Fixed die core-pulling mechanism capable of self-locking and backstopping

A core-pulling mechanism and anti-retraction technology, applied in the field of fixed-mold core-pulling mechanism, can solve problems such as difficult to guarantee accuracy, difficult to control product quality, and decreased overall strength of fixed formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

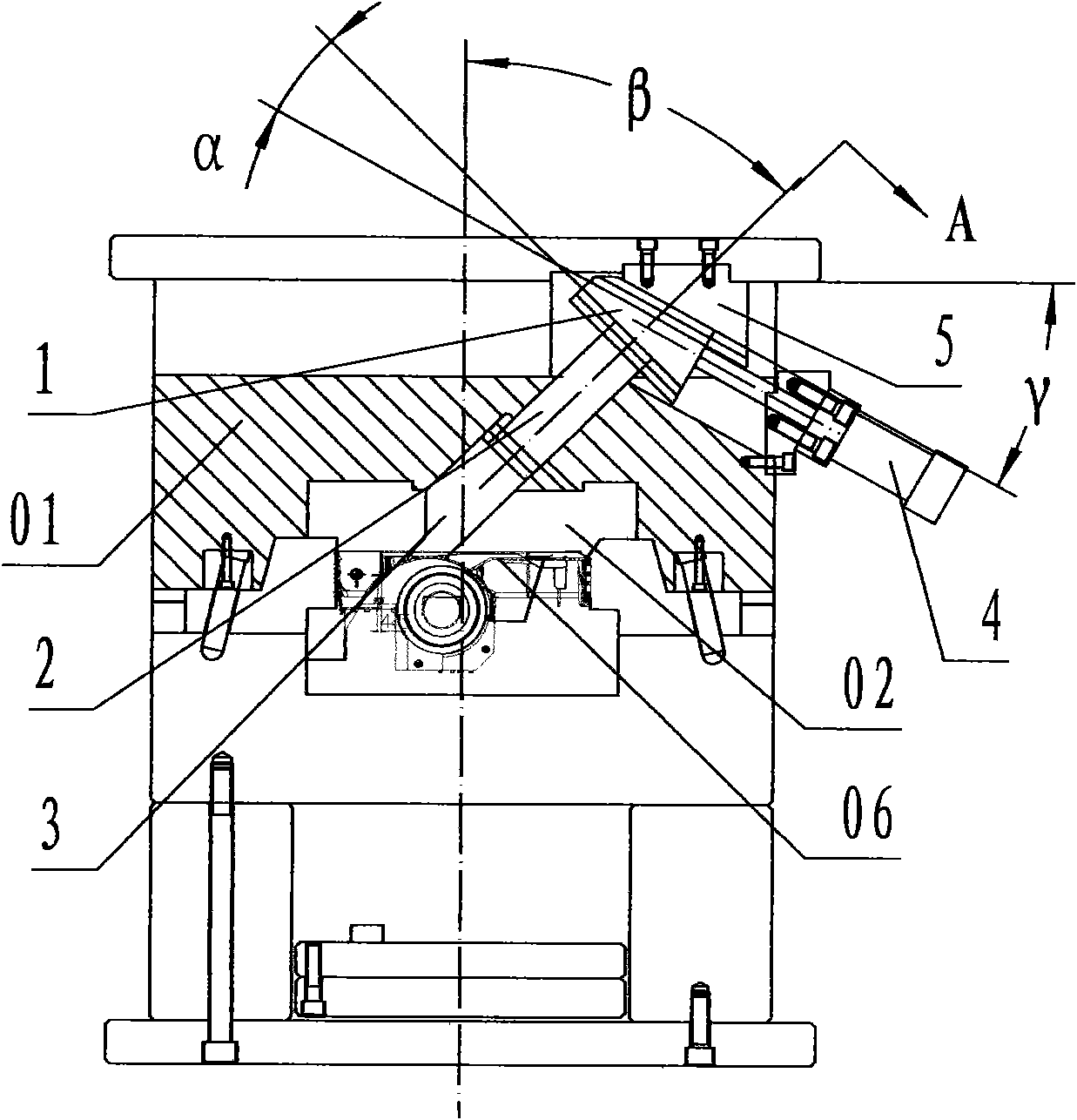

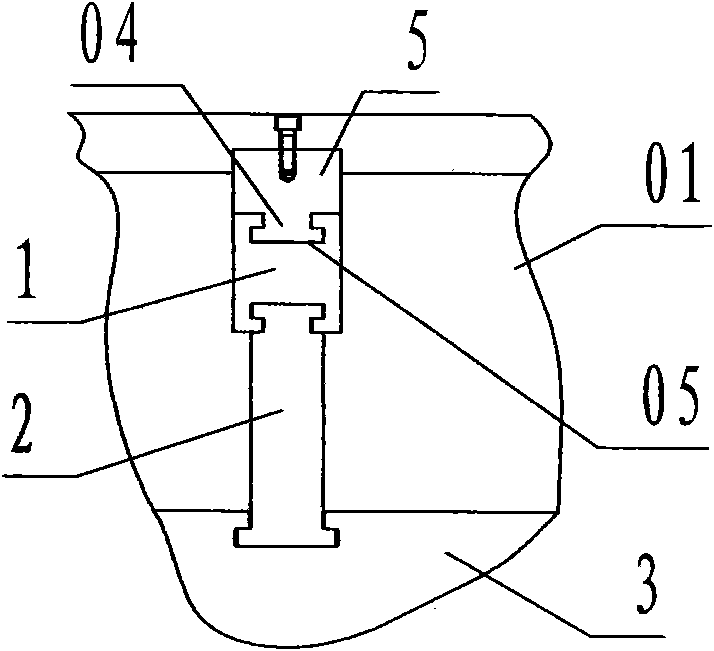

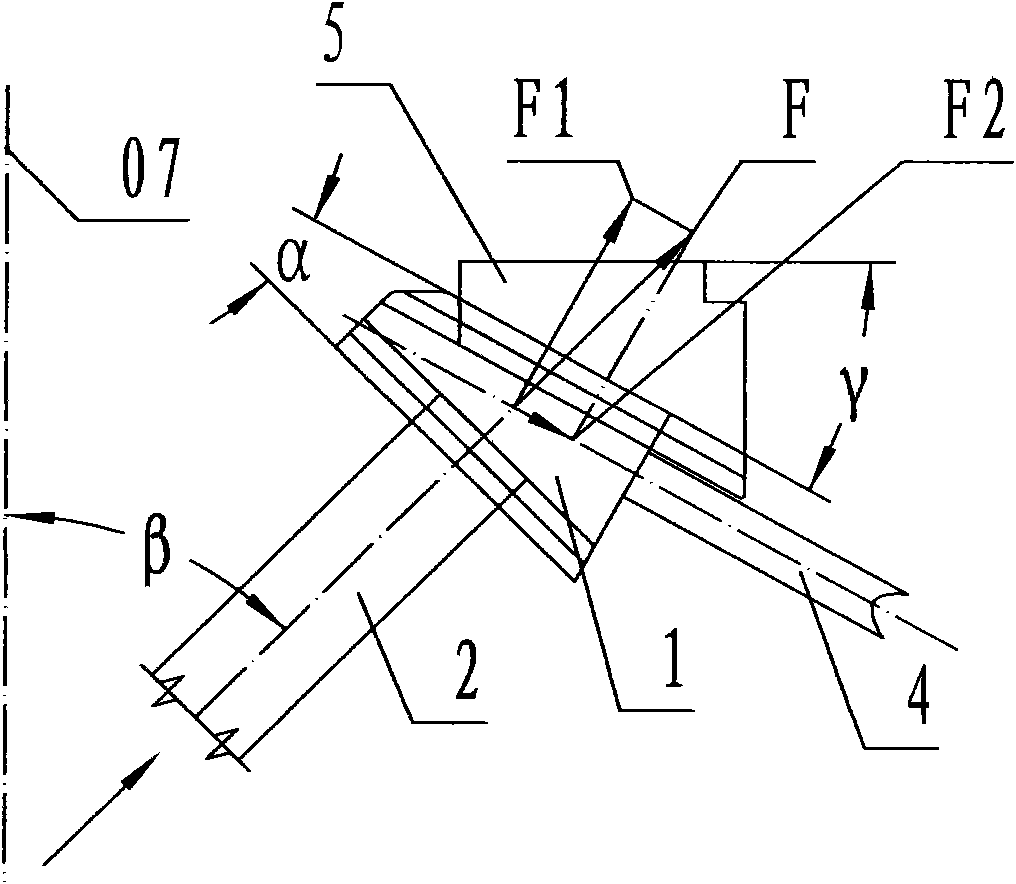

[0025] refer to Figure 1 ~ Figure 3 , a fixed-die core-pulling mechanism capable of self-locking and anti-retraction of the present invention, including a wedge-shaped slider 1, an inclined ejector rod 2, an inclined core-pulling block 3, an oil cylinder 4, and a support seat 5, wherein: the wedge-shaped slider 1 is a wedge shape with an angle of α between the upper and lower end faces along the long side direction, the side of the small end of the wedge is a plane orthogonal to the lower end face, the side of the big end of the wedge is a plane orthogonal to the upper end face, and the two long sides The side is a wedge-shaped steel block body that is orthogonal to the upper and lower end faces and parallel to each other; along the long side direction, the upper and lower end faces of the wedge-shaped slider are equipped with T-shaped slides with inverted T-shaped grooves in cross section. Groove 05; the value range of the α included angle is 12°~16°;

[0026] The inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com