SMT carrier band dismantling packaging feeding device

A technology of feeding device and carrier tape, applied in the field of dismantling SMT carrier tape packaging feeding device, can solve the problems of low efficiency, difficult to determine the main reason, and difficult to calculate the number of products, and achieves quality consistency assurance, simple structure, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

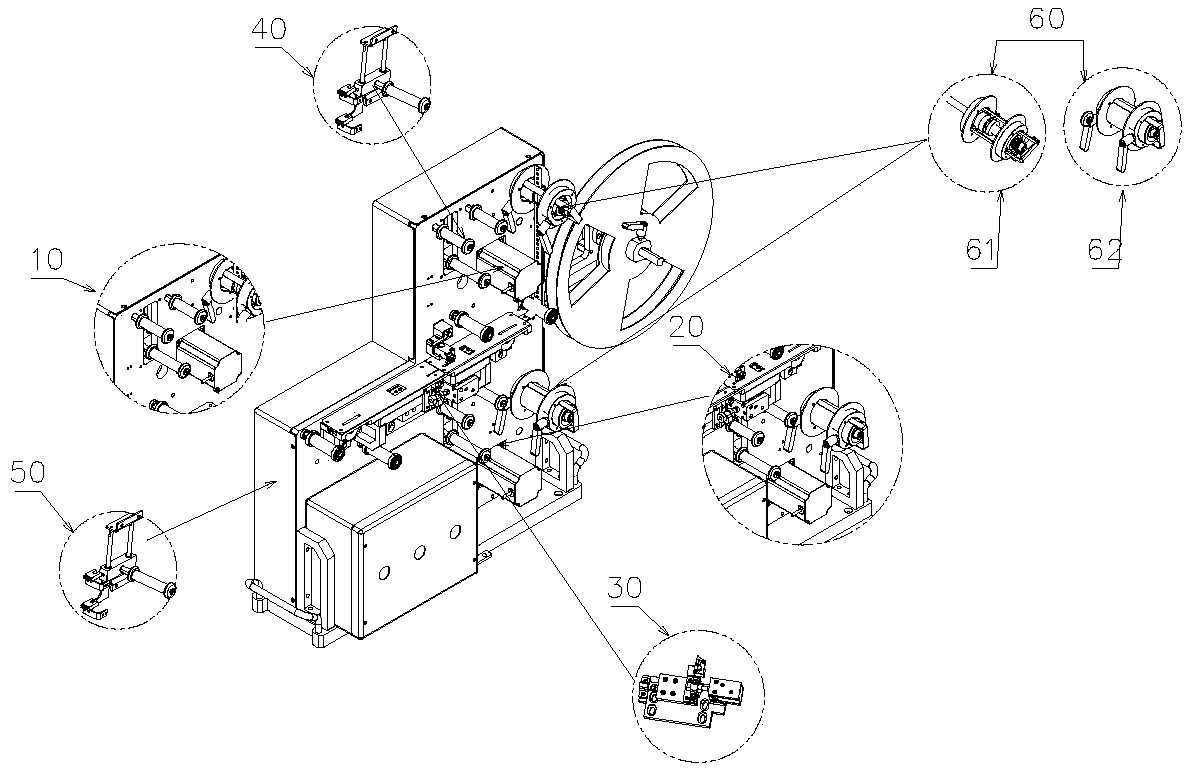

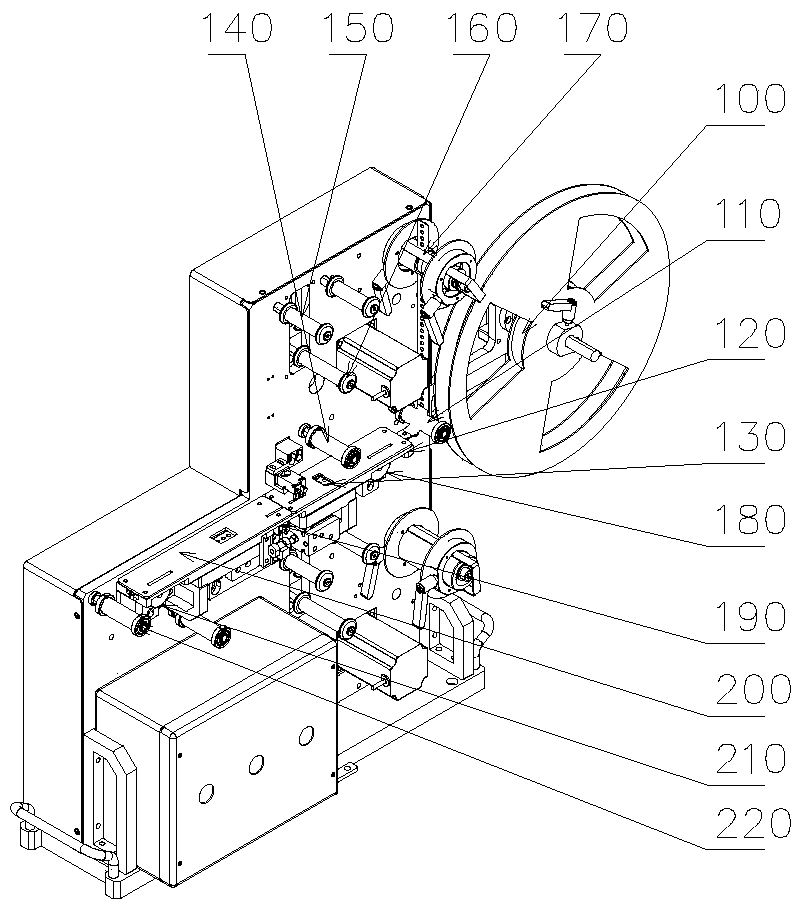

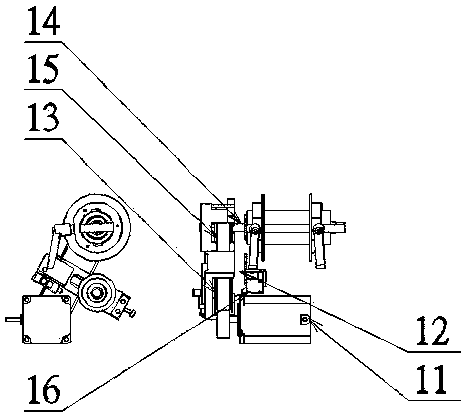

[0029] Such as figure 1 with figure 2 As shown, the dismantling SMT carrier tape packaging and feeding device of the present invention includes a carrier tape film cover tape mechanism 10, a waste carrier tape coil material mechanism 20, a step feed mechanism 30, and a carrier tape film cover tape start-stop control device 40. The start-stop control device 50 and the overload slip control device 60 for collecting waste carrier tape coils are used to protect the film cover tape of the film collection tape and the waste collection tape motor from damage due to excessive load, and use the overload slip control device The start-stop control device for the film cover tape of the film cover tape and the start-stop control device for the waste carrier tape and the coil material are used to realize the start and stop of the rewinding motor of the film cover tape and the waste carrier tape, so as to achieve the goal of collecting the film cover tape and the waste carrier tape. Purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com