Method for continuously coating high-viscosity sizing agent used for preparing positive pole piece of lithium-manganese primary cell

A technology of a battery positive electrode and a coating method, which is applied to the electrodes of primary batteries, devices for coating liquid on the surface, coatings, etc., can solve the problems of reduced battery performance, complicated processes, affecting production efficiency, and the quality of positive electrode pieces. Achieve high-speed coating, reduce water content, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

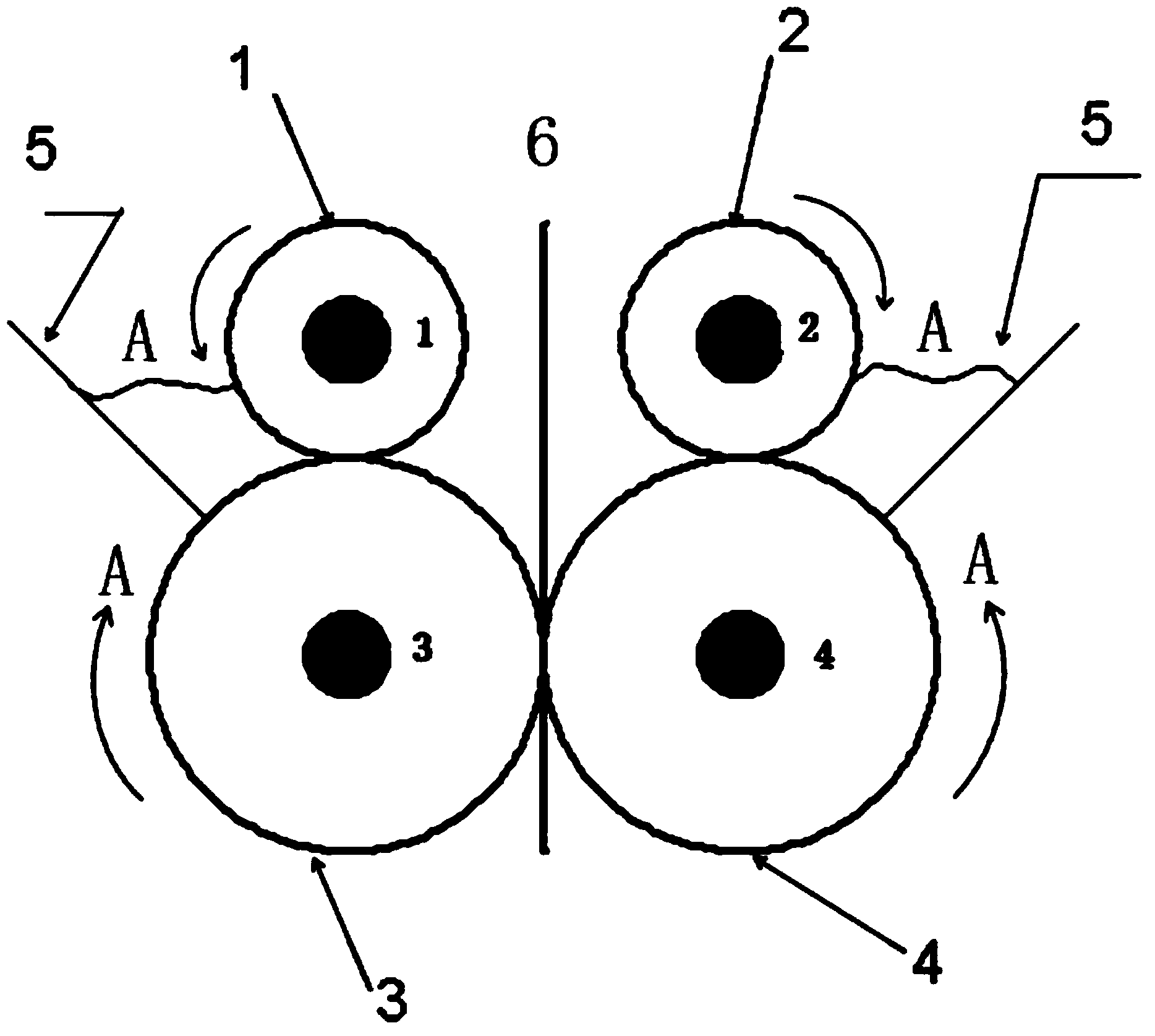

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0015] In the present invention, electrolytic manganese dioxide and conductive carbon black after heat treatment at 200°C-600°C for 2-20h are mixed (mixing time 0.1-10h), and then polar alcohol-containing solvents (such as ethanol, isopropanol, n-butyl alcohol, etc.) Alcohol) in deionized water or distilled water, continue to mix for 0.1-10 hours to obtain a wet mixture; then add the aqueous solution of the common binder for lithium batteries in proportion and continue to mix (mix for 0.5-60 minutes) to obtain a high-viscosity slurry. The above-mentioned electrolytic manganese dioxide, conductive carbon black and common binders for lithium batteries (for example: polytetrafluoroethylene (PTFE), sodium carboxymethylcellulose (CMC), polyvinyl alcohol (PVA), polyolefins (PP, P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com