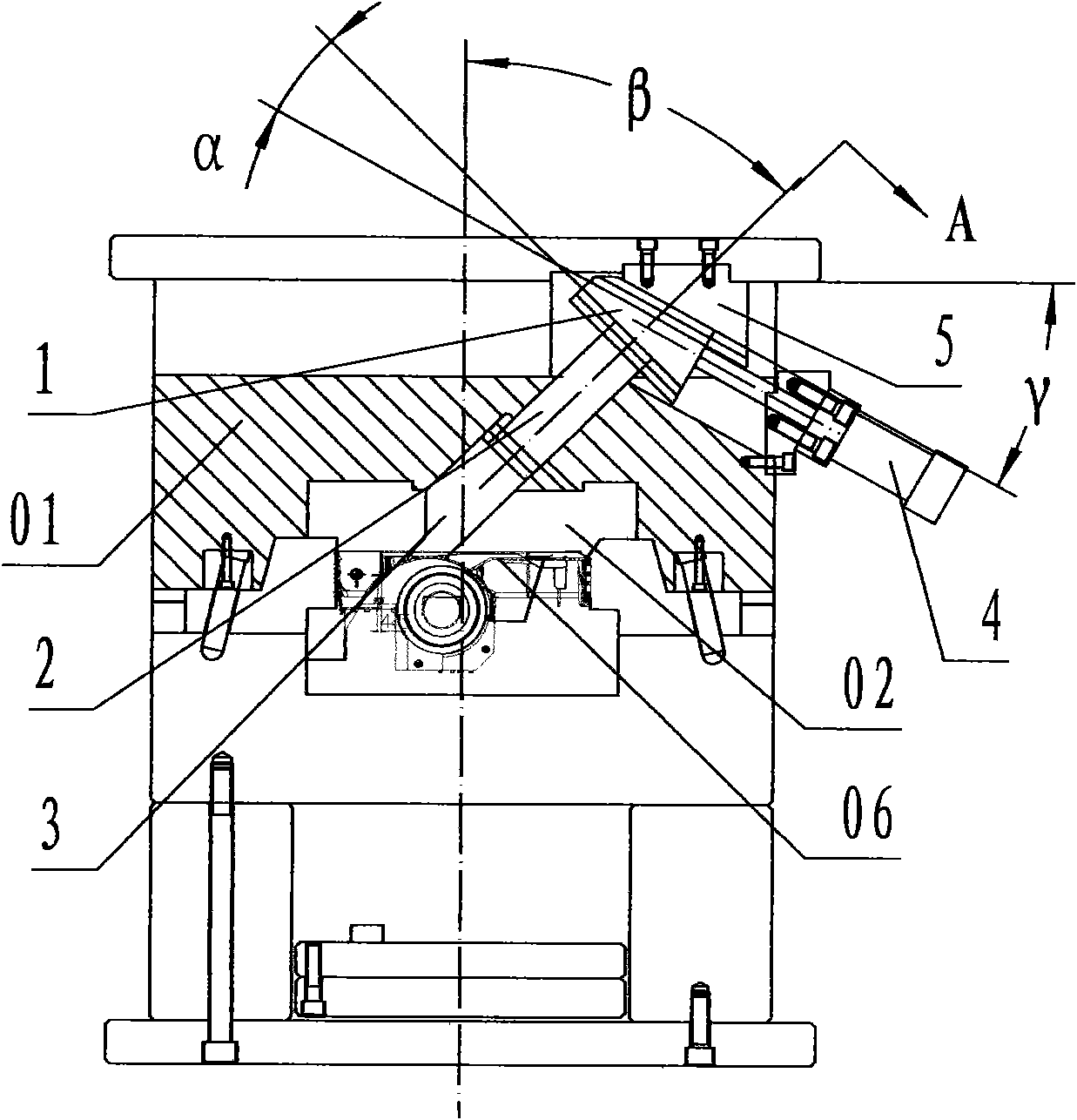

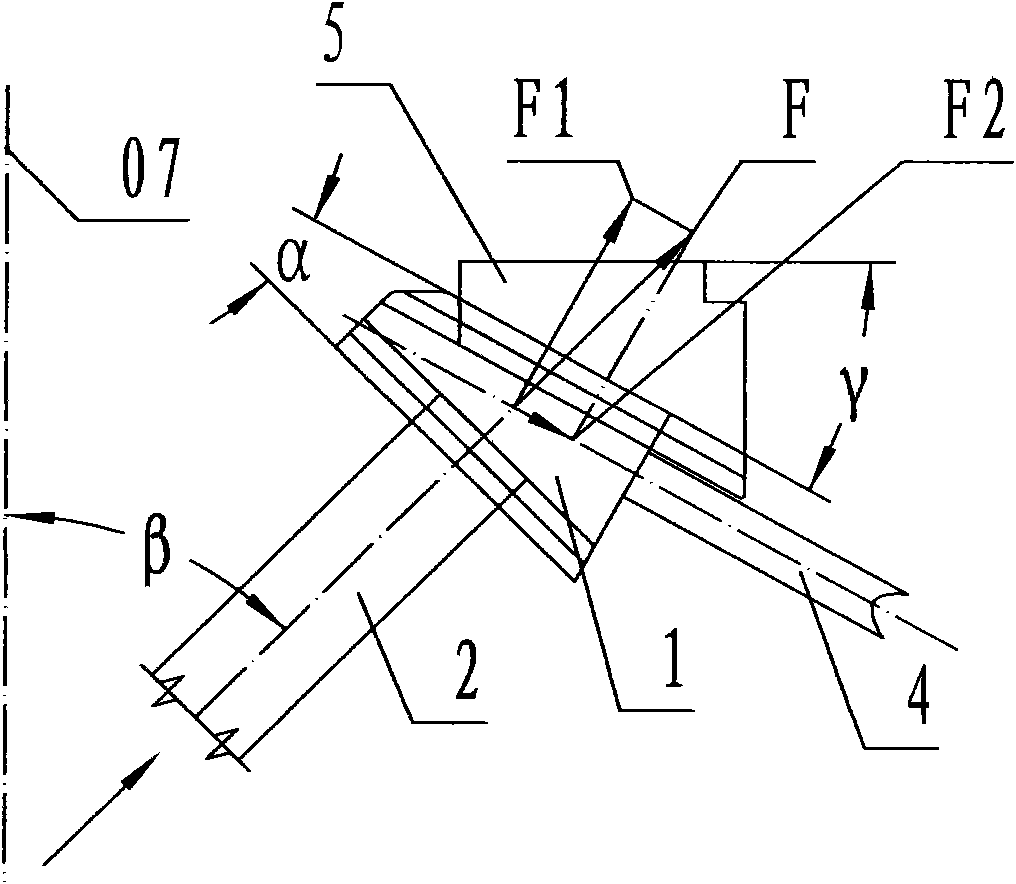

Fixed die core-pulling mechanism capable of self-locking and backstopping

InactiveCN101913231AHigh strengthOvercoming the disadvantages of reducing the strength of the fixed formworkSelf lockingFault occurrence

The invention discloses a fixed die core-pulling mechanism capable of self-locking and backstopping, which comprises a wedge-shaped sliding block (1), an oblique ejection rod (2), an oblique core-pulling block (3), an oil cylinder (4) and a support seat (5). By using the technical scheme that the oblique core-pulling block is connected with the wedge-shaped sliding block through the oblique ejection rod by using the frictional self-locking principle, and the oil cylinder is arranged obliquely so that the stressed included angle between the wedge-shaped sliding block and the oblique ejection rod is smaller than a frictional self-locking angle of the material, the mechanism overcomes the defects of unreliable work of a die, easy fault occurrence and instable product quality because the oblique core-pulling block retreats. In the fixed die core-pulling mechanism capable of self-locking and backstopping, the retreat of the oblique core-pulling block is prevented by the self-locking and backstopping effect of the wedge-shaped sliding block, and core pulling and resetting of the oblique core-pulling block with great retraction force are driven by the small-specification oil cylinder so that the injection molding die fulfills the purposes of reducing cost, obtaining reliable work, eliminating fault hidden dangers, stabilizing product quality and ensuring product quality consistency.

Owner:宁海县第一注塑模具有限公司

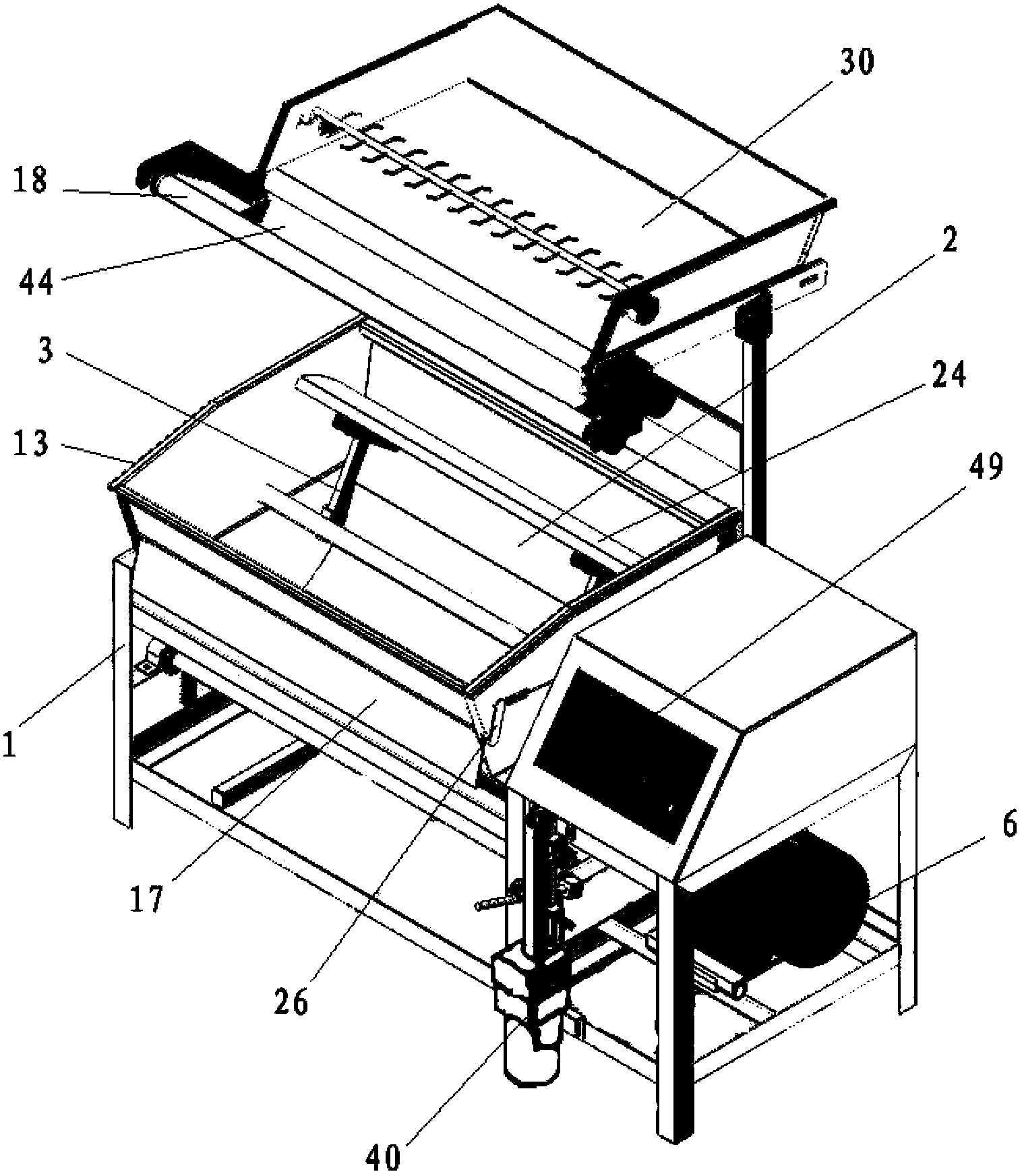

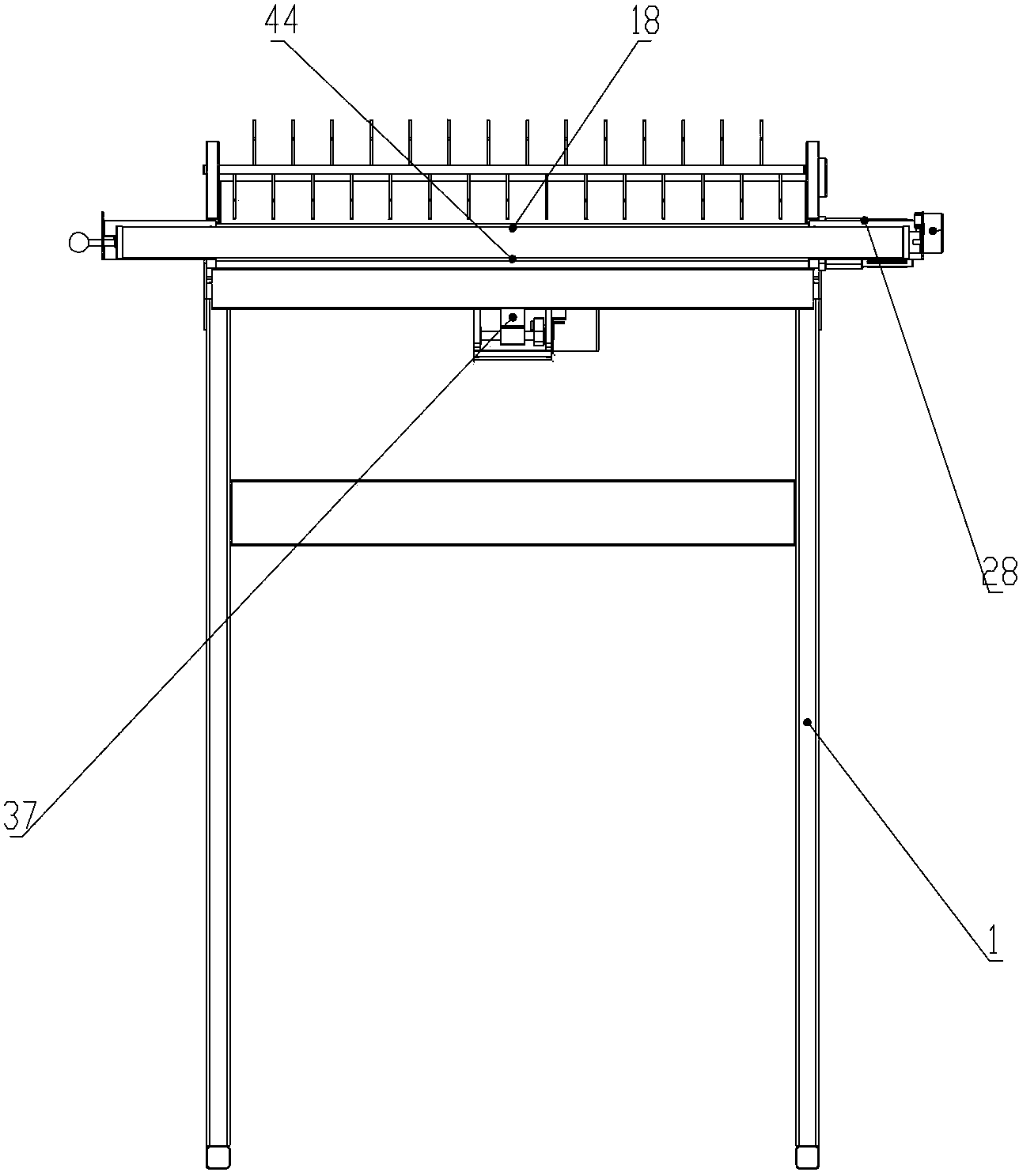

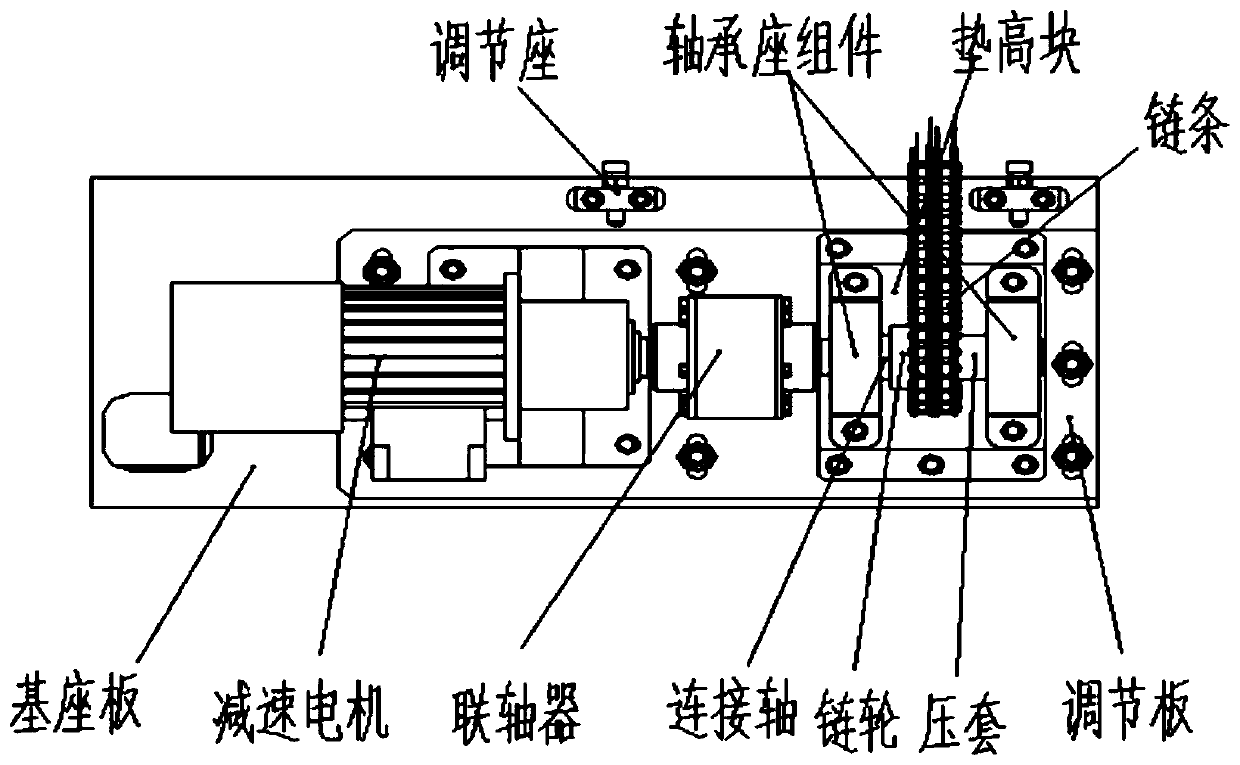

Automatic tea leaf roasting machine and automatic tea leaf processing method thereof

InactiveCN103564068AReduce consumptionSave electricityPre-extraction tea treatmentAgricultural engineeringTea leaf

The present invention discloses an automatic tea leaf roasting machine and an automatic tea leaf processing method. According to the present invention, the mechanical system of the automatic tea leaf roasting machine comprises a rack, an automatic feeding device, a main shaft, a roasting plate, a roasting pan, an electric heater, and a discharge port; the power system comprises a main shaft motor and a pressing motor, wherein the main shaft motor drives the main shaft to rotate through a power transmission device, and the pressing motor adjusts a position of the roasting pan in an up and down manner through the power transmission device; and the control system comprises an operation panel, a temperature control device and a main controller, wherein the operation panel is connected with the main controller through a control circuit, the main controller is respectively connected with the main shaft motor, the pressing motor, a feeding hopper, the electric heater, the discharge port and the temperature control device through the control circuit, the temperature control device is connected with the roasting pan or the electric heater, the main controller adopts a AVR microcomputer controller, and the control system further comprises a frequency converter for controlling the main shaft motor. With the automatic tea leaf roasting machine and the automatic tea leaf processing method, energy consumption is reduced, the tea production process is accurately simulated, and tea leaf quality uniformity is ensured.

Owner:SHANGHAI CHUANGYU ELECTROMECHANICAL TECH

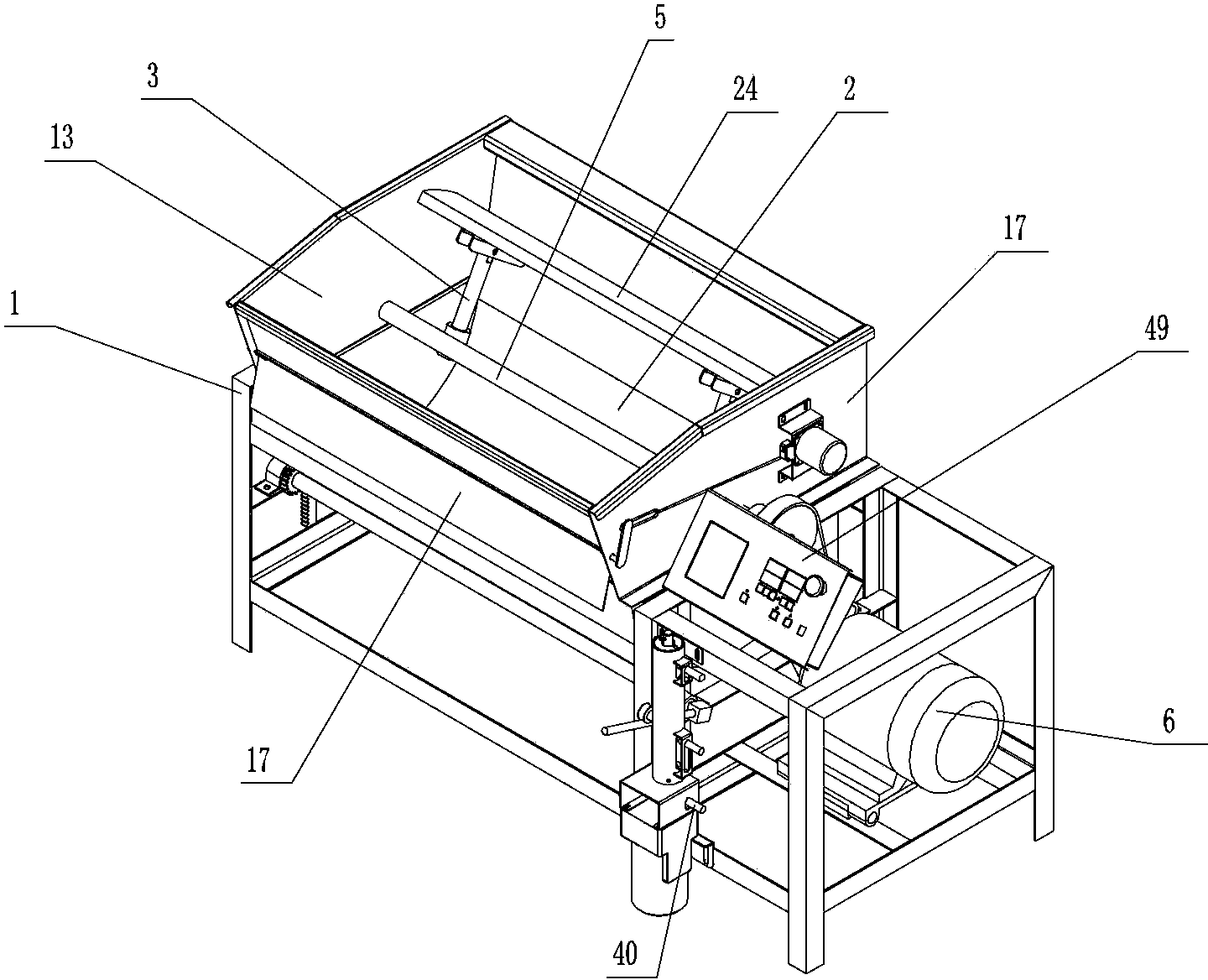

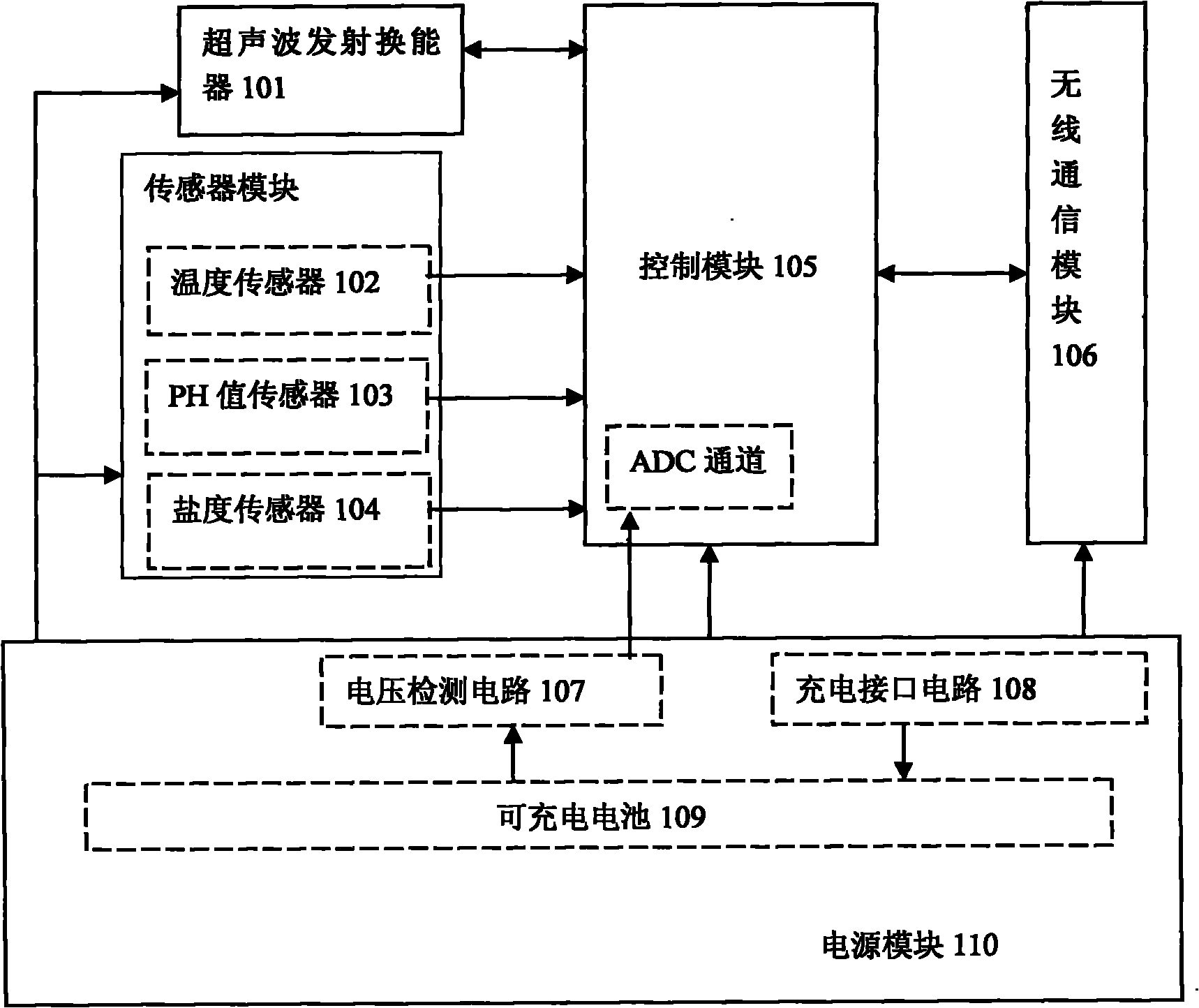

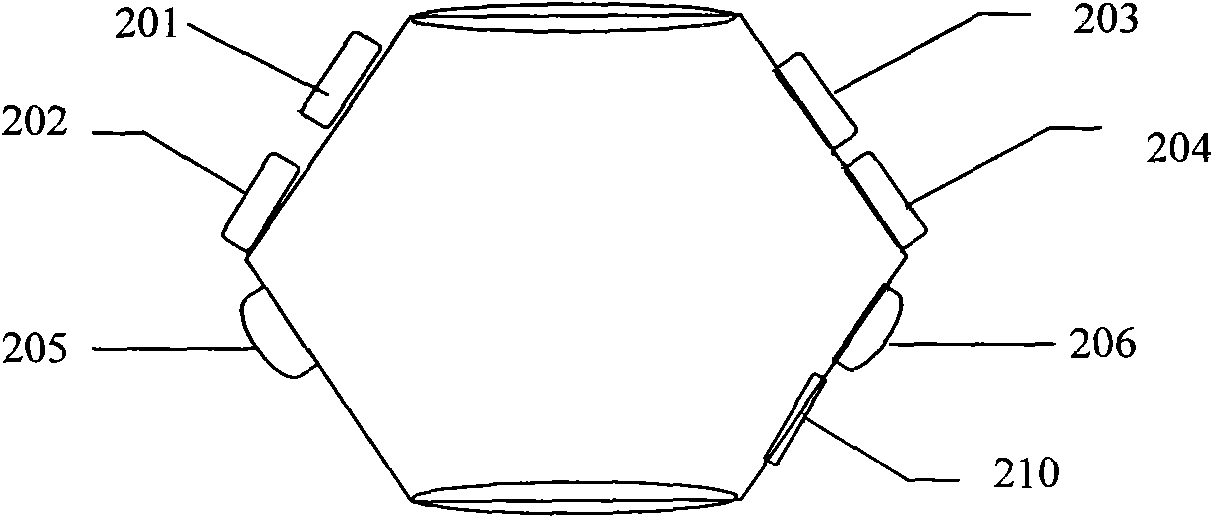

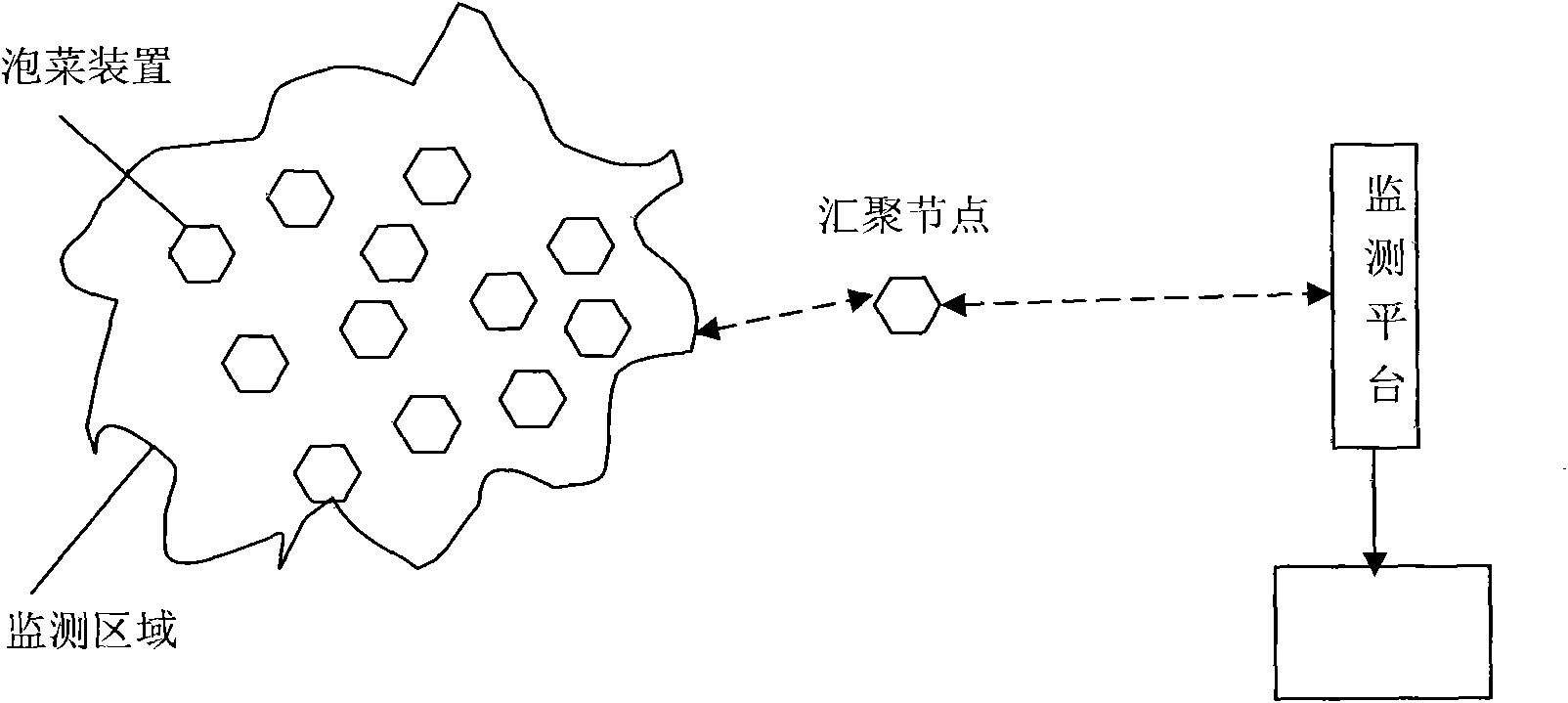

Electronic pickle making method and device

The invention discloses an electronic pickle making method and a device. The device is characterized in that a control module is respectively connected with an ultrasound transmitting transducer, a sensor module, a power supply module and a wireless communication module and is in charge of controlling data acquisition, ultrasound transmitting and data processing and transmitting; and the ultrasound transmitting transducer transmits ultrasound under the control of the control module, quickens the molecular motion through transmitting the ultrasound and accelerates the preservation. The making method comprises the steps of quickening the penetration of fresh vegetables through transmitting the ultrasound to realize rapid preservation of the pickle; and monitoring the maturity of the pickle through online comparing temperature values, PH values and salinity values acquired by the sensor module and controlling the preserving process. The invention provides real-time online monitoring for preservation conditions, is flexible and convenient to control, can immediately inform the worker of taking measures such as alarm, and has the advantages of rapidness, high efficiency and intelligence.

Owner:SOUTH CHINA UNIV OF TECH

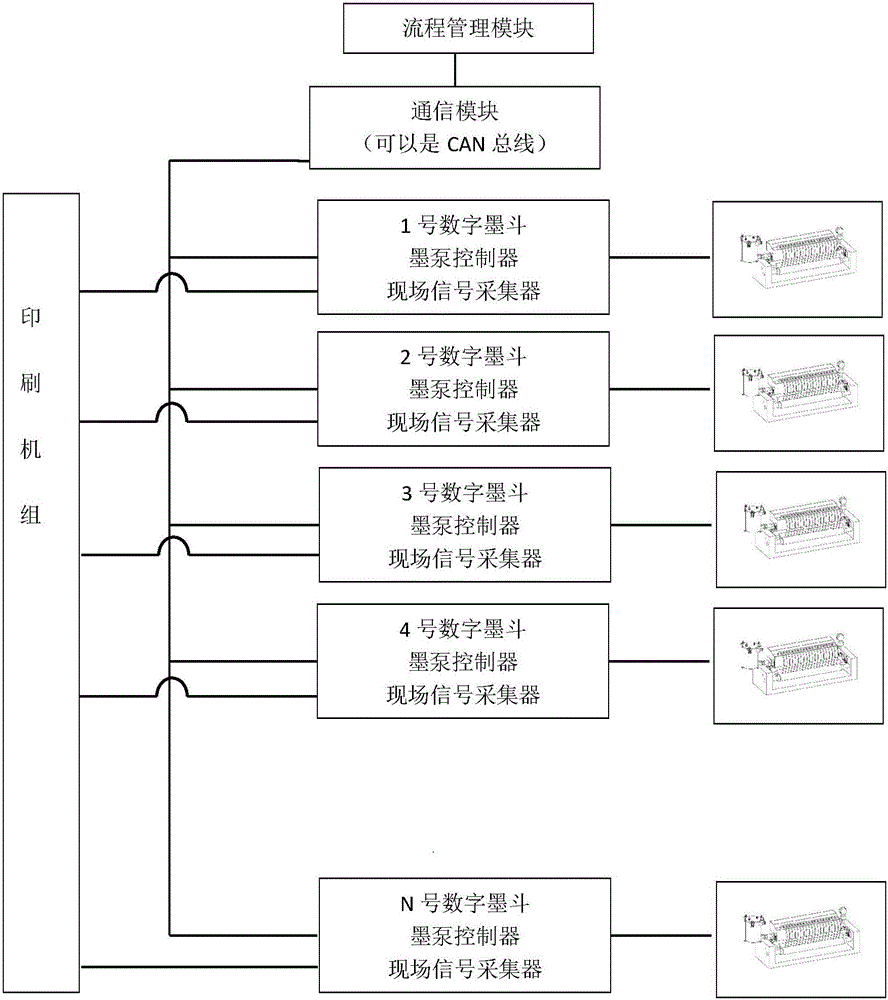

Digitized accurate ink supply method of printing machine

ActiveCN105818533ARealize precise quantitative controlReal-time supplyPrinting press partsEngineeringPrinting ink

The invention discloses a digitized accurate ink supply method of a printing machine. Metering printing ink conveying units replace ink keys on a traditional printing machine; each metering printing ink conveying unit directly conveys printing ink to corresponding ink areas; and the volume or mass serves as metering basis, quantitative supply of the printing ink for each ink area is achieved. In the working state, the ink supply flow speed of each metering printing ink conveying unit is obtained through calculation according to the consumption amount of the printing ink of corresponding color plates and the corresponding ink areas in each printed sheet and the operation speed of the printing machine, and the ink supply flow speed of each metering printing ink conveying unit is calculated and adjusted in real time along with change of the operation speed of the printing machine. By means of the digitized accurate ink supply method of the printing machine, real-time accurate adjustment can be achieved, the automation degree and digitization degree are high, the adjustable range is wide, one-way printing ink conveying is achieved, and printing ink return is avoided.

Owner:杭州科雷智能印刷科技有限责任公司

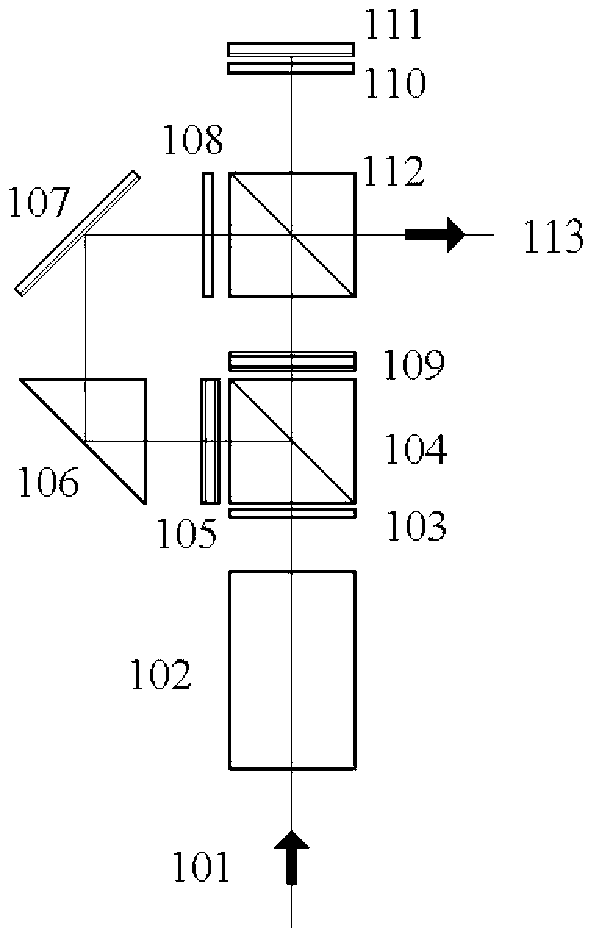

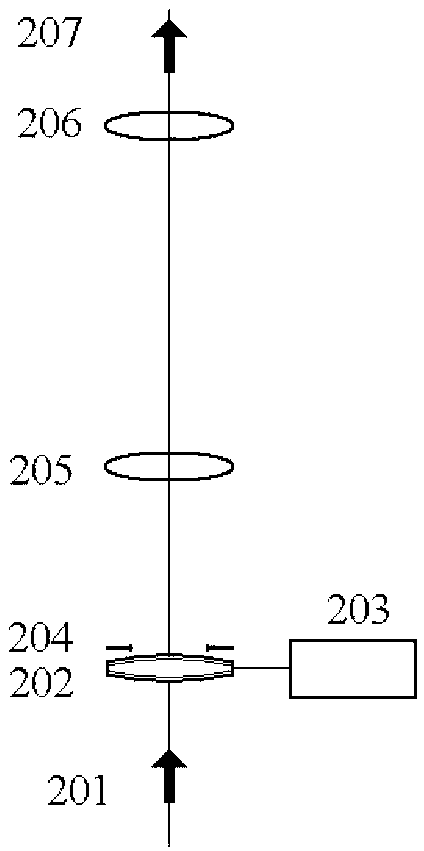

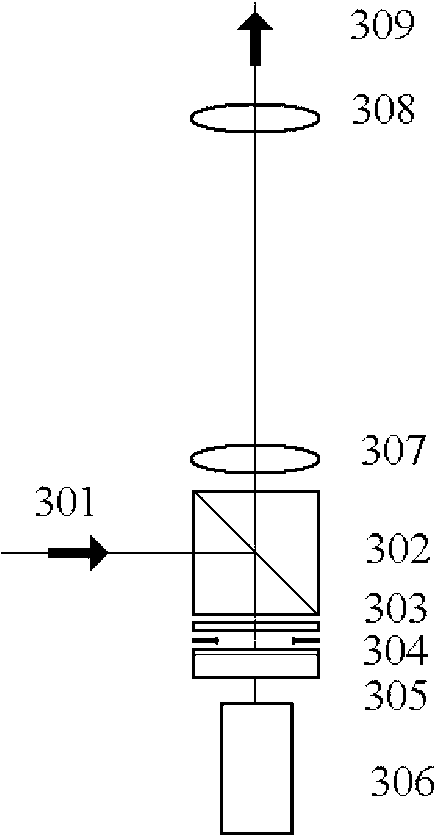

Separate type wave surface conversion scanning device of direct-vision synthetic aperture laser imaging radar

ActiveCN103344952AGuaranteed synchronization accuracyAchieving Spatial Linear Phase ScanningWave based measurement systemsTarget surfaceRadar imaging

The invention discloses a separate type wave surface conversion scanning device of a direct-vision synthetic aperture laser imaging radar. The separate type wave surface conversion scanning device is placed between a laser light source and a transmitting primary mirror and is composed of a cross-track direction wave surface conversion scanning structure and an along-track direction orthogonal polarization wave surface conversion structure. According to the theory, the cross-track direction wave surface conversion scanning structure converts and scans a cross-track direction wave surface generated by an incident beam wave surface by means of a movement method of single cylindrical lens translation or reflecting mirror deflection, the along-track direction orthogonal polarization wave surface conversion structure further decomposes the incident beam wave surface into two orthogonal polarized separated space channels, an along-track direction cylindrical mirror is arranged in each channel to conduct wave surface conversion and wave surface reversal, two coaxial polarized orthogonal scanning transmitting wave surfaces are synthesized, and finally the two scanning transmitting wave surfaces are directly imaged onto a target surface through a transmitting optic primary mirror. The direct-vision synthetic aperture laser imaging radar separate wave surface conversion scanning device has the advantages of being simple and reliable in structure, and capable of achieving two wave surface bidirectional scanning through one drive and conveniently changing the operating performance parameters of radar by the adoption of cylindrical mirrors with different focal lengths or different deflection ranges of a reflecting mirror.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

High-temperature sealed electrode and preparation method thereof

ActiveCN106972122APrevent intrusionStop erosionSecondary cellsCell sealing materialsEngineeringLiquid metal

The invention belongs to the technical field of energy storage batteries and particularly relates to a high-temperature sealed electrode. The high-temperature sealed electrode comprises a negative electrode core, an upper transition ring, an insulating sleeve, a lower transition ring, a positive electrode cover plate, a salt-sealing partition and a salt-sealing groove, wherein the upper transition ring, the insulating sleeve, the lower transition ring, the positive electrode cover plate, the salt-sealing partition and the salt-sealing groove sequentially sleeve the middle of the negative electrode core from top to bottom; a negative current collector is also welded at the bottom of the negative electrode core; the salt-sealing partition is fixed at the lower end of the positive electrode cover plate; the salt-sealing groove is also fixed in the negative electrode core at the lower end of the salt-sealing partition; the lower end of the salt-sealing partition extends into a sealed salt in the salt-sealing groove; and sealing of the electrode is achieved through heating and solidifying the sealed salt. The invention further discloses a preparation method of the high-temperature sealed electrode. According to the high-temperature sealed electrode, corrosion of steam to solder can be prevented, cracking of a connection part of the sealed electrode caused by thermal stress is prevented, long-term insulated sealing in a high-temperature condition is achieved, the sealed electrode is compact in structure and the space volume of a liquid metal battery is effectively compressed.

Owner:HUAZHONG UNIV OF SCI & TECH +2

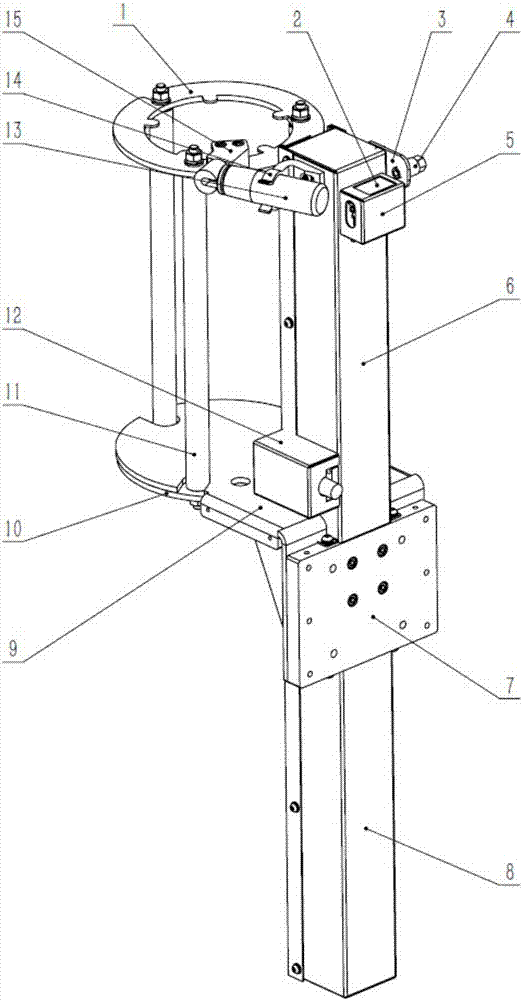

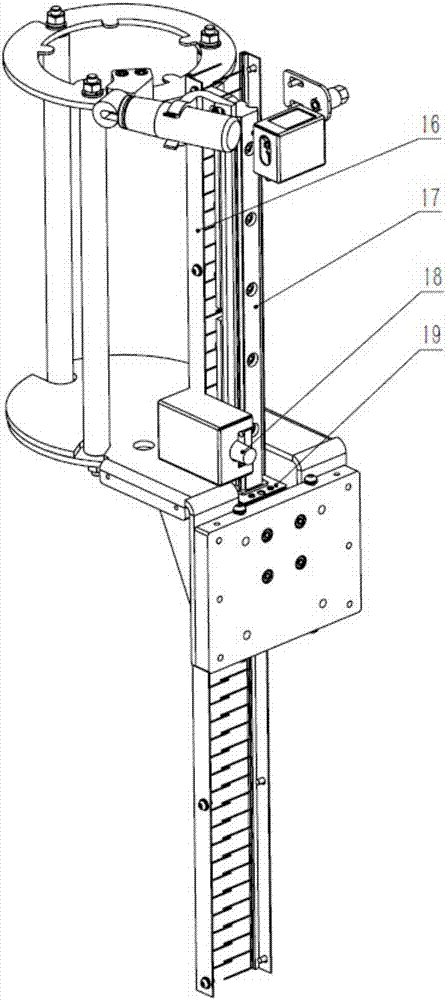

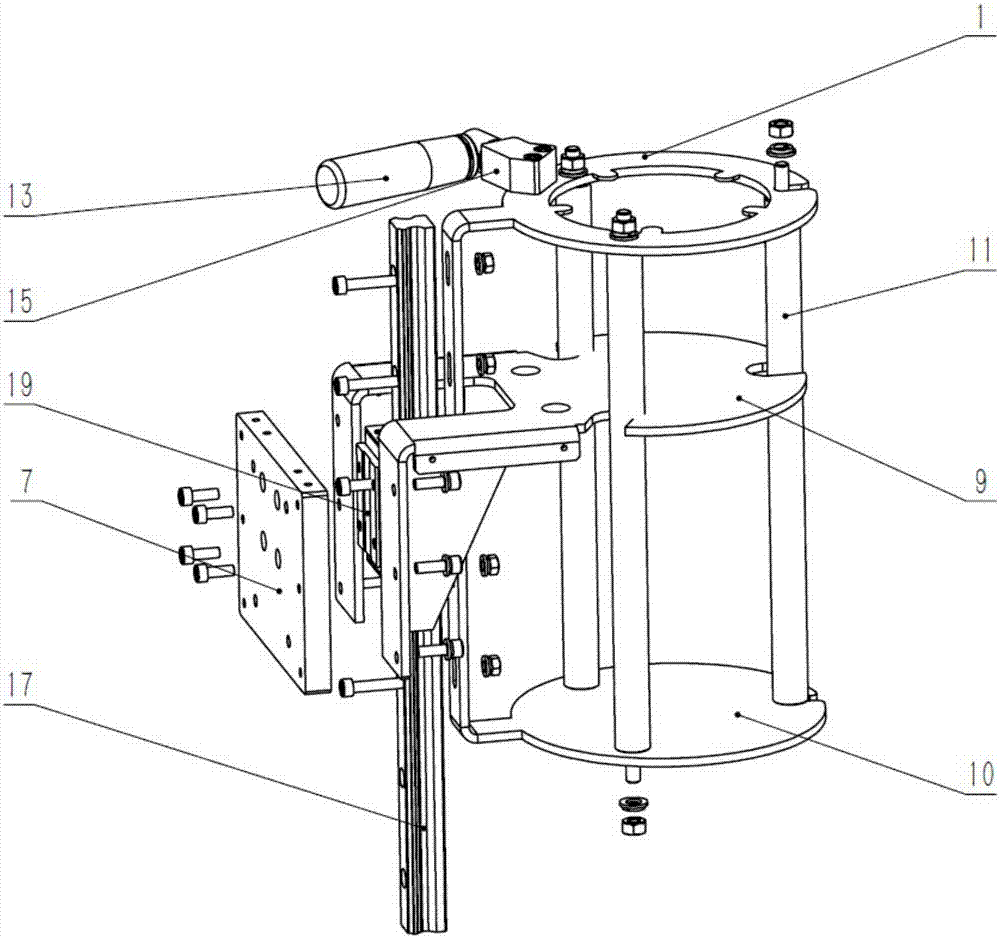

Intelligent abrasive paper sticking device used for robot grinding and polishing

PendingCN107199509ASolve manual dependenciesReduce enterprise labor costsGrinding wheel securing apparatusGrinding feed controlGrindingEmery paper

Owner:YUYI INTELLIGENT TECH SHANGHAI CO LTD

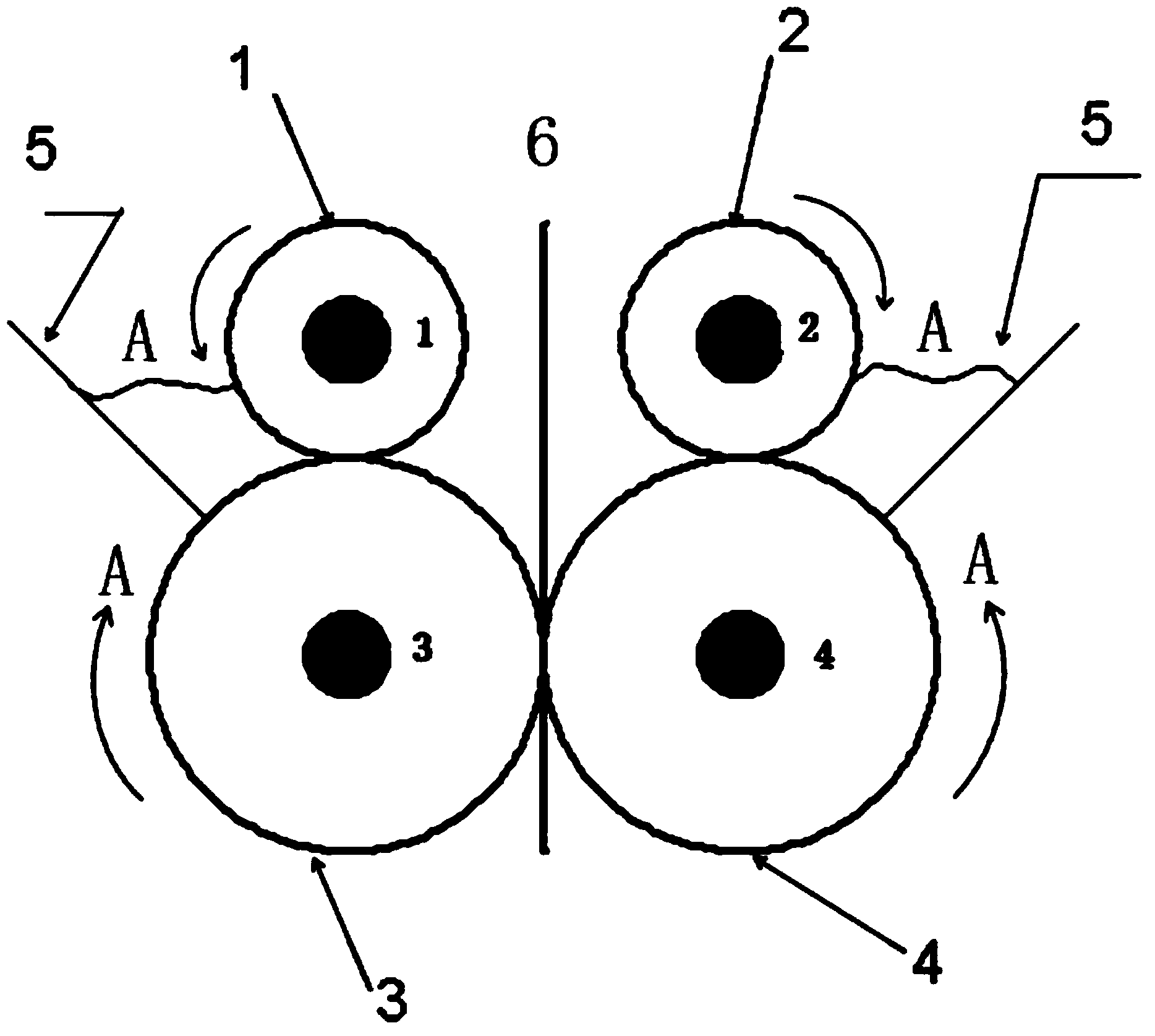

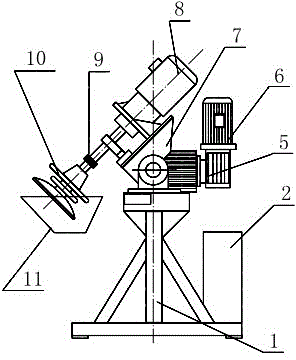

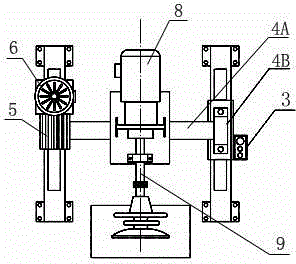

RTV anti-contamination flashover paint coating equipment for porcelain or glass umbrella or bell jar shaped insulator

The invention discloses RTV anti-contamination flashover paint coating equipment for a porcelain or glass umbrella or bell jar shaped insulator. The equipment comprises a main frame, a machine head rotary frame, a reducing frequency conversion motor and a fast insulator connector. The machine head rotary frame is rotationally connected to the main frame through a rotary shaft and bearing seats of two ends; the reducing frequency conversion motor is fixedly arranged on the machine head rotary frame; the output shaft of the reducing frequency conversion motor is connected to the fast insulator connector. The equipment has the advantages that the dip-coated porcelain or glass insulators of different specifications are stable in quality, the surfaces are smooth and are free of bubbles, the coating layers are free of accumulation and drop hanging, and the thickness is even; in the dip-coating process, the VOC emission amount is small, and the production is environment-friendly and safe; the dip-coating automation level is high, operation is easy, factories of the porcelain or glass insulators of different specifications can implement porcelain and glass insulator industrial automatic RTV anti-contamination flashover paint coating production through the equipment, and large amount of cost can be saved.

Owner:眉山拓利科技有限公司

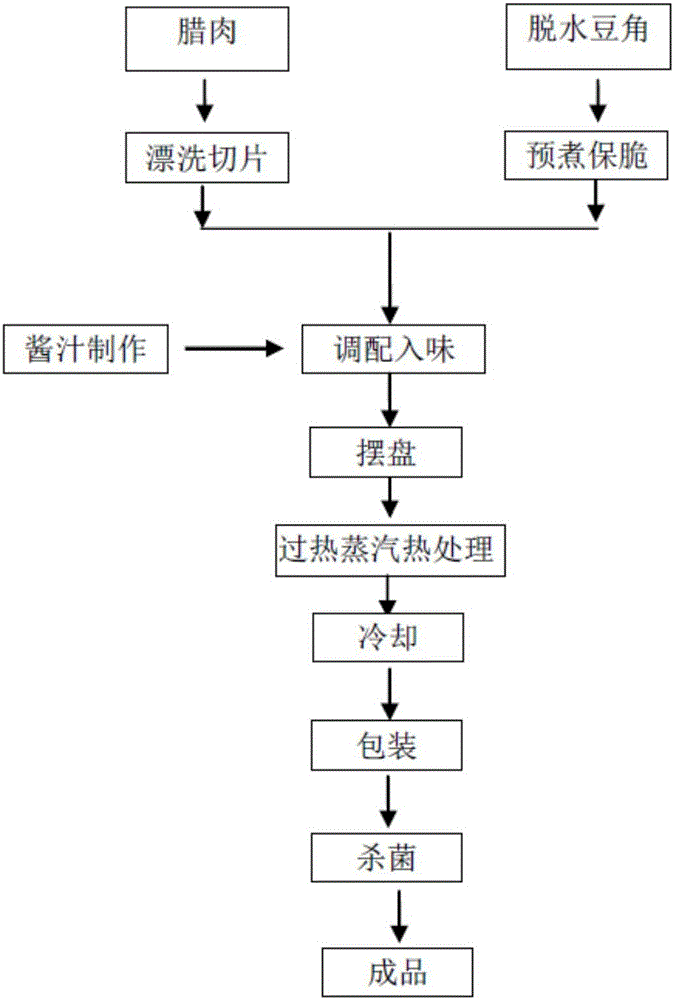

Convenient preserved meat dish and superheated steam processing method thereof

The invention discloses a superheated steam processing method of a convenient preserved meat dish. The method comprises the following steps of: placing raw materials in a superheated steam device; heating the raw materials for 3-10 min under the conditions that the upper fire temperature is 120-150 degrees, the lower fire temperature is 130-160 degrees and the superheated steam temperature is 120-180 degrees to obtain the convenient preserved meat dish, wherein the raw materials include preserved meat slices and blanched dehydrated green beans. The invention also discloses the convenient preserved meat dish. The convenient preserved meat dish is cooked by using the superheated steam, the time consumption for processing is short, the method is simple and convenient; a finished product of the convenient preserved meat dish has the characteristics of bright color, rich meat fragrance, lubrication and refreshing, rich nutrition, convenience for eating and the like, and is especially suitable for being eaten together with rice. A processing technique of the method is normative and scientific and convenient for mechanical operation; according to the method of the product, the raw materials are precooked, the precooked raw materials are pickled by sauce and the pickled raw materials are cooked by the superheated steam, the qualitative and quantitative standardized production can be realized, the quality consistency of preserved meat dishes is kept, and the method can be applied to central kitchen type industrial production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

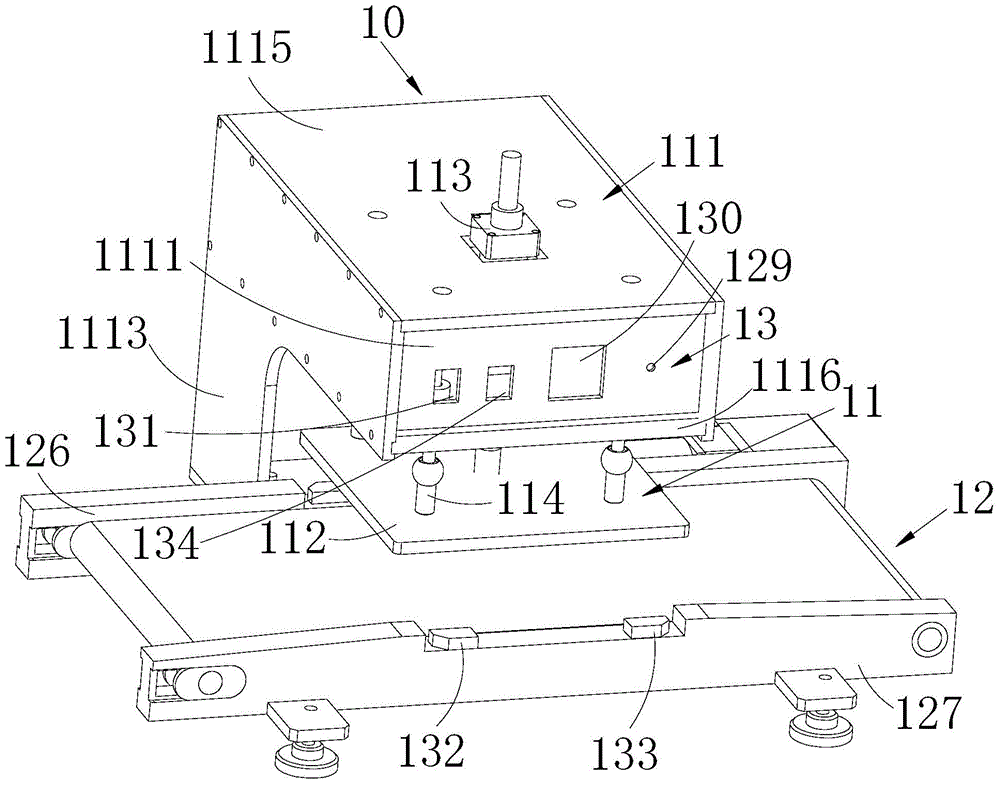

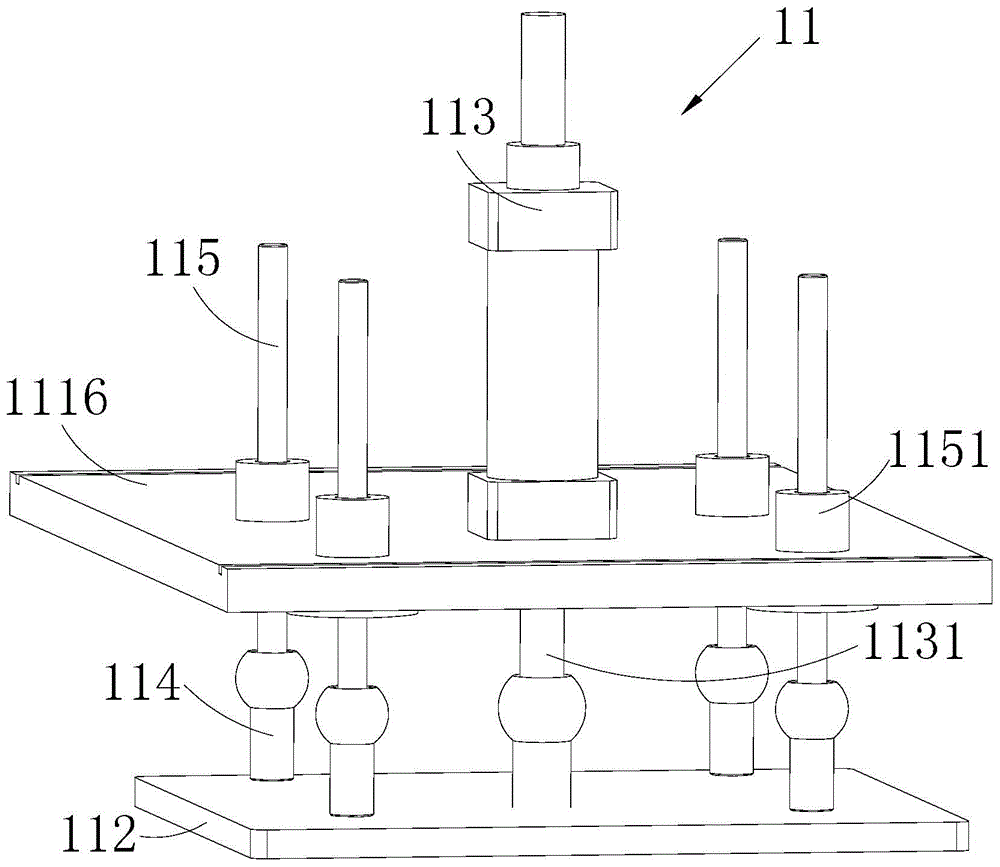

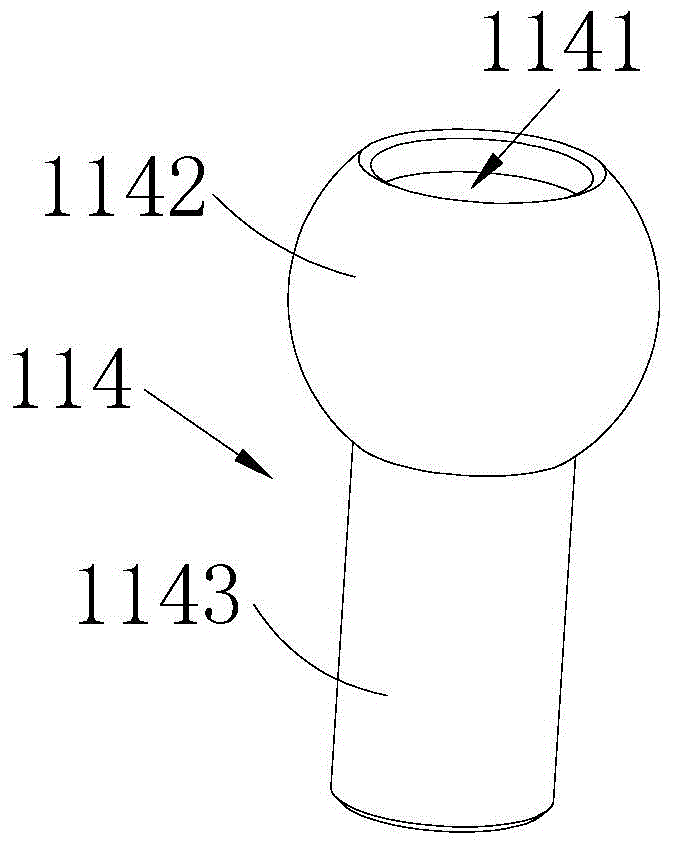

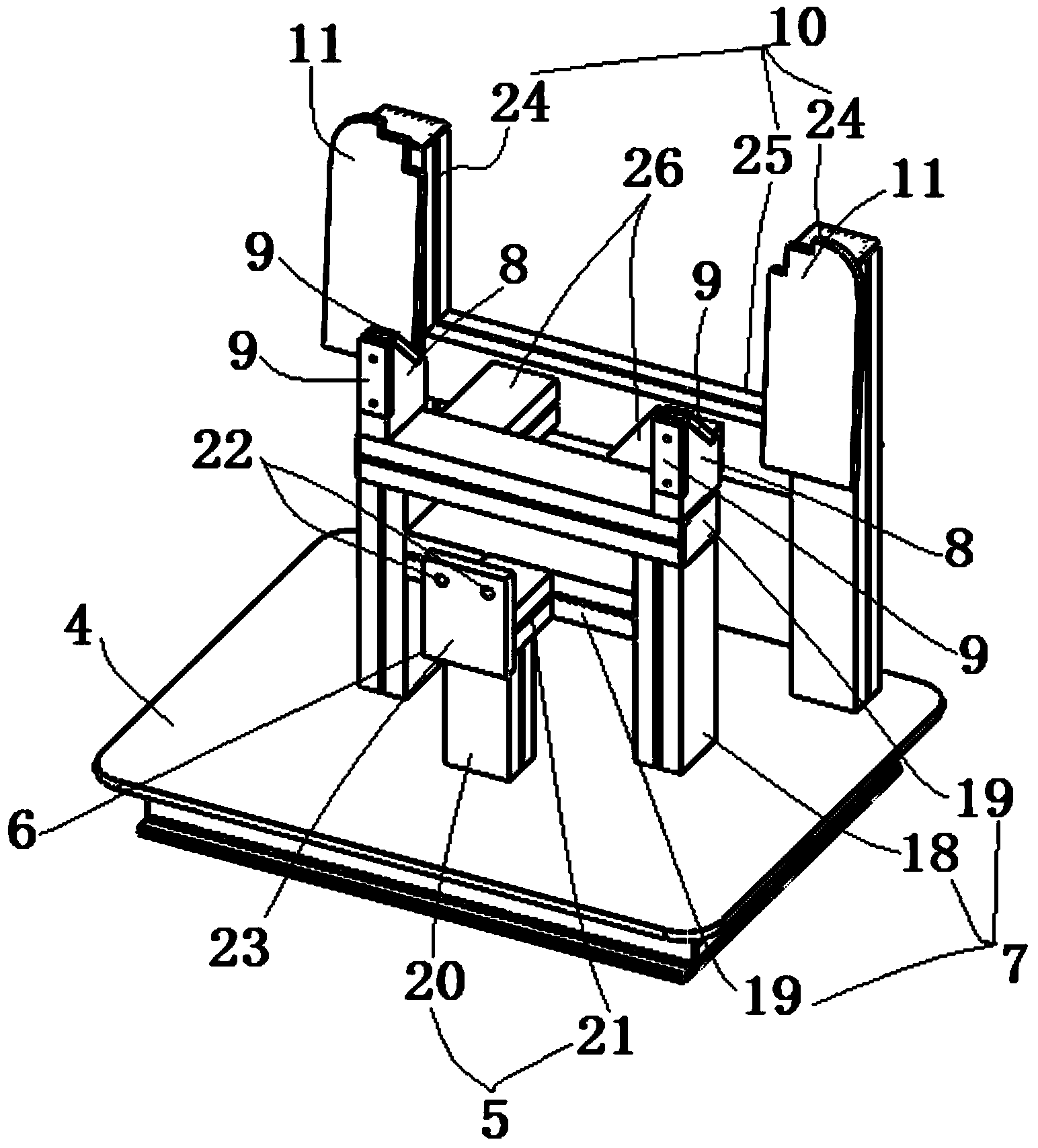

Automatic foot pad pressing machine

ActiveCN104440031AConsistent deformationUniform downforceMetal working apparatusMechanical engineeringEngineering

The invention relates to the technical field of electronic product production equipment, and provides an automatic foot pad pressing machine. The automatic foot pad pressing machine comprises a pressing mechanism, a conveying mechanism and an electronic control module. The pressing mechanism comprises a support. A pressing plate and a driving component are arranged on the support. Guide rods are arranged on the support. The guide rods are connected with the pressing plate through knuckle bearings respectively. The knuckle bearings are sleeved with balance pressure springs. The conveying mechanism is adopted to convey foot pads to the position below the pressing plate, and the driving component drives the pressing plate to press the foot pads downwards under the control of the electronic control module. The balance pressure springs can automatically adjust deformation to adapt to the different foot pads whether the surfaces of the foot pads are planes or inclined faces. In this way, the automatic food pad pressing machine is simple in structure, easy to operate, convenient to maintain, stable in work, high in reliability, small in labor intensity and high in production efficiency, and the pressing-in effect of the foot pads and the product quality are ensured.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

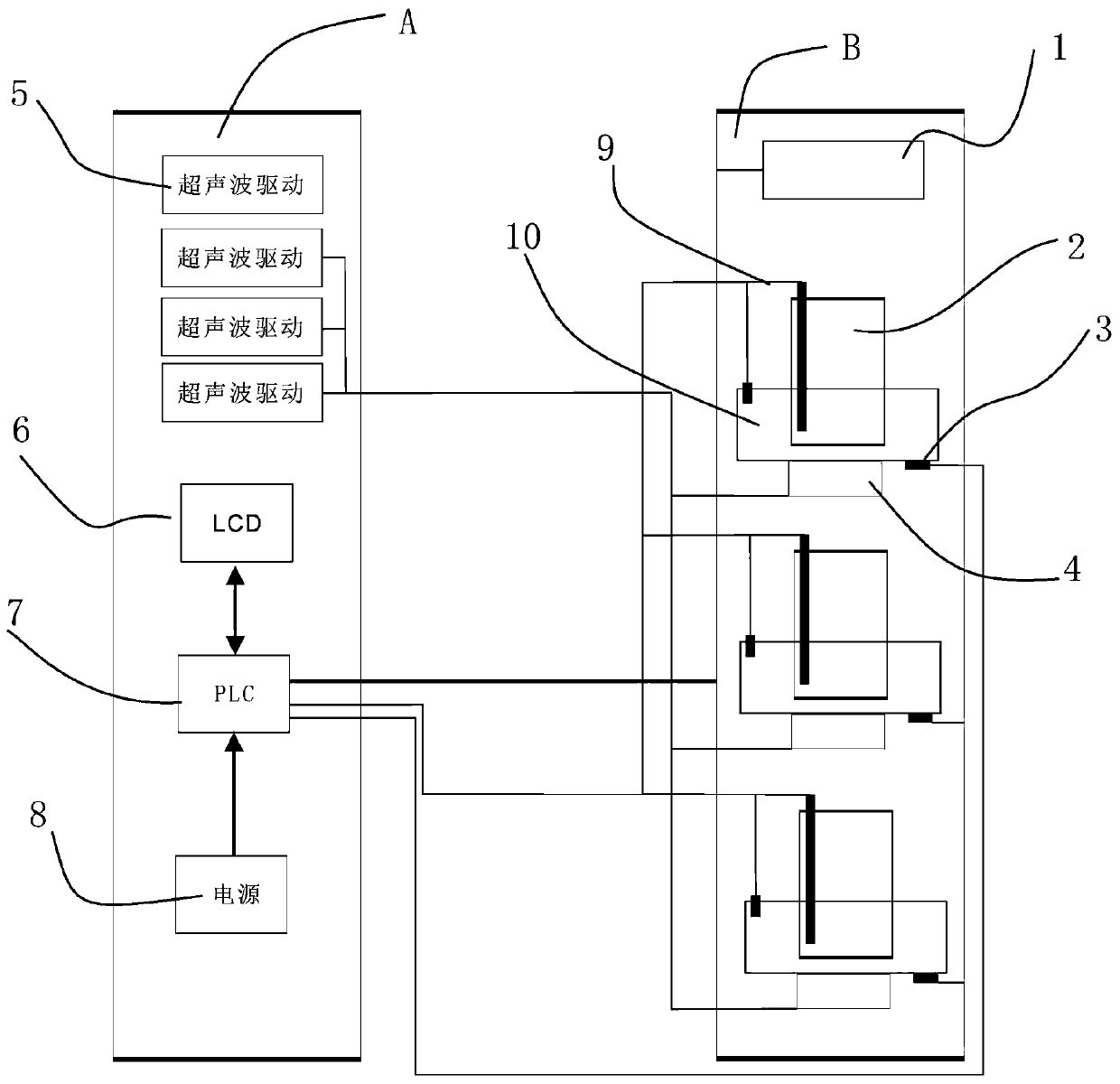

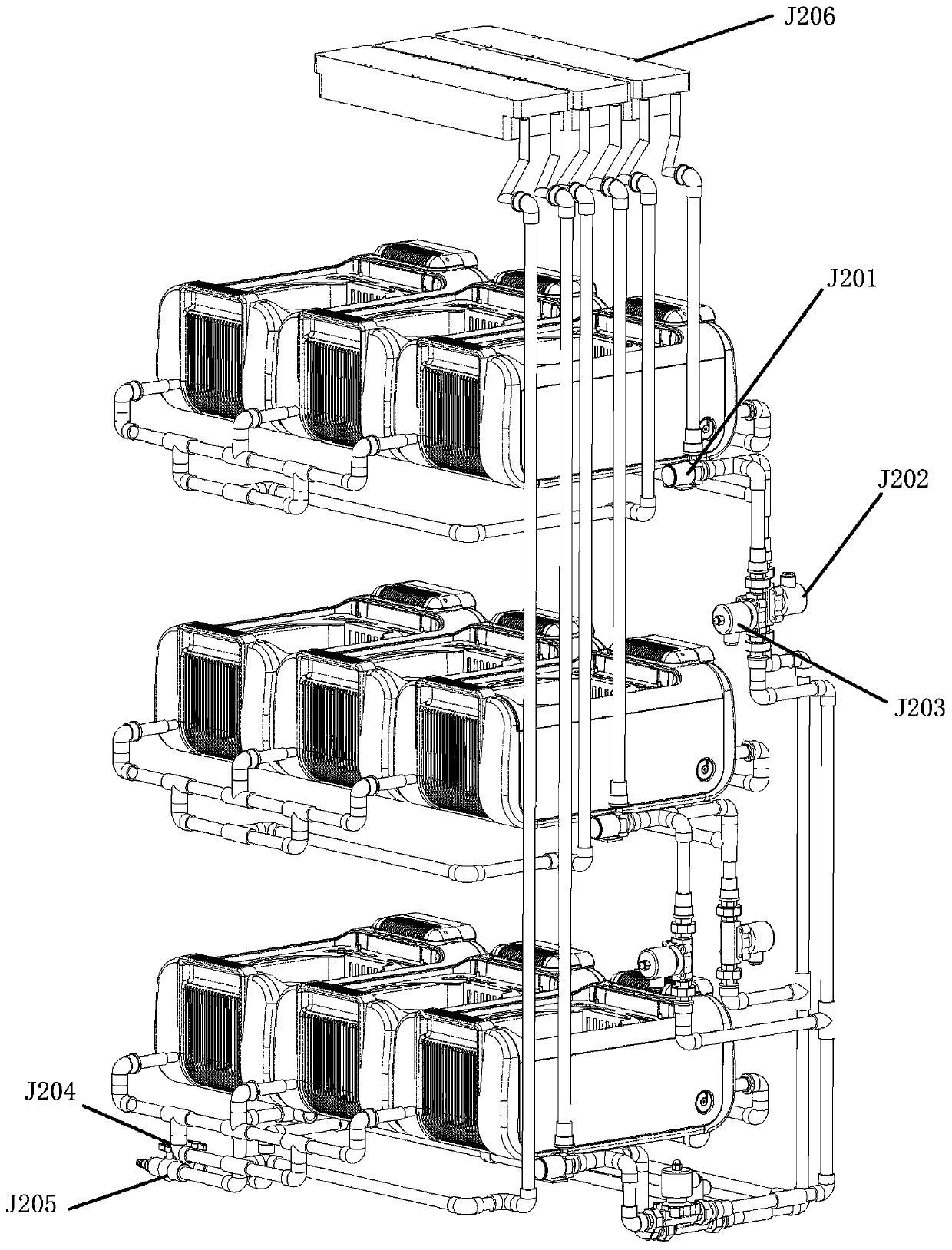

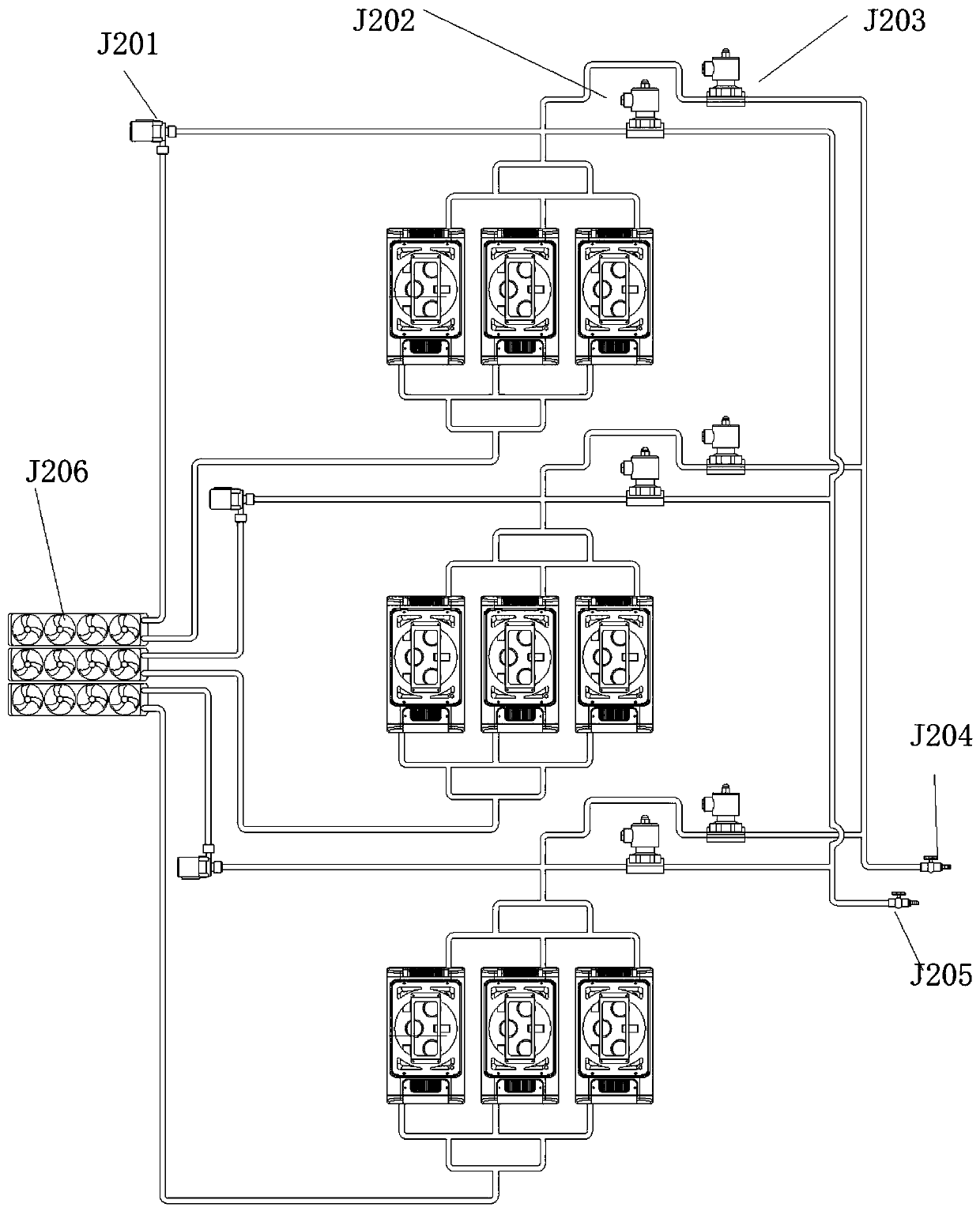

Intelligent ultrasonic liquor aging system

PendingCN110527612AGuaranteed aging effectEnsure consistent qualityAlcoholic beverage preparationTime to marketAutomatic control

The invention provides an intelligent ultrasonic liquor aging system. The intelligent ultrasonic liquor aging system comprises a machine frame, a control terminal, and a plurality of sub-aging platforms; stainless-steel aging cylinders are arranged on brackets; a liquor inlet and outlet pipe is arranged on a top cover of each of the stainless-steel aging cylinders; the other end of the liquor inlet and outlet pipe is firstly connected with a sub-control liquor valve, and then, respectively connected with liquor passage pipelines; and a water inlet and outlet opening is arranged at the bottom of a stainless steel tank, and is connected with water passage pipelines. Electrically controlled valves are controlled so as to respectively realize injection of new liquor to be aged into the stainless-steel aging cylinders and discharge of duly aged liquor from the stainless-steel aging cylinders; and electrically controlled valves are controlled so as to respectively realize injection of waterinto the stainless-steel tanks and discharge of water from the stainless-steel tanks. The intelligent ultrasonic liquor aging system realizes automatic control over whole aging process with temperature and airtight condition strictly controlled, thereby effectively guaranteeing liquor aging effects and quality consistency; so that, the intelligent ultrasonic liquor aging system can be widely applied in breweries and liquor dispensers so as to shorten time to market of new liquor. In addition, the intelligent ultrasonic liquor aging system is capable of greatly improving quality of new liquor;so that, the intelligent ultrasonic liquor aging system has wide range of application scenarios.

Owner:SHENZHEN CODYSON ELECTRICAL

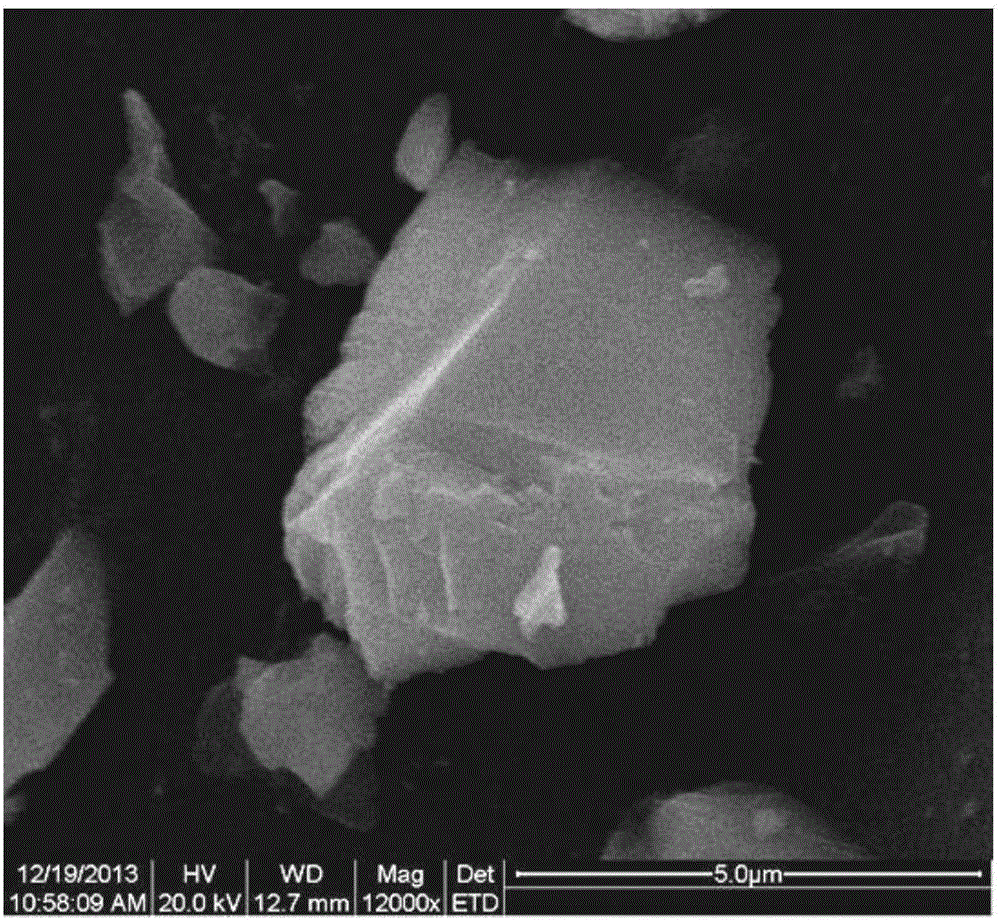

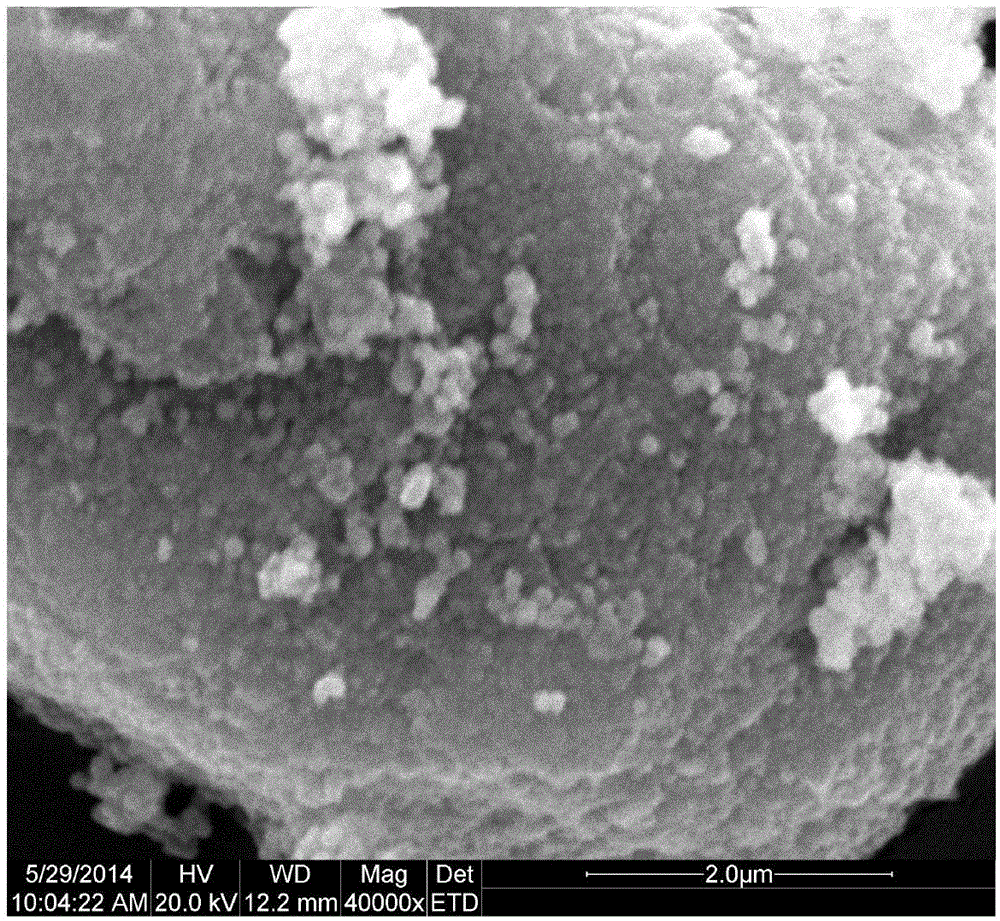

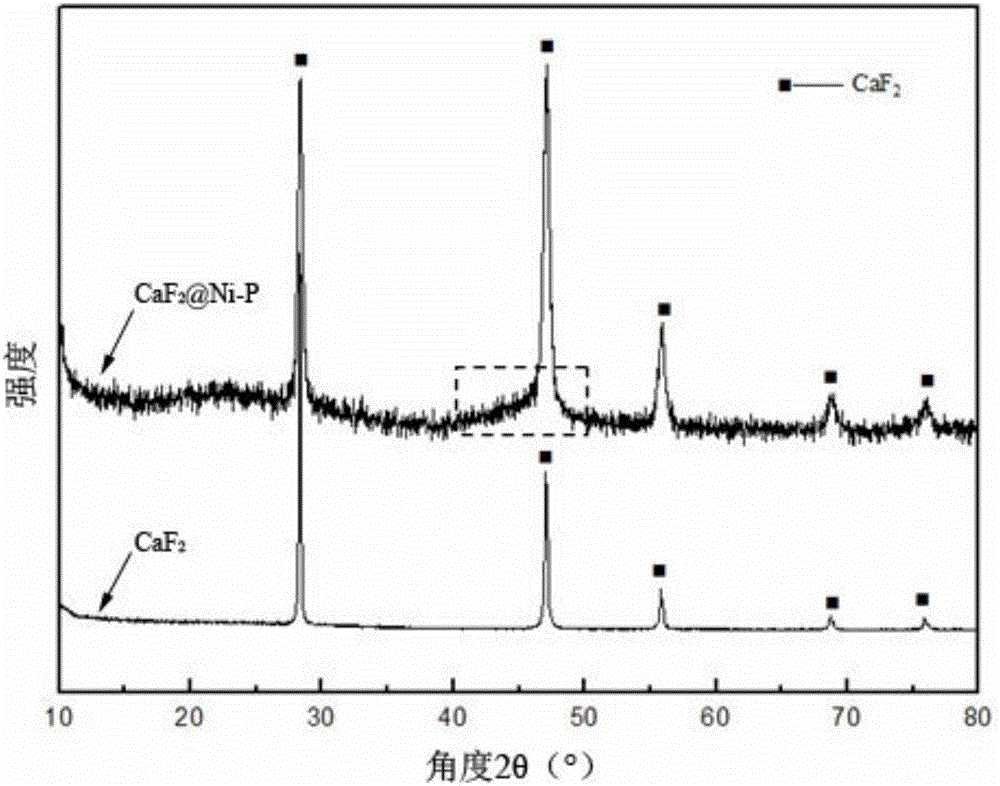

Self-lubricating ceramic tool material with nickel-phosphorus alloy coated calcium fluoride composite powder and preparation method thereof

The invention relates to self-lubricating ceramic tool material with nickel-phosphorus alloy coated calcium fluoride composite powder and a preparation method thereof; the self-lubricating ceramic tool material comprises 30-48% of Alpha-Al2O3, 42-66.5% of (W, Ti)C, CaF2@Ni-P accounting for 3-12% by weight of CaF2, and 0.4-1.5% of MgO, wherein preparation of the CaF2@Ni-P includes: washing CaF2 powder, coarsening, adding the coarsened CaF2 powder into sensitizing-activating liquid for ultrasonic vibration, and chemically plating under the ultrasonic vibration with pH of 8.5-9.5 and the temperature of 35-45 DEG C. The invention also provides a preparation method of the self-lubricating ceramic tool material with nickel-phosphorus alloy coated calcium fluoride composite powder. The coating of nickel-phosphorus alloy can improve microscopic structure of the self-lubricating ceramic material; the self-lubricating ceramic tool material can be toughened and reinforced.

Owner:QILU UNIV OF TECH

Forklift balancing weight detecting device and detecting method

InactiveCN104266564AEnsure safetyGuaranteed aestheticsMechanical measuring arrangementsEngineeringMass Consistency

The invention discloses a forklift balancing weight detecting device and a detecting method. The detecting device comprises a detecting platform. The detecting platform is provided with a supporting mechanism for supporting a balancing weight. An installation hole detecting mechanism for detecting a balancing weight installation hole in the balancing weight is arranged on one side of the supporting mechanism, and a side portion detecting mechanism for detecting the side portion of the balancing weight is arranged on the other side of the supporting mechanism. According to the detecting method, the quality of the balancing weight is detected through the detecting device. The detecting device is easy to manufacture and achieve. According to the detecting device, the detecting accuracy is high, the accumulated error in detection is effectively reduced, the detection quality is improved, and the data accuracy rate is increased. Meanwhile, detecting is convenient and fast, and the detection efficiency is improved. The detecting method is easy to operate, and the accuracy degree and the efficiency are high. According to the detecting device and the detecting method, the quality consistence of produced balance weights is guaranteed.

Owner:ZOOMLION HEAVY MASCH CO LTD

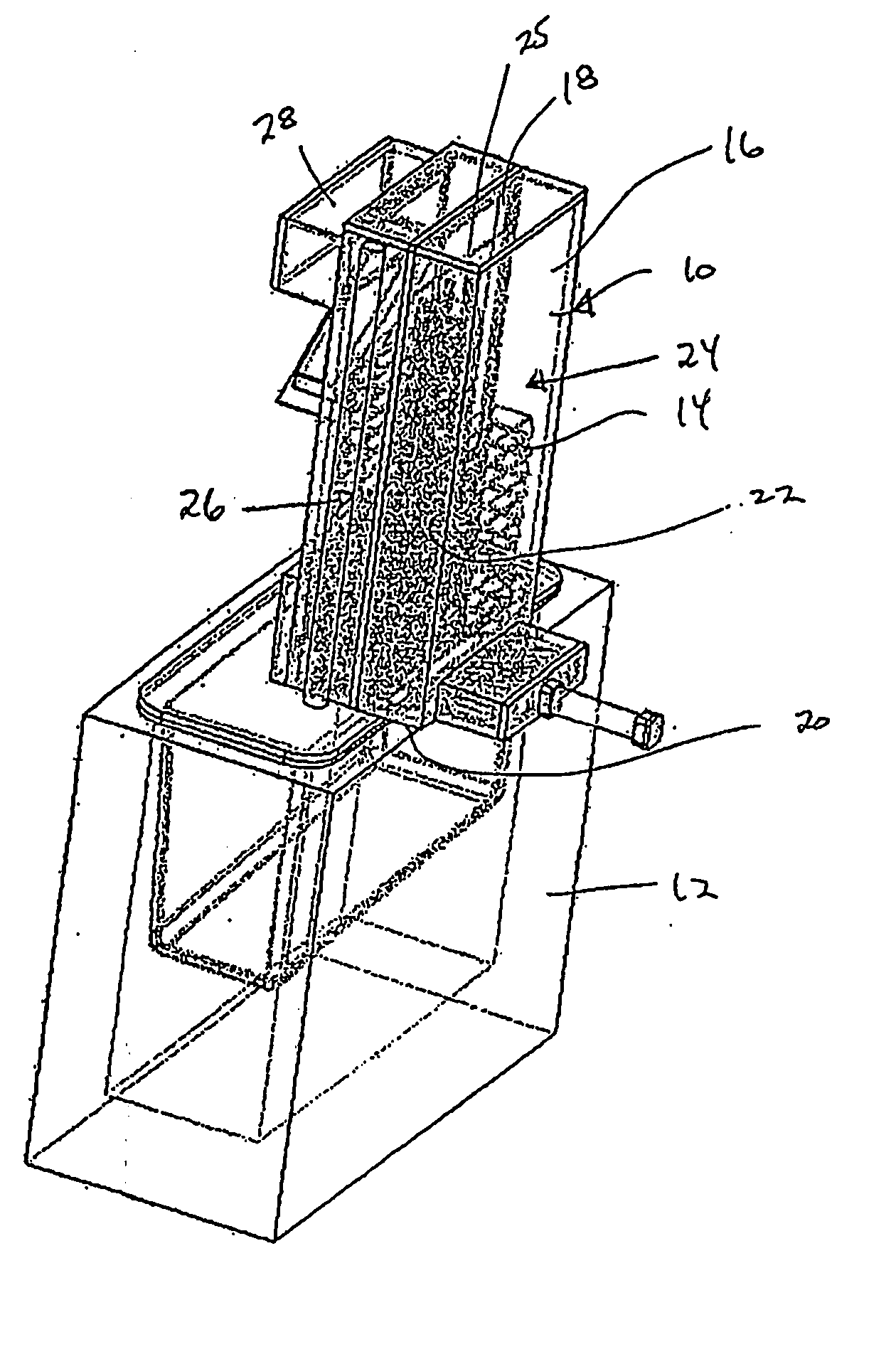

Method and apparatus for preheating and distributing ingots

InactiveUS20050011595A1Safe and energy efficientEnsuring energy securityFurnace typesHeat treatment furnacesDie castingIngot

A method and apparatus for preheating and distributing magnesium ingots used in magnesium die casting wherein the heating efficiency is improved thus reducing the energy required to heat the ingots to a temperature varying between 150° C.-350° C. prior to charging into a molten magnesium bath. A housing comprising a ceiling, a floor, side walls extending from the floor to the ceiling for defining a chamber which is divided into at least a storage area and a heating area, and means for moving the ingots from one side to another as well as out to the molten magnesium bath are provided. The apparatus of the invention is adapted to be securely positioned directly atop of a melting furnace whereby the heat generated by said furnace is used to preheat the ingots located within the apparatus prior to charging.

Owner:BOWMAN DAVID

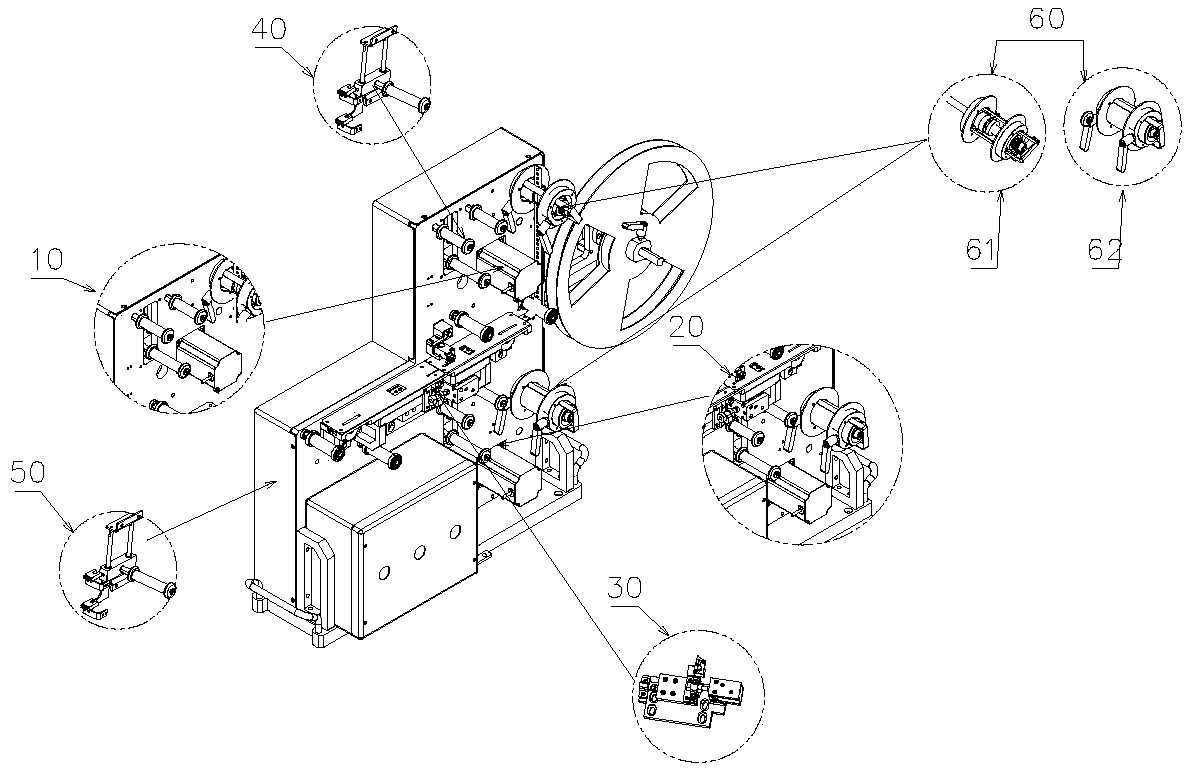

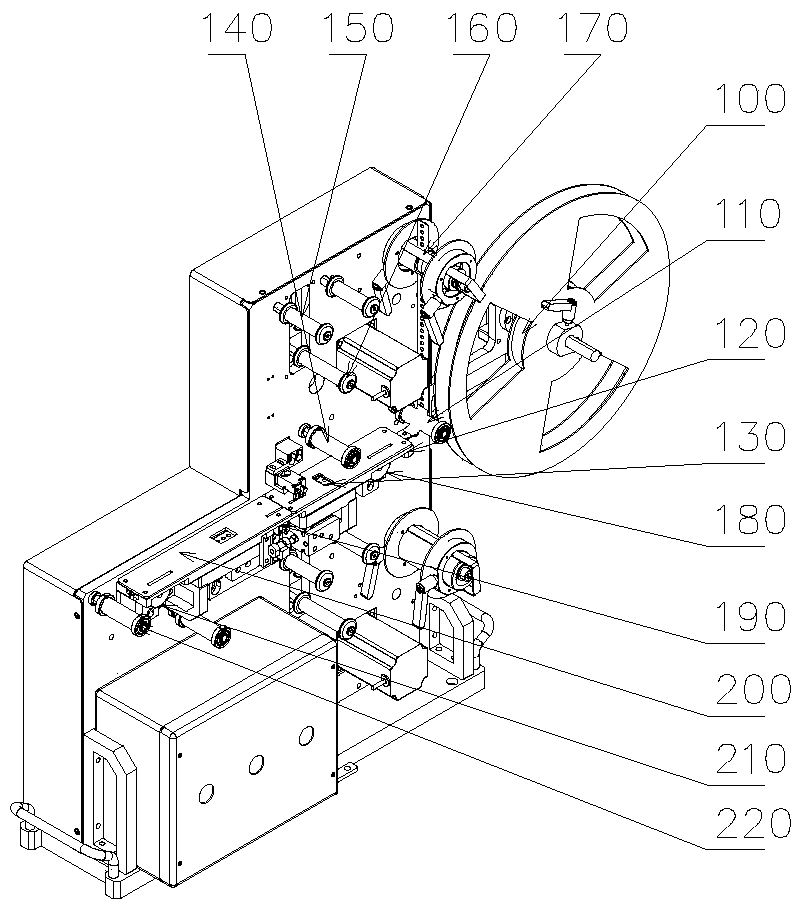

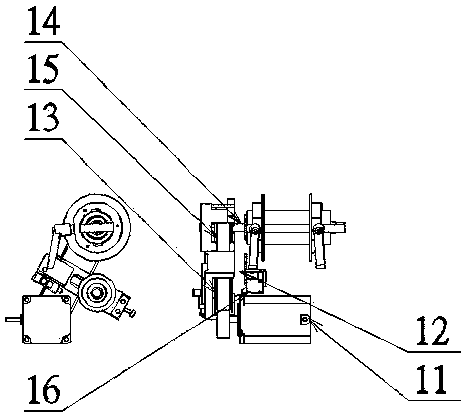

SMT carrier band dismantling packaging feeding device

InactiveCN108622449AImprove pick-and-place efficiencyEnsure consistent qualityPackagingStart stopMass Consistency

Owner:SHANGHAI SHARETEK TECH CO LTD

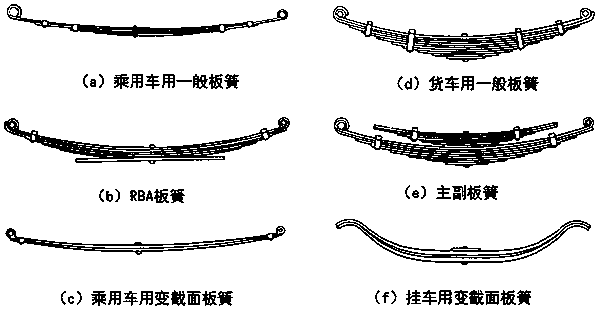

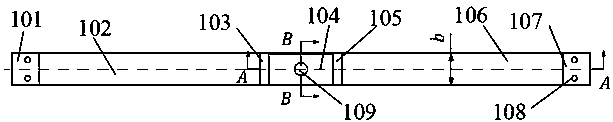

Leaf spring and manufacturing technology thereof

ActiveCN107606014AReduce weightImprove local stressLeaf springsDomestic articlesDynamic stiffnessFiber

The invention relates to a leaf spring and a manufacturing technology thereof. The leaf spring comprises a leaf middle section, a transition section, a variable-section section and a winding lug installing section, and all the sections are the same in width. The material of the leaf spring is an FRP composite material. The manufacturing technology comprises the fiber cloth weaving procedure, the fiber cloth laminating procedure, the laminated layer spot welding procedure, the pre-forming procedure, the cutting procedure, the HP-RTM procedure, the unloading and shaping procedure and the post-machining procedure. The technical scheme solves the problems of design and process of leaf spring leaves in the prior art, the leaf spring leaf performance is improved, the volume production beat is fast, and the market value of the leaf spring is huge; one leaf spring can be independently used, two leaf springs can be combined to form a main and auxiliary spring structure, different loads are achieved, and all steel plate spring structures can be replaced by changing structures of winding lugs and other accessories; complete fracture at a time is avoided, the active failure mode is achieved, and the vehicle running safety is sufficiently guaranteed; the weight of a leaf spring suspension is reduced, the dynamic stiffness is very small, the vehicle running smoothness is improved, and fuel affinity is improved as well; and the service life is 5 or more times of the steel plate springs, and the cost of using the leaf spring by users is greatly reduced.

Owner:合肥前卫复合材料有限公司 +1

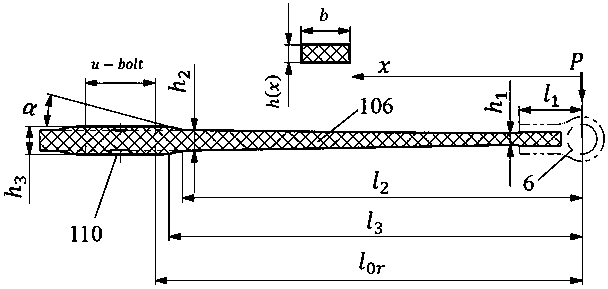

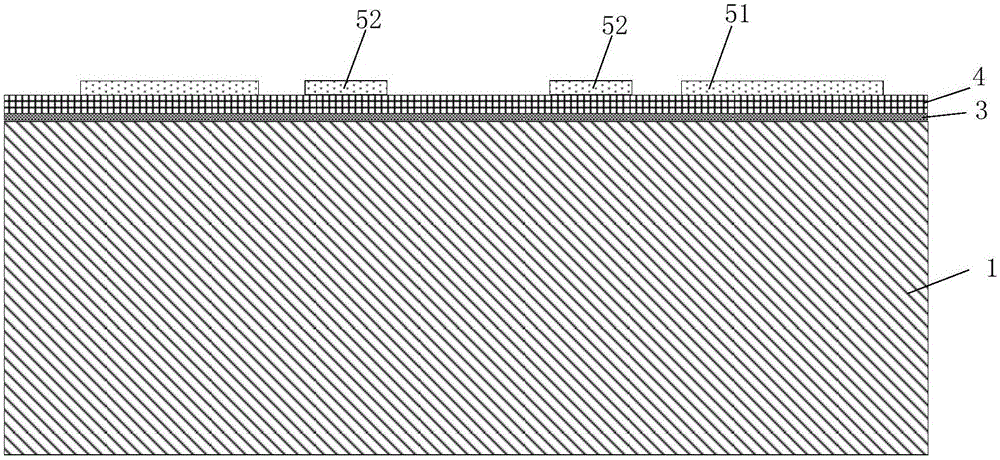

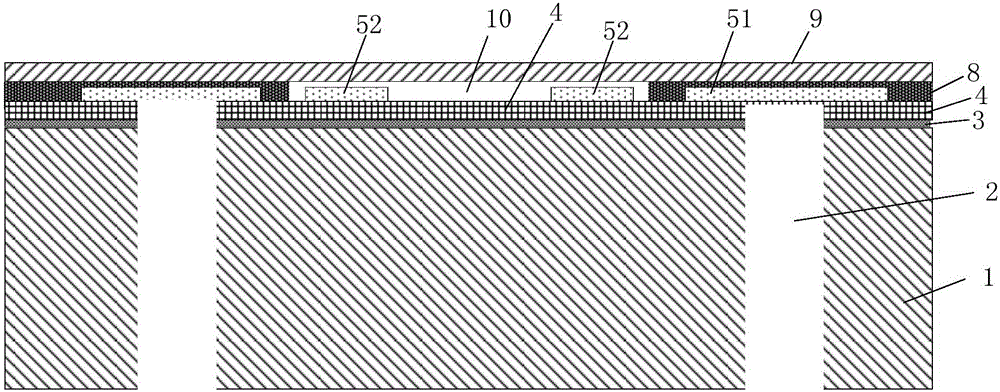

Packaging structure of SAW filter and manufacturing method thereof

InactiveCN106505967AReduce volumeLow costImpedence networksSemiconductor/solid-state device detailsSolder ballViscose

The invention provides a packaging structure of a SAW filter. The structure comprises a base body. A through hole which connects a front side and a back side of the base body is arranged in the base body. Insulating layers covers a front side surface, a back side surface and a through hole side wall of the base body. A piezoelectric material covers the insulating layer on the front side of the base body. Positions on the front side and the back side of the base body, which correspond to the through hole, are provided with a front side extraction electrode and a back side extraction electrode respectively. The front side extraction electrode and the back side extraction electrode are connected through a metal conducting structure in the through hole. The front side extraction electrode is located on a piezoelectric material surface. The back side extraction electrode is located on an insulating layer surface of the back side of the base body. The front side extraction electrode and an edge of the SAW filter on an outer side of the front side extraction electrode are covered by a viscose glue. A cover plate covers the viscose glue. A cavity is arranged between the cover plate and the piezoelectric material of the front side of the base body. The piezoelectric material surface in the cavity is provided with an energy transducer electrode. A solder ball extraction electrode is made on a portion position opening on a back side passivation layer, wherein the portion position opening corresponds to the back side extraction electrode. The packaging structure possesses low cost and high reliability.

Owner:XIAMEN SKY SEMICON TECH CO LTD

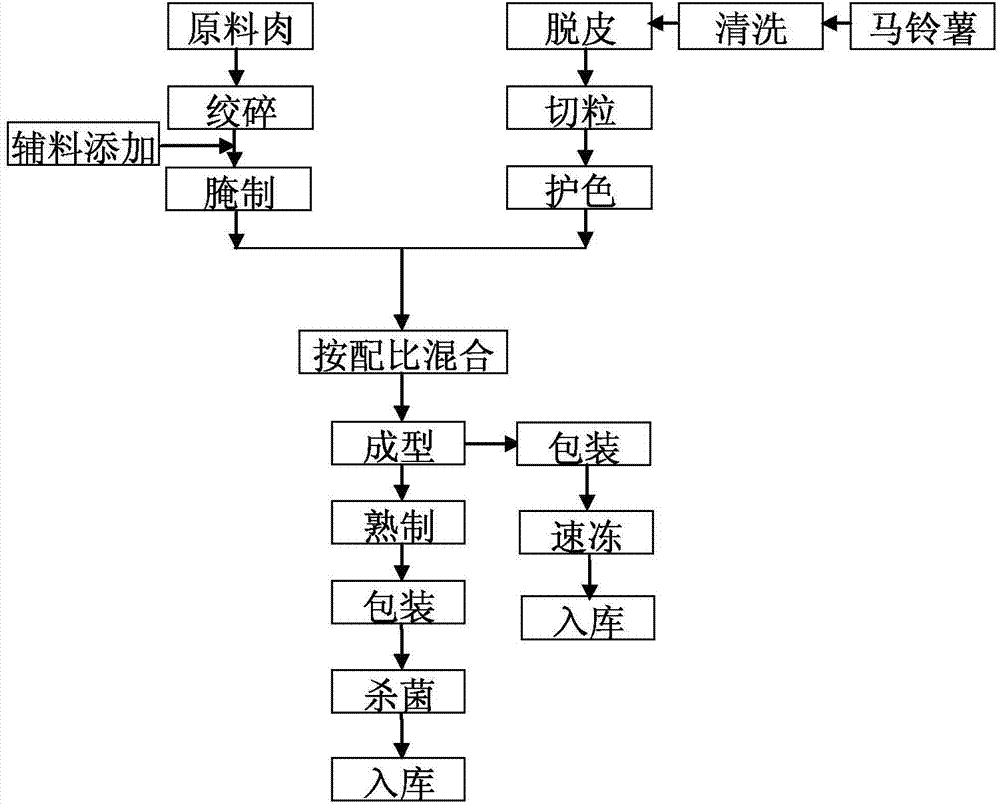

A recombined potato patty and a processing method thereof

The present invention relates to the field of patty processing, in particular to a recombined potato patty and a processing method thereof. The patty comprises the following components: lean meat fillings, fat meat fillings, common salt, white granulated sugar, monosodium glutamate, polyphosphate, sodium erythorbate, sodium nitrite, red rice starter, potato whole powder, pepper powder, star anise powder, Chinese red pepper powder, cassia powder, clove powder, fennel powder, Amomum tsao-ko powder, nutmeg powder, ice water and potato particles. The patty has a bright color and luster, an outstanding meat flavor, balanced nutrition, moderate energy values, a soft and tender texture, and a tasty, refreshing and non-greasy taste, and quantified and industrialized production of the patty can be achieved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

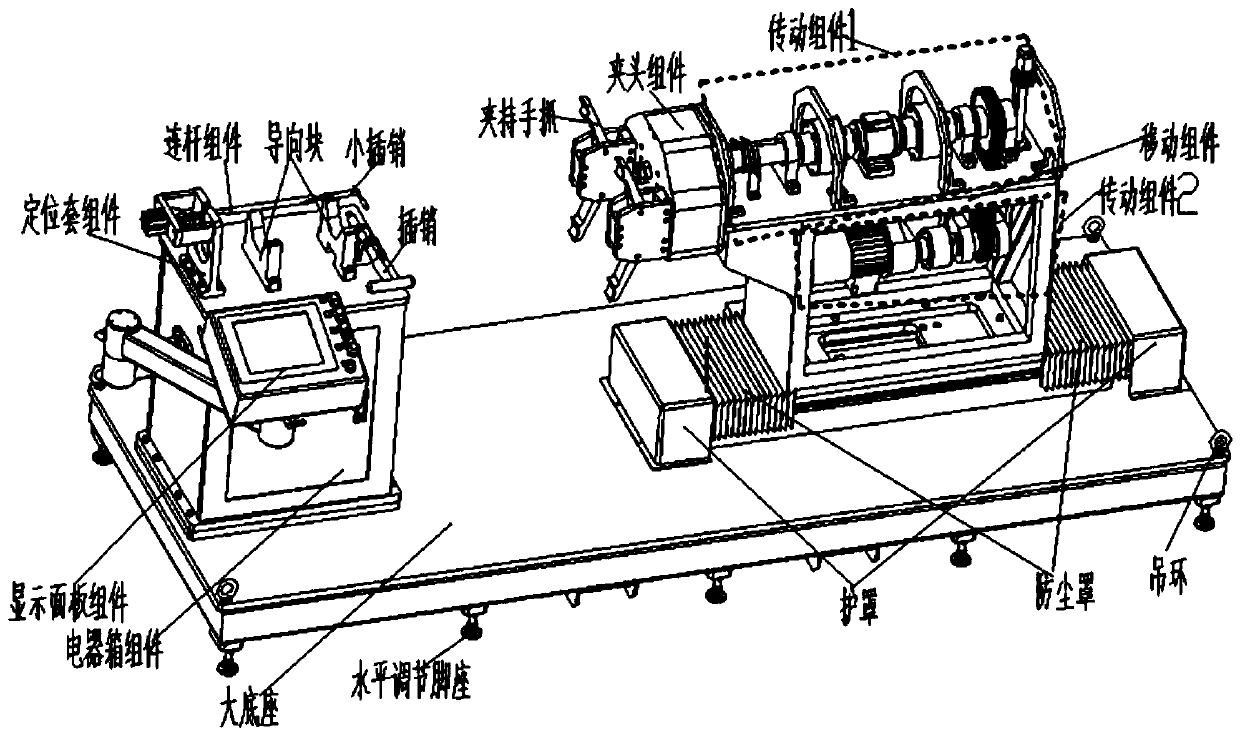

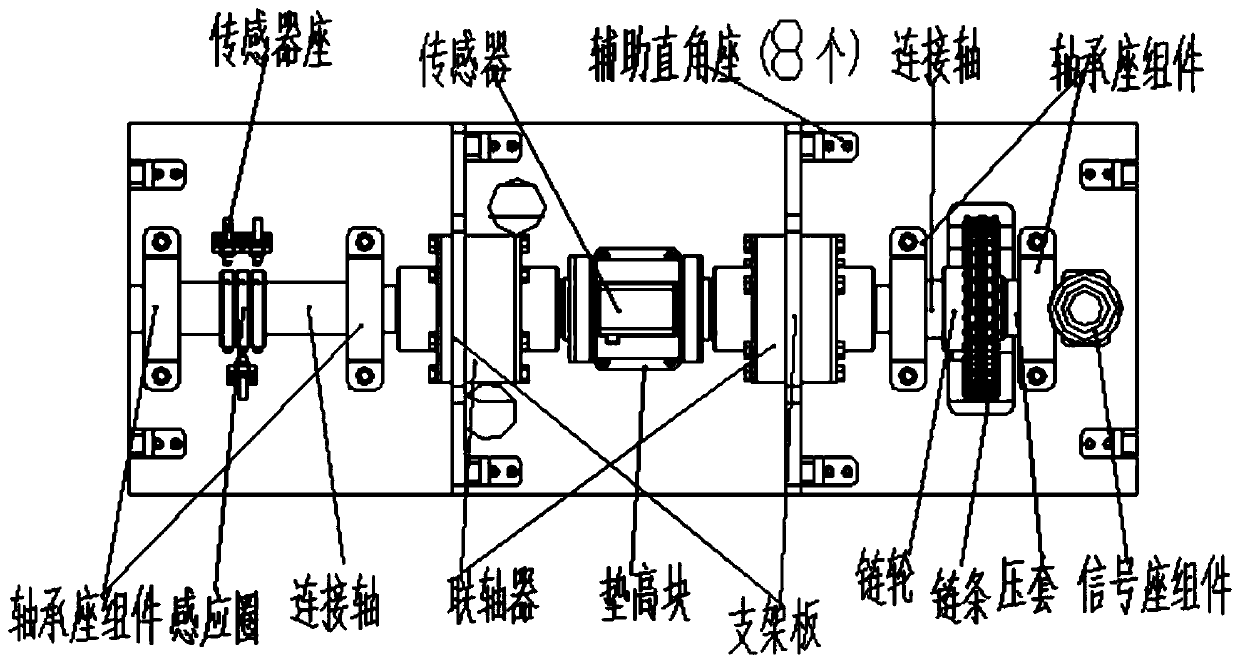

Undercarriage automatic return-to-center test device

InactiveCN110341985AAccurate collectionLabor-saving operationAircraft components testingDigital controlTest object

The invention provides an undercarriage automatic return-to-center test device. The device includes an electrical box assembly, a display panel assembly, guide blocks, a position sleeve assembly, a latch, clamping grippers, a chuck assembly, a first transmission assembly, a second transmission assembly and a large pedestal; the position sleeve assembly and the guide blocks are used for supportinga test object; the latch is used to connect the test object and plays a role of limitation; the clamping grippers are used for tightly grasping the test object and fixedly connected to the chuck assembly; and the chuck assembly receives the torque jointly transmitted by the first transmission assembly and the second transmission assembly so that the chuck assembly can be driven to perform torsionin a positive direction or a negative direction. According to the embodiments, the device is laborsaving in operation and convenient; torsion can be accurately realized by only arranging rotation angles and forward and reverse buttons on a display screen, so that efficiency can be enhanced, the quality consistency of products can be guaranteed, and the purposes of digital control and accurate rotational moment value collection can be achieved.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

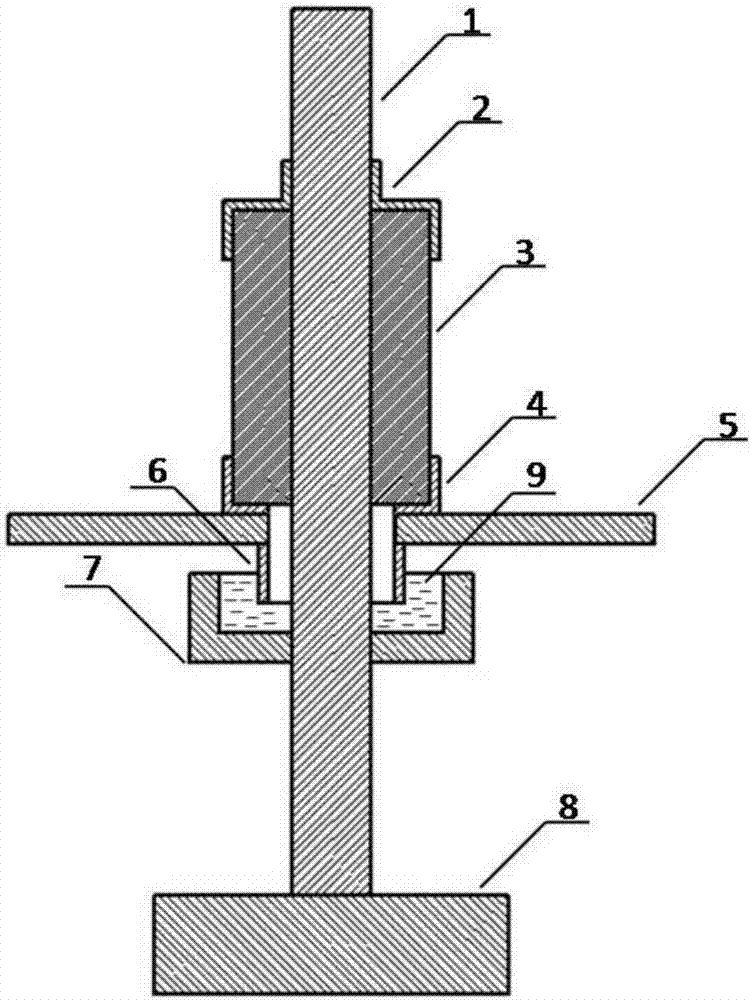

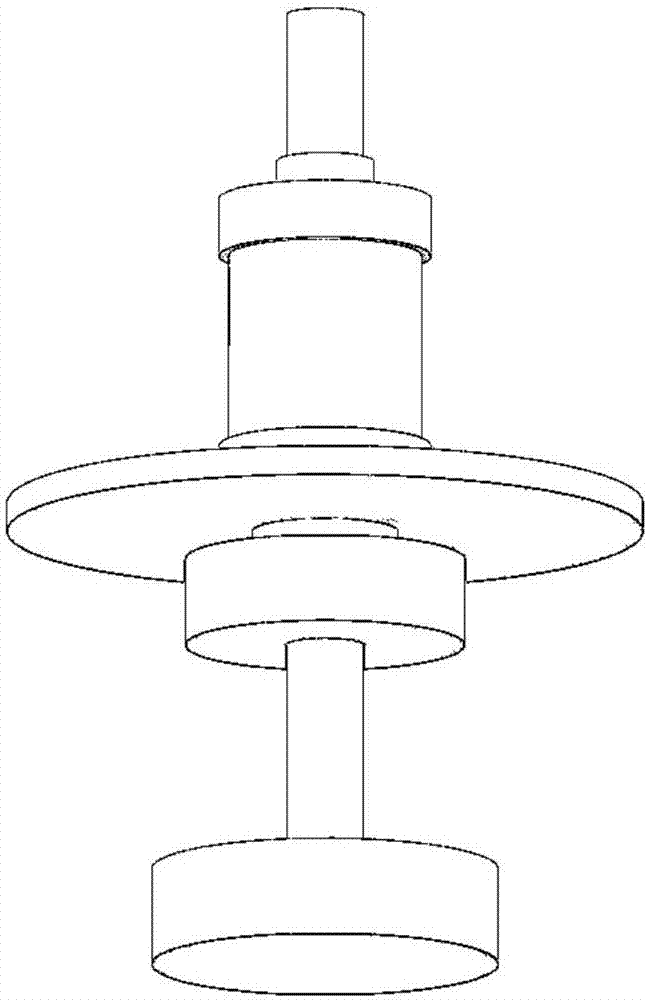

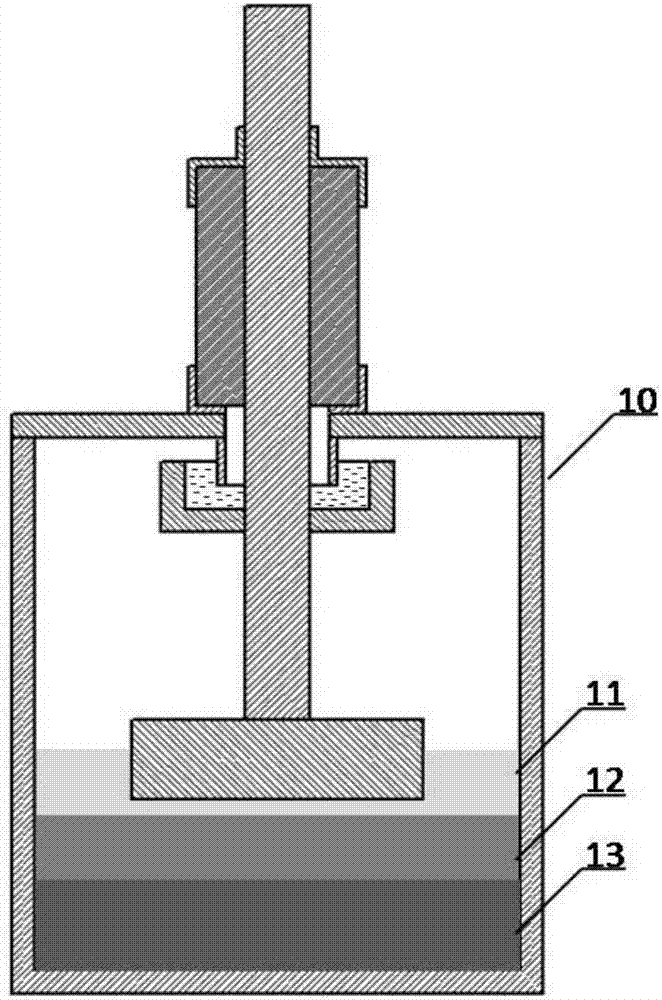

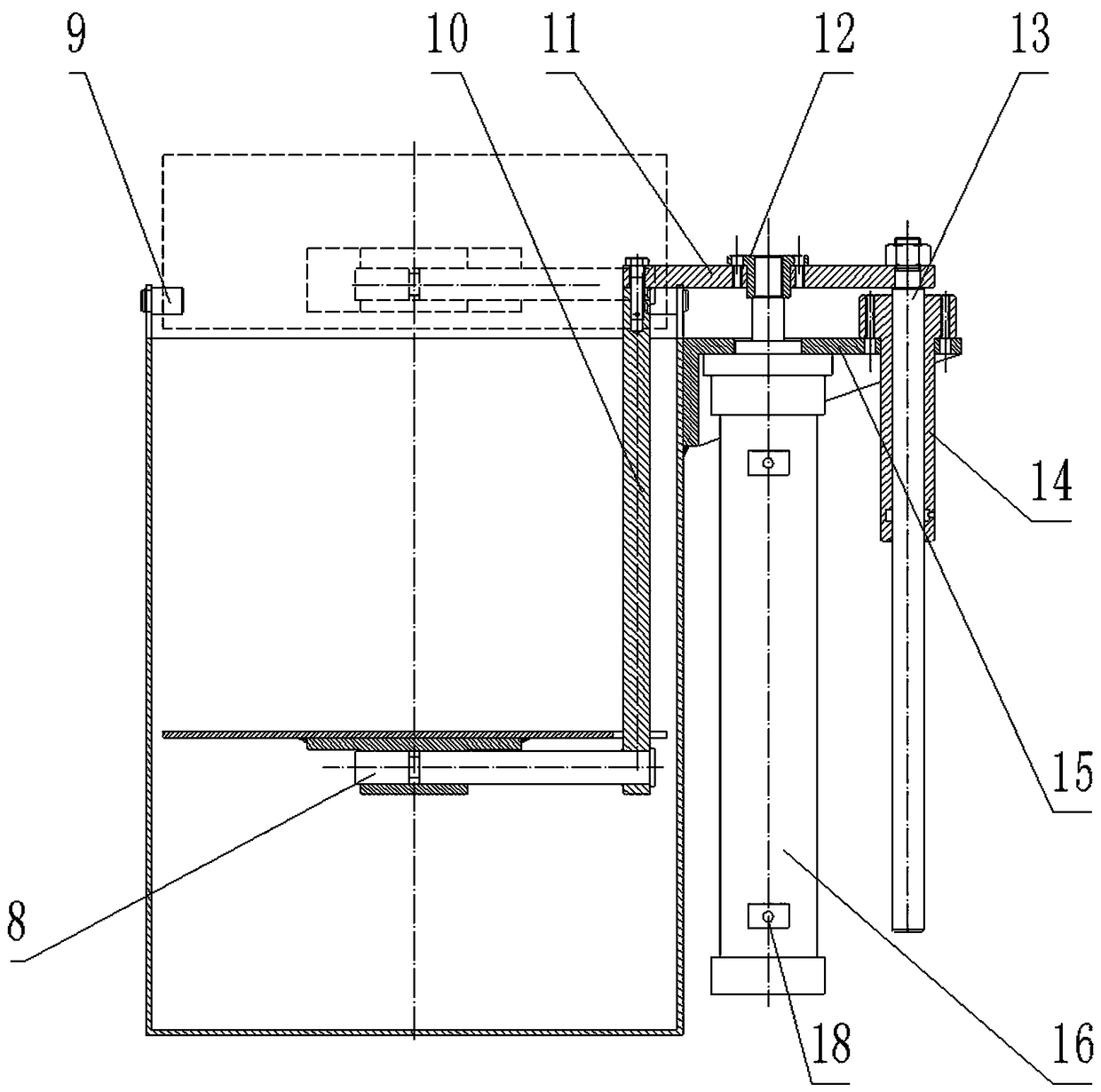

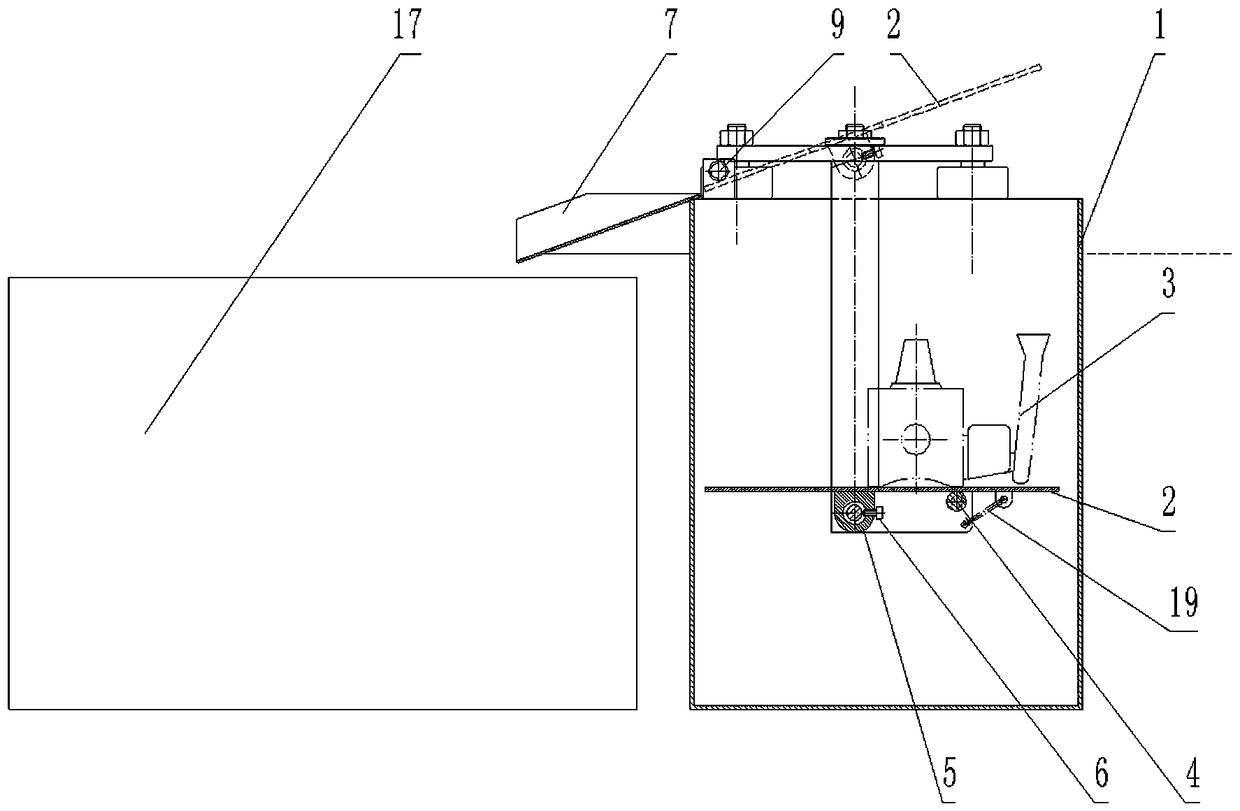

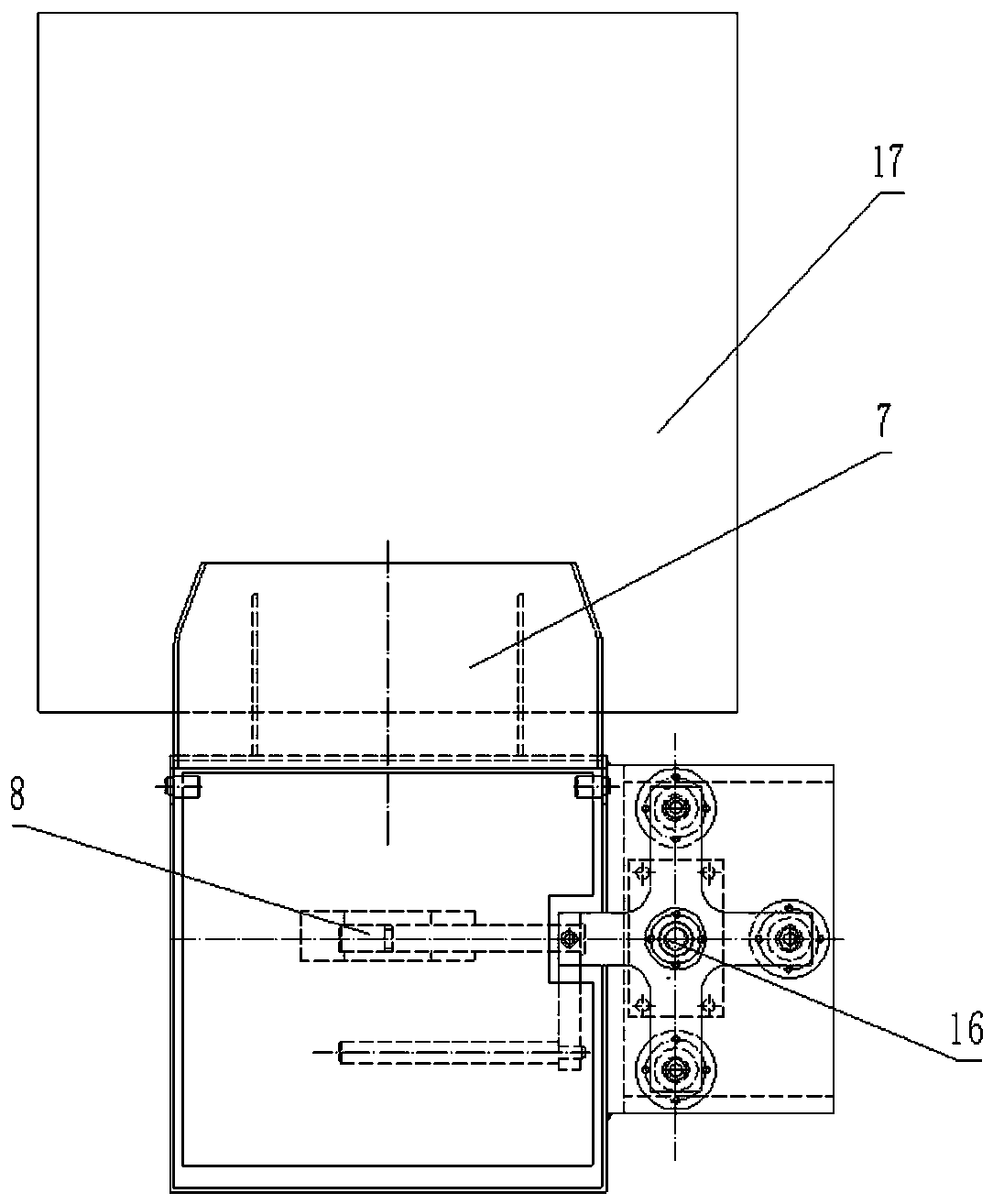

Piston automatic quenching device and method based on incomplete solution treatment technology

InactiveCN108103281ASave energy and man hoursIncrease productivityFurnace typesHeat treatment process controlQuenchingPiston

The invention discloses a piston automatic quenching device based on an incomplete solution treatment technology. The piston automatic quenching device comprises a quenching water tank, wherein a lifting mechanism is arranged outside the quenching water tank; a material receiving plate bracket is arranged along the vertical direction in the quenching water tank; a material receiving plate supportis arranged along the horizontal direction at the lower end of the material receiving plate bracket; the material receiving plate support is connected with a material receiving plate; the lifting mechanism is connected with the material receiving plate bracket; the piston automatic quenching device also comprises a material receiving plate tilting device for driving the material receiving plate totilt for material discharge; the piston automatic quenching device further comprises a material discharge device. The device can work independently or in combination, realizes automation and programcontrol of the quenching process, and can guarantee the quenching quality and process stability and reduce the labor intensity of workers.

Owner:ANHUI WHITE RABBIT POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com